Page 1

HP DesignJet ColorPro CAD

HP DesignJet ColorPro GA

Service Manual

Page 2

For HP Internal U s e Onl y

©Copyright Hewlett-Packard

Compa n y 1999

This document contains

proprietary information that is

protected by copyright. All rights

are reserved. No part of this

document may be photocopied,

reproduced, or translat ed to

another language with out th e

prior written con sen t of He wle ttPackard Company.

First Edition, September 1999

Warra nt y

The information contained in this

document is subject to change

without notice.

Hewlett-Packard makes no

warrant y of any kind wit h

regard to this material,

including, but not limited to,

the implied warranties of

merchantability and fitness for

a particular purpose.

Hewlett- Packard shall not be

liable for errors contained herein

or for incidental or con s equential

damages in connection with the

furnishing, performance, or use

of this material.

WARNING

The procedu r es des cribed in this

manual are to be perf or m ed by

HP-qualified service pe r s onnel

only.

Electrical Shock Hazard

Serious shock hazard leading to

death or injury may result if you

do not take t he following

precautions:

- Ensure that th e ac pow er outlet

(mains) has a protective earth

(ground) terminal.

- Disconnect the Printer from the

power source prior to performing

any maintenance.

- Prevent water or any other

liquids from running onto

electrical components or circuits,

or through openings in the

enclosure.

Electrostatic Discharge

Refer to the beginning of Chapter

10 of this man ual , for preca utio ns

you should take to prevent

damage to the Printer circuits

from electrost atic discharge.

WARNING

The Warning symb ol calls

attention to a procedure, pract ice,

or the like, which, if not correctly

performed or adhered to, could

result in personal injury. Do not

proceed beyond a War ning

symbol until the in di cated

conditions are fully unders tood

and met.

CAUTION

The Caution symbol calls

attention to an oper atin g

procedure, practice, or the like,

which, if not correctly performed

or adhered to, could result in

damage to or destruction of part

or all of t h e pr o duct. Do not

proceed beyond a Caution

symbol until the in di cated

conditions are fully unders tood

and met.

Technical Marketing,

Barcelona Division,

Hewlett-Packard Espanola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Valles

Spain

Page 3

1

HP DesignJet ColorPro CAD

HP DesignJet ColorPro GA

Service Manual

Page 4

Using this Manual

Purpose

This Service Manual contains information necessary to test,

calibrate and service:

n

HP DesignJet ColorPro CAD Printer (Model C7777A)

n

HP DesignJet ColorPro GA Printer (Model C7778A)

For information about using these printers, refer to the

corresponding User and Quick Reference Guides.

Readership

The procedures described in this Service Manual are to be

performed by HP Certified service personnel only.

Part Numbers

Part Numbers for Printer options, accessories and service parts are

located in Chapter 9.

2

HP DesignJets ColorPro CAD and GA Printers Servi ce Manua l

Page 5

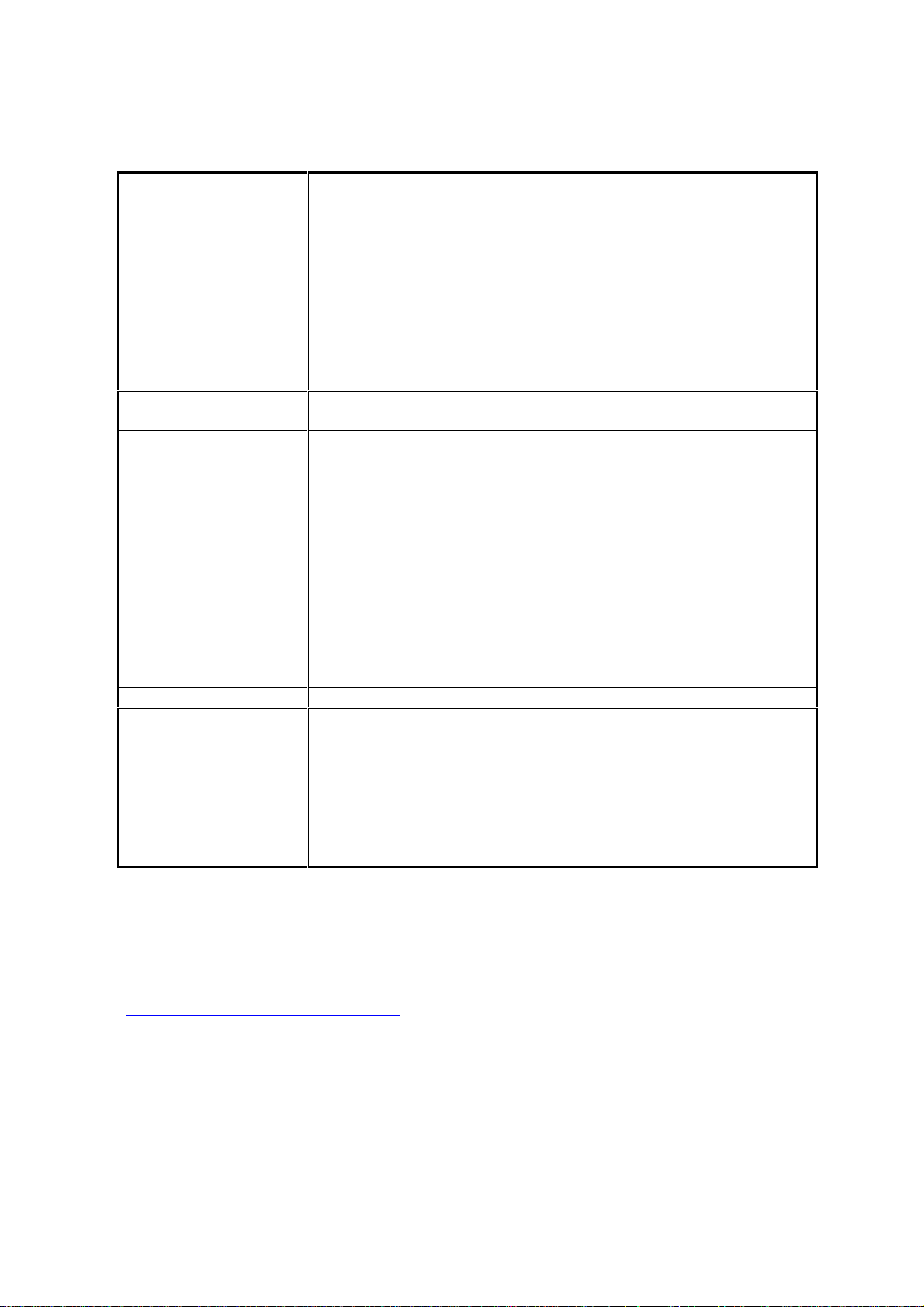

Table of Contents 1

Chapter 1 - Product Information

Chapter 2 - Operating Overview

Chapter 3 - Loading Paper and paper Beha viour

Chapter 4 - Install/Uninstall print er Softwa re

Chapter 5 - Maintenance and Ink

Chapter 6 - Functional Overview

Table of Contents

Chapter 7 - Removal & Replacement w/o Calibration

Chapter 8 - Troubleshooting

Chapter 9 - Parts & Diagrams

Chapter 10 - Removal & Replacement with Calibration

Chapter 11 - Calibration

HP DesignJets ColorPro CAD and GA Printers Service Manual

3

Page 6

Table of Contents

4

HP DesignJets ColorPro CAD and GA Printers Servi ce Manua l

Page 7

Chapter 1 Product Information

Technology Update

Modular Ink Delivery System

A modular ink delivery system is the separation of ink car tridges and printheads into

individual, single-color components. Traditional inkjet printers use one black and one tricolor ink cartridge, each with integrated printheads. HP’s modular ink delivery system

features four separat e ink cartr idges--o ne for each primary printing color--and four

corresponding long-life printheads, with tubes connecting the components. I nc luding the

standard and high-capacit y black ink cartr idges, t here are actually nine consumables, with

on ly eight used in the printer at o ne time.

Product Information 1-1

Page 8

Technology Update

How It Works

By separating the ink cartridge from the pr intheads, a modu lar ink delivery syste m allows

the ink supply to remain in a permanent, fixed position. The printheads re main attached

to the carriage and move back and forth, delivering ink to the page as the paper advances

through the printer. Each printhead and ink cartridge is embedded with a tiny memory

device called a smart chip that recognizes and stor es t he unique operat ing characteristics

of the component to cr eate a totally integrat ed pr inting system that ensures consistent ,

high-quality printing at the lowest cost available.

A unique pressurization system maintains a constant supply of ink to the printheads.

Smart chips monitor the amount of ink used by counting every drop that passes through

each printhead. When the smart chips sense more ink is needed to maintain cont inuous

printing, a plunger in each cartridge temporarily pressurizes the cartridges to deliver more

ink to the printheads. With the modular ink delivery system, ink supply is instantly

replenished, even at top speeds.

