HP Officejet Enterprise Color X555, Officejet Enterprise Color MFP X585 Repair Manual and Troubleshooting Manual

Page 1

Officejet Enterprise Color X555

Officejet Enterprise Color MFP X585

Troubleshooting Manual

c

aps

l

ock

A S D

shift

F

Z

X

G

C

@

H

J

a

V

K

l

t

B

N

L

M

:

“

;

e

nt

,

e

r

‘

?

.

a

lt

s

hi

f

t

/

www.hp.com/support/ojcolorX555

www.hp.com/support/ojcolorMFPX585

Page 2

Page 3

HP Officejet Enterprise Color X555 and MFP

X585 Series

Troubleshooting Manual

Page 4

Copyright and License

Trademark Credits

© 2014 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Edition 1, 4/2014

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered trademarks

of Microsoft Corporation.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging the

product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal injury,

catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

Table of contents

1 Theory of operation ....................................................................................................................................... 1

Basic operation ...................................................................................................................................................... 2

Function structure ............................................................................................................................... 2

Operation sequence ............................................................................................................................ 4

System control ....................................................................................................................................................... 7

Formatter and data path ..................................................................................................................... 7

Engine control ..................................................................................................................................... 8

Pen interface (I/F) .............................................................................................................................. 10

Power supply ..................................................................................................................................... 10

Print subsystem ................................................................................................................................................... 12

Printbar .............................................................................................................................................. 13

Printbar lift ........................................................................................................................................ 14

Ink cartridges ..................................................................................................................................... 15

Optical scan carriage ......................................................................................................................... 15

Print system operational states ....................................................................................................... 15

Paper-handling system ....................................................................................................................................... 17

Input trays ......................................................................................................................................... 24

Paper path zones .............................................................................................................................. 24

Servicing system .................................................................................................................................................. 28

Service sled ....................................................................................................................................... 30

Aerosol management system ............................................................................................................................. 31

Document feeder (X585 models) ........................................................................................................................ 33

Document feeder operation .............................................................................................................. 33

Document feeder paper path and sensors ....................................................................................... 33

Document feeder jam detection ....................................................................................................... 34

Scanner system (X585 models) .......................................................................................................................... 35

Scanner power-on sequence of events ............................................................................................ 35

Copy or scan-to-computer sequence of events ............................................................................... 36

Fax functions and operation (X585 models) ....................................................................................................... 37

Computer and network security features ........................................................................................ 37

PSTN operation ................................................................................................................................. 37

The fax subsystem ............................................................................................................................ 37

ENWW v

Page 8

Fax card in the fax subsystem .......................................................................................................... 37

Fax page storage in flash memory ................................................................................................... 39

2 Solve problems ........................................................................................................................................... 41

Problem-solving checklist ................................................................................................................................... 42

Step 1: Check that the product power is on ...................................................................................... 42

Step 2: Check the control panel for error messages ........................................................................ 42

Step 3: Test print functionality ......................................................................................................... 43

Step 4: Test copy functionality ......................................................................................................... 43

Step 5: Test the fax sending functionality ........................................................................................ 43

Step 6: Test the fax receiving functionality ...................................................................................... 43

Step 7: Try sending a print job from a computer .............................................................................. 43

Step 8: Test the Plug and Print USB Drive printing functionality ..................................................... 44

Factors that affect product performance ......................................................................................... 44

Troubleshooting process .................................................................................................................................... 45

Determine the problem source ......................................................................................................... 45

Power subsystem .............................................................................................................................. 46

Scanning subsystem (X585) ............................................................................................................. 47

Control panel checks ......................................................................................................................... 47

Tools for troubleshooting ................................................................................................................................... 57

Print the configuration page ............................................................................................................. 57

Event log messages .......................................................................................................................... 59

Error messages ................................................................................................................................. 60

Individual component diagnostics .................................................................................................. 149

Diagrams ......................................................................................................................................... 154

Print-quality troubleshooting tools ............................................................................................... 156

Preboot menu options .................................................................................................................... 164

Control-panel menus ........................................................................................................................................ 172

Administration menu ...................................................................................................................... 172

Device Maintenance menu .............................................................................................................. 233

Solve image quality problems .......................................................................................................................... 236

Clean ink smears ............................................................................................................................. 236

Recover the printhead .................................................................................................................... 236

Solve paper jam or feed problems .................................................................................................................... 237

Product does not pick up paper or misfeeds .................................................................................. 237

Clear jams ........................................................................................................................................ 238

Solve performance problems ............................................................................................................................ 254

The product does not print ............................................................................................................. 254

The product prints slowly ............................................................................................................... 254

Solve connectivity problems ............................................................................................................................. 256

Solve USB direct-connect problems ............................................................................................... 256

vi ENWW

Page 9

Solve network problems ................................................................................................................. 256

Solve wireless network problems .................................................................................................. 257

Service mode functions ..................................................................................................................................... 262

Service menu and Secondary service menu ................................................................................... 262

Product resets ................................................................................................................................. 262

Solve fax problems ............................................................................................................................................ 263

Fax reports ...................................................................................................................................... 263

Possible fax issues .......................................................................................................................... 266

Product upgrades .............................................................................................................................................. 275

Appendix A Service and support .................................................................................................................... 277

Hewlett-Packard limited warranty statement ................................................................................................. 278

UK, Ireland, and Malta ..................................................................................................................... 279

Austria, Belgium, Germany, and Luxemburg .................................................................................. 279

Belgium, France, and Luxemburg ................................................................................................... 279

Italy .................................................................................................................................................. 281

Spain ................................................................................................................................................ 281

Denmark .......................................................................................................................................... 281

Norway ............................................................................................................................................ 281

Sweden ............................................................................................................................................ 282

Portugal ........................................................................................................................................... 282

Greece and Cyprus ........................................................................................................................... 282

Hungary ........................................................................................................................................... 282

Czech Republic ................................................................................................................................ 282

Slovakia ........................................................................................................................................... 283

Poland ............................................................................................................................................. 283

Bulgaria ........................................................................................................................................... 283

Romania .......................................................................................................................................... 283

Belgium and The Netherlands ........................................................................................................ 283

Finland ............................................................................................................................................. 284

Slovenia ........................................................................................................................................... 284

Croatia ............................................................................................................................................. 284

Latvia ............................................................................................................................................... 284

Lithuania .......................................................................................................................................... 284

