Page 1

HPE StoreEver LTO-8 Ultrium 30750 SAS Tape Drive User Guide

Abstract

This document provides information about installing, operating, and troubleshooting an HPE

StoreEver LTO-8 Ultrium 30750 Tape Drive. This guide is intended for system administrators

and other users who need physical and functional knowledge of the tape drive. Installing an

internal tape drive requires experience with installing server components.

Part Number: BC023-60004a

Published: February 2018

Edition: 2

Page 2

©

Copyright 2018 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Acknowledgments

Intel®, Itanium®, Pentium®, Intel Inside®, and the Intel Inside logo are trademarks of Intel Corporation in

the United States and other countries.

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Adobe® and Acrobat® are trademarks of Adobe Systems Incorporated.

Java® and Oracle® are registered trademarks of Oracle and/or its affiliates.

UNIX® is a registered trademark of The Open Group.

Page 3

Contents

Overview.................................................................................................. 5

Installing drivers and backup software.................................................9

Installation requirements...............................................................................................................5

Rackmount drives...............................................................................................................5

Server requirements......................................................................................................................5

Cable requirements.......................................................................................................................5

About using hardware encryption................................................................................................. 7

When to use encryption..................................................................................................... 7

About managing encryption keys....................................................................................... 7

About enabling encryption..................................................................................................8

Diagnostic, management, and support tools.................................................................................8

Tape drivers...................................................................................................................................9

For Windows...................................................................................................................... 9

For Linux and UNIX............................................................................................................9

For IA64..............................................................................................................................9

Backup software requirements..................................................................................................... 9

Installing an internal tape drive........................................................... 10

Verifying the server SAS connector type.................................................................................... 10

Installing the tape drive............................................................................................................... 10

Connecting the cable ..................................................................................................................11

Securing the drive....................................................................................................................... 12

Installing an external tape drive.......................................................... 13

Connecting to an external SAS port............................................................................................13

Verifying the installation.......................................................................15

Powering on the drive and the server ........................................................................................ 15

Completing the installation..........................................................................................................15

Operating the tape drive.......................................................................17

Front panel overview...................................................................................................................17

Understanding the LEDs.................................................................................................. 17

Data and cleaning cartridges...................................................................................................... 18

Loading a cartridge..................................................................................................................... 21

Unloading a cartridge..................................................................................................................21

Cleaning the tape drive............................................................................................................... 21

Troubleshooting.................................................................................... 23

General troubleshooting procedure............................................................................................ 23

LED sequences...........................................................................................................................24

Problems with cartridges.............................................................................................................28

Contents 3

Page 4

The cartridge is jammed...................................................................................................28

The drive will not accept the cartridge (or ejects it immediately)......................................30

Methods for troubleshooting encryption......................................................................................30

Replacing a tape drive.......................................................................... 31

Disconnecting the tape drive.......................................................................................................31

Replacing an existing SAS hard drive cable...................................... 32

Support and other resources...............................................................35

Accessing Hewlett Packard Enterprise Support......................................................................... 35

Accessing updates......................................................................................................................35

Customer self repair....................................................................................................................36

Remote support.......................................................................................................................... 36

Warranty information...................................................................................................................36

Regulatory information................................................................................................................37

Documentation feedback............................................................................................................ 37

Warranty and regulatory information..................................................38

4 Contents

Page 5

Overview

Installation requirements

The server must have a SAS Smart Array controller or SAS HBA that supports tape devices.

NOTE:

All non Hewlett Packard Enterprise servers require an additional HBA.

Hewlett Packard Enterprise recommends purchasing and installing one of the supported HBAs to connect

the tape drive to the server. For compatibility information, see the HPE Data Availability, Protection, and

Retention Compatibility Matrix at: http://hpe.com/storage/DAPRcompatibility.

Rackmount drives

Specific installation instructions for rackmount drives are not included in this guide. For information, see

the rackmount enclosure website:

http://www.hpe.com/storage/rackmount.

Server requirements

Internal tape drives

The tape drive is installed into a spare drive bay in the server and is attached to the host server’s internal

SAS controller or HBA.

The server will need one industry-standard 5¼-inch, half-height bay for the tape drive. Different server

models have different mounting methods. For server-specific information, see the server documentation.

For general installation instructions, see Installing an internal tape drive on page 10.

The tape drive connects to a SAS Smart Array controller or SAS HBA that supports tape devices.

• If the host does NOT have a spare SAS port, install a new SAS HBA and any required HBA drivers.

• If the server does not have a PCI slot available for a new HBA, see Replacing an existing SAS hard

drive cable on page 32 for additional options.

External tape drives

External tape drives connect to a SAS Smart Array controller or SAS HBA that supports tape devices and

has an external SAS connector. If the server does not have an active external SAS port, install an

additional HBA with an external SAS connector.

For current information about supported SAS HBAs, see the HPE Data Availability, Protection, and

Retention Compatibility Matrix at: http://hpe.com/storage/DAPRcompatibility

Cable requirements

Internal tape drives

The cable supplied with the tape drive is suitable for connecting to a mini-SAS (SFF-8086/8087)

connector on a dedicated HBA or on the server's SAS controller. If your server has a SAS 4i connector

(SFF-8484), a suitable cable is available, and must be purchased separately.

Overview 5

Page 6

NOTE:

Power for the tape drive is supplied through the SAS cable.

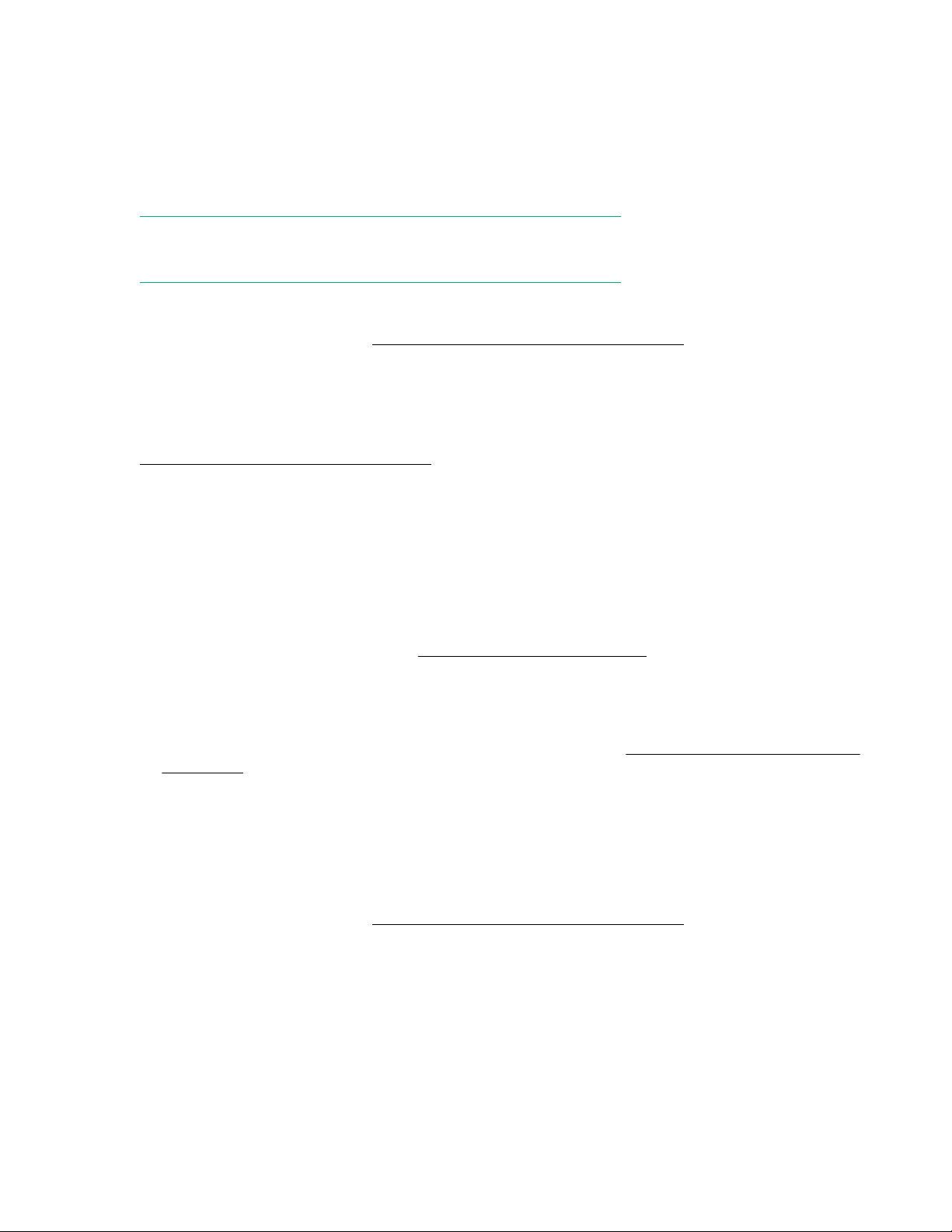

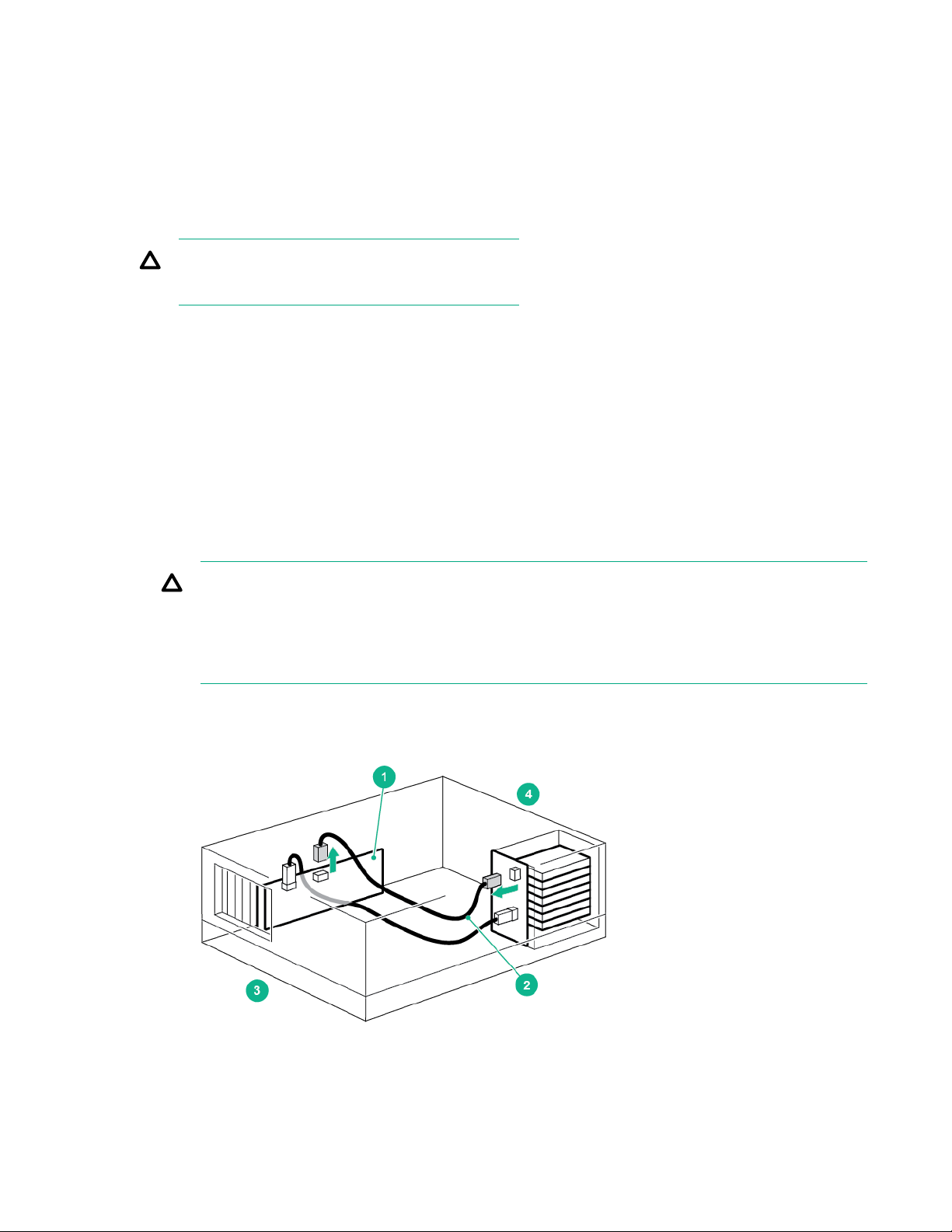

Figure 1: SAS cable supplied with the internal tape drive

1. Mini SAS connector to server (remove cover) 2. Unused second branch on supplied cable

3. Mini SAS connector on second branch (unused,

do not remove cover)

