Husqvarna 50 Rancher User Manual

Chain saw

50 Rancher

TECHNICAL SPECIFICATION

Displacement . . . . 48.7 cm

Bore . . . . . . . . . . . 44 mm

Stroke. . . . . . . . . . 32 mm

Ignition advance. . . . . 26˚ bef ore t.d.c.at 8400 rpm

Sparking Plug . . . . Champion CJ 7Y

Electrode gap . . . . 0.5 mm

Carburettor . . . . . . Diaphragm type

Owner’s maintenance manual

3

Fuel tank capacity . . . .0.6 l

Oil tank capacity . . . . . 0.3 l

Sawing chain. . . . . . .325” pitch

Guide Bar . . . . . . . . . . 15” (38 cm)

Weight empty, incl.38 cm

guide bar , chain

and chain brake . . . . . 6.0 kg

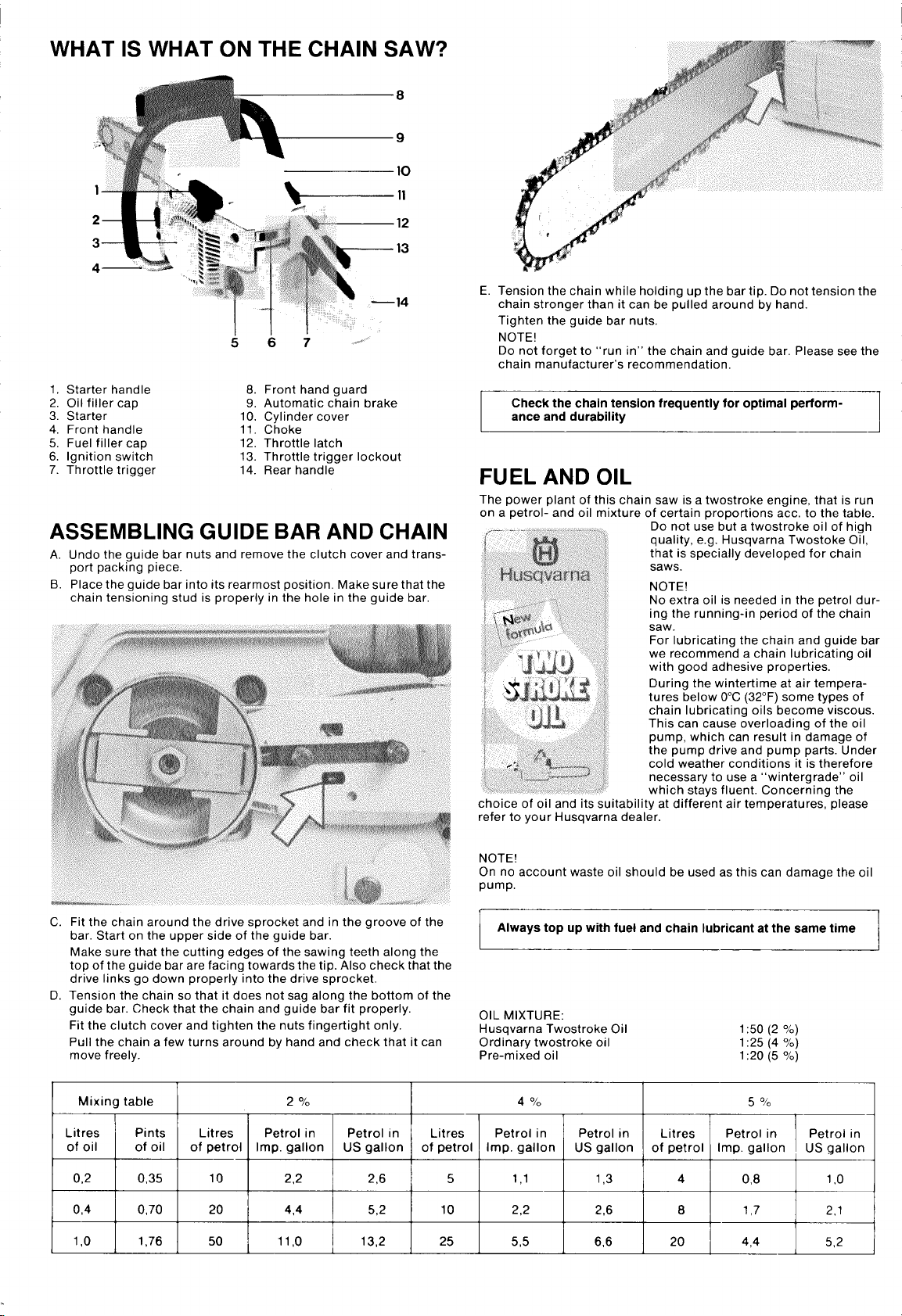

WHAT IS WHAT ON THE CHAIN SAW?