Estonia ............................................................................................................................................. 285

End User License Agreement ............................................................................................................................ 286

OpenSSL ............................................................................................................................................................. 288

Customer self-repair warranty service ............................................................................................................. 289

Customer support .............................................................................................................................................. 290

ENWW vii

Page 10

Appendix B Product specifications ................................................................................................................. 291

Physical specifications (X555 models) ............................................................................................................. 292

Physical specifications (X585 models) ............................................................................................................. 292

Power consumption, electrical specifications, and acoustic emissions .......................................................... 292

Environmental specifications ............................................................................................................................ 292

Appendix C Regulatory information ............................................................................................................... 293

FCC regulations .................................................................................................................................................. 294

Environmental product stewardship program ................................................................................................. 295

Protecting the environment ........................................................................................................... 295

Ozone production ............................................................................................................................ 295

Power consumption ........................................................................................................................ 295

Paper use ......................................................................................................................................... 295

Plastics ............................................................................................................................................ 295

HP Officejet print supplies .............................................................................................................. 295

Return and recycling instructions ................................................................................................... 296

Paper ............................................................................................................................................... 297

Material restrictions ........................................................................................................................ 297

Disposal of waste equipment by users ........................................................................................... 297

Electronic hardware recycling ........................................................................................................ 298

Chemical substances ....................................................................................................................... 298

Material Safety Data Sheet (MSDS) ................................................................................................ 298

EPEAT .............................................................................................................................................. 298

For more information ...................................................................................................................... 298

Declaration of conformity (X555 models) ........................................................................................................ 299

Declaration of conformity (X585dn model) ...................................................................................................... 301

Declaration of conformity (X585f and X585z models) ..................................................................................... 303

Certificate of volatility (X555 models) .............................................................................................................. 305

Certificate of volatility (X585 models) .............................................................................................................. 307

Safety statements ............................................................................................................................................. 309

Canada - Industry Canada ICES-003 Compliance Statement ......................................................... 309

VCCI statement (Japan) ................................................................................................................... 309

Power cord instructions .................................................................................................................. 309

Power cord statement (Japan) ....................................................................................................... 309

EMC statement (China) .................................................................................................................... 309

EMC statement (Korea) ................................................................................................................... 309

EMI statement (Taiwan) .................................................................................................................. 310

GS statement (Germany) ................................................................................................................ 311

Substances Table (China) ................................................................................................................ 311

SEPA Ecolabel User Information (China) ........................................................................................ 311

Restriction on Hazardous Substances statement (India) .............................................................. 312

viii ENWW

Page 11

Restriction on Hazardous Substances statement (Turkey) ........................................................... 312

Restriction on Hazardous Substances statement (Ukraine) .......................................................... 312

Eurasian Conformity (Belarus, Kazakhstan, Russia) ...................................................................... 312

Additional statements for telecom (fax) products ........................................................................................... 313

EU Statement for Telecom Operation ............................................................................................ 313

New Zealand Telecom Statements ................................................................................................. 3 13

Additional FCC statement for telecom products (US) .................................................................... 313

Telephone Consumer Protection Act (US) ...................................................................................... 314

Industry Canada CS-03 requirements ............................................................................................ 314

Vietnam Telecom wired/wireless marking for ICTQC Type approved products ............................ 315

Japan Telecom Mark ....................................................................................................................... 315

Index ........................................................................................................................................................... 317

ENWW ix

Page 12

x ENWW

Page 13

List of tables

Table 1-1 Operation sequence ............................................................................................................................................. 4

Table 1-2 Power supply module operating modes ............................................................................................................ 11

Table 1-3 Printbar components ......................................................................................................................................... 14

Table 1-4 Product sensors ................................................................................................................................................. 20

Table 1-5 Paper-handling system motors ......................................................................................................................... 23

Table 1-6 Paper path zones ............................................................................................................................................... 26

Table 1-7 Service sled components ................................................................................................................................... 30

Table 1-8 Aerosol management system components ...................................................................................................... 32

Table 2-1 Troubleshooting flowchart ................................................................................................................................ 45

Table 2-2 Control panel diagnostic functions .................................................................................................................... 47

Table 2-3 Important information on the configuration pages .......................................................................................... 59

Table 2-4 Heartbeat LED status ....................................................................................................................................... 150

Table 2-5 Plug/jack locations (X555) ............................................................................................................................... 154

Table 2-6 Plug/jack locations (X585) ............................................................................................................................... 155

Table 2-7 Preboot menu options (1 of 6) ......................................................................................................................... 165

Table 2-8 Preboot menu options (2 of 6) ......................................................................................................................... 167

Table 2-9 Preboot menu options (3 of 6) ......................................................................................................................... 168

Table 2-10 Preboot menu options (4 of 6) ...................................................................................................................... 169

Table 2-11 Preboot menu options (5 of 6) ...................................................................................................................... 169

Table 2-12 Preboot menu options (6 of 6) ...................................................................................................................... 170

Table 2-13 Reports menu ................................................................................................................................................. 172

Table 2-14 General Settings menu .................................................................................................................................. 174

Table 2-15 Copy Settings menu (X585) ........................................................................................................................... 179

Table 2-16 Scan/Digital Send Settings menu (X585) ...................................................................................................... 185

Table 2-17 Fax Settings menu (X585) ............................................................................................................................. 195

Table 2-18 General Print Settings menu ......................................................................................................................... 207

Table 2-19 Print Options menu ........................................................................................................................................ 210

Table 2-20 Display Settings menu ................................................................................................................................... 211

Table 2-21 Manage Supplies menu .................................................................................................................................. 213

Table 2-22 Manage Trays menu ....................................................................................................................................... 217

Table 2-23 Network Settings menu ................................................................................................................................. 219

Table 2-24 Jetdirect Menu ................................................................................................................................................ 219

ENWW xi

Page 14

Table 2-25 Troubleshooting menu .................................................................................................................................. 230

Table 2-26 Backup/Restore menu ................................................................................................................................... 233

Table 2-27 Calibrate/Cleaning menu ............................................................................................................................... 233

Table B-1 Physical specifications (X555 models), with ink cartridges ............................................................................ 292

Table B-2 Physical specifications (X585 models), with ink cartridges ............................................................................ 292

Table B-3 Operating-environment specifications ........................................................................................................... 292

xii ENWW

Page 15

List of figures

Figure 1-1 Main components (X555 models) ....................................................................................................................... 2

