Page 1

HP Jet Fusion 580 Color 3D Printer

Product Documentation

User Guide

Page 2

© Copyright 2018–2019 HP Development

Company, L.P.

Edition 5

Legal notices

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be construed as

constituting an additional warranty. HP shall not

be liable for technical or editorial errors or

omissions contained herein.

Safety notice

Read and follow the operating and safety

instructions before turning on the printer.

Page 3

Table of contents

1 Welcome to your MJF system ................................................................................................................................................................. 1

Documentation ......................................................................................................................................................................... 2

Product usage requirements .................................................................................................................................................. 2

MJF technology ......................................................................................................................................................................... 2

Usage recommendations ........................................................................................................................................................ 3

2 Safety precautions .................................................................................................................................................................................... 5

Introduction ............................................................................................................................................................................... 6

General safety guidelines ........................................................................................................................................................ 6

Final parts/builds ...................................................................................................................................................................... 7

Explosion hazard ...................................................................................................................................................................... 7

Electrical shock hazard ............................................................................................................................................................ 8

Heat hazard ............................................................................................................................................................................... 8

Fire hazard ................................................................................................................................................................................. 8

Mechanical hazard .................................................................................................................................................................... 9

Light radiation hazard .............................................................................................................................................................. 9

Chemical hazard ....................................................................................................................................................................... 9

Ventilation ............................................................................................................................................................................... 10

Air conditioning ....................................................................................................................................................................... 10

Sound pressure level ............................................................................................................................................................. 10

Printer transport hazard ....................................................................................................................................................... 10

3D part retrieval ..................................................................................................................................................................... 10

Personal protective equipment ........................................................................................................................................... 10

Use of tools ............................................................................................................................................................................. 11

Warnings and cautions .......................................................................................................................................................... 11

Warning labels ........................................................................................................................................................................ 11

Emergency stop button ........................................................................................................................................................ 13

3 Main components ................................................................................................................................................................................... 14

Printer ...................................................................................................................................................................................... 15

Front panel .............................................................................................................................................................................. 16

Set the administrator password .......................................................................................................................................... 19

Software .................................................................................................................................................................................. 19

ENWW iii

Page 4

4 Power on and o .................................................................................................................................................................................... 21

Turn the printer on and o ................................................................................................................................................... 21

Main power switch ................................................................................................................................................................. 22

Away mode ............................................................................................................................................................................. 23

5 Printer networking ................................................................................................................................................................................. 24

Introduction ............................................................................................................................................................................. 24

Connectivity requirement and remote monitoring ........................................................................................................... 24

Conguration .......................................................................................................................................................................... 25

6 Design and printing guidelines ............................................................................................................................................................. 26

Introduction ............................................................................................................................................................................. 27

File preparation ....................................................................................................................................................................... 27

7 Send a job ................................................................................................................................................................................................ 39

8 Select a job .............................................................................................................................................................................................. 40

Job list app .............................................................................................................................................................................. 40

Select a job to be printed ...................................................................................................................................................... 40

9 Printer preparation ................................................................................................................................................................................. 41

Job preparation list ................................................................................................................................................................ 42

Agents ...................................................................................................................................................................................... 42

Material .................................................................................................................................................................................... 45

Distilled or deionized water .................................................................................................................................................. 48

How to recycle consumables and printed parts ................................................................................................................ 50

10 Print ........................................................................................................................................................................................................ 52

Indemnity to HP for 3D parts printed by the printer ........................................................................................................ 53

Cancel a job ............................................................................................................................................................................. 53

Check status on the front panel .......................................................................................................................................... 53

Check status remotely ........................................................................................................................................................... 55

Possible errors while printing ............................................................................................................................................... 55

11 Cooling and part retrieval ................................................................................................................................................................... 56

12 Post-processing ................................................................................................................................................................................... 59

13 Troubleshooting ................................................................................................................................................................................... 60

Network troubleshooting ...................................................................................................................................................... 61

Start-up issues ....................................................................................................................................................................... 61

Power-on issues ..................................................................................................................................................................... 62

iv ENWW

Page 5

Agent troubleshooting .......................................................................................................................................................... 62

Material cartridge troubleshooting ...................................................................................................................................... 62

Printhead health troubleshooting ....................................................................................................................................... 63

How to get the diagnostic package ..................................................................................................................................... 63

14 Maintenance .......................................................................................................................................................................................... 65

Safety precautions ................................................................................................................................................................. 66

Maintenance resources ......................................................................................................................................................... 66

Maintenance tools recommended but not provided ........................................................................................................ 66

Printer maintenance schedule ............................................................................................................................................. 70

Clean the print area ................................................................................................................................................................ 71

Wipe the recoating roller ....................................................................................................................................................... 73

Scrape and wipe the fusing lamp ........................................................................................................................................ 75

Vacuum the air exhaust lter compartment ...................................................................................................................... 77

Vacuum the material reclamation sieve drawer ............................................................................................................... 80

Clean the inside of the viewing window (500 series only) ............................................................................................... 81

Clean the build-chamber front rail ...................................................................................................................................... 82

Clean the scanner ................................................................................................................................................................... 82

Replace a fusing lamp ........................................................................................................................................................... 84

Replace the cleaning roll ....................................................................................................................................................... 87

Replace the material reclamation lter .............................................................................................................................. 91

Replace the air exhaust lter ................................................................................................................................................ 93

Replace a printhead ............................................................................................................................................................... 96

Replace the print-area lter ............................................................................................................................................... 103

Replace the air intake lter ................................................................................................................................................. 106

Replace the printhead cap .................................................................................................................................................. 107

Align the printheads ............................................................................................................................................................ 109

15 Move or store the printer .................................................................................................................................................................. 115

16 Print-quality optimization ................................................................................................................................................................ 116

General advice ...................................................................................................................................................................... 116

17 Ordering information and end-of-life recommendations ........................................................................................................... 117

18 System errors ..................................................................................................................................................................................... 118

19 When you need help .......................................................................................................................................................................... 119

Request support .................................................................................................................................................................. 119

Customer Self-Repair .......................................................................................................................................................... 119

Service information ............................................................................................................................................................. 119

ENWW v

Page 6

20 Accessibility ......................................................................................................................................................................................... 120

Front panel ............................................................................................................................................................................ 120

Index ........................................................................................................................................................................................................... 121

vi ENWW

Page 7

1 Welcome to your MJF system

●

Documentation

●

Product usage requirements

●

MJF technology

●

Usage recommendations

ENWW 1

Page 8

Documentation

The following documents are available:

● Site preparation guide

● Introductory information

● User guide (this document)

● Videos supplementing the user guide

● Legal information

● Limited warranty

Product usage requirements

The products, services, and consumables are subject to the following additional terms:

● The customer agrees to use only HP Branded Consumables and HP Certied Materials in the 3D HP printer

product, and understands that use of any consumables other than HP consumables may cause serious

product functionality and/or safety issues, including, but not limited to those outlined in the user guide. The

customer agrees not to use the product and/or consumables for uses not permitted by US, EU, and/or other

applicable law.

● The customer agrees not to use the product and/or consumables for the development, design,

manufacture, or production of nuclear weapons, missiles, chemical or biological weapons, and/or

explosives of any kind.

● The customer agrees to comply with the connectivity requirement outlined below.

● The customer may use rmware embedded in the product only to enable the product to function in

accordance with its published specications.

● The customer agrees to comply with the user guide.

Products, services, and/or technical data provided under these terms are for the customer’s internal use and not

intended for further resale.

MJF technology

HP Multi Jet Fusion technology oers control over part and material properties and speed advantages beyond

those found in other 3D printing technologies.

The HP MJF printing process begins by depositing a thin layer of material in the printer’s work area. Next, the

carriage containing an HP Thermal Inkjet array passes over the full work area, printing chemical fusing, detailing,

and coloring agents. During another pass of the carriage, the work area is exposed to fusing energy, which bonds

part layers together. The process continues, layer-by-layer, until a complete part is formed.

2 Chapter 1 Welcome to your MJF system ENWW

Page 9

a. The material is recoated across the work area.

b. A fusing agent (F) is selectively applied where the particles are to fuse together.

c. A detailing agent (D) is selectively applied where the fusing action needs to be reduced or amplied. In this

example, the detailing agent reduces fusing at the boundary to produce a part with sharp and smooth

edges.

d. The work area is exposed to fusing energy.

e. The part now consists of fused and unfused areas.

The process is repeated until the complete part has been formed.

NOTE: The sequence of steps above is typical, but may be changed in specic hardware implementations.

By leveraging proven HP Thermal Inkjet technology and HP’s in-depth technical knowledge of rapidly and

accurately placing precise, minute quantities of multiple types of uids, MJF enables customers to produce highly

detailed parts and prototypes.

As agents are deposited point-by-point across each cross-section of each part, MJF technology can transform

part properties at each voxel, or volumetric pixel.

For example, when printing in color, MJF technology selectively prints color at the voxel level with cyan, magenta,

yellow, and black agents.

With MJF technology, HP will enable customers to realize the full potential of 3D printing.

