Page 1

HP Indigo Division Installation Instructions

Installation Manual

Purpose

To provide information and instructions for performing the installation of the HP Indigo press w3250.

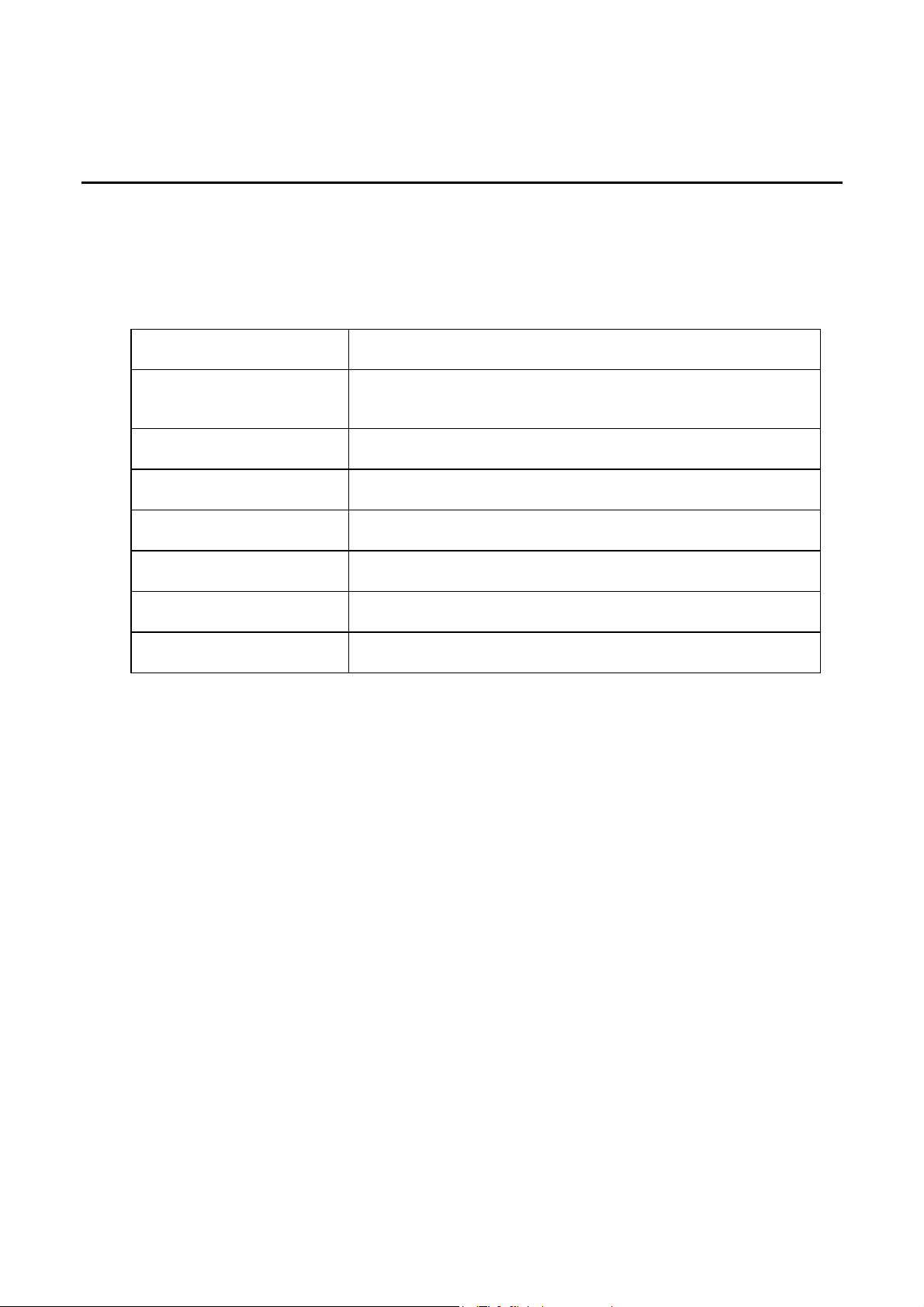

Installation instruction details

Item Details

Objective

Scope

Document number

Kit number

Date

Related ECO

Security level

Modification available - performance/ Modification available reliability

HP Indigo press w3250

CA294-03070

As per press

13 Feb 07

N/A

HP confidential

Contents

Installation instruction details ...................................................................................................................1

Overview...................................................................................................................................................6

Warranty disqualifier.................................................................................................................................7

Quick reference checklist .........................................................................................................................8

General information................................................................................................................................17

How to use this manual.....................................................................................................................17

Packing list ........................................................................................................................................17

The alignment jig ...............................................................................................................................19

The parallel jig ...................................................................................................................................20

Prerequisites...........................................................................................................................................22

Estimated installation time......................................................................................................................22

Special skills ...........................................................................................................................................22

Special jigs and tools..............................................................................................................................22

Pre-installation procedure ......................................................................................................................23

Verifying site preparation...................................................................................................................23

Marking the pressroom floor for press components..........................................................................23

Unpacking the boxes.........................................................................................................................23

Procedure ...............................................................................................................................................24

Installing the electrical cabinets ........................................................................................................24

Installing the printing engines............................................................................................................24

Mounting the turnbar .........................................................................................................................44

Mounting the PE1..............................................................................................................................45

Leveling the printing engines ............................................................................................................46

filename: CA294-03070-00.doc page 1 of 153

Page 2

Installation Manual

Securing the turnbar..........................................................................................................................54

Electrical cabling ...............................................................................................................................58

Installing the vacuum hoses..............................................................................................................70

Install the floor platform.....................................................................................................................72

Installing the chiller and cooling water hoses....................................................................................72

Install the UPS...................................................................................................................................75

Install the writing head.......................................................................................................................76

Install the HVPS (High Voltage Power Supply).................................................................................77

Install the roof covers ........................................................................................................................79

Install system components................................................................................................................80

Unpacking the ILP, unwinder, utility cabinets, and ink cabinets .......................................................80

Installing the ILP................................................................................................................................81

Installing the ILP web rollers .............................................................................................................97

Installing the unwinder.....................................................................................................................100

Unwinder electrical connections......................................................................................................104

ILP electrical connections................................................................................................................105

Connect the air supply.....................................................................................................................108

Install the ILP vacuum hoses ..........................................................................................................112

Installing the ink cabinets ................................................................................................................113

Adjusting the web guide ..................................................................................................................116

Install the utility cabinet ...................................................................................................................117

Connect the computers ...................................................................................................................121

Install the master console ...............................................................................................................127

Connecting the master computer ....................................................................................................128

Production flow................................................................................................................................130

Install the finishing components ......................................................................................................130

Installing the turnbar stepping plate ................................................................................................130

Install the main power connection and transformer ........................................................................130

Initial power-up ................................................................................................................................131

Emergency stop tests......................................................................................................................136

Threading the web...........................................................................................................................138

Configure the press software ..........................................................................................................139

Install PIP and blankets...................................................................................................................139

Testing and calibrating the press ....................................................................................................139

Customer acceptance test procedure (CATP) ................................................................................145

CATP specification checklist ...........................................................................................................147

Complete the installation.................................................................................................................150

Appendix A: Image placement parameters ..........................................................................................151

Revision history ....................................................................................................................................153

Confidentiality Notice............................................................................................................................153

List of figures

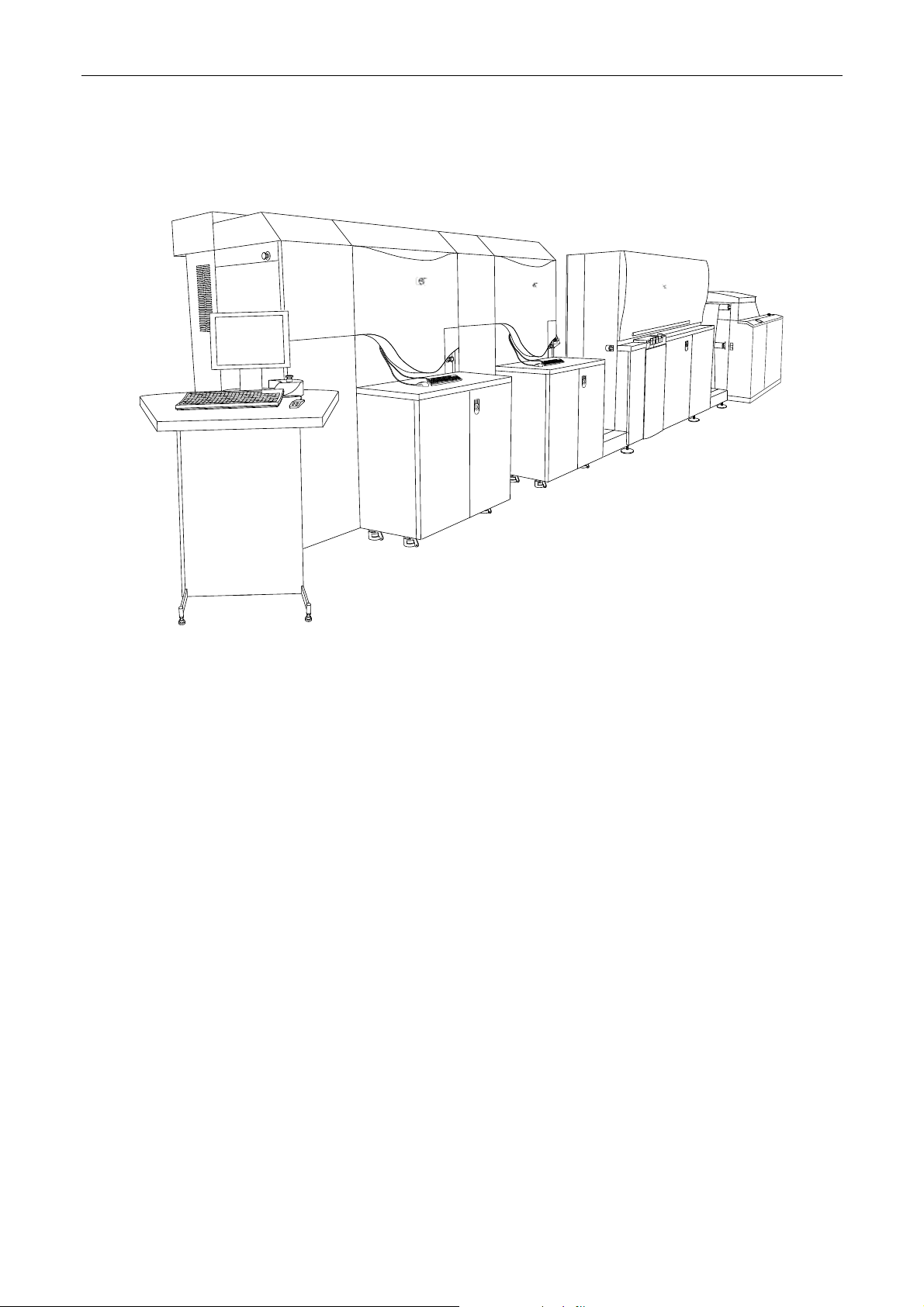

Figure 1 The HP Indigo press w3250 ...................................................................................................6

Figure 2 The alignment jig ..................................................................................................................19

Figure 3 The alignment jigs mounted .................................................................................................19

Figure 4 Sections of the new Parallel jig ............................................................................................20

Figure 5 Mounting the v-section of the Parallel jig..............................................................................21

Figure 6 Mounting the dial bracket on the extension..........................................................................22

Figure 7 Positioning the u-bases ........................................................................................................25

Figure 8 Remounting the u-base slip plates .......................................................................................26

Figure 9 Adjusting the u-base height..................................................................................................27

Figure 10 Placing the foresight on the PE2 u-base ............................................................................28

CA294-03070 rev 00 page 2 of 153

Page 3

Installation Manual

Figure 11 Setting up the surveying tool ..............................................................................................29

Figure 12 Focusing the surveying tool on the foresight stand target..................................................30

Figure 13 Leveling the surveying tool.................................................................................................30

Figure 14 Loosening the u-base connecting rods ..............................................................................31

Figure 15 Installing the junction bars between the u-bases ...............................................................31

Figure 16 Removing the front exit service door..................................................................................33

Figure 17 The lifting and positioning assembly ..................................................................................34

Figure 18 Positioning the link bar under the feed side .......................................................................35

Figure 19 Positioning the link bar under the exit side of the engine - view from rear.........................36

Figure 20 Positioning the lifting frames against the engine................................................................37

Figure 21 Leveling pad .......................................................................................................................38

Figure 22 Placing the leveling pads on the u-base.............................................................................38

Figure 23 Moving the raised engine to the u-base .............................................................................39

Figure 24 Press positioned over u-base .............................................................................................40

Figure 25 Lowering the engine on to the u-base and leveling pads...................................................41

Figure 26 Engine mounted on the u-base ..........................................................................................42

Figure 27 Final position of printing engine on u-base.........................................................................43

Figure 28 Identifying the turnbar components ....................................................................................44

Figure 29 Inserting the turnbar into the exit side of PE2 ....................................................................45

Figure 30 Using a level at the printing engine front ............................................................................46

Figure 31 Leveling at the printing engine input – PE2 shown ............................................................47

Figure 32 Mounting an alignment jig on the ITM end cap ..................................................................48

Figure 33 Aligning the printing engines - alignment jigs.....................................................................50

Figure 34 Identifying the u-base adjustment screws ..........................................................................51

Figure 35 Aligning the surveying tool crosshairs and sights ..............................................................51

Figure 36 Measuring the parallelism between rollers of opposing printing engines...........................52

Figure 37 The link brackets ................................................................................................................53

Figure 38 Mounting the front link bracket ...........................................................................................53

Figure 39 Inserting the rear connection bracket .................................................................................54

Figure 40 Securing the front connection bracket and input idler ........................................................55

Figure 41 Securing the rear connection bracket and input idler.........................................................56

Figure 42 Connecting the main electrical power in the electrical cabinet...........................................58

Figure 43 Securing the electrical cabinet cables ................................................................................59

Figure 44 Components of electrical cabinet M1 .................................................................................60

Figure 45 Components of electrical cabinet M2 .................................................................................61

Figure 46 The Unidrive assembly and components ...........................................................................65

Figure 47 The Unidrive unit ................................................................................................................66

Figure 48 Electrical cabinet M1 PLC, MPI, and Profibus connections ...............................................68

Figure 49 Routing the MPI (MODBUS) cable.....................................................................................69

Figure 50 Installing the vacuum hoses and adaptors .........................................................................70

Figure 51 Routing vacuum hoses to PE1 ...........................................................................................71

Figure 52 Routing vacuum hoses to PE2 ...........................................................................................72

Figure 53 Chiller pipe routing (Europe)...............................................................................................73

Figure 54 Chiller pipe routing (Japan) ................................................................................................74

Figure 55 The rear UPS panel............................................................................................................75

CA294-03070 rev 00 page 3 of 153

Page 4

Installation Manual

Figure 56 Connecting the UPS to the PDU ........................................................................................76

Figure 57 HVPS installation................................................................................................................77

Figure 58 The HVPS cage assembly..................................................................................................77

Figure 59 Installing the HVPS on the baseplate.................................................................................78

Figure 60 Installing the baseplate on the press..................................................................................78

Figure 61 Attaching the top cover to the baseplate ............................................................................79

Figure 62 Connecting the cables to the HVPS ...................................................................................79

Figure 63 ILP rollers............................................................................................................................81

Figure 64 Distinguishing the ILP feed and exit stepping plate assemblies ........................................82

