Husky HRDC-NOZZLE-SELECTION-061117 User Manual

Nozzle Selection

NOZZLE SELECTION

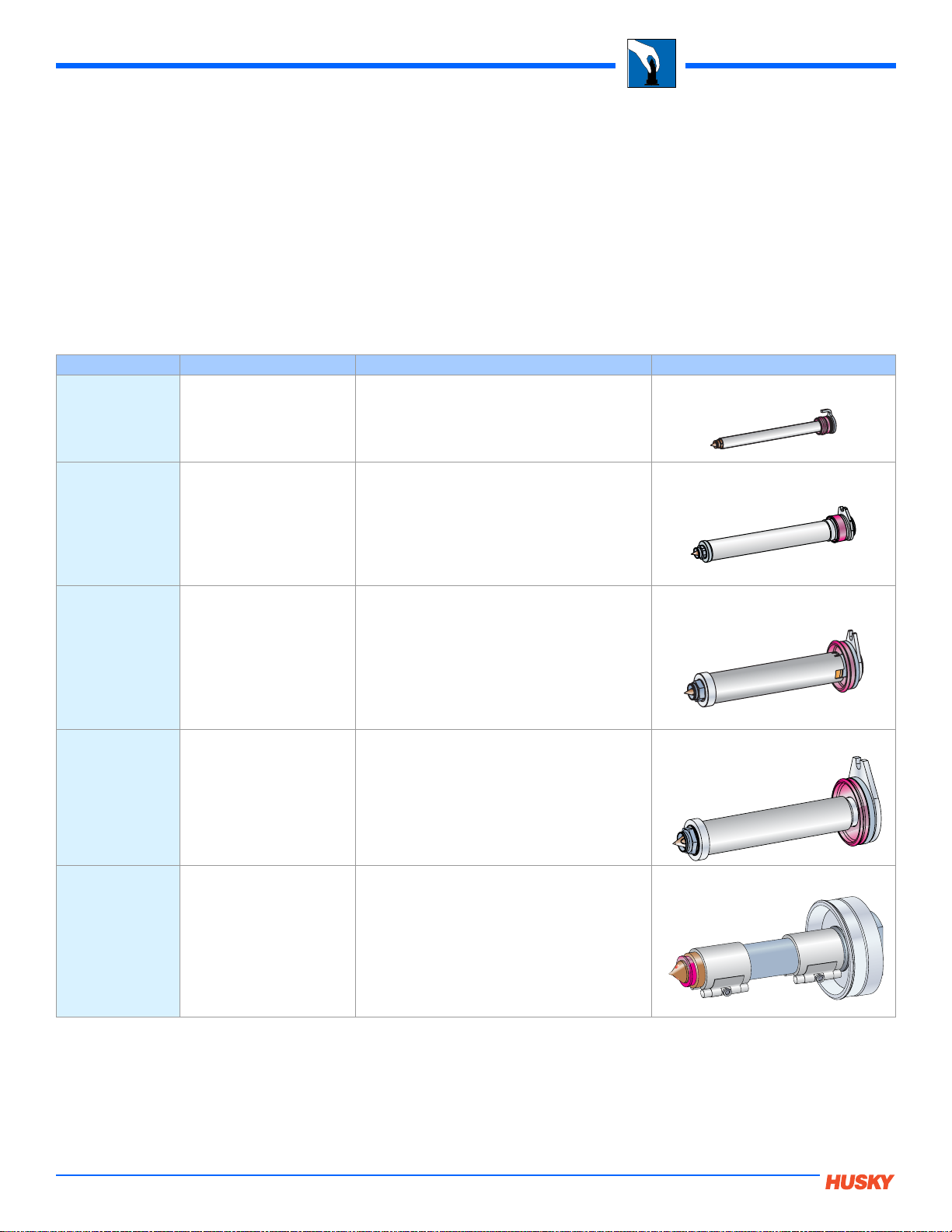

To select the correct nozzle for an application, the following information is required.

• Part weight and desired throughput per nozzle.

• Material and additives.

• Acceptable vestige and gate location.