The new, individually replaceable pr intheads ar e des igned for long life and each should

print 12,000 pages in black, 24,000 pages in color. As a result, you’ll go through many

ink cartridges before the corresponding printhead will need replacement. With their

modular design, ink cartridges contain twice the ink supply of current HP cartridges, so

you’ll also get longer lasting cartridges. When a co mponent approaches the end of its

print life, the smart chip not ifies the user through on-screen messages so a rep lacement

can be purchased prior to the part expiring.

By separating the pr intheads and ink cartridges, you only replace the co mponent t hat is

no longer usable. Pr intheads can be replaced one at a time without the need for cost ly or

extensive servicing and aren’t discarded when the ink is expended. HP printheads also use

a wet wiping system to eliminate nozzle clogging that plagues other permanent printhead

designs. Component replacement is easy. Simply pull out t he used part and snap in a

replacement.

Product Info rmation1-2

Page 9

Technology Update

The Benefit s

Cuts up to 30 percent off the printing costs of other methods

Modular design means only the component that is no longer useful is replaced.

Longer-life printheads and higher-capacity ink cartridges means less frequent

replacement.

Achieves color laser speed in a personal desktop printer

Each Printhead has 304 nozzles (1,216 total, the most in the industry) resulting in

faster pr int sp eeds.

Prints in 1/2-inch swath as opposed to the 1/5- or 1/3-inch swaths of integrated

print cartridges.

Ink cartridge pressurization system keeps constant flow of ink to printhead. Smart

chips store component information and alert user to low-ink, ink-out and

printhead failure status.