Figure 65 Mounting the ILP stepping plate assemblies on the ILP ....................................................83

Figure 66 Installing the stepping plates to the ILP..............................................................................84

Figure 67 Installing the ILP exit cover on the exit-side stepping plate assembly ...............................85

Figure 68 Positioning the ILP next to PE1..........................................................................................86

Figure 69 Aligning the stepping plate to the PE1 front wall................................................................87

Figure 70 Unlocking the ILP alignment plates ....................................................................................88

Figure 71 Leveling and aligning the ILP ............................................................................................89

Figure 72 Adjust the ILP feet height ...................................................................................................90

Figure 73 Leveling the ILP..................................................................................................................91

Figure 74 Leveling the ILP at the rollers.............................................................................................92

Figure 75 Aligning the PE1 and ILP using the Parallel jig ..................................................................93

Figure 76 Aligning the ILP feed stepping plate rollers........................................................................94

Figure 77 Aligning the ILP feed stepping plate rollers - between stepping plate rollers.....................95

Figure 78 The priming unit rollers - position in the ILP .......................................................................97

Figure 79 Identifying the rollers ..........................................................................................................98

Figure 80 Installing the priming rollers - outer and inner stations.......................................................99

Figure 81 Moving the unwinder into its final position........................................................................100

Figure 82 Leveling the unwinder.......................................................................................................101

Figure 83 Checking the level at the unwinder exit............................................................................102

Figure 84 Aligning the unwinder with the ILP feed stepping plate assembly ...................................103

Figure 85 Aligning the unwinder with the ILP ...................................................................................104

Figure 86 Install cable securing clamps at the ILP ...........................................................................106

Figure 87 ILP rear connection panel.................................................................................................107

Figure 88 Connection the air supply at the ILP ................................................................................108

Figure 89 Routing the air hose from the ILP.....................................................................................109

Figure 90 Routing and connecting the air hoses at PE1 and PE2 ...................................................110

Figure 91 Installing the safety cover on the ILP rear panel ..............................................................111

Figure 92 Routing the vacuum hose to the ILP ................................................................................112

Figure 93 The 4-color configuration – front view ..............................................................................113

Figure 94 The 7-color configuration – front view ..............................................................................113

Figure 95 The ink cabinet – rear view...............................................................................................114

Figure 96 Mapping the BID hoses from the ink cabinet to the BIDs.................................................115

Figure 97 Removing the transport securing screws ..........................................................................116

Figure 98 Hinging the utility cabinet to the printing engine...............................................................117

Figure 99 Connecting the utility cabinet to the printing engine.........................................................118

Figure 100 Closing the utility cabinet on the sealing gasket ............................................................119

CA294-03070 rev 00 page 4 of 153

Page 5

Installation Manual

Figure 101 Adjusting the height of the utility cabinet ........................................................................120

Figure 102 The network configuration ..............................................................................................121

Figure 103 The switchbox unit..........................................................................................................121

Figure 104 Identifying the slave computer connections ...................................................................122

Figure 105 Mounting the slave computer and switchbox in electrical cabinet M2 ...........................123

Figure 106 Connecting a slave computer to its printing engine .......................................................124

Figure 107 Connecting the master console computer......................................................................127

Figure 108 Installing the monitor base..............................................................................................128

Figure 109 switching the UPS on .....................................................................................................132

Figure 110 The web feed system .....................................................................................................138

Figure 111 The image placement parameters..................................................................................151

CA294-03070 rev 00 page 5 of 153

Page 6

Installation Manual

Overview

Figure 1 The HP Indigo press w3250

The procedure to install the HP Indigo press w3250 involves the following main steps:

• Verifying site preparation

• Marking the pressroom floor

• Unpacking the boxes

• Install the electrical cabinets

• Install the printing engines and turnbar

• Install the In-Line Primer (ILP)

• Installing the unwinder

• Install the main electrical cabling

• Install the slave computers and switchboxes

• Install the printing engine vacuum hoses

• Install the cooling water hoses

• Install the floor platform

• Install system components such as ink cabinets, utility cabinets, and writing heads

• Install the master console and computer

• Powering up the press

• Installing the system electrical cabling

• Configuring the press software

• Testing and calibrating press systems

• Performing CATP

CA294-03070 rev 00 page 6 of 153

Page 7

Installation Manual

Warranty disqualifier

The boxes addressed to the customer may be opened only by a qualified HP Indigo Customer

Engineer. Any unauthorized opening of the boxes may void the warranty on the press and its parts.

This manual and the corresponding Quick Reference Checklist are intended for use by the Customer

Engineer. The engineer should obtain the manual prior to the installation of the press.

CAUTION: The HP Indigo press w3250 printing engines,

unwinder and rewinder may be lifted or transported

only by specially trained and qualified personnel

using lifting bars, lifting straps, and other

specialized equipment that meet HP Indigo

specifications as well as any additional

requirements imposed by central and local

government regulations.

Improper lifting may cause serious personal injury

and/or damage to the press or other property.

Do not lift the printing engines (PE) from the paper

input or paper exit side.

When lowering the printing engines from the fork

lift, place wedges on the floor in front of the wheels

to prevent slipping.

The press must be hard connected to the mains by a qualified local electrician in accordance with

local safety regulations. The connection must be through a lockable mains supply disconnect switch

rated at 32 A 5000 AIC type G. The cables must be protected by a conduit.

CA294-03070 rev 00 page 7 of 153

Page 8

Installation Manual

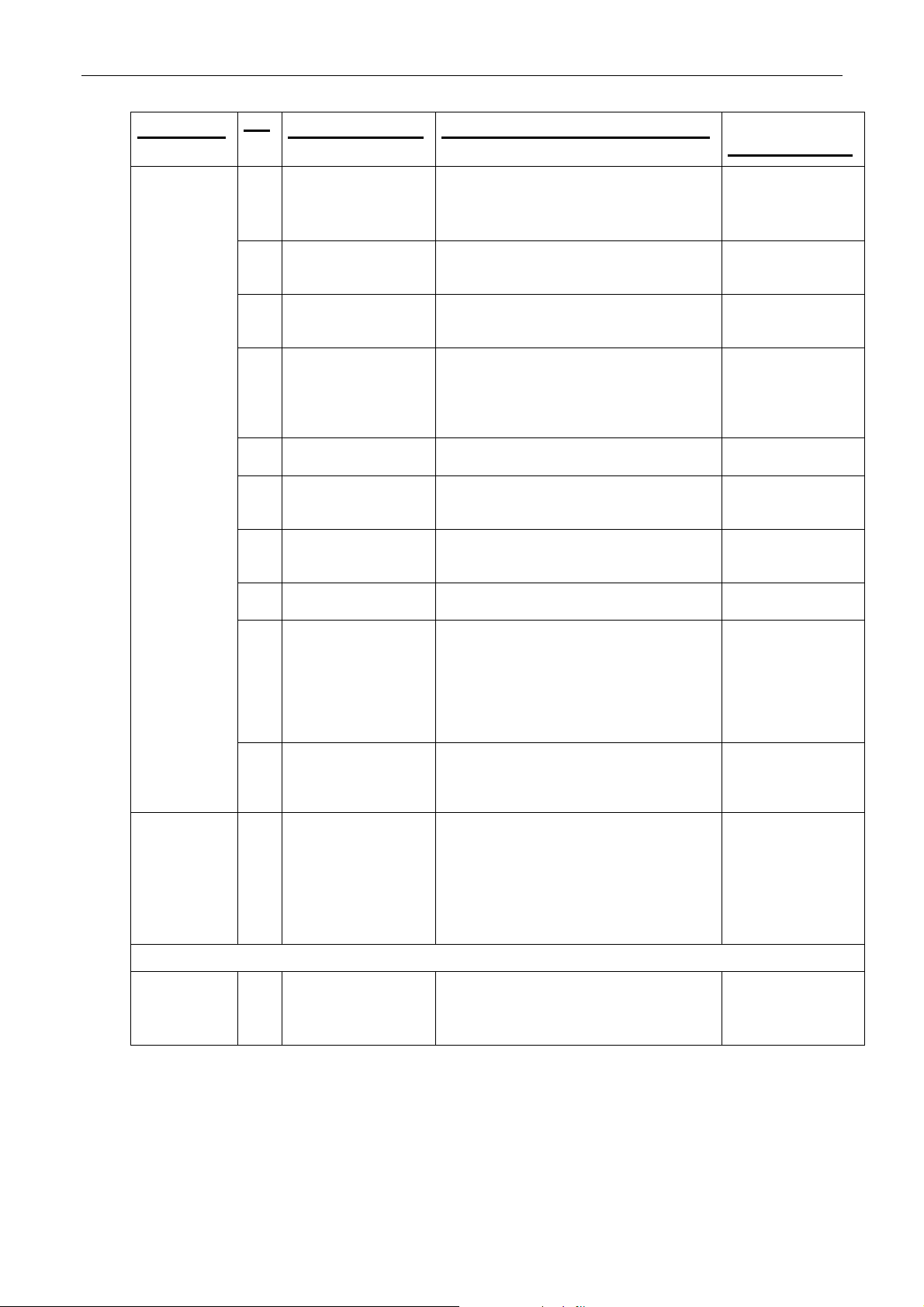

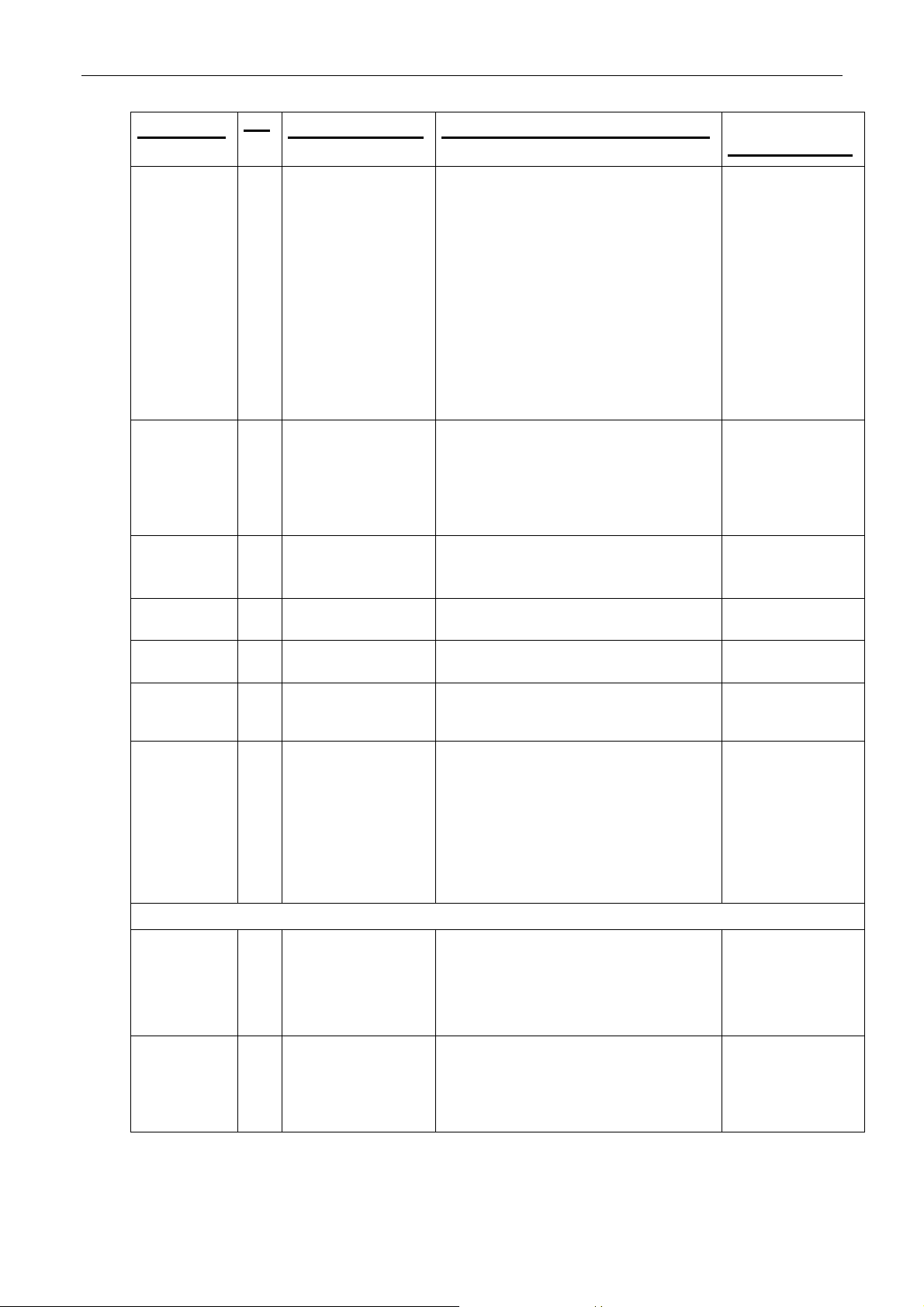

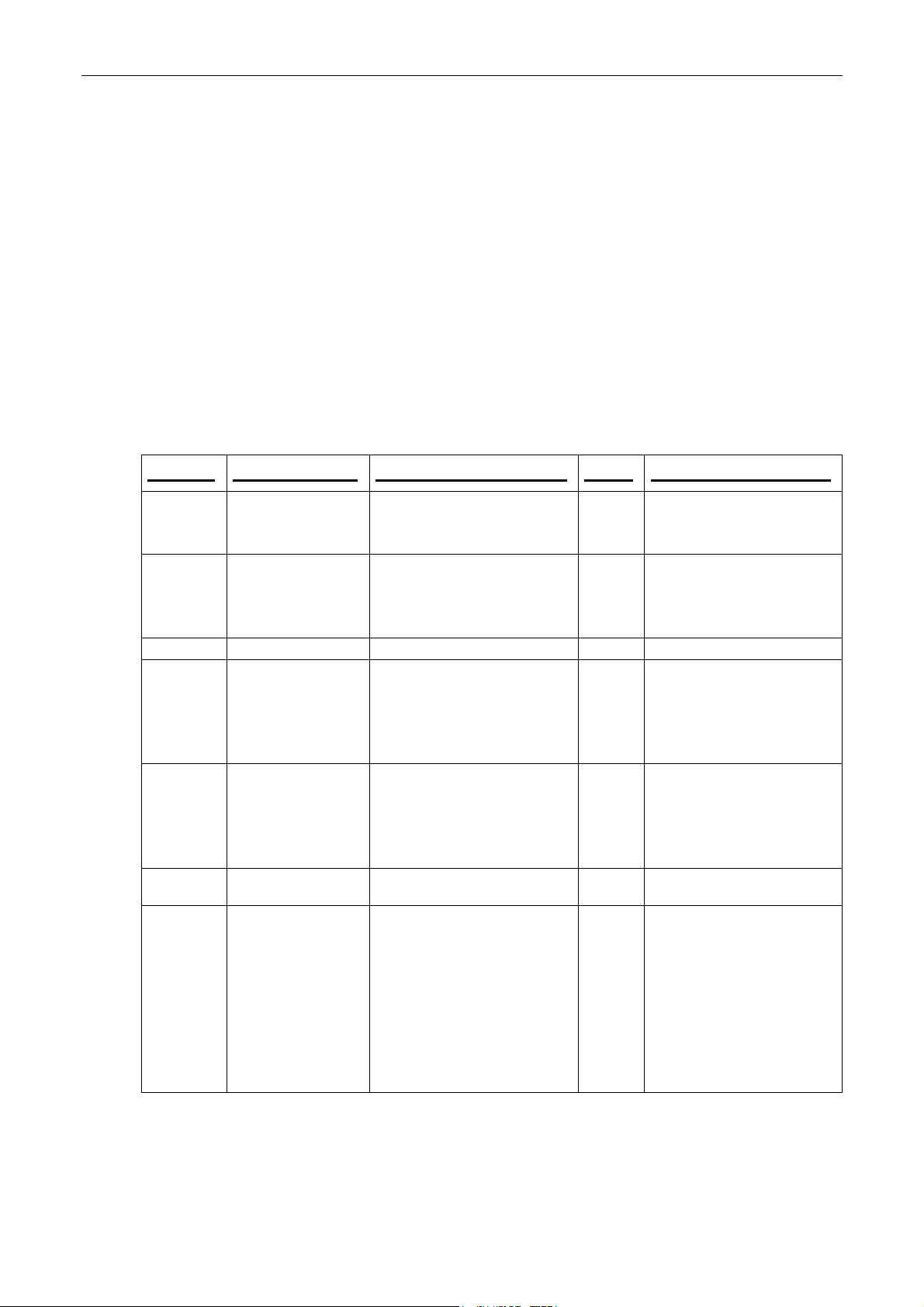

Quick reference checklist

The following procedure is a quick reference guide of the installation procedure intended for two

integrators and extended over five days.