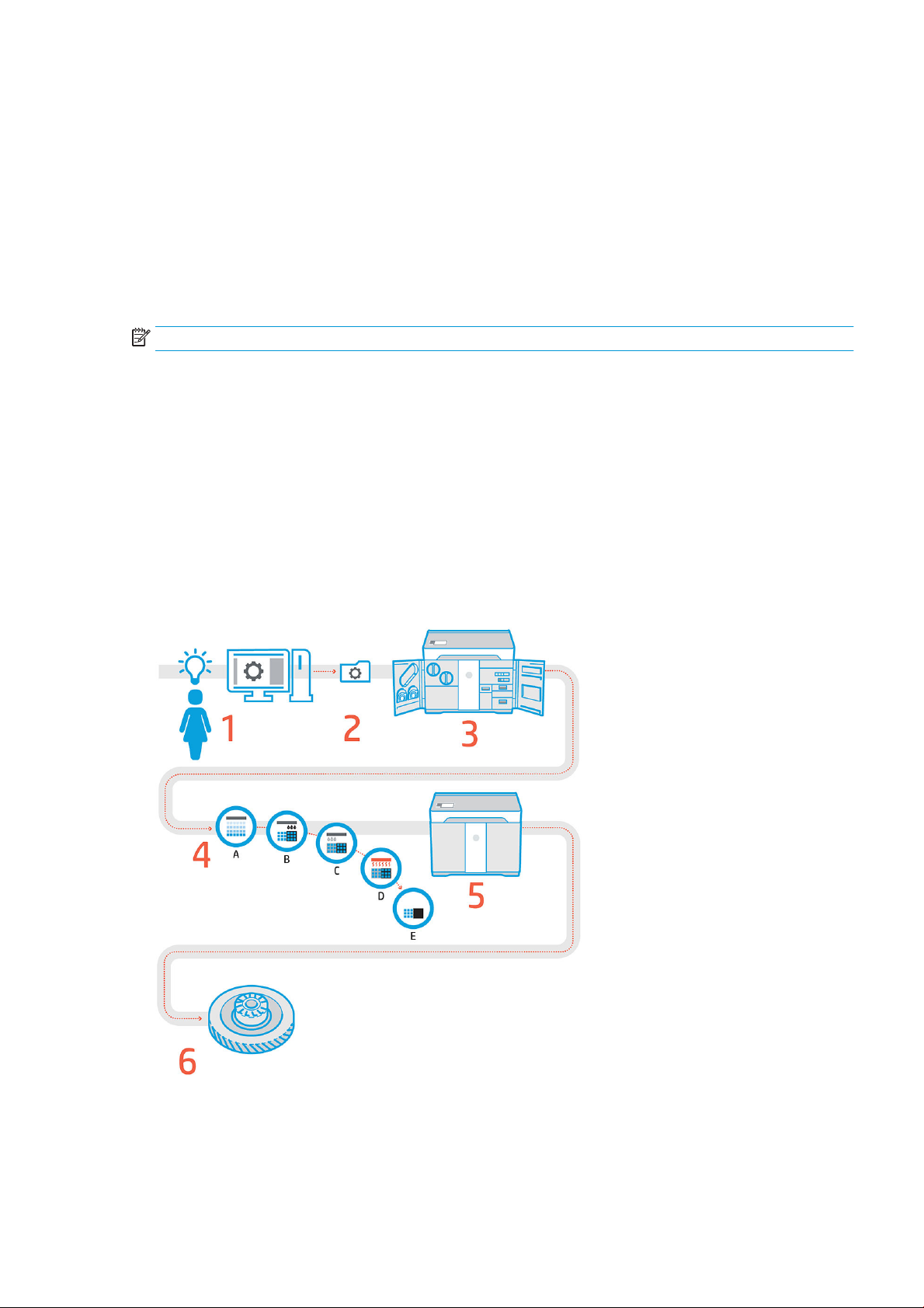

Usage recommendations

1. Prepare design: Open your 3D model(s) and check for errors in the easy-to-use HP SmartStream 3D Build

Manager software.

2. Pack models and send to printer: Arrange your 3D models in the HP SmartStream 3D Build Manager and

submit the job to the printer.

ENWW Usage recommendations 3

Page 10

3. Prepare printer: Clean your printer, check your long-term consumables, automatically check mechanical

systems.

4. Printing with voxel-level control: Just tap Start to start building parts with extreme dimensional accuracy

and ne detail, thanks to HP’s unique multi-agent printing process.

5. Automated material management: Unused material is automatically reclaimed and stored to be reused in

the next print job.

6. Retrieve and clean parts: The beacon and front panel indicate when parts are ready for retrieval. Retrieve

your parts from the build chamber and remove excess material with a bead and air blast system.

4 Chapter 1 Welcome to your MJF system ENWW

Page 11

2 Safety precautions

●

Introduction

●

General safety guidelines

●

Final parts/builds

●

Explosion hazard

●

Electrical shock hazard

●

Heat hazard

●

Fire hazard

●

Mechanical hazard

●

Light radiation hazard

●

Chemical hazard

●

Ventilation

●

Air conditioning

●

Sound pressure level

●

Printer transport hazard

●

3D part retrieval

●

Personal protective equipment

●

Use of tools

●

Warnings and cautions

●

Warning labels

●

Emergency stop button

ENWW 5

Page 12

Introduction

Before using the printer, read the following safety precautions and operating instructions to make sure you can

use it safely.

You are expected to have the appropriate technical training and experience necessary to be aware of hazards to

which you may be exposed in performing a task, and to take appropriate measures to minimize the risks to

yourself and to others.

Perform the recommended maintenance and cleaning tasks to ensure the correct and safe operation of the

printer.

The printer is stationary, and should be located in a restricted-access area, for authorized personnel only.

General safety guidelines

Turn o the printer, using the branch circuit breakers located in the building's Power Distribution Unit (PDU), and

call your support representative (see When you need help on page 119) in any of the following cases:

● The power cord is damaged.

● The heating and fusing lamp enclosures are damaged, the glass is missing or broken, or the sealing is

defective.

● The printer has been damaged by an impact.

● Condensation has entered the printer.

● There is smoke or an unusual smell coming from the printer.

● Fuses have blown.

● The printer is not operating normally.

● There is any mechanical or enclosure damage.

Turn o the printer using the branch circuit breakers in either of the following cases:

● During a thunderstorm

● During a power failure

Take special care with zones marked with warning labels.

Use HP-certied and HP-branded material and agents only. Do not use unauthorized third-party material or

agents.

In case of unexpected malfunction, anomaly, ESD (ElectroStatic Discharges), or electromagnetic interference,

press the emergency stop button and disconnect the printer. If the problem persists, contact your support

representative.

The print-production area in which the printer is installed should be free from liquid spillage and environmental

condensation. The operating climatic conditions should be maintained within the specied ranges for both

product and material (see the site preparation guide for the specied ranges).

The printer should always be kept within rated environmental conditions.

Ensure that there is no condensation inside the printer before turning it on.

To repair or reinstall the printer, contact your nearest authorized service provider. Do not repair, disassemble, or

replace any part of the printer or attempt any servicing yourself, unless specically recommended in the usermaintenance instructions or in published user-repair instructions that you understand and have the skills to carry

6 Chapter 2 Safety precautions ENWW

Page 13

out. Do not use any part other than original HP spare parts. Unauthorized attempts at repair may result in

electric shock, re, printer malfunction, or injury.

Final parts/builds

The customer assumes all risk relating to or arising from the 3D printed parts.

The customer is solely responsible for the evaluation of and determination of the suitability and compliance with

applicable regulations of the products and/or 3D printed parts for any use, especially for uses (including but not

limited to medical/dental, food contact, automotive, heavy industry, and consumer products) that are regulated

by US, EU, and other applicable governments.

Explosion hazard

WARNING! Dust clouds can form explosive mixtures with air. Take precautionary measures against static

charges, and keep away from sources of ignition.

NOTICE: The printer is not intended for hazardous locations or ATEX classied zones: ordinary locations only.

To avoid the risk of explosion, take the following precautions:

● Smoking, candles, welding, and open ames should be forbidden close to the printer or material storage

area.

● Inside and outside the printer should be cleaned regularly with an explosion-protected vacuum cleaner to

avoid dust accumulation. Do not sweep the dust or or try to remove it with a compressed-air gun.

● An explosion-protected vacuum cleaner certied for collection of combustible dust is required for cleaning.

Take measures to mitigate material spillage and avoid potential ignition sources such as ESD (ElectroStatic

Discharges), ames, and sparks. Do not smoke nearby.

● The printer and accessories must be properly grounded at mains outlets only; do not manipulate internal

bonding. If static discharges or electrical sparks are noticed, stop operation, disconnect the printer, and

contact your support representative.

● Check the air lters and the sealing of the heating lamps regularly.

● Use HP-certied and HP-branded material and agents only. Do not use unauthorized third-party material

or third-party agents.

● HP recommends the use of HP accessories for retrieving 3D parts and relling the build chamber. If other

methods are used, read the following notes:

– Dust clouds generated during handling and/or storage can form explosive mixtures with air. Dust

explosion characteristics vary with the particle size, particle shape, moisture content, contaminants,

and other variables.

– Check that the printer is properly grounded and installed to satisfy electrical classication

requirements. As with any dry material, pouring this material or allowing it to fall freely or be

conveyed through chutes or pipes can accumulate and generate electrostatic sparks, potentially

causing ignition of the material itself, or of any ammable materials which may come into contact

with the material or its container.

● Material storage, handling, and disposal as per local laws. See the Safety Data Sheets at

http://www.hp.com/go/msds for adequate handling and storage. Follow your Environmental, Health, and

Safety processes and procedures.

● Do not place the printer in a hazardous location area, and keep it separated from other equipment that

could create a combustible dust cloud during its operation.

● Auxiliary post-processing equipment, such as for bead blasting, must be suitable for combustible dust.

ENWW Final parts/builds 7

Page 14

● Stop operation immediately if sparks or material spillages are seen, and call your support representative

before continuing.

● All personnel, when handling combustible dust, should be freed from static electricity by using conductive

or dissipative footwear and clothing, and a conductive oor.

Electrical shock hazard

WARNING! The internal circuits inside the e-cabinet, and the heating and fusing lamps, operate at hazardous

voltages capable of causing death or serious personal injury.

Turn o the printer using the branch circuit breakers located in the building's Power Distribution Unit (PDU) before

servicing. The printer must be connected to earth at mains outlets only.

To avoid the risk of electric shock:

● Do not attempt to dismantle the internal circuit enclosures, heating or fusing lamps, or e-cabinet except

during hardware maintenance tasks. In that case, follow the instructions strictly.

● Do not remove or open any other closed system covers or plugs.

● Do not insert objects through slots in the printer.

NOTE: A blown fuse may indicate malfunctioning electrical circuits within the system. Call your support

representative (see When you need help on page 119), and do not attempt to replace the fuse yourself.

Heat hazard

The heating, fusing, and build-chamber subsystems of the printer operate at high temperatures. To avoid

personal injury, take the following precautions:

● Take special care when accessing the printing area. Let the printer cool down before you open the covers.

● Take special care with zones marked with warning labels.

● Do not place objects inside the printer while operating.

● Do not cover enclosures while operating.

● Remember to let the printer cool down before performing some maintenance operations.

● Wait for at least the minimum cooling time before retrieving parts from the printer. HP recommends

wearing safety gloves to retrieve parts after printing, as the parts may be hot.

