Page 1

HP Integrity cx2600 Operations and

Maintenance Guide

HP Part Number: AB216-90006

Published: December 2010

Edition: 2

Page 2

© Copyright 2006, 2010 Hewlett-Packard Development Company, L.P

Legal Notices

The informationcontained hereinis subjectto changewithout notice.The onlywarranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Printed in U.S.A.

Intel, Pentium, Intel Inside, Itanium, and the Intel Inside logo are trademarks or registered trademarks of Intel Corporation or its subsidiaries in

the United States and other countries.

Warranty

To obtain a copy of the warranty for this product, see the warranty information website:

BCS Global Limited Warranty and Technical Support

Page 3

Table of Contents

About This Document.........................................................................................................8

Typographic Conventions......................................................................................................................8

Related Documents.................................................................................................................................8

HP Encourages Your Comments............................................................................................................8

1 Controls, Ports, and Indicators......................................................................................9

Introduction............................................................................................................................................9

Front Panel.........................................................................................................................................9

Switch/Button and LED Definitions............................................................................................9

Additional Controls and Indicators................................................................................................10

Hot-Plug Disk Drive LEDs.........................................................................................................10

DVD/DVD-R/DVD-RW Drives..................................................................................................11

Rear Panel........................................................................................................................................11

10/100 System Management LAN LEDs....................................................................................12

Locator LEDs and Button...........................................................................................................12

MP Reset and TOC Buttons........................................................................................................12

Power Supply Status LEDs.........................................................................................................13

Gigabit LAN LEDs.....................................................................................................................13

Management Processor LAN LEDs...........................................................................................14

System Board LEDs....................................................................................................................14

Management Processor Board LEDs..........................................................................................15

2 External Connectors.....................................................................................................17

Connector Pinouts.................................................................................................................................17

Universal Serial Bus (USB) Ports.....................................................................................................17

Serial Ports.......................................................................................................................................18

System Management LAN Port.......................................................................................................18

Management Processor VGA Port...................................................................................................19

Gigabit Ethernet (LAN) and MP LAN Port.....................................................................................19

SCSI Port, Ultra 3, 68-Pin.................................................................................................................20

3 Installing Additional Components..............................................................................22

Safety Information................................................................................................................................22

Service Tools Required..........................................................................................................................22

Accessing a Rack-Mounted Server.......................................................................................................22

Installing Components When the Server Is in a Rack.....................................................................22

Removing the Server From a Rack..................................................................................................23

Install the Server into a Rack...........................................................................................................24

Installing Disk Drives...........................................................................................................................24

Removing Hot-Plug Disk Drives.....................................................................................................24

Installing Hot-Plug Disk Drives......................................................................................................25

Installing Hot-Swap Power Supply Units.............................................................................................26

Removing and Replacing a Hot-Swap Power Supply.....................................................................26

Installing the Front Grill and Top Cover..............................................................................................28

Removing the Front Grill.................................................................................................................28

Installing the Front Grill..................................................................................................................28

Removing the Top Cover.................................................................................................................29

Installing the Top Cover..................................................................................................................30

Installing Hot-Swap Chassis Fan Units................................................................................................30

Removing and Installing a Front Panel Hot-Swap Fan...................................................................31

Removing and Installing a Rear Panel Hot-Swappable Fan...........................................................33

PCI Card Installation............................................................................................................................34

Removing the PCI Card Cage Assembly.........................................................................................34

Table of Contents 3

Page 4

Removing a PCI Card......................................................................................................................35

Installing a PCI Card.......................................................................................................................36

Installing the PCI Card Cage Assembly..........................................................................................36

Installing Processors.............................................................................................................................37

Removing a Processor.....................................................................................................................38

Installing a Processor.......................................................................................................................44

Installing Memory.................................................................................................................................49

Supported DIMM Sizes...................................................................................................................49

Removing DIMMs...........................................................................................................................49

Installing DIMMs.............................................................................................................................50

4 Troubleshooting............................................................................................................53

Introduction..........................................................................................................................................53

Troubleshooting Methodology.............................................................................................................53

Troubleshooting Using the Front Panel Power Button.........................................................................53

Server Does Not Power On...................................................................................................................54

EFI Menu is Not Available....................................................................................................................54

Operating System Does Not Boot.........................................................................................................54

Operating System Boots with Problems...............................................................................................55

Intermittent Server Problems................................................................................................................55

DVD Problems......................................................................................................................................55

Hard Drive Problems............................................................................................................................55

Console Problems.................................................................................................................................55

Troubleshooting Using Beep Codes (System e-buzzer)........................................................................55

Troubleshooting Using LED Indicators................................................................................................56

Front Panel LEDs.............................................................................................................................56

Rear Panel LEDs..............................................................................................................................60

Error Messages......................................................................................................................................62

EFI Error and Warning Messages....................................................................................................62

Event Logs for Troubleshooting Diagnostics..................................................................................64

Accessing the Logs Through the MP.........................................................................................64

SEL and FPL Log Entries............................................................................................................65

Accessing the Logs With BMC CLI Commands........................................................................65

Accessing the Logs with MP Commands..................................................................................66

Disk and I/O Path Logging.........................................................................................................66

Troubleshooting Using Offline Support Tools......................................................................................67

Offline Diagnostic Environment (ODE)..........................................................................................67

E-Diag Tools.....................................................................................................................................67

Other Event Logs and General Diagnostic Tools............................................................................68

Building Up the System...................................................................................................................68

5 Utilities...........................................................................................................................73

Extensible Firmware Interface Boot Manager......................................................................................73

EFI Commands................................................................................................................................74

EFI/POSSE Commands.........................................................................................................................76

help..................................................................................................................................................76

Syntax.........................................................................................................................................76

Parameters..................................................................................................................................76

Operation....................................................................................................................................76

baud.................................................................................................................................................80

Syntax.........................................................................................................................................80

Parameters..................................................................................................................................80

Operation....................................................................................................................................80

boottest............................................................................................................................................81

Syntax.........................................................................................................................................81

Parameters..................................................................................................................................81

4 Table of Contents

Page 5

cpuconfig.........................................................................................................................................82

Syntax.........................................................................................................................................82

Parameters..................................................................................................................................82

Operation....................................................................................................................................82

default..............................................................................................................................................83

Syntax.........................................................................................................................................83

Parameters..................................................................................................................................83

Operation....................................................................................................................................83

errdump...........................................................................................................................................83

Syntax.........................................................................................................................................83

Parameters..................................................................................................................................83

Operation....................................................................................................................................83

info...................................................................................................................................................83

Syntax.........................................................................................................................................83

Parameters..................................................................................................................................84

lanaddress........................................................................................................................................90

Syntax:........................................................................................................................................90

Parameters..................................................................................................................................90

monarch...........................................................................................................................................91

Syntax.........................................................................................................................................91

Parameters..................................................................................................................................91

Operation....................................................................................................................................91

pdt....................................................................................................................................................91

Syntax.........................................................................................................................................91

Parameters..................................................................................................................................91

Operation....................................................................................................................................92

sysmode...........................................................................................................................................92

Syntax.........................................................................................................................................92

Parameters..................................................................................................................................92

Operation....................................................................................................................................92

Specifying SCSI Parameters..................................................................................................................93

Using the SCSI Setup Utility............................................................................................................93

Management Processor.........................................................................................................................98

Accessing the Management Processor............................................................................................98

Interacting with the Management Processor.............................................................................98

Management Processor Command Interface........................................................................................98

MP Welcome Screen..............................................................................................................................99

Management Processor Commands.....................................................................................................99

Reset BMC Passwords...................................................................................................................100

Configure Serial Port Parameters..................................................................................................100

Certificate Generate.......................................................................................................................101

Console Log...................................................................................................................................101

Command Mode............................................................................................................................101

Console..........................................................................................................................................101

Connect to Service Processor.........................................................................................................101

Date................................................................................................................................................102

Default Configuration....................................................................................................................102

Display FRUID...............................................................................................................................102

Disconnect Remote or LAN Console.............................................................................................102

MP Firmware Update....................................................................................................................102

Help...............................................................................................................................................102

Display System ID.........................................................................................................................103

Inactivity Timeout.........................................................................................................................103

Configure LAN Console................................................................................................................103

LAN Status.....................................................................................................................................103

Table of Contents 5

Page 6

Return to Main Menu....................................................................................................................103

Modem Reset.................................................................................................................................104

Modem Status................................................................................................................................104

Power Control................................................................................................................................104

Configure Paging...........................................................................................................................104

Power Status..................................................................................................................................104

Reset BMC......................................................................................................................................104

Reset System..................................................................................................................................104

Set Access.......................................................................................................................................105

Create Local Session......................................................................................................................105

Display Logs..................................................................................................................................105

Security Options............................................................................................................................106

Firmware Revision Status..............................................................................................................106

System Status.................................................................................................................................106

Transfer of Control.........................................................................................................................106

Tell..................................................................................................................................................106

User Configuration........................................................................................................................106

Virtual Front Panel.........................................................................................................................107

Who................................................................................................................................................107

Exit from MP..................................................................................................................................107

Diagnostics.....................................................................................................................................107

Management Processor Help System............................................................................................107

Booting the Server...............................................................................................................................108

Fibre Channel (FC) Boot Configuration..............................................................................................108

6 Parts Information........................................................................................................112

Replacement Parts List........................................................................................................................112

7 Removing and Replacing Components...................................................................114

Safety Information...............................................................................................................................114

Required Service Tools........................................................................................................................114

Accessing a Rack-Mounted Server......................................................................................................114

Installing Components When the Server Is in a Rack...................................................................114

Removing the Server From a Rack................................................................................................115

Inserting the Server Into a Rack.....................................................................................................116

Removing and Replacing Disk Drives................................................................................................117

Removing Hot-Plug Disk Drives...................................................................................................117

Installing Hot-Plug Disk Drives....................................................................................................118

Removing and Replacing Hot-Swappable Power Supplies................................................................118

Removing a Hot-Swappable Power Supply..................................................................................119

Installing a Hot-Swappable Power Supply....................................................................................120

Removing and Replacing the Front Grill............................................................................................122

Removing the Front Grill...............................................................................................................122

Replacing the Front Grill...............................................................................................................122

Removing and Replacing the Top Cover............................................................................................123

Removing the Top Cover...............................................................................................................123

Replacing the Top Cover................................................................................................................124

Removing and Replacing Hot-Swappable Chassis Fan Units............................................................124

Removing a Front Panel Hot-Swappable Fan...............................................................................124

Installing a Front Panel Hot-Swappable Fan.................................................................................125

Removing a Rear Panel Hot-Swappable Fan.................................................................................126

Installing a Rear Panel Hot-Swappable Fan..................................................................................127

Removing and Replacing Airflow Guides..........................................................................................127

Removing the Memory Airflow Guide.........................................................................................128

Installing the Memory Airflow Guide...........................................................................................128

Removing the Processor Airflow Guide........................................................................................128

6 Table of Contents

Page 7

Installing the Processor Airflow Guide.........................................................................................128

Removing the PCI Airflow Guide.................................................................................................128

Installing the PCI Airflow Guide...................................................................................................128

Removing and Replacing System Memory DIMMs...........................................................................128

Supported DIMM Sizes.................................................................................................................129

Removing DIMMs.........................................................................................................................129

Installing DIMMs...........................................................................................................................130

Removing and Replacing the PCI Card Cage ....................................................................................131

Removing the PCI Card Cage Assembly.......................................................................................131

Installing the PCI Card Cage Assembly........................................................................................133

Removing and Replacing PCI Cards..................................................................................................134

Removing a PCI Card....................................................................................................................134

Installing a PCI Card......................................................................................................................135

Removing and Replacing the LED Status Panel.................................................................................136

Removing the LED Status Panel....................................................................................................136

Installing the LED Status Panel.....................................................................................................137

Removing and Replacing the CD/DVD Optical Drive.......................................................................138

Removing the Optical Drive..........................................................................................................138

Installing the Optical Drive...........................................................................................................138

Removing and Replacing the Hard Drive Backplane Assembly........................................................138

Removing the Hard Drive Backplane............................................................................................139

Installing the Hard Drive Backplane.............................................................................................140

Removing and Replacing the Power Supply Interface Assembly......................................................141

Removing the PSI Assembly..........................................................................................................141

Installing the PSI Assembly...........................................................................................................142

Removing and Replacing the Fan Control Board...............................................................................143

Removing the Fan Control Board..................................................................................................143

Installing the Fan Control Board...................................................................................................144

Removing and Replacing the Management Processor Board............................................................145

Removing the Management Processor Board...............................................................................146

Replacing the Management Processor Board Battery...................................................................147

Installing the Management Processor Board.................................................................................147

Removing and Replacing a System Processor....................................................................................147

Removing a Processor....................................................................................................................148

Replacing a Processor....................................................................................................................154

Removing and Replacing the System Battery ....................................................................................160

Removing the System Battery........................................................................................................161

Installing the System Battery.........................................................................................................162

Removing and Replacing the System Board.......................................................................................163

Removing the System Board..........................................................................................................163

Installing the System Board...........................................................................................................165

8 Specifications.............................................................................................................166

Introduction........................................................................................................................................166

Hardware Specifications.....................................................................................................................166

Dimensions and Weights....................................................................................................................166

Index...............................................................................................................................167

Table of Contents 7

Page 8

About This Document

This documentdescribes how tooperate and maintain your hp Integrity cx2600Server, Regulatory

Model Number: RSVLA-0303-DC.

TThe document printing date and part number indicate the document’s current edition. The

printing date will change when a new edition is printed. Minor changes may be made at reprint

without changing the printing date. The document part number will change when extensive

changes are made.

Document updatesmay be issued between editions to correct errors or document product changes.

To ensure you receive the updated or new editions, subscribe to the appropriate product support

service. See your HP sales representative for details.

The latest version of this document can be found on line at http://www.hp.com/go/

integrity_cx2600_servers-docs

Typographic Conventions

This document uses the following conventions.

Title The title of a document or a CD.

KeyCap The name of a keyboard key. Note that Return and Enter both refer to the

same key.

Emphasis Text that is emphasized.

Bold Text that is strongly emphasized, such as the summary text in bulleted

paragraphs.

ComputerOut

Text displayed by the computer.