Step

Heading

Reference Procedure

1st Day

Pre-installation

Site

preparation

Measuring

and marking

Unpacking 3. Unpacking the boxes

Installation

Electric

cabinets

(20 mins)

U-bases

(40 mins)

Printing

engines

(160 mins)

1. Verifying site

preparation on page

23

2. Marking the

pressroom floor on

e 23

pag

on page 23

4. Installing the

electrical cabinets on

pag

e 24

5. Position the u-bases

on page 24

6. Position the foresight

stand on page 28

7. Install the junction

bars on page 32

8. Mount the PE2 on

page 33

9. install the platform on

page 43

10. Mounting the turnbar

on page 44

11. Mounting the PE1 on

page 45

12. level each printing

engine on page 46

13. align the printing

engines on page 49

14. Securing the turnbar

on page 54

15. connect the printing

ines on page 56

eng

y site preparation as per Site

Verif

Preparation Guide

Use marker pen to mark profile of press,

cabinets, unwinder, ILP and Finisher on

floor

Unp

ack the boxes and verify their contents

either with the BOM or Packing list on page

17.

Install electrical cabinet M1 and M2 in their

marked position.

n the u-bases on the floor. Adjust

Positio

distance between u-bases to 693.0 mm at

a height of 200 mm. from the floor.

Use surve

accurately. Raise the tripod and surveying

tool to 1550.0 mm.

Install the junction bars between the two ubases.

Mount the PE2 on the u-base. Use the

lifting and positioning assembly.

Install the platform between the printing

engines.

Mount the turn

Mount the PE1 on the u-base. Use the

lifting and positioning assembly.

Leve

of 0.0 ± 0.1 mm

Accuratel

horizontally using the surveying tool.

Mount the front

brackets on the extended shaft of idler 3.

Install using M5 screws at front and rear.

Install collar on idler at rear.

Recheck the alignment using the surveying

tool.

Install front link

Recheck alignment using surveying tool.

Check parallelism between PEs using the

parallel jig. Measure to an accuracy of

0.00 ± 0.01 mm

ying tool to align u-bases

bar assembly to PE1.

l each printing engine to an accuracy

y align the printing engines

and rear connection

brackets to attach two PEs.

Notes and

check

Site Preparation

check list

Marker pen

Cable meter

Packing list

Packed with PE2

CA294-03070 rev 00 page 8 of 153

Page 9

Installation Manual

Step

Heading

Electrical

wiring

(180 mins)

Vacuum

hoses

(40 mins)

Reference Procedure

16. Install the electrical

cabinet-to-cabinet

cables on page 61

17. Install the electrical

cabinet M1 cables to

PE1, PE2 on page 62

18. Install the electrical

cabinet M2 to PE1,

PE2 on page 62

19. Install the electrical

cabinet M1-to-master

console cables on

e 63

pag

20. Install all Unidrive

cables on page 66

21. Install the PE1-toPE2 cables on page

67

22. Install the PROFIBUS

cables as on page 67

23. Install the CTNET

cables on page 68

24. Route the MPI

(MODBUS) cables on

pag

e 69

25. Connect the ProfiBus

and CT

Net cable

connections on page

69

26. Installing the vacuum

hoses on page 70

2nd Day

Floor platform 27. Install the floor

platform on page 72

Install electrical cabinet M2 to cabinet M1

cabling.

Install electrical cabinet M1 to cabinet M2

cabling.

Install electrical cabinet M1 to PE1 and

PE2.

Install electrical cabinet M2 to PE1 and

PE2.

Install the electrical cabinet M1-to-master

console cables.

Leave the cables ends at the cabinet until

installation of the raised floor and master

console.

Install al

electrical cabinets M1 and M2.

Install the PE1-

Install ProfiBus

between electrical cabinets M1 and M2 and

PLC in cabinet M1.

Install CT

at electrical cabinets M1 and M2.

Route the MPI (MODBUS) cable through

the ILP connection panel to the front of

PE1 and connect JTBD of the cable to

PTBD of the TBD.

Route the remaining connector JTBD to the

exit are of PE2 and connect it to PTBD of

the TBD.

Con

cable connections at electrical cabinets M1

and M2

Remov

Install and route all vacuum hoses from

electrical cabinets M1 and M2 to PE1, PE2

(short hoses 2-3 m), and ILP.

Wait for the raised floor and ILP to install

long hose (3-4 m).

Reinstall lower under-panel

Install floor p

specifications in Site Preparation Guide.

Start at unwinder and ILP area. For press,

start at corners of press or wall.

l PE1 and PE2 Unidrive cables in

to-PE2 cables.

communication cable

Net cables between all Unidrives

nect the following ProfiBus and CTNet

e under-panel

latform according to

Notes and

check

Wait for floor and

ILP to connect.

CA294-03070 rev 00 page 9 of 153

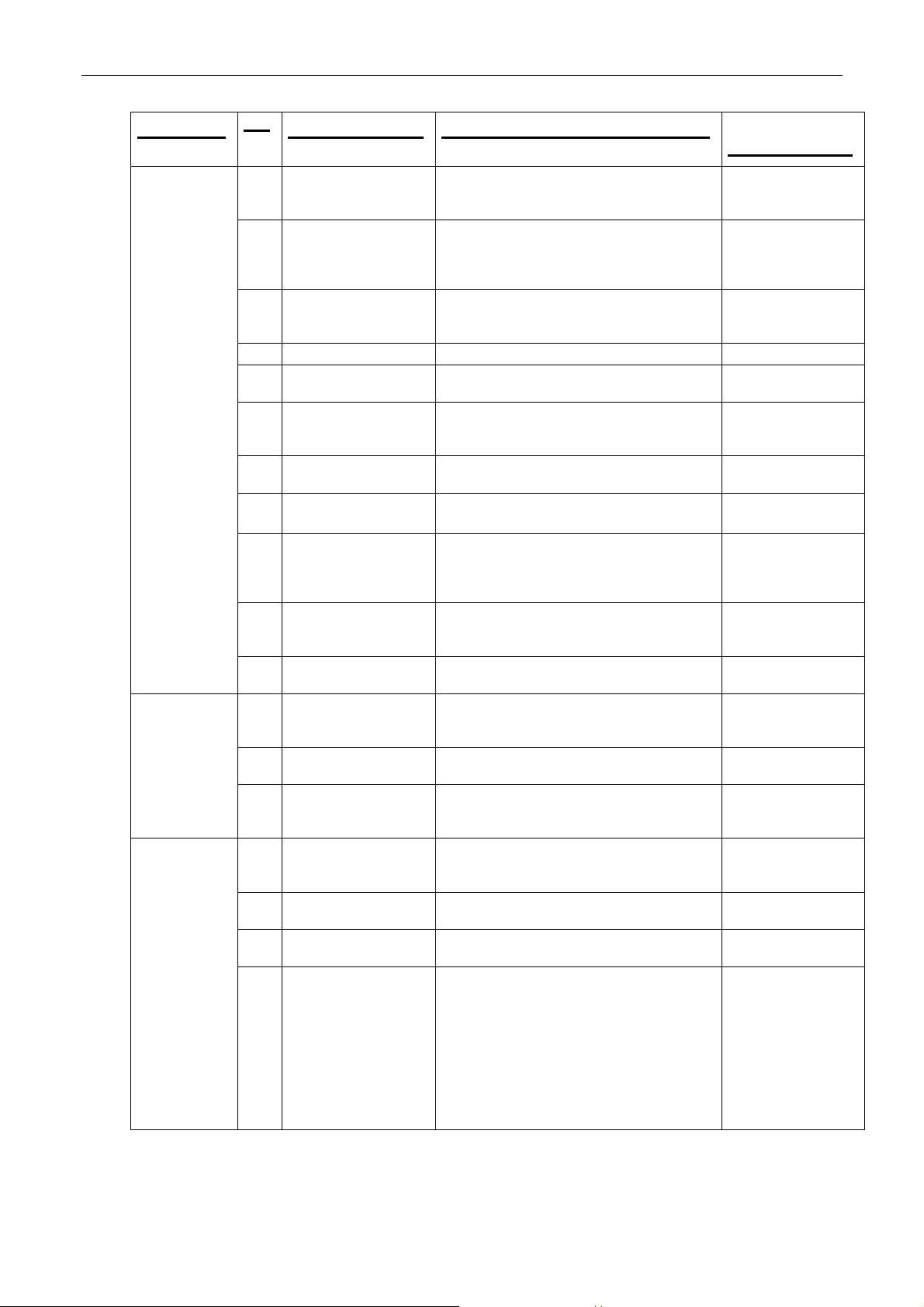

Page 10

Installation Manual

Heading

Chiller and

chiller pipes

(60 mins)

UPS

(10 mins)

Writing head

(30 mins)

HVPS

(40 mins)

Roof

(15 mins)

Utility cabinet

top cover

(15 mins)

Various

components

(45 mins)

3rd Day

Lift ILP,

unwinder,

utility

cabinets, ink

cabinets

(20 mins)

ILP

(120 mins)

Step

Reference Procedure

Notes and

check

28. Installing the chiller

on page 72

29. Install the UPS on

e 75

pag

30. Install the writing

head on page 76

31. Install the HVPS on

page 77

32. Install the HVPS on

page 77

33. install on page 117 Install utility cabinet top cover.

34. Install system

nents on page

compo

80

35. Lift and move the ILP,

unwinder, utility

cabinets, and ink

cabinets on page 80

36. Installing the ILP on

page 81

Install chi

connections.

Install chiller according to specifications.

Refer to the UltraFilter ultracool 0400

installation guide:

Flow rate of 56 ±5 liters/minute

Temperature (measured at the press

Make sure that the external filter supplied

by the supplier is installed. The filter should

be installed at the chiller return pipe.

Connect the cooling water hoses to the

press as shown in Figure 53 and Figure 54

(dep

Install and connect the UPS cables.

Cables to be found in cabinet M1.

Check the installation of all UPS cables

between the electrical cabinet M1, PE1,

and PE2.

Connect the cables to the internal battery.

Remov

Remove under-plate at heater window.

Install and align writing head.

Install HVPS units and covers.

Install roof covers.

Install the foll

PTE/air knife.

Scorotron units.

Cleaning station and wiper blade.

ITM cover.

BID units.

Ametek filters.

Lift the ILP, unw

ink cabinets to the raised platform floor.

Position ILP near PE1. Position ILP feed

and exit stepping plate assemblies near

ILP.

ller pipes adapters and

inlet) of 6°C

ending on country of installation).

e writing head from box 8.

owing in each engine:

Thoroughly clean the BID units.

inder, utility cabinets, and

Hoses from chiller

should be prepared

CA294-03070 rev 00 page 10 of 153

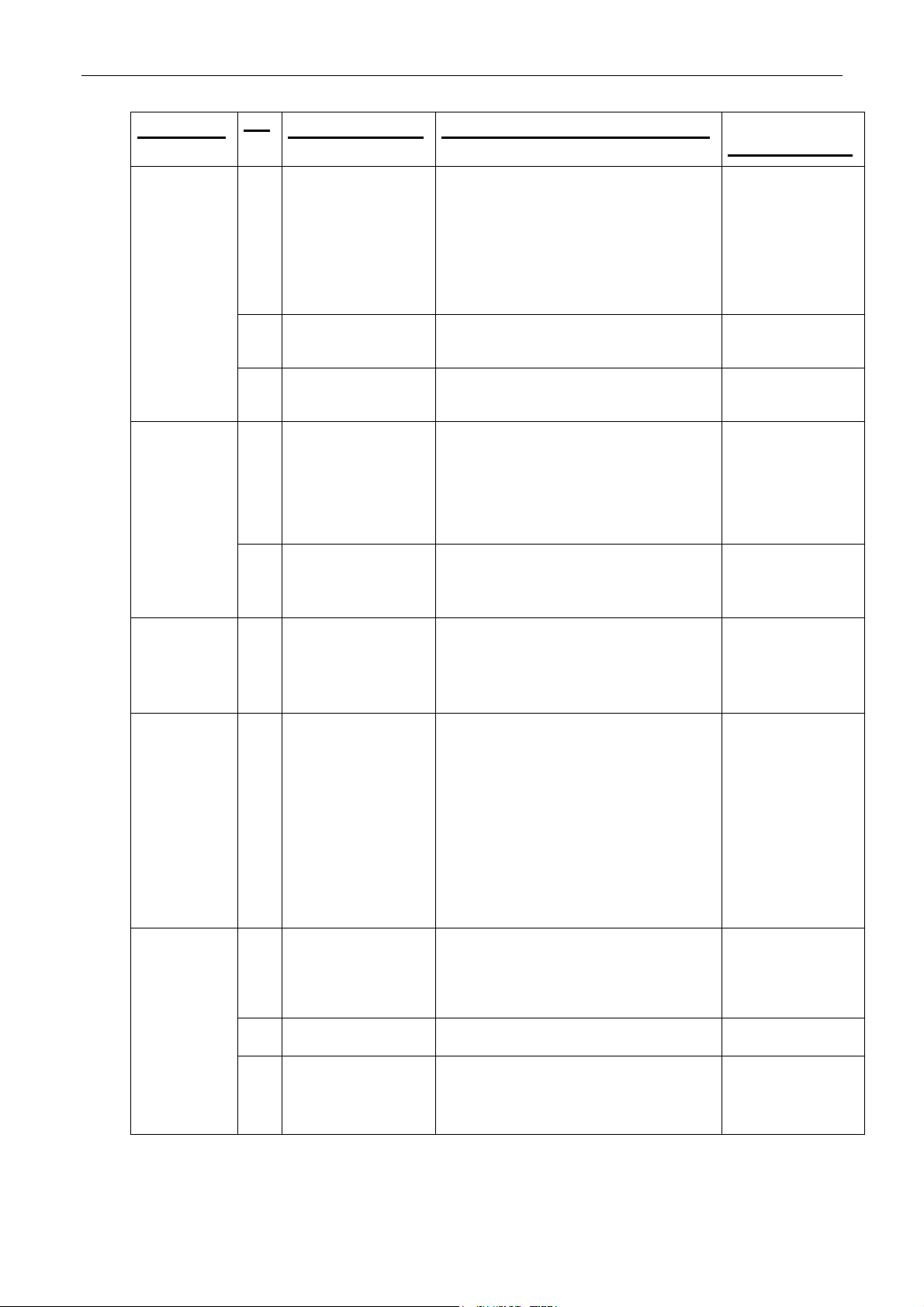

Page 11

Installation Manual

Heading

Unwinder

(60 mins)

ILP wiring and

air hose

connections

(160 mins)

Step

Reference Procedure

Notes and

check

37. install the ILP exit

stepping plate on

pag

e 83

38. align the ILP and

stepping plate

assembly on page 86

39. Measure on page 87 Measure distance between stepping plate

40. Release on page 88 Release (do not remove) six ILP alignment

41. Lower on page 88 Lower four ILP feet until castors

42. level and align the

ILP on page 89

43. align the ILP on page

93

44. level and align the

ILP exit stepping

plate rollers on page

94

45. Install the ILP feed

stepping plate on

pag

e 96

46. install the priming

rollers on page 99

47. Installing the

unwinder on page

100

48. align the unwinder on

page 103

49. Unwinder electrical

conn

ections on page

104

50. ILP electrical

connections on page

105

51. Install on page 105 Install cables between cabinet M1and the

52. Connect on page 105 Connect air hoses and cables to the ILP

53. Install on page 106 Install the cable securing clamps on the

Install the ILP exit stepping plate assembly

to the ILP.