Figure 1-2 Main components (X585 models) ....................................................................................................................... 3

Figure 1-3 System control .................................................................................................................................................... 7

Figure 1-4 Print subsystem components (X555 models) .................................................................................................. 12

Figure 1-5 Print subsystem components (X585 models) .................................................................................................. 13

Figure 1-6 Printbar components ........................................................................................................................................ 14

Figure 1-7 Paper-handling system paper path (X555 models) ......................................................................................... 17

Figure 1-8 Paper-handling system paper path (X585 models) ......................................................................................... 18

Figure 1-9 Product sensors (X555 models) ....................................................................................................................... 19

Figure 1-10 Product sensors (X585 models) ..................................................................................................................... 20

Figure 1-11 Paper-handling-system motors (X555 models) ............................................................................................ 22

Figure 1-12 Paper-handling-system motors (X585 models) ............................................................................................ 23

Figure 1-13 Paper path zones (X555 models) ................................................................................................................... 25

Figure 1-14 Paper path zones (X585 models) ................................................................................................................... 26

Figure 1-15 Servicing system components (X555 models) ............................................................................................... 28

Figure 1-16 Servicing system components (X585 models) ............................................................................................... 29

Figure 1-17 Service sled components ................................................................................................................................ 30

Figure 1-18 Aerosol management process ........................................................................................................................ 31

Figure 1-19 Aerosol management system components ................................................................................................... 32

Figure 1-20 Document feeder paper path and sensors ..................................................................................................... 34

Figure 2-1 Touchscreen blank, white, or dim (no image) .................................................................................................. 51

Figure 2-2 Touchscreen is slow to respond or requires multiple presses to respond ...................................................... 52

Figure 2-3 Touchscreen has an unresponsive zone .......................................................................................................... 53

Figure 2-4 No control panel sound ..................................................................................................................................... 54

Figure 2-5 Home

Figure 2-6 Hardware integration pocket (HIP) is not functioning (control panel functional) ........................................... 56

Figure 2-7 Configuration page ........................................................................................................................................... 57

Figure 2-8 HP embedded Jetdirect page ............................................................................................................................ 58

Figure 2-9 LEDs ................................................................................................................................................................. 149

Figure 2-10 Plug/jack locations (X555) ........................................................................................................................... 154

Figure 2-11 Plug/jack locations (X585) ........................................................................................................................... 155

Figure 2-12 Mark the web wipe ........................................................................................................................................ 163

button is unresponsive ..................................................................................................................... 55

ENWW xiii

Page 16

Figure C-1 Certificate of volatility (X555 models) (1 of 2) ............................................................................................... 305

Figure C-2 Certificate of volatility (X555 models) (2 of 2) ............................................................................................... 306

Figure C-3 Certificate of volatility (X585 models) (1 of 2) ............................................................................................... 307

Figure C-4 Certificate of volatility (X585 models) (2 of 2) ............................................................................................... 308

xiv ENWW

Page 17

1 Theory of operation

●

Basic operation

●

System control

●

Print subsystem

●

Paper-handling system

●

Servicing system

●

Aerosol management system

●

Document feeder (X585 models)

●

Scanner system (X585 models)

●

Fax functions and operation (X585 models)

ENWW 1

Page 18

Basic operation

Function structure

The product consists of the following components.

Figure 1-1 Main components (X555 models)

Control panel

Output bin

Optical

scan

carriage

Printbar

Service sled

Multipurpose tray

(Tray 1)

Main input tray (Tray 2)

Duplex module\

Waste ink module

Optional tray (Tray 3)

2 Chapter 1 Theory of operation ENWW

Page 19

Figure 1-2 Main components (X585 models)

Document feeder

Optical

scan

carriage

Control panel

Scanner

Output bin

Printbar

Multipurpose tray

(Tray 1)

Duplex module\

Waste ink module

The product contains the following systems:

●

Engine control system

●

Print subsystem

Service sled

Main input tray (Tray 2)

Optional tray (Tray 3)

●

Paper-handling system

●

Servicing system

ENWW Basic operation 3

Page 20

●

Aerosol management system

●

Scanner and document feeder system (X585 models)

Two elements influence the product architecture:

●

Orienting the printbar with its active face downward and statically located above the print media. This

requires the printbar to move vertically to access its active face.

●

Producing face-down output. Rather than ejecting the page face-up immediately after the ink is

applied, as many inkjet printers do, the printed page is routed up and back over the printbar to eject

face-down.

Operation sequence

The engine-control system on the formatter PCA controls the operational sequences. The following table

describes durations and operations for each period of a print operation from when the product is turned on to

when the motors stop rotating.

Table 1-1 Operation sequence

Period Duration Purpose

Initial startup and

calibrations

Servicing operations When the printbar is entering

When the product is set up for

the first time from the factory.

the capping state after printing,

when leaving capping state after

a print job is initiated, or during

extended print jobs.

This period gets the product ready to print for the first time.

●

The product flushes the shipping and handling fluid out of the

printbar and replaces it with ink.

●

Die alignment—The product aligns the 10 die on the printbar

active face.

●

Die density leveling—The product measures and compensates

for the drop variation.

Servicing maintains the print quality by ensuring debris and excess

ink are removed and missing nozzles are replaced.

●

Nozzle presence detection—The optical scan carriage detects

and disables inoperable nozzles, and replaces them with

operable nozzles.

●

Printbar servicing—The web wipe on the service sled moves

under the printbar to clean the active face and fire the nozzles

into the waste ink module to clear clogs.

4 Chapter 1 Theory of operation ENWW

Page 21

Table 1-1 Operation sequence (continued)

Period Duration Purpose

Print preparation From the time the product

receives a print command until

paper enters the print zone.

Printing From the end of the preparation

period until the last sheet is

delivered.

Prepares the product for a print job.

●

The printbar leaves the capping state as the service sled

moves away from the printbar.

●

If needed, some servicing occurs.

●

The printbar lowers to the printing position. The media type

and printing mode determine the print zone height.

●

The product picks media from one of the input trays.

●

Every page from Tray 1 is scanned. For Tray 2 and optional

Tray 3, the product performs media edge detection after

printing the first sheet after the main or optional tray is

loaded. The last sheet of each job is also scanned if at least

five sheets have been printed.