Fire hazard

The heating, fusing, and build-chamber subsystems of the printer operate at high temperatures. Call your

support representative if the fuses are repeatedly blowing.

To avoid the risk of re, take the following precautions:

● Use the power supply voltage specied on the nameplate.

● Connect the power cord to a dedicated line, protected by a branch circuit breaker according to the

information detailed in the site preparation guide.

● Do not insert objects through slots in the printer.

● Take care not to spill liquid on the printer. After cleaning, make sure all components are dry before using

the printer again.

8 Chapter 2 Safety precautions ENWW

Page 15

● Do not use aerosol products that contain ammable gases inside or around the printer. Do not operate the

printer in an explosive atmosphere.

● Do not block or cover the openings of the printer.

● Do not attempt to modify the heating, fusing, build chamber, e-cabinet, or enclosures.

● Proper maintenance and genuine HP consumables are required to ensure that the printer operates safely

as designed. The use of non-HP consumables may present a risk of re.

● Take special care with zones marked with warning labels.

● Do not place objects covering top cover, enclosures, or air ventilation.

● Do not leave tools or other materials inside the printer after maintenance or servicing.

Suitable materials for re-ghting include carbon dioxide, water spray, dry chemicals, or foam.

CAUTION: Do not use a jet of water, as it could scatter and spread the re.

WARNING! Depending on the material used, some unhealthy substances can be released into the air in case of

incidental re. Wear self-contained pressure-demand breathing apparatus and full protective gear. Your EHS

specialist should consult the Safety Data Sheet (SDS) about each material, available at http://www.hp.com/go/

msds, and advice on the appropriate measures for your location.

Mechanical hazard

The printer has moving parts that could cause injury. To avoid personal injury, take the following precautions

when working close to the printer.

● Keep your clothing and all parts of your body away from moving parts.

● Avoid wearing necklaces, bracelets, and other hanging objects.

● If your hair is long, try to secure it so that it will not fall into the printer.

● Take care that sleeves or gloves do not get caught in moving parts.

● Avoid standing close to the fans, which could cause injury and could also aect print quality (by obstructing

the air ow).

● Do not operate the printer with covers bypassed.

Light radiation hazard

Infrared (IR) radiation is emitted from the heating and fusing lamps. The enclosures limit radiation in compliance

with the requirements of the exempt group of IEC 62471:2006, Photobiological safety of lamps and lamp

systems. Do not modify the top cover enclosure, nor the glasses or windows.

Chemical hazard

See the Safety Data Sheets available at http://www.hp.com/go/msds to identify the chemical ingredients of your

consumables (material and agents). Suicient ventilation needs to be provided to ensure that potential airborne

exposure to these substances is adequately controlled. Consult your usual air conditioning or EHS specialist for

advice on the appropriate measures for your location.

Use HP-certied material and agents only. Do not use unauthorized third-party material or third-party agents.

ENWW Mechanical hazard 9

Page 16

Ventilation

Fresh air ventilation is needed to maintain comfort levels. For a more prescriptive approach to adequate

ventilation, you could refer to the latest edition of the ANSI/ASHRAE (American Society of Heating, Refrigerating

and Air-Conditioning Engineers) document Ventilation for Acceptable Indoor Air Quality.

Adequate ventilation needs to be provided to ensure that potential airborne exposure to materials and agents is

adequately controlled according to their Safety Data Sheets.

Ventilation should meet local environmental, health, and safety (EHS) guidelines and regulations.

Follow the ventilation recommendations in the site preparation guide.

NOTE: The ventilation units should not blow air directly onto the printer.

Air conditioning

As with all printer installations, to maintain ambient comfort levels, air conditioning in the work area should take

into account that the printer produces heat. Typically, the printer's power dissipation is in the range of 4–6 kW

(13.6–20.5 kBTU/h).

Air conditioning should meet local environmental, health, and safety (EHS) guidelines and regulations.

NOTE: The air conditioning units should not blow air directly onto the printer.

An HVAC unit is required which can consistently maintain the recommended operating temperature in order to

achieve optimal printing performance. More specic technical information can be found in the site preparation

guide.

Sound pressure level

The HP VCVRA-1804 maximum A-weighted sound pressure level over bystander positions while printing is 80

dB(A). Hearing protection may be required as per local laws; consult your EHS specialist.

Printer transport hazard

Special care must be taken to avoid personal injury when moving the printer.

● Move the printer over smooth, at surfaces without steps.

● Move with care and avoid shocks during transport, which could spill the material.

● Lock the front casters when not moving the printer. Remember to unlock them before moving it.

If you move the printer between dierent rooms, bear in mind that it should be kept in constant environmental

conditions, and recalibrated when it reaches its new location: recalibrate the load cells, check the spacing

between the spreader roller and the preheat plate, and check printhead alignment, realigning if necessary.

3D part retrieval

Wear heat-resistant gloves when retrieving 3D printed parts manually. Safety gloves are also recommended

when retrieving 3D printed parts after auto-extraction, as the parts may still be hot.

Personal protective equipment

HP recommends safety gloves, masks, goggles, and hearing protection for certain printing and maintenance

tasks.

10 Chapter 2 Safety precautions ENWW

Page 17

Use of tools

No tools are required for daily operations including printer settings, printing, retrieving and relling, replacement

of agent intermediate tanks, and daily checks.

NOTE: During installation, the designated personnel receive training for the safe operation and maintenance of

the printer. The printer should not be used without this training.

Warnings and cautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent it from

being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious personal injury or

death.

CAUTION: Failure to follow the guidelines marked with this symbol could result in minor personal injury or

damage to the product.

Warning labels

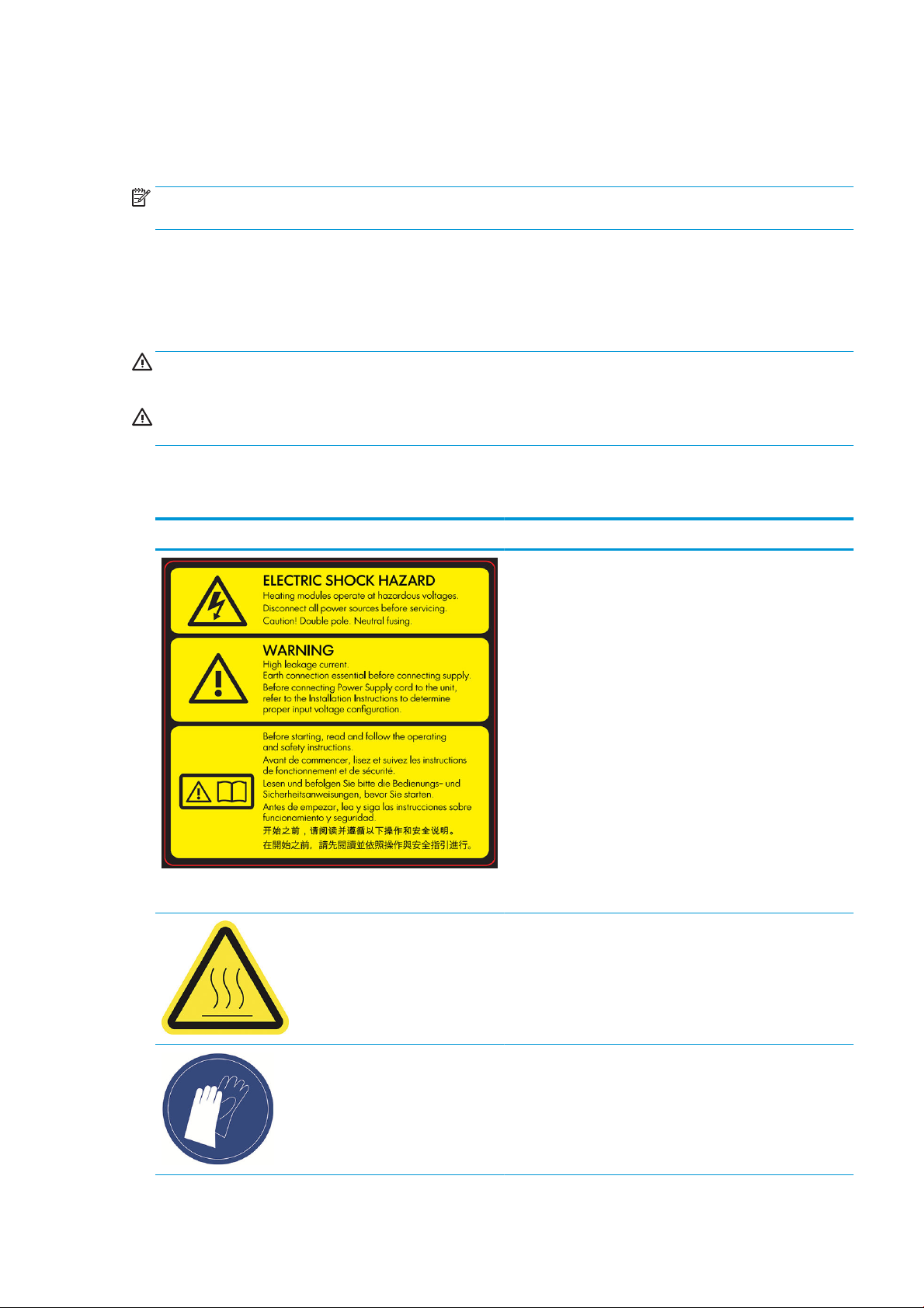

Label Explanation

For service personnel only

Electric shock hazard

Heating modules operate at hazardous voltage. Disconnect power

source before servicing.

CAUTION: Refer servicing to qualied service personnel.

In case of operation of the fuse, parts of the printer that remain

energized may represent a hazard during servicing. Before

servicing, turn o the printer using the Branch Circuit Breakers

located in the building's Power Distribution Unit (PDU).

WARNING! High leakage current. Current leakage may exceed 3.5

mA. Earth connection essential before connecting supply.

Equipment to be connected to earthed mains only.

See installation instructions before connecting to the supply. Ensure

that the input voltage is within the printer's rated voltage range.

Before starting

Read and follow the operating and safety instructions before

starting the printer.