Align the ILP and stepping plate assembly

with the press. Verify gap between ILP exit

cover and web entrance cover at PE1 is

approximately 4-5 mm.

front edge and PE1 front wall. Distance

should measure 30 mm.

plate locking screws.

approximately 5 mm above floor platform

and feet touch floor.

Leve

l the the ILP

Align the ILP using the parallel jig.

Level and align the ILP exit stepping plate

rollers.

Install the ILP feed stepping plate. Align

and level the stepping plate to the ILP.

Install the ILP primin

n, install, level and align the

Positio

unwinder.

Align the unwinder with the ILP feed

stepping plate.

Install an

and air hoses.

Install cab

panel and cabinet M1.

ILP connections panel

connections panel

clamp rail.

d connect all appropriate wiring

les between the ILP connections

g rollers

CA294-03070 rev 00 page 11 of 153

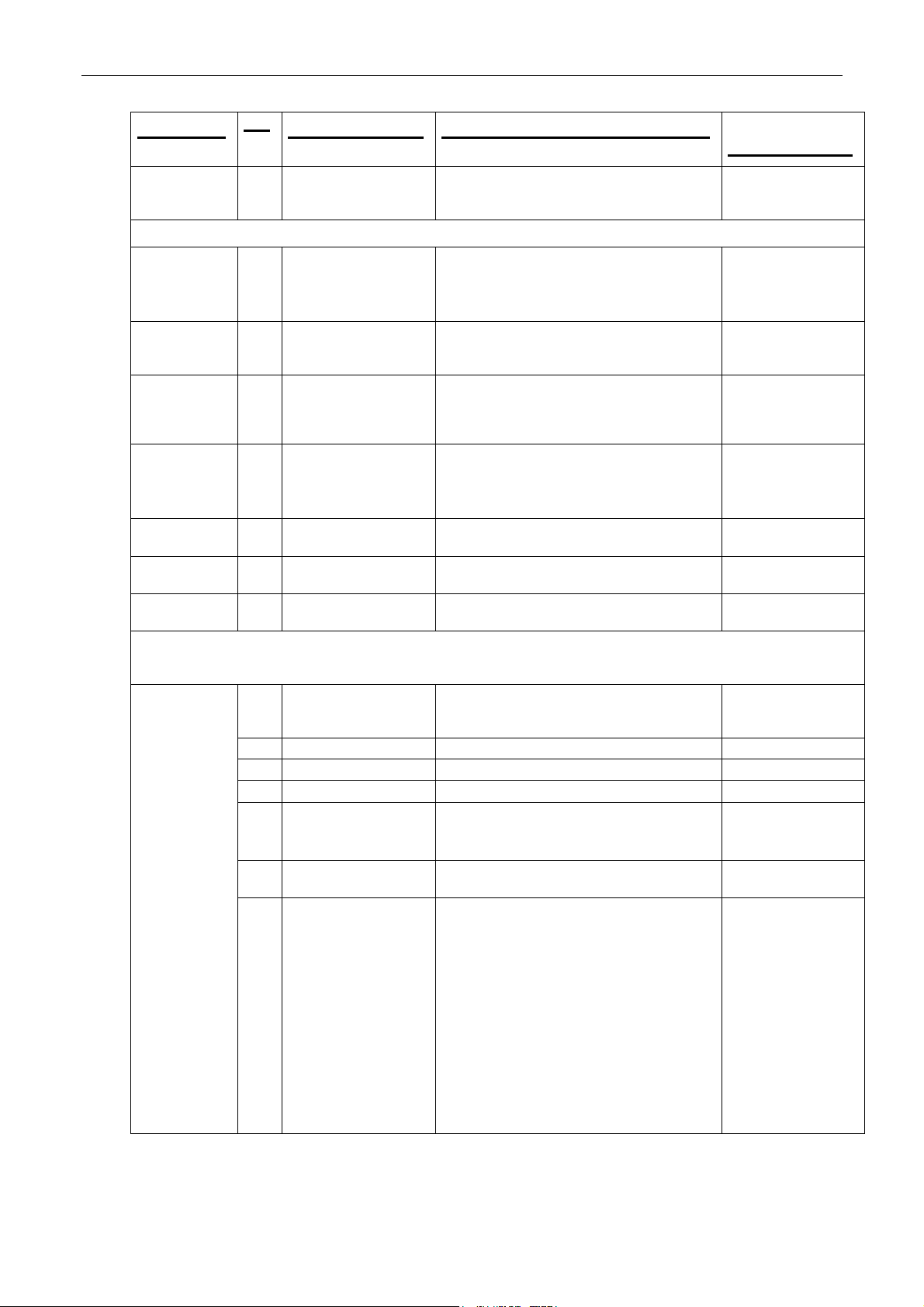

Page 12

Installation Manual

Step

Heading

Ink cabinets

(90 mins)

Web guide

(10 mins)

Utility

cabinets

(20 mins)

Computers

installation

(40 mins)

Reference Procedure

54. Connect on page 108 Connect the following air hoses at the ILP

55. Install the ILP rear

panel safety cover on

e 111

pag

56. Install the ILP

vacuum hoses on

pag

e 112

57. Installing the ink

cabinets on page 113

58. Place on page 116 Mount and install the corian working

59. Adjusting the web

de on page 116

gui

60. Install the utility

net on page 117

cabi

61. Connect the

computers on page

121

62. Install the computer

cables on page 126

63. Install the master

le on page 127

conso

front:

Input hose from mains air supply to

Inlet connection.

Long outlet hose from Outlet to PE

connection to PE1.

Long outlet hose from Outlet to UW

connection to unwinder.

Install safety cover at the ILP front.

Connect the vacuum hose to the ILP.

Install eac

order shown in Figure 93 on page 113 for

four colors, and Figure 94 on page 113 for

seven colors.

If more than four colors to be

make sure that relevant calibration kit is

ordered for extra colors.

surface.

Mount the mo

on working surface.

Remov

adjust the web guide.

Customer to save screws.

To troubleshoot, refer to w3200 service

manual Calibrations.

Install the util

hoses from utility cabinets to the printing

engines.

Cooling water in

Cooling water out

Solid add compressed air

Impression drum cooling drain

Vacuum

Air flow

Connect control cable and power cable to

utility cabinets.

Check the n

Figure 103, and Figure 104 on page 121 -

122.

Install Slav

electrical cabinet M2.

Install the com

computers.

Install master c

master computer.

h ink cabinet according to color

installed,

nitor, keyboard and mouse

e the two securing screws and

ity cabinets and connect

etwork diagrams in Figure 102,

es 1 and 2 computers in

puter cables to both slave

onsole, and connections to

Notes and

check

CA294-03070 rev 00 page 12 of 153

Page 13

Installation Manual

Heading

Production

flow

4th Day

Rewinder jig

and finishing

components

Turnbar

stepping plate

Transformer

Initial

power-up

Thread web

Configure

press

PIP and

blankets

5th Day

ATP

Step

Reference Procedure

64. Production flow on

page 130

65. Install the finishing

components on page

130

66. Installing the turnbar

ng plate on

steppi

e 130

pag

67. Install the main power

conn

ection and

transformer on page

130

68. Initial power-up on

e 131

pag

69. Threading the web on

e 138

pag

70. Configure the press

software on page 139

71. Install PIP and

blankets on page 139

72. Testing and

calibrating the press

on page 139

Emergency stop tests on page 139.

Checking the web flow on page 140.

Checking the ILP priming unit on page 140.

Testing the printing engine on page 141.

Testing printing engine voltages on page

Performing integration and testing on page

Organize and install network cabling, RIP

systems, HPPF units to aid production

flow.

Install the re

After testing, install finishing components

according to customers design and Site

Preparation Guide.

Install turnbar stepping plate.

A local qualified electrician should install

and connect the transformer and electrical

mains power connections.

Perform initial power up as detailed on

page 131.

Local electrician to be present at startup to

check mains power connections.

Mount a roll at unwinder and thread to

finisher according to

Install latest version of press soft

authorization codes.

Mount an

relevant drums.

Test and calibrate press:

In the Diagnostics>Elements Ink Flow

tab perform tests

142.

143:

1.

2. Verify that the ink flows.

3. Verify that the second transfer

4. Install a new blanket and PIP foil.

5. Adjust the BID pressure.

6. Perform the first transfer pressure

7. Verify the writing head skew.

Changing the skew may affect focus.

winder jig to test the press.

ware with

d install PIP and blankets on

Build the inks.

pressure is correct.

calibration.

Notes and

check

CA294-03070 rev 00 page 13 of 153

Page 14

Installation Manual

Heading

Step

Reference Procedure

Notes and

check

8. Verify the writing head focus.

9. Verify the accuracy of the front to

back and side to side prints:

a. Perform the natural web length

calibration for duplex. See HP

Indigo Service Instruction

Calibrations,

MNU-1633-01.

b. Perform the eye mark sensor

vertical positioning. See HP

Indigo Service Instruction

Calibrations, MNU-1633-01.

c. Perform the eye mark sensor

lateral positioning. See HP Indigo

Service Instruction Calibrations,

MNU-1633-01.

d. Perform the eye mark distance to

nip adjustment. See HP Indigo

Service Instruction Calibrations,

MNU-1633-01.

e. Make sure that the substrate is

centered at PE1. Print and check.

f. Make sure that the substrate is

centered at PE2. Print and check.

10. Perform color adjustment using the

paper roll supplied with the press.

If a different substrate is to be

installed on the press, perform the

following:

a. Load glossy paper on the press.

b. From the Adjustments menu,

click Color Adjustment &

Calibration.

The Color Adjustment Wizard

Manager window opens.

c. In the Automatic Color

Adjustment area, click Custom

Color Adjustment.

The Custom Color Adjustment

wizard opens.

d. Select the desired matrix.

e. In the Electrode Voltage

Calibration field, select Include

Velectrode Calibration.

f. Click Next. The OD step opens.

g. In the Select Method of Substrate

OD Usage field, select Read

Substrate OD.

CA294-03070 rev 00 page 14 of 153

Page 15

Installation Manual

Heading

Step

Reference Procedure

Notes and

check

h. Click Next and Print.

The color adjustment is

performed.

Make sure that the wizard

completes all of its steps, and that

all colors pass the color adjust

procedure.

i. Click Finish.

j. Load the desired substrate on the

press.

k. Print the CATP job.

l. In the 9th and 10th copy of the

CATP printout, measure the solid

patches (J area), and calculate

the average values.

Note the values.

m. Change the press software to

technician mode.

n. From the Options menu, click

Systab Editor.

The Systab editor window opens.

o. Expand the mmiCATopic tree.

p. In the right window, double-click

SpecOdLowerDeltaOsm.

The mmiCATopic

SpecOdLowerDeltaOsm window

opens.

q. In the Saved field, type -0.7.

r. Click OK. The window closes.

s. Double-click

SpecOdLowerDelta5.

The mmiCATopic

SpecOdLowerDelta5 window

opens.

t. In the Saved field, type -0.7.

u. Click OK. The window closes.

v. Close the Systab Editor.

w. From the Adjustments menu,

click Color Adjustment &

Calibration.

The Color Adjustment Wizard

Manager window opens.

x. In the Automatic Color

Adjustment area, click Custom

Color Adjustment.

The Custom Color Adjustment

wizard opens.

y. In the Electrode Voltage

Calibration field, make sure that

Include Velectrode Calibration is

not selected.

z. Click Next. The OD step opens.

CA294-03070 rev 00 page 15 of 153

Page 16

Installation Manual

Step

Heading

COI 74. Complete the

Reference Procedure

Testing during normal operation on page

73. CATP on page 145 Perform CATP test procedure:

Printing CATP test on page 147.

Check CATP against CATP specification

installation on page

150

aa. Click Setup.

The Setup OD of 100% Spec

Values window opens.

bb. Enter the optical density values

noted in step l above in the

opriate color fields.

appr

cc. Click OK.

A warning may appear. Click OK

to close the warning.

dd. In the wizard, complete the wizard

steps.

Make sure that the color

calibration is completed

successfully.

ee. From the Diagnostics menu,

click Writing Head.

The Writing Head window opens.

ff. Click the Laser Power tab.

gg. Check that the Laser Power

values do not approach the upper

or lower limits (30 to 1).

If the values are at either

extremity, perform the Machine

LUT Calibration wizard from

Adjustments > Machine LUT

Calibration.

11. If necessary, perform the Machine

LUT using 180 lpi.

145.

checklist on page 147.

Compl

ete installation as detailed on page

150.

Notes and

check

CA294-03070 rev 00 page 16 of 153

Page 17

Installation Manual

General information

How to use this manual

Read the manual carefully prior to installing the press. This manual is intended to guide the CE

throughout the installation of the press.

The packing list in the boxes takes priority over the list in this manual. Check off parts against the

packing list in the boxes.

The Quick Reference Installation Guide at the end of the document is intended to provide the

experienced installer with reminders of the key steps and information.

Packing list

The table below lists the main contents of each box. The full contents list provided with the boxes

takes priority over this table.

Box no.

1

2

3 MPQ-0620-51 U-base assembly 2 U-base

4

5

6 CA290-0523X Vacuum hose pipes kit for

7

Part number Contents Qty Name and weight (kg)

CA254-01592

CA294-03070

CA254-00322

CA271-00263

EBC-3005-01

CA290-05140

MPQ-0024-33

MSQ-0017-02

MJX-2427-51

MZH-0328-02

CA290-05130

MPQ-0024-33

MSQ-0017-02

MZH-0328-02

MPT-3515-54

MPT-8636-51

EAS-2041-52

MPT-2609-55

MKT-3354-02

MPT-6787-53

MPQ-0028-01

MZH-0333-06

MPT-7387-52

WHS electrical cabinet M1b

Keys

Installation Manual

WHS electrical cabinet M2b

Keys

Computer Slave #1 and #2

Network Ethernet SW1

Printing engine 2 (PE2)

Working surface

Leveler 75x150-55 Airloc

Fixing bracket assembly

Pipe Insulation 1-1/8”

Printing engine 1 (PE1)

Working surface

Leveler 75x150-55 Airloc

Exit inverter roller

Pipe Insulation 1-1/8”

w3250

Back right cover assy

Roof top cover assy

HVPS assy

Utility cabinet

Kit ink cabinet- s3200

Cover t4

Cover guide closure (stage)

Pipe flex od-1+5/16

Bottom cover for pub

1

3

1

1

4

2

2

1

1

4

2

1

1

1

4

1

1

1 Vacuum pipes kit for w3250

1

1

2

1

1

2

1

2

1

Electric Cabinet

Electric Cabinet

PE2 engine

PE1 engine

Miscellaneous PE2

CA294-03070 rev 00 page 17 of 153

Page 18

Installation Manual

Box no.