●

The product monitors environmental conditions. The product

can decrease the print speed if conditions are significantly

different from a normal office environment (23 degrees C (73

degrees F), 50% relative humidity).

●

The formatter PCA processes print data and transmits the data

to the printbar.

Processes the print job.

●

As the page travels through the print zone, the printbar

applies ink to the page.

●

Simplex print job: the page moves up, over the printbar, and

out to the output bin (face-down).

●

Duplex print job: the page moves up until the trailing edge is

40 mm past the star-wheel jam reflective sensor, then

reverses direction down through the duplex path underneath

the waste ink module, and then reenters the print zone where

the printbar applies ink to the second side.

●

The process continues until all the pages of the print job are

completed. Occasional nozzle presence detection and

servicing events might occur if the job includes many pages.

ENWW Basic operation 5

Page 22

Table 1-1 Operation sequence (continued)

Period Duration Purpose

End of print job Performed after the print job is

completed, and continues until

the next job is initiated.

Standby The product is sitting idle,

waiting for the next print job to

be initiated.

Puts the product in a state where it’s ready for the next print job.

●

If needed, some servicing occurs.

●

The printbar moves to the capping position after a short dwell

interval.

●

The service sled moves to cap the printbar.

Conserves energy while the product is sitting idle. Certain functions

might be disabled to save power, then are restarted when needed.

The product has three sleep modes:

●

Idle mode—The printbar is capped and the product is ready to

immediately start a new job

●

Sleep1 mode—After the product is inactive for about 10

minutes, the control panel dims and the power LED blinks to

indicate the unit is in Sleep1. All product functions are

available. This setting can be adjusted from the control panel.

●

Sleep2 mode—After the product is inactive for a longer period

of time (typically 2 hours), the engine controller powers down

to minimize power consumption. This setting can be adjusted

from the control panel.

6 Chapter 1 Theory of operation ENWW

Page 23

System control

The system control coordinates all the other systems, according to commands from the formatter.

Figure 1-3 System control

I/O

Formatter

I/O, PDL, UI control

Scanner/

document feeder

(X585 models)

Power supply

Datapath

ASIC +memory

Engine control

Motor + sensor drive

Pen I/F

• Pen energy control

• Pen voltage

sequencing

• Signal integrity

• Ink-short protection

• Printhead

interconnects

• Ink supply

Printbar

40,000 nozzles

The system consists of the following major sections:

●

Formatter

●

Data path

●

Engine control

●

Pen interface

●

Scanner/document feeder (X585 models)

●

Power supply

The engine control electronics are located on the engine control board (ECB). The formatter PCA is a separate

assembly. The fax module (X585 models) is attached to the formatter PCA.

Formatter and data path

The formatter controller ASIC controls the input/output (I/O) control, the user interface, and the rendering of

page description language files into printer-specific commands.

Input/output (I/O) control

The products support 10/100 Ethernet, a rear USB host port, a rear USB device port, a control panel USB host

port, and analog fax port (some X585 models). For Ethernet networks, the formatter PCA uses a separate

integrated circuit (Broadcom 57761) to provide the physical network interface.

The formatter PCA also controls the USB device and USB host.

User interface

The products contain either a 4.2-in (X555 models) or an 8-in (X585 models) color graphics display. The

control panels include a USB host port for connection to thumb drives.

Formatter digital ASIC

The formatter digital ASIC has an ARM CPÙ (792 MHz) that executes firmware code that provides high-level

device control. The digital ASIC uses a standard PCle interface to pass data to the engine control ASIC. The

ENWW System control 7

Page 24

formatter firmware is located on either a rotating hard disk drive (HDD) or, on some X555 models, a solid

state drive (SSD).

Additionally, the formatter digital ASIC manages the real-time clock, interfaces to the mass storage

controller ASIC, provides control of USB ports, and interfaces with the Ethernet LAN ASIC and fax module.

Formatter Ethernet ASIC

The formatter Ethernet ASIC connects to the formatter digital ASIC with a PCIe interface to transmit and

receive network packets.

Formatter mass storage ASIC

The formatter mass storage ASIC bridges between the formatter digital ASIC (via PCIe interface) and the mass

storage device (via SATA interface). Both HDD and SSD mass storage media are supported. The X585 models

all use a rotating media HDD, while the X555 models use either HDD or SSD depending upon the bundle

option.

Formatter memory

Formatter memory is installed on-board and there is no support for additional DIMM memory installation.

The size of the memory on the formatter is fixed at 1 GB.

Real-time clock

The real-time clock (RTC) allows the fax module to time-stamp outgoing faxes. It also determines the

elapsed time between printhead and ISS calibration events. The RTC uses a separate device connected to the

formatter digital ASIC, along with a crystal and a battery.

Engine control

The engine controller digital ASIC receives high-level commands from the formatter, and then provides lowlevel control to the print mechanism. The engine controller digital ASIC and its firmware control motors,

system sensors, and the printbar. The engine controller analog ASIC integrates motor drivers, voltage

regulators, sensor interfaces, and supervisory circuits.

Engine controller digital ASIC

The engine controller digital ASIC has a high-performance 480 MHz ARM CPU and DSP co-processors that

execute firmware code to provide low-level engine control. It also drives the printbar via 15 high-speed LVDS

transmission lines, which are routed from the engine PCA to the printbar via two large FFC cables. The engine

controller digital ASIC receives pre-rendered data from the formatter digital ASIC over a standard PCle

interface.

In some product sleep modes, the digital ASIC powers down. If a print job is received while the product is in

this mode, power resumes to the digital ASIC, which then must “boot up”. This can take approximately 15

seconds, which will delay the first page out (FPO) time accordingly. This sleep mode typically begins after two

hours of product inactivity.

Engine controller analog ASIC

The engine uses two analog ASICs to generate the system voltages for the engine, drive the engine motors,

control various engine sensors, and monitor printbar power delivery for correct operation.

The engine has seven motors, some of which are shared with other subsystems:

8 Chapter 1 Theory of operation ENWW

Page 25

●

Pick motor

●

Feed motor

●

Duplex motor

●

Lift motor

●

Eject motor

●

Sensor carriage motor

●

Aerosol fan motor

Each one is a DC motor with encoder feedback, to provide precision servo control. These motors are driven

directly by one of the engine analog ASICs. Small DC motors also are used to drive the ISS pump and the

aerosol fan. Solenoids actuate the ejection flap and the ISS priming system.