UserInput

Commands and other text that you type.

Command

A command name or qualified command phrase.

Related Documents

The HP Server Documentation CD-ROM has been providedwith your server. It contains a complete

documentation set for the server, including localized versions of key documents. Included on

the CD-ROM are the Site Preparation and Operations and Maintenance guides, which contain

in-depth troubleshooting, installation, and repair information.

The CD will autorun when you insert it into a Windows® workstation, or, point your browser

at the index.htm file located under the Start directory of the CD. All users, including

UNIX®/Linux, can access acomplete manual set by viewing the directory manuals.The manuals

are in Adobe® Acrobat® Reader (pdf) format.

In addition, the latest versions of these documents, and any updates to these documents, are

posted under the appropriate server at http://www.hp.com/go/integrity_cx2600_servers-docs.

For online access to technical support information, self-solve tools, online assistance, community

forums of IT experts, broad multivendor knowledge base, and monitoring and diagnostic tools,

go to http://www.hp.com/support.

HP Encourages Your Comments

HP encourages your comments concerning this document. We are truly committed to providing

documentation that meets your needs.

Please send any comments by contacting us at docsfeedback@hp.com.

Please include document title, manufacturing part number, and any comment, error found, or

suggestion for improvement you have concerning this document.

8

Page 9

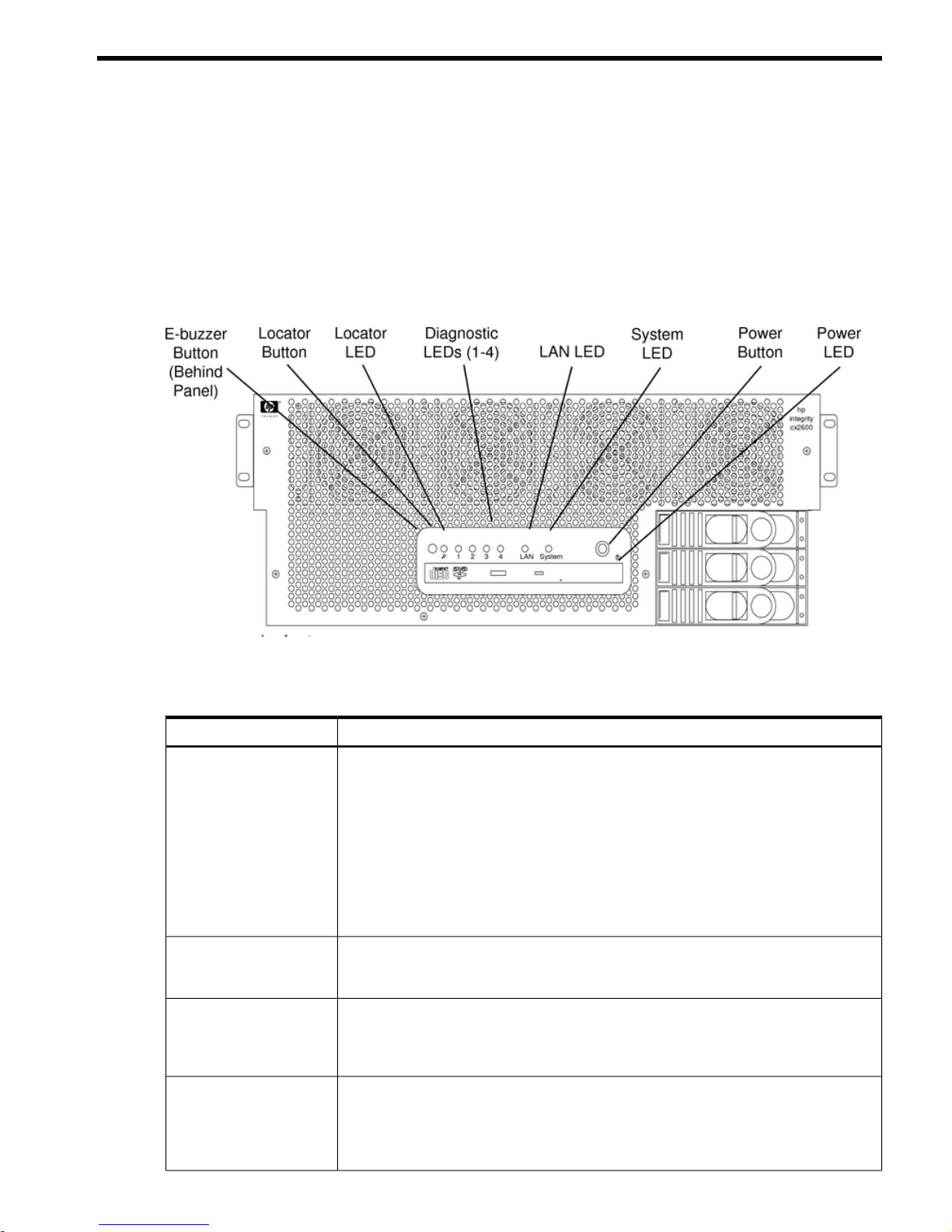

1 Controls, Ports, and Indicators

Introduction

This chapter describes the controls, ports, and indicators found on the front panel, rear panel,

and internal locations of the hp Integrity cx2600 Server.

Front Panel

The front panel of the hp Integrity cx2600 Server provides the controls and indicators commonly

used for operation.

Figure 1-1 Front View of hp Integrity cx2600 Server

Switch/Button and LED Definitions

Table 1-1 Switch/Button and LED Definitions

DescriptionSwitch or Button

Sounds when an error has been detected during boot or operation.e-buzzer (behind front

grill)

One beep Processor absent or failing.

Two beeps Power supply malfunction.

Three beeps Memory malfunction.

Four beeps Management processor card malfunction.

Five beeps PCI I/O card malfunction.

Six beeps Critical system failure.

Seven beeps System board malfunction.

Remotely activate or deactivate the server locator LED through the LAN or locally by

pressing the Locator button onthe front or rear panel. This device isused to help identify

or locate a particular server among many.

Locator LED and Button

These LEDs, together with the server LED, display system error and fault status. The

states of the LEDs can be decoded to identify an error or fault condition or the failing

Diagnostic LEDs(1 thru 4)

customer repair unit (CRU). (For more information on LEDs, see “Troubleshooting”

(page 53).)

Shows the activity status of the server LAN as follows:LAN LED

OFF System power is off.

Lit steady green LAN link established but LAN is inactive.

Flashing green LAN is active.

Introduction 9

Page 10

Table 1-1 Switch/Button and LED Definitions (continued)

DescriptionSwitch or Button

Shows the server status as follows:System LED

Off Operating power is not available to the server.

Flashing amber at 1 Hz rate Attention required. Check the diagnostic LEDs

and the MP Status log for information. The LEDs

turn off when you access the MP log.

NOTE: Input power must be maintainedto both

power supplies (even those that have failed) for

LEDs to display accurate system faults.

Flashing red at a 2 Hz rate Fault detected. Check the diagnostic LEDs and

the MP status log for information. Turn off the

LED by using the MP dc command, or by

correcting the problem.

Flashing green at 0.5 Hz rate System is booting or running EFI.

Lit steady green System normal. The operating system is up and

running.

Controls the power supply (turns system power on or off) if power is available to the

power supply. (Controls both power supplies if two are installed.)

If power is off but available, pressing the Power button:

Power Button

1 - 3 seconds turns on the power supplies and applies power to the server.

3 - 5 seconds causes the e-buzzer to repeat the last stored error message (beep

code).

If power is on and the server is booting or executing an EFI function, pressing the Power

button:

1 - 3 seconds turns off the server power (hard power off).

3 - 5 seconds causes e-buzzer to repeat the last stored error message

(beep code).

5 seconds or longer turns off the server power (hard power off).

If power is on and the operating system is running, pressing the Power button:

1 - 3 seconds turns off system power (software-controlled power off).

3 - 5 seconds causes the e-buzzer to repeat the last stored error message

(beep code).

5 seconds or longer turns off system power (hard power off).

Shows system power status as follows:Power LED

Off Power is not available to the server.

Flashing green Standby power is available. Power supplies are off.

Lit steady green At least one power supply is operating normally.

Additional Controls and Indicators

Storage devices have additional LEDs that show their status.

Hot-Plug Disk Drive LEDs

The hot-swap disk drives have two LEDs per drive, as described below.

• Drive Status LED: The drive status LED is tri-color and may display green, amber, or yellow

at any given time. These colors indicate a normal, warning, or failure condition.

• Drive Activity LED: The drive activity LED is green and indicates disk drive activity. This

LED is controlled by the disk drive and turns on when a drive is accessed.

10 Controls, Ports, and Indicators

Page 11

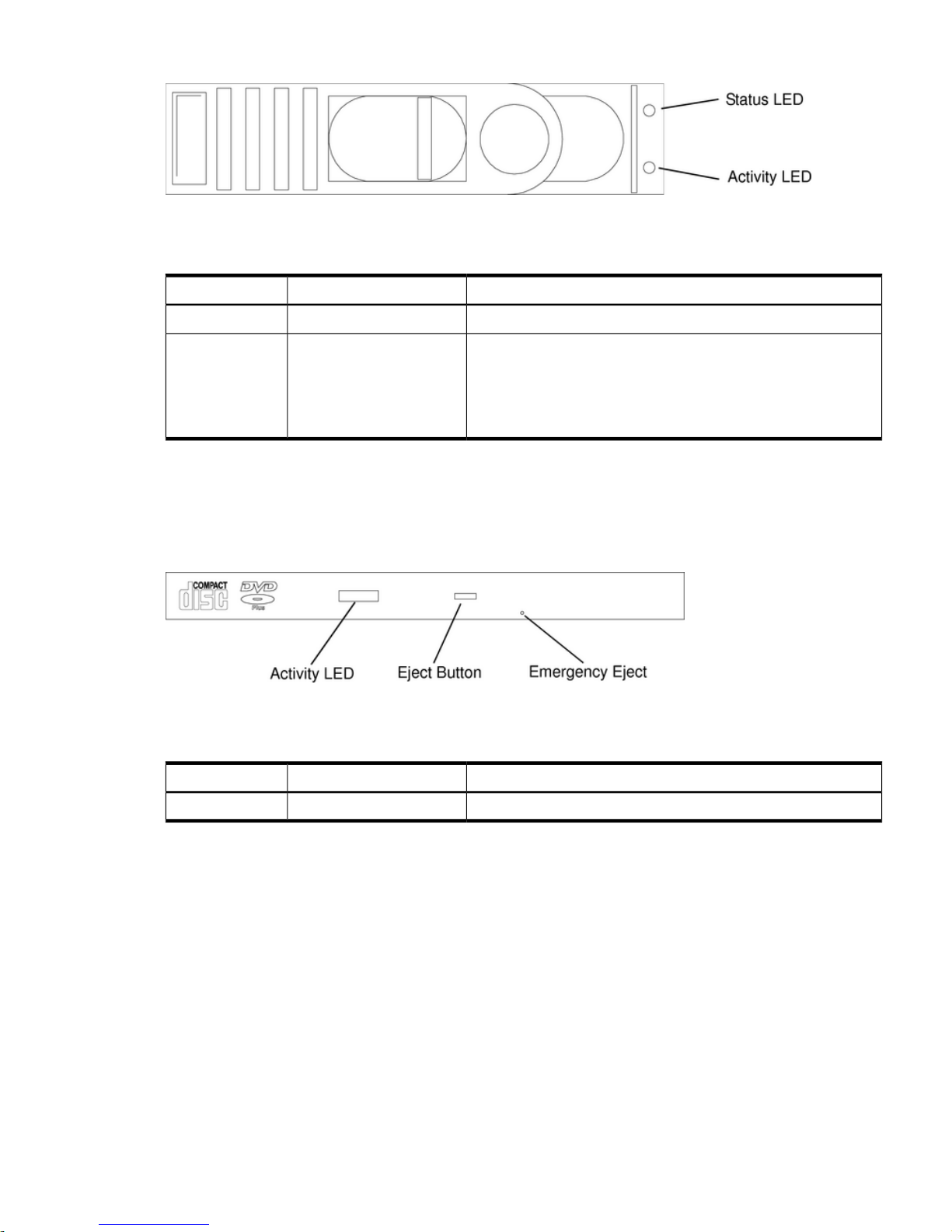

Figure 1-2 Hot-Swap Disk Drive LED Indicators

Table 1-2 lists the disk drive LED definitions.

Table 1-2 Hot-Swap Disk Drive LED Definitions

DescriptionColorLED

Drive access under hard drive control.Flashing greenActivity LED

Drive or slot normal (drive present).

Drive fault.

Green

Amber

Status LED

Missing MP card or missing jumper cable. For all HDD on SCSI

bus A or B.

Yellow

Blank

Pass through mode.

DVD/DVD-R/DVD-RW Drives

The server is delivered with one DVD-ROM drive. A CD/DVD-RW and DVD-RW are optional.

Each of these devices has one activity LED.

Figure 1-3 DVD Drive

Table 1-3 lists the DVD drive LED definitions.

