HP Elite Slice for Meeting Rooms G2 Disassembly Instructions Manual

Product Category: Personal Computers

Marketing Name / Model

[List multiple models if applicabl e.]

HP Elite Slice for Meeting Rooms

1.0 Items Requiring Selective Treatment

Quantity

in product

Printed Circuit Boards (PCB) or Printed Circuit

Assemblies (PCA)

With a surface greater than 10 sq cm

1

Batteries

All types including standard alkaline and lithium

coin or button style batteries

1

Mercury-containing components

For example, mercury in lamps, display backlights,

scanner lamps, switches, batteries

0

Liquid Crystal Displays (LCD) with a surface

greater than 100 sq cm

Includes background illuminated displays with gas

discharge lamps

0

Cathode Ray Tubes (CRT)

0

Capacitors / condensers (Containing PCB/PCT)

0

Electrolytic Capacitors / Condensers measuring

greater than 2.5 cm in diameter or height

0

External electrical cables and cords

0

Gas Discharge Lamps

0

Plastics containing Brominated Flame Retardants

already listed as a separate item above)

0

Components and parts containing toner and ink,

including liquids, semi-liquids (gel/paste) and toner

Include the cartridges, print heads, tubes, vent

chambers, and service stations.

0

Components and waste containing asbestos

0

Product End-of-Life Disassembly Instructions

Purpose: The document is intended for use by end-of-life recyclers or treatment facilities. It provides the basic instructions

for the disassembly of HP products to remove components and materials requiring selective treatment, as defined by EU

directive 2002/96/EC, Waste Electrical and Electronic Equipment (WEEE).

1.1 Items listed below are classified as requiring selective treatment.

1.2 Enter the quantity of items contained within the product which require selective treatment in the right column, as

applicable.

Item Description Notes

weighing > 25 grams (not including PCBs or PCAs

of items

included

EL-MF877-00 Page 1

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Components, parts and materials containing

refractory ceramic fibers

0

Components, parts and materials containing

radioactive substances

0

2.0 Tools Required

List the type and size of the tools that would typically be used to disassemble the product to a point where components

Tool Description

Tool Size (if

applicable)

T15, T8 Electric Screwdriver

Support fixture

M/B B side support fixture

Suction pen

Cross electrical screwdriver

3.0 Product Disassembly Proc ess

and materials requiring selective treatment can be removed.

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

1. Follow steps described in Disassembly instruction (file attached)

2. If parts can be removed without using a tool, remove it first

3. Use correct screwdriver and torque value before unlock the screw.

4. Disconnect RTC battery cable and remove battery from M/B.

5. Dispose of all removed components according to regulation requirements.

6.

7.

8.

9.

3.2 Optional Graphic. If the disassembly process is complex, insert a graphic illustration below to identify the items

contained in the product that require selective treatment (with descriptions and arrows identifying locations).

EL-MF877-00 Page 2

Template Revision B

PSG instructions for this template are available at EL-MF877-01

MANUFACTURING PROCESS INSTRUCTIONS

MECHANICAL ASSEMBLY

MODEL : Slice

auditor:

Stanley Chen

Notes : If finding anything uncommon, notice foreman or assistant at once.

Standard Operation Procedure

Document No. : Slice FA Disassembly SOP Station :

Operation name : Ver. : Date :

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Step:

Issue Dept.:Auditor:

Stanley Chen

NPSU-PPE

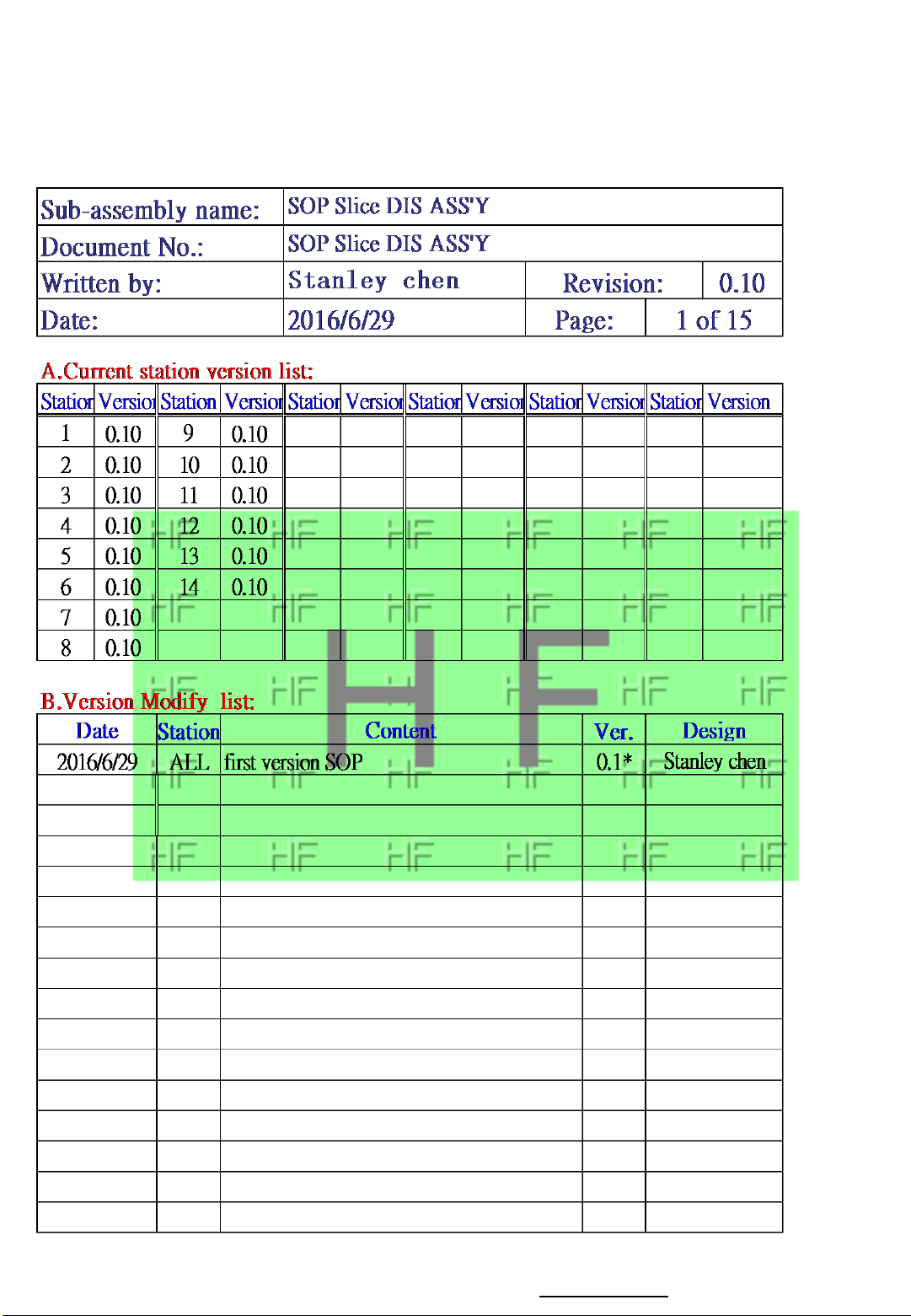

1. Loosen screw *4 of bottom case (Fig.1)

Torque:3.0 ± 0.2 Kgf.cm

2. Take off bottom case (6070B1043901) ,and

put it in the box

Disassembly bottom case

1(1/1)

0.10

2016/6/29

Fig. 1

3

1

2

4

Cross electrical screw driver #1 1

Fig. 2

Notes : If finding anything uncommon, notice foreman or assistant at once.

Standard Operation Procedure

Document No. : Slice FA Disassembly SOP Station :

Operation name : Ver. : Date :

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Step:

Issue Dept.:Auditor:

Stanley Chen

NPSU-PPE

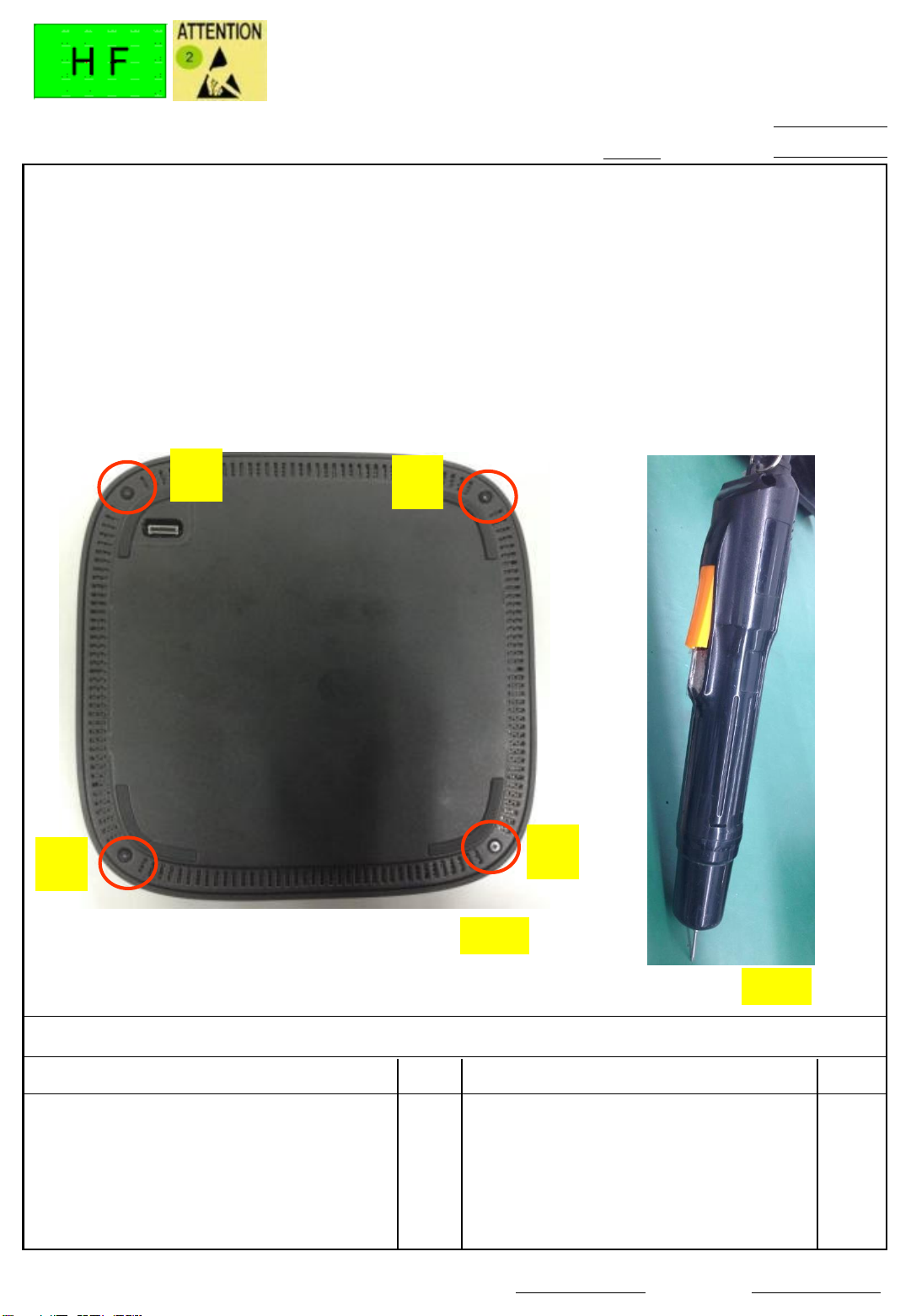

1. Disassembly Speaker connector form MB

2. Disassembly Speaker

module(6039B0082201) and put it in the

box

Do not press the Speaker eardrum when

disassembly the speaker .

Disassembly Speaker

2(1/1)

0.10

2016/6/29

Speaker

Connector

eardrum

Put the right side hook , and

release the speaker .

Notes : If finding anything uncommon, notice foreman or assistant at once.

Standard Operation Procedure

Document No. : Slice FA Disassembly SOP Station :

Operation name : Ver. : Date :

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Step:

Issue Dept.:Auditor:

Stanley Chen

NPSU-PPE

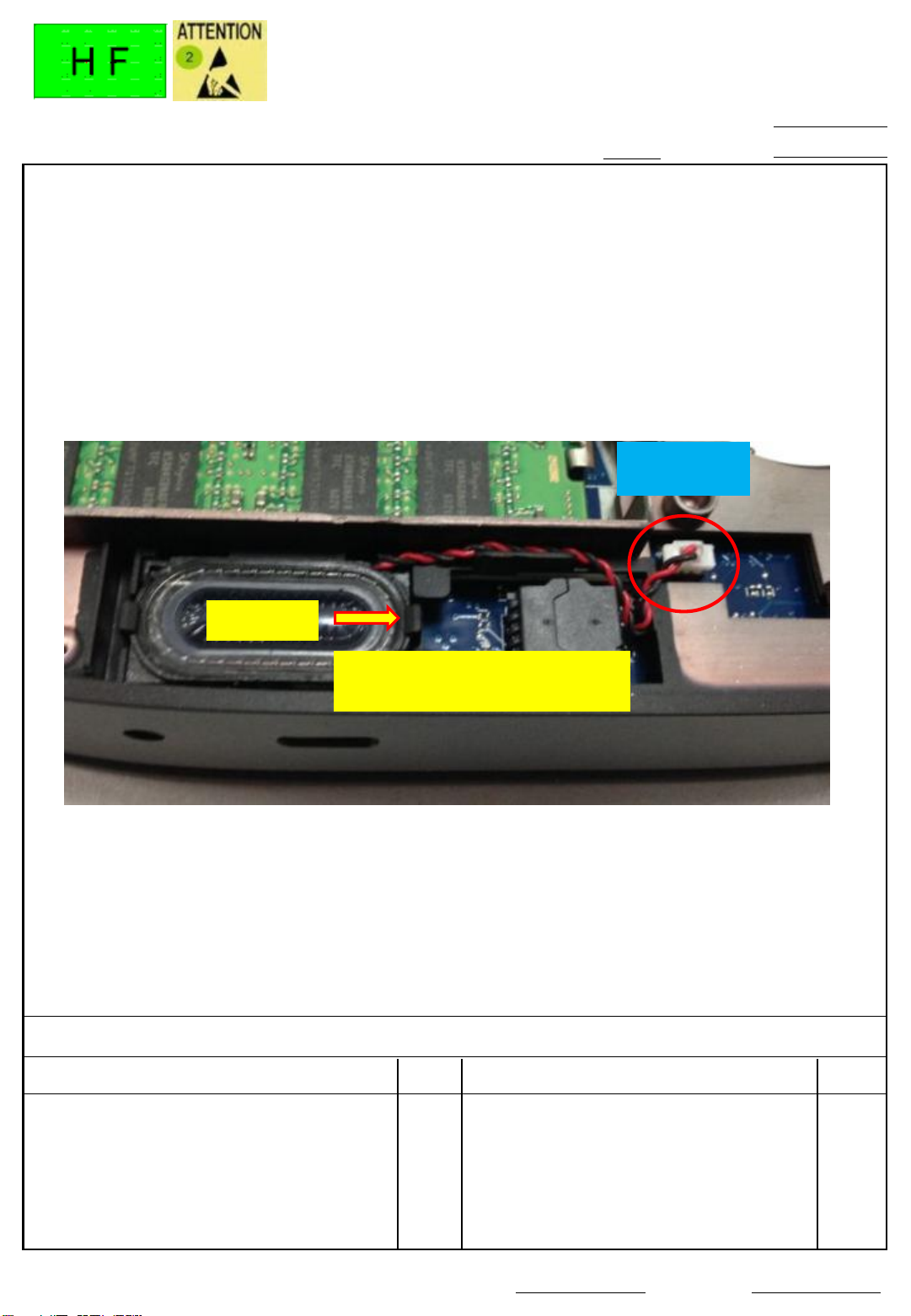

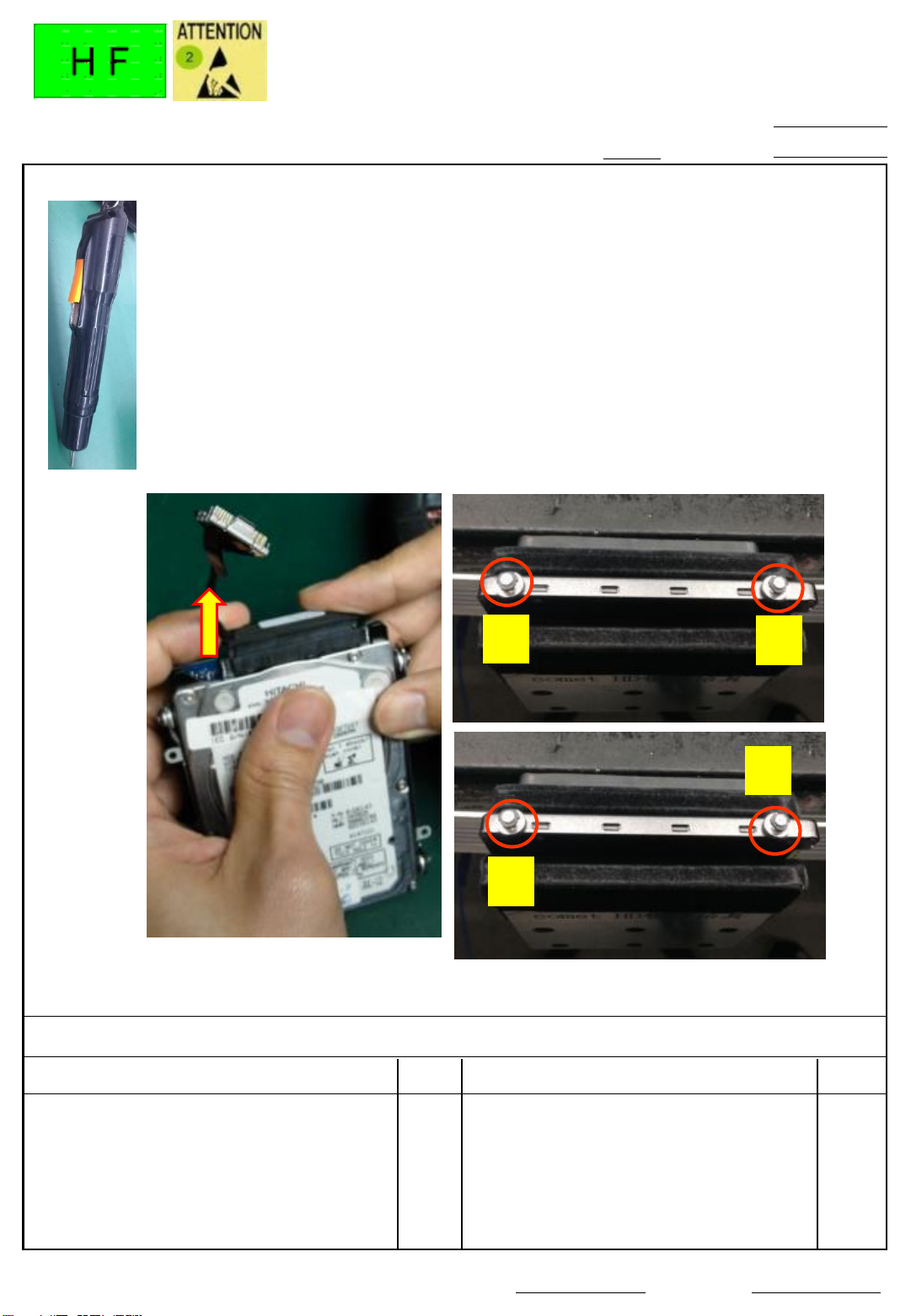

1. Disassembly HDD connector from MB(Fig.

2)

2. Loosen HDD bracket screw *4 (Fig.1)

Torque:2.5 ± 0.2 Kgf.cm

Disassembly HDD

3(1/1)

0.10

2016/6/29

Cross electrical screw driver #1 1

HDD

connector

1

2

3

4

Fig.1

Fig.2

Fig.3

Notes : If finding anything uncommon, notice foreman or assistant at once.

Standard Operation Procedure

Document No. : Slice FA Disassembly SOP Station :

Operation name : Ver. : Date :

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Step:

Issue Dept.:Auditor:

Stanley Chen

NPSU-PPE

1. Take HDD and remove the HDD cable

from the HDD . Put it in the box . (fig.1)

2. Loosen HDD bracket screw

(6054B1636401)*4 from the both side of

the HDD . (Fig.2)

Torque:2.5 ± 0.2 Kgf.cm

3. Put the HDD bracket and HDD in the

different box .

Disassembly HDD

4(1/1)

0.10

2016/6/29

1

3

4

2

Fig. 2

Fig.1

Cross electrical screw driver #1 1

HDD support fixture 1

Fig.3

Notes : If finding anything uncommon, notice foreman or assistant at once.