Product Information 1-3

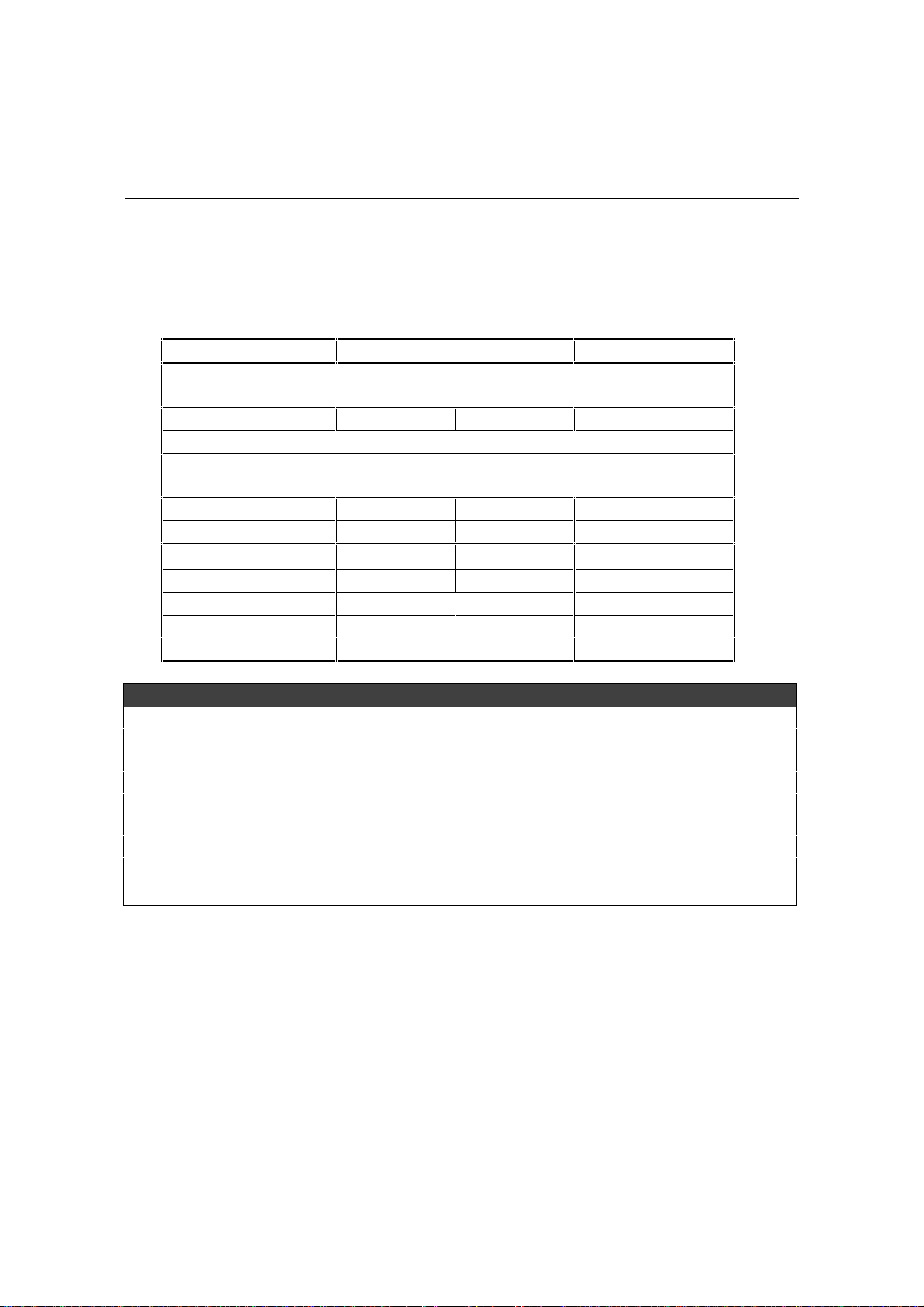

Page 10

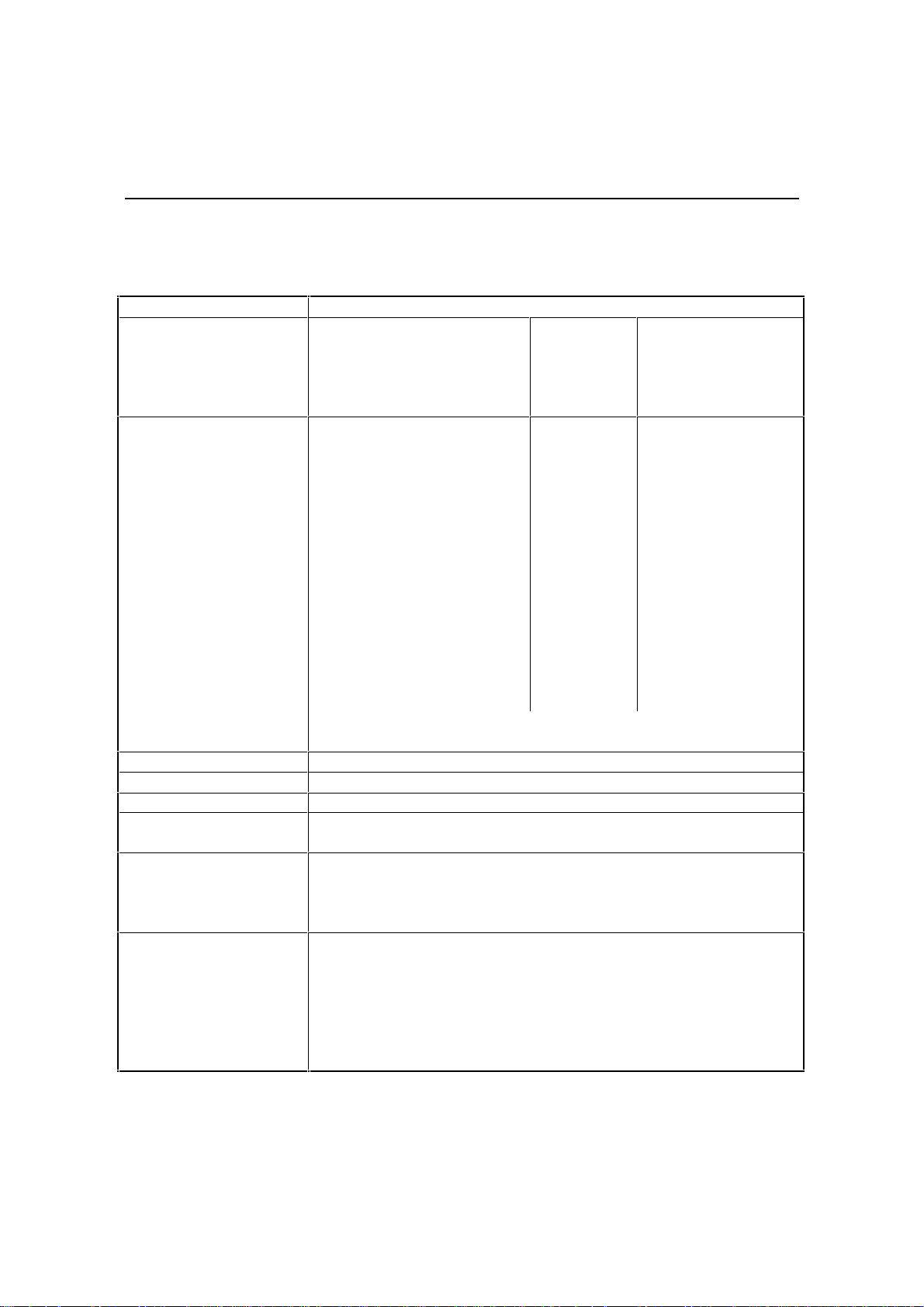

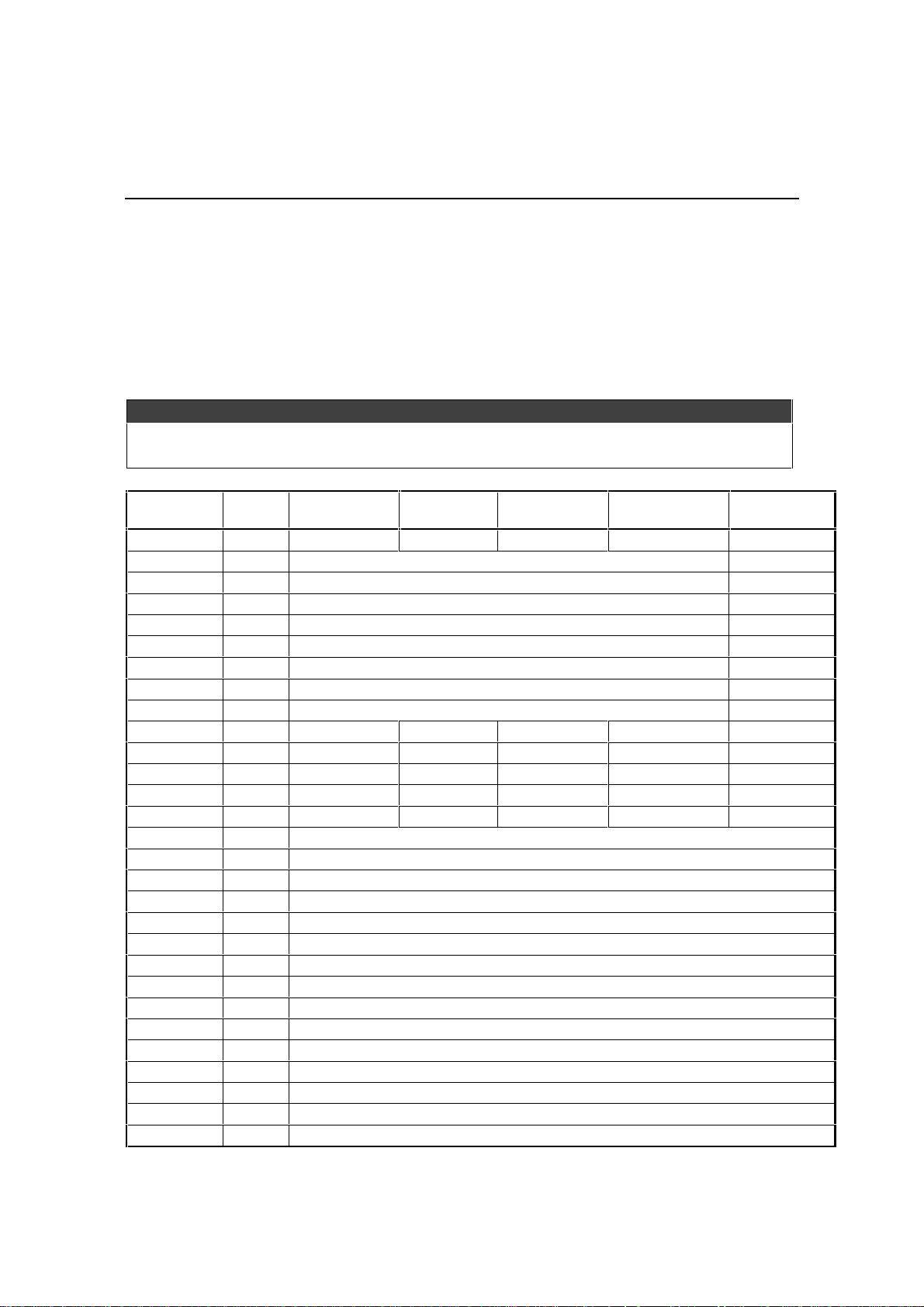

Spe cif ica tion s

Data Sheet

Print Method

Print Speed 1 Black Black Text

Print Speed 1 Color

Black Resolution

Color Resolution

Printhead Nozzles

Printer Command

Languag e

Font Capability

Memory HP DesignJet ColorPro CAD

Plain paper drop on-demand thermal inkjet printing.

Econofast Mode

Normal Mode

Best Mode

Color Highlights

Econofast Mode

Normal Mode

Best Mode

Mixed Text & Grap h i c s

Econofast Mode

Normal Mode

Best Mode

Full Page Color

Econofast Mode

Normal Mode

Best Mode

1

Approximate figures. Exact speed dependent on the system

conf igur ation, software program, and doc ument comp lexit y

Up to 600x600 dpi

PhotoREt II for photo qu ality

304 black, 912 color (304 per color printhead)

HP PCL 3 enhanced

Adobe PostScript 3 (With HP 2500CM onl y)

HP FontSmart v2.5 (110 TrueType fonts for windows)

HP FontSmart software provides easy-t o- use font manage me nt

capabilit i es

136 PostScript fonts with Adobe PostScript 3

4 Mb ytes st andard RAM

Letter / A4

11.0 ppm

9.0 ppm

7.5 ppm

Letter / A4

9.0 ppm

6.5 ppm

5.5 ppm

Letter / A4

9.0 ppm

3.0 ppm

1.5 ppm

Letter / A4

2.5 ppm

1.2 ppm

0.4 ppm

11x17 / A3

7.0 ppm

5.0 ppm

4.5 ppm

11x17 / A3

5.5 ppm

3.5 ppm

2.5 ppm

11x17 / A3

6.0 ppm

2.0 ppm

1.0 ppm

11x17 / A3

1.7 ppm

0.7 ppm

0.3 ppm

Product Info rmation1-4

HP DesignJet ColorPro GA

20 M bytes s tandard RAM

Two 72-pin SIMM slots for additional memory (EDO, 60ns)