8

9

10

11

12

Part number Contents Qty Name and weight (kg)

CA245-15320

CA290-00121

CA245-00132

CA245-00332

MPT-3989-51

CA245-09891

MPT-3515-54

MPT-8636-51

MPT-2609-55

MKT-3354-02

CA270-00101

CA290-06290

CA290-05260

CA297-00350

MPK-3072-05

MPQ-0028-01

CA244-05941

CA245-08182

CA245-08352

CA245-01234

CA240-47210

CA245-16791

CA245-04963

5188-1250

CA240-60860

5188-4872

PX848AA#ABB

MPT-7383-53

CA271-00263

DD817AV

MPT-7646-32

EHE-4069-51

CA261-07420

CA248-00230

DD837AV

SRO-0070-01

MNU-1050-82

EMS-2008-81

CA290-05580

Air Knife

Kit S/P Cleaning station and

wiper

Scorotron

BID unit

Filter box assembly

Arms, Cover holder assembly

Back right cover assembly

Roof top assembly

Utility cabinet

Kit ink cabinet

Writing head assembly for u\s

Kit acc. Installation For w3250

Kit access for w3250

Sp UPS w/extension cables

Skid pallet

Cover guide closure (stage)

Keyboard & mouse

Screws M8x40, flat

Washers, Spring Washers

Cover for left ramp

Left ramp assembly – ILP

Right ramp assembly -ILP

ILP

Air pipe black dia.=12

Upper rubber roller assy

ILP, lower roller assy

UW6 - Unwinder for w3250

Pipe air 8mm

Panel front

Perspex covers for uw6

Feed roller

Unwinder book

Monitor

Console assy

Emergency stop panel

Computer

Keyboard ps/2 hp

Working surface master

console

Cable assy cc69

Cable assy cc70

PC software kit

Mouse PS/2 HP

Siemens software

Machine system info

Mouse pad

Kit S/W 6.7 w3250

1

2

6

8

2

2

1

1

1

1

2

1

1

2

1

1

2

8 of

each

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

3

1

Miscellaneous PE1

Ramp

ILP

Unwinder

Master Console

CA294-03070 rev 00 page 18 of 153

Page 19

Installation Manual

Box no.

13 Q5391-00680 Kit cons. Instl. W3250 1 Consumables kit

14 MPR-1309-11 Pap. Roll condat 115 1 Paper roll condat 115

Part number Contents Qty Name and weight (kg)

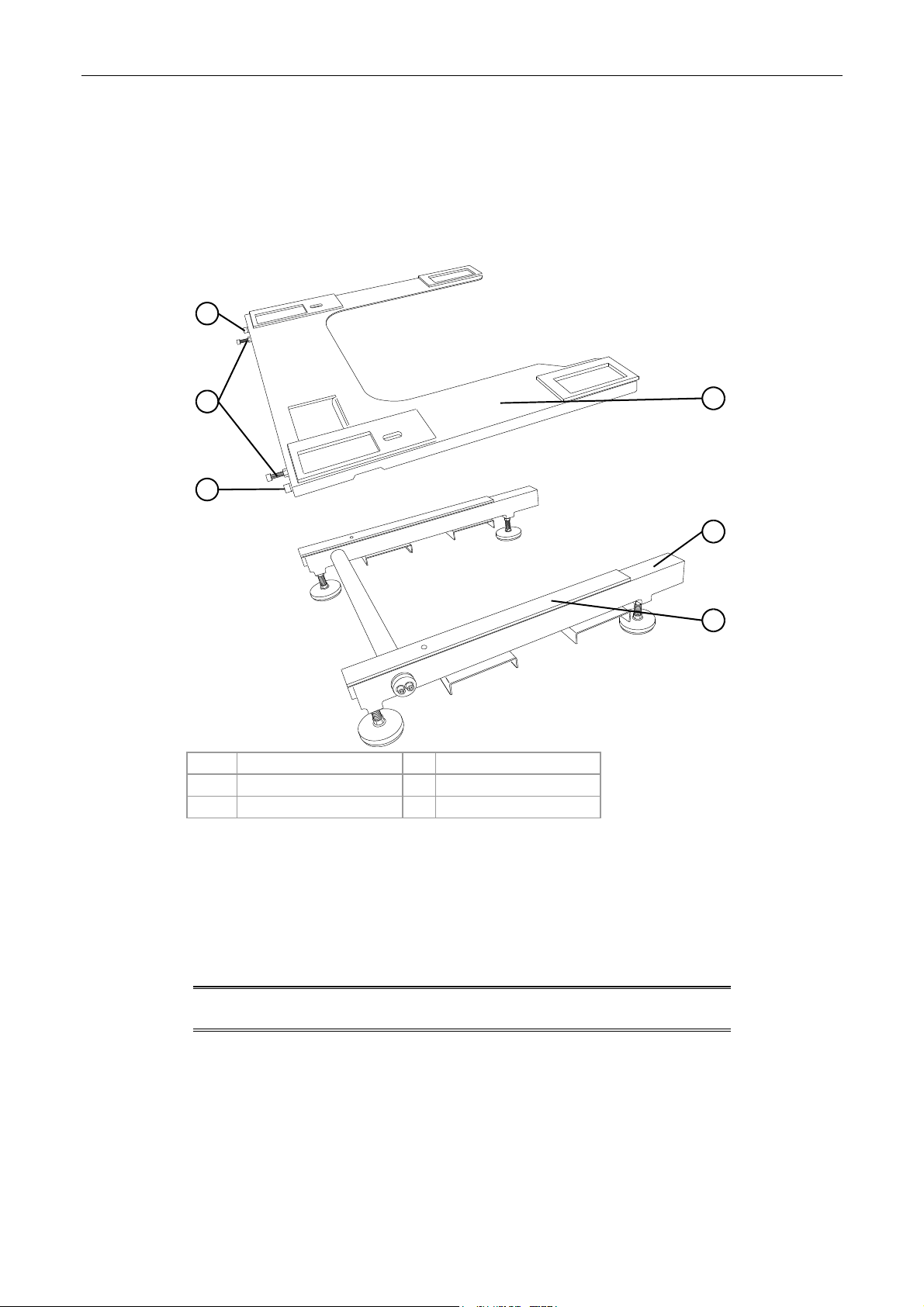

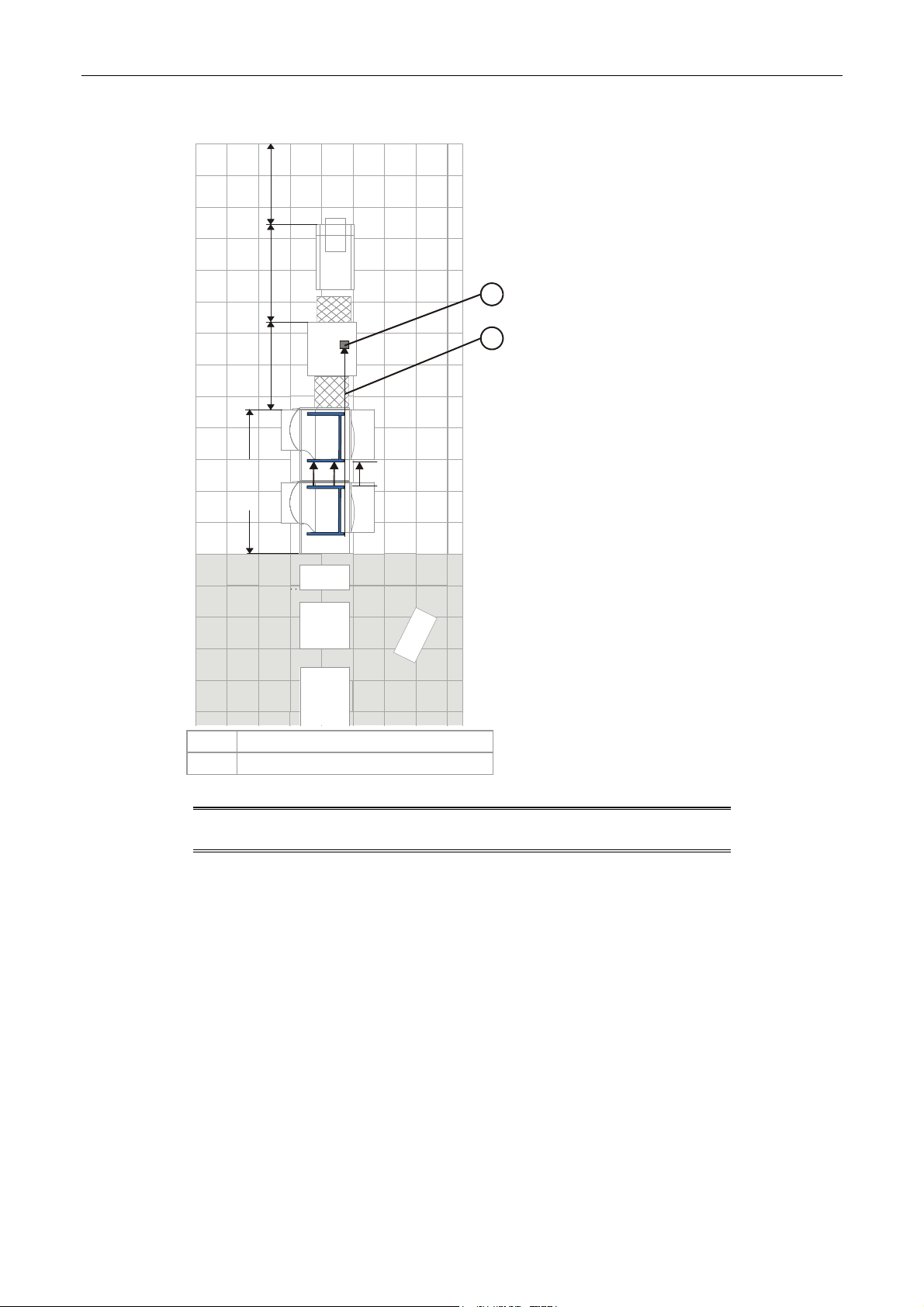

The alignment jig

Figure 2 The alignment jig

Figure 3 The alignment jigs mounted

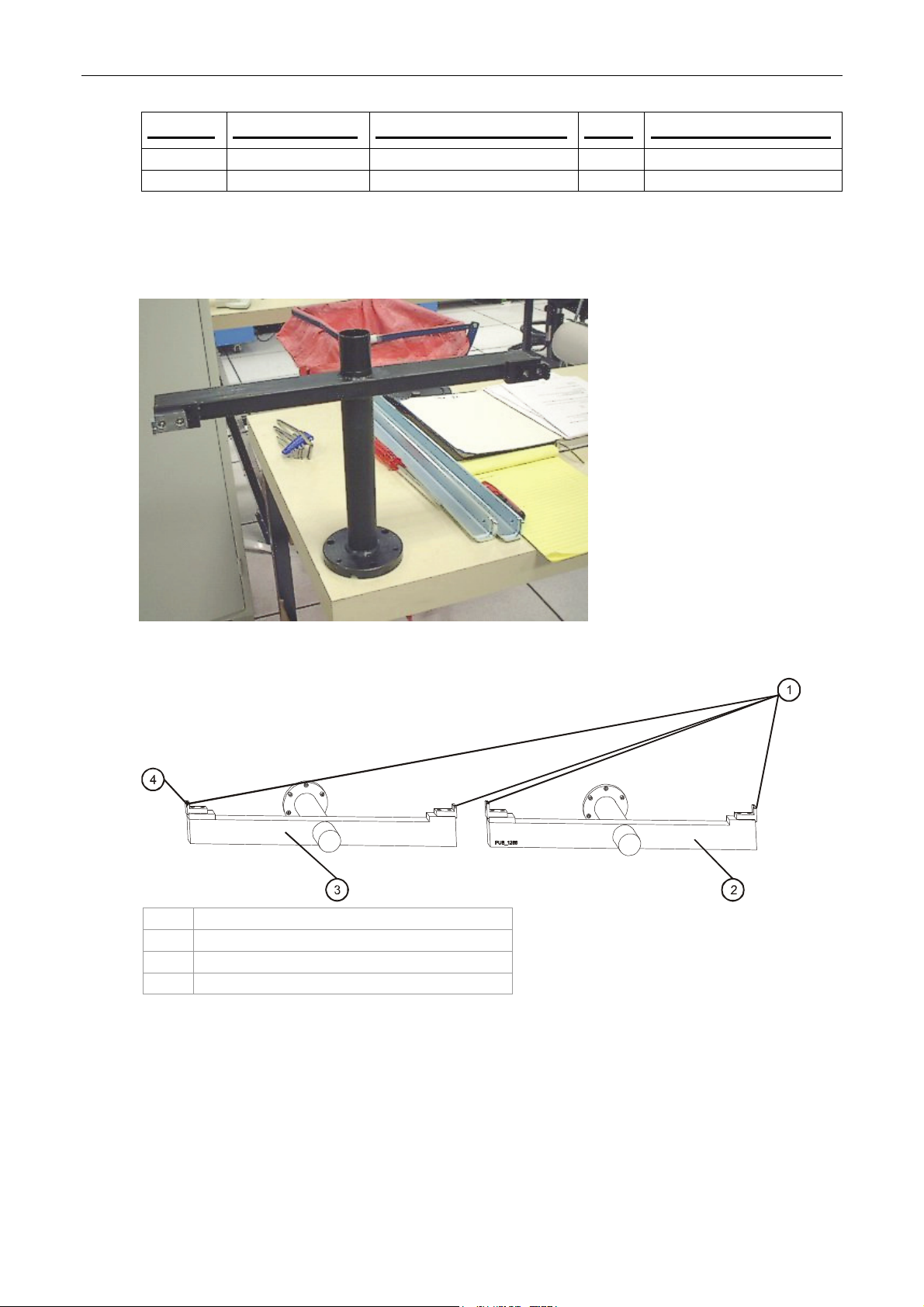

1 Sights increasing in height from PE1 to PE2

2 PE1 jig

3 PE2 jig

4 Highest sight

Alignment jigs are used to adjust the forward/rearward alignment of the printing engines.

The jigs are used with a surveying tool (scope). They are not identical. When mounted properly, the

sights on the jigs increase in height going from PE1 to PE2. The increase in height allows all the sites

to be visible in the surveying tool. Adjustments can then be made to the position of the printing

CA294-03070 rev 00 page 19 of 153

Page 20

Installation Manual

engines until all the sights are lined up with the crosshairs in the surveying tool (Figure 2 and

Figure 3).