5. Power cable and connector to server's power

supply

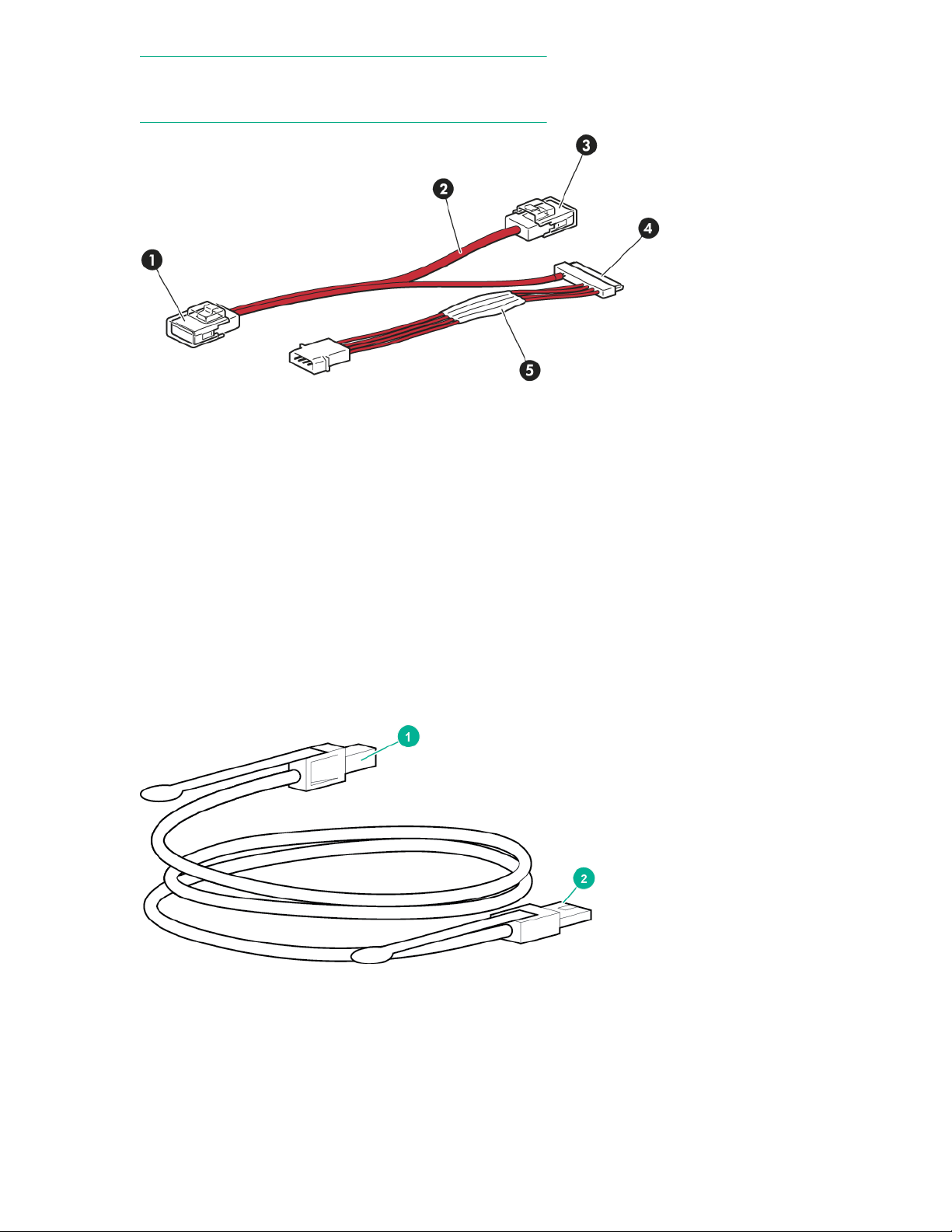

External tape drives

External tape drives must be connected to an external port. The cable supplied with the tape drive is

suitable for connecting to an External Mini SAS High Density (SFF-8644) port on a dedicated HBA

(recommended) or the host SAS Smart Array controller. If your server has an external mini SAS

(SFF-8088) or Infiniband (SFF-8470) connector, a suitable cable is available, and must be purchased

separately.

4. SAS connector to tape drive

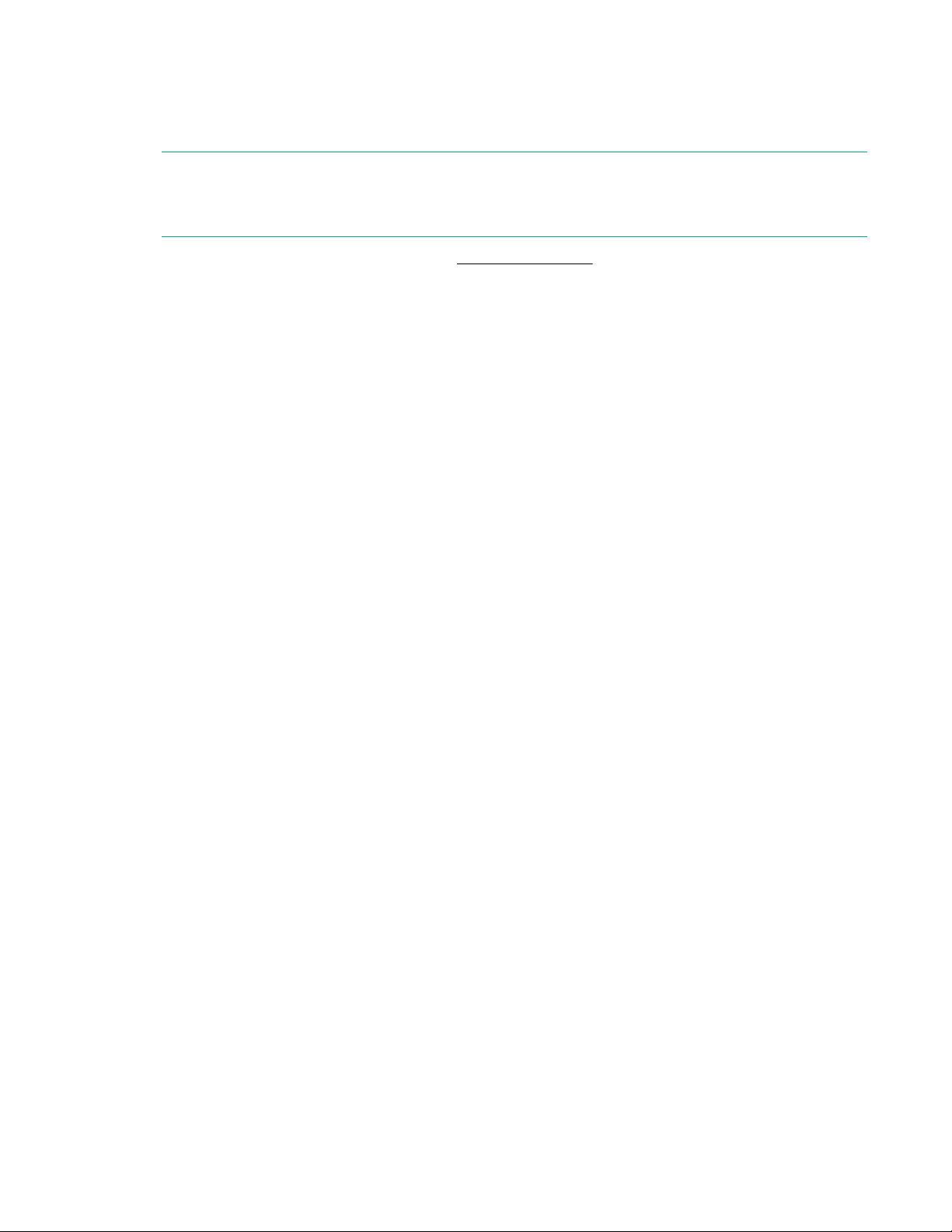

Figure 2: SAS cable supplied with the external tape drive

1. High-Density Mini SAS connector for the server

2. Mini SAS connector for the tape drive

6 Overview

Page 7

If the server has a different type of SAS port, either purchase the appropriate cable, or purchase and

install a recommended HBA and associated drivers before installing the tape drive. For current

information about supported cables and HBAs, see the HPE Data Availability, Protection, and Retention

Compatibility Matrix at: http://hpe.com/storage/DAPRcompatibility.

About using hardware encryption

Encryption protects data from unauthorized access and use by changing it into a form that cannot be read

until it is deciphered with the encryption key.

LTO-4 and later generation tape drives include hardware capable of encrypting data while writing, and

decrypting data when reading. Hardware encryption can be used with or without compression while

maintaining the full speed and capacity of the tape drive and media.

LTO tape drives use the 256-bit version of the industry-standard AES encryption algorithm to protect data.

IMPORTANT:

Hardware encryption is a powerful feature and must be used with care. If you need to import media

onto another machine or to recover after disaster, you will be required to enter the encryption key

used to write the tape. A lost encryption key cannot be recovered by you or a service engineer.

Without the key, an encrypted tape is unreadable.

To use hardware encryption, you need:

• A backup application that supports hardware encryption.

• LTO-7 or LTO-8 media.

For additional cartridge compatibility information, see Data and cleaning cartridges on page 18.

When to use encryption

Your company policy determines when you need to use encryption. For example, encryption might be

mandatory for company confidential and financial data, but not for personal files. Company policy will also

define how encryption keys will be generated and managed. Backup applications that support encryption

generate a key for you or allow you to enter a key manually.

NOTE:

Encryption with keys that are generated directly from passwords or passphrases might be less secure

than encryption using truly random keys. The backup application will explain the available options and

methods. For more information, see the application user documentation.

About managing encryption keys

Encryption is primarily designed to protect the media content once the media is offline and to prevent it

from being accessed from another machine. If the encryption keys are managed by an application,

typically the application loads the necessary encryption key automatically when it is needed for reading or

writing, provided that the application is the one that was used to encrypt the data.

There are two main instances when you will need to know the key:

• If you try to import the media to another system, such as another instance of the backup application or

a different backup application

• If you are recovering your system after a disaster

About using hardware encryption 7

Page 8

If you are unable to supply the key when requested to do so, you or a support engineer will not be able to

access the encrypted data.

It guarantees the security of the data, but also means that you must manage the encryption keys

carefully.

WARNING:

Keep a record or backup of the encryption keys and store it in a secure place separate from the

computer running the backup software.

About enabling encryption

If you wish to use the encryption capability, you must enable this feature through the backup software

application. See the application documentation for information and instructions on enabling encryption.

For a list of applications that support hardware encryption, see the HPE Data Availability, Protection, and

Retention Compatibility Matrix at: http://hpe.com/storage/DAPRcompatibility.

Diagnostic, management, and support tools

The following utilities are available from Hewlett Packard Enterprise, free of charge, and are highly

recommended:

• HPE Library & Tape Tools (L&TT) is the recommended diagnostic and support tool for Hewlett Packard

Enterprise tape drives. You can use L&TT to confirm proper installation, test performance, and retrieve

information for troubleshooting and support. L&TT is available free at:

tapetools

http://www.hpe.com/support/

• HPE Tape Smart Components provide easy-to-use driver and firmware updates.

◦ HPE Storage Tape Drivers (Windows)

◦ HPE Storage Tape Firmware (Windows)

◦ HPE Storage Tape Firmware (Linux)

These components are available for download without cost at: http://www.hpe.com/storage/

buracompatibility

8 About enabling encryption

Page 9

Installing drivers and backup software

Tape drivers

For Windows

Hewlett Packard Enterprise recommends installing the drivers on the server before connecting the tape

drive. The driver available from Microsoft Update is acceptable. However, the HPE Tape driver provides

better support for all the features of your new tape drive.

NOTE:

The HPE Tape driver is suitable for use in most applications. To ensure that you are using the

recommended driver, refer also to the documentation of your software application.

Use the HPE Tape driver with the Windows operating systems unless the software application requires a

different driver.

For driver, firmware, and software updates, see Drivers & Downloads on the Hewlett Packard Enterprise

Support website:

http://www.hpe.com/support/storage

For Linux and UNIX

The recommended backup applications use the OS standard, built-in device drivers. To upgrade drivers,

patch the operating system to the latest version or configure device files, as described in the HPE

StoreEver LTO-8 UNIX, Linux, and OpenVMS Configuration Guide at: http://www.hpe.com/info/

enterprise/docs

For IA64

For the latest information on backup application upgrades and drivers for IA64 system, such as an HPE

Integrity server, see the HPE Data Availability, Protection, and Retention Compatibility Matrix at: http://

hpe.com/storage/DAPRcompatibility

Backup software requirements

Verify that you have a backup application that supports the HPE LTO-8 Ultrium 30750 tape drive.

Download and install any upgrades or patches if required.

For optimum performance, use a backup application that is appropriate for your system configuration. In a

direct attach configuration, where the tape drive is attached to a standalone server, use backup software

that is designed for a single-server environment. In network configurations, you will need backup software

that supports enterprise environments. Hewlett Packard Enterprise, Veritas, EMC, Yosemite, and

Computer Associates all provide suitable products. Further details about these and other products that

may be appropriate can be found on the HPE Data Availability, Protection, and Retention Compatibility

Matrix at: http://hpe.com/storage/DAPRcompatibility

Installing drivers and backup software 9

Page 10

Installing an internal tape drive

2

2

2

2

1

1

Verifying the server SAS connector type

The cable supplied with the product connects to a Mini SAS (SFF-8087) connector on a dedicated HBA or

host SAS controller. This is a split cable, but the second branch is not normally required. Do not remove

the plastic cover on the spare connector.

NOTE:

To connect the tape drive to a SAS 4i (SFF-8484) or other type of SAS port, you must supply the

appropriate cable.

Installing the tape drive

CAUTION:

The tape drive is installed in one industry-standard, 5¼-inch half-height bay. For specific information

about mounting methods and requirements, see the server documentation.