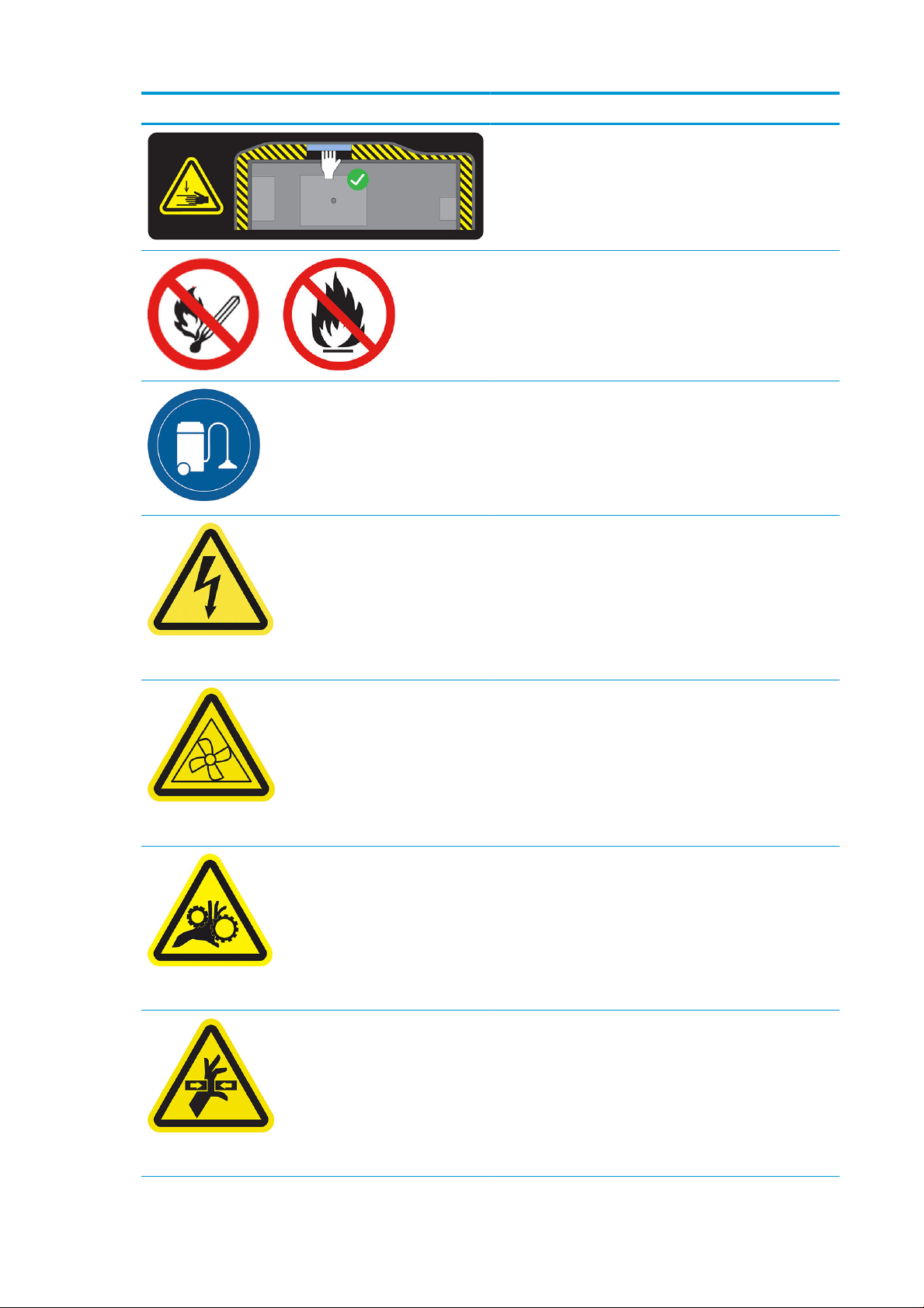

Risk of burns. Let the printer cool down before accessing internal

parts.

HP recommends that you wear gloves when performing certain

maintenance and cleaning tasks. Wear heat-resistant gloves when

retrieving parts, either through manual extraction or after material

reclamation. The parts may be very hot.

ENWW Use of tools 11

Page 18

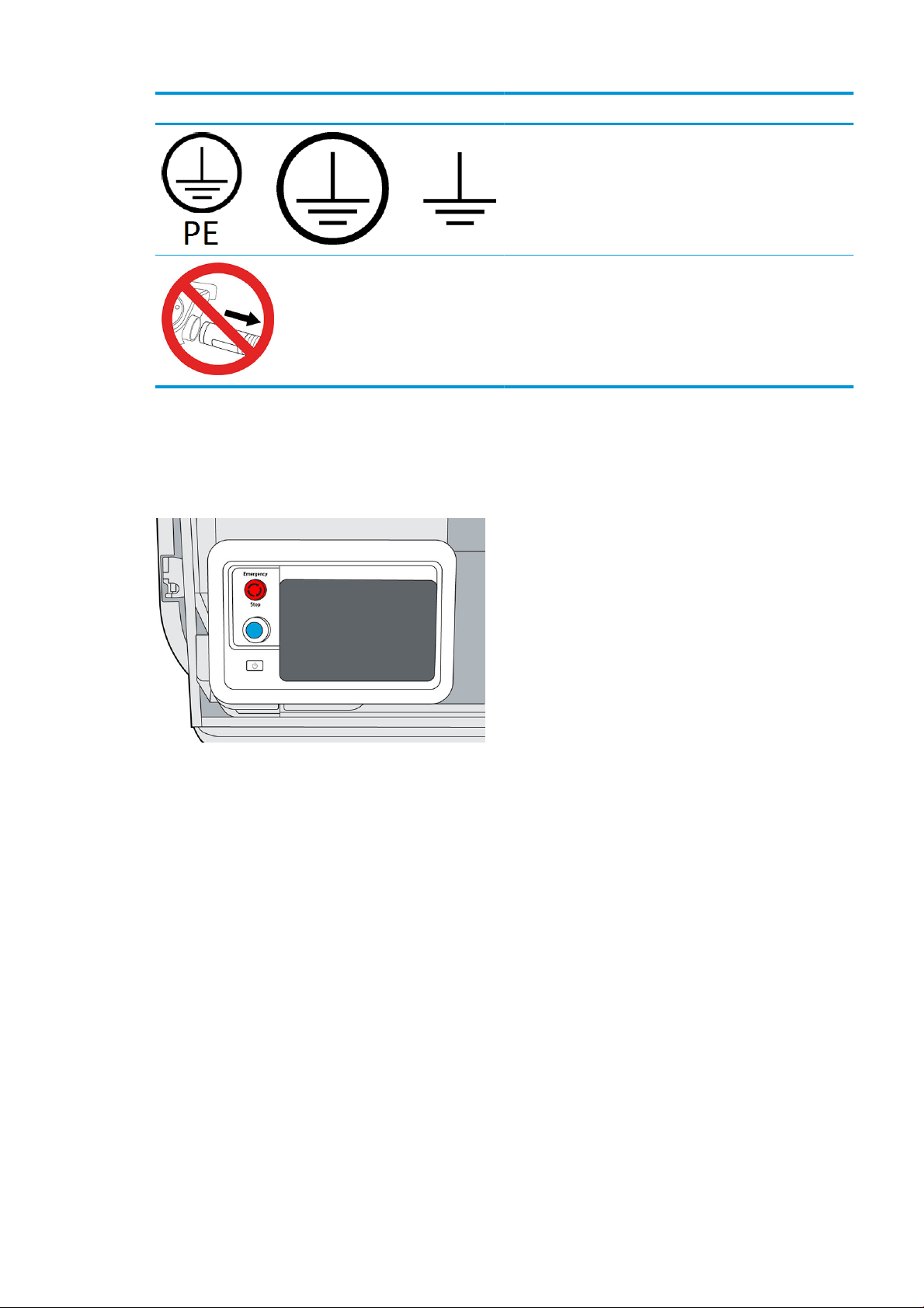

Label Explanation

Crush hazard. Keep your hands clear of the edge of the top cover.

Open and close the top cover using the handle (highlighted in blue)

only.

WARNING! Dust clouds can form explosive mixtures with air. Take

precautionary measures against static charges, and keep away

from sources of ignition.

No smoking, matches, or open ames close to printer or material

storage area.

An explosion-protected vacuum cleaner certied for collection of

combustible dust is required for cleaning.

Take measures to mitigate material spillage and avoid potential

ignition sources such as ESD (ElectroStatic Discharges), ames, and

sparks. Do not smoke nearby.

Disposal as per local laws.

Electric shock hazard. Disconnect power before servicing. Heating

modules and electrical cabinets operate at hazardous voltage.

For maintenance and service personnel only

For maintenance and service personnel only

For maintenance and service personnel only

Hazardous moving parts. Keep away from moving fan blades.

Risk of trapped ngers. Do not touch gears while moving: your

hands may be trapped between the gearwheels.

Hazardous moving parts. Keep away from the moving printhead,

lamp, and heater carriages. When printing, the print carriage travels

back and forth.