To accommodate a wide range of molded part sizes, Husky offers 4 standard nozzle sizes. Each nozzle offers a variety of

different gating methods.

Nozzle Size Nozzle Throughput Notes

• Designed for molding smaller parts and

Ultra 250 up to 10 grams/sec.

Ultra 500 up to 20 grams/sec.

restricted access.

• 5 gating options are available.

• 3-year leakproof guarantee

• Targeted for closures and small parts

requiring excellent gate quality and rapid

color change

• 11 gating options available

• 3-year leakproof guarantee

• PRONTO Hot Runners are available.

Ultra 750 up to 250 grams/sec.

Ultra 1000 up to 750 grams/sec.

1250

Series

up to 900 grams/sec.

• Improved thermal profile and wider operating window

• Suitable for a wide variety of engineering

and commodity resins

• 10 gating options available

• 3-year leakproof guarantee

• PRONTO Hot Runners are available.

• Designed for molding large sized parts.

• 5 gating options are available.

• 3-year leakproof guarantee

• PRONTO manifold systems are

available.

• Designed for molding larger parts and

high viscosity materials.

• 5 gating options are available.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

9

Nozzle Selection

GATING METHODS

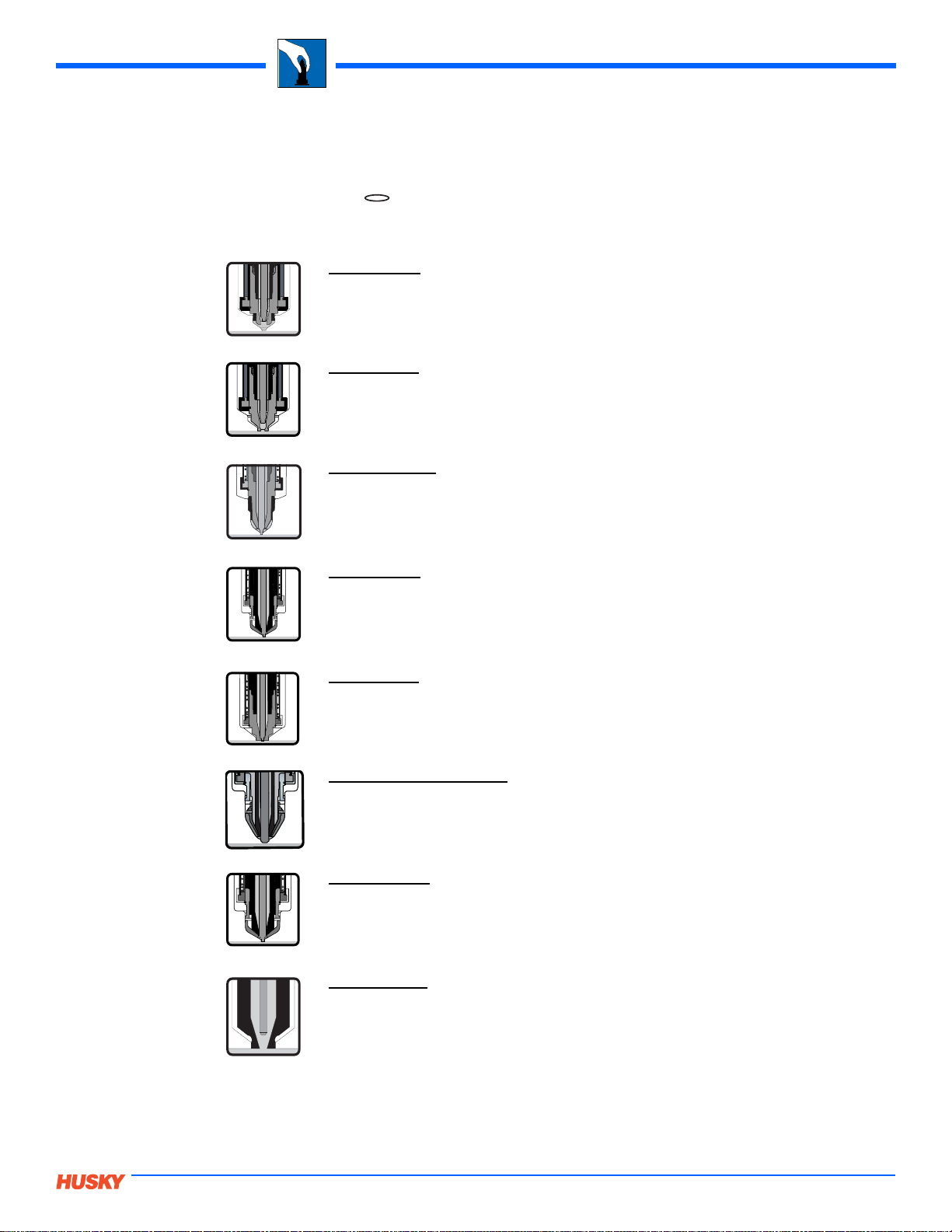

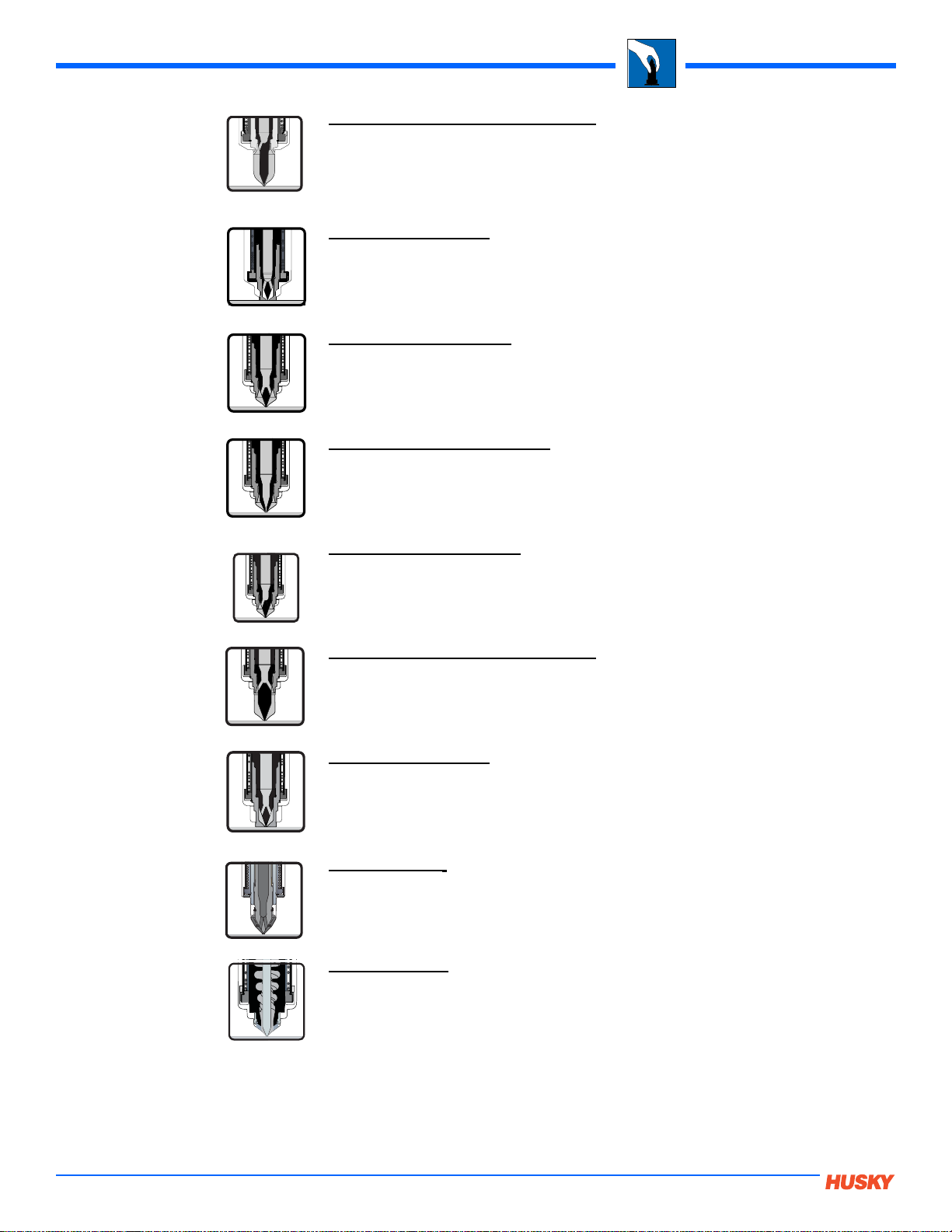

VALVE GATING

Valve gating is used when a flush gate mark with minimal vestige height is required on the molded part. Valve gating