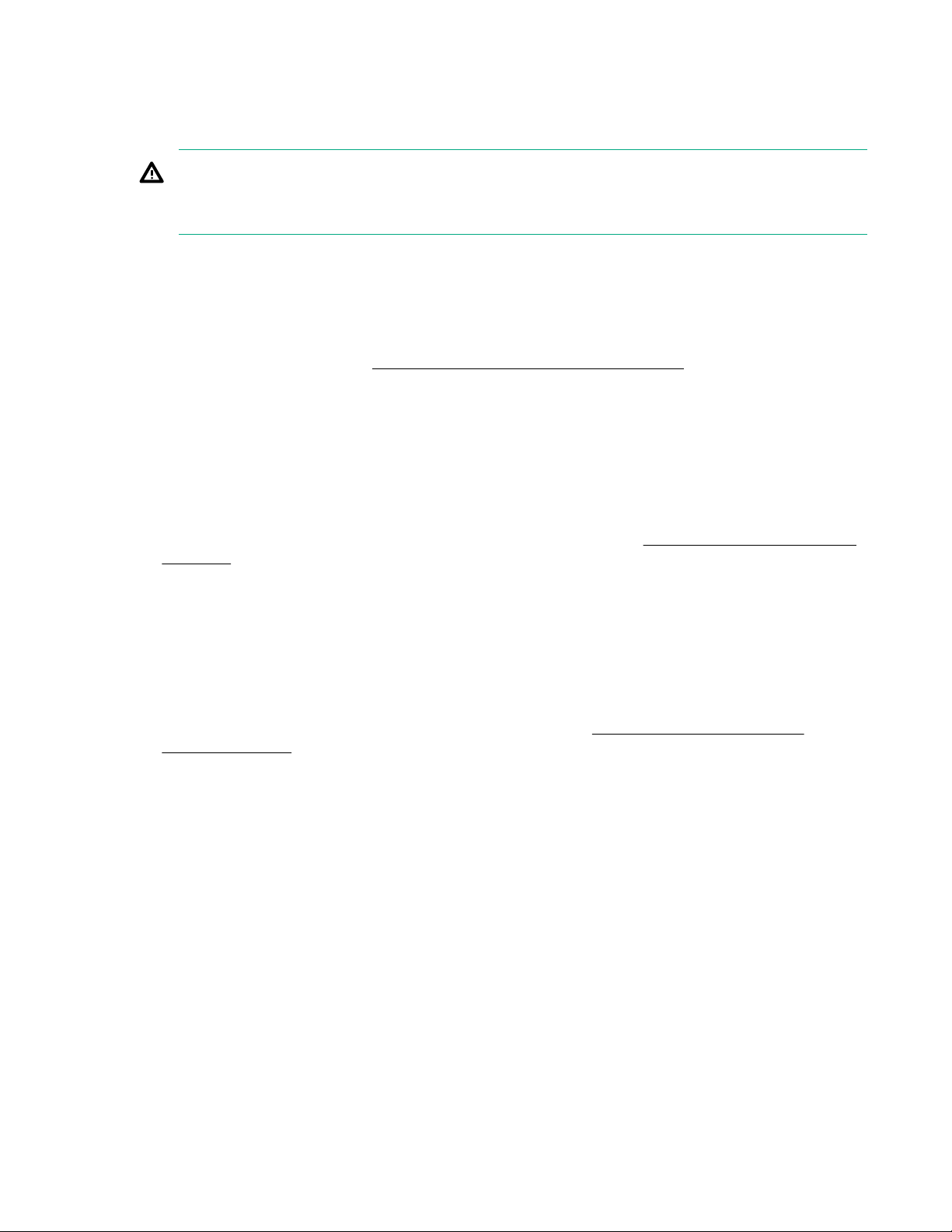

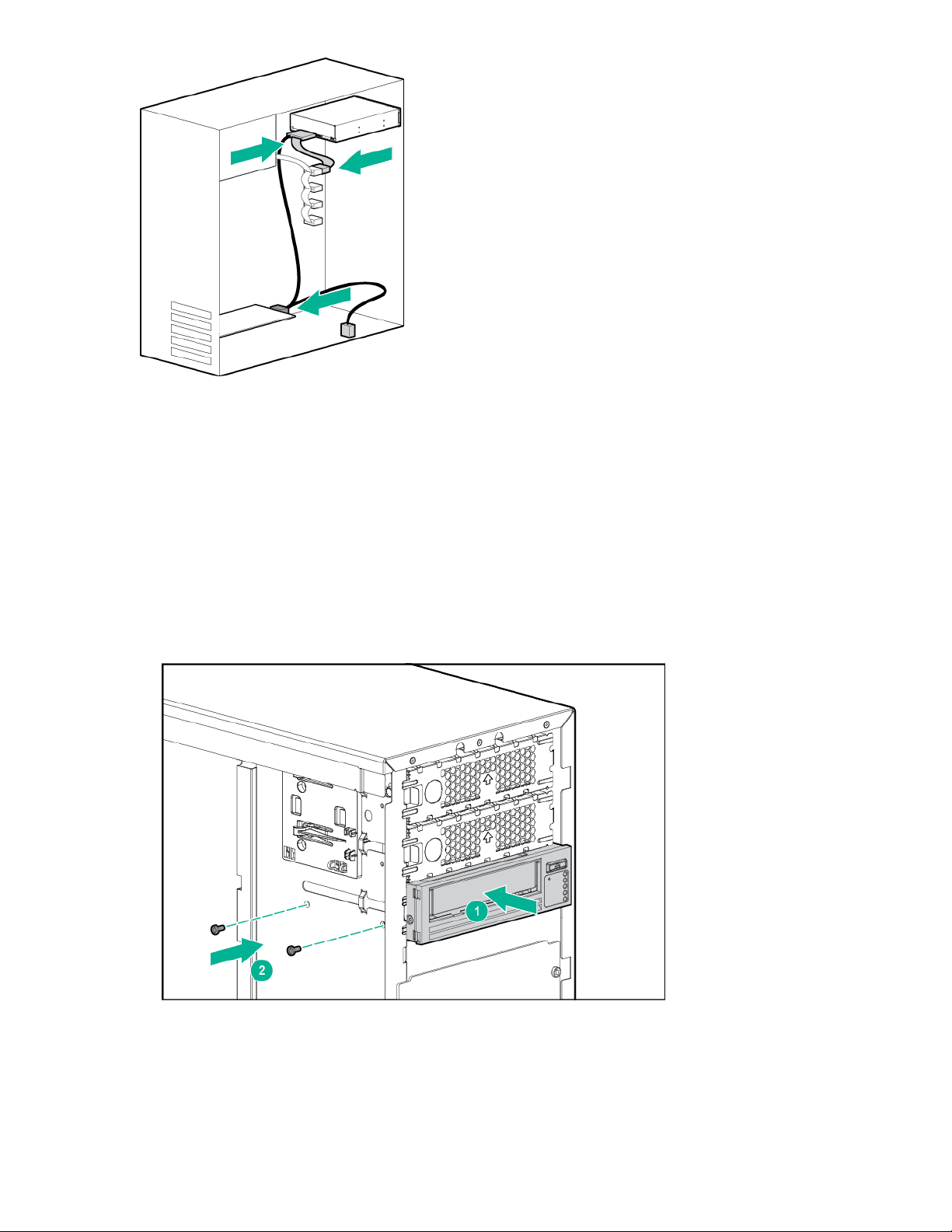

Attach the alignment screws or mounting hardware

Procedure

1. If the server or enclosure requires alignment screws, special rails, or other hardware, attach them to

the tape drive with the screws supplied with the tape drive. See the instructions with the screw kit for

required washers or shims.

Example: Attaching a metal shim and alignment screws

10 Installing an internal tape drive

Page 11

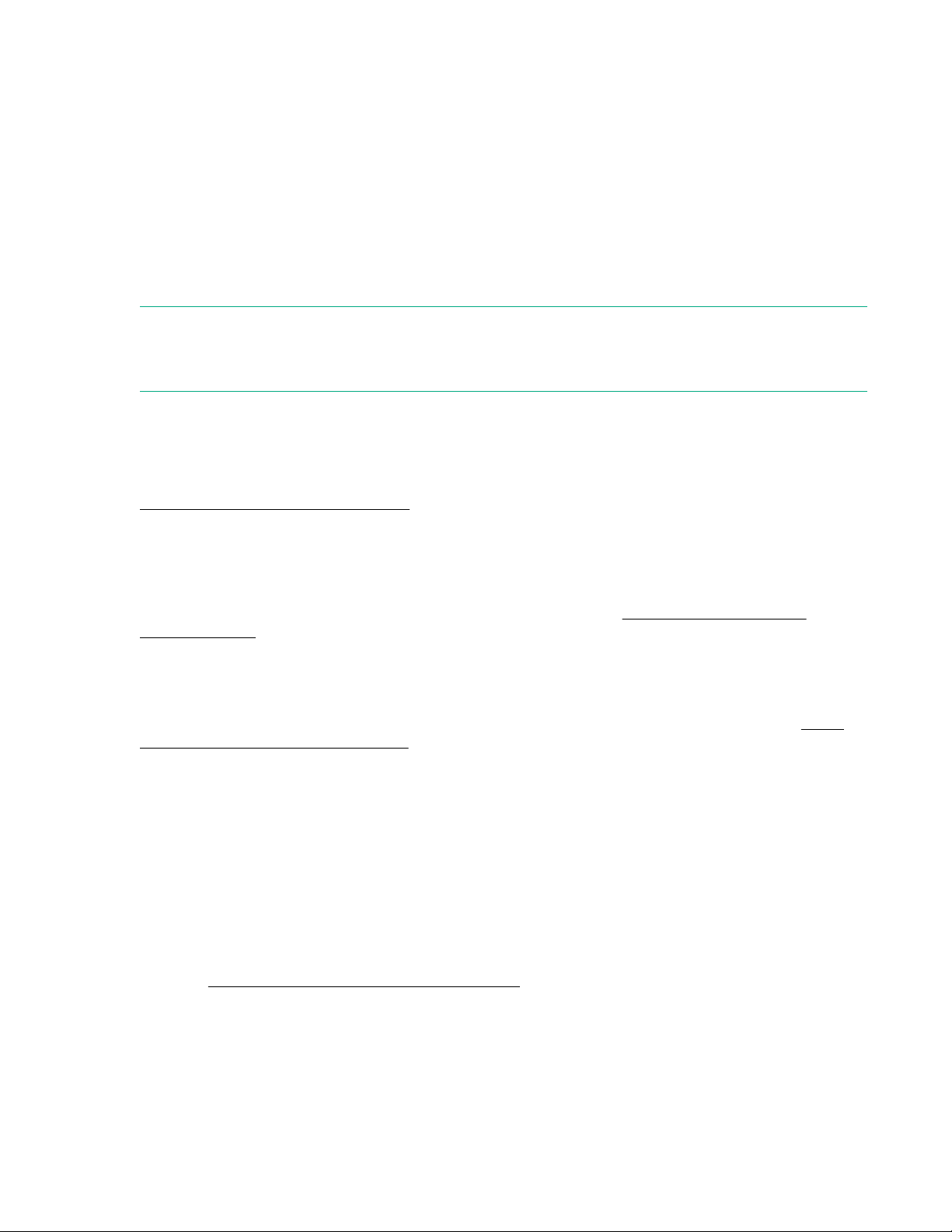

Example: Attaching server rails

2

2

2

2

1

1

2. If the server or enclosure rails are less than 1.5 mm thick, use the washers from the GENERAL

MOUNTING SCREWS screw pack for a proper fit.

Connecting the cable

If you are installing the tape drive in an enclosure using the cable that came with the enclosure, skip this

section. Follow the instructions included with the enclosure to cable the drive.

NOTE:

If both ports on the host controller are in use, in some server models you can replace one of the existing

cables with the supplied SAS cable. (This option is not recommended; use this option with care.) For

instructions, see Replacing an existing SAS hard drive cable on page 32.

Procedure

1. Connect the combined SAS and power connector to the tape drive port.

2. Connect the SAS connector without the cover to the host port, which could be on an HBA or on the

controller board.

Leave the cover on the unused SAS connector.

3. Plug the power connector into the power supply cabling.

Connecting the cable 11

Page 12

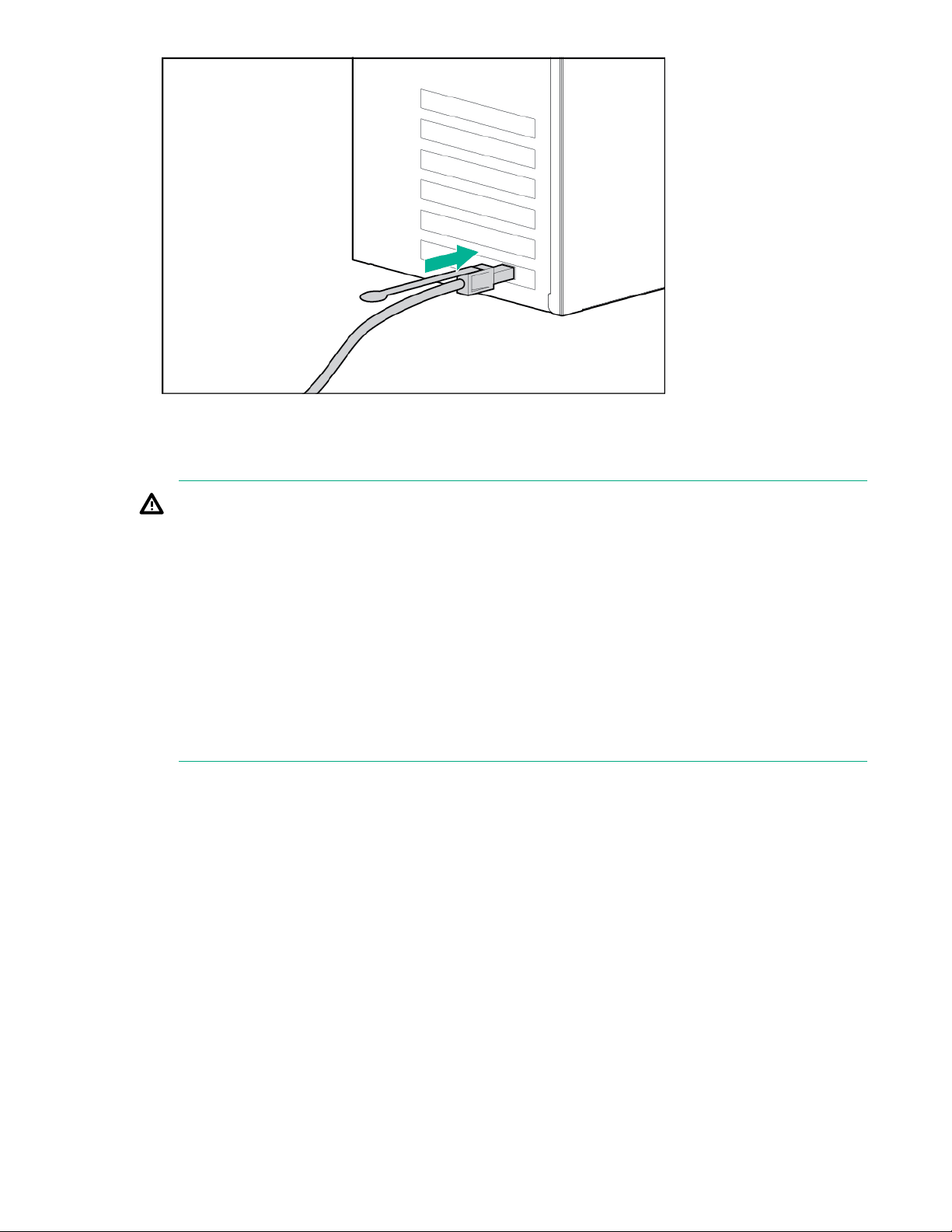

Securing the drive

Procedure

1. Slide the tape drive fully into the drive bay.

2. If the drive is secured with clips, verify that they are engaged and that the drive is secure.

If the drive is secured with fasteners, use a PoziDrive #1 screwdriver to secure the 4mm M3 screws

provided with the tape drive.

If the server sheet metal is less than 1.5mm thick, use the screws and washers provided in the

GENERAL MOUNTING SCREWS screw pack so the screws can be tightened without damaging the

drive. (The washers are not needed if the server sheet metal is at least 1.5mm thick.)