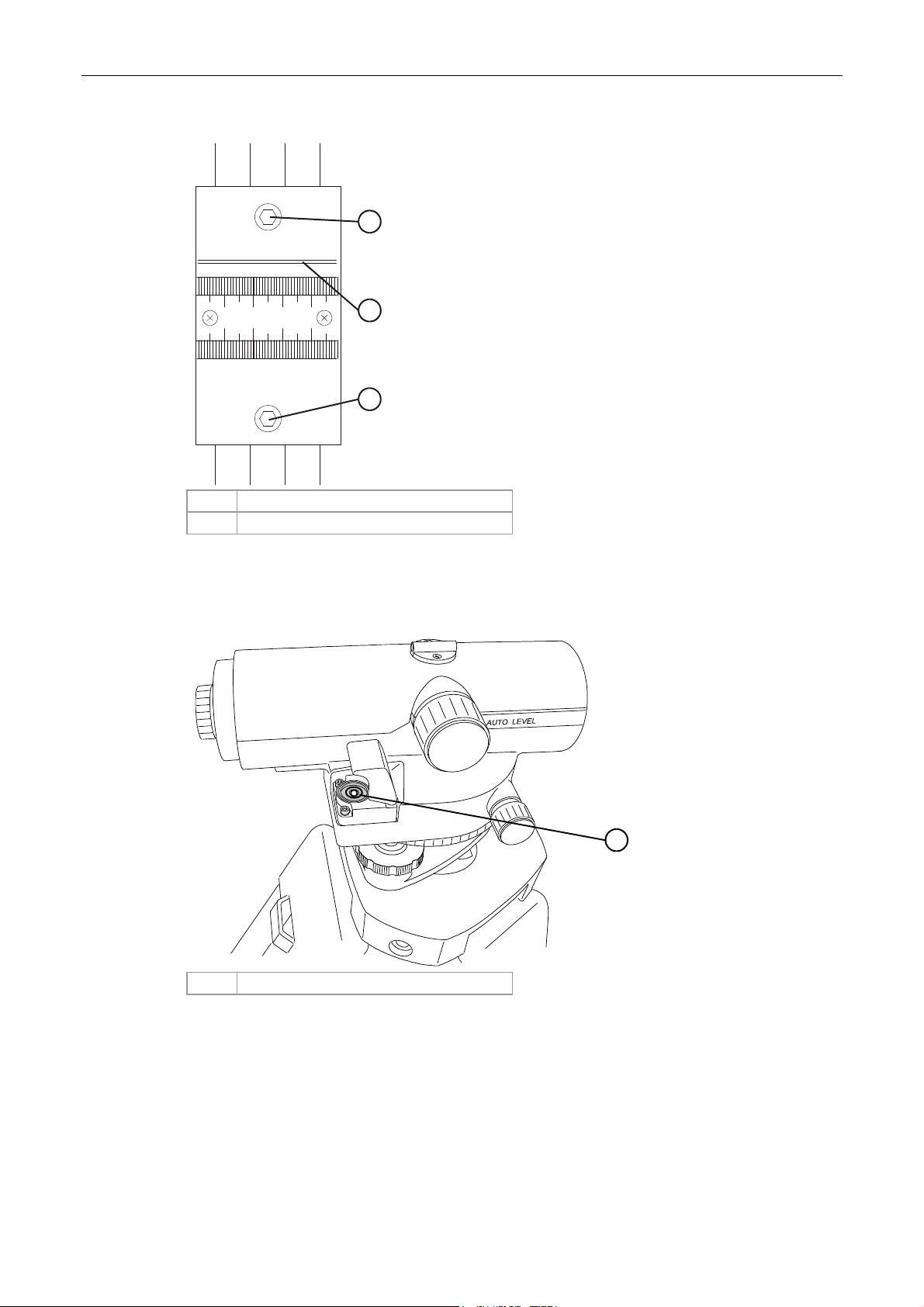

The parallel jig

The Parallel jig measures the variation in distance (parallel) along the length of two rollers. It is used

to accommodate the various adjustments necessary to bring the rollers of all the press components

(printing engines, ILP, unwinder) into parallel with the rollers of the adjacent one. Adjustments can

then be made to the press component position until the variation in distance is either zero or minimal.

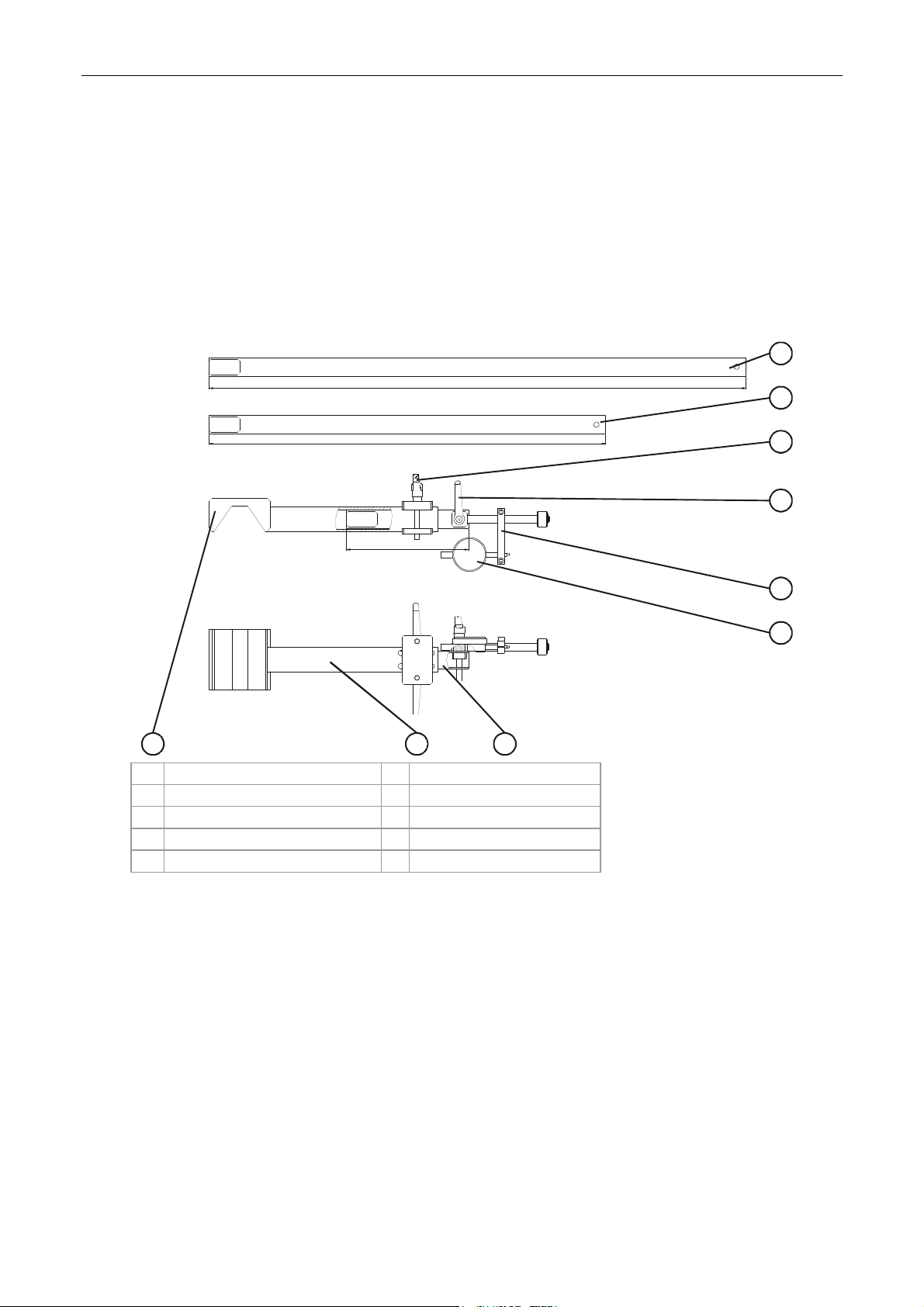

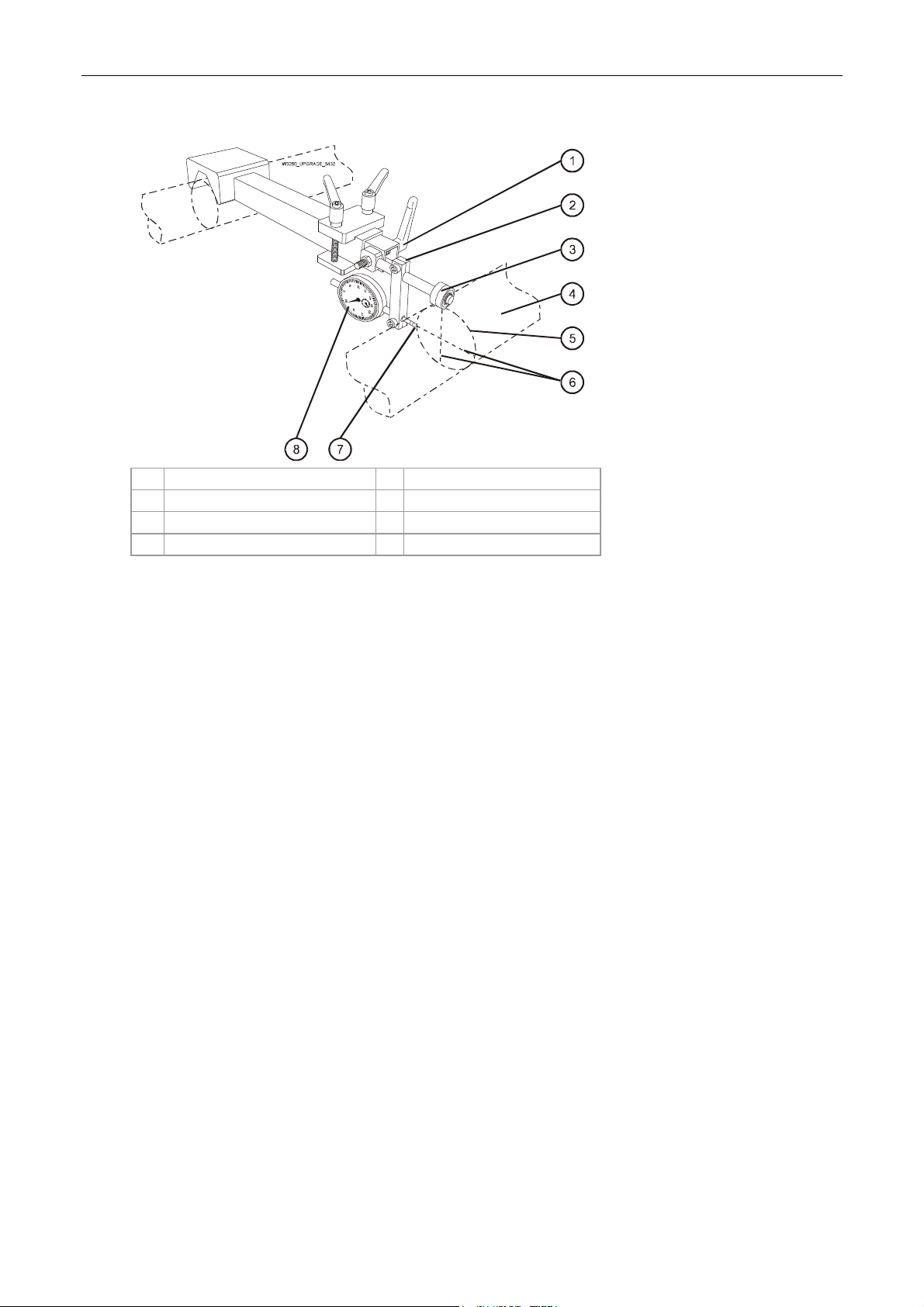

Figure 4 Sections of the new Parallel jig

880

650

200

9

1 880 mm long extension 6 Dial

2 650 mm medium extension 7 Base

3 Extension securing screw 8 200 mm short extension

4 Dial bracket securing screw 9 V-section

5 Dial bracket

87

1

2

3

4

5

6

The jig may be extended between rollers of distances using the three extensions which are attached

to the base. The v-section is suitable for rollers of diameter 50 - 79 mm, whereas the dial bracket,

buffer and dial are suitable for rollers 79 - 80 mm in diameter (Figure 4).

The long

•

configuration is used to make the following alignments (Figure 4):

To align the ILP to PE1

• To align the unwinder to the ILP

The intermediate configuration is used to make the following alignments (Figure 4):

•

To align one of the rollers in the exit-side stepping plate of the ILP to PE1

• To align one of the rollers in the input-side stepping plate of the ILP to the ILP itself

CA294-03070 rev 00 page 20 of 153

Page 21

Installation Manual

The short configuration is used to align the remaining roller in each stepping plate to its companion

roller aligned previously (Figure 4).

To assem

1.

ble the new Parallel jig to align two rollers (Figure 4):

Insert the measuring gauge fixture into the desired extension (long, intermediate, short).

Tighten the handle.

2. Insert the extension into the base so that the V-section and the gauge are facing the same

direction.

Tighten the two handles to secure the extension.

NOTE: Disassembly is the reverse of the above two steps.