The product uses many sensors to track the media as it travels through the paper path. Most of these are

optical REDI sensors, which are used in conjunction with mirrors to sense the presence or absence of paper in

a particular location. These are carefully aligned and calibrated at the factory, so care must be taken when

servicing these sensors. See the Remove and Replace chapter in the repair manual for more details.

Other printed circuit-board assemblies (PCAs)

In addition to hosting the system ASICs, the engine PCA is home to many circuits needed to interface to

sensors and other sub-system components. In some cases, this circuitry is located on a smaller remote PCA

(SLB) to optimize cable interconnects.

●

Humidity sensor—The humidity sensor causes the product to adjust printing speed if ambient

conditions are outside the optimal humidity range. This sensor is calibrated at the factory to ensure

maximum accuracy.

●

Temperature sensor—The temperature sensor causes the product to adjust printing speed if ambient

conditions are outside the optimal temperature range. In some products, this sensor resides on a

separate, remote PCA.

●

Main tray presence sensor—The hall-effect sensor that detects if the main tray is properly engaged

resides on the back of the engine PCA. A small magnet on the back of the main tray actuates the sensor.

If the tray is fully engaged, the magnetic field strength is sufficient to trigger the sensor.

Additionally, the product includes the following PCAs:

●

Fax PCA—Governs the product fax module.

●

Duplex module presence sensor—A hall-effect sensor that detects that the duplex module is properly

seated.

●

Power button PCA—Includes the power button and power LED, as well as interface cables to the duplex

module presence sensor and the MP tray empty REDI sensor.

●

Accessory tray interconnect PCA—Provides communication to optional Tray 3.

●

Pick encoder distribution PCA—Includes the pick motor encoder and the pick motor interconnect cable.

●

Eject encoder distribution PCA—Includes the eject motor encoder and the interconnect cables to the

eject motor and the aerosol fan.

ENWW System control 9

Page 26

●

Print zone distribution PCA—Joins interconnect cables to the following sensors: separator REDI, feed

motion encoder, main tray empty sensor, feed roller OOPs REDI sensor, and the starwheel jam REDI

sensor.

●

REDI distribution PCA—Includes hall-effect sensors that detect ink cartridge door and left door

positions. It also combines the interconnect cables for the eject jam REDI sensor, the upper drying path

REDI sensor, the lower drying path REDI sensor, and the eject flap opto flag sensor.

●

Sensor carriage PCA—Includes a carriage motion encoder, a ZIM sensor, and the BDD sensor.

●

Printbar lift encoder distribution PCA—This PCA includes the printbar lift motion encoder, and combines

interconnect cables to the printbar lift motor, carriage motor, and eject flap solenoid.

●

Duplex encoder PCA—Contains the motion encoder for the duplex motor.

●

SHAID PCA —Contains interfaces to the out-of-ink sensors for the ink cartridges, and combines the

interface cables to the acumen PCA, the ISS pump, and the ISS solenoids.

●

Acumen PCA—Contains interfaces to the acumen memory devices for the ink cartridges.

Pen interface (I/F)

The printbar is the key component that differentiates this product from other inkjet printers. The

conventional approach is to print a page in horizontal swaths by moving a “scanning” printhead horizontally

over a fixed sheet of paper, advancing the paper a fixed amount, and then printing the next swath. With this

product, the paper moves underneath a fixed page-wide printhead in a single smooth motion.

Single pass page-wide printing requires that data and power be delivered to the printbar at a very high rate,

while also maintaining good control of paper position as it moves past the printhead nozzles.

The engine PCA sends power and data to the printbar via two large flat flexible cables (36 and 38 pins). The

printbar PCA routes power and data to 10 printhead die, which are attached to the PCA using a flexible tab

circuit and wire-bonding process.

Electronics control the ink supply station (ISS). The SHAID PCA detects low-ink conditions. It gauges ink levels

by electrically sensing the presence of ink and/or ink foam in the X-chamber. The SHAID PCA also collects and

distributes electrical signals that drive the push-prime pump(s), engage the solenoids, and read the ink

supply acumen data. All are routed through a single 17-pin FFC from the SHAID PCA to the engine PCA.

Each ink supply has a memory tag that stores information about its type of ink, the amount of ink remaining,

and other critical data. It uses a special authentication scheme to ensure that only genuine HP supplies are

used and the product is not damaged by using invalid supplies. Acumen uses a two-line serial bus, which,

along with 3.3 V and ground, is cabled via the SHAID PCA to the engine PCA and the engine control digital

ASIC.

Power supply

The power supply module converts 100-240 VAC to 33 VCD and 5.1 VCD to power the system. The 33 V rail

goes to the engine and the scanner/document feeder, and the 5.1 V rail is supplies power to the formatter.

The power supply module has a sleep mode that reduces power consumption in system low-power modes.

The power supply module has four operating modes, depending on certain control signals, as outlined in the

table below. The power supply has a power factor correction (PFC) circuit to improve efficiency when the

system is in the active mode.

10 Chapter 1 Theory of operation ENWW

Page 27

Table 1-2 Power supply module operating modes

Mode n33V_OFF input signal nPFC_OFF input signal PFC Status 33 V rail status 5.1 V rail status

OFF Low Low Off Off On

Sleep 2 Low Low Off Off On

Sleep 1 High Low Off On On

Active High High On On On

The power supply is a self-contained module that can be replaced if it is defective (see the Remove and

Replace chapter of the Repair Manual).

To ensure safe operation, the power supply will “latch off” if a persistent over-current fault condition exists.

This is typically caused by a short-circuit from 33 V or 5.1 V to ground in the product. Less severe faults also

can cause the power supply to latch off, if present for an extended period of time, or if the product is

operated above the recommended operating range.

ENWW System control 11

Page 28

Print subsystem

The print subsystem includes the following components:

●

Printbar

●

Printbar lift

●

Ink cartridges

●

Optical scan carriage

Figure 1-4 Print subsystem components (X555 models)

Optical

scan

carriage

Ink cartridges

Printbar lift

Printbar

12 Chapter 1 Theory of operation ENWW

Page 29

Figure 1-5 Print subsystem components (X585 models)

Ink cartridges

Optical

scan

carriage

Printbar lift

Printbar

Printbar

The printbar converts the digital firing instructions from the product electronics into properly formed and

timed microscopic drops of the four ink colors. The printbar spans the full width of a letter/A4-size sheet

(216 mm (8.5 in)), which allows it to be statically positioned within the product and have the media move

underneath it, printing the entire page in a single motion.