3. Cover any empty bays with blanking plates and then replace the cover on the server.

12 Securing the drive

Page 13

Installing an external tape drive

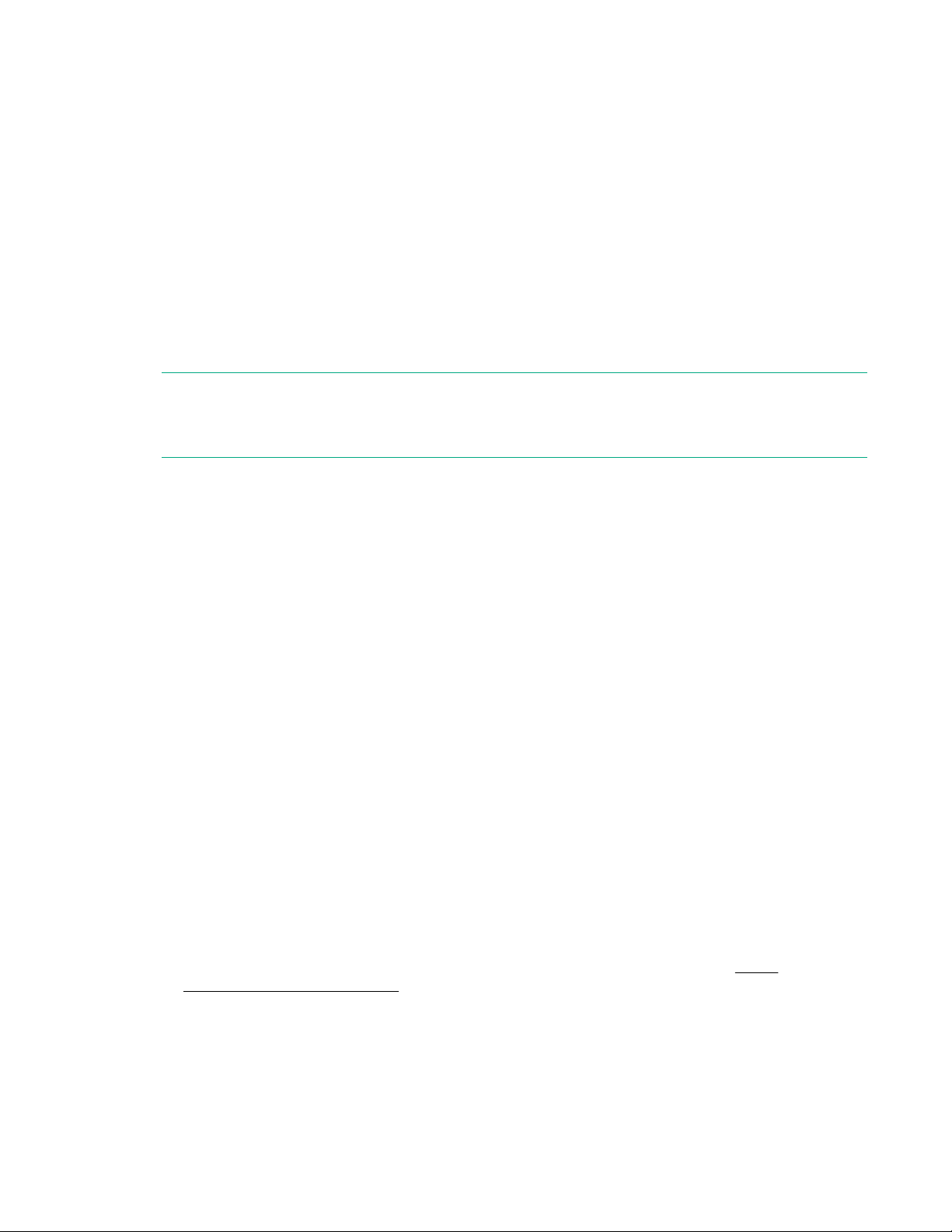

Connecting to an external SAS port

The product includes a cable to connect the tape drive to an External Mini SAS High Density (SFF-8644)

port.

If the server has a different type of SAS port, either purchase the appropriate cable, or purchase and

install a recommended HBA and associated drivers before installing the tape drive. For current

information about supported cables and HBAs, see the HPE Data Availability, Protection, and Retention

Compatibility Matrix at:

Procedure

1. Power off the server.

2. If the server does not have an active external SAS port, install the new HBA.

3. Plug the SAS cable Mini SAS connector into the Mini SAS port on the tape drive.

http://hpe.com/storage/DAPRcompatibility.

4. Plug the connector on the other end of the SAS cable into the SAS port on the server.

Installing an external tape drive 13

Page 14

5. Connect the power cord to the tape drive.

6. Connect the other end of the power cord to a grounded power outlet.

WARNING:

The supplied power cord is approved for your specific geographic region. Use of a non Hewlett

Packard Enterprise approved power cord can result in:

• not meeting individual country-specific safety requirements

• insufficient conductor ampacity that could result in overheating with potential personal injury

and/or property damage

• an unapproved power cord could fracture resulting in the internal contacts being exposed which

potentially could subject the user to a shock hazard.

Hewlett Packard Enterprise disclaims all liability in the event a non-Hewlett Packard Enterprise

approved power cord is used.

14 Installing an external tape drive

Page 15

Verifying the installation

Powering on the drive and the server

Procedure

1. For an external drive, power on the tape drive by pressing the power button on the front panel.

2. Power on the server.

3. If the BIOS for the controller in your server displays connected devices, watch the server boot screen

to verify that the new SAS tape drive is listed in the boot sequence.

If you see any error or unexpected messages, verify that the SAS cables are connected correctly. If

this does not resolve the problem, see the user guide for further troubleshooting information.

NOTE:

If you use a recommended cable to attach an external tape drive directly to the external SAS port and

the tape drive does not function, the port might be inactive or not supported for external tape devices.

When power is applied, the tape drive runs a hardware self-test, which takes up to 60 seconds.

If the self-test passes, the green Ready LED flashes and then all LEDs illuminate for a few seconds,

and finally the Ready LED remains illuminated.

If the test fails, the Drive Error and Tape Error LEDs flash, while the Ready LED remains illuminated.

This continues until the drive is reset.

Completing the installation

Verify that the correct drivers and versions of backup software are installed and that the tape drive is

functioning properly before storing data.

Procedure

1. If you have not already installed the tape drivers, install them now.

a. If you installed tape drivers before connecting the tape drive (Windows only)

The tape drive will be detected automatically and the correct drivers used.

If the Windows Found New Hardware wizard runs, cancel it and then use Device Manager to

verify that the driver is installed.

b. If tape drivers are not installed (Windows only)

If you have not already installed drivers, the Windows Found New Hardware wizard will run when

you power on the server and tape drive. Follow the on-screen instructions to search for the required

driver on the server. If necessary, download the driver from the support website: http://

www.hpe.com/support/hpesc

c. If tape drivers are not installed (other operating systems)

Drivers are included with the operating system and will be loaded automatically. To upgrade drivers,

Hewlett Packard Enterprise recommends upgrading to the latest version of the operating system.

Verifying the installation 15

Page 16

NOTE:

Certain backup applications require their own Tape driver instead of the Tape driver included with the

operating system.

2. Install Library & Tape Tools (L&TT) and then use it to verify that the tape drive installation was

successful.

L&TT is designed to diagnose any issues when using tape drives. Use it to confirm that the tape drive

is installed and functioning correctly before you use the tape drive for backup. L&TT is available

without charge at:

http://www.hpe.com/support/tapetools

3. Download and install any operating system upgrades necessary for the backup application.

4. Conduct a backup and restore test to verify that the drive can write data to tape. Use a blank cartridge.

For operating systems that contain a native backup application that supports tape devices, you can

use the native backup application to test basic tape drive operation. Native backup applications do not

support all the advanced features of the tape drive so you will need to test the advanced features with

your backup application. When testing with a third-party application, upgrade the application before

running this test.

5. If the server is using StoreOpen with LTFS, verify that the server has the latest LTFS software. If

necessary, download the latest version at:

http://www.hpe.com/storage/StoreOpen

16 Verifying the installation

Page 17

Operating the tape drive

2

1

7

3

4

5

6

1

2

3

4

5

Front panel overview

Figure 3: Tape drive front panel (external drive)

1. Eject button 2. Ready LED

3. Drive LED 4. Tape LED

5. Clean LED 6. Encryption LED

7. Power button (external drives only)

Understanding the LEDs

Figure 4: Tape drive front panel (internal drive)

1. Ready — green

• On: the drive is ready for use or there was a failure during self-test

• Off: the drive power is off

• Flashing: the drive is reading/writing data or rewinding/loading/unloading a cartridge

2. Drive — amber

Operating the tape drive 17

Page 18

• Off: no fault has been detected

• Flashing: the drive mechanism has detected a hardware error

3. Tape — amber

• Off: no fault has been detected

• Flashing: The cartridge currently in the drive is faulty (damaged or unsupported) or an attempt was

made to write to a write-protected tape. To determine if the tape is a supported generation, writeprotected, or has physical damage, inspect the cartridge. If physical damage is noted, discard the

cartridge.

4. Clean — amber

• On: cleaning cartridge in use

• Off: the drive does not require cleaning

• Flashing: the drive needs cleaning

5. Encryption — blue

• On: at power-on

• Off: some or all the data on the tape is not encrypted

• On: all data on the tape is encrypted

• On with Ready LED flashing: drive is reading/writing encrypted data and all data on the cartridge is

encrypted

• Flashing: encryption or decryption error

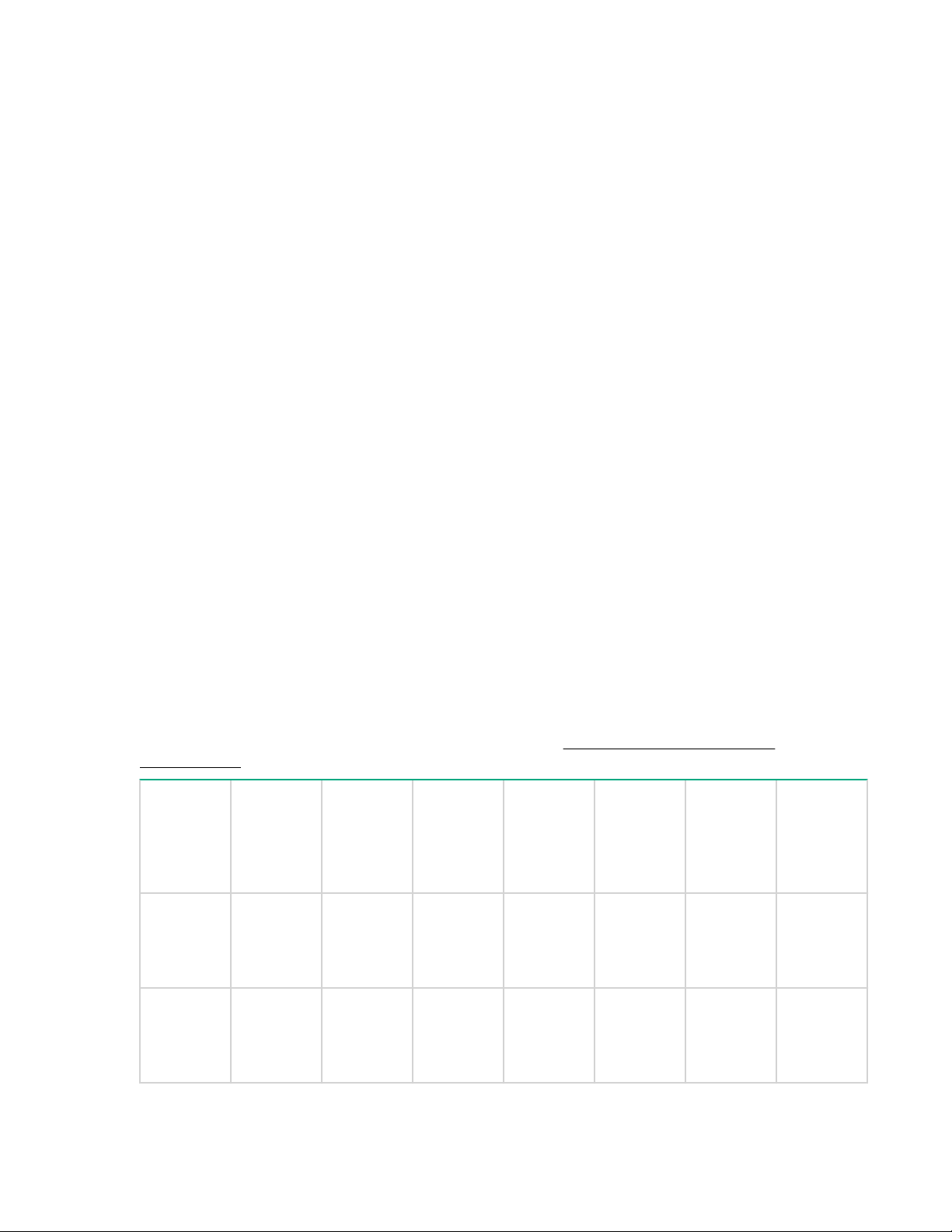

Data and cleaning cartridges

Always use Hewlett Packard Enterprise storage media to prolong the life of the tape drive. To learn more

about, or to purchase media, visit the storage media website: http://www.hpe.com/storage/

storagemedia

Tape drive

model

LTO-8

Ultrium

30750

LTO-3

800 GB

1

cartridge

not

supported

LTO-4

1.6 TB

1

cartridge

not

supported

LTO-5

1

3 TB

cartridge

not

supported

LTO-6

6.25 TB

2

cartridge

not

supported

LTO-7

2

15 TB

cartridge

read/write,

WORM

LTO-7

Type M

22.5 TB2,

cartridge

read/write

(C7977A)

LTO-8

30 TB

3

cartridge

read/write

4

(Q2078A),

WORM

(Q2078W)

2

LTO-7

Ultrium

not

supported

15000

18 Data and cleaning cartridges

not

supported

read only read/write,

WORM

read/write

(C7977A),

WORM

(C7977W)

not

supported

not

supported

Table Continued

Page 19

Tape drive

model

LTO-3

800 GB

1

cartridge

LTO-4

1.6 TB

1

cartridge

LTO-5

1

3 TB

cartridge

LTO-6

6.25 TB

cartridge

2

LTO-7

2

15 TB

cartridge

LTO-7

Type M

22.5 TB2,

cartridge

LTO-8

30 TB

3

cartridge

2

LTO-6

Ultrium

6250

not

supported

read only read/write,

WORM

read/write

(C7976A,

C7976B),

not

supported

not

supported

not

supported

WORM

(C7976W)

LTO-5

Ultrium

3000

read only read/write,

WORM

read/write

(C7975A),

WORM

not

supported

not

supported

not

supported

not

supported

(C7975W)

LTO-4

Ultrium

1760

read/write,

WORM

read/write

(C7974A),

WORM

not

supported

not

supported

not

supported

not

supported

not

supported

(C7974W)

LTO-3

Ultrium 920

read/write

(C7973A),

not

supported

not

supported

not

supported

not

supported

not

supported

not

supported

WORM

(C7973W)

1

Capacity assumes 2:1 compression

2

Capacity assumes 2.5:1 compression

3

LTO-7 Type M requires unused LTO-7 media which is initialized to allow data to be written at a higher track density.