For service personnel only

12 Chapter 2 Safety precautions ENWW

Page 19

Label Explanation

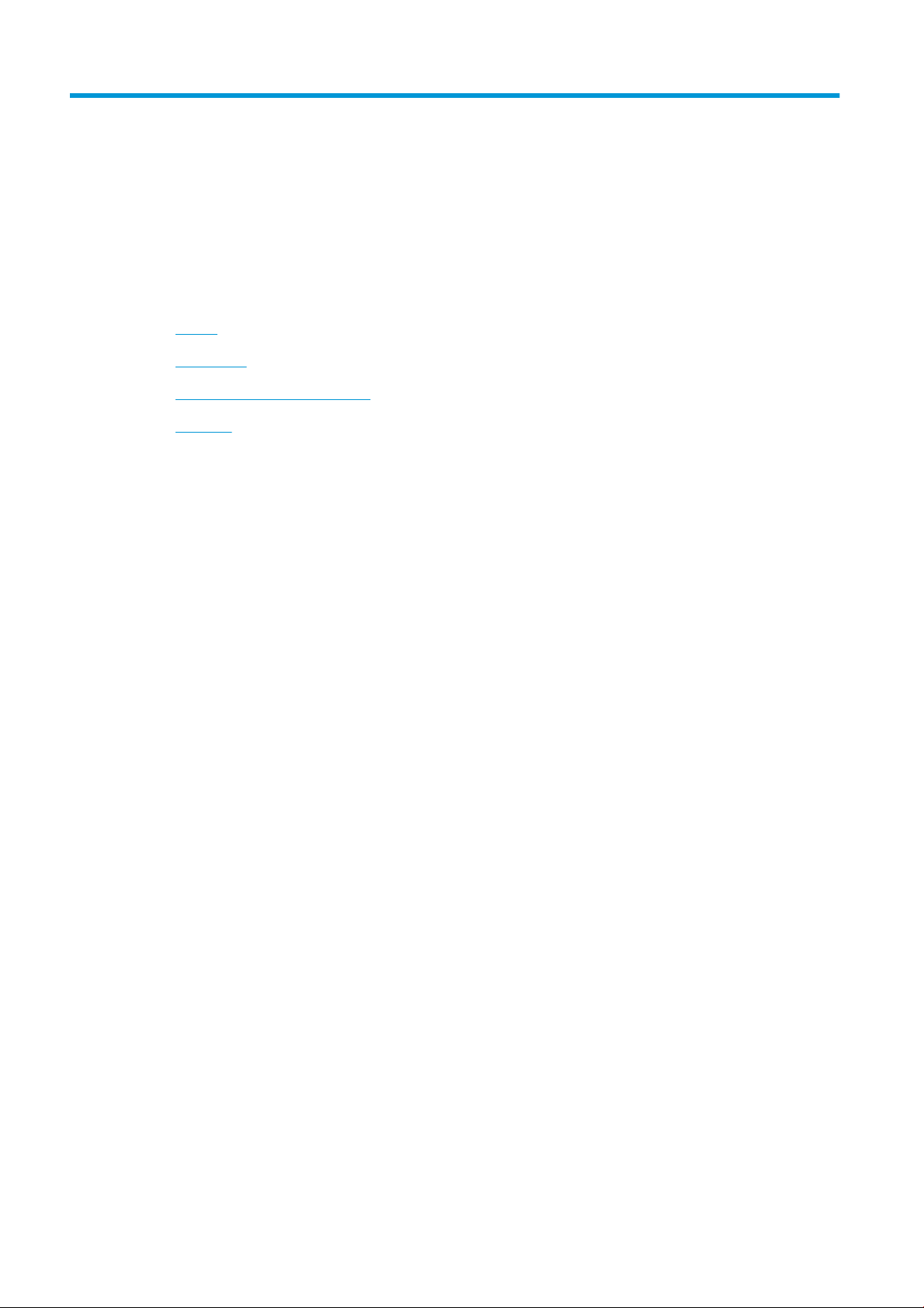

Emergency stop button

There is a red emergency stop button on top of the printer, beside the front panel. If an emergency occurs,

simply push the emergency stop button to stop all processes.

Identies the Protective Earth (PE) terminal for qualied electricians,

and bonding terminals for maintenance/service personnel only. An

earth connection is essential before connecting to the supply.

Do not disconnect the hoses during the purging process.

The printer carriages, the fans, and the lamp module are halted; the top cover is locked until the internal

temperature decreases. A system error message is displayed.

Ensure that the emergency stop button is released before restarting the printer.

For safety reasons, access to the print zone is not permitted while printing is in progress. Let the printer cool

down before touching anything inside it.

To stop the printer completely, turn it o.

ENWW Emergency stop button 13

Page 20

3 Main components

●

Printer

●

Front panel

●

Set the administrator password

●

Software

14 Chapter 3 Main components ENWW

Page 21

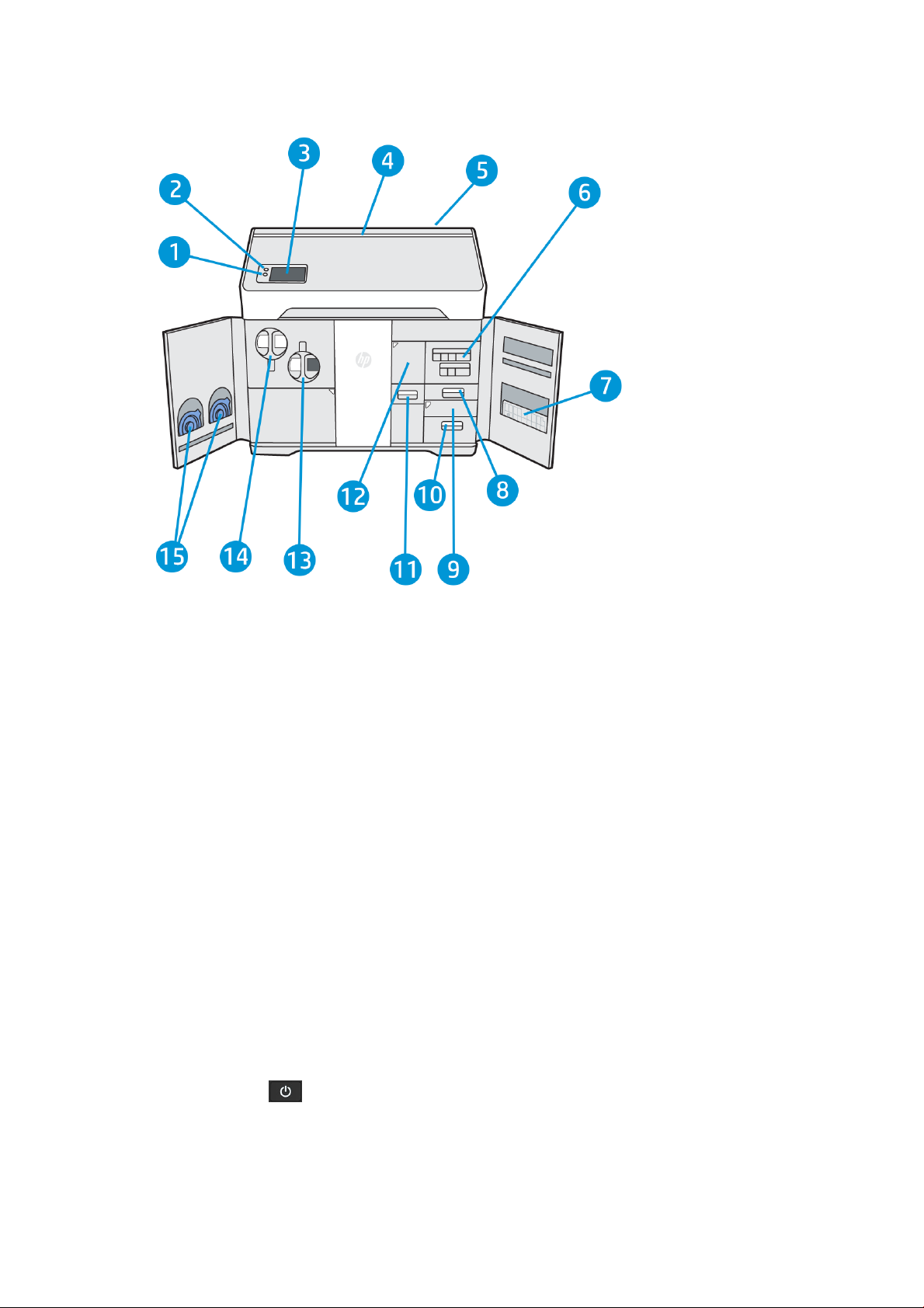

Printer

1. Rearm button

2. Emergency stop button

3. Front panel

4. Status beacon (500 series only)

5. Air intake lter (behind the printer)

6. Agent cartridges

7. Alignment plate

8. Distilled water tank (B3)

9. Scanner (B4)

10. Air exhaust compartment and lter (B5)

11. Material reclamation sieve (B2)

12. Material reclamation lter (B1), and access to the reclamation intermediate tank

13. Reusable material cartridge

14. Fresh material cartridge

15. Cartridge caps

The power button is beside the front panel, just below the rearm button.