Table 1-3 DVD Drive LED Definitions

DescriptionStateLED

Drive access under hard drive control.Flashing greenActivity LED

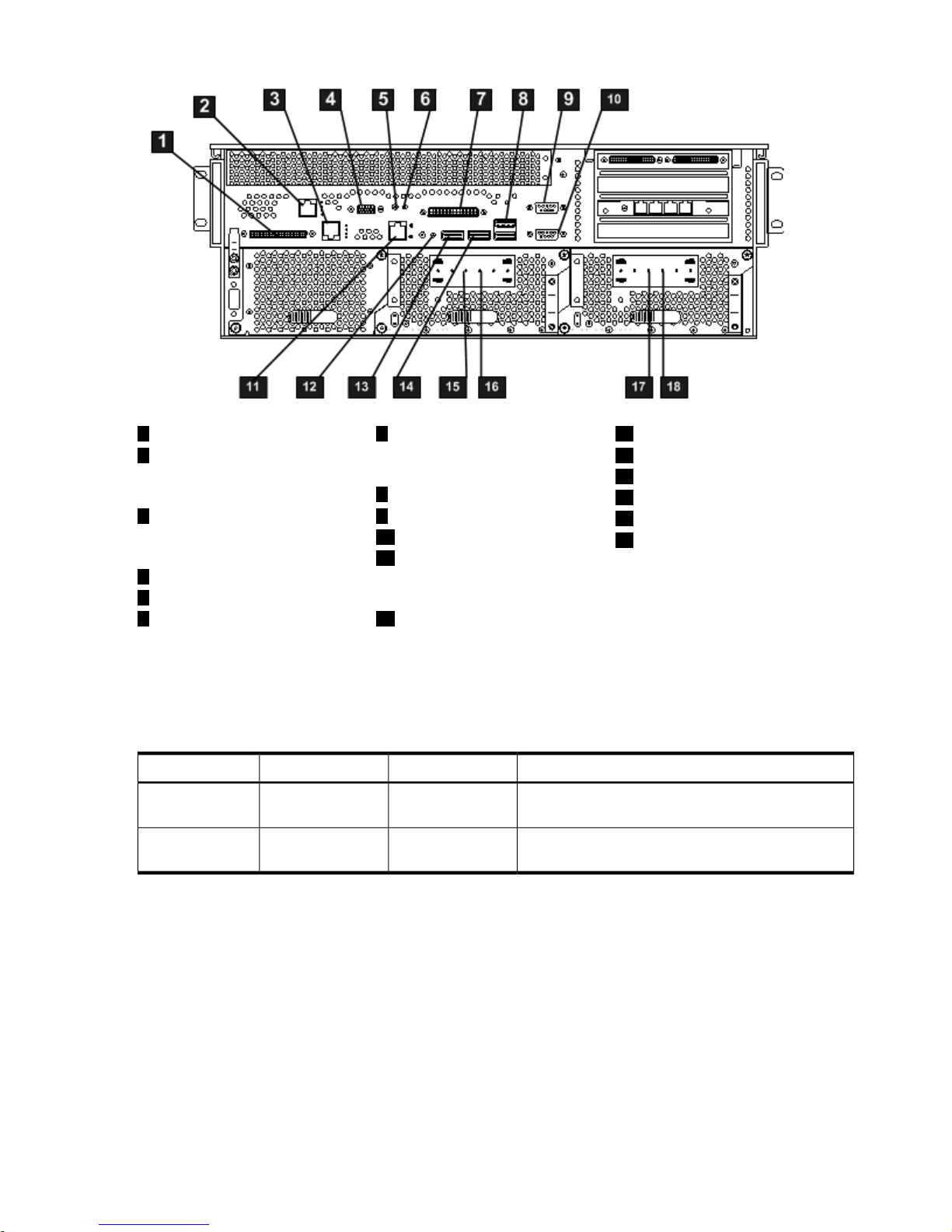

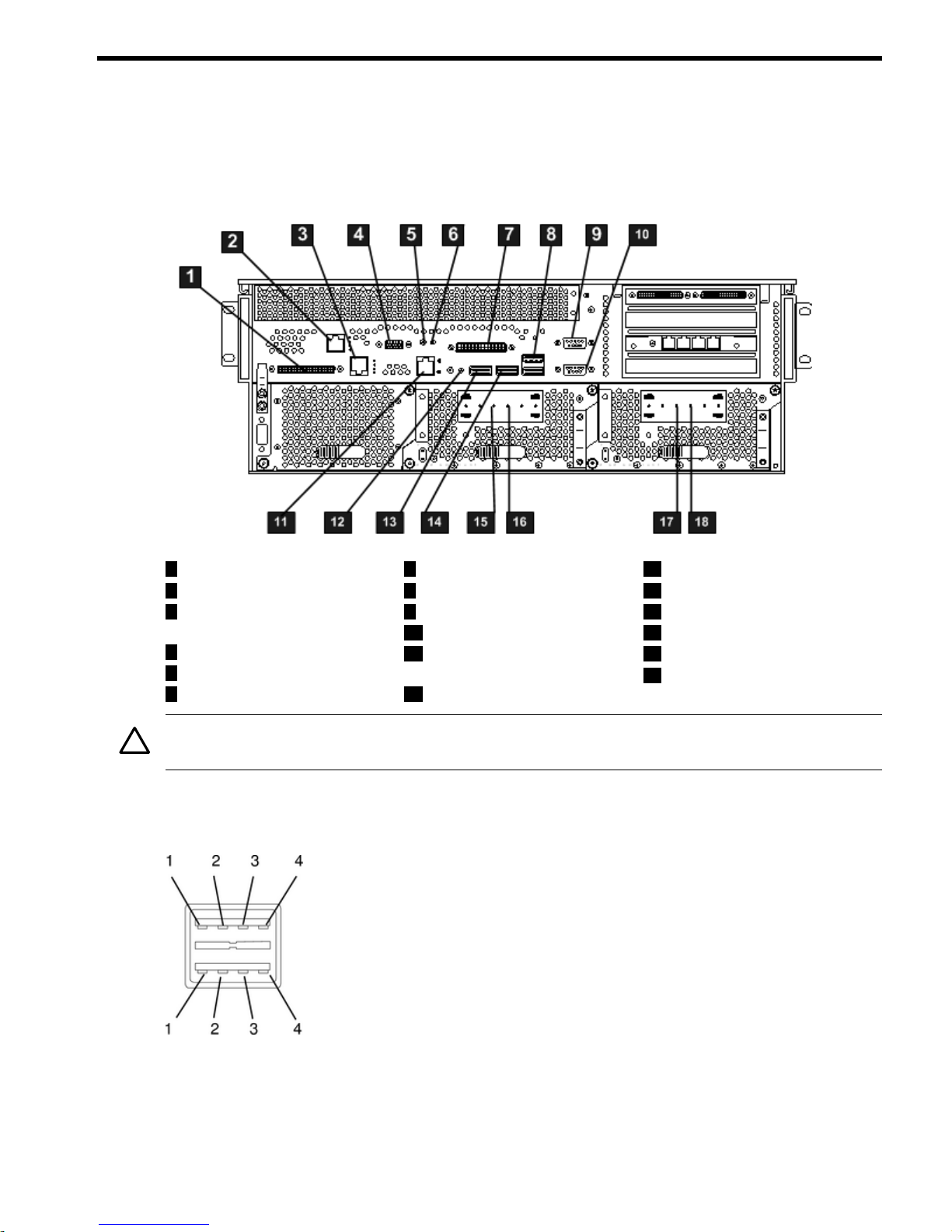

Rear Panel

The HP Server rear panel includes communication ports, I/O ports, two DC power supplies, and

the locator LED/button. LEDs visible on the rear panel of the HP Server signal the operational

status of:

• System management LAN

• Locator function

• Power supplies

• Gigabit LAN

• Management processor LAN

Introduction 11

Page 12

Figure 1-4 HP Integrity cx2620 Server Rear Panel

13

Keyboard USB Port

7

RS-232 MP Serial Console

Port (console, remote,

UPS)

1

LVD/SE SCSI Port

2 14

Management Processor

LAN (10/100 LAN) Port

and LEDs

Mouse USB Port

15

DC Power Supply Wire

8

USB Port

16

DC Power Supply Wire

3 9

Gigabit Ethernet LAN A

(10/100/1000 LAN) Port

and LEDs

Serial Port A (Console)

17

DC Power Supply Wire

10

Serial Port B

18

DC Power Supply Wire

11

System Management

LAN B (10/100/1000

LAN) Port and LEDs

4

MP VGA Port

5

MP Reset Button

126

TOC ButtonLocator Button and LED

10/100 System Management LAN LEDs

The two system management LAN LEDs display the status of the management LAN. The LEDs

are described in Table 1-4.

Table 1-4 Management Processor LEDs

StatusStateColorLED

Port is linked at 10 Mbps.

Port is linked at 100 Mbps.

Off

On

Yellow1. Speed

No link has been detected.

Port is linked.

Off

On

Green2. Activity

Locator LEDs and Button

Locator LEDs and buttons are provided on the front and rear panels of the server. The buttons

enable or disable the locator function. You can activate the locator LED from a remote location

through the LAN. The locator LED is lit to help call attention to locate the server when it is one

among many.

MP Reset and TOC Buttons

The MP Reset button resets the MP. The Transfer of Control (TOC) button halts all system

processing andI/O activity and restarts the computer system preserving system memory contents

and leaving the MP in communication with the console.

12 Controls, Ports, and Indicators

Page 13

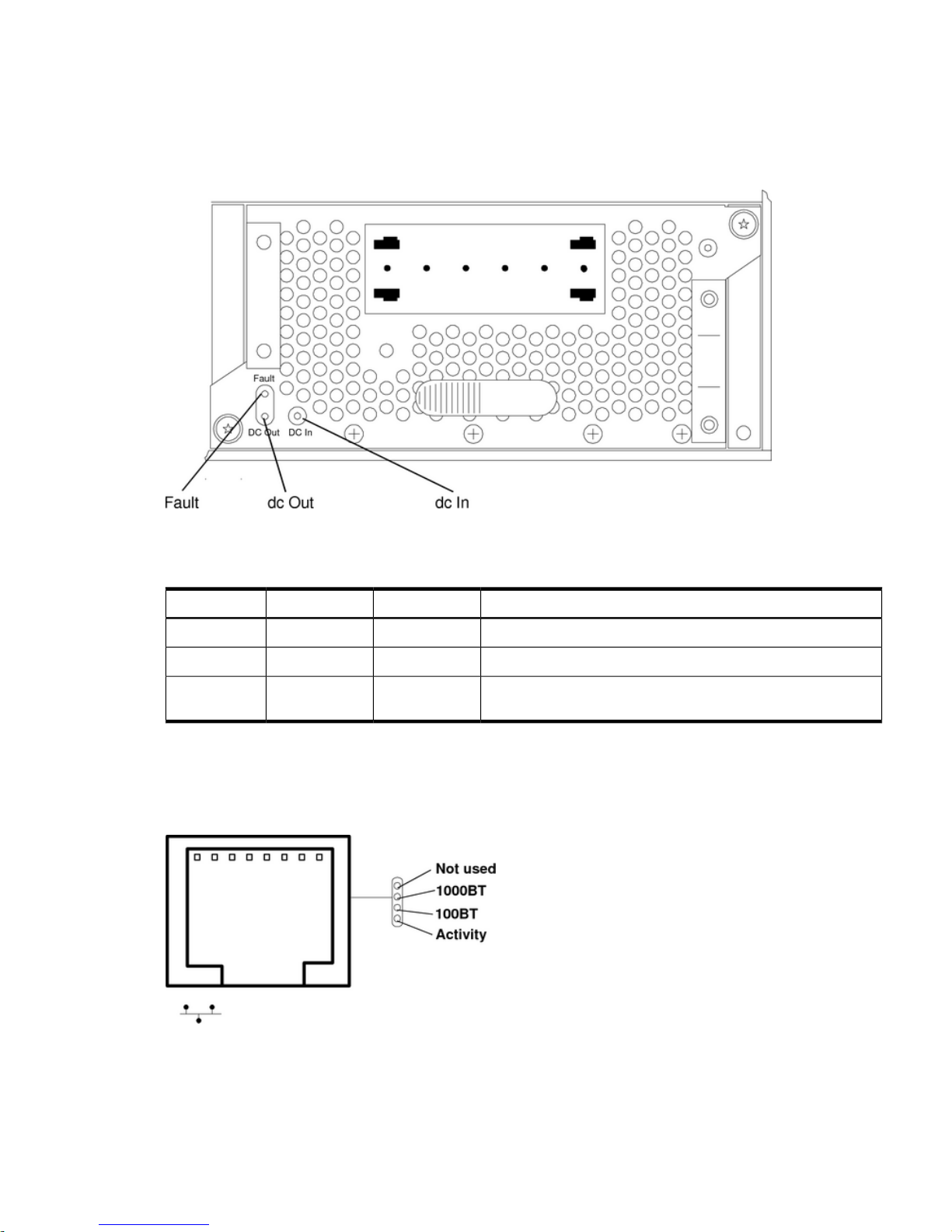

Power Supply Status LEDs

A power supply unit has three status LEDs located on the back of the power supply. Consolidated

status of two power supplies is reported by the front control panel by the power status LED. The

LEDs are described in Table 1-5.

Figure 1-5 Rear View of DC Power Supply

Table 1-5 lists and describes the power supply status LEDs.

Table 1-5 Power Supply Status LEDs

StatusStateColorLED

DC power (-40 to -72 VDC) is available to the power supply.OnGreenDC In

DC power is applied to system circuits.OnGreenDC Out

Power is applied to this power supply, and a fault has been

detected.

OffAmberFault

Gigabit LAN LEDs

The four Gigabit LAN LEDs display the status of the system LAN. The LEDs are described in

Figure 1-6 Gigabit 1 LAN LEDs

Introduction 13

Page 14

Table 1-6 Gigabit 10/100/1000 base-T Ethernet LAN A Status LEDs

StatusStateColorLocationLED

No 1000 Mbps link has been detected.

Port is linked at 1000 Mbps.

Off

On

GreenTop1. Gbit

No 100 Mbps link has been detected.

Port is linked at 100 Mbps.

Off

On

Green2nd from top2. 100 Mbit

No 10 Mbps link has been detected.

Port is linked at 10 Mbps.

Off

On

Green2nd from

bottom

3. Link

No LAN activity has been detected.

Flashing or lit solid indicates LAN activity.

Off

On

GreenBottom4. Activity

Management Processor LAN LEDs

The four management processor LAN LEDs display the status of the management LAN. The

LEDs are described in Table 1-7.

Table 1-7 Management LAN LEDs

StatusStateColorLocationLED

Self test is active.

Self test is active.

Off

On

YellowTopSelf Test

No Link detected or

100BT is active

Indicates 10BT LAN

activity.

Off

Flashing

Lit Steady

Green2nd from top10BT

10BT link established.

No Link detected or

10BT is active

Indicates 100BT LAN

activity.

Off

Flashing

Lit Steady

Green2nd from bottom100BT

100BT link

established.

Standby power is not

applied to

Off

On

GreenBottomStandby Power

management LAN

circuits.

Power is connected to

the server but the

server is not on.