4

LTO-7 cartridges used for LTO-7 Type M must have a M8 bar code label applied. Prelabeled M8 cartridges are also

available (Q2078MC, Q2078ML, Q2078MN)

LTO-7 cartridges initialized as Type M media

LTO-8 tape drive has a feature which allows 9 TB to be stored on an LTO-7 cartridge instead of 6 TB.

Such a cartridge is referred to as LTO-7 cartridge initialized as Type M media. When used in automation,

LTO-7 cartridges initialized as Type M media use barcode labels whose last two characters are ‘M8’. Only

new, unused LTO-7 cartridges may be initialized as LTO-7 Type M and once initialized, cannot be

changed back to a normal 6TB LTO-7 cartridge. In addition, an initialized LTO-7 Type M cartridge can only

be written and read in an LTO-8 drive; LTO-7 drives are not capable of reading LTO-7 cartridges initialized

as Type M media. LTO-7 Type M cartridges must be initialized in a library that supports the format and

this is determined by the number on the cartridge barcode label. As stated above, if the barcode ends in

‘M8’ it will be initialized as LTO-7 Type M media, otherwise it will be initialized as a normal LTO-7. To

avoid the confusion of labels not matching the cartridge format, LTO-7 Type M cartridges can only be

initialized in libraries or autoloaders. Although standalone LTO-8 drives cannot initialize LTO-7 Type M

cartridges, they are fully compatible and able to read and write any LTO-7 Type M cartridges which have

been previously initialized in a library. LTO-7 Type M media media is only available as Read/Write

cartridges, not as WORM.

WORM data cartridges

The LTO-8 tape drive includes support for both rewritable and WORM (Write Once, Read Many) data

cartridges. WORM cartridges provide an enhanced level of data security against accidental or malicious

alteration of data on the tape cartridge. Data can be appended to the WORM data cartridge to maximize

its full capacity, but data cannot be erased or overwritten. Any attempt to modify a WORM cartridge to

Operating the tape drive 19

Page 20

enable writing over existing data will result in the media becoming permanently write protected. It will still

be readable in a WORM drive, depending upon the severity of the tampering, but no further data can be

appended to the cartridge.

WORM data cartridges are clearly identified by their distinctive, two-tone cartridge color. They can only be

used with LTO Ultrium tape drives that support the WORM feature.

To verify that your backup or archive software application supports WORM cartridges, see the HPE Data

Availability, Protection, and Retention Compatibility Matrix at: http://hpe.com/storage/

DAPRcompatibility

For information on how your Hewlett Packard Enterprise LTO Ultrium tape drive and WORM cartridge can

help your business meet Information Lifecycle Management and regulatory compliance requirements, see

the Hewlett Packard Enterprise Business Support Center at: http://www.hpe.com/storage

Caring for media

Many tape drive and backup failures are caused by damaged or improperly handled tape cartridges.

• Keep the cartridge in the case provided.

• Store and transport cartridges in the vertical orientation.

• Follow the temperature, humidity, and acclimatization guidelines on the cartridge packaging.

• Avoid dropping the cartridge or handling it roughly because doing so is likely to damage the cartridge.

• Inspect cartridges regularly for damage.

• Do not exceed the normal cartridge life.

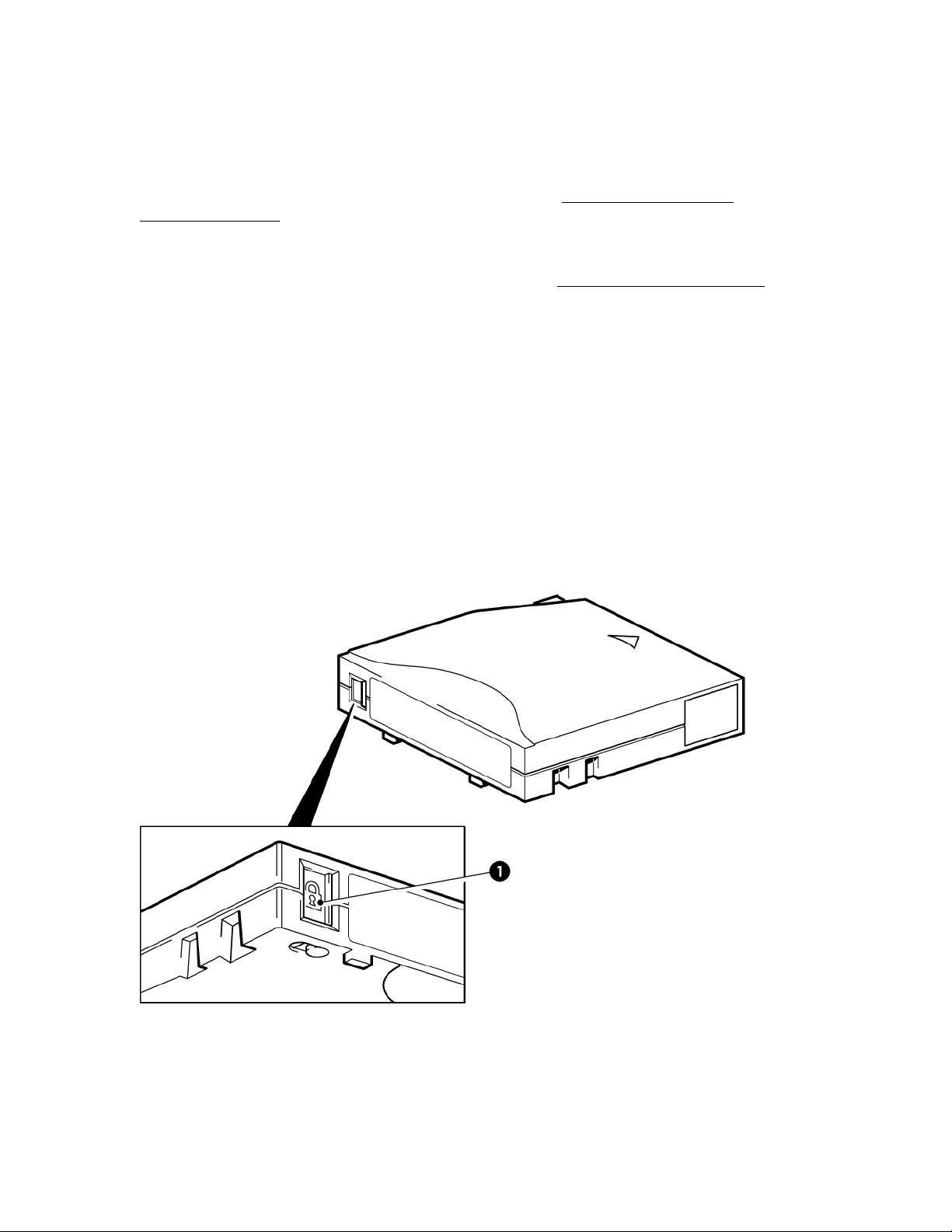

Using the cartridge write-protect switch

1. Write-protect switch

Close the write protect switch (1) to protect the data on the tape. When locked, a padlock will be visible

on the switch.

20 Operating the tape drive

Page 21

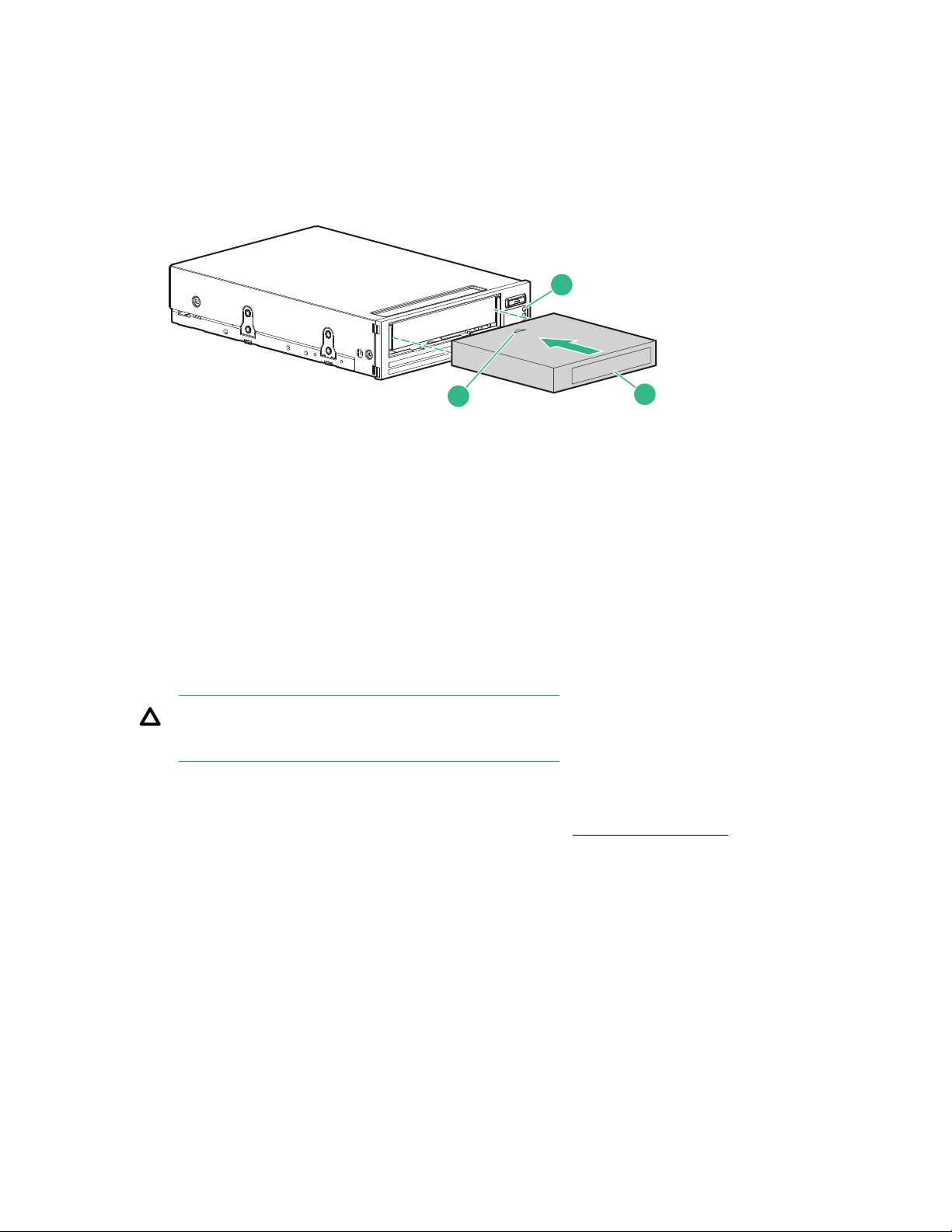

Loading a cartridge

1

3

2

Procedure

1. Insert the cartridge into the slot in the front of the drive with the arrow uppermost and facing the front

of the tape drive.

1. Ready light 2. Arrow indicates leading direction

3. Label area

Figure 5: Inserting a cartridge

2. Apply gentle pressure until the drive takes the cartridge and loads it.

3. The Ready light (3) flashes green while the drive performs its load sequence. When the cartridge is

loaded, the Ready light shows steady green.

Unloading a cartridge

CAUTION:

Never try to remove a cartridge before it is fully ejected.

Procedure

Press the Eject button on the front panel above the LEDs. See Front panel overview on page 17.

The drive will complete its current task, rewind the tape to the beginning, and then eject the cartridge. The

rewind process can take up to 10 minutes. The Ready light will flash to indicate the unload is still in

progress.

Cleaning the tape drive

LTO Ultrium tape drives do not require regular cleaning. An Ultrium universal cleaning cartridge should

only be used when the orange Clean LED is flashing.

You must use the Ultrium Universal Cleaning cartridge, (C7978A), with HPE LTO Ultrium tape drives, as

other cleaning cartridges will not load and run.

Each Ultrium universal cleaning cartridge (C7978A) can be used up to 50 times with LTO Ultrium tape

drives.

Loading a cartridge 21

Page 22

Procedure

1. Insert the Ultrium Universal Cleaning cartridge.

NOTE:

If the drive ejects the cleaning cartridge immediately with the Tape LED on, the cleaning cartridge has

expired.

The drive performs its cleaning cycle, which can take up to 5 minutes. During the cleaning cycle, the

orange Clean LED will be on solidly and the green Ready LED will flash.

The drive ejects the cleaning cartridge when the cleaning cycle is complete.

2. Remove the cleaning cartridge from the drive.

22 Operating the tape drive

Page 23

Troubleshooting

NOTE:

HPE Library & Tape Tools can be used to help diagnose many problems, see Diagnostic, management,

and support tools on page 8. For comprehensive troubleshooting information, see the detailed

troubleshooting guide at: http://www.hpe.com/support/storage

General troubleshooting procedure

If a problem occurs, the first step is to try to establish whether the problem lies with the cartridge, the

drive, the host computer and connections, or the way the system is being operated.

Has the system just been installed?

There could be an installation problem:

Procedure

1. Review the relevant installation chapters of this guide.

2. Has the system booted?

If not, verify that all hard disks are correctly seated in the hard disk bays and then verify the cabling

between the disks and the SAS controller.

3. Does an error appear during the boot sequence about a change to the RAID configuration?

This error only appears if you used the supplied cable to replace an existing SAS cable. Verify that of

the SAS cables between the disks and the SAS controller are properly seated. If the problem persists,

you probably disconnected a hard disk drive bay that was in use. For more information, see

Replacing an existing SAS hard drive cable on page 32.