ENWW Printer 15

Page 22

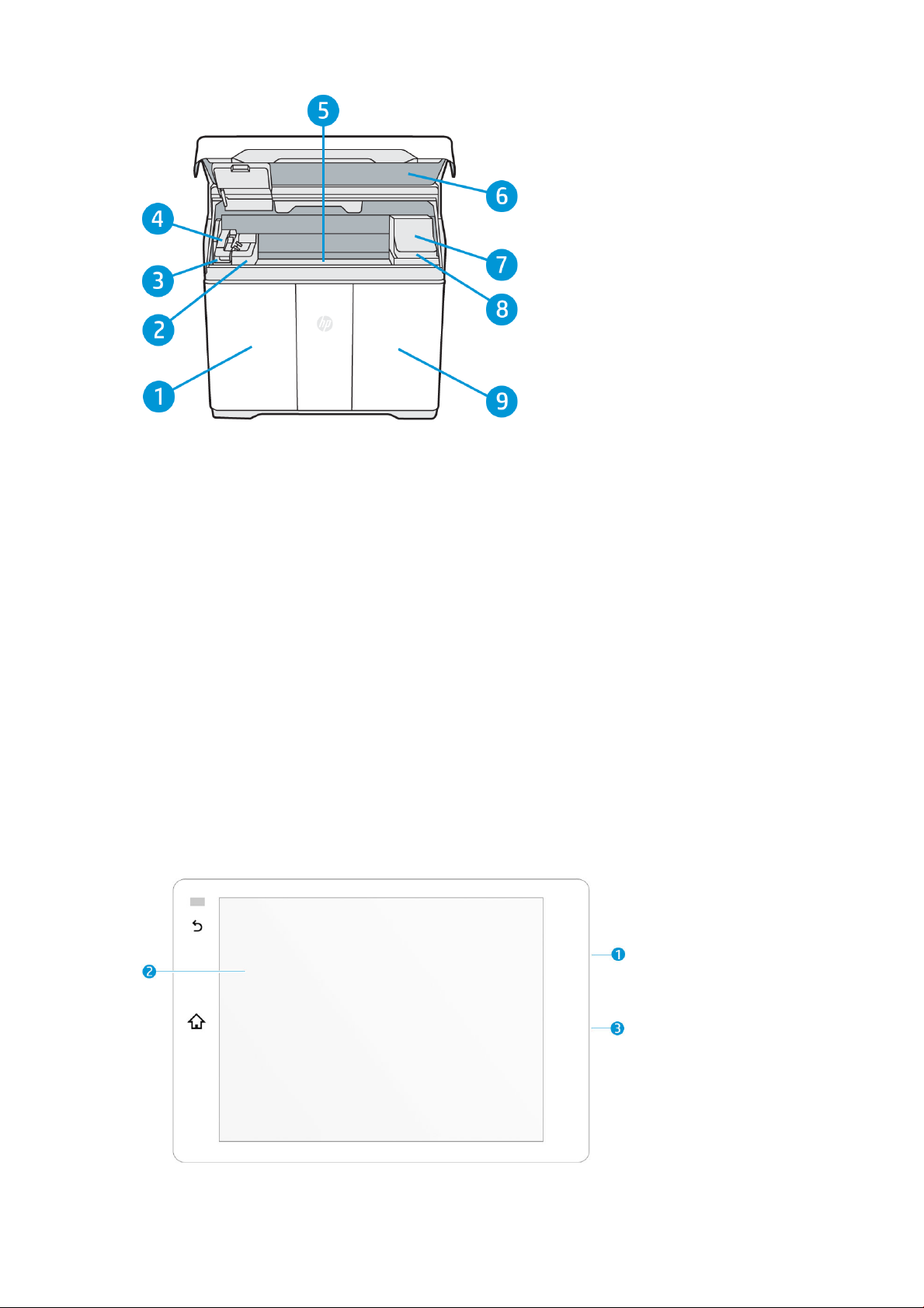

1. Material door

2. Fusing lamp

3. Recoating roller and cover

4. Fusing carriage (C1)

5. Build platform and build chamber

6. Top cover and viewing window (500 series only)

7. Print carriage (C2)

8. Printhead cleaning roll (under the print carriage)

9. Agent door

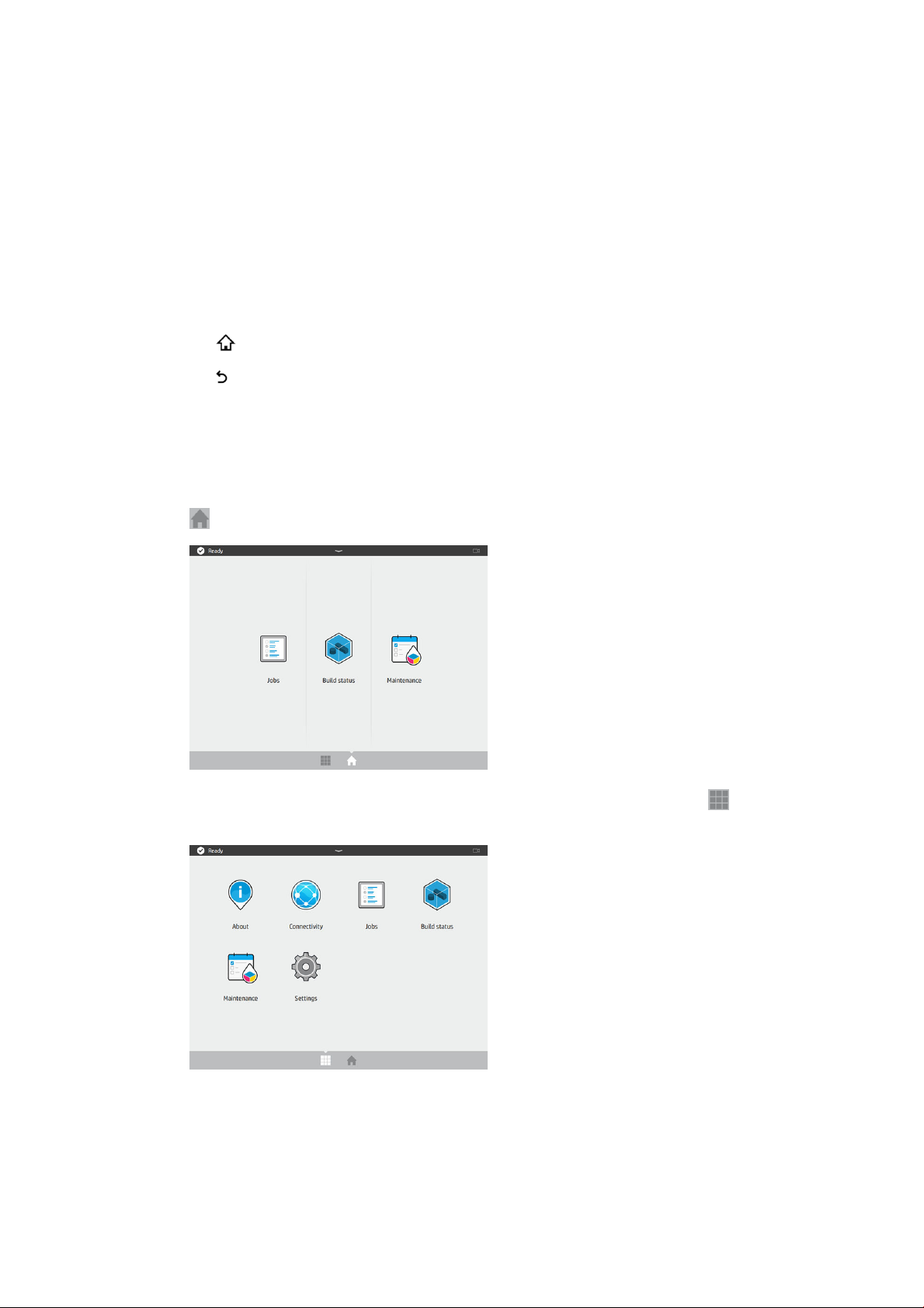

Front panel

The front panel is a touch-sensitive screen situated on the front left of the printer.

The front panel gives you complete control of your printer: from the front panel, you can view information about

the device, change device settings, monitor device status, and perform tasks such as supplies replacement and

printhead alignment. The front panel displays alerts (warning and error messages) when necessary.

16 Chapter 3 Main components ENWW

Page 23

It includes the following components:

1. A Hi-Speed USB 2.0 host port, intended for connecting a USB ash drive, which can provide rmware

2. The front panel itself: an 8 inch, full-color, touch-sensitive screen with a graphical user interface

3. The loudspeaker

The front panel has a large central area to display dynamic information and icons. On the left side you can see

one or two xed icons.

Left xed icons

● Tap to return to the home screen.

● Tap to go back to the previous screen. This does not discard any changes made in the current screen.

Home screens

There are two top-level screens that you can move between by swiping your nger across the screen, or tapping

the appropriate icon at the bottom of the screen:

● The rst main screen provides direct access to the most important functions. It can be displayed by tapping

update les to the printer; it is located behind the front panel, accessible when the front panel is tilted up.

at the bottom of the screen.

● The all-app screen displays a list of all available apps. It can be displayed by tapping at the bottom of

the screen.

Status center

At the top of the front panel is the status center, which can be expanded by swiping down from the top. This is

visible on almost all screens, except when an action is taking place. In the status center, you can see the status of

the printer, and access various controls and alerts.

ENWW Front panel 17

Page 24

Status beacon (500 series only)

The printer has a beacon strip across the top cover; it gives a summary of the printer and job status, which can be

seen from a distance.

IMPORTANT: The information provided in the beacon is for functional information purposes only, and is not

relevant to your safety. Warning labels on the printer should always be heeded, regardless of the status indicated

by the beacon lights.

Beacon o The printer is ready for the next job.

White moving light The printer is in the middle of a process.

White light The printer has completed a process and is waiting for you.

Blue moving light The printer is printing a job.

Blue light A job is complete and the parts are ready to be retrieved.

Red light The printer is unable to print because of a system error; a job may have been canceled.

Change system options

You can change various printer system options from the front panel. Tap , then System.

● Language to change the language in which the printer operates.

● Select altitude to tell the printer its height above sea level.

● Display brightness to change the brightness of the front-panel display. The default brightness is 50.

● Speaker volume to change the volume of the printer's loudspeaker. Select O, Low, or High.

● Time zone to view or set the printer's time zone.

● Printer logs to request detailed troubleshooting information about system errors, system warnings,

printheads, or agents.

● Restore factory settings to restore the printer settings to their original values as set in the factory. This

option restores all of the printer settings except the Gigabit Ethernet settings and paper presets.

● Unit selection to select between imperial and metric measurements for your printer.

18 Chapter 3 Main components ENWW

Page 25

Set the administrator password

You can set the administrator password from the front panel. Tap , then Security > Manage password, and

enter the password. If a password has already been set, you will need to give the old password in order to set a

new one.

The administrator password must be given in order to change printer settings.

Software

HP SmartStream 3D Command Center

HP Smartstream 3D Command Center is a client application that fully monitors your HP 3D printers, and all other

complementary devices such as processing stations and build units, to fully utilize the power of the HP 3D

ecosystem. Command Center must be installed with your 3D devices. It helps you to make all of your 3D printing

builds successful: review print jobs and be ahead of the printer’s needs by remotely viewing rmware updates,

warnings, and errors.

HP Smartstream 3D Command Center software, manuals, and support for your 3D printing solution can be

downloaded from:

● http://www.hp.com/go/SmartStream3DCommandCenter/software

● http://www.hp.com/go/SmartStream3DCommandCenter/manuals

● http://www.hp.com/go/SmartStream3DCommandCenter/support

For more information about the Command Center, see the HP SmartStream 3D Command Center User Guide.

HP SmartStream 3D Build Manager

Use the powerful 3D print-preparation capabilities of HP SmartStream 3D Build Manager to help make all of your

3D printing jobs successful:

1. Add parts to begin preparing the print job.

2. Rotate, size, and position the part on the build platform.

3. Add, change, or remove part color.

4. Automatically locate and x 3D geometry errors.

5. Send a printer-ready le to a connected 3D printer or save the printable le.

ENWW Set the administrator password 19

Page 26

HP Smartstream 3D Build Manager software, manuals, and support for your 3D printing solution can be

downloaded from:

● http://www.hp.com/go/SmartStream3DBuildManager/software

● http://www.hp.com/go/SmartStream3DBuildManager/manuals

● http://www.hp.com/go/SmartStream3DBuildManager/support

For more information about the Build Manager, see the HP SmartStream 3D Build Manager User Guide.