System Board LEDs

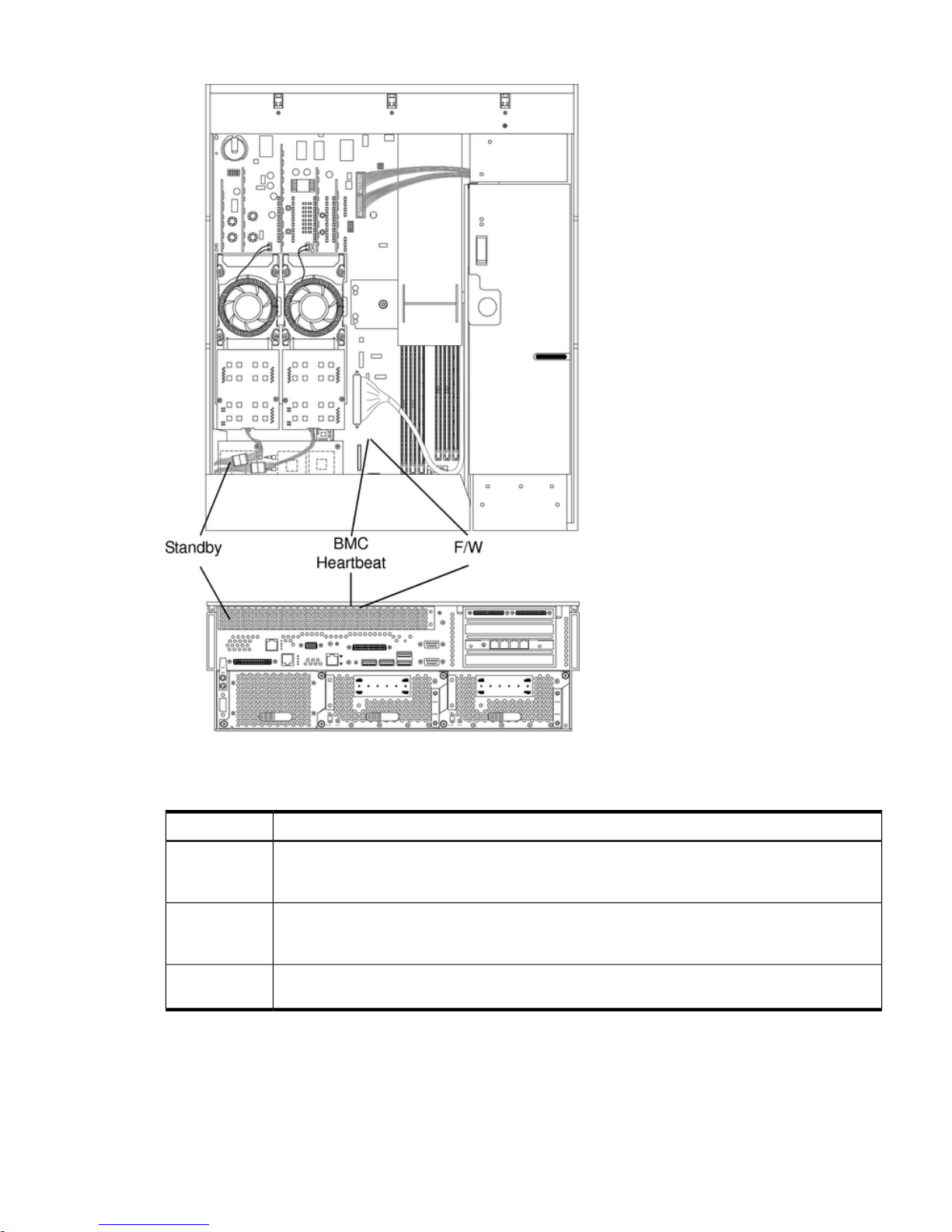

There are three LEDs located on the system board that can be of assistance when troubleshooting.

These LEDs are located close to the rear of the server. View these LEDs through cooling holes

in the rear panel of the server. The LEDs are located as shown in Figure 1-7 and are described

in Table 1-8.

14 Controls, Ports, and Indicators

Page 15

Figure 1-7 System Board LEDs

Table 1-8 lists the system board LEDs.

Table 1-8 System Board LEDs

DescriptionLED

The standby LED displays the power status of the server. It is lit when power is applied (DC In

LED on either power supply is lit). If power is applied and this indicator is off, you may have to

replace the system board.

Standby (STBY)

The baseboard management controller (BMC) heartbeat LED flashes whenever the BMC is active.

If this indicator is not blinking when the server is powered on (STBY LED is lit), you may have to

replace the system board.

BMC

The firmware LED lights when the boot process begins. If the server will not boot, and this LED

is off, you may have to replace the system board.

Firmware (F/W)

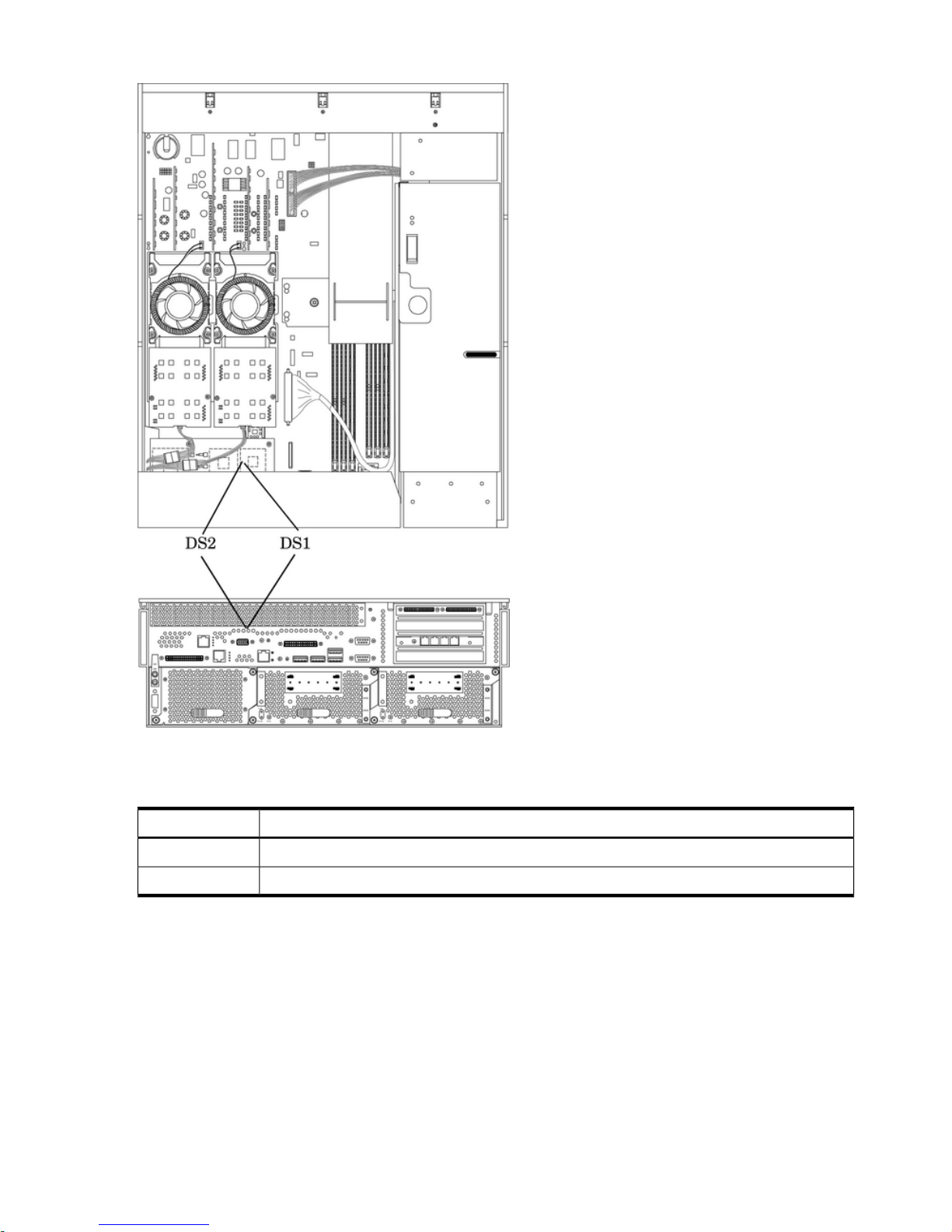

Management Processor Board LEDs

There are two LEDs located on the management processor (MP) board that may be of assistance

when troubleshooting. These LEDs are located close to the rear of the server and can be viewed

through cooling holes in the rear panel of the server. The LEDs are located as shown in Figure 1-8

and are described in Table 1-9.

Introduction 15

Page 16

Figure 1-8 LEDs on Management Processor Board

Table 1-9 lists the MP card LEDs.

Table 1-9 Management Processor Board LEDs

DescriptionLED

This fault indicator flashes when an MP fault is detected.DS1

The MP heartbeat indicator flashes when the MP is active.DS2

16 Controls, Ports, and Indicators

Page 17

2 External Connectors

Connector Pinouts

The following ports and connectors are found on the rear panel of the hp Integrity cx2600 Server.

Figure 2-1 Server Ports and Connectors

13

Keyboard USB Port

7

Console/Remote/UPS

1

LVD/SE SCSI Port

2

MP LAN Port

14

Mouse USB Port

8

USB Port

9

Serial Port A/Console

3

Gigabit Ethernet LAN

Port

15

DC Power Supply Wire

1610

DC Power Supply WireSerial Port B

4

MP VGA Port

1711

DC Power Supply WireSystem Management

10/100 LAN

5

MP Reset Button

18

DC Power Supply Wire

12

TOC Button

6

Locator Button and LED

CAUTION: To protect against intra-building lighting surges, use shielded cables that are

grounded at both ends. Failure to heed this caution can result in equipment damage.