allows for larger gate diameters, minimizing molded-in stress and providing easier part filling. All valve gating options use a

pneumatically operated valve stem to mechanically shut off resin flow at the gate.

Ultra 500 VG

• Minimal gate vestige

• For a wide variety of amorphous resins

• Pneumatically operated valve stem

• Cylindrical (UltraGuide™) and angled shut-off standard

Ultra 500 VX

• Minimal gate vestige

• For abrasive and crystalline resins

• Pneumatically operated valve stem

• Cylindrical (UltraGuide™) and angled shut-off standard

Ultra 750 VG-X

• Minimal gate vestige

• Extended option for tight gate access

Ultra 750 VG

• Minimal gate vestige

• Pneumatically operated valve stem

• Cylindrical (UltraGuide™) and angled shut-off standard

Ultra 750 VX

• Minimal gate vestige

• For abrasive and crystalline resins

• Pneumatically operated valve stem

• Cylindrical (UltraGuide™) and angled shut-off standard

Ultra 750 VG-R (Retrofit)

• Minimal gate vestige

• Fits 750 Series gate detail

Ultra 1000 VG

• Minimal gate vestige

• Pneumatically operated valve stem

• Tip insulator facilitates faster color change

Ultra 1000 VX

• Minimal gate vestige

• Pneumatically operated valve stem

• For abrasive and crystalline resins

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

10

2006.08

Nozzle Selection

1250 Series VG

• Minimal gate vestige

• Pneumatically operated valve stem

1250 Series VX

• Minimal gate vestige

• Pneumatically operated valve stem

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

11

Nozzle Selection

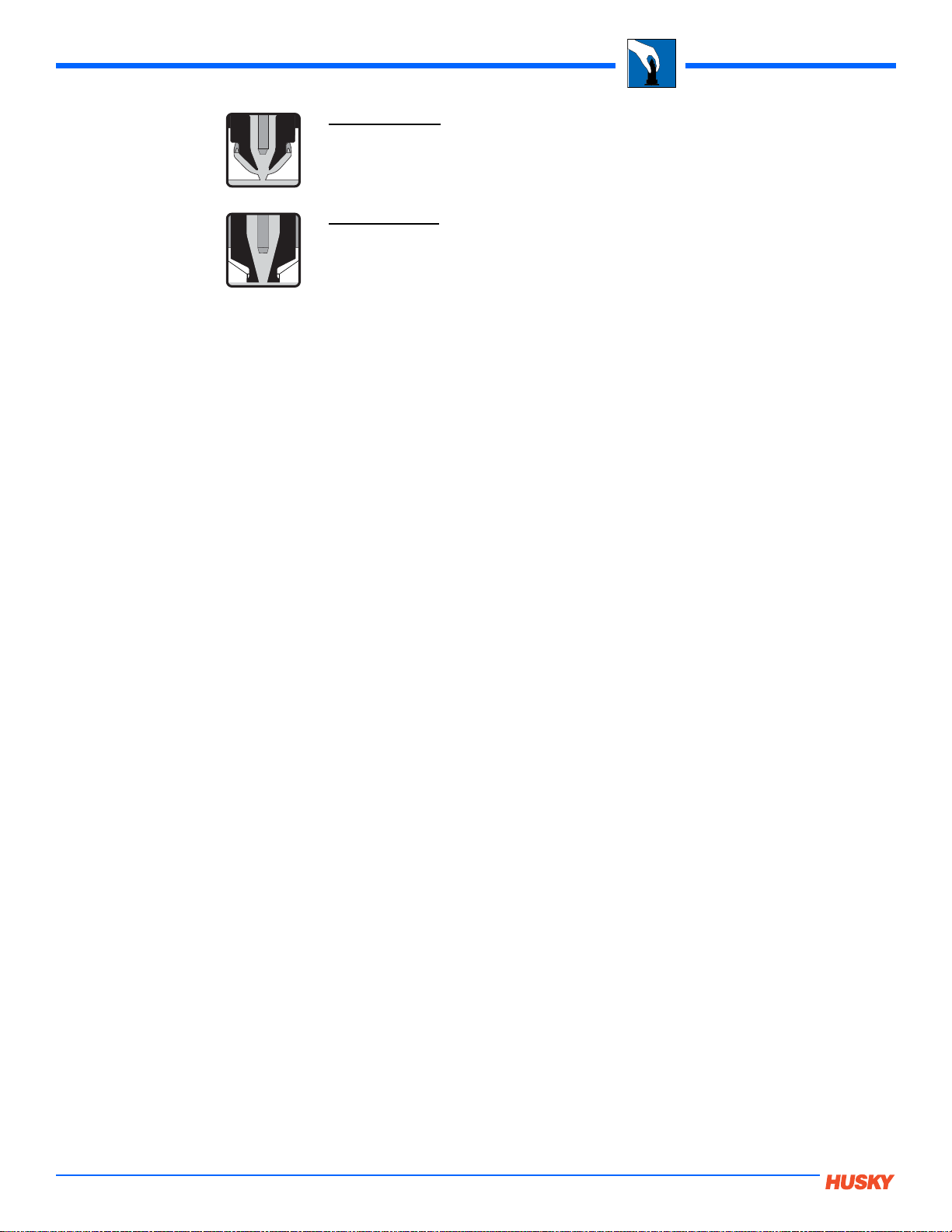

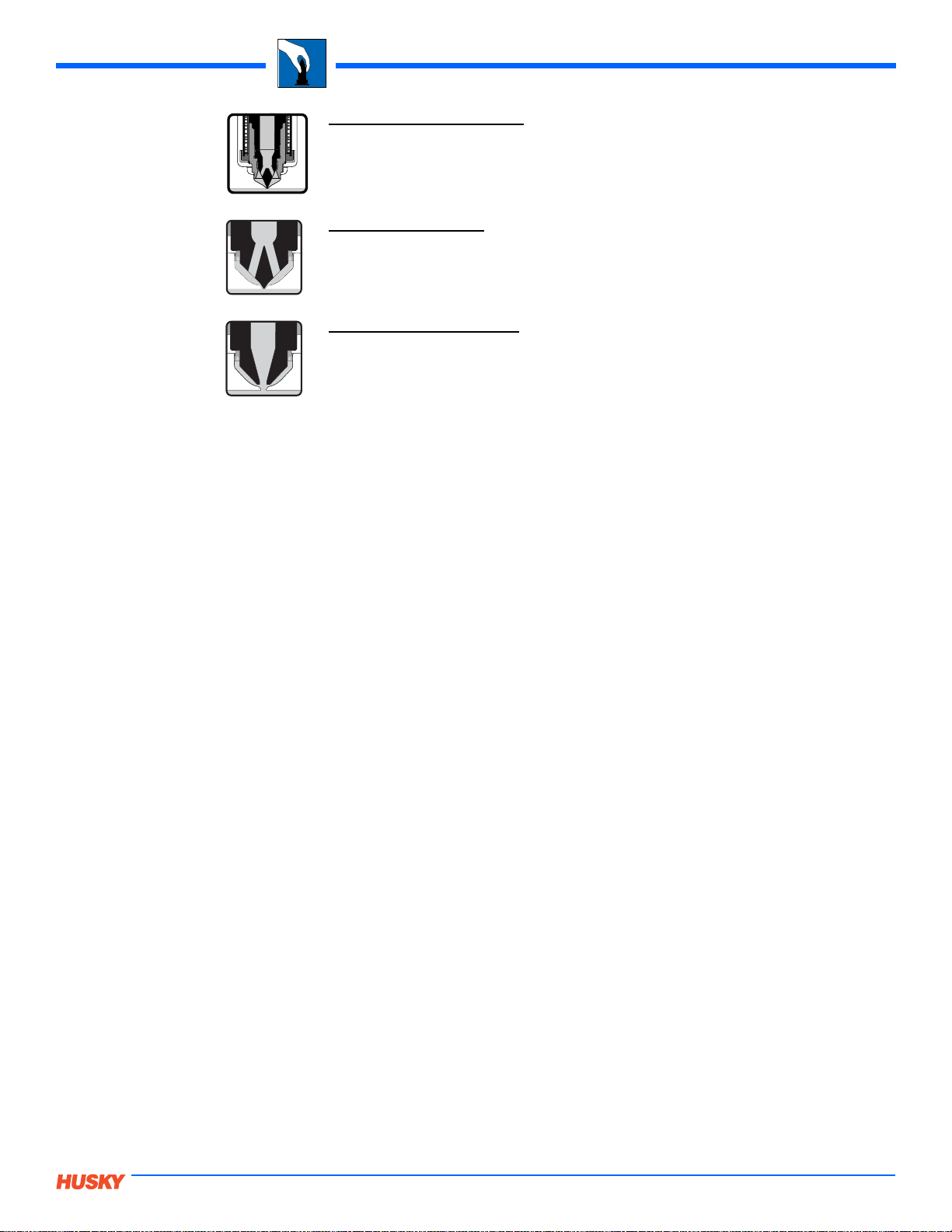

HOT TIP GATING

Hot tip gating is used when a small gate mark on the molded part is acceptable. The size of the vestige is affected by

the gate size, gate cooling, material, and processing conditions. Gate solidifica tion is achieved b y the r emoval of he at from

the gate area following the injection cycle.

Ultra 250 HT-D (Diverted)

• Suited for general purpose applications

• Fast color changes

Ultra 250 HT-T (Through Flow)

• No flow lines

• Fast color changes

Ultra 250 HT-DX (Diverted Extended)

• Extended tip enables inside/difficult to access gating

Ultra 250 HT-DX (Through Flow Extended)

• Extended tip enables inside/difficult to access gating

• No flow lines

Ultra 250 HT-U (Univerted)

• Wear resistant tip material for abrasive resins

Ultra 500 HT-D (Diverted)

• Small bubble facilitates fast color change

• Minimized gate vestige

Ultra 500 HT-T (Through Flow)

• No flow lines

• Slightly higher vestige than HT-D

Ultra 500 HT-U (Univerted)