20 Chapter 3 Main components ENWW

Page 27

4 Power on and o

NOTICE: Operate the printer only within the specied ranges of operating temperature and humidity (see the

site preparation guide). If the printer or supplies are exposed to conditions outside the environmental operating

range, wait at least 12 hours for everything to reach environmental operating conditions before turning on the

printer or using the supplies.

●

Turn the printer on and o

●

Main power switch

●

Away mode

Turn the printer on and o

Turn on the printer for the rst time

1. Ensure that the printer’s doors are all closed.

2. Turn the main switch at the rear of the printer to the on position.

3. Wait for the front panel to tell you that the printer is waiting for rearm.

4. Perform a visual check of the printer.

ENWW Turn the printer on and o 21

Page 28

5. When requested, press the blue rearm button beside the front panel, at the front left of the printer. This

enables all of the printer's high-power subsystems.

6. Wait for the front panel to indicate that the printer is ready. This can take several minutes. When

initialization is complete, the front panel displays a ready message. If a system error message is displayed,

see System errors on page 118.

Turn the printer on and o

Use the button beside the front panel to turn the printer on and o.

To turn o the printer for an extended period of time, rst turn it o with the button; wait for it to shut

down completely; then turn o the main switch at the rear of the printer.

Main power switch

Leave the main power switch on at all times, unless you intend to move the printer.

If you plan to leave the printer unattended for more than a week, set it to away mode.

22 Chapter 4 Power on and o ENWW

Page 29

Away mode

If you plan to leave the printer unattended for more than a week, select Away mode from the maintenance

menu. The printer will perform a series of minor maintenance tasks in order to maintain the health of your

printheads.

Entering away mode is preferable to shutting the printer down completely. It will minimize the frequency of

printhead replacement, as well as help maintain steady operating procedures with predictable costs based on

usage. The printer will remain locked throughout away mode; it can be returned to normal operation from the

front panel.

CAUTION: If you turn o the printer for an extended amount of time, it cannot maintain printhead nozzle

health, and you may nd that you need to replace the printheads when you eventually turn it back on.

ENWW Away mode 23

Page 30

5 Printer networking

Introduction

The printer provides a single RJ-45 port for a network connection. For optimal performance, HP recommends

using Cat 5/5e or Cat 6 cabling and gigabit-capable local network equipment.

A correct network setup is required to operate the printer, as all communication with printing and management

software goes through the network.

IMPORTANT: In order to print, the printer must be connected to the Command Center, and the Command Center

must be connected to the cloud.

Connectivity requirement and remote monitoring

The customer will allow HP to install the HP Command Center software (or other applicable HP software that

controls the HP product and enables remote monitoring) on the customer’s computer.

The customer will keep that computer connected to the HP product, and the customer will keep the

HP Command Center software running on that computer and connected to the HP product at all times.

The customer will provide, at the customer’s sole expense, permanent HP Command Center software

connectivity to the HP secure cloud via permanent Internet connection through an HP-approved communications

channel and ensure such connectivity at all times as further specied in the site preparation guide. The customer

is responsible for restoring connectivity in a timely manner in the event of interruptions.

THE CUSTOMER AGREES THAT FAILURE TO MAINTAIN THE PRODUCT’S CONNECTION TO THE HP CLOUD AS

SPECIFIED IN THE SITE PREPARATION GUIDE WILL RESULT IN LIMITED OR NO PRODUCT FUNCTIONALITY AND

LIMITED SERVICE LEVEL.

HP products may collect the customer machine data. The customer grants HP and/or an HP authorized agent

permission to access remotely, via the HP Command Center software, the customer machine data from

HP products.

The customer machine data will be used by HP and/or an HP authorized agent for the purpose of providing

remote support, enabling enhanced diagnostics, preventive maintenance, software updating, calculating

supplies and consumables usage and statistics, and evaluating improvements to HP’s products and oerings in

the future. In addition, the customer machine data will help HP to determine how HP products are being used,

which product features are used the most, and to calculate various aggregate HP product usage statistics.

HP and/or HP authorized agents respect your privacy, are committed to protecting your machine data, and will

take reasonable precautions to prevent unauthorized access or disclosure and ensure the appropriate use of

your machine data. In the event that some data may be categorized as individual level data, HP and/or an

HP authorized agents will maintain the privacy of any such data, as well as all data collected, in accordance with

the HP Privacy Statement (http://www.hp.com/go/privacy) and the Personal Data Rights Notice

(http://welcome.hp.com/country/privacy/privacynotice) where applicable.

"Customer machine data" means data from the customer’s HP product that may include but is not limited to the

following: HP product usage data; HP product production data; HP product system events; HP product

24 Chapter 5 Printer networking ENWW

Page 31

maintenance and calibration history; HP product model number; HP product serial number; HP product rmware

version; HP product IP address; consumable status and history; sensor activity; quantity and type of printheads

used; build ID; build duration; and/or print mode. Customer machine data does not include: design les, parts

les, job names, job contents, part geometries, thermal maps, user names, or part names.

Conguration

To access the network settings, tap and then on the front panel.

Hostname

You can assign a customized hostname to the printer. If the network infrastructure supports it, the printer will

attempt to register the hostname to the DNS service, making it possible to address the printer using the

hostname rather than the IP address.

Similarly, you can assign the domain suix, to dene the printer’s fully qualied domain name.

IPv4 conguration

You can select whether the printer should try to discover automatically the IPv4 network settings using the DHCP

protocol, or whether you want to congure them manually. These settings include:

● IP address: The unique Internet Protocol address assigned to the printer.

● Subnet mask: The mask corresponding to the printer’s IP address.

● Default gateway: The IP address of the network gateway.

● DNS conguration method: Whether DNS servers should be assigned by DHCP service or manually.

● Primary and secondary DNS servers: The IP addresses of the DNS servers.

Link speed

The embedded network controller supports connection to IEEE 802.3 10Base-T Ethernet, IEEE 802.3u 100BaseTX Fast Ethernet, and 802.3ab 1000Base-T Gigabit Ethernet compliant networks. When connected and powered

on, the printer auto-negotiates with your network to operate with a link speed of 10, 100, or 1000 Mbps, and to

communicate using full- or half-duplex mode. However, you can manually congure the link using the printer's

front panel, or through other conguration tools once network communication is established.

ENWW Conguration 25

Page 32

6 Design and printing guidelines

●

Introduction

●

File preparation

–

File usage in the end-to-end workow

–

Minimum specication for parts

–

Coloring parts

–

Saving and exporting les

–

Recommended le export formats for color models

–

Tesselation problems

–

Repairing les

–

HP SmartStream 3D Build Manager

26 Chapter 6 Design and printing guidelines ENWW

Page 33

Introduction

3D printing oers a much higher level of freedom in terms of design than any other traditional manufacturing

technology. Designers and engineers can benet from this, and use new geometries and concepts that were not

feasible before. However, in order to optimize the design to be printed with MJF, you should be aware of some

characteristics of the printing process and its capabilities, as this could help to get the best of the technology.

The design and printing guidelines oer an overview of the steps to follow before sending a job to print, from le

preparation to the considerations that should be taken into account in the design of the parts and the orientation

of them in the build chamber to optimize the nal part quality and printing performance.

File preparation

File usage in the end-to-end workow

In the end-to-end workow of the printing process, the les pass through dierent software applications. For

example, the rst design may be done in a CAD program, while the job preparation will be handled in

HP SmartStream 3D Build Manager. If required, the printed part can be scanned in 3D and compared with the

original design.

Minimum specication for parts

When designing parts in your 3D modeling software, HP recommends keeping this minimum specication in

mind to avoid issues with parts and to achieve the best quality.

The minimum printable features in planes X, Y, and Z are as follows:

Minimum hole diameter at 1 mm thickness 0.5 mm (0.02 in)

Minimum shaft diameter at 10 mm height 1 mm (0.04 in)

Minimum printable font size for embossed or debossed letters or numbers 6 pt (2.1 mm) (0.083 in)

Minimum clearance at 1 mm thickness 0.5 mm (0.02 in)

Minimum slit between walls 0.5 mm (0.02 in)

ENWW Introduction 27

Page 34

● Engraving. Multi Jet Fusion technology allows you to print letters and drawings with a very high resolution

and denition.

For the best possible output, any text, number, or drawing included in a part of the same color should have

at least 1 mm of depth or height. When using contrasting colors, there is no minimum.

The best orientation for embossing and debossing letters is to place them upside down in the build

chamber.

28 Chapter 6 Design and printing guidelines ENWW

Page 35

● Solid part or structural ll. Multi Jet Fusion allows you to print topology-optimized, generative designs or

even small lattice structures. This kind of design helps to reduce the weight of the part and the quantity of

material used, which not only reduces the cost of the part but also helps to reduce the operating cost in

applications that are very weight-sensitive.

The minimum gap recommended in a lattice structure to ensure that all the material inside the part can be

removed is 5 mm.

● When printing a cantilever, the minimum wall thickness depends on the aspect ratio, which is the length

divided by the width.

Aspect ratio = Length/Width

For a cantilever with a width less than 1 mm, the aspect ratio should be less than 1. There are no specic

recommendations for widths greater than 1 mm.

ENWW File preparation 29

Page 36

● In general, the minimum recommended wall thickness is 0.5 mm for short walls oriented in the XY plane,

and 1 mm for short walls oriented in the Z plane.

For parts with a high aspect ratio (>10:1), HP recommends increasing the wall thickness, or adding ribs or

llets to reinforce the part.

Very thick walls can accumulate heat and cause spot shrinkage in dense areas with an accumulation of

material.

For best results, ribs should be no thicker than their base wall.

TIP: Hollow out the part as much as possible, saving agent and material, and reducing sink marks.

● Minimum gap between parts to be assembled after printing. Sometimes a pair of printed parts need to t

together for the nal application. In these cases, HP recommends gaps of at least 0.5 mm between the

interface areas that should t together, in order to ensure correct assembly.

30 Chapter 6 Design and printing guidelines ENWW

Page 37

● Minimum spacing and clearance between parts printed as assemblies. Assembly parts that are printed

together should have a minimum clearance of 0.7 mm. Parts with thick walls should have a larger gap to

ensure suicient material escape paths.