8

11

5

1, Starter handle 8.

2. Oil filler cap 9.

3. Starter 10,

4. Front handle

5. Fuel filler cap

6. Ignition switch

7. Throttle trigger 14.

11.

12.

13.

%--

6 7 ---

Front hand guard

Automatic chain brake

Cylinder cover

Choke

Throttle latch

Throttle trigger lockout

Rear handle

ASSEMBLING GUIDE BAR AND CHAIN

A. Undo the guide bar nuts and remove the clutch cover and trans-

port packing piece.

B. Place the guide bar into its rearmost position. Make sure that the

chain tensioning stud is properly in the hole in the guide bar.

E[Tension the chain while holding up the bar tip. Do not tension the

chain stronger than it can be pulled around by hand.

Tighten the guide bar nuts.

NOTE!

Do not forget to “run in” the chain and guide bar. Please see the

chain manufacturer’s recommendation.

Check the chain tension frequently for optimal performance and durability

FUEL AND OIL

C. Fit the chain around the drive sprocket and in the groove of the

bar. Start on the upper side of the guide bar.

Make sure that the cutting edges of the sawing teeth along the

top of the guide bar are facing towards the tip. Also check that the

drive links go down properly into the drive sprocket.

D, Tension the chain so that it does not sag along the bottom of the

guide bar. Check that the chain and guide bar fit properly.

Fit the clutch cover and tighten the nuts fingertight only,

Pull the chain a few turns around by hand and check that it can

move freely.

Mixing table 2 % 4 %

Litres Pints Litres Petrol in Petrol in

of oil of oil

0,2 0,35

0,4 0,70

1,0 1,76 50 11,0 13,2 25

of petrol Imp. gallon

10

20 4,4

2,2

US gallon

2,6 5

5,2

Litres

of petrol Imp, gallon

10 2,2 2,6 8 1,7

NOTE!

On no account waste oil should be used as this can damage the oil

pump.

Always top up with fuel and chain lubricant at the same time

OIL MIXTURE:

Husqvarna Twostroke Oil

Ordinary twostroke oil

Pre-mixed oil

Petrol in

1,1

5,5

Petrol in

US gallon

1,3

6,6 20

Litres Petrol in Petrol In

of petrol Imp. gallon

4

1:50 (2 %)

1:25 (4 %)

1:20 (5 %)