4. Has the system booted but the operating system has not seen the tape drive?

Verify that the drive has power. The tape drive READY LED should be illuminated. If it is not, verify

that the power cord is connected correctly to the tape drive. If the READY LED is illuminated, inspect

the cabling between the tape drive and the SAS controller. Ensure that the HBA port to which the drive

is connected is enabled. If an external drive was powered on after the server, power cycle the server.

5. Are appropriate Tape drivers and HBA drivers, as well as supported application software, installed on

the host?

6. Verify that the environmental conditions are within the specified limits.

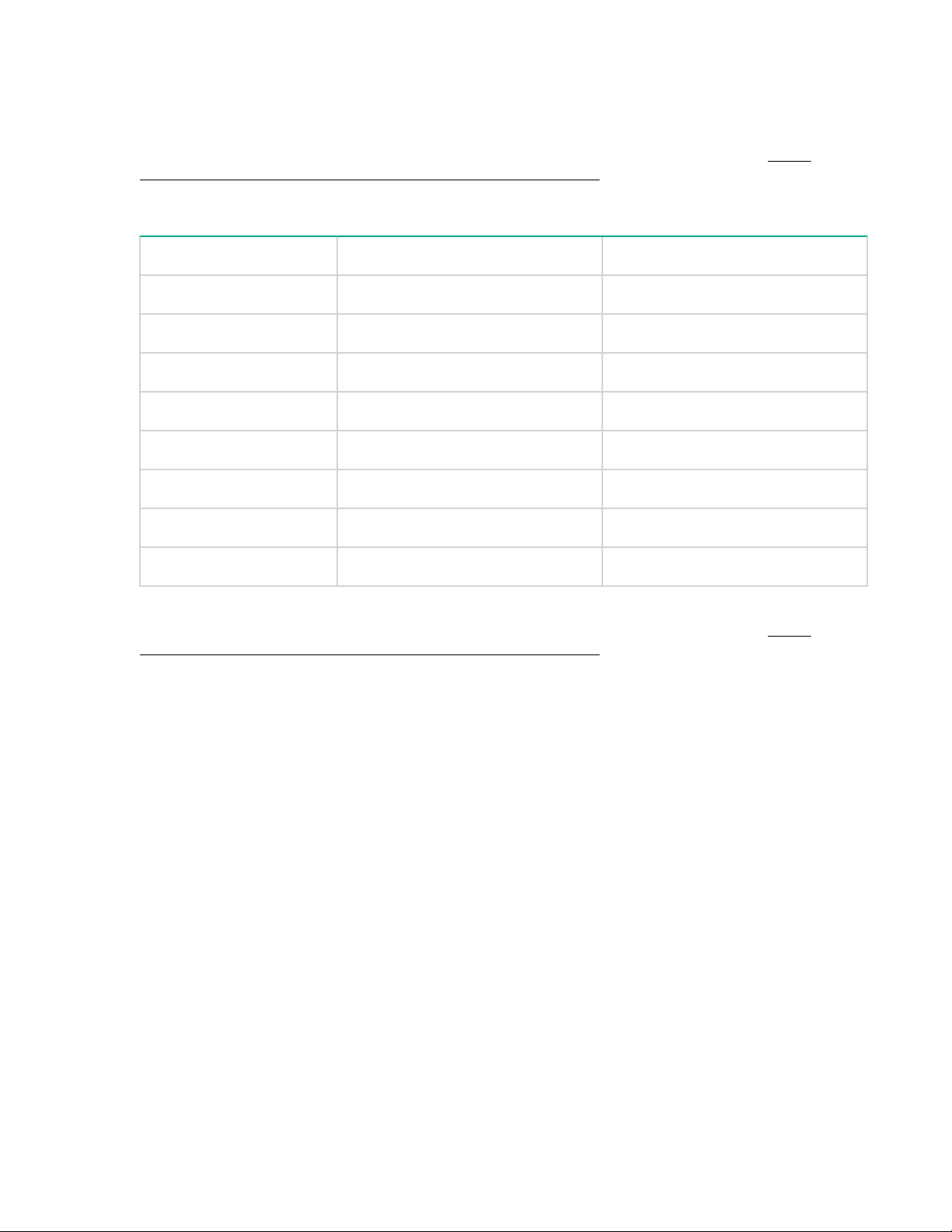

Table 1: Environmental specifications for LTO-8 Ultrium 30750 tape drives

Temperature range Non-condensing humidity range

Operating

10° to 40° C up to 3000m with 3 CFM airflow

10° to 30° C up to 4000m with 3 CFM or

greater airflow

20% to 80% RH (non-condensing)

Storage

-40° to 60° C 10% to 90% RH (non-condensing)

Troubleshooting 23

Page 24

Are you using new cartridges or a different brand of cartridge? Have you been using the particular

cartridge for a long time?

The problem could lie with the cartridge:

1. Review the media information in Data and cleaning cartridges on page 18.

2. Check that you are using an Ultrium cartridge. Compatible media can be recognized by the Ultrium

logo, which is the same as the logo on the front of your drive.

3. Use the correct media type. For media compatibility, see Data and cleaning cartridges on page 18.

4. Verify that the cartridge is not write-protected. See Data and cleaning cartridges on page 18

5. Clean the tape heads with the cleaning cartridge, see Cleaning the tape drive on page 21.

Verify that you are using the HPE Ultrium Universal cleaning cartridge, C7978A.

6. If the Tape LED is flashing, the cartridge is probably faulty. Try using a different cartridge.

7. Try the operation again.

8. If the problem still occurs and you have not yet replaced the cartridge, try using a different cartridge.

9. If the problem is still there, the problem probably lies with the drive or the host computer.

For additional troubleshooting help with cartridges, see Problems with cartridges on page 28.

Has the drive been moved recently? Have any cables been disconnected and reconnected? Has

the environment changed—unusually hot, cold, damp, or dry? Has there been dust or dirt near the

drive. Have reasonable precautions against static been taken?

The problem could lie with the drive:

1. Inspect the cables and connectors.

2. Clean the tape heads with the cleaning cartridge.

3. If the problem persists, verify that the environmental conditions are within the specified limits, see the

previous table. Consider moving the drive to a more suitable site.

Has a new operating system been installed in the host computer? Has new backup software been

installed?

The problem could lie with the host or the software. Consult the host computer’s operating system

documentation, the software documentation, or seek help from a service engineer.

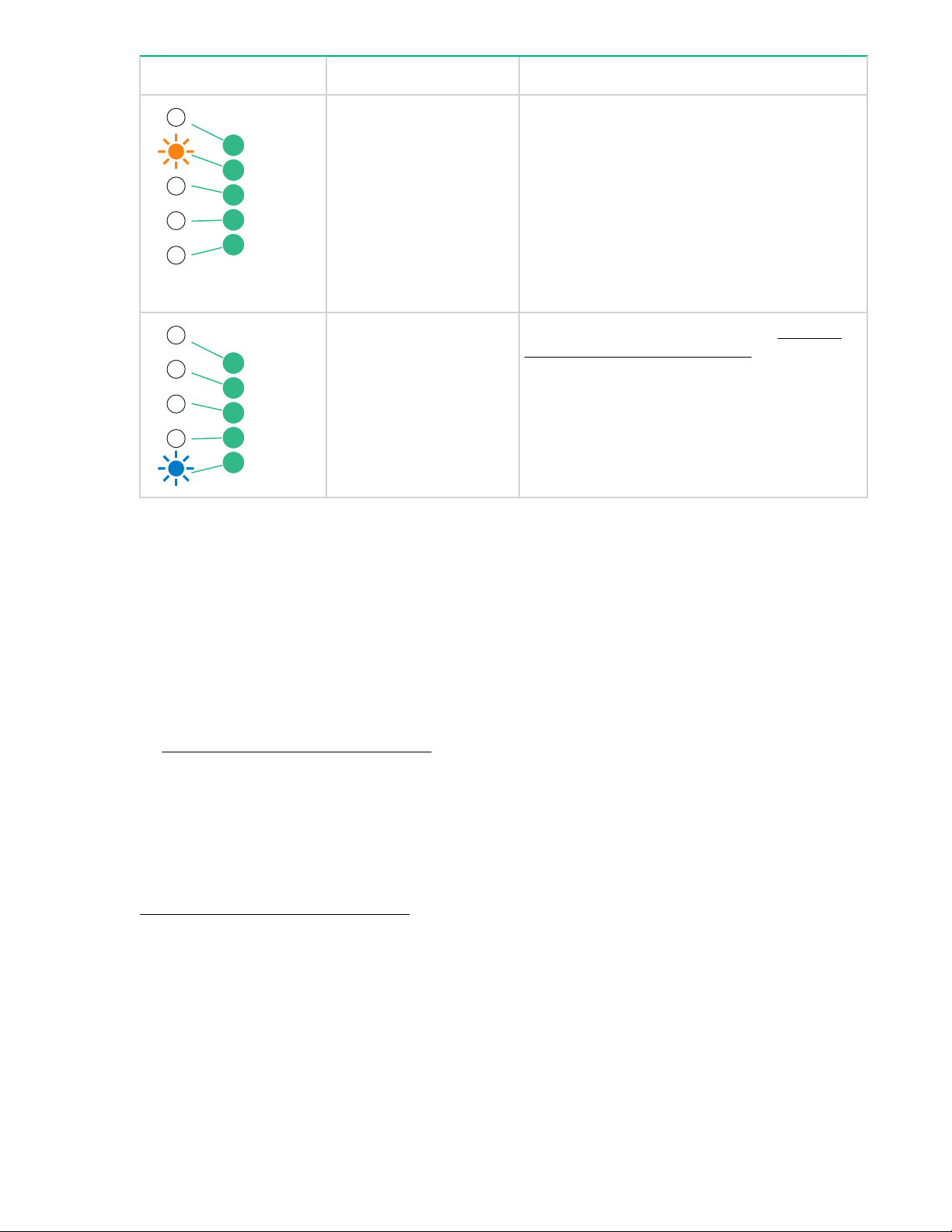

LED sequences

For basic LED operation during normal operation, see Understanding the LEDs on page 17.

24 LED sequences

Page 25

1

2

3

4

5

The following table shows the meaning of different LED patterns.

1

2

3

4

5

1

2

3

4

5

Table 2: LED troubleshooting

1. Ready: green

2. Drive: amber

3. Tape: amber

4. Clean: amber

5. Encryption: blue

LED Sequence

All LEDs OFF.

Cause Action required

Drive might not have

power, may be faulty, or

may have been power

cycled or reset during a

firmware upgrade.

Make sure that the drive is powered on. The

power on/off switch on an external drive

incorporates a green LED.

Check the power cable connection and replace

the cable if necessary. On external drives, you

can use the power cable from your monitor or

another device to check that the connection is

working.

If the power supply is present and all LEDs

remain off, power cycle or reset the drive (see

Problems with cartridges on page 28). If it

still fails, call for service.

The drive has failed the

power-on self-test

(POST).

Power cycle or reset the drive (see Problems

with cartridges on page 28).

If the error condition reappears, call for service.

Ready is ON, Drive and

Tape FLASH.

Table Continued

Troubleshooting 25

Page 26

LED Sequence

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Cause Action required

Ready is ON.

Ready FLASHES.

The drive is ready for

operation.

The drive is carrying out a

normal activity (read,

write).

The drive is reading or

writing encrypted data

and all data on the

cartridge is encrypted.

None. This is normal.

None.

If the drive is upgrading firmware, do not reset or

power cycle it.

None. This is normal.

Ready FLASHES and

Encryption is ON.

Ready FLASHES fast.

26 Troubleshooting

The drive is downloading

firmware.

None.

Do not reset or power cycle the drive.

Table Continued

Page 27

LED Sequence

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Cause Action required

Ready is OFF, others

are ON.

Clean FLASHES.

Firmware is being

reprogrammed.

The drive requires

cleaning.

None.

Do not reset or power cycle the drive.

Load the Ultrium cleaning cartridge. For

supported cartridges and instructions, see Data

and cleaning cartridges on page 18.

If the Clean LED is still flashing when you load a

new or known good data cartridge after cleaning,

call for service.

Ready FLASHES and

Clean is ON.

Tape FLASHES.

Cleaning is in progress. None. The cleaning cartridge will eject on

completion.

The cleaning cycle can take up to 5 minutes to

complete.

The drive believes the

current tape or the tape

just ejected is write

protected, unsupported,

or faulty.

Unload the tape cartridge. Verify that you are

using the correct format cartridge; an Ultrium

data cartridge or Ultrium universal cleaning

cartridge. For supported cartridges and

instructions, see Data and cleaning cartridges

on page 18.

Reload the cartridge. If the Tape LED still flashes

or starts flashing during the next backup, load a

new or known good cartridge.

If the Tape LED is now off, discard the 'suspect'

tape cartridge. If it is still on, call for service.

Table Continued

Troubleshooting 27

Page 28

LED Sequence

1

2

3

4

5

1

2

3

4

5

Cause Action required

The drive mechanism has

detected an error or there

is a firmware error.

Drive FLASHES.

The drive has an

encryption error.

Problems with cartridges

Load a new cartridge. If the error persists, power

cycle or reset the drive.

If the error persists, upgrade the drive firmware

to the most recent version.

If the Drive LED remains on, call for service.

For troubleshooting information, see Methods

for troubleshooting encryption on page 30.

If you experience any problems using Hewlett Packard Enterprise branded cartridges, verify the following:

• The cartridge case is intact and that it contains no splits, cracks, or damage.

• The cartridge has been stored at the correct temperature and humidity. It prevents condensation. See

the insert included with the tape cartridge for storage conditions.

• The write-protect switch is fully operational. It will move from side to side with a positive click.

• The support website for additional troubleshooting information:

http://www.hpe.com/support/storage

The cartridge is jammed

If the cartridge is jammed or the backup application is unable to eject it, you can force eject the cartridge.

Once the cartridge is successfully ejected, it is good practice to run Library & Tape Tools to diagnose the

problem and to upgrade the firmware. If the failure occurs regularly, contact customer service:

http://www.hpe.com/support/storage

Procedure

1. Attempt a drive unload/eject operation from the backup software.

Many backup applications will issue a Prevent Media Removal (PMR) command to the drive in an

attempt to prevent human interference during a backup job. If this command occurs, the software

that issued the PMR must be used to load and unload tapes.

2. Shut down backup software and, if in a Windows environment, stop removable storage services.

28 Problems with cartridges

Page 29

3. Press the Eject button on the front of the tape drive.

Sometimes it is necessary to use the Eject button instead of software to unload a tape because

software can lose communication with the product or a rogue application can prevent the software

from unloading the tape.