Universal Serial Bus (USB) Ports

Figure 2-2 USB Port Connector

Connector Pinouts 17

Page 18

Table 2-1 USB Port Connector Pinouts

Signal DescriptionPin Number

+5VDC1

MR2

PR3

Ground4

Serial Ports

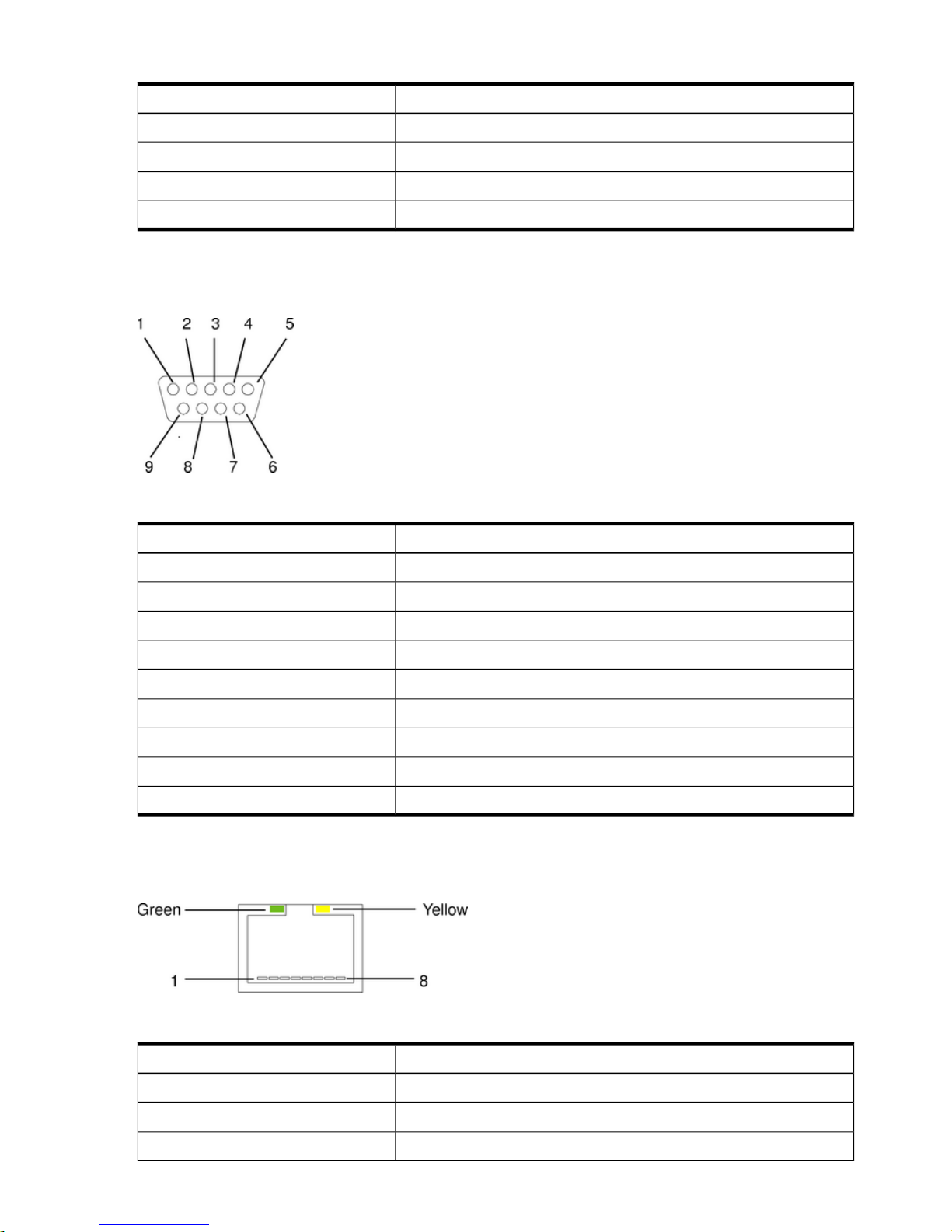

Figure 2-3 Serial Port Connector

Table 2-2 RS-232 Serial Console Port Pinouts

Signal DescriptionPin Number

Data carrier detect1

Receive data2

Transmit data3

Data Term ready4

Ground5

Ring indicator6

Clear to send7

Request to send8

Data set ready9

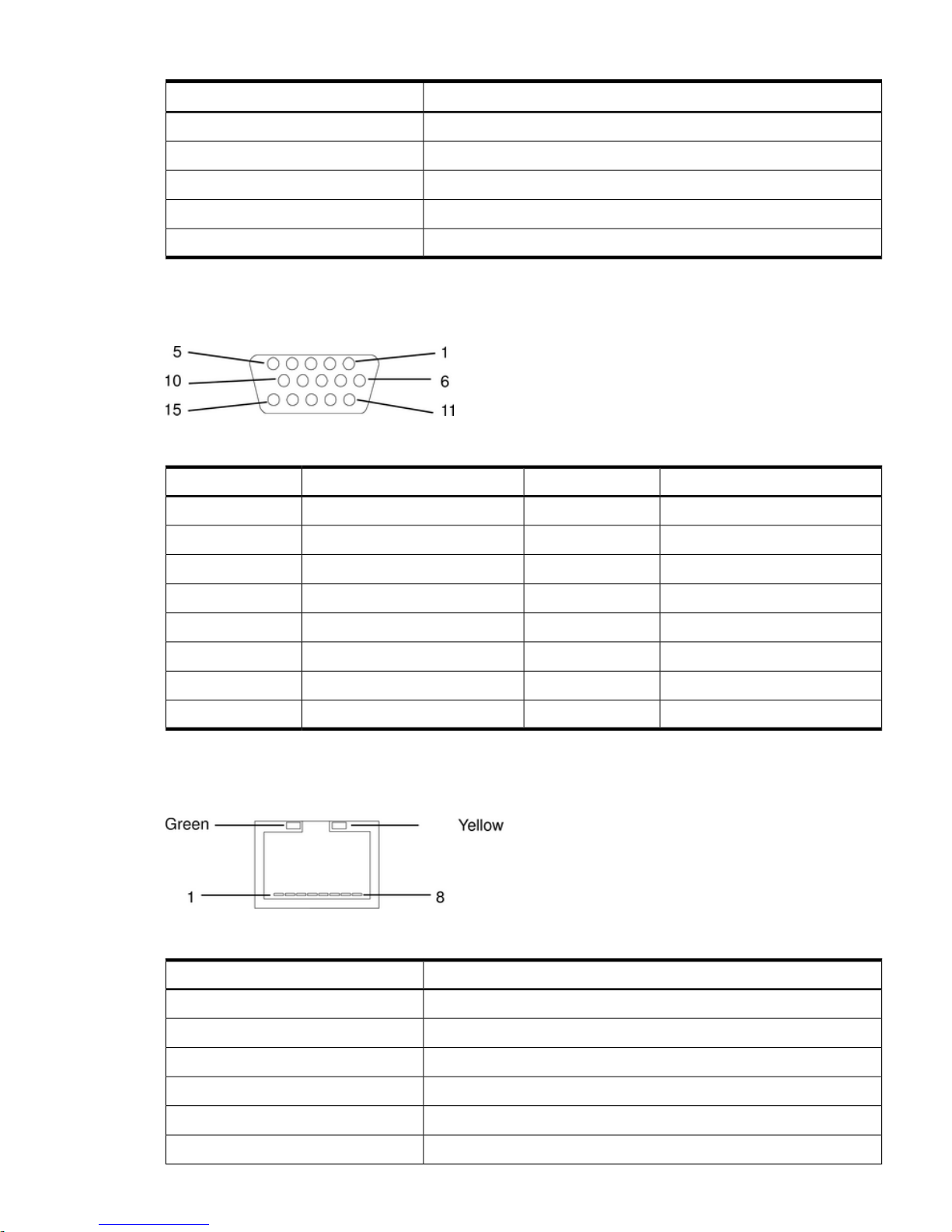

System Management LAN Port

Figure 2-4 System Management LAN Port

Table 2-3 System Management LAN Port Pinouts

Signal DescriptionPin Number

TXP1

TXN2

RXP3

18 External Connectors

Page 19

Table 2-3 System Management LAN Port Pinouts (continued)

Signal DescriptionPin Number

Not used4

Not used5

RXN6

Not used7

Not used8

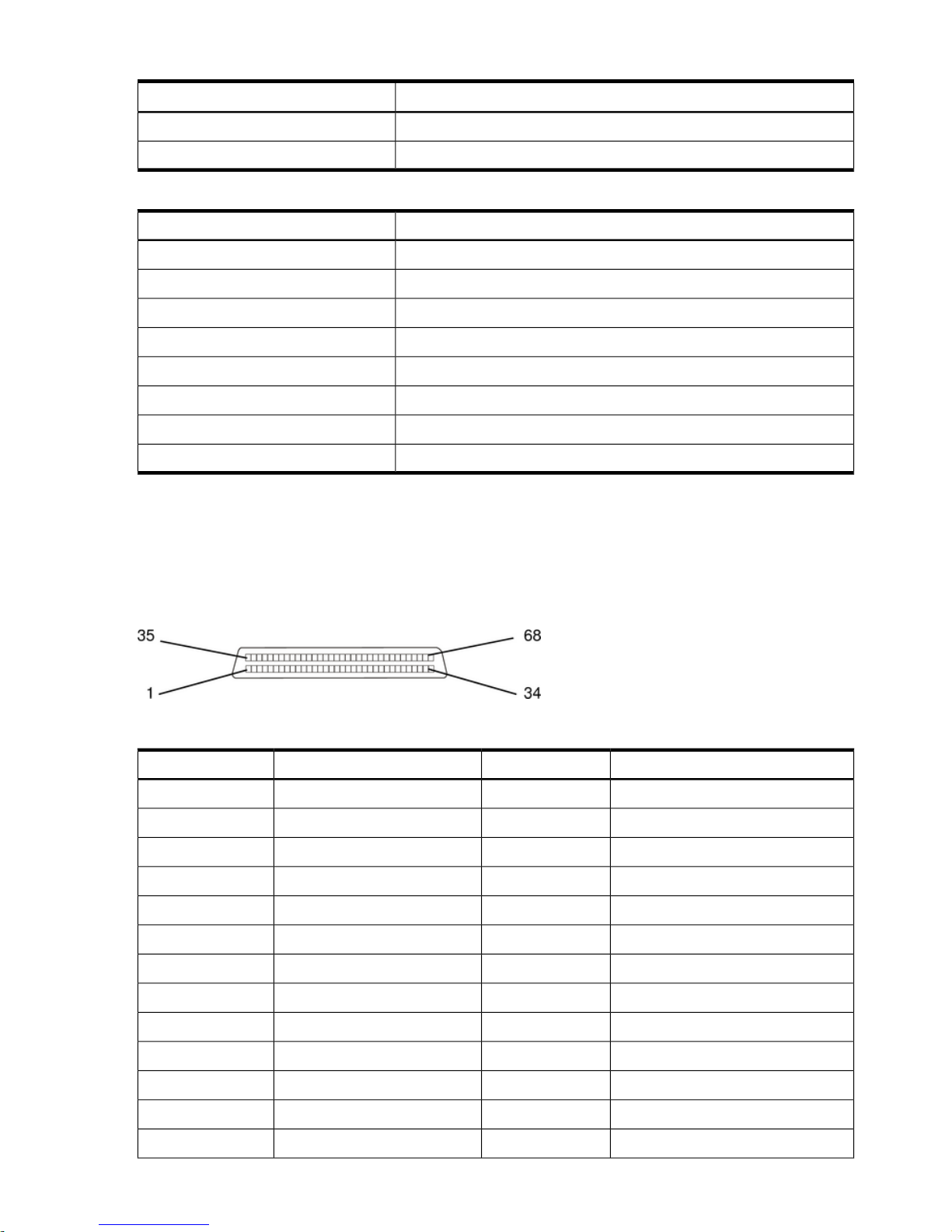

Management Processor VGA Port

Figure 2-5 MP VGA Port

Table 2-4 MP VGA Port Pinouts

Signal DescriptionPin NumberSignal DescriptionPin Number

+5 VDC9Red1

Sync return (ground)10Green2

Not used11Blue/RXP3

Monitor ID bit 112Not used4

Horizontal sync (+)13Video self test (ground)5

Vertical sync (–)14Red return (ground)6

Video ID bit 215Green return (ground)7

Blue return (ground)8

Gigabit Ethernet (LAN) and MP LAN Port

Figure 2-6 Gigabit LAN/MP LAN Port

Table 2-5 Gigabit LAN Port Pinouts

Signal DescriptionPin Number

TXP1

TXN2

RXP3

Not used4

Not used5

RXN6

Connector Pinouts 19

Page 20

Table 2-5 Gigabit LAN Port Pinouts (continued)

Signal DescriptionPin Number

Not used7

Not used8

Table 2-6 MP LAN Port Pinouts

Signal DescriptionPin Number

TXP1

TXN2

RXP3

Not used4

Not used5

RXN6

Not used7

Not used8

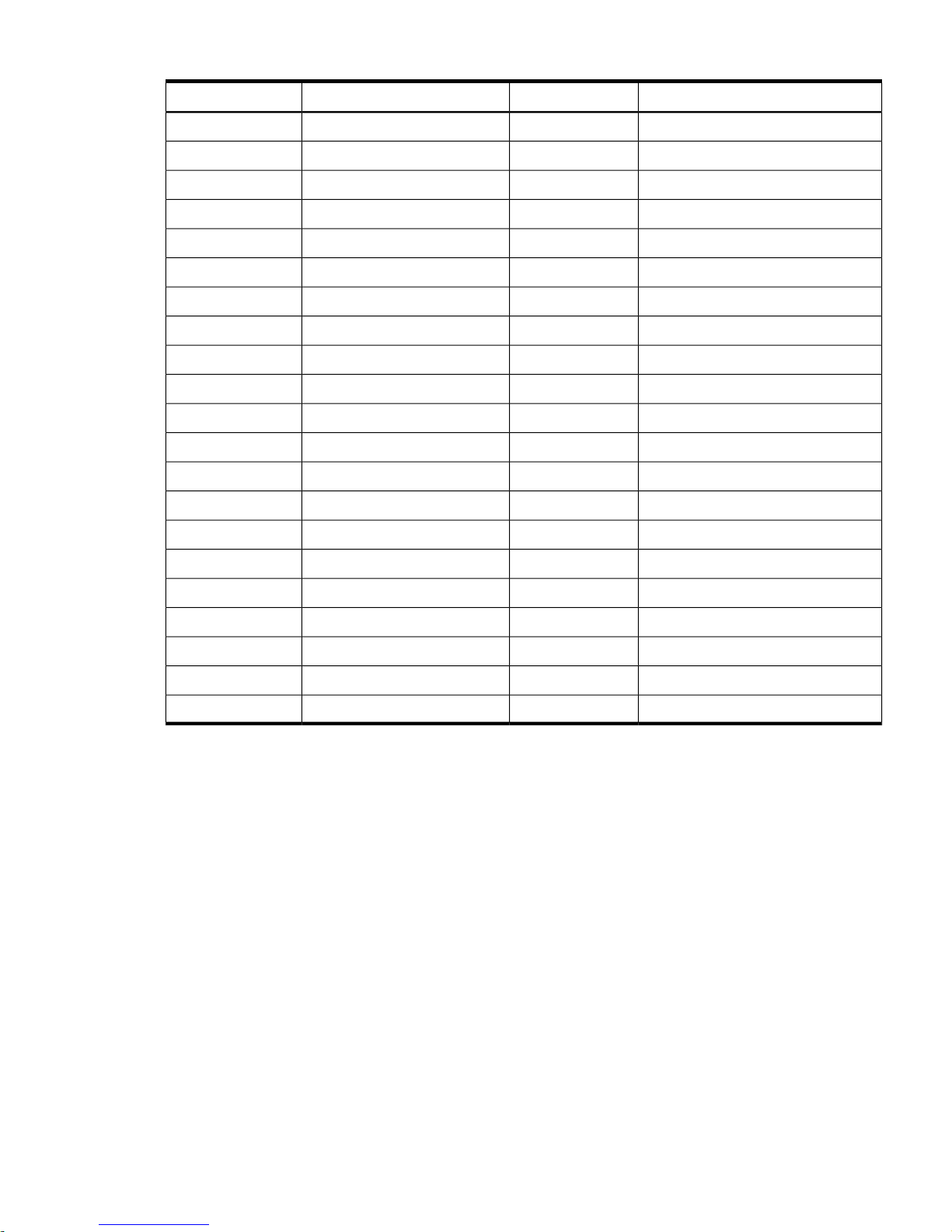

SCSI Port, Ultra 3, 68-Pin

Two Ultra 3, 68-pin SCSI connectors are located on the host bus adapter (HBA) located in PCI

slot 1. The upper connector supports SCSI channel A and the lower connector supports SCSI

channel B.

Figure 2-7 SCSI Port, Ultra 3, 68-Pin

Table 2-7 SCSI Port Pinouts

Signal DescriptionPin NumberSignal DescriptionPin Number

S35 (–DB 12)35S1 (+DB 12)1

S36 (–DB 13)36S2 (+DB 13)2

S37 (–DB 14)37S3 (+DB 14)3

S38 (–DB 15)38S4 (+DB 15)4

S39 (–DB P1)39S5 (+DB P1)5

S40 (–DB 0)40S6 (+DB 0)6

S41 (–DB 1)41S7 (+DB 1)7

S42 (–DB 2)42S8 (+DB 2)8

S43 (–DB 3)43S9 (+DB 3)9

S44 (–DB 4)44S10 (+DB 4)10

S45 (–DB 5)45S11 (+DB5)11

S46 (–DB 6)46S12 (+DB 6)12

S47 (–DB 7)47S13 (+DB 7)13

20 External Connectors

Page 21

Table 2-7 SCSI Port Pinouts (continued)

Signal DescriptionPin NumberSignal DescriptionPin Number

S48 (–DB P)48S14 (+DB P)14

S49 (GND)49S15 (GND)15

S50 (GND)50S16 (DIFFSENS)16

S51 (TERMPWR)51S17 (TERMPWR)17

S52 (TERMPWR)52S18 (TERMPWR)18

S53 (RESERVED)53S19 (RESERVED)19

S54 (GND)54S20 (GND)20

S55 (–ATN)55S21 (+ATN)21

S56 (GND)56S22 (GND)22

S57 (–BSY)57S23 (+BSY)23

S58 (–ACK)58S24 (+ACK)24

S59 (–RST)59S25 (+RST)25

S60 (–MSG)60S26 (+MSG)26

S61 (–SEL)61S27 (+SEL)27

S62 (–C/D)62S28 (+C/D)28

S63 (–REQ)63S29 (+REQ)29

S64 (–I/O)64S30 (+I/O)30

S65 (–DB 8)65S31 (+DB 8)31

S66 (–DB 9)66S32 (+DB 9)32

S67 (–DB 10)67S33 (DB 10)33

S68 (–DB 11)68S34 (DB 11)34

Connector Pinouts 21

Page 22

3 Installing Additional Components

Safety Information

This chapter describes installing additional or optional hardware to your hp Integrity cx2600

Server.