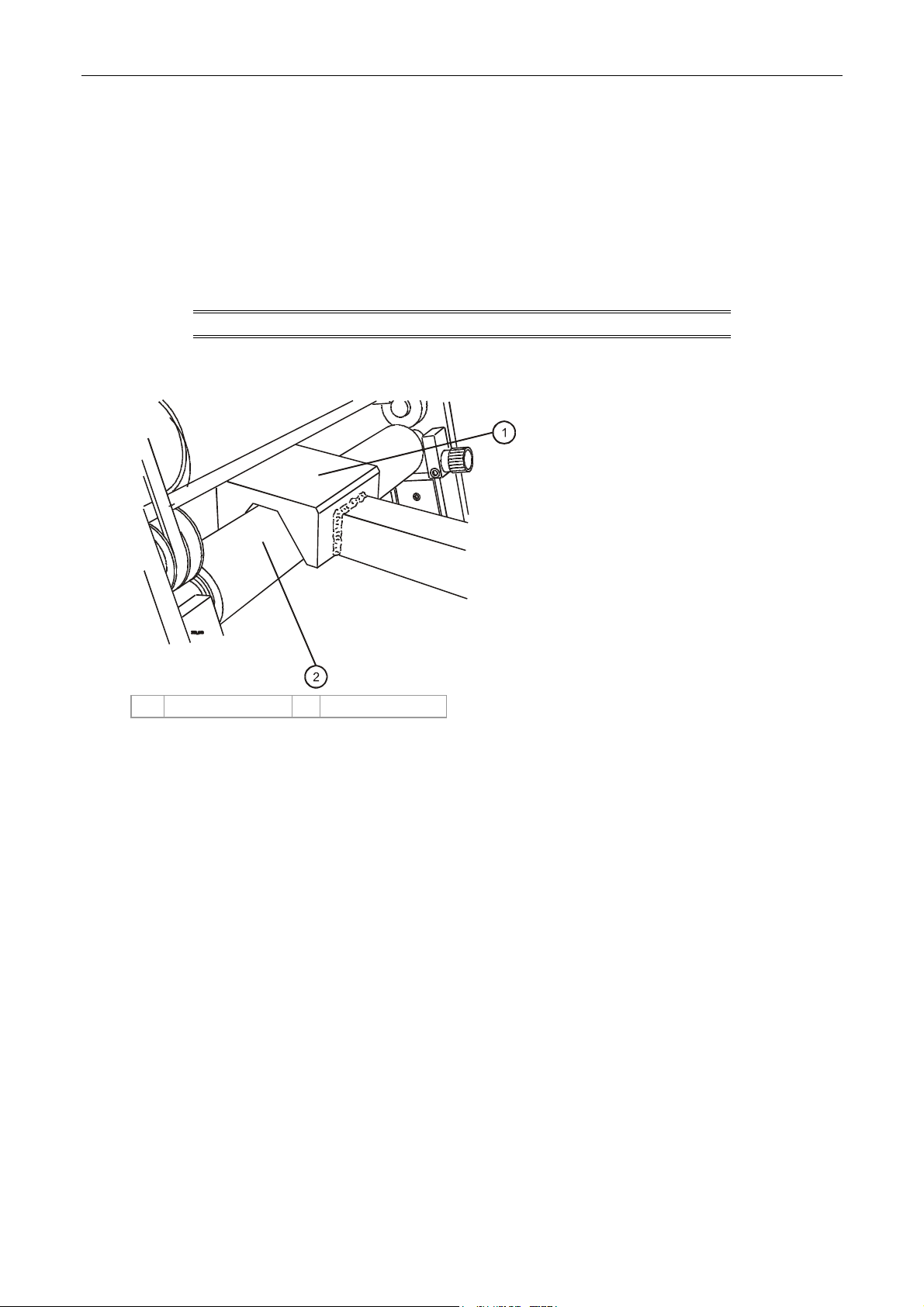

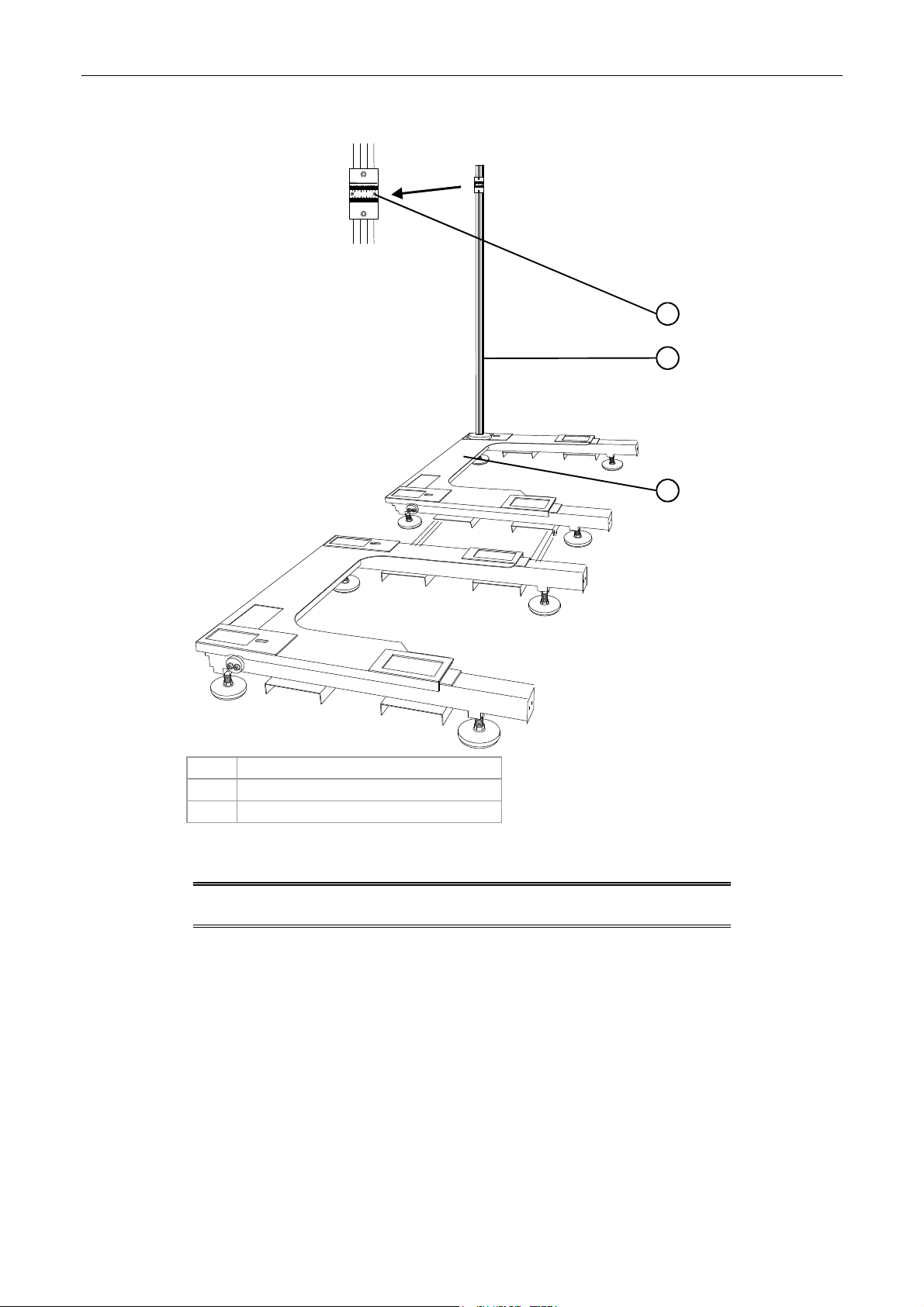

Figure 5 Mounting the v-section of the Parallel jig

1 Base v-section 2 Roller

3. Mount the v-section on the first roller (Figure 5).

Make sure that the extension reaches the second roller and tighten the extension securing

screws.

CA294-03070 rev 00 page 21 of 153

Page 22

Installation Manual

Figure 6 Mounting the dial bracket on the extension

1 Dial bracket securing screw 5 Positioning circle

2 Dial bracket 6 Center lines of roller

3 Buffer 7 Position of dial sensor tip

4 Roller 8 Dial

4. Mount the gauged end of the jig on the specified roller needing to be aligned.

5. Loosen the screw securing the gauge support on the fixture, and slide it back so it does not

interfere with placing the wheel.

6. Loosen the lock nut for the handle securing the gauge fixture in the extension.

7. Adjust the position of the gauge fixture in the extension so that the wheel rests on the roller

and coincides with the vertical centerline of the roller.

Tighten the handle and the lock nut.

8. Slide the gauge support back until the contact touches the roller.

Continue sliding the gauge until the needle makes one complete turn.

Tighten the screw to secure the gauge support in place.

Prerequisites

Completion of site preparation.

Estimated installation time

4 days

Special skills

Only specially trained personnel should perform this installation.

Special jigs and tools

All special jigs and tools required for the installation of the press are included in the installation kit.

Confirm the contents of the installation kit with the Bill of Materials (BOM).

CA294-03070 rev 00 page 22 of 153

Page 23

Installation Manual

Pre-installation procedure

Verifying site preparation

Verify that the pressroom has been equipped with the following per the HP Indigo press w3250 site

preparation guide:

Chiller input and output

Power for press

Air conditioning of work area

Fast Ethernet networking

Parts cleaning station

External densitometer

Lockable main switch

Electrical outlets installed near pluggable equipment and are easily accessible

The printing engines may be mounted on the u-bases on-site or off-site. Make sure that the entrance

to the site is large enough to allow an object 2200 mm high to enter.

Marking the pressroom floor for press components

1. Open the installation kit and select the marking pen.

2. Use the marking pen to mark the pressroom floor with the profile of the main press

components and indicate their placement. Refer to the HP Indigo press w3250 site

preparation guide for details of the floor area.

Unpacking the boxes

1. Before opening the boxes, check that the shock and tilt sensors have not changed color to

red. If either of the sensors has changed color to red, then the boxes were mishandled. Notify

the Regional Service Manager or Installation Manager immediately.

2. Unpack the box containing the accessories kit.

Open the accessories kit, and remove the System Information File.

Remove the customer letter about residual ink (P/N SV8-0039-00) from the System

Information File.

3. Give the letter to the customer.

4. The boxes are opened in the order of installation. At each stage of the installation open each

box carefully and inspect the part for damage before installing. If any part shows signs of

damage, immediately notify the Response Center or Regional Service Manger.

Verify the contents of each box according to the contents list included with the boxes.

5. Notify the Regional Manager or Installation Manager regarding any installation problems or

damage found when unpacking the boxes.

CA294-03070 rev 00 page 23 of 153

Page 24

Installation Manual

Procedure

NOTE: Two persons are required for this installation.

Installing the electrical cabinets

1. Place electrical cabinet M1 and electrical cabinet M2 in their positions.

2. If any of the finishing components include electrical cabinets, position that cabinet opposite its

corresponding finishing component and in line with the main electrical cabinets.

Installing the printing engines

Positioning the printing engines

1. Position the u-bases as follows

a. Unpack the u-bases and loosen the front two securing screws to remove the u-base

slip plates.

Place the slip plates aside for later use.

CA294-03070 rev 00 page 24 of 153

Page 25

Installation Manual

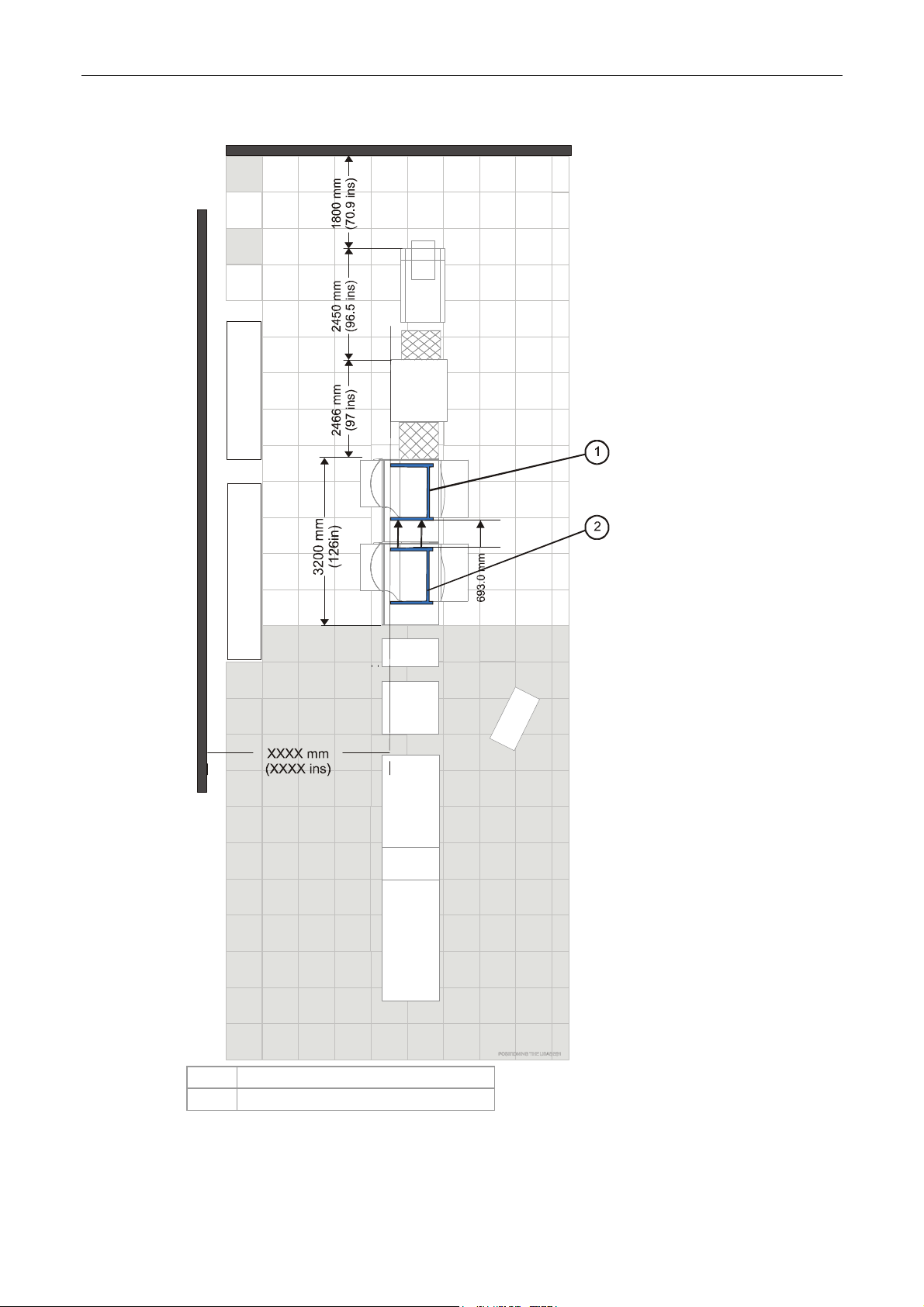

Figure 7 Positioning the u-bases

1 PE1 u-base

2 PE2 u-base

CA294-03070 rev 00 page 25 of 153

Page 26

Installation Manual

b. Lay the u-bases on the floor at a distance of 6716 mm (1800+2450+2466 mm

(264.4 ins)) from the wall at the unwinder end and at a distance of 693.0 mm

(27.3 ins) apart (Figure 7).

. Measure a distance of XXX mm (XXX ins) from the rear of the u-base to the wall at

c

the electrical cabinets.

Figure 8 Remounting the u-base slip plates

4

5

4

1 U-base slip plate 4 Securing screws (2)

2 U-base 5 Adjustment screws

3 Grease applied here

1

2

3

d. Remount the u-base slip plates on the u-bases (Figure 8).

Grease the u-bases before mounting the u-base slip plates.

The grease facilitates easy adjustment during the aligning procedure.

e. Secure the slip plates with the outer screws.

NOTE: The inner screws are for adjusting. They move the slip plate

from front to rear a total of 10.0 mm.

CA294-03070 rev 00 page 26 of 153

Page 27

Installation Manual

Figure 9 Adjusting the u-base height

1

2

3

4

1 U-base

2 U-base slip plate

3 Height of 200.00 mm

4 Height adjustment screw

f. Adjust the u-base feet to give a height of 200.0 mm from the floor to the u-base top

side (Figure 9).

CA294-03070 rev 00 page 27 of 153

Page 28

Installation Manual

Figure 10 Placing the foresight on the PE2 u-base

5

1 12 23 34 45

0.5 mm

0.5 mm

1

2

3

PUB_1596

1 Sight

2 Foresight stand

3 PE2 u-base

g. Position the foresight stand on the PE2 u-base at the front left corner (Figure 10).

NOTE

: The initial position of the foresight stand is used as the

reference for leveling both u-bases.

CA294-03070 rev 00 page 28 of 153

Page 29

Installation Manual

Figure 11 Setting up the surveying tool

XXX

1

2

(125in)

3175 mm

693.0 mm

1 Position of surveying tool

2 Surveying line

NOTE: The surveying tool is setup on its tripod in accordance with

its instruction manual at the position shown in Figure 11.

h. Raise the height of the tripod and surveying tool to 1550.0 mm.

CA294-03070 rev 00 page 29 of 153

Page 30

Installation Manual

Figure 12 Focusing the surveying tool on the foresight stand target

1

2

1234

0.5 mm

5

1

1 Height adjustment screws

2 Crosshair target

i. Position the surveying tool facing and parallel to the foresight stand (Figure 12).

Figure 13 L

1 Level bubble

eveling the surveying tool

PUB_1346

1

j. Adjust the level of the surveying tool until the bubble is centered in the level

(Figure 13).

k.

Focus the surveying tool so that the cross target on the foresight is clearly seen and

centered with the crosshairs of the surveying tool (Figure 11).

If necessary, adjust the height of the cross target on the foresight stand.

CA294-03070 rev 00 page 30 of 153

Page 31

Installation Manual

l. Tighten the lock nut to secure the height of the u-base foot at that corner.

m. Move the foresight stand to the next corner facing the surveying tool.

Adjust the height of the u-base foot at this corner so that the foresight cross target is

centered in the crosshairs of the surveying tool.

n. Repeat step m for all the corners of the u-bases.