Standard Operation Procedure

Document No. : Slice FA Disassembly SOP Station :

Operation name : Ver. : Date :

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Step:

Issue Dept.:Auditor:

Stanley Chen

NPSU-PPE

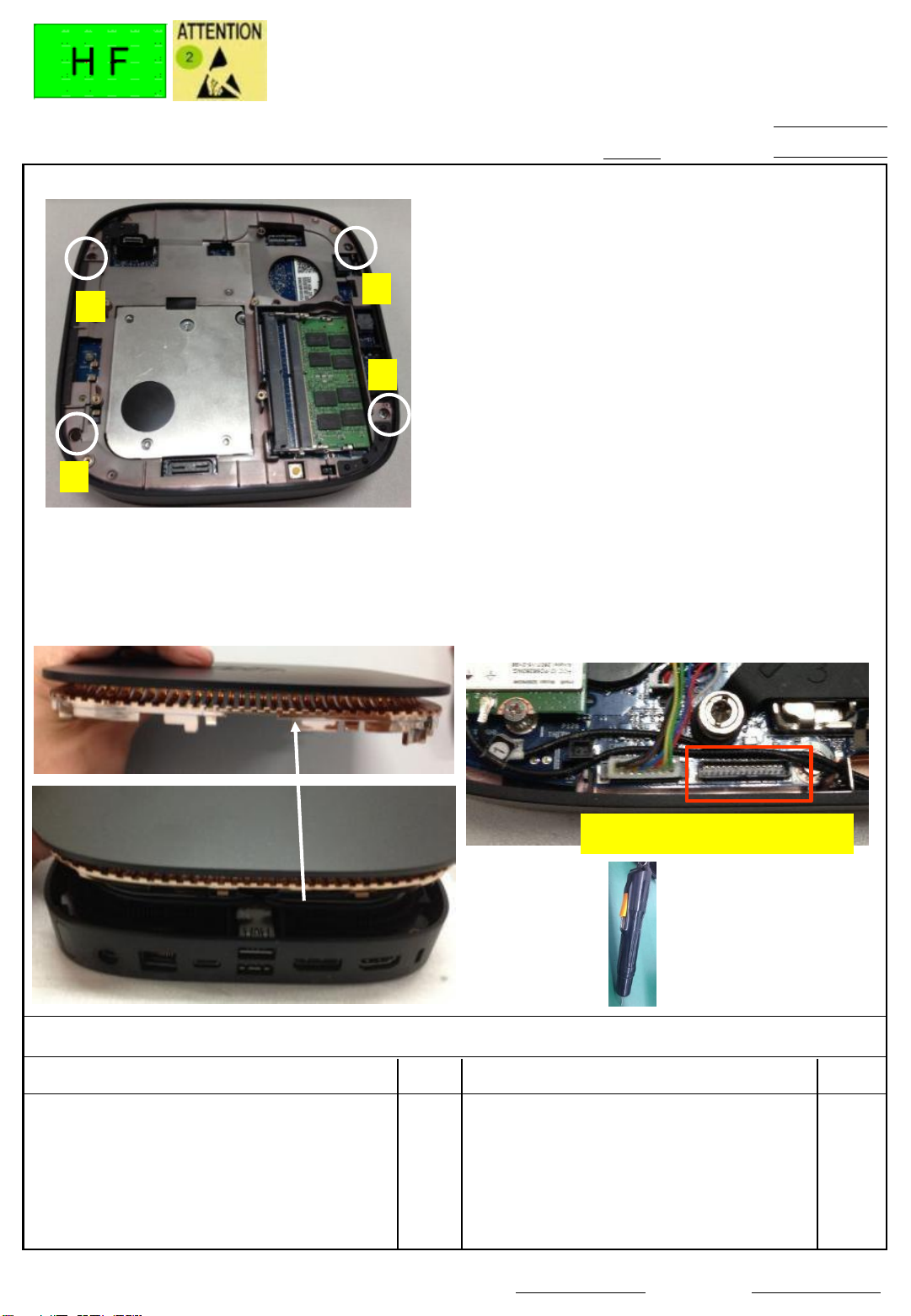

1. Loosen screw *4 of the middle frame (Fig.

1)

Torque:3.0 ± 0.2 Kgf.cm

2. Turn over the machine , and disassembly

top case . (Fig.2)

3. Only for Touch model

Disassembly cable (6017B0773101)

connector on touch/B , and disassembly

the other side connector on M/B . Put the

cable in the box . (Fig.3)

4. Only for charger model

Disassembly cable connector on touch/B ,

and disassembly the other side connector

on M/B . Put the cable in the box . (Fig.3)

Disassembly top cover

5(1/1)

0.10

2016/6/29

Cross electrical screw driver #1 1

4

1

3

2

Fig.2

Fig. 1

Touch ,charger CNTR

Fig. 3

Fig.4

Notes : If finding anything uncommon, notice foreman or assistant at once.