ENWW Print subsystem 13

Page 30

Figure 1-6 Printbar components

1

4

23

Table 1-3 Printbar components

Item Description

1 Ink cartridge connections

2 Thermal inkjet (TIJ) die array

3 Data/power flow and regulation

4 Inkflow channels and pressure regulation

The printbar has a fixed array of 10 thermal inkjet (TIJ) die oriented in two staggered rows. Each die contains

over one thousand nozzles for each of the four ink colors (black (K), cyan (C), magenta (M) and yellow (Y)).

Behind the die array are the ink flow channels and pressure regulation mechanisms that supply the die array

with ink at the proper pressure and flow. Onboard electronic circuitry feeds power and data to the die at the

appropriate levels and rates. Four ink cartridge receptacles, one for each color, are located at the top of the

printbar. Flow connections link these cartridges to the rest of the printbar to supply the ink necessary for its

operation.

A sensor technology called back-scatter drop detect (BDD) monitors printbar health and calibrations. This

system looks at the reflection of the miniscule drops in flight and passes these signals through proprietary,

advanced high-speed, high-gain, bandpass filters. An artificial intelligence (AI) system decides which drop

ejectors are currently in or out of specifications.

After the AI system determines which drop ejectors are out of specification, the product compensates for

them. Some ejectors use neighboring nozzles and at times even tiny amounts of other inks – whichever

combination of methods necessary to deliver the best print quality possible at that moment. Up to half of the

nozzles can be “out” without a noticeable degradation in quality. The compensation is done in real time with

a dedicated high-speed DSP. The system can scan portions of the system after print jobs, but it is fully

interruptible by new incoming print jobs.

Printbar lift

The printbar lift positions the printbar within the product and moves it up and down as required. This vertical

motion establishes proper spacing to the paper during printing. It also raises the printbar to access the active

face or perform necessary calibrations.

14 Chapter 1 Theory of operation ENWW

Page 31

During printing, the lift mechanism sets the printbar height and paper height depending on the type of paper.

Ink cartridges

This product has new, state-of-the-art pigmented inks. They are filtered using proprietary processes to

prevent printhead contamination. These inks are designed to produce optimal print quality on ColorLok office

papers, but also produce very good print quality on regular office papers and specialty media.

Optical scan carriage

The optical scan carriage has optical sensors used for calibration. Its motion is along the long axis of the

printbar. These sensors are used by a number of in-printer calibration features that are important for proper

subsystem function. The BDD sensor is located on the optical scan carriage.

Print system operational states

The print subsystem has a number of distinct operational states besides active printing.

Startup

As it comes from the factory, the printbar is initially filled with an inert ink-substitute called Shipping and

Handling Fluid (SHF). This fluid, essential for the manufacture and transportation of the printbar, must be

flushed and replaced with actual ink. This is accomplished during the Startup phase. The flushing process

automatically commences when ink supplies are inserted and the unit powered up for the first time. The SHF

is removed by sustained printbar operation and replaced by ink from the supplies. The process terminates

once all the SHF has been flushed from the printbar.

Special host supplies are supplied with the product prior to its first use. These supplies contain additional ink

so that there will be 100 percent ink level after the SHF is replaced with ink. These supplies can be used only

to initialize the product. You cannot use them in another product that has been initialized.

NOTE: The initial startup time is noticeably longer than the following regular startup times.

Die alignment

Die alignment is done by printing a special diagnostic image on a sheet of paper and then scanning it with the

optical scan carriage. It is performed as part of initial unit startup, and can be manually invoked as part of the

print quality recovery tool. Die alignment calibrates the positions of the 10 die. It also allows a uniform

application of ink to the media, without gaps or overlaps between adjacent die.

Die density leveling

A set of diagnostic images is printed and scanned by the optical scan carriage to achieve uniform application

of ink droplets to the media. Die alignment and die density leveling are usually paired together.

Nozzle presence detection

In printing, since all the ink is applied in a single smooth motion of the media past the printbar, any

inoperable nozzle can show up as a streak. The operational state of each of the thousands of nozzles on the

printbar is periodically measured. The printbar is raised by the printbar lift, and the BDD assembly on the

optical scan carriage watches for drop presence as each nozzle is fired. Inoperable nozzles are turned off and

other operable nozzles used on subsequent printed pages to apply the missing ink. Nozzle presence

detection is fully interruptible by new incoming print jobs.

ENWW Print subsystem 15

Page 32

Media edge position detection

The product uses a learning algorithm to define media center as a function of input source—multipurpose

tray, main tray, or accessory tray. The edge scan is located downstream of the print zone. As media is

scanned, the media center database is updated. The image is registered to the page using the media center

database.

Servicing and capping

When in the capped state, the printbar is fully raised, the service sled is positioned underneath, and the

printbar cap is engaged against the printbar active face. Servicing—the cleaning of the active face and the

firing of the nozzles—can occur either during Sleep2 mode or after extended time in storage. It can also

occur during extended print jobs.

Printing

The printing state begins by the printbar leaving the capping state, and being lowered to the printing position

after the service sled moves out of the way. At the same time, a sheet of media is picked from one of the

three trays and the leading edge staged at the entrance to the print zone. Once the print data has been sent,

the media sheet is fed at a constant velocity through the print zone and the ink applied by the printbar.

In the case of one-sided printing the inked sheet is conducted up, over and out to the output tray. For twosided printing the sheet is moved until its trailing edge is past the merge to the vertical path, and then it is

reversed down through the duplex path underneath the waste ink module, and reintroduced into the print

zone for inking of the second side.

This process continues until all the pages of the print job are completed, perhaps being interrupted by

servicing events if the job is many pages.

16 Chapter 1 Theory of operation ENWW

Page 33

Paper-handling system

The paper-handling system moves paper through the product according to commands from the formatter.

The following figure shows the product paper path.

Figure 1-7 Paper-handling system paper path (X555 models)

ENWW Paper-handling system 17

Page 34

Figure 1-8 Paper-handling system paper path (X585 models)

The paper path consists of the following major components:

●

Two integrated input trays plus one optional accessory tray

●

Four motors and a solenoid plus two more motors in the accessory tray

●

Duplex module

●

Fourteen sensors plus four more sensors in the accessory tray

18 Chapter 1 Theory of operation ENWW

Page 35

●

Feed rollers, pinch rollers, star wheels, and media guides

●

Transmission components (gears, shafts, levers, swing arms) that interface with other subsystems such

as the printbar and service sled.