Follow the procedures listed below to ensure safe handilng of components and to prevent harm

to both you and the HP Server:

• Use an antistatic wrist strap and a grounding mat, such as those included in the Electrically

Conductive Field Service Grounding Kit (HP 9300-1609).

• Handle accessory boards and components by the edges only. Do not touch any metal-edge

connectors or any electrical components on accessory boards.

• Do not wear clothing that is subject to static charge build-up, such as wool or synthetic

materials.

WARNING! Hazardous energy is present inside the HP Server. Always remove power from

the server before working inside the unit. Serious injury may result if this warning is not observed.

Service Tools Required

The HP Integrity cx2620 server may require one or more of the following tools for service:

• Electrically Conductive Field Service Kit (P/N 9300-1609)

• 1/4 inch flat blade screwdriver

• ACX-15 Torx screwdriver

• ACX-10 Torx screwdriver

• IPF CPU install tool (P/N 5069-4551—supplied with processors shipped separately)

Accessing a Rack-Mounted Server

The HP Integrity cx2600 server is designed to be rack-mounted. The following procedure explains

how to gain access to a server that is mounted in an approved rack.

WARNING! Ensure that all anti-tip features (front and rear anti-tip feet installed; adequate

ballast properly placed, and so on) are employed prior to extending the server.

Installing Components When the Server Is in a Rack

Power supplies, fans, and disks can be installed when the server is fully inserted into a rack.

Only front and rear access is required.

Internal components can be accessed by removing the top cover. Proceed as follows:

WARNING! Hazardous energy is present inside the HP Server. Always remove power from

the server before working inside the unit. Serious injury may result if this warning is not observed.

NOTE: Ensure that there is enough area (approximately 1.5 meters [5 ft.]) to fully extend the

server out the front of the rack to work on it.

1. Turn off and disconnect the system power. Disconnect power at the DC source end of the

power cables, using the disconnect device that is part of the rack or facility power system.

2. Label and disconnect all cables from the unit rear panel connectors.

3. Remove or loosen (as appropriate) the screws that fasten the server to the rack.

4. If the server is slide-mounted, slowly pull the chassis forward (or push from the rear) to

extend the chassis from the rack. The server is fully extended when the rail clips are locked

22 Installing Additional Components

Page 23

in place. If the server is tray-mounted, it is not held in the rack and can fall from its mounting.

Do not extend the server from the rack, remove it from the rack for internal access.

5. Remove the top cover. See “Removing the Top Cover” (page 29).

Removing the Server From a Rack

WARNING! Do notattempt to lift the server alone. The server can weigh as much as 32 kilograms

(70 lbs.). Serious injury may result if this warning is not observed.

NOTE: Ensure there is enough area (approximately 1.5 meters [5 ft.]) to fully extend the server

from the front of the rack to work on it.

To remove the server from the rack, follow these steps:

1. Turn off and disconnect system power. Disconnect power at the DC source end of the power

cables, using the disconnect device that is part of the rack or facility power system.

2. Label and disconnect all cables from the unit rear panel connectors.

3. Remove or loosen (as appropriate) the screws that fasten the server to the rack.

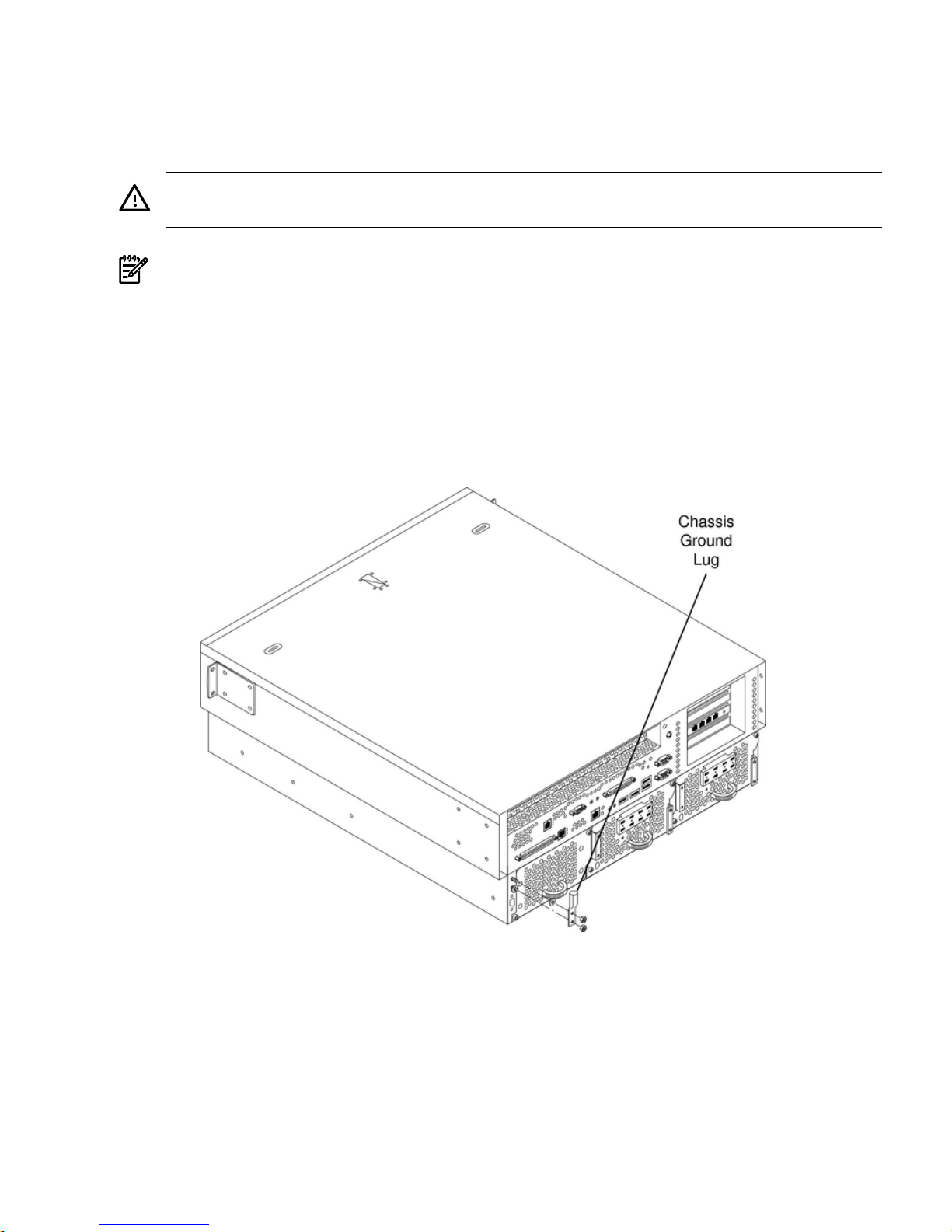

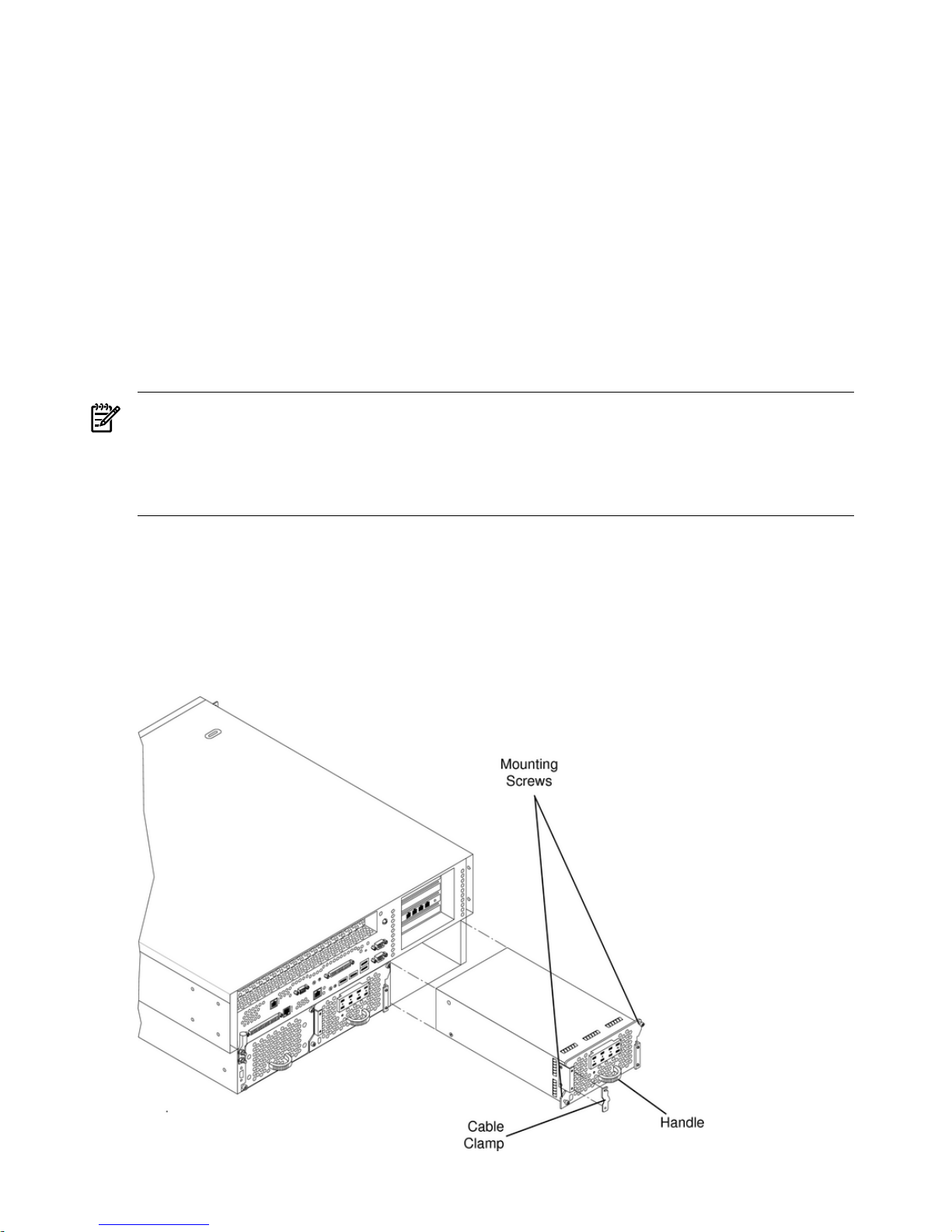

4. Label and disconnect the rack or facility ground cable from the chassis rear panel (Figure 3-1).

Figure 3-1 Chassis Ground Lug

5. If the server is slide-mounted, slowly pull the chassis forward (or push from the rear) to

extend the chassis from the rack. The server is fully extended when the rail clips are locked

in place. Do not extend tray-mounted servers. Tray-mounted servers are not locked in place

and can fall if extended from a rack.

6. Disengage the slides or mounting hardware and take the server to a static-free work station.

Accessing a Rack-Mounted Server 23

Page 24

Install the Server into a Rack

WARNING! Do notattempt to lift the server alone. The server can weigh as much as 32 kilograms

(70 lbs.). Serious injury may result if this warning is not observed.

To insert the server into the rack, follow these steps:

1. Engage the server slides or mounting kit, as appropriate.

2. Slide the server inward and push the server into the rack until it is in position.

3. Connect server cables to rear panel connectors.

4. Connect the rack/facility ground cable to chassis ground lug.

5. Replace or tighten (as appropriate) the screws that fasten the server to the rack.

Installing Disk Drives

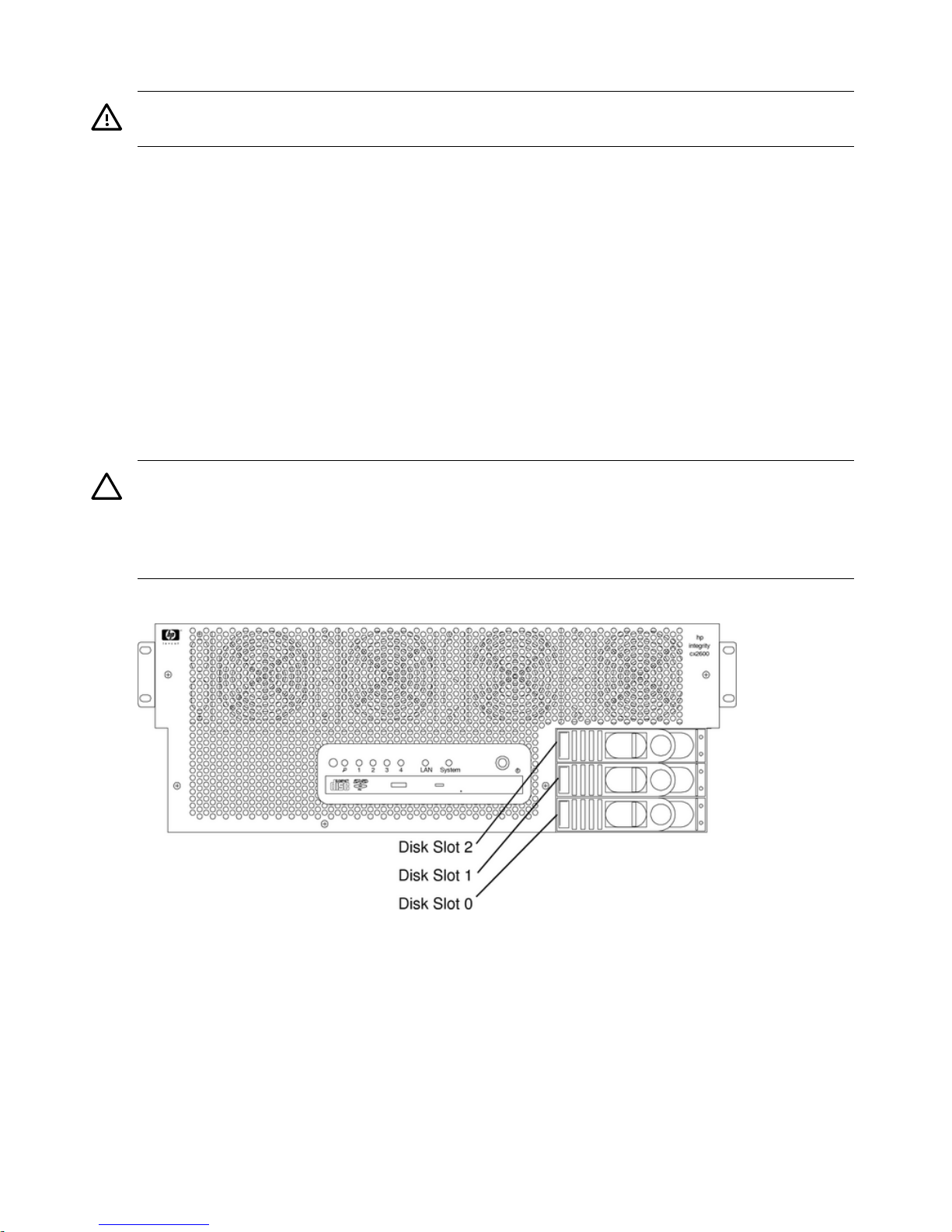

The supported configuration of a server includes one, two, or three Low-Voltage-Differential

(LVD), hot-plug disk drives. If any of the three disk drives are not installed, you must install a

disk filler in the disk location.