Standard Operation Procedure

Document No. : Slice FA Disassembly SOP Station :

Operation name : Ver. : Date :

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Step:

Issue Dept.:Auditor:

Stanley Chen

NPSU-PPE

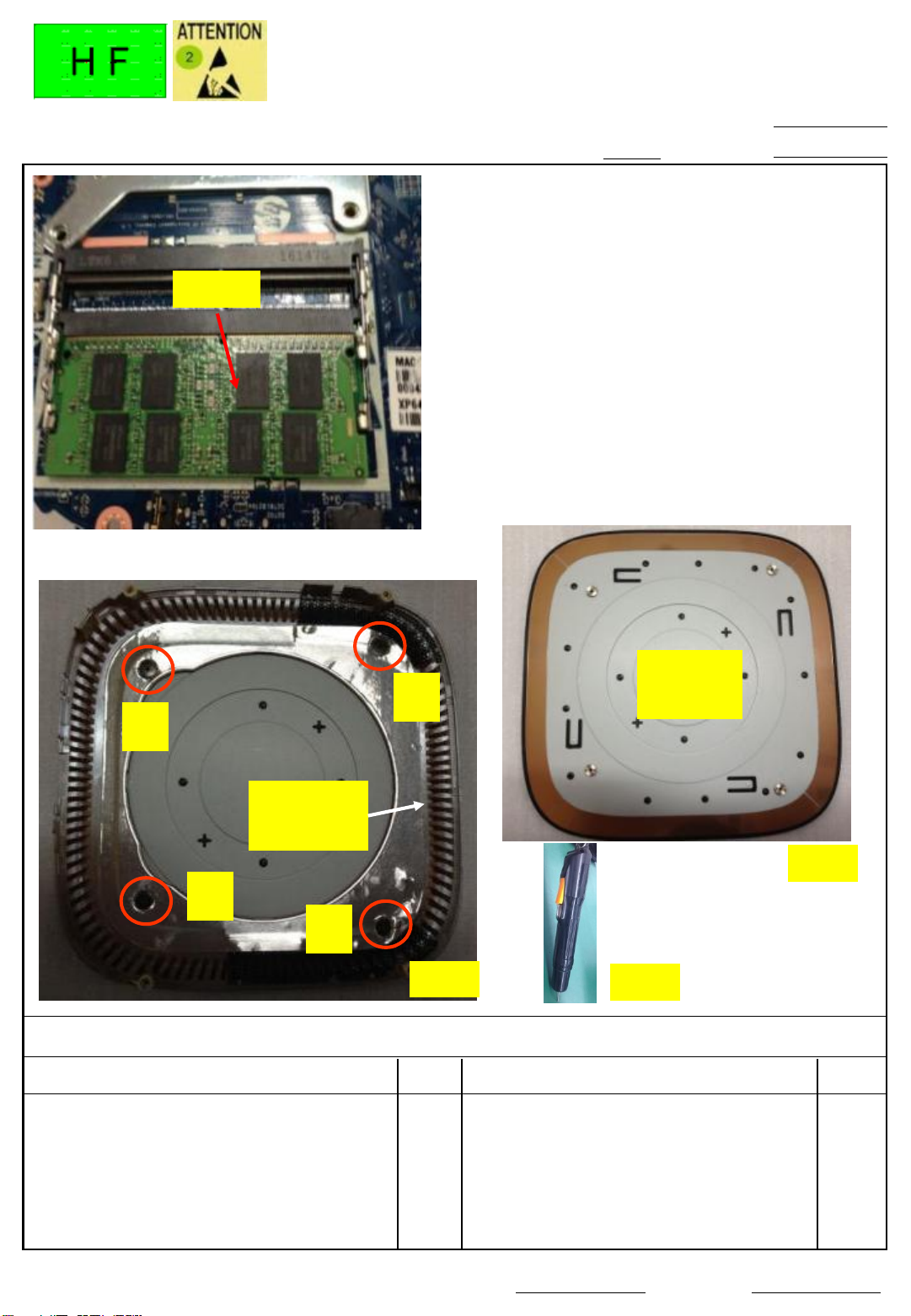

1

4

3

2

Thermal

cover

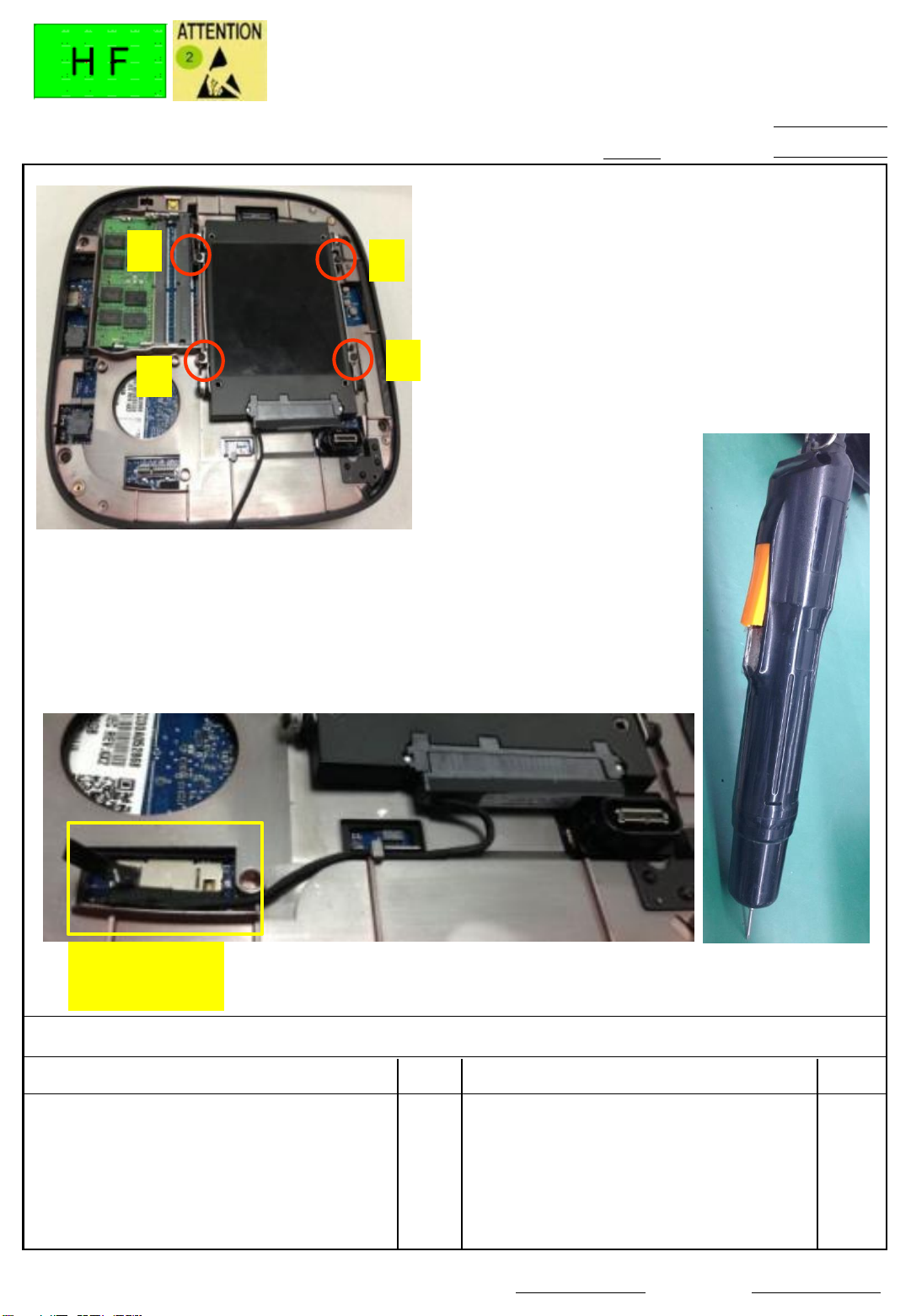

1. Disassembly DDR from the M/B , and put

it in the box .(Fig.1)

The numbers of DDR disassembly is base

on it on the M/B .

2. Loosen thermal cover

screw(6052B0156301) *4 (Fig.2)

Torque:2.0 ± 0.2 Kgf.cm

3 . Put top cover & thermal cover

(6070B1042401) in the different box.

Disassembly DDR & thermal cover

6(1/1)

0.10

2016/6/29

Cross electrical screw driver #1 1

Fig.2

Top

cover

Fig.3

Fig.1

DDR

Fig.4

Loading...

Loading...