• Wear resistant tip material for abrasive resins

• Slightly higher vestige than HT-D

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

12

2006.08

Nozzle Selection

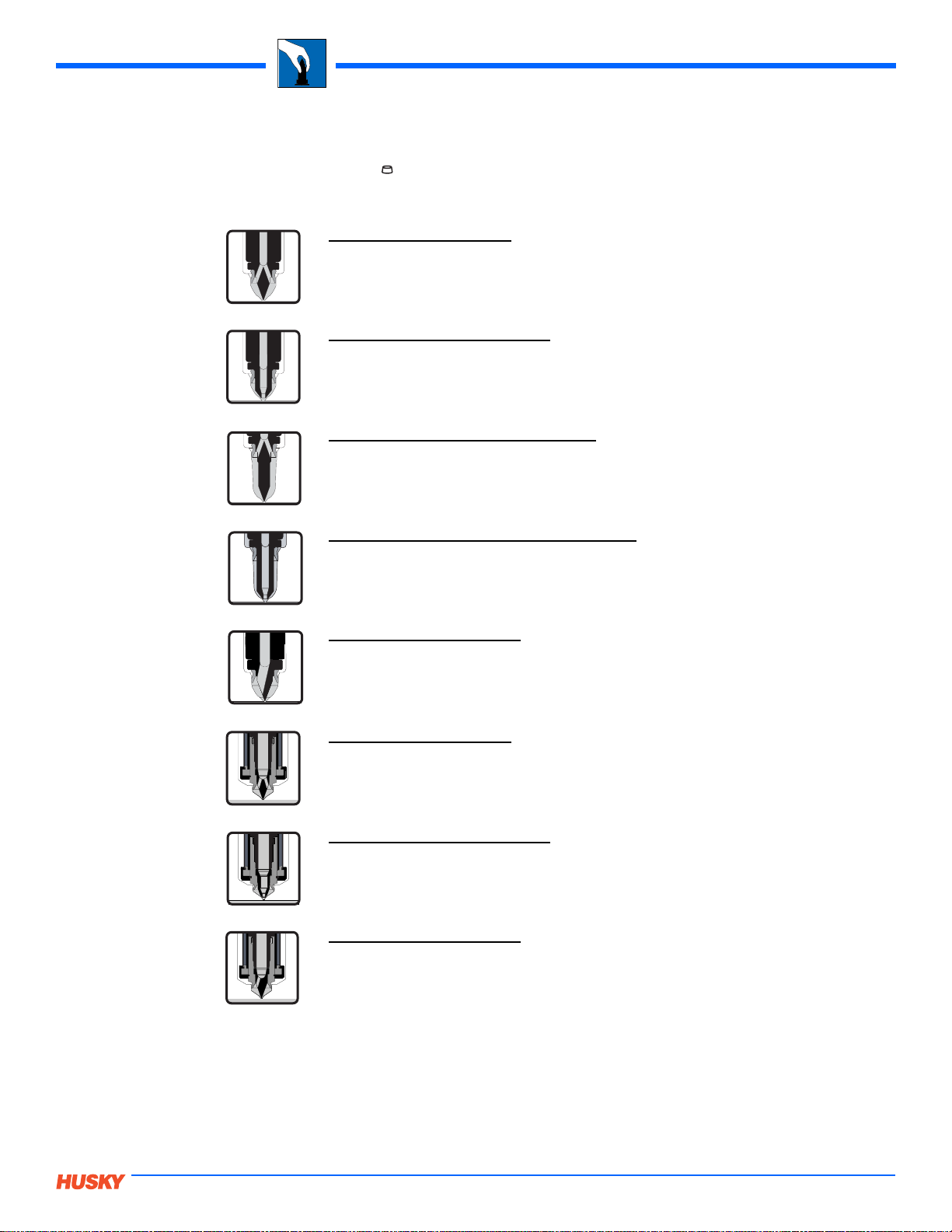

Ultra 500 HT-DX (Diverted Extended)

• Extended tip enables inside/difficult to access gating

Ultra 500 HT-DC (Cap)

• Identical to HT-D, except screw-on cap simplifies gate

geometry machining

• Wear resistant (WR) tip insert available

• HT-UC, HT-TC also available.

Ultra 750 HT-D (Diverted)

• Wear resistant (WR) tip insert available

• Minimal gate vestige

• No tip insulator required for color change/heat sensitive

resins

Ultra 750 HT-T (Through Flow)

• No flow lines

• Wear resistant (WR) tip insert available

Ultra 750 HT-U (Univerted)

• Slightly higher vestige than HT-D

• Wear resistant (WR) tip insert available

• Well suited for filled resins with large filler particle size

• One flowline

Ultra 750 HT-DX (Diverted Extended)

• Extended tip enables inside/difficult to access gating

• Wear resistant (WR) tip insert available

Ultra 750 HT-DC (Cap)

• Identical to HT-D, except screw-on cap simplifies gate

geometry machining

• Wear resistant (WR) tip insert available

• HT-UC, HT-TC also available.

Ultra 750 HT-S6

• Ideal when closer gate cooling access is required

• Excellent for fast cycle times

Ultra 750 HT-UF

• Fastest color change

• No flow lines

• High pressure option available

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

13

Ultra 1000 HT-D (Triverted)

• Wear resistant carbide insert tip

• Tip insulator facilitates fast color change

• Minimized gate vestige

1250 HT-D (Triverted)

• Small gate vestige

• High throughput

1250 HT-T (Through Flow)

• No flow lines

• Small gate vestige

Nozzle Selection

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

14

2006.08

Loading...

Loading...