“10

5

0,8

4,4

US gallon

1,0

2,1

5,2

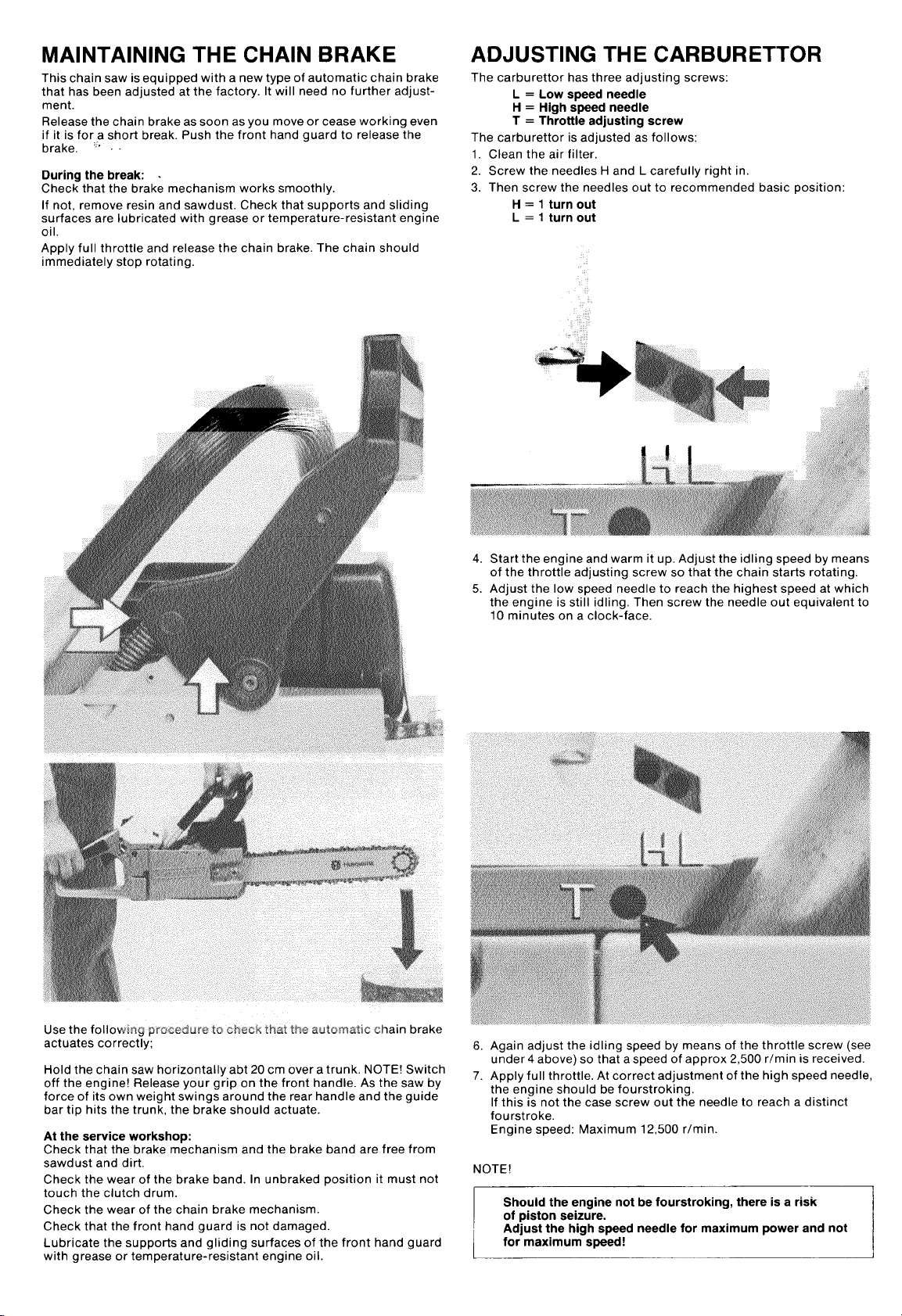

MAINTAINING THE CHAIN BRAKE

This chain saw is equipped with a new type of automatic chain brake

that has been adjusted at the factory. It will need no further adjustment.

Release the chain brake as soon as you move or cease working even

if it is for a short break. Push the front hand guard to release the

brake. ‘:”

During the break: .

Check that the brake mechanism works smoothly.

If not, remove resin and sawdust. Check that supports and sliding

surfaces are lubricated with grease or temperature-resistant engine

oil.

Apply full throttle and release the chain brake. The chain should

immediately stop rotating.

ADJUSTING THE CARBURETOR

The carburetor has three adjusting screws:

L = Low speed needle

H = High spaed needle

T = Throttle adjusting screw

The carburetor is adjusted as follows:

1. Clean the air filter.

2. Screw the needles H and L carefully right in.

3. Then screw the needles out to recommended basic position:

H = 1 turn out

L = 1 turn out

4.

Start the engine and warm it up. Adjust the idling speed by means

of the throttle adjusting screw so that the chain starts rotating.

Adjust the low speed needle to reach the highest speed at which

5.

the engine is still idling, Then screw the needle out equivalent to

10 minutes on a clock-face.

~,,

Use the following procedw’e to check that the automatic chain brake

actuates correctly;

Hold the chain saw horizontally abt 20 cm over a trunk. NOTE! Switch

off the engine! Release your grip on the front handle. As the saw by

force of its own weight swings around the rear handle and the guide

bar tip hits the trunk, the brake should actuate.

At the service workshop:

Check that the brake mechanism and the brake band are free from

sawdust and dirt.

Check the wear of the brake band. In unbraked position it must not

touch the clutch drum.

Check the wear of the chain brake mechanism.

Check that the front hand guard is not damaged.

Lubricate the supports and gliding surfaces of the front hand guard

with grease or temperature-resistant engine oil.

67Again adjust the idling speed by means of the throttle screw (see

under 4 above) so that a speed of approx 2,500 r/rein is received.

ADDIV full throttle, At correct adjustment of the hiqh sDeed needle,

the e’ngine should be fourstrok~ng.

If this is not the case screw out the needle to reach a distinct

fourstroke.

Engine speed: Maximum 12,500 r/rein.

NOTE!

Should the engine not be fourstroking, there is a risk

of piston seizure.

Adjust the high speed needle for maximum power and not

for maximum speed!

-

-.

Loading...

Loading...