● Hollow closed geometries. Multi Jet Fusion is a process in which the parts are built by selectively fusing the

desired areas of a material-based layer. If the parts printed are hollow, drain holes need to be added to the

design to remove the material. The minimum recommended diameter of the holes is 5 mm; preferably

larger, for ease of cleaning. HP recommends including at least two holes.

● Glue lines. Parts larger than the maximum build size can be printed with Multi Jet Fusion by splitting them

into dierent parts. They can then be joined together by glueing, welding, or by pin inserts.

If you plan to glue parts together, HP recommends including interlocking features such as those shown in

the pictures below: as a guide to position the parts, to help them to bond together, and to facilitate the

glueing process. Remember to leave an additional space of 0.2 mm between parts for the glue, in addition

to the minimum spacing between parts printed as assemblies (see above).

ENWW File preparation 31

Page 38

● Ducts. To remove material from narrow ducts, consider designing and printing a strip or a chain through the

duct. When the parts have been printed, you can pull out the chain to dislodge most of the material. Any

remaining material can be removed by the normal cleaning process.

Coloring parts

After creating your 3D model, it is recommended to color your model before bringing it into the HP SmartStream

3D Build Manager since coloring options are limited there. There are two primary ways of adding color to 3D

models:

● Color addition by part, face, or shell: Commonly seen in CAD programs, this allows you to color specic

areas of a part.

A model with the entire part colored

A model with the dierent colors on dierent faces

32 Chapter 6 Design and printing guidelines ENWW

Page 39

● Texture mapping: Commonly seen in graphic art programs, texture mapping takes an image and wraps it

around a 3D object.

A model with a texture map

See your CAD or graphic arts software guidelines for how to use these features. You can also color previously

uncolored models in a free program, such as Microsoft 3D Builder, which is free on all Windows systems. 3D

Builder has easy-to-use color and texture map additions for beginners.

Saving and exporting les

After your les are designed and colored, your model needs to be tessellated, or converted into triangles, which

are used by the printer to create layers. Tessellation occurs when you save or export your model le into specic

le formats. The HP SmartStream 3D Build Manager accepts four dierent le formats:

● 3MF

NOTE: 3MF is the preferred le format for HP SmartStream 3D Build Manager.

However, defer to the recommended le export format chart below for color models.

● VRML 2 (.wrl)

● OBJ

● STL

NOTE: STL les do not carry color information. Use 3MF, VRML 2, or OBJ le formats for color models.

When saving or exporting your le, note that a normal le size for a model is about 1–200 MB, but the size

depends on the type of software that created it, the number of triangles, the number and level of details, and so

on. HP does not recommend working with les of more than 4 GB—beyond that size, the extra resolution in the

le may have no eect on the printed part.

When exporting to STL, OBJ, or VRML 2 from a CAD package, you are often required to introduce some

parameters such as angle tolerance and deviation chord height. These parameters dene the resolution and le

size of the part. The recommended parameters when exporting parts are an angle tolerance in the range 1–5

and a deviation chord height in the range 0.05–0.2. The angle tolerance should be reduced for parts with

cylindrical or spherical shapes, and the chord height should be minimized for parts with ne details and small

features.

Below, you will nd some recommended export parameters/settings for common 3D modeling programs.

Siemens NX recommended export settings

Recommended export format: VRML (.wrl)

ENWW File preparation 33

Page 40

SolidWorks recommended export settings

Recommended export format: 3MF (.3mf)

Solid Edge recommended export settings

Recommended export format: 3MF (.3mf)

34 Chapter 6 Design and printing guidelines ENWW

Page 41

Creo Elements recommended export settings

Recommended export format: VRML (.wrl)

Recommended le export formats for color models

In addition to having the correct export settings, HP recommends saving your color models in specic le

formats, depending on which 3D modeling software program you use. Note that not all programs can export

texture maps, even though texture mapping features may be available in the software. If this is the case, it is

recommended to bring your uncolored model into a software that can export texture maps, and then add the

texture map in that software. There are free software options, such as Microsoft 3D Builder and Blender, that

allow you to do this.

Software Recommended le export format Can export texture?

3D Builder (16.1.651.0) 3MF Yes

Adobe Photoshop (19.1.4) VRML or OBJ Yes

Autodesk 3ds Max (2019) VRML Yes

Autodesk Fusion 360 (2019) STEP No

Autodesk Inventor (2019) OBJ No

Autodesk Maya (2019) OBJ Yes

Autodesk Netfabb (2019.2) 3MF Yes

Blender (2.79) OBJ Yes

Dassault CATIA (5) VRML Yes

Dassault SOLIDWORKS (2019) 3MF Yes

Materialise Magics (21.0) 3MF Yes

PTC Creo Elements (19) VRML No

PTC Creo Parametric (3.0) OBJ No

Rhino (6) VRML Yes

Siemens NX (12.0) VRML No

Siemens Solid Edge (ST10) 3MF No

NOTE: If you are saving your color models in the recommended format and are still experiencing issues

correctly opening your color models in HP SmartStream 3D Build Manager, see the printing tips and tricks

document.

ENWW File preparation 35

Page 42

Tesselation problems

These are some common problems that you could experience during tessellation/exporting your les:

● Too many or too few triangles

Too many triangles are diicult to process and, when a certain size is reached, the extra triangles do not

provide any further accuracy. For this reason, an excess of triangles could increase processing time for no

benet.

Triangulation of a surface causes faceting of the 3D model. The parameters used to output an STL model

aect how much faceting occurs.

Example of tessellation

● Holes in triangles

STL models commonly suer from surfaces that are not joined to their neighbors, and missing surfaces.

Repairing les

File-repairing software

● Magics – Materialise

● Autodesk Netfabb

● HP SmartStream 3D Build Manager

Common errors

Some common errors that cause part-quality-related issues are illustrated below. They can be xed in the native

CAD software; or, if that is not available, in Magics, Netfabb, or HP Smartstream 3D Build Manager. If these les

are not xed before attempting to build the design, either the software will not allow you to proceed due to poor

le quality, or your part will not have good quality. Therefore, it is prudent to spend time at this stage to check

that the CAD le designer produced a high-quality and printable design.

● Triangles not joined

36 Chapter 6 Design and printing guidelines ENWW

Page 43

● Overlapping triangles

● Holes in parts

● Flipped-direction triangles

● Tiny shells

ENWW File preparation 37

Page 44

HP SmartStream 3D Build Manager

The HP SmartStream 3D Build Manager must be used to send jobs to print. Therefore, after les are exported,

either from your CAD, graphic arts, or separate 3D build manager software, they must be brought into

SmartStream 3D Build Manager.

NOTE: For optimal dimensional accuracy, export parts separately instead of grouping them within one le.

In HP SmartStream 3D Build Manager, you will be able to access some color editing features, including:

● The ability to color an entire part with one color of your choosing

● The ability to edit the hue, lightness, and saturation of existing colors

● The ability to display a print preview of the color part to be printed

● The ability to print a color set model to test colors

See the HP SmartStream 3D Build Manager User Guide (http://www.hp.com/go/SmartStream3DBuildManager/

manuals) for full descriptions of these features, or view this video: https://www.youtube.com/watch?

v=3IfrpLMrJ4U&t=14s.

The software preparation process may take from 15 minutes to 2 hours depending on the complexity of the job.

It can be done while printing other jobs. Once ready, you can select the job to be printed from the job queue on

the printer’s front panel. If an error occurs while processing, a message appears on the front panel, and the

printer cancels the job. To retry, you have to resubmit the job.

38 Chapter 6 Design and printing guidelines ENWW

Page 45

7 Send a job

Use appropriate software to send the job to the printer, such as the HP SmartStream 3D Build Manager (see the

HP SmartStream 3D Build Manager User Guide).

Before printing any job, the printer performs various checks. See Job preparation list on page 42.

ENWW 39

Page 46

8 Select a job

Job list app

The job list app in the printer’s front panel displays the status of all jobs. Possible statuses are:

● Waiting to process: The job has been received by the printer and is queued for processing.

● Processing: The job is being analyzed by the printer.

● Processed: The job is ready to be sent for printing. Either it has never been printed, or it is ready for

reprinting.

● Ready to print: The job is ready to be printed. When this job is selected, the Print button is available.

● Sent to print: The job has started printing.

Select a job to be printed

1. Tap Jobs on the home screen.

2. Select the processed job and tap Print.

3. The printer checks that all subsystems and supplies are ready to complete the build (see Job preparation

list on page 42). If your attention is needed, the printer noties and advises you: a list appears with all of

the required and recommended tasks to ready your printer. To print the job, address any issues on the list

by following the front-panel instructions. Once you have completed all the tasks on the list, the printer will

run a second check to ensure it is ready to print the job. If there are any additional issues, the front panel

will again provide instructions.

4. The printer starts the printing process. Wait until the printer tells you that the process is complete.

40 Chapter 8 Select a job ENWW

Page 47

9 Printer preparation

●

Job preparation list

●

Agents

●

Material

–

Mix ratio

–

Material cartridges

○

Replace a material cartridge

○

Maintain the cartridges

○

Store the cartridges

●

Distilled or deionized water

●

How to recycle consumables and printed parts

ENWW 41

Page 48

Job preparation list

Before printing, the printer performs some checks to ensure that it is ready to print the whole build. These

include the following checks:

● Printer clean (see Clean the print area on page 71)

● Job compatible with device

● Printhead ready (see Align the printheads on page 109)

●

Cloud connected (see Printer networking on page 24)

● Enough agent (see Agents on page 42)

● Enough material (see Material on page 45)

● Enough water in the distilled water tank (see Distilled or deionized water on page 48)

● Printhead cleaning roll ready (see Replace the cleaning roll on page 87)

● Filters ready (see Maintenance on page 65)

● Lamp clean

● Doors closed

If the printer nds any problem, it may ask you to contact your support representative for assistance.

Agents

Please note:

Status

The printer uses seven types of agents: black, detailing, fusing, yellow, magenta, cyan, and bright fusing agents.

● This is a dynamic security-enabled printer. Cartridges using a non-HP chip will not work. For more

information, see http://www.hp.com/go/learnaboutsupplies.

● This printer is not designed to use continuous agent systems. To print successfully, remove any continuous

agent system and install genuine HP cartridges.

● This printer is designed for agent cartridges to be used until they are empty. Relling cartridges prior to