expansion up to a total of 76 Mbytes

Page 11

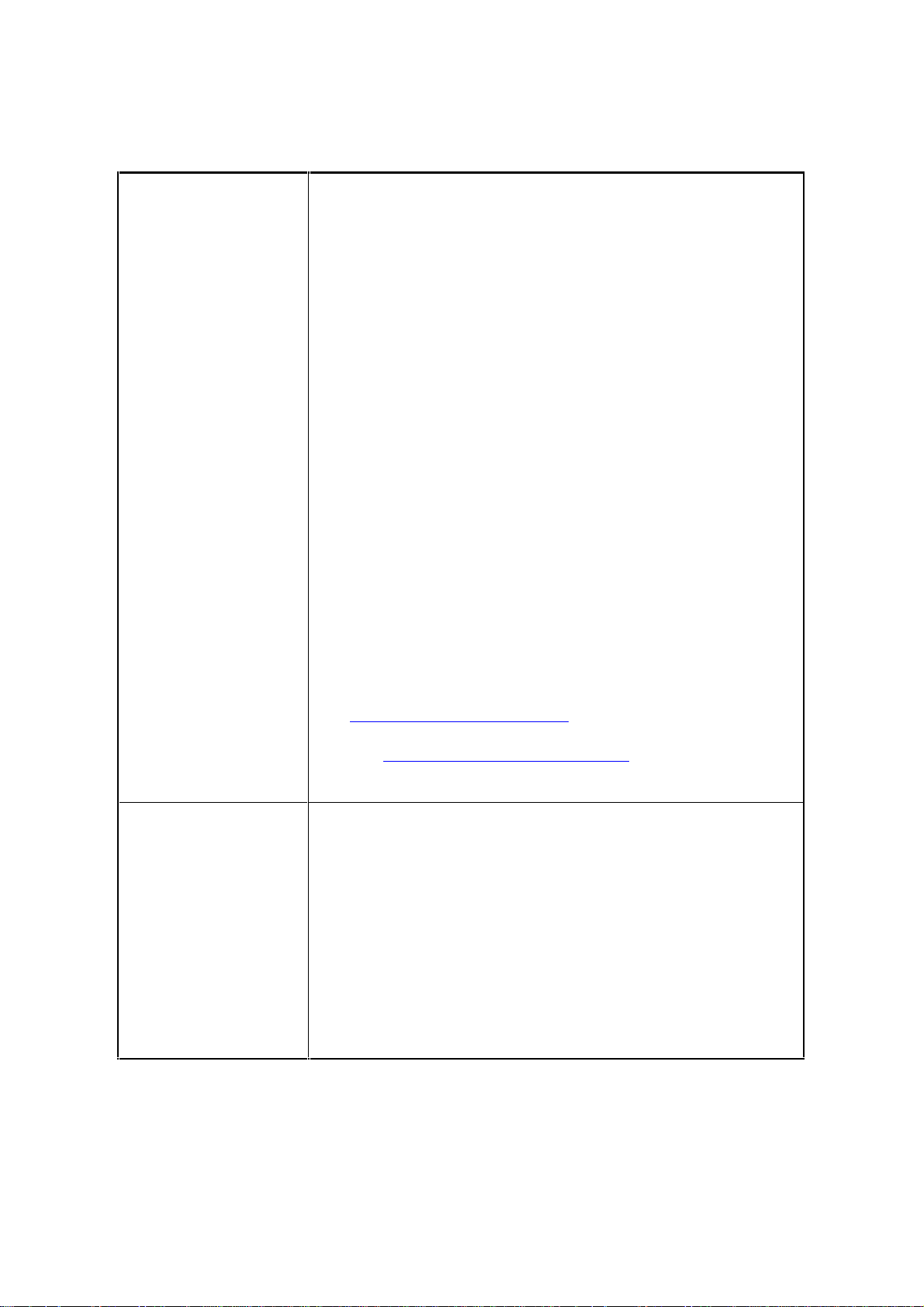

Connectivity /Network

Management

HP DesignJet ColorPro CAD

Network-capable printer for DOS and Windows environments

Enhanced HP PCL 3e Windows Driver Support for Windows NT 4.0,

Windows 3.1x/95/98

Centronics parallel, IEEE 1284 comp liant

One n etwor k interface slot accepts opt ional H P MIO Print Server s

with support for Novell Netware, Microsoft LAN Manager, Windows

for Workgroups, Windows for NT, IBM LAN Server, Unix

environment and Apple Talk (Ether Talk)

HP DesignJet ColorPro GA

Network-ready printer for DOS, Windows and Macintosh

environments

Enhanced HP PCL 3e Windows Driver Support for Windows NT 4.0,

Windows 3.1x/95/98

Centronics parallel, IEEE 1284 comp liant

HP MIO 10/100Base-TX print server with support for Novell

Netware, Microsoft LAN Ma nager , Win dows for Wor kgroups,

Windows NT, IBM LAN Server, Unix environment and AppleTalk

(EtherTalk)

Supports networking protocols IP X/S P X, TCP/IP, DLC/LLC,

AppleTalk and NetBE UI

Adobe PostScript 3 drivers for Windows a nd Macintosh QuickDraw

Paper Handling

Automatic switching between languages and ports.

HP JetAdmin printer management software provides easy printer

setup and configuration. Latest versions available from HP’s web

site (http:/ /www.hp.com/go/jetadmin)

HP WebJetAdmin printer management software available from HP’s

web site (http://www.hp.com/ go/webjetadmin) for simple

installa tions and co nfiguration fro m a common web b rowser.

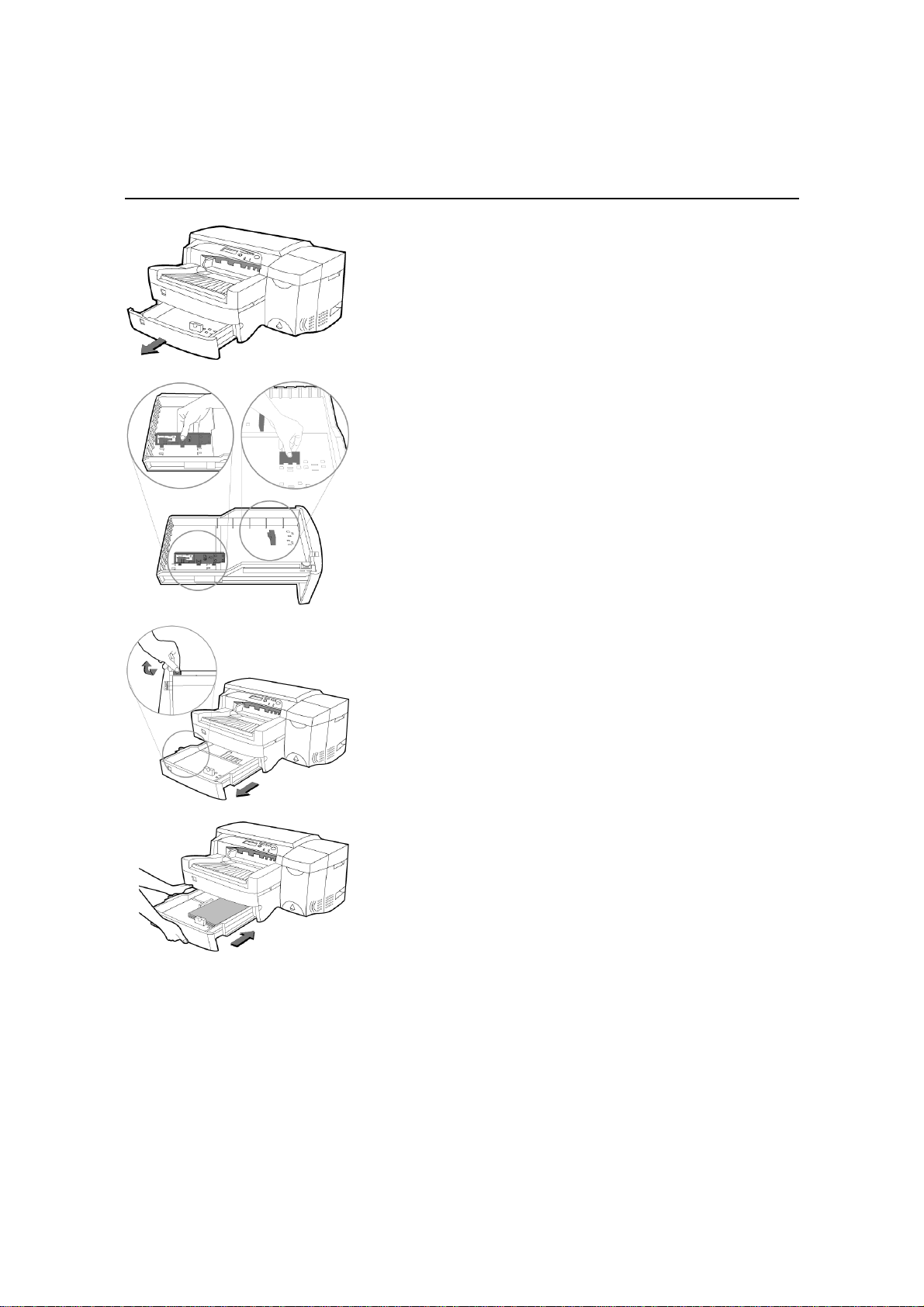

Standard input capacity of 400 sheets through two trays (Tray 2 & 3)

of 150 sheet and 250 sheet capacity.

Standard output capacity of 150 sheets (face-up)

Rear Manu al feed – single she et only

Tray 1 (Input / Output Tray) – Sheets: up to 10, Cards: up to 4

Tray 2 (Upper Tray) – Sheets: up to 150, Cards: up to 60

Tray 3 (Lower Tray) – Sheets: up to 250

All input paths ha ndle standard media sizes (as listed below) up to

13 in.x19 in. (Supper A3)

Additionally, Tray 1 and the rear manual feed support all media sizes

as small as 4 in.x6 in. (101.6mmx152.4mm)

