Humanscale Extended Ergo Lift User Manual

Extended Ergo Lift Assembly Instructions

Lift

.38

Cable Mount

Hex Nut

Washer

Screw

Cable

Bracket

Release

Lever

Hardware Bag Components: Hex Head Bolt (2) • Hex Locknut (4) • Flat Washer (6) • Cap (4) • Screw (20)

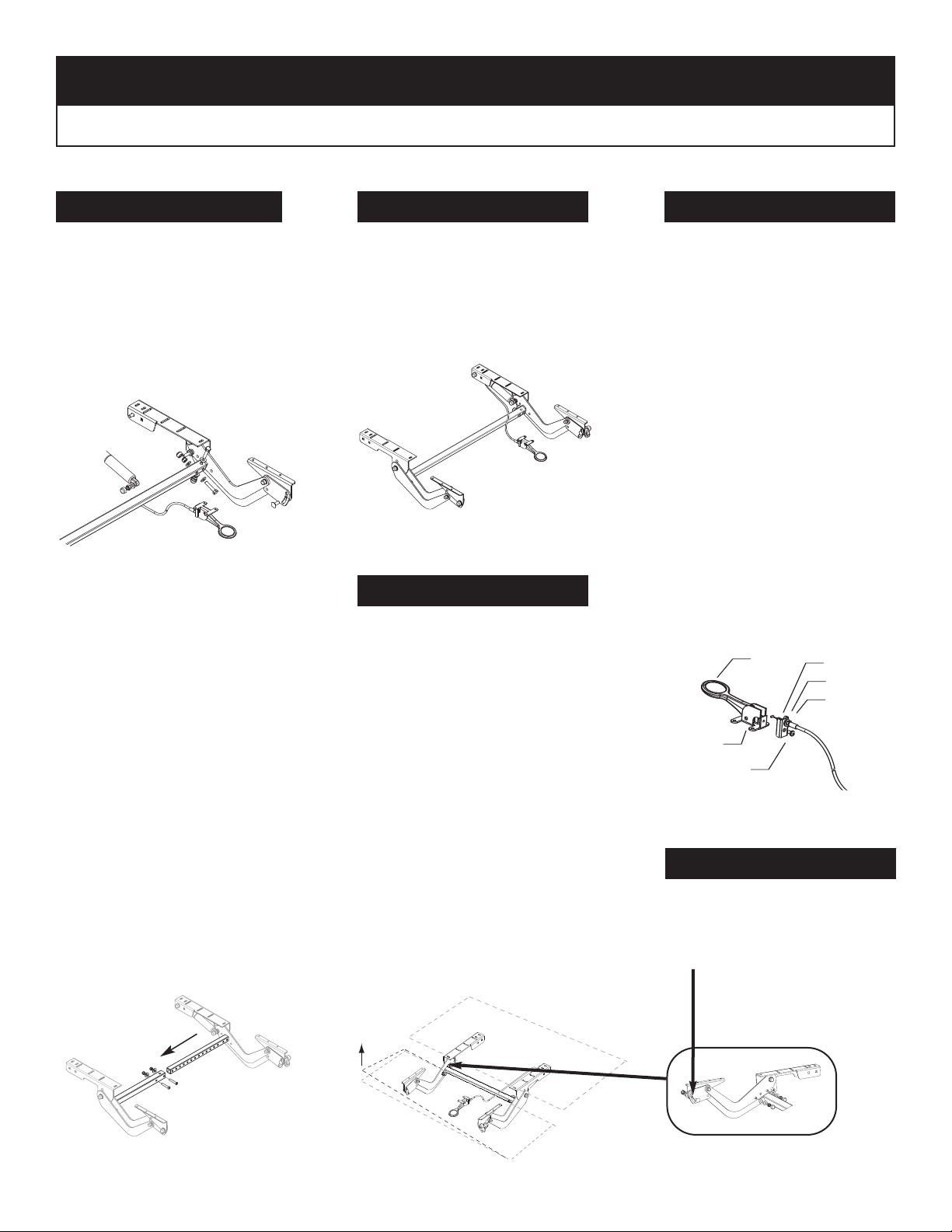

Assemble the Cross Tube

1.

Fixed Width Models

Slide cross tube over square

mounting stud on R.H. Assembly

Insert (2) hex bolts with (2) flat

washers through cross tube and

stud. Assemble (2) flat washers

and (2) hex locknuts. Tighten

fasteners to 200 in-lbs or until tube

is flattened against mounting stud.

Note: Improper tightening of hardware may result in excess keyboard movement. Install opposite

end of cross tube over (2) studs on

L.H. Assembly and fasten with (2)

flat washers and (2) hex locknuts.

DO NOT TIGHTEN AT THIS TIME!

Adjustable Width Models

Follow same procedure used for

mounting fixed width R.H. & L.H.

Arm assemblies except as follows:

o adjust for desir

T

ed width remove & save hardware used to

position two cross halves for shipping. Slide assembly either in or

out to final width and replace hard-

e. Tighten hardware between

war

tube halves to 200 in-lbs. or until

play between tubes is removed.

Install Brackets to Table

2.

Attach assembled Ergo Lift brack-

.

work surfaces. Attach release lever

ets to underside of fr

ont and rear

to underside of front work surface

with (4) scr

ews provided.

Adjust Cables

4.

(if necessar

y)

Cable is pre-set at factory.

Adjustment should only be made if

elease lever does not lock key-

r

board in position (Cable to tight) or

if lever does not release keyboard.

(Cable to loose)

A. To adjust the cable free play,

remove the cable mount from the

cable bracket by removing screw.

B. Loosen the cable hex nut.

C. Adjust the position of the cable

mount by screwing on or off the

desired amount.

D. Tighten the cable hex nut.

E. Make sure the cable end is

installed in the release lever.

3. Level Keyboard (if necessary)

Reinstall the cable mount onto the

handle assembly.

Left side of tube is designed to

provide leveling capability.

A. Activate release lever so front

surface right hand side is approximately level with rear surface.

Release lever.

B. Manually raise the left hand

side of front work surface approximately 1/2” above the right hand

side, hold in this position and tighten (2) nuts to 200 in-lbs.

Re-adjust if not level. (Use

C.

5. Tilt Tension (if necessary)

dimension less then 1/2” if left

hand side is too high.)

Tilt tension nut is pre-set at the factory, but can be adjusted by tight-

D. Install caps over hex nuts.

ening or loosening the hex locknut

as shown.

Rev. 6-26-06

Loading...

Loading...