IMPORTANT:

This can take several minutes in many cases. Ensure that drive activity has stopped before

continuing on (waiting 10 minutes is a good rule of thumb). It is important that you allow

sufficient time for the drive to complete rewinding the cartridge. If you interrupt it, you may

damage the media or the tape drive.

4. Initiate a force eject or emergency unload operation by pressing and holding the Eject button for 10

seconds. This step causes the drive to try everything possible to unload the tape.

CAUTION:

You may lose data if you force eject a cartridge that is in the middle of a backup. The tape may

also become unreadable because an EOD (End of Data) mark may not be properly written.

5. Run the L&TT Stuck Tape test.

Run L&TT on a host connected to the product, select the drive, select the tests, and run the Stuck

Tape test.

NOTE:

it is good practice to obtain a Support Ticket to capture all the logs in case they are needed by

Hewlett Packard Enterprise Support.

• This test can overcome many nonphysical causes of a stuck tape.

• Follow the instructions in L&TT. It may take several minutes and may not appear to be doing

anything. Allow the test to complete on its own.

• Check the results when the test is complete for additional information and suggestions.

6. If the cartridge could be ejected prior to this step, there is no problem with the drive or media and the

following steps are not required. If it could not be ejected using the preceding steps, there may be a

problem with the cartridge or drive.

Power down the drive.

7. Disconnect the data cable.

8. After at least 15 seconds, power the drive back up and wait until the drive is idle/ready.

CAUTION:

Use care when disconnecting data cables.

IMPORTANT:

Powering up with a cartridge in the drive can take several minutes. It is important that you allow

sufficient time for the drive to complete rewinding the cartridge. If you interrupt it, you may

damage the media or the tape drive.

Troubleshooting 29

Page 30

9. Ensure that drive activity has stopped (waiting 10 minutes after power-up is a good rule of thumb).

Push the Eject button.

This step attempts to overcome unload issues due to the drive being in an abnormal state or

because Prevent Media Removal has been incorrectly left on after being set by a rogue application.

10. If the cartridge is still jammed, the tape drive has failed. Contact customer support at:

http://www.hpe.com/support/storage

Once the cartridge is successfully ejected, it is good practice to run Library & Tape Tools to diagnose the

problem and upgrade the firmware. If the failure occurs regularly on multiple cartridges, contact customer

support at:

http://www.hpe.com/support/storage

The drive will not accept the cartridge (or ejects it immediately)

The cartridge might be unsupported, have been damaged (for example, dropped), or the drive might have

a fault. If it is a cleaning cartridge, it has probably expired and must be discarded immediately. For data

cartridges:

Procedure

1. Verify that the drive has power (the power cord is properly connected and the Ready LED is on).

2. Verify that the drive has the correct media. Use only Ultrium media. For supported cartridges, see

Data and cleaning cartridges on page 18.

3. Make sure that you have loaded the cartridge with the correct orientation (see Loading a cartridge on

page 21).

4. Inspect the cartridge for damage and discard it, if it is damaged.

5. Use a new or known good piece of media and see if it loads. If it does, the original cartridge is faulty

and must be discarded.

6. See if another LTO Ultrium drive of the same model will accept the cartridge. If it does, the original

drive might be faulty. Before calling customer service, verify that the tape drive is responding.

Methods for troubleshooting encryption

• Ensure that you are using an LTO-8 tape drive and an HPE LTO-7 or LTO-8 data cartridge.

• Verify that your application software supports the LTO-8 tape drive. If not, update the application

software.

• Verify that your software supports hardware encryption. Update the firmware if necessary. For more

information consult your software vendor or see the HPE Data Availability, Protection, and Retention

Compatibility Matrix at: http://hpe.com/storage/DAPRcompatibility

• Ensure that the correct key or passphrase has been entered.

30 The drive will not accept the cartridge (or ejects it immediately)

Page 31

Replacing a tape drive

If a tape drive proves to be faulty, cannot be repaired, and is still covered by the original warranty, it will be

replaced under warranty. Based on availability and where geography permits, the replacement tape drive

will be shipped for next business day delivery. Same day or four-hour delivery may be offered at an

additional charge where geography permits. If you request Hewlett Packard Enterprise to install the

replacement tape drive, you will be charged for the travel and labor costs of this service.

NOTE:

If you are not replacing an internal tape drive immediately, insert a blanking plate into the empty bay.

Replace the cover on the server and secure with screws, as appropriate.

See the complete Hewlett Packard Enterprise limited warranty statement at:

http://www.hpe.com/support/Storage-Warranties

Disconnecting the tape drive

Procedure

1. Unpack the replacement drive, and retain the packaging.

2. Power off the server and disconnect from the mains power supply.

3. Internal drives only: Remove the cover from the server. Observing normal anti-static precautions

remove any screws that are holding the tape drive in place.

4. Disconnect the drive's power and SAS cables. Slide internal drives carefully out of the mounting bay.

5. Put the drive into the packaging that contained the replacement drive.

6. Return the faulty drive to your local Hewlett Packard Enterprise Service Center. Instructions on where

to return faulty drives will be shipped with the replacement drive. You must ship the defective drive

back to Hewlett Packard Enterprise within a defined period, normally five (5) business days. The

defective part must be returned with the associated documentation in the provided shipping material.

Failure to return the defective part may result in Hewlett Packard Enterprise billing you for the

replacement. Hewlett Packard Enterprise will pay all shipping and part return costs and determine the

courier/carrier to be used.

To install the replacement drive, follow the instructions in Installing an internal tape drive on page 10 or

Installing an external tape drive on page 13

Replacing a tape drive 31

Page 32

Replacing an existing SAS hard drive cable

The following instructions are valid for some HPE ProLiant servers.

This installation uses the HPE SAS split cable to replace one of the existing SAS cables from the host

SAS controller to the server's SAS hard disk drive bays. The SAS data cable has four datapaths; this

configuration diverts the wiring from one of the hard disk drive bays to the tape drive. You might lose the

use of a hard disk drive bay with this cabling solution.

CAUTION:

Do NOT use this option with RAID configurations.

Procedure

1. Remove the plastic covers from both connectors on the supplied mini-SAS cable. You will need to use

the SAS connector on the second branch of the cable for this installation.

2. Hewlett Packard Enterprise strongly recommends that the tape drive is connected to the second SAS

port on the host controller (this is the port that connects to the hard disk drive bays with the highest

numbers). Look at the front of the server and establish which SAS cable is connected to the hard disk

drive bays with the highest numbers.

Cable routing varies from one server to another. You may need to remove other components, such as

fan banks, while you work with the cable. Always refer to your server documentation for server-specific

cabling instructions.

CAUTION:

It is not possible to identify which disk drive bay will be lost for all servers (it is normally the

highest-numbered disk bay). The only way to be sure, is to check the disk LEDs after installing

the tape drive. For this reason, you should never attempt this installation if you have a disk RAID

configuration.