Tighten the u-base foot lock nuts at each corner after it is leveled.

o. Recheck all the corners to confirm the heights. Re-adjust if necessary.

p. Use a marker pen to mark the position of the u-base feet on the floor.

Figure 14 Loosening the u-base connecting rods

1

PUB_455

1 Connecting rod

q. Loosen the four screws securing the connecting rod of each u-base (Figure 14).

Figure 15 Installing the j

unction bars between the u-bases

1

2

3

4

1 Junction bars 3 Junction bar securing screws

2 PE1 u-base 4 PE2 u-base

CA294-03070 rev 00 page 31 of 153

Page 32

Installation Manual

r. Install the junction bars (P/N MJX-1852-01) between the two u-bases using two M6

Allen screws, spring washers and flat washers to secure each bar (Figure 15).

NOTE: Make sure to mount each PE to the correct u-base. PE1 has

The lifting jig should only be used if a forklift is either

The distance between the u-bases is now fixed at 693.0 mm.

a web feed door. PE2 has a web exit door.

unavailable or the site does not allow entry to a forklift.

CAUTION: Each section of the lifting jig has a diagram label

describing the position of the section when lifting

the press. Use each specific section in its correct

position as labeled.

Make sure to adhere to all the safety warnings

labeled on the lifting jig. The lifting jig should only

be used on horizontal surfaces and the maximum

lifting weight for the jig is 1800 Kg.

CA294-03070 rev 00 page 32 of 153

Page 33

Installation Manual

Figure 16 Removing the front exit service door

1 Remove these screws

2 Door lower hinge

3 Front exit service door

2. Mount the PE2 on the u-base as follows:

At PE2

a. Remove the three screws securing the upper shaft of the front exit service door

frame.

b. Remove the door by lifting it out of its frame.

CA294-03070 rev 00 page 33 of 153

Page 34

Installation Manual

c. Remove the three screws securing the front exit door lower hinge (Figure 16).

Keep the hinge and screws for later reinstallation.

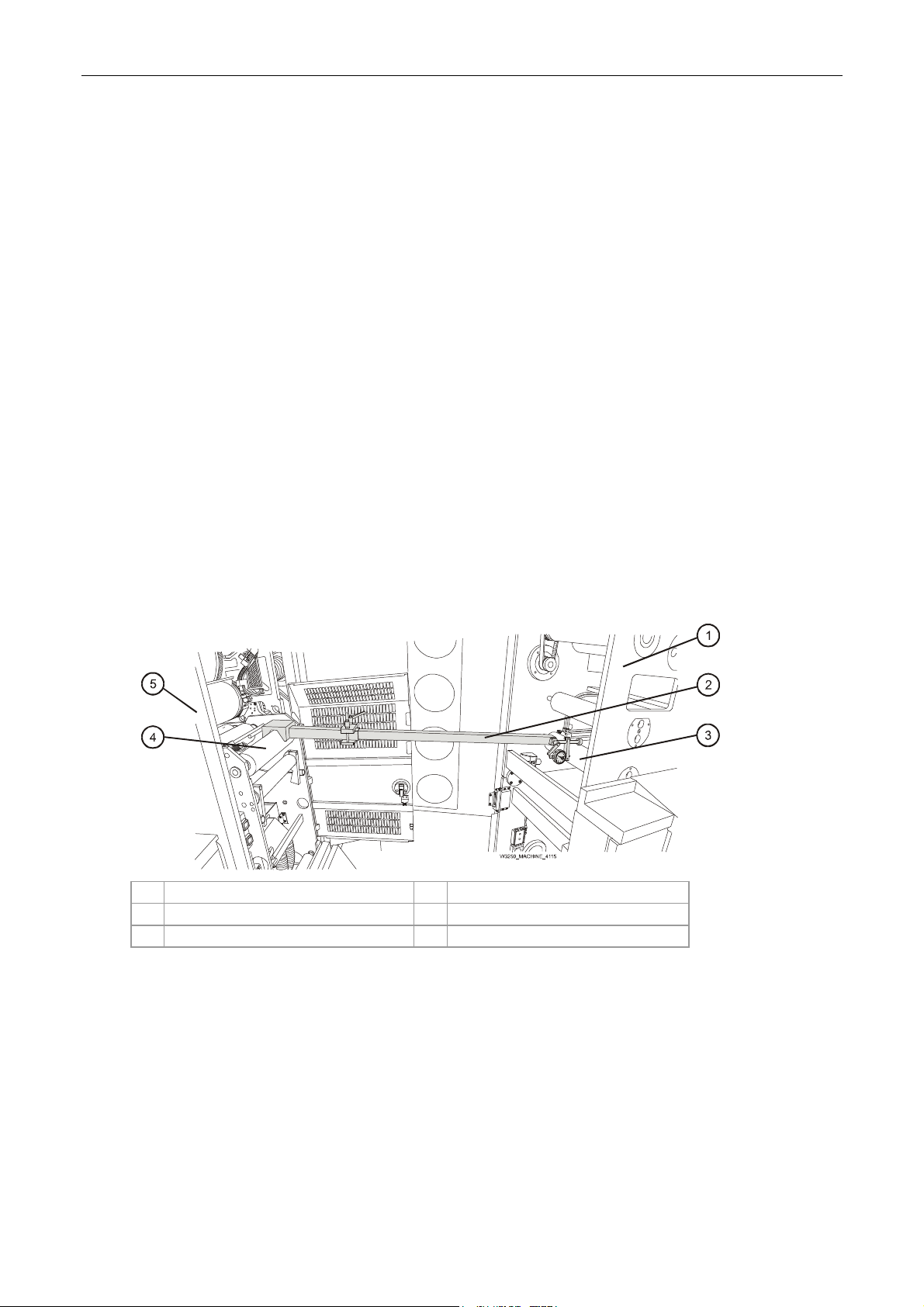

Figure 17 The lifting and positioning assembly

1 Orientation labels 6 Link bar

2 Support wedges 7 Maximum lifting weight label

3 Pneumatic gun connector /adapter for wheel jack 8 CE label

4 Wheel jack 9 Support wedges

5 Warning label

For use on horizontal surfaces only

CAUTION: Do not use a pneumatic gun to raise or lower the

wheel jack.

CA294-03070 rev 00 page 34 of 153

Page 35

Installation Manual

Figure 18 Positioning the link bar under the feed side

1 Engine rear 4 Positioning label

2 Base frame 5 Feed link bar

3 Support wedges

d. Position the feed link bar under the base frame (Figure 18).

Make sure to insert the support wedges under the engine feed base frame.

CA294-03070 rev 00 page 35 of 153

Page 36

Installation Manual

Figure 19 Positioning the link bar under the exit side of the engine - view from rear

1 Rear electronic cabinet door 5 Support wedge

2 Support wedge 6 Exit link bar

3 Positioning label 7 Exit base frame

4 Rear engine frame

e. Fully open the rear electronic cabinet door (Figure 19).

f.

Position the exit link bar under the exit engine frame (Figure 19).

Make sure to insert the support wedges under the exit base frame (Figure 19).

CA294-03070 rev 00 page 36 of 153

Page 37

Installation Manual

Figure 20 Positioning the lifting frames against the engine

1 Engine frame 5 Metal securing peg

2 Rear lifting frame 6 Lifting frame slot securing end of exit link

bar.

3 Front lifting frame 7 Metal securing peg

4 Lifting frame slot securing end of feed link bar

g. Position the front and rear lifting frames against the engine so that the feed and exit

link bars are inserted in the lifting frame slots (Figure 20).

h.

Make sure that the link bars are inserted sufficiently to the lifting frame slots so that

metal securing pegs can be fully inserted to the holes between the link bars and the

lifting frames.

i. Insert the metal securing pegs to the holes between the link bars and the lifting

frames.

j. Turn each wheel jack (Figure 17) at the four corners of the lifting frames an equal

numbe

r of turns, in steps of 3-4 turns, to raise the engine 20 cm.

This will allow mounting of the engine on the u-base (Figure 17).

CAUTION: Do not tilt the press, as this could cause the press

to fall and become damaged.

CA294-03070 rev 00 page 37 of 153

Page 38

Installation Manual

Figure 21 Leveling pad

1 Pad 3 Allen M10 screw

2 Default height adjustment wedge position 4 Height adjustment wedge

Figure 22 Placing the leveling pads on the u-base

1 Leveling pad slots 4 Leveling pad slots

2 U-base cover 5 Leveling pads

3 Allen M10 height adjustment screw 6

k. Mount four leveling pads (Figure 21) at the four corner slots of the u-base (Figure 22).

Make sure that the pads are mounted centrally on the slotted areas of the u-base

cover as shown in Figure 22.

CA294-03070 rev 00 page 38 of 153

Page 39

Installation Manual

The Allen M10 height adjustment screw (Figure 21) should be facing towards the

outer si

des of the press for easy access.

l. Make sure that the leveling pads are at their default height (Figure 21-4).

If not use an Allen M10 key to lower or raise the height adjustment wedges to their

default level (Figure 21).

Figure 23 M

oving the raised engine to the u-base

1 Front lifting frame 3 Leveling pads

2 U-base 4 Direction of lifting jig and engine over u-base

CA294-03070 rev 00 page 39 of 153

Page 40

Installation Manual

Figure 24 Press positioned over u-base

1 Feed base frame underside slot 4 Feed base frame underside slot

2 Leveling pad 5 Leveling pads

3 U-base 6 Exit base frame underside slot

m. Carefully move the lifting jig and press over the u-base until the feed and exit base

frame underside slots (Figure 30) are aligned correctly with the top surfaces of the

leveling pad

If necessary, move the u-base to correctly align the underside slots with the leveling

s (Figure 23 and Figure 24).

pads top surfaces.

CA294-03070 rev 00 page 40 of 153

Page 41

Installation Manual

Figure 25 Lowering the engine on to the u-base and leveling pads

1 Printing engine raised above u-base 3 Printing engine correctly positioned on leveling

pads and u-base

2 Correct position of leveling pads 4 Correct position of leveling pad

n. Turn each wheel jack (Figure 17) an equal number of turns, in steps of 3-4 turns, to

lowe

r the engine on the leveling pads and u-base (Figure 32, Figure 25).

CA294-03070 rev 00 page 41 of 153

Page 42

Installation Manual

Figure 26 Engine mounted on the u-base

1 Position of link bar secured against

press frame beam

2 Frame slot 5 Leveling pad

3 U-base 6 Frame slot

4 Leveling pad

o. Make sure that the pads are correctly aligned within their slots on the u-base and

under the press (Figure 26).

CA294-03070 rev 00 page 42 of 153

Page 43

Installation Manual

Figure 27 Final position of printing engine on u-base

1 Securing bracket 2 U-base

p. Disassemble the lifting and positioning jig away from the printing engine.

The printing engine and u-base should appear as shown in Figure 27.

CAUTION: When transporting the printing engine, secure the

engine to the u-base using the securing brackets

(Figure 27).

3. To install the platform between the two printing engines:

a. Insert the platform between the two engines.

b. Use two bolts, washers, and nuts to install the platform at each engine side.

CA294-03070 rev 00 page 43 of 153

Page 44

Installation Manual

Mounting the turnbar

Figure 28 Identifying the turnbar components

1 Turnbar end roller 7 Front connection bracket

2 Turnbar idler 1 8 Rear connection bracket

3 Turnbar air pressure valve and dial 9 Turnbar idler 2

4 Turnbar air vacuum control valve 10 Turnbar idler 3

5 Turnbar lateral adjust control 11 Turnbar cross lower roller

6 Air pressure supply 12 Turnbar air pressure cross upper roller

CA294-03070 rev 00 page 44 of 153

Page 45

Installation Manual

Figure 29 Inserting the turnbar into the exit side of PE2

1 Notch for turnbar end roller shaft

2 Turnbar end roller shaft

1. Mount the turnbar in the exit side of PE2.

The turnbar end roller shaft fits into the notches in the output assembly of the PE2 WHS

(Figure 29).

Mounting the PE1

At the PE1

1. Repeat step 2. on page 33 for the PE1.

2.

Make sure to move PE1 close to PE2, but leave a gap of at least 1 cm between the engines.

3. Use an Allen M6 key to verify the tightness of the junction bar securing screws between PE1

4. Tighten all other securing screws of the two u-bases.

CA294-03070 rev 00 page 45 of 153

Use a manual forklift to move the presses and u-bases to their fixed marked positions on the

floor

and PE2 u-bases.

Page 46

Installation Manual

5. Reinstall the front exit door lower hinge using the original screws.

6. Remount the front exit service door within its frame.

7. Reinstall the top bracket to secure the door.

Use the original screws to secure the bracket.

Leveling the printing engines

Figure 30 Using a level at the printing engine front

1

2

3

1

PUBLISHER-1022

1 Front base

2 Level

3 Leveling bar jig

8. To level each printing engine, do the following (Figure 30):

a.

Remove the grounding cable screws at the front base.

Place the jig and level on the flat surface of the front base.

CA294-03070 rev 00 page 46 of 153

Page 47

Installation Manual

Figure 31 Leveling at the printing engine input – PE2 shown

1 Level

2 Idler

WARNING AVERTISSEMENT

WARNIN G

1

2

b. Place the level at the following positions, and level the printing engine:

• On the input idler (Figure 31)

•

Exit idlers. Remove the ILD securing bracket and place aside temporarily.

If necessary, adjust the leveling pads until the printing engine is level.

Use a 19 mm wrench to turn the nut at the front of the pads to adjust the level.

If necessary, use the following to adjust the position and level of the engine:

• A long crow-bar to slightly adjust the position of the engine.

• 2 mm spacers placed between the pads and the engine frame. Use a

lift-jack to slightly raise the engine and insert the pads.

Level to an accuracy of 0.00 ± 0.01 mm.

c. After the printing engine is level, make sure that the four wheels are not in contact

with the ground.

If not, use the pads to lift the wheels evenly off the ground.

d. Make sure that the printing engine is still level. Re-level if required.

e. Repeat steps a through d to level the remaining printing engine.

NOTE

: There are two parts to the printing engine alignment

procedure. The first part uses the alignment jigs to align both

printing engines horizontally. The second part uses the

CA294-03070 rev 00 page 47 of 153

Page 48

Installation Manual

parallel jig to bring the centerlines of the printing engines into

parallel.

Both adjustments are then checked and repeated, if

necessary, until the centerlines of the printing engines are

collinear.

Figure 32 Mounting an alignment jig on the ITM end cap

1 ITM bearing housing plate 3 Sights

2 Alignment jig adapter 4 Alignment jig mounted on ITM end cap

CAUTION: When installing the alignment jigs, make sure not

to damage the ITM lamp or any wires exiting from

the lamp.

NOTE: See General information on page 17 for details on mounting

and using the jigs.

CA294-03070 rev 00 page 48 of 153

Page 49

Installation Manual

At the engine front

9. To align the printing engines horizontally: (Figure 32):

For each pri

nting engine

a. Remove three screws securing the ITM front bearing housing plate.

Save the screws for immediate reinstallation.

b. Install the alignment jig adapter on the plate. Insert the three screws previously

removed in the same holes.

Make sure of the following:

• The ITM heater cable is routed through the adapter inner groove.

• The adapter is suitable for the plate and there is no gap between the plate

and the adapter. On some engines, three of the plate securing screws

protrude, and only the specific adapter suitable should be used.

c. Mount the PE1 alignment jig (P/N MJX-3055-51) on the ITM end cap of PE1.