Hot-plug disk drives are located at the front of the server. The following sections describe how

to install a hot-pluggable disk drive.

CAUTION: A hot-plug device may require interaction with the operating system before the

device can be safely removed from or installed into the server. Determine if the operating system

supports replacement of disk drives while the operating system is running. If the operating

system does not support this feature, shut down the operating system before performing these

procedures. Failure to observe this caution could result in system failure.

Figure 3-2 Front View of hp Integrity cx2600 Server

Removing Hot-Plug Disk Drives

Slots are provided for up to three hot-plug disk drives in your hp Integrity cx2600 Server. When

disk drives are not installed, filler assemblies are installed to prevent air leakage and ensure

adequate cooling.

24 Installing Additional Components

Page 25

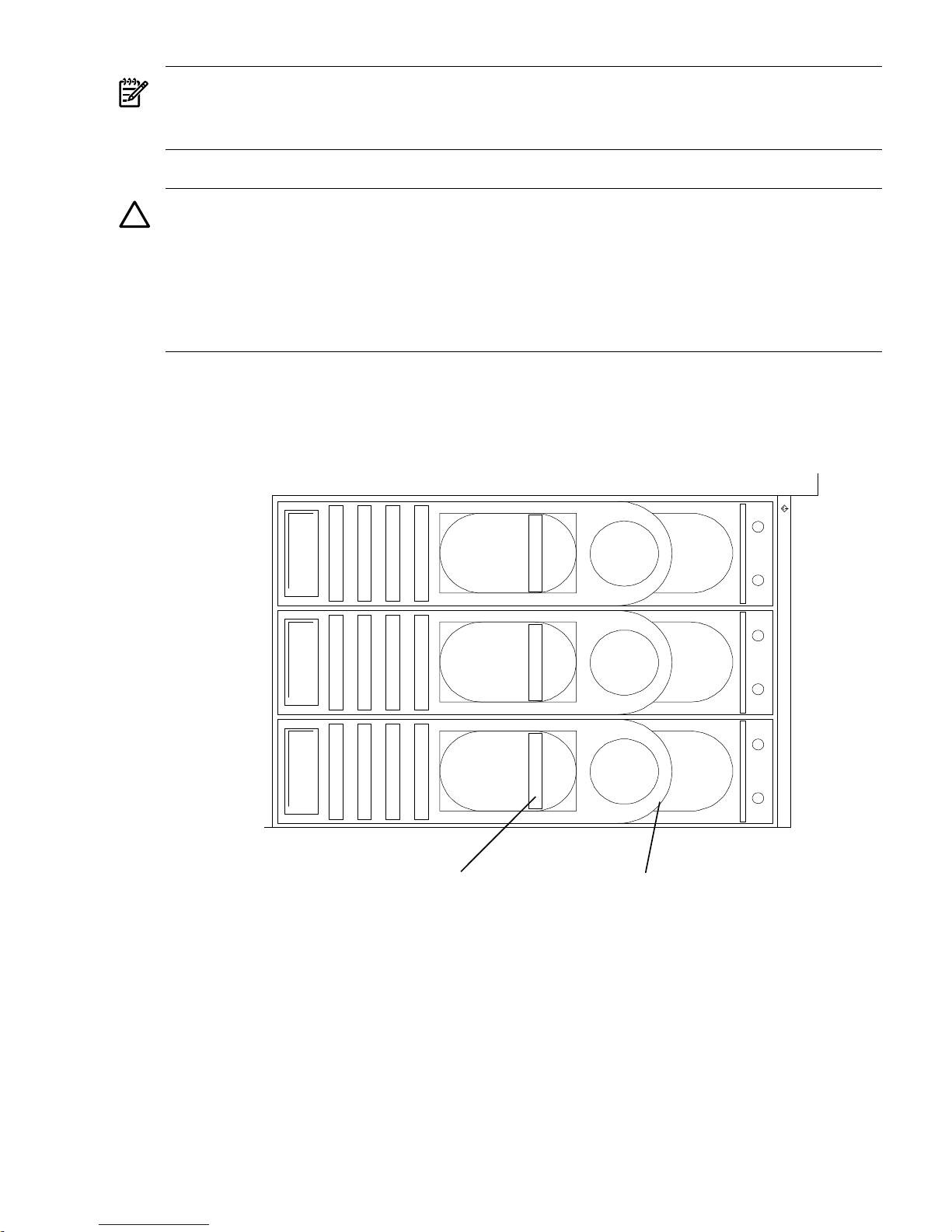

NOTE: The filler assemblies are removed and installed in the same manner as described for

hard drives. Simply pull the dummy release lever to pull the filler from the server.

When inserting a filler, push the filler into position.

To remove a hot-plug disk drive, perform the following steps:

CAUTION: The disk drives in the server are not hot-swappable: they are merely hot-pluggable.

A manual software procedure may be required to safely remove or insert disk drives while the

server is running. To avoid damage to the hard drives:

• Refer to the documentation provided with the disk drive for additional information about

removing and inserting a drive.

• Refer to the operating system documentation for additional information about removing

and inserting hot-plug assemblies.

1. If required (OS does not support hot-plugging devices), stop the operating system.

2. Squeeze inward on the release clip and pull the release lever to pull the drive from the server

chassis.

Figure 3-3 Disk Drives in Server

dskdrvfrnt1

2

1

0

S

C

S

I

Release

Clip

Release

Lever

Installing Hot-Plug Disk Drives

Up to three hot-plug disk drives can be installed in your hp Integrity cx2600 Server. Always use

low profile disk drives (1.0" height) in your server.

To install a hot-plug disk drive, follow these steps:

1. If required, (OS does not support hot-plugging) stop the operating system.

2. If a disk filler is installed, remove it by pulling the dummy release lever.

3. With the release lever pulled out, slide a hot-plug hard disk into the disk slot until it is

seated.

Installing Disk Drives 25

Page 26

4. Press the release lever until it is flush with the front of the server. The release lever clicks as

it locks into position.

5. If the operating system was stopped in step Step 1, reset the system to the EFI Boot

Maintenance Menu to rescan the hard drives.

6. If the operating system was stopped in step Step 1, use the EFI Shell map command to verify

that you correctly installed the newly inserted drive. Refer to “Troubleshooting” (page 53)

and “Utilities” (page 73), for information about connecting a console andusing the EFI shell.

Installing Hot-Swap Power Supply Units

The supported configuration of the hp Integrity cx2600 Server requires that two power supplies

be installed. During normal operations, the two power supplies share the load. Each provides

power through a separate power rail. A single power supply can provide all power needed for

normal operations, but a second power supply is installed to provide backup capability.

Hot-swappable power supplies 1 and 2 are located at the rear of the chassis. The power supplies

are identical and interchangeable.

NOTE: A hot-swappable device does not require interaction with the operating system before

the device is removed from or installed into the server. If the second power supply is functioning

correctly, you can power off and remove a power supply with no effect on server operations.

The power to the server (other power supply) does not have to be off to remove or replace a

hot-swap power supply.

Removing and Replacing a Hot-Swap Power Supply

A power supply can be replaced while the server is installed in a rack, with the server operating

normally. Removal and installation of a power supply will have no effect on operations if the

other power supply is functioning correctly.

To install a hot-swap power supply, follow these steps:

Figure 3-4 Removing a Hot-Swap Power Supply

26 Installing Additional Components

Page 27

1. If rack-mounted, you mayneed to extend a slide-mounted server out from the rack for better

access. If necessary, slide the server out to the fully extended position.

2. Remove power from the power supply being replaced. Disconnect power at the DC source

end of the power cable, using the disconnect device that is part of the rack or facility power

system.

3. Loosen the two knurled knobs on the power-supply cable clamp to release the power feed

leads.

4. Press up on the two lower tabs of the terminal barrier strip cover to snap off the cover.

WARNING! Always check that the power cable is not connected to a power source before

attempting to disconnect the power cable from power supply terminals. Failure to heed this

warning could result in injury.

5. Loosen or remove (as appropriate) the screws that secure power cable leads to the terminal

strip and disconnect the power cable leads from the power supply.

6. Reinstall the terminal strip hardware and barrier strip cover (removed in steps 4 and 5) to

prevent loss. Hang the cover on the upper tabs and snap the cover into place.

7. Using an ACX-15 torx screwdriver, loosen the two captive mounting screws that secure the

power supply to the server chassis.

8. Pull the power supply from the server chassis by pulling the curved handle.

9. Orient the power supply such that the securing screws are aligned with the corresponding

holes in the server chassis. Gently push the power supply into position.

10. When the power supply is fully inserted into the server chassis, tighten the two mounting

screws to secure the power supply in place.

11. Press up on the two lower tabs on the terminal barrier strip cover to snap off the cover.

WARNING! Always check that the power cable is not connected to a power source before

attempting to connect the power cable to power supply terminals. Failure to observe this

warning can result in injury.

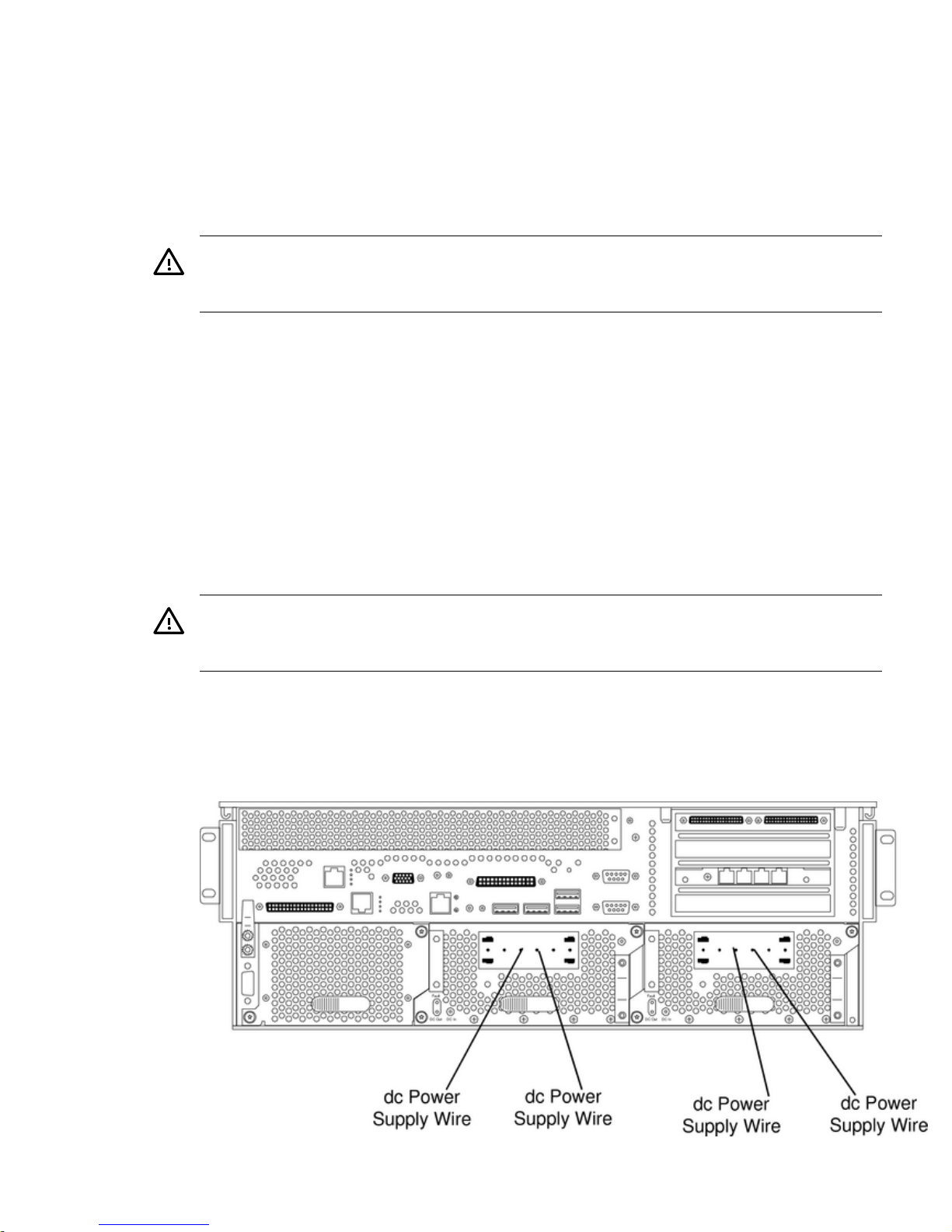

12. Connect the power cable leads to the power supply terminals (Figure 3-5).

For -48V, the most positive wire is 0V.

For -48V, the most negative wire is -48V.