Built-in media size sensors prevents printing on the wrong size of

media

Product Information 1-5

Page 12

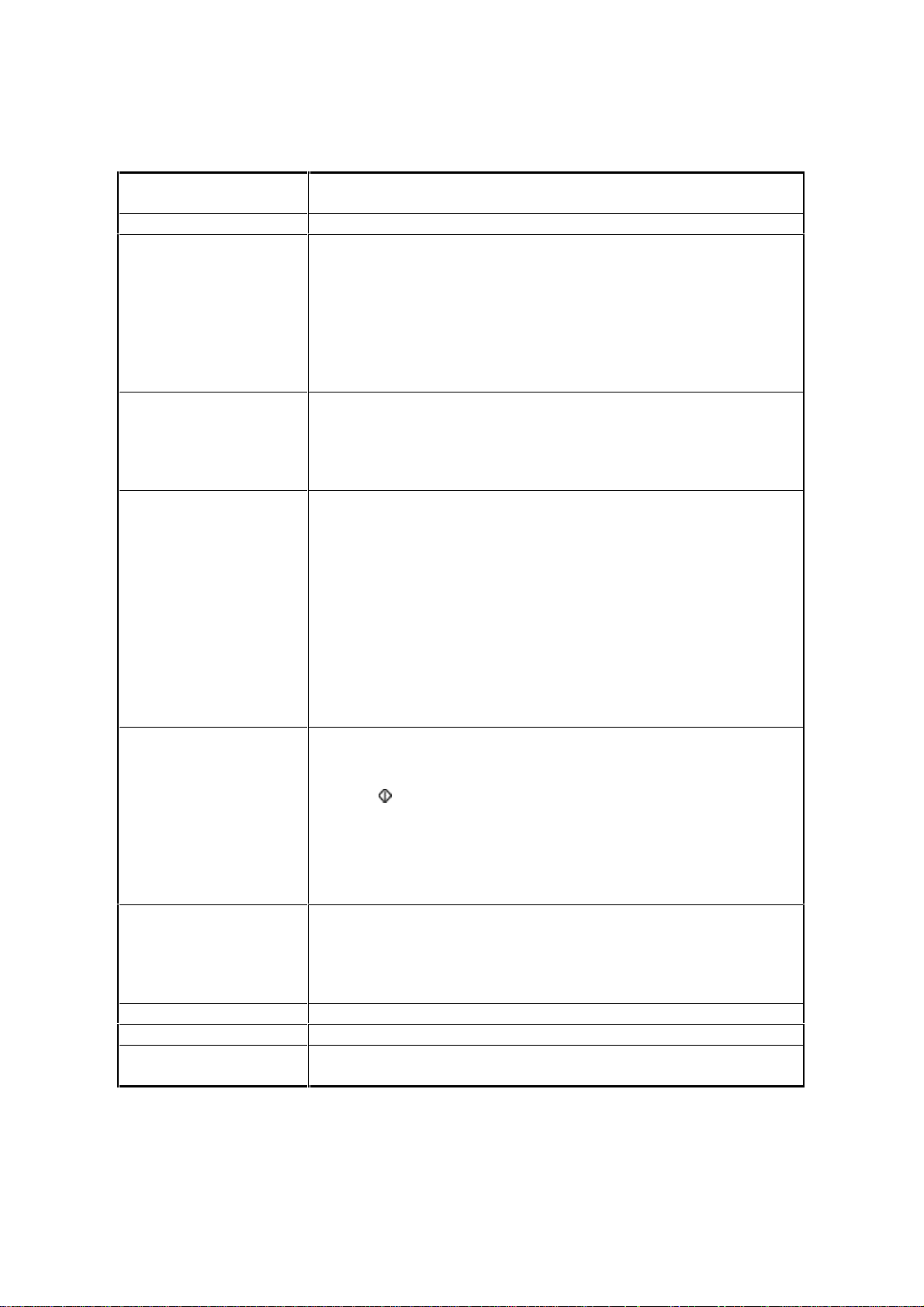

Paper Size Handling

Maximum Print Wid th

Recommended Media

Weight

Minimum Width: 76.2 mm (4in.) x 127.0 mm (6 in.)

Maximum Width: 330.2 mm (13in. ) x 482. 6 mm (19 in.)

320 mm (12.61 in.) x 470 mm (18.49 in.) on 13 in. x 19 in. media

All input paths handle the following pa per weights with the rear

straight-through paper path handling up to 0.3 mm thickness of paper

Smart Software

Features

Media Size / Type

Co ntrol Panel

Paper / Labels: 60 to 135 g/m

Cards: 110 to 200 g/m

Straight-through path: up to 0.3 mm thickness (0.012 in.) or approx.

200 g/m

2

(110 lb. Index)

2

2

(16 to 36 lb. Bond)

(110 lb. Index)

Built-in printer driver features:

HP ZoomSmart scaling technology, Billboard, Handout (N- up

printing), Mirror, Watermark, Print Pr eview, Quick Sets, LaserJet

Margin Emu lation

Paper: Super B 13 x 19 in., U.S. Tabloi d 11 x 17 in.,

U.S. Legal 8.5 x 14 in., U.S. Letter 8. 5 x 11 in.,

European A3 297 x 420 mm, European A4 210 x 297 mm,

European B4 257 x 364 mm

Transparencies: U.S. Letter 8.5 x 11 in. , Eur opean A4 210 x 297mm

Cards: U.S. Index card 4 x 6 in., Index card 5 x 8 in.,

European A5 card 105 x 148.5 mm, P ostcard 100 x 148 mm

Labels: U.S. Labels, 8.5 x 11 in.; European A4 Labels, 210 x 297mm

Intuitive operation and c omplete, easy-to-unders tand messages

Two- line 3 2 charact er LCD display and 2 L EDs

Buttons:

(Go), Job Cancel, Menu, Item, Value, Select

Indicators: Attention, Ready

Messages can be displayed in 14 languages: English, French, Italian,

Ger man, S panish, Por tugues e, Dutc h, Norwegian, Fi nnish, Swedish,

Danish, Polish, Cz ech and Russian

o

Operating

Environment

Opera ting temper ature: 5

Recommended operating conditions: 15

Storage temp era ture: -40

to 40oC (41o to 104oF)

o

to 60oC (-40o to 140oF)

o

to 35oC (59o to 95oF)

Relative Humidity: 20 to 80% RH non-condensing

Noise levels per ISO 9614-1: S ound Pressure, LwAm 62 dB(A)

Power Supply

Built-in Univer sal Power Supply

Power Requirements Input Voltage 100 – 240 AC (±10%), 50/60 Hz (±3 Hz)

Power Consumption

Less than 2 watts when off, 8 watts maximum non-printing, 35 wa tts

average printing, 65 watts maximum printing

Product Info rmation1-6

Page 13

Dimensions

With paper tray closed

685 mm (26.97in.) W x 610 mm (24.02in.) D x 337 mm (13.27in.) H

With paper tray fully extended

685 mm (26.97in.) W x 745 mm (29.33in.) D x 337 mm (13.27in.) H

Desk Spac e Required

685 mm (26.97 in.) W x 532 mm (20.94 in.) D

Weight

Reliability & Es ti mated

Usage

System Requirements

Warranty

Produc t Ce r tifications

26.5 kg (58.48 lb.) without printheads and ink cartridges

27.0 kg (59.52 lb.) with printheads and ink cartridges

Up to 12,000 pages / month

Minimum:

Recommended:

50 Mb Free HardDisk space for 11 x 17 or A3 size pr inting.

Graphics intensive f iles ma y requ ire more disk space.

1 year on site warranty

Safety Certificat i o ns : CCIB (China), CSA (Canada), PSB (Singapore),

UL (USA), NOMi(Mexico), TUV-GS (Germany), SABS (South

Africa), J UN (Kor ea)

EMI C ertifica tions: FCC Part 15B C lass B when used with a Class B

computing device (USA), FCC Part 15B Class A when connected to

Local Area Network (LAN ) Devices, CTICK (Australia & New

Zealand), VCCI (Japan), CE (European Union), B mark (Poland), Gost

(Russia), BCIQ (Taiwan), RRL (Korea)

Windows 3.1x: 486DX-66, 8Mb R AM

Windows 95/98: 486DX-100, 8Mb RAM

Windows NT 4.0: 486DX-100, 16Mb RAM

Macintosh System 7.5.3: 68040 – 8Mb RAM

Windows 3.1x: Pentium 150/166, 16Mb RAM

Windows 95/98: Pentiu m 150/166, 16Mb RAM

Windows NT 4.0: Pentium 150/166, 32 Mb R AM

Mac i ntosh Syst e m 8 or la ter: P ow er PC – 16 Mb

Brands and product names listed are trademarks or registered trademarks of their

respective co mpanies.

Information in this document is subject to change without notice – for more information