3. Remove the existing SAS cable.

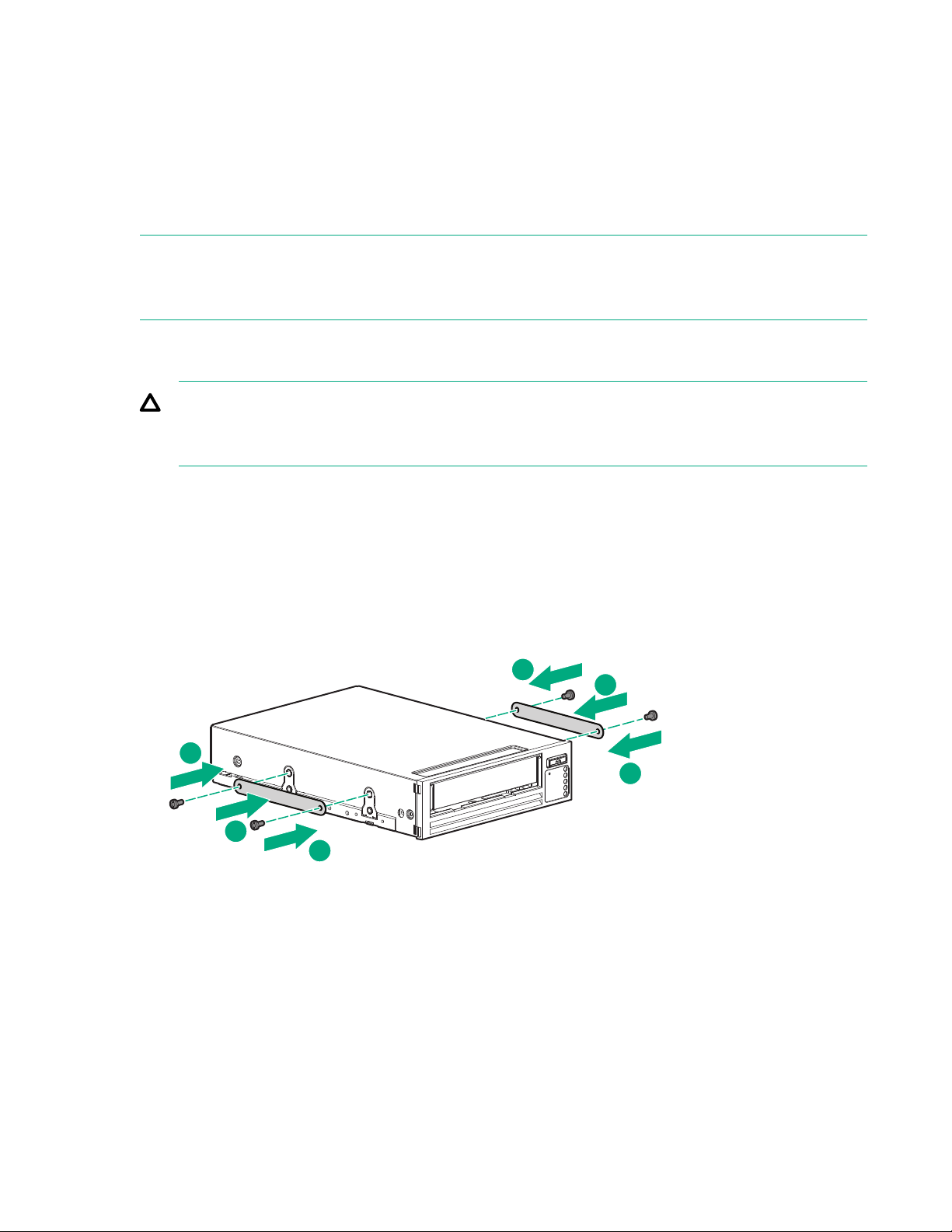

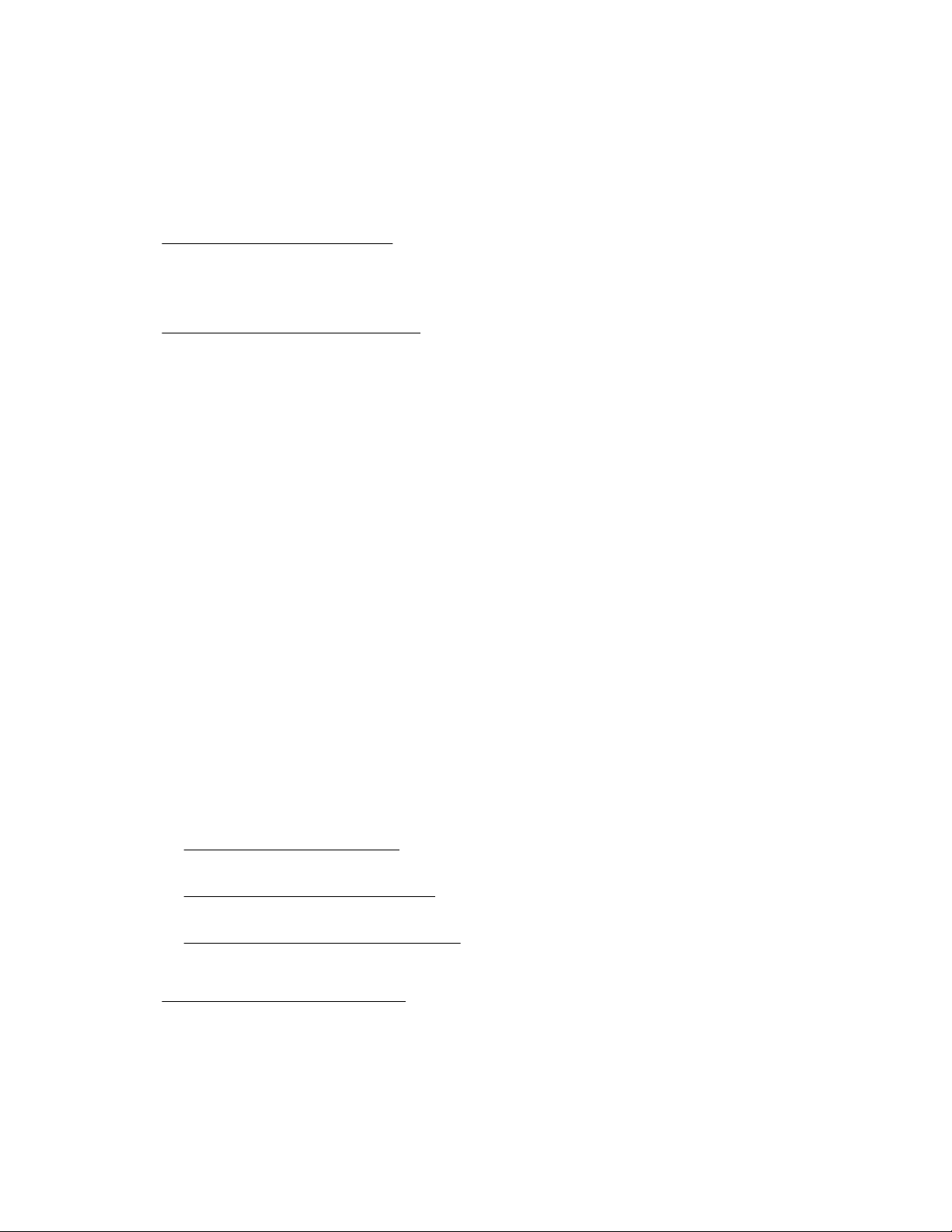

Figure 6: Removing the existing SAS cable

32 Replacing an existing SAS hard drive cable

Page 33

1. Host SAS controller (HBA) 3. Rear of server

2. Cable to be removed 4. Front of server

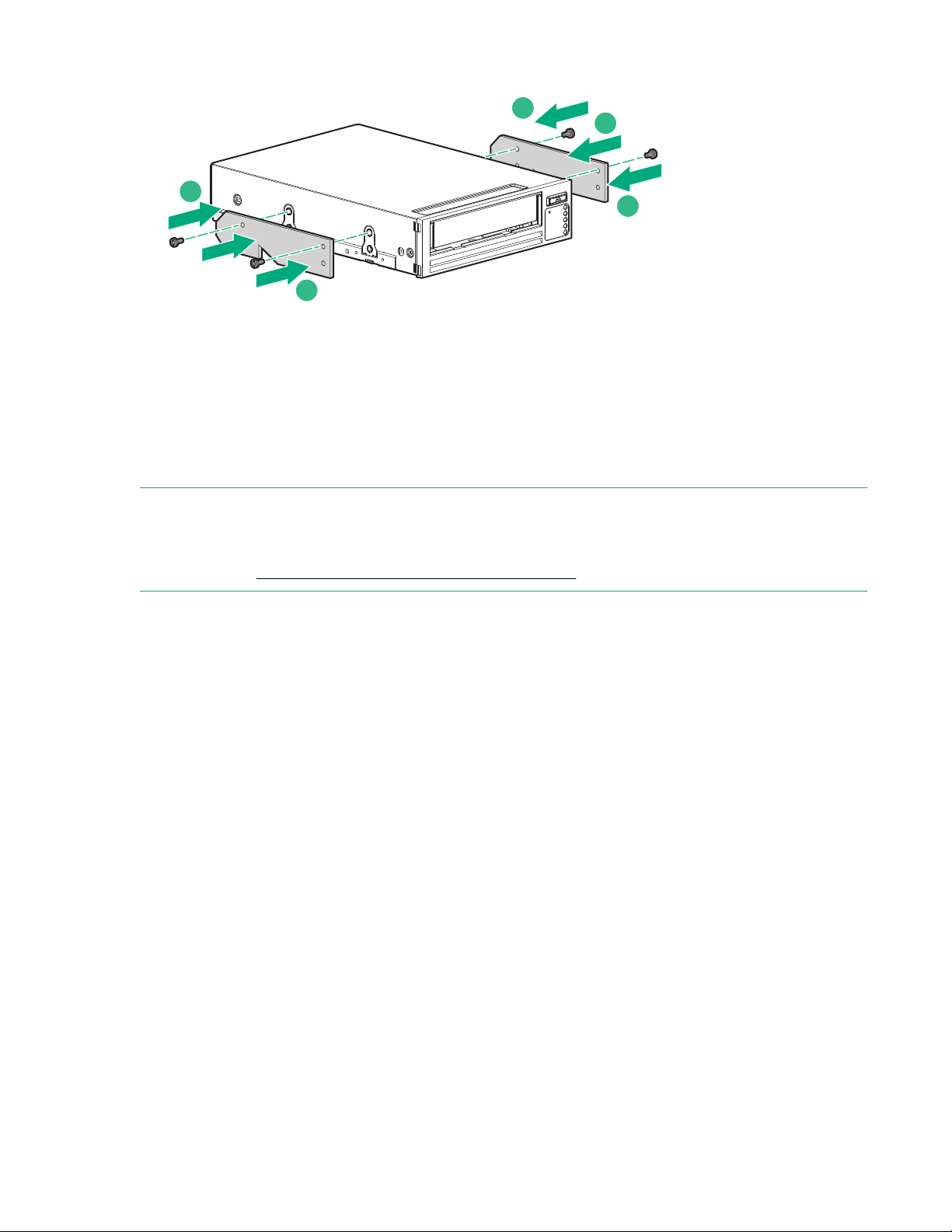

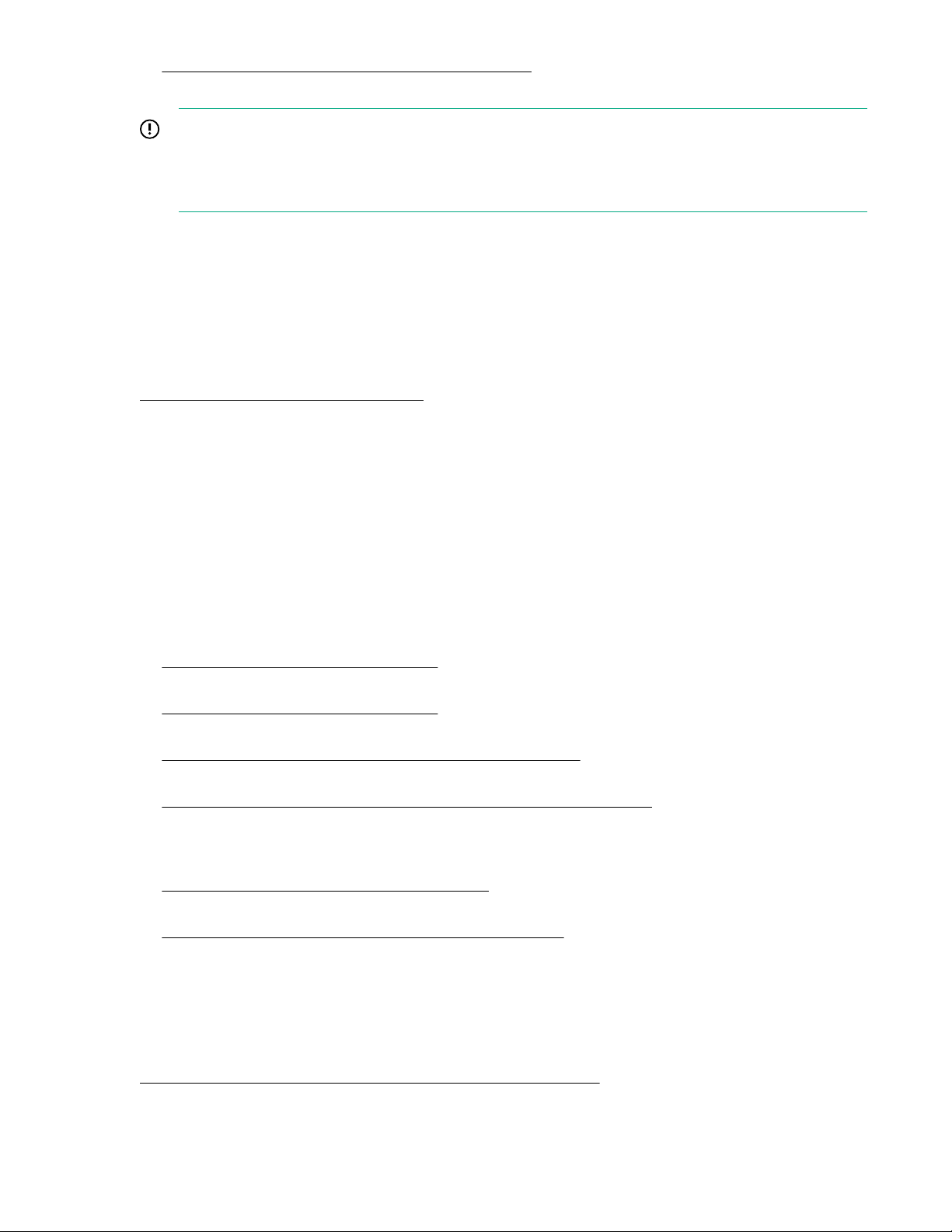

4. Connect the replacement cable supplied with the tape drive to the host SAS controller, as illustrated in

the following diagram.

Figure 7: Cable routing with replacement SAS cable

1. Replacement SAS cable 3. Connect replacement SAS cable to disk bay

2. Connect replacement SAS cable to host SAS

HBA

5. Power connector to server

5. Attach the SAS cable to the SAS connector on the tape drive.

4. SAS connector to tape drive

Replacing an existing SAS hard drive cable 33

Page 34

Connect a spare power cable from the server's internal power supply to the power connector on the

SAS data cable.

6. If the server lost the use of a disk bay, apply the supplied sticker to the blanking plate of the disk bay to

show that it is disconnected.

NOTE:

If you subsequently install a hard disk in this bay, it will not work. This does not mean that there is a

fault with either the disk or the server.

7. To continue the installation procedure, see Securing the drive on page 12.

34 Replacing an existing SAS hard drive cable

Page 35

Support and other resources

Accessing Hewlett Packard Enterprise Support

• For live assistance, go to the Contact Hewlett Packard Enterprise Worldwide website:

http://www.hpe.com/assistance

• To access documentation and support services, go to the Hewlett Packard Enterprise Support Center

website:

http://www.hpe.com/support/hpesc

Information to collect

• Technical support registration number (if applicable)

• Product name, model or version, and serial number

• Operating system name and version

• Firmware version

• Error messages

• Product-specific reports and logs

• Add-on products or components

• Third-party products or components

Accessing updates

• Some software products provide a mechanism for accessing software updates through the product

interface. Review your product documentation to identify the recommended software update method.

• To download product updates:

Hewlett Packard Enterprise Support Center

www.hpe.com/support/hpesc

Hewlett Packard Enterprise Support Center: Software downloads

www.hpe.com/support/downloads

Software Depot

www.hpe.com/support/softwaredepot

• To subscribe to eNewsletters and alerts:

www.hpe.com/support/e-updates

• To view and update your entitlements, and to link your contracts and warranties with your profile, go to

the Hewlett Packard Enterprise Support Center More Information on Access to Support Materials

page:

Support and other resources 35

Page 36

www.hpe.com/support/AccessToSupportMaterials

IMPORTANT:

Access to some updates might require product entitlement when accessed through the Hewlett

Packard Enterprise Support Center. You must have an HPE Passport set up with relevant

entitlements.

Customer self repair

Hewlett Packard Enterprise customer self repair (CSR) programs allow you to repair your product. If a

CSR part needs to be replaced, it will be shipped directly to you so that you can install it at your

convenience. Some parts do not qualify for CSR. Your Hewlett Packard Enterprise authorized service

provider will determine whether a repair can be accomplished by CSR.

For more information about CSR, contact your local service provider or go to the CSR website:

http://www.hpe.com/support/selfrepair

Remote support

Remote support is available with supported devices as part of your warranty or contractual support

agreement. It provides intelligent event diagnosis, and automatic, secure submission of hardware event

notifications to Hewlett Packard Enterprise, which will initiate a fast and accurate resolution based on your

product's service level. Hewlett Packard Enterprise strongly recommends that you register your device for

remote support.

If your product includes additional remote support details, use search to locate that information.

Remote support and Proactive Care information

HPE Get Connected

www.hpe.com/services/getconnected

HPE Proactive Care services

www.hpe.com/services/proactivecare

HPE Proactive Care service: Supported products list

www.hpe.com/services/proactivecaresupportedproducts

HPE Proactive Care advanced service: Supported products list

www.hpe.com/services/proactivecareadvancedsupportedproducts

Proactive Care customer information

Proactive Care central

www.hpe.com/services/proactivecarecentral

Proactive Care service activation

www.hpe.com/services/proactivecarecentralgetstarted

Warranty information

To view the warranty for your product or to view the Safety and Compliance Information for Server,

Storage, Power, Networking, and Rack Products reference document, go to the Enterprise Safety and

Compliance website:

www.hpe.com/support/Safety-Compliance-EnterpriseProducts

36 Customer self repair

Page 37

Additional warranty information

HPE ProLiant and x86 Servers and Options

www.hpe.com/support/ProLiantServers-Warranties

HPE Enterprise Servers

www.hpe.com/support/EnterpriseServers-Warranties

HPE Storage Products

www.hpe.com/support/Storage-Warranties

HPE Networking Products

www.hpe.com/support/Networking-Warranties

Regulatory information

To view the regulatory information for your product, view the Safety and Compliance Information for

Server, Storage, Power, Networking, and Rack Products, available at the Hewlett Packard Enterprise

Support Center:

www.hpe.com/support/Safety-Compliance-EnterpriseProducts

Additional regulatory information

Hewlett Packard Enterprise is committed to providing our customers with information about the chemical

substances in our products as needed to comply with legal requirements such as REACH (Regulation EC

No 1907/2006 of the European Parliament and the Council). A chemical information report for this product

can be found at:

www.hpe.com/info/reach

For Hewlett Packard Enterprise product environmental and safety information and compliance data,

including RoHS and REACH, see:

www.hpe.com/info/ecodata

For Hewlett Packard Enterprise environmental information, including company programs, product

recycling, and energy efficiency, see:

www.hpe.com/info/environment

Documentation feedback

Hewlett Packard Enterprise is committed to providing documentation that meets your needs. To help us

improve the documentation, send any errors, suggestions, or comments to Documentation Feedback

(docsfeedback@hpe.com). When submitting your feedback, include the document title, part number,

edition, and publication date located on the front cover of the document. For online help content, include

the product name, product version, help edition, and publication date located on the legal notices page.

Regulatory information 37

Page 38

Warranty and regulatory information

For important safety, environmental, and regulatory information, see Safety and Compliance Information

for Server, Storage, Power, Networking, and Rack Products. The information is available at

www.hpe.com/support/Safety-Compliance-EnterpriseProducts.

Table 3: Regulatory model numbers

Product Regulatory Model Number FCC and CISPR classification

LTO-8 Ultrium HH SAS BRSLA-7HSS-AC Class A

LTO-7 Ultrium HH SAS BRSLA-7HSS-AC Class A

LTO-6 Ultrium HH SAS BRSLA-1204-AC Class A

LTO-5 Ultrium HH SAS BRSLA-0904-AC Class A

LTO-4 Ultrium HH SAS BRSLA-0703-AC Class A

LTO-4 Ultrium HH SCSI BRSLA-0704-AC Class A

LTO-3 Ultrium HH SAS BRSLA-0705-AC Class B

http://

LTO-3 Ultrium HH SCSI BRSLA-0605-AC Class B

For important safety, environmental, and regulatory information, see Safety and Compliance Information

for Server, Storage, Power, Networking, and Rack Products. The information is available at http://

www.hpe.com/support/Safety-Compliance-EnterpriseProducts.

Manufacturer: Hewlett Packard Enterprise Company, Palo Alto, California

Manufacturer’s representative: ZAO Hewlett Packard Enterprise A.O.

38 Warranty and regulatory information

Loading...

Loading...