Components of the paper path move the paper from the input tray to a position 1 to 2 mm underneath the

printbar, and then deliver the printed result to the output tray. The combined orientations and actions of the

printbar, the printbar lift, and the paper path establish the print-zone, where the ink drops move from the

active face of the printbar to the paper.

The following figure shows the product sensors.

Figure 1-9 Product sensors (X555 models)

24

23

22

21

20

19

18

17

16

15

14

1

2

3

13

12 11 10 89 999997 6 45

ENWW Paper-handling system 19

Page 36

Figure 1-10 Product sensors (X585 models)

24

23

22

21

20

19

18

17

16

15

14

1

2

3

13

12 11 10 89 999997 6 45

Table 1-4 Product sensors

Item Description Item Description

1 Output flap jam sensor 13 Feed roller jam sensor

2 Ambient temperature sensor 14 Feed roller encoder

3 Ambient humidity sensor 15 Feed roller home sensor

20 Chapter 1 Theory of operation ENWW

Page 37

Table 1-4 Product sensors (continued)

Item Description Item Description

4 Tray 2 pickup tire home sensor 16 Duplex module presence sensor

5 Tray 2 tray presence sensor 17 Star-wheel jam sensor

6 Tray 3 pickup tire home sensor 18 Back-scatter drop detect sensor

7 Tray 3 paper presence sensor 19 Print calibration/Media edge detect sensor

8 Tray 3 separation sensor 20 Lower left door jam sensor

9 Tray 2 paper presence sensor 21 Left door open sensor

10 Tray 3 tray presence sensor 22 Upper left door jam sensor

11 Tray 1 paper presence sensor 23 Ink supply door open sensor

12 Tray 3 cleanout presence sensor 24 Eject jam sensor

There are several motors in the product for pick, feed, duplexing, printbar lift, delivery, and the scanning

sensor carriage.

ENWW Paper-handling system 21

Page 38

Figure 1-11 Paper-handling-system motors (X555 models)

8

7

6

1

5

234

22 Chapter 1 Theory of operation ENWW

Page 39

Figure 1-12 Paper-handling-system motors (X585 models)

8

1

7

6

5

234

Table 1-5 Paper-handling system motors

Item Description

1 Eject (or output drive) motor

2 Tray 2 pickup motor

3 Tray 3 pickup motor

ENWW Paper-handling system 23

Page 40

Table 1-5 Paper-handling system motors (continued)

Item Description

4 Duplex Tray 1 motor

5 Tray 3 feed motor

6 Feed motor

7 Optical carriage motor

8 Printbar lift motor

Input trays

The product comes standard with two input trays, and also accepts an accessory tray.

●

●

50-page multipurpose (MP) tray—Tray 1: The tray shares a motor with the duplex module and has one

sensor. This reflective (REDI) sensor determines if media is present in the tray. The feed roller REDI

sensor determines if a sheet of media is successfully picked from the tray.

500-sheet letter/A4 size main tray—Tray 2: The tray has a pick motor, which is also moves the service

sled. Both the main tray motor and the duplex MP tray motor operate at the same time when picking

paper from the main tray. The main tray has three sensors:

◦

A hall effect sensor determines if the tray is closed.

◦

A flag/opto sensor determines if there is media in the tray.

◦

A flag/opto sensor determines if the pick roller is in home position.

The feed roller jam sensor determines if a sheet of media is successfully picked from the main tray.

●

Optional 500-sheet legal size accessory tray—Tray 3: This optional tray has two motors, one for picking

paper and one for the turn roller. The turn roller receives paper from the pickup roller and transfers it to

the multipurpose tray ITR that is driven by the duplex module/MP tray motor. Both the accessory tray

motor and the duplex module/MP tray motor operate at the same time when picking paper out of the

accessory tray.

The accessory tray has the following sensors:

◦

A hall effect sensor detects if the tray is closed.

◦

A flag/opto sensor detects if there is media in the tray.

◦

A flag/opto sensor detects if the pickup roller is in home position.

◦

A hall effect sensor detects if the left door is closed.

◦

A separation sensor detects if the product successfully picked media.

Paper path zones

The product paper path includes the following elements.

●

Deskew buckle

●

Print zone

24 Chapter 1 Theory of operation ENWW

Page 41

●

Duplex

●

Output

●

Eject

Figure 1-13 Paper path zones (X555 models)

5

4

1

3

2

ENWW Paper-handling system 25

Page 42

Figure 1-14 Paper path zones (X585 models)

5

1

4

3

2

Table 1-6 Paper path zones

Item Zone Description

1 Deskew buckle This is the area between the turn roller and feed roller. All print job paper passes through this zone.

During the deskew operation, the duplex module/MP tray motor rotates forward, driving the paper

into the feed roller nip while the feed roller is not moving. The feed roller REDI sensor determines the

leading edge for accurate deskew buckle size, jam detection, and if the tray successfully picked

media.

26 Chapter 1 Theory of operation ENWW

Page 43

Table 1-6 Paper path zones (continued)

Item Zone Description

2 Print zone This is the path between the feed roller and output pinch 1 roller. The feed roller, which has an analog

quadrature encoder, precisely controls the paper in the paper feed direction . In the vertical direction,

a combination of the platen, feed roller, and output pinch roller 1 controls the paper. The user can

rotate the platen down for jam access after removing the duplex module.

There are no paper path sensors in the print zone. If a jam occurs in the print zone, it is not detected

until the leading edge of the paper is determined to be “late” in reaching the jam sensor in the output

path.

When a user pulls on jammed media in the print zone that is still partially in the feed roller nip, the

servo control will detect a slight movement of the feed roller and assist the user by applying a

forward torque to the roller. Also, the motion control system will disengage the duplex module

rectifier (swing arm) so that the turn roller can spin freely. This feature reduces the pulling force

needed by the user and therefore reduces the chance of leaving torn pieces of paper in the path—

especially in the deskew buckle zone.

3 Duplex By opening the left door, the duplex module can be removed to clear jams. The duplex module also

serves as waste collection unit for the print bar and will expose the user to waste ink when it is

removed. Therefore there are warnings on the module to not touch certain areas.