or the latest updates, please go to the HP DesignJet web site locat ed at

http://www.designjet-online.hp.com/

Product Information 1-7

Page 14

Spe cif ica tion s

Cable Specifications

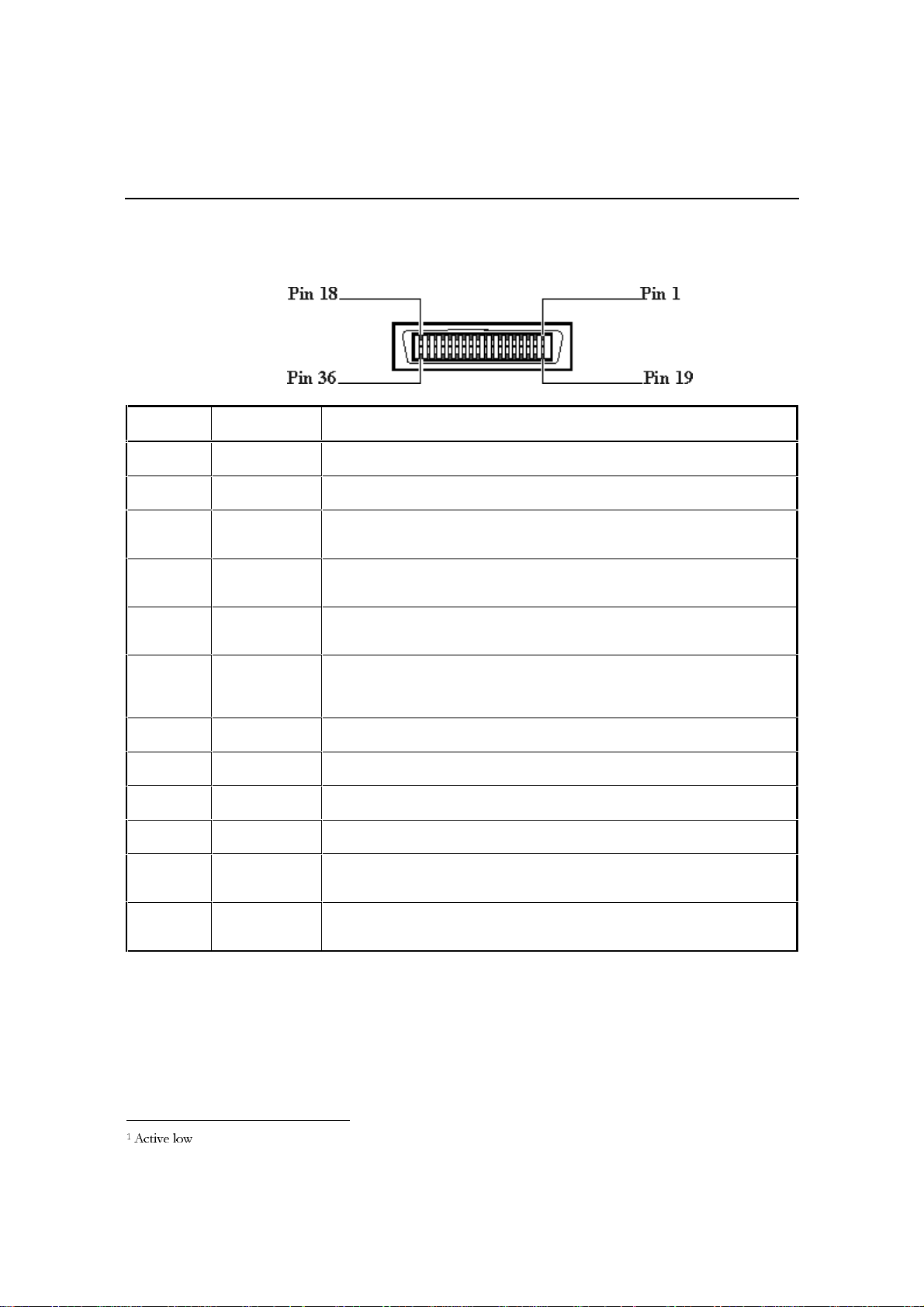

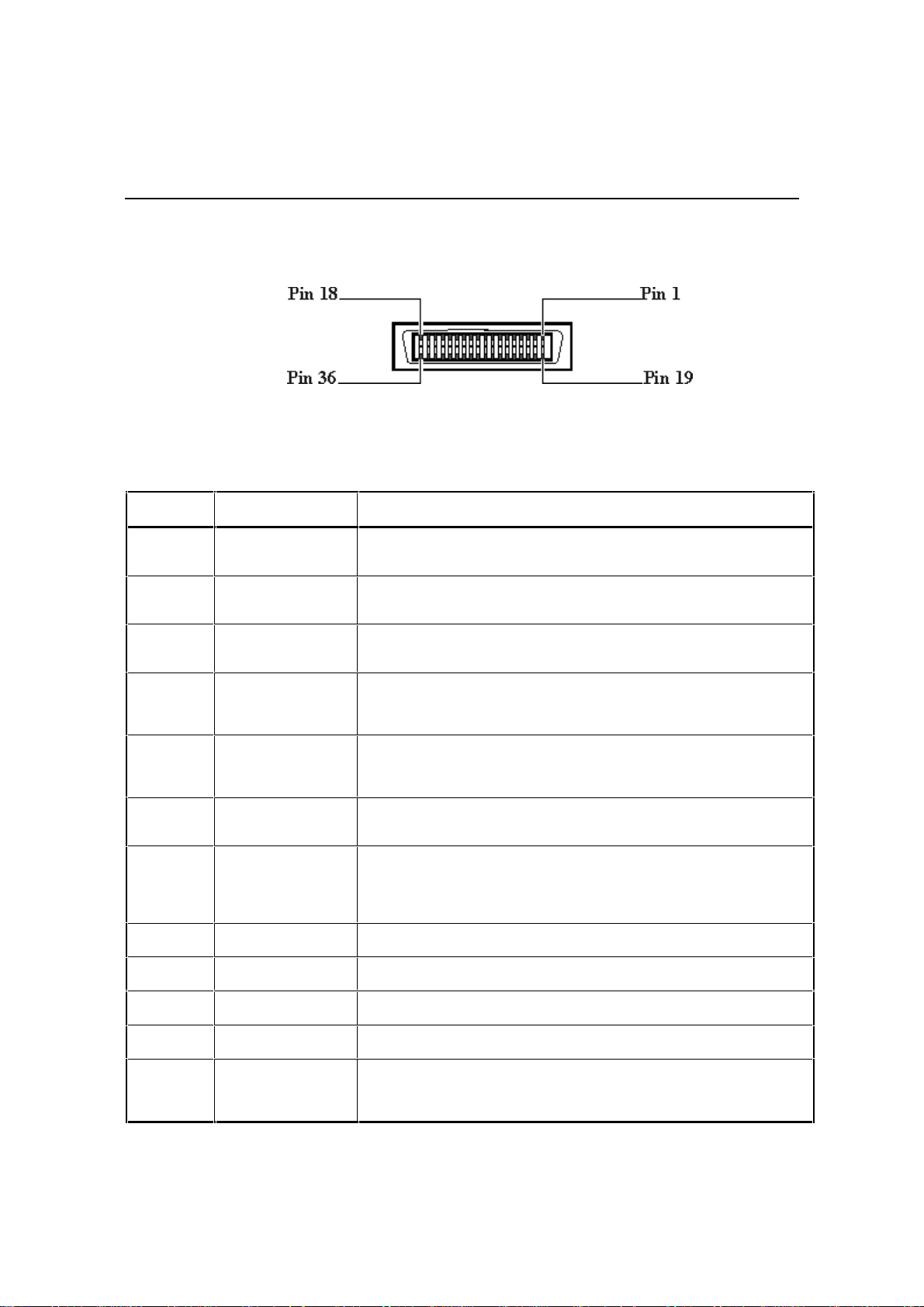

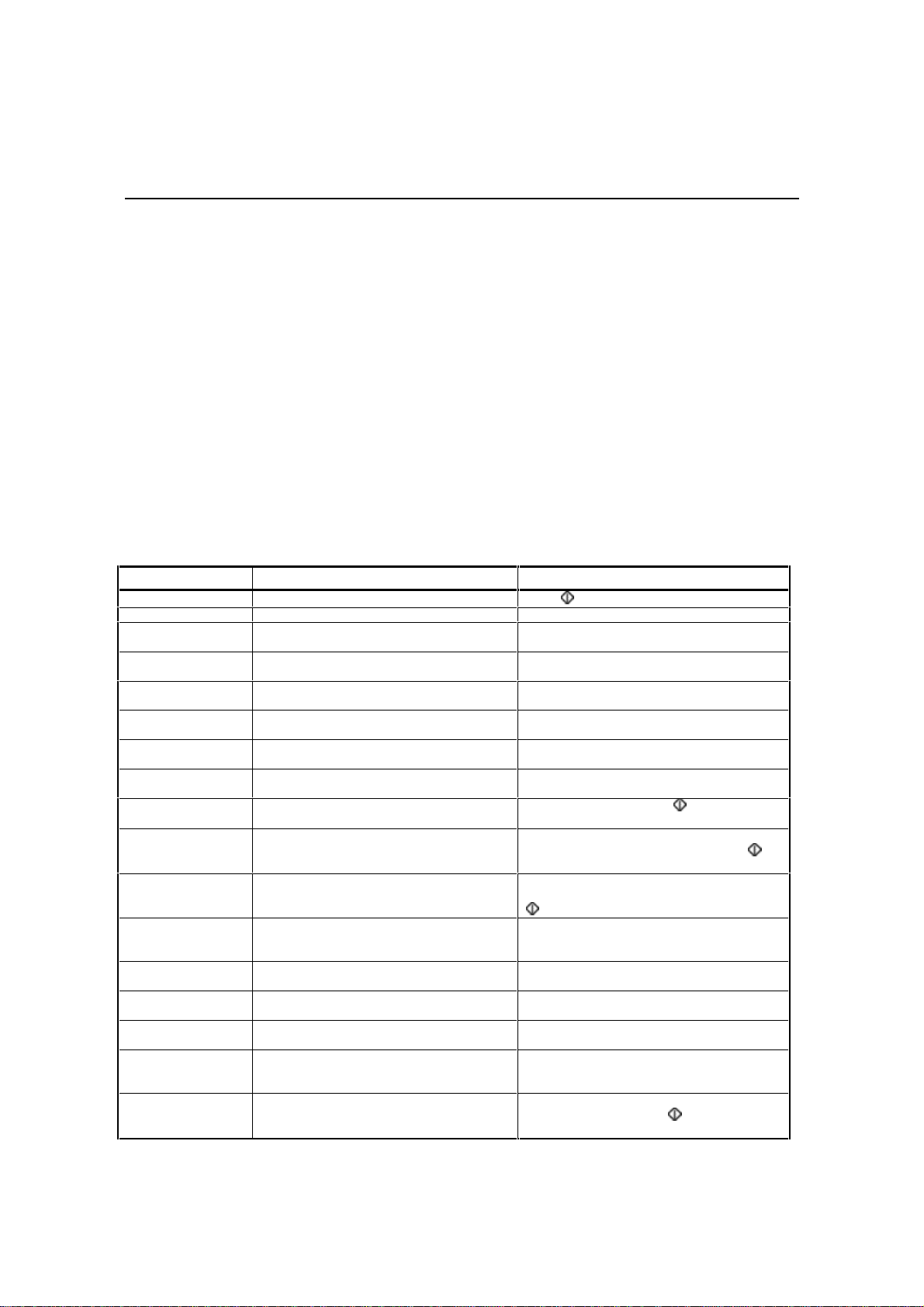

1284-B Connector Pin Assignments

The pin numbers and their assigned signal names for the 1284-B connectors are given

below.

Note

The abbreviat ions used in the "Source" column:

H = host; P = printer; Bi-Di = bi-directional

PIN#SOURCE COMPATIBLE NIBBLE BYTE ECP EPP

1 H nStrobe HostClk HostClk HostClk nWrite

2 Bi-Di* Data 1 (Leas t Signific ant B it) AD1

3 Bi-Di* Data 2 AD2

4 Bi-Di* Data 3 AD3

5 Bi-Di* Data 4 AD4

6 Bi-Di* Data 5 AD5

7 Bi-Di* Data 6 AD6

8 Bi-Di* Data 7 AD7

9 Bi-Di* Data 8 (Most Significant Bit) AD8

10 P nAck PtrCl k PtrClk PeriphClk Intr

11 P Busy PtrBusy PtrBusy PeriphAck nW ait

12 P PError AckDataReq AckDataReq nAckReverse User Defined 1

13 P Select Xflag Xflag Xflag User Defined 3

14 H nAutoFd HostBusy HostBusy HostAck nDStrb

15 Not Defined

16 Logic Gnd

17 Chassi s Gnd

18 P Peripheral Logic High

19 Signal Ground (nStrobe)

20 Signal Ground (Data 1)

21 Signal Ground (Data 2)

22 Signal Ground (Data 3)

23 Signal Ground (Data 4)

24 Signal Ground (Data 5)

25 Signal Ground (Data 6)

26 Signal Ground (Data 7)

27 Signal Ground (Data 8)

28 Signal Ground (PError, Select, nAck)

29 Signal Ground (Busy, nFault)

Product Info rmation1-8

Page 15

30 Signal Ground (nAutoFd, nSelectIn, nInit)

31 H nInit nInit nInit nReverseRequest nInit

32 P nFault nDataAvail nDataAvail nPeriphRequest User Defined 2

33 Not Defined

34 Not Defined

35 Not Defined

36 H nSel ectI n 1284 Acti ve 1284 Active 1284 Acti ve nA St r b

∗

Data signals will be driven by s ome but not all peripheral devices.

∗

Pins not defined by this sp ec ar e us ed by manuf actu rers at their own risk.

Product Information 1-9

Page 16

Spe cif ica tion s

Centronics Parallel Pinout Information

PIN NUMBER PIN ID DESCRIPTION

1Strobe1A low puls e c aus es the printer to read on e byte of data

2 - 9 Data 0 - Dat e 7 These pins ar e t h e dat a lines. Data 0 is th e leas t sig nificant bit ( LS B )

10 Ac kn owledge The printer sends a low pulse to indic ate t h at it has accept ed a byt e of data and is

11 Busy The print er sen ds a high logic level t o indicate to the c om put er th at it c ann ot

12 P aper E rror The printer sends a high log ic level to indicate to the c om put er t h at it is ou t of

13 R ead y T he pr in ter sends a high log ic lev el to indicat e to th e c om put er th at it is in an onl in e

16 Sig n al Gr ound Signal interfac e gr oun d.

17 Chassis Ground Chassis ground.

18 +5 V The print er outputs a +5 volt hi gh logic level through a 2.2K ohm resist or .

19 - 30 Ground These pins are tied to signal ground

31 Reset/Input

32 Error

Clear

1

1

ready for more data.

receive data due to data entry, a full buffer or error status.

paper.

conditi on . T h e printer sends a low logic l ev el to indicat e that it is off line or that the

input buffer is full.

A low pulse sent by the computer resets the printer and clears the print buffer. The

reset occurs on the trailing edge of the pulse

The printer sends a low log ic lev el t o th e c omp ut er to in dicate that it is in an er ror

state.

$FWLYHORZ