Figure 3-5 DC Power Supply Wire Connectors

Installing Hot-Swap Power Supply Units 27

Page 28

13. Install the terminal barrier strip cover (removed in step 11). Hang the cover on the upper

tabs and snap the cover into place.

14. Route the power cable through the power supply cable clamp and tighten the two knurled

knobs to secure the cable in place.

15. Connect the power cable to the DC power source.

Installing the Front Grill and Top Cover

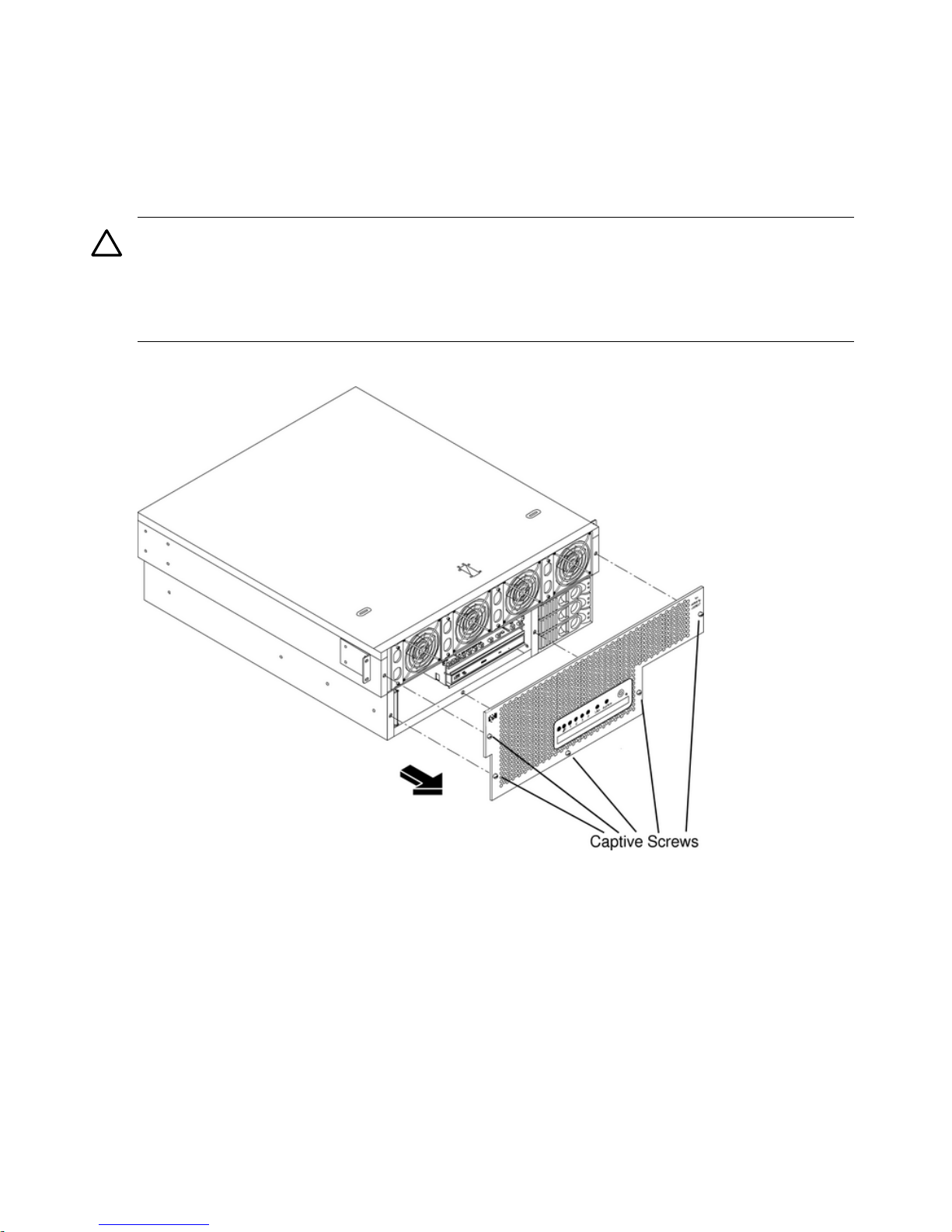

CAUTION: Operation of the server without the front grill and top cover in place makes the

server susceptible to electromagnetic interference (EMI) and overheating problems, which can

result in system failure. Keep the front grill and top cover in place during normal operation.

Observe all electrostatic discharge (ESD) safety precautions while performing this procedure.

Failure to follow ESD safety precautions can result in damage to the server.

Figure 3-6 Removing the Front Grill

Removing the Front Grill

You must remove the front grill for access to the front mounted fans or the optical drive. To

remove the front grill, perform the following steps:

To remove the front grill, follow these steps:

1. Use the ACX-15 Torx screwdriver to loosen the five captive screws that secure the grill to

the chassis.

2. Pull the grill from the front of the server chassis.

Installing the Front Grill

To install the front grill, follow these steps:

1. Hold the grill against the front of the server chassis in mounting position.

2. Tighten the five captive screws to secure the grill to the server chassis (Figure 3-6).

28 Installing Additional Components

Page 29

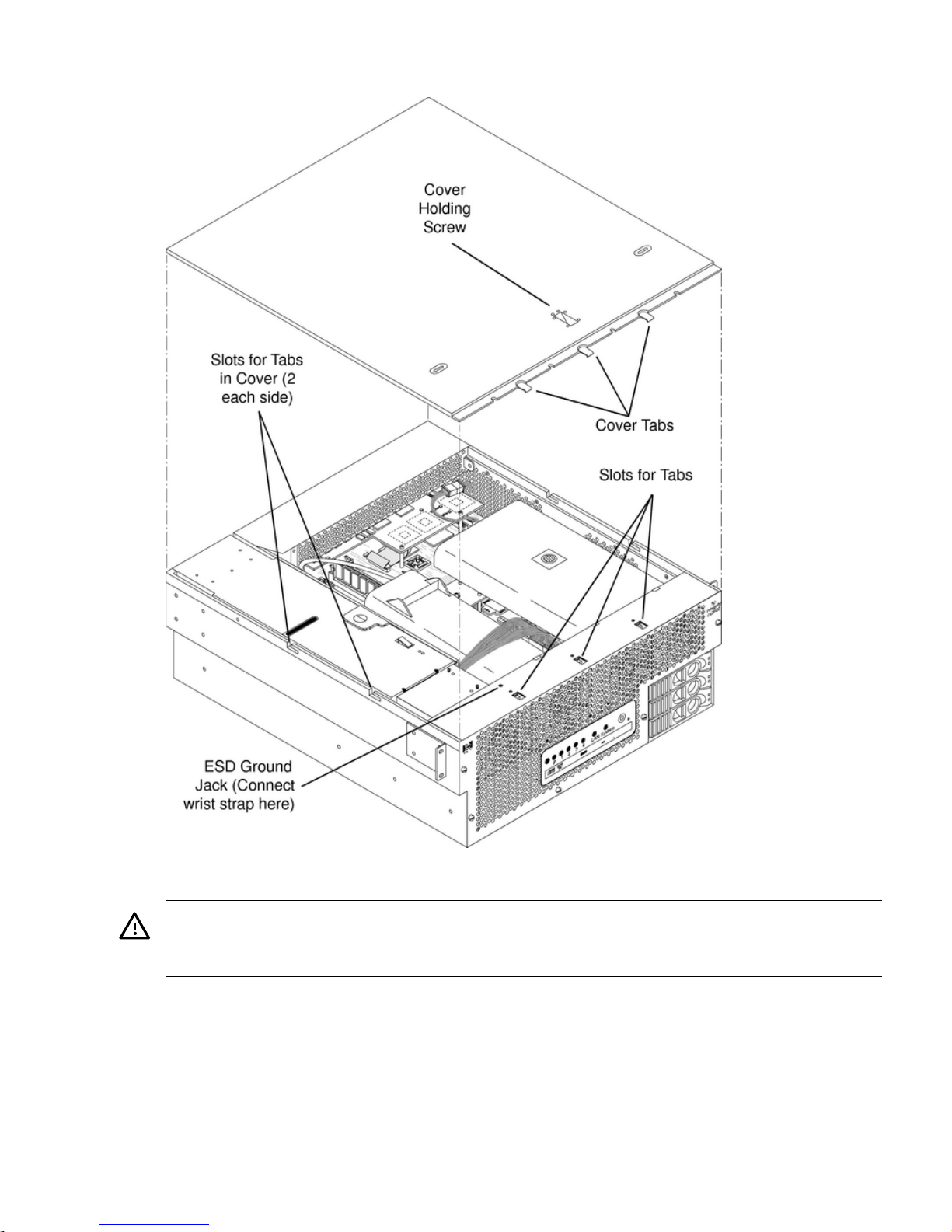

Removing the Top Cover

To remove the top cover, follow these steps:

WARNING! Hazardous voltages are present within the server when power is applied. Do not

remove the server top cover without first turning off and disconnecting power. Always replace

the top cover before turning the system on.

1. Power off and disconnect system power. Disconnect power at the DC source end of the

power cables, using the disconnect device that is part of the rack or facility power system.

2. Slide the server out from the rack until it stops. See “Accessing a Rack-Mounted Server”

(page 22).

3. Remove the server from the rack and place it on an ESD-protected work surface. See

“Removing the Server From a Rack” (page 23).

4. Use the ACX-15 Torx screwdriver to loosen the captive screw that holds the top cover in

place.

Installing the Front Grill and Top Cover 29

Page 30

5. Slide the cover toward the rear of the server chassis and lift it straight up.

Installing the Top Cover

To install the top cover, follow these steps:

1. Align each pair of tabs on the left and right sides of the cover with the corresponding slots

in the chassis. Set the cover in place on the chassis.

2. Align the three tabs on the front of the cover with the corresponding apertures at the top

front of the chassis and insert the tabs into the slots.

3. Push the cover forward until it seats on the chassis.

4. Tighten the captive screw to secure the cover in place.

Installing Hot-Swap Chassis Fan Units

There are five hot-swappable chassis fan units in the HP server. Fan units 1, 2, 3 and 4 are

accessible from the front of the chassis. Fan unit 5 is accessible from the rear of the chassis. Fan

units 1, 2, 3 and 4 are identical and interchangeable.

If a fan failure is total (both rotors), or if the fan has been removed from the chassis for more than

30 seconds, the system logs the event as a critical error. A critical error causes the system LED

to flash red, and requires a reboot to reset the error status. A total fan failure (including removal)

for more than two minutes results in system shutdown. If you are hot-swapping a fan assembly

in response to an error message, and the system is operating normally, hot-swapping the fan in

30 Installing Additional Components

Page 31

less than 30 seconds eliminates the requirement for a system reboot. Hot-swapping a fan in less

than two minutes enables continued operation and prevents automatic shutdown.

CAUTION: Operating the server with the front grill removed risks EMI. Operate the server

with the front grill removed only when hot-swapping a fan. Always replace the front grill

immediately after replacing a fan.

Observe all ESD safety precautions while performing this procedure. Failure to follow ESD safety

precautions can result in damage to the server.

NOTE: A hot-swap device does not require interaction with the operating system before the

device is removed from or installed into the server.

The power to the server does not have to be off to remove or replace a hot-swappable chassis

fan unit.

Removing and Installing a Front Panel Hot-Swap Fan

Figure 3-7 Removing a Front Panel Hot-Swappable Fan

The server does not need to be removed or extended from the rack to enable fan replacement.

Installing Hot-Swap Chassis Fan Units 31

Page 32

To removeand install a hot-swappable fan from the front of the server chassis, follow these steps:

CAUTION: Hot-swapping a fan can interrupt system operation.

If you are hot-swapping a fan assembly in response to an error message, and the system is

operating normally, hot-swapping the fan in less than 30 seconds eliminates the requirement for

a system reboot.

Hot-swapping the fan in less than two minutes enables continued operation and prevents

automatic shutdown.

1. Remove the front grill. See “Removing the Front Grill” (page 28).

2. Use the ACX-15 Torx screwdriver to loosen the two captive screws on the plastic fan extractor

handle (left side of fan) (Figure 3-7).

3. Using the extractor handle, pull the fan from the server chassis.

4. Orient the replacement fan so that the extractor handle is on the left. Insert the fan into the

chassis opening and press it firmly into place.

5. Tighten the two captive screws that secure the fan in place.

32 Installing Additional Components

Page 33

Removing and Installing a Rear Panel Hot-Swappable Fan

Figure 3-8 Removing a Rear Panel Hot-Swap Fan

To remove and install the hot-swap fan from the rear of the server chassis, follow these steps:

NOTE: The server does not need to be removed from the rack for fan replacement.

1. Use the ACX-15 Torx screwdriver to loosen the two captive mounting screws that secure

the fan unit to the server chassis (Figure 3-8).

CAUTION: Hot-swapping a fan can interrupt system operation. If you are hot-swapping

a fan assembly and the system is operating normally, hot-swapping the fan in less than 30

seconds eliminates the requirement for a system reboot. Hot-swapping the fan in less than

two minutes enables continued operation and prevents automatic shutdown.

2. Pull the fan assembly from the server chassis by pulling the curved handle.

3. Orient the replacement fan assembly so that the curved handle is at the bottom. Gently push

the fan unit into position.

Installing Hot-Swap Chassis Fan Units 33

Page 34

4. Tighten the two captive screws that secure the fan unit to the server chassis.

PCI Card Installation

The hp Integrity cx2600 Server has four 64-bit, 133 MHz PCI-X accessory card sockets located in

a removable card cage. You must remove the PCI card cage before you can remove or install PCI

cards. The following sections describes how to remove and open the card cage, install PCI cards,

and reinstall the PCI card cage.

Removing the PCI Card Cage Assembly

To remove the PCI-X card cage assembly, follow these steps:

1. If rack-mounted, extend a slide-mounted server out from the rack until it stops. See

“Accessing a Rack-Mounted Server” (page 22).

2. Turn off the system. Disconnect all external cables.

3. If desired, remove the server from the rack and place it on an ESD-protected work surface.

See “Removing the Server From a Rack” (page 23).

WARNING! Ensure that the system is powered down and all power sources have been

disconnected from the server prior to removing or replacing the PCI card cage assembly.

Voltages and hazardous energy can be present at various locations within the server whenever