When the user pulls on jammed media from the duplex module (or any of the trays) that is partially in

the feed roller nip, the servo control detects a slight movement of the feed roller and assists the user

by applying a reverse torque to the feed roller and disengages. Also, the motion control system

disengages the duplex module rectifier so the turn roller can spin freely. This feature reduces the

pulling force needed by the user and therefore reduces the chance of leaving torn pieces of paper in

the path—especially in the deskew buckle zone.

In order for the product to determine the duplex module's presence, the duplex module has a magnet

that triggers a hall effect sensor mounted to the structure.

4 Output The output path begins at output pinch roller 1 and continues to output pinch roller 5. There are four

REDI sensors in this path that detect leading and trailing edges and jams.

The feed motor drives the rollers in the output path, except output pinch roller 5. All the pinch rollers

in the output and exit path are star wheels to prevent roller tracking on wet/damp ink. However, the

turn roller pinch is solid and has a high amount of force for deskew buckle formation. Also, the feed

motor drives all output shafts except shafts 5 and 6.

The REDI dry path lower, REDI dry path upper, and eject jam REDI sensor in the output path all track

the leading and trailing edges of media.

The outer and top portions of the vertical path are formed by paper guides molded in and attached to

the left door. The left door can be opened for jam clearance and has a hall effect sensor to determine

if it is closed. Also when the left door is opened, drive rollers that form pinches 3 and 4 disengage

from the feed motor for safety purposes.

5 Eject The eject portion of the paper path includes the zone from output pinch roller 5 to the eject flap.

The eject motor powers output pinch roller 5 and eject pinch roller 6.

The eject flap has 3 positions:

●

Closed when not printing.

●

Partially open for heavy ink printing in dry environments, to limit severe curl.

●

Ofpen for all other printing. This position controls moderately curled media.

The flap is opened and closed by a torque clutch on the eject roller shaft. The flap also has a locking

feature that is controlled by a solenoid. In order for the door to open all the way, or move between

positions, the solenoid must be actuated.

ENWW Paper-handling system 27

Page 44

Servicing system

The servicing system comprises the service sled, which maintains print quality by wiping debris and ink off

the print nozzles, and the service ink module, where waste ink is deposited.

Figure 1-15 Servicing system components (X555 models)

Service sled

Duplex module\

Waste ink module

28 Chapter 1 Theory of operation ENWW

Page 45

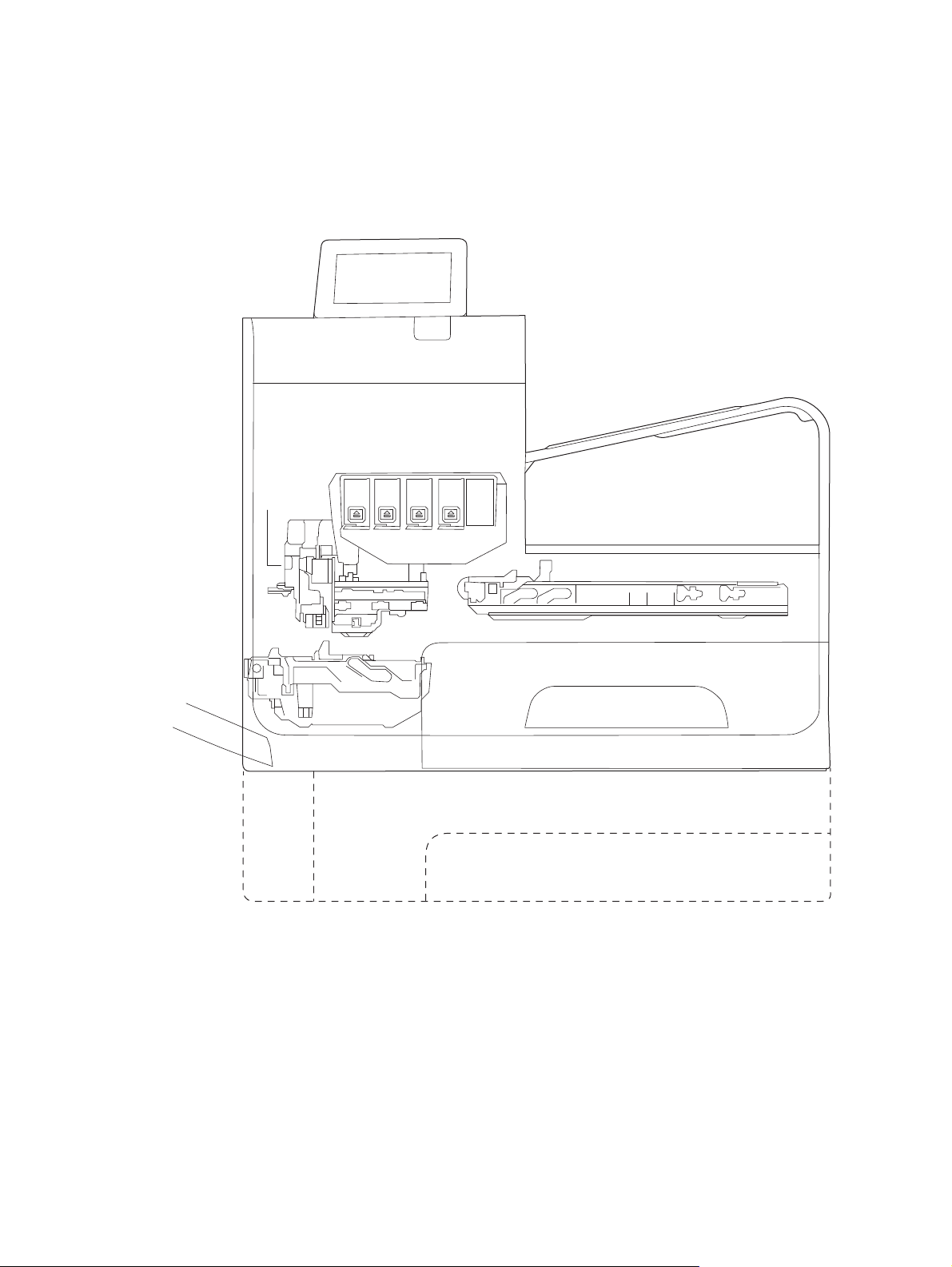

Figure 1-16 Servicing system components (X585 models)

Duplex module\

Waste ink module

Service sled

ENWW Servicing system 29

Page 46

Service sled