Product Info rmation1-10

Page 17

Spe cif i cati ons

The Centronics Parallel Cable has only 8 data lines, 5 status lines, 4 ground lines and

ground connections bet ween t he host PC and the peripheral. Each of the signal lines has a

correspond ing bit posit ion in a memor y address (register) in the host where data is read or

written. Sending data to the printer follows the sequence below:

Host places data in Data Out register

Host sends pulse on Strobe line

Printer sends pulse on Bus y in re sp onse to pulse on Strobe

Printer reads data on Data Out lines

Printer sends pu lse on ACK (Ackno wledge) line after data is read

This method of data transfer is also known as the Compatibility mode and the transfer

rate of data is slow. The printer while operating in compatibility mode is capable of

indicating limited printer error feedback to t he host computer. Su ch feedback includes:

Paper jam

Out of paper

Printer on or off line

Time out

Product Information1-11

Page 18

Spe cif ica tion s

IEEE 1284 Pinout Information

Any standard IEEE 1284 compliant printer cable will work with the printer. The

customer can order the HP IEEE 124 Compliant Parallel Interface Cable C2950A (2

meters) or C2951A (3 meters).

PIN NUMBER PIN ID DESCRIPTION

1 HostClk Used in a closed-loop handshake with PeriphAck to transfer data or address

2 - 9 AD 1 - AD8 Host to peripheral device or periph eral devic e to h os t ad dress or data. D at a 1 is

10 PeriphClk Used in a clos ed-loop han ds h ak e w ith H ostA ck (nAut oFd) t o tr ans f er dat a f r om

11 PeriphAck The peripheral uses this signal for flow control in the forward direction.

12 nAckReverse The peripheral drives this signal low to acknowledge nReverseRequest. The

13 Xflag This is used by the peri pheral device to reply to the requested extensibility byte

14 HostAck The host drives this signal for flow control in the reverse direction. It is used in

16 Logic Ground Logic board ground.

17 Chassis Ground Chassis Ground.

inform at i on from the host to t h e peripheral d evice.

the least significant bit (bit 0).

the peripheral device to host.

Pherip hAc k also provid es a ni nth data bit to det ermi ne whether c omm an d or

data information is present on the data signals in the reverse direction.

host reli es up on nAckR everse to deter mi ne when it is per mit ted to drive the

data signals.

during the negotiation phase.

an interlocked han ds h ak e w ith PeriphClk. Host Ac k also provid es a ninth data

bit used to d etermine wh eth er c om m and or data information is present on the

data sign als in th e forward dir ec ti on .

18 Peripheral Logic H ig h This sign al is us ed t o pr ovi d e +5V high logic .

19-30 Ground These pins are tied to signal ground

31 nReverseRequest This signal is driven low to place the channel in the reverse direction. While in

ECP mode, the peripheral is only allowed to driver the bi-directional data

signals w h en nRevers eR equest is low and 1284 Activ e is hi gh.

Product Info rmation1-12

Page 19

32 nPeriphRequest During EC P m ode the peripheral may drive this pin low to request

communications with the host. This request merely “hints” to the host; the host

has ultim at e c ontrol over th e trans fer direc ti on. This sign al pr ovides a

mechanism for peer-to-peer communication. This signal is valid in the forward

and reverse directions.

36 1284 Active Driven high by host whi le in ECP mode. Set low by the host to terminate ECP

mode and return the link to the Centronics (uni-directional) mode

The 1284 compliant cable supports the ECP (Extended Capabilities Port) mode in the

transfer of data. The ECP protocol includes a series of protocols that differ from standard

Centronics para llel port operation. These add it ional signaling methods a llow the host and

peripheral to negotiate any of faster transfer modes (e.g. DMA, FIFO and RLE

decompression). The protocol is hardware driven and the performance is limited by the

ISA bus bandwidth. The primary advantage is that once data transfer is negotiated, data

can flow without t he need of an ackno wledge or a return stat us signal. This ca n r e sult in a

transfer rate of up to 10 times faster than that of the compatibility mode that the

Centronics parallel cable supports.

To transfer data, the host first goes through a negotiation phase, which allows the host

and peripheral to select a mutually-supported communications mode. During the

negotiation phase, the host indicates which communication mode and options it would

like to use via the Extensibility Request Value. If the peripheral device does not support

the requested mode or options, it sets the Extensibility Flag low and the interface returns

to Compatibil ity Mode.

Product Information1-13

Page 20

Spe cif ica tion s

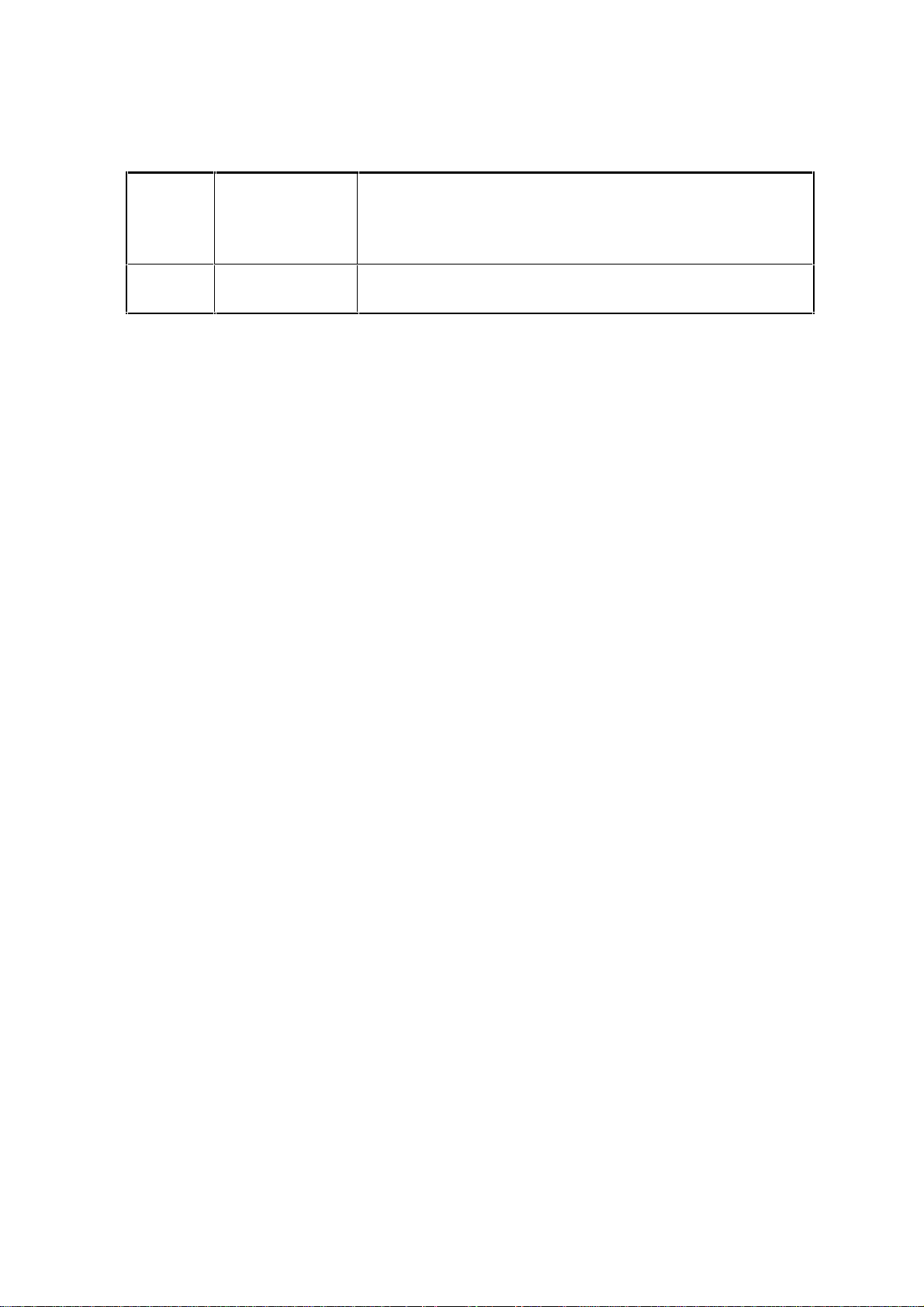

Reliability Specifications

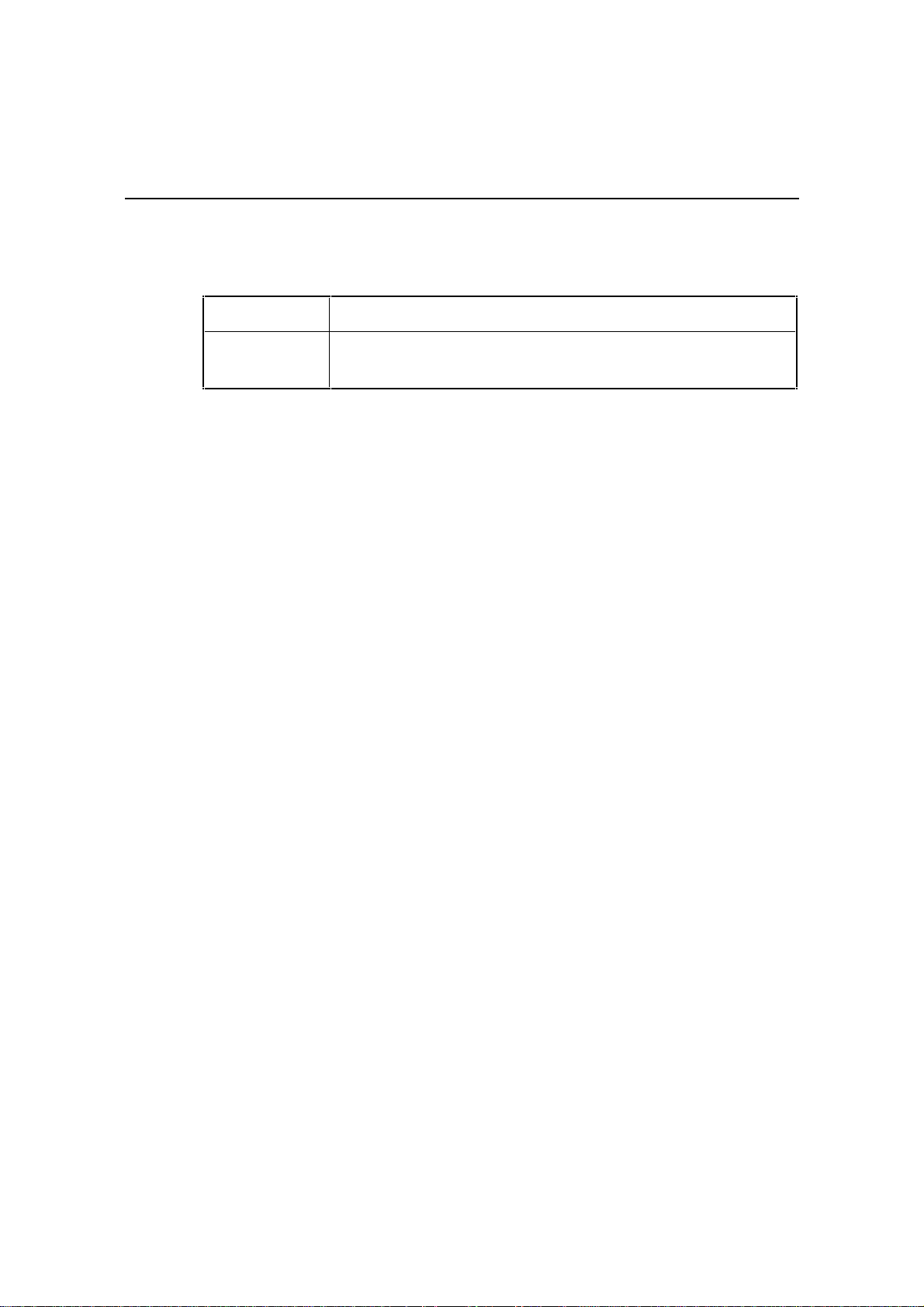

Category Specifications

Printer Usage Up to 12,000 pages / month

Mechanism Life 150,000 A size pages / 5 years

Product Info rmation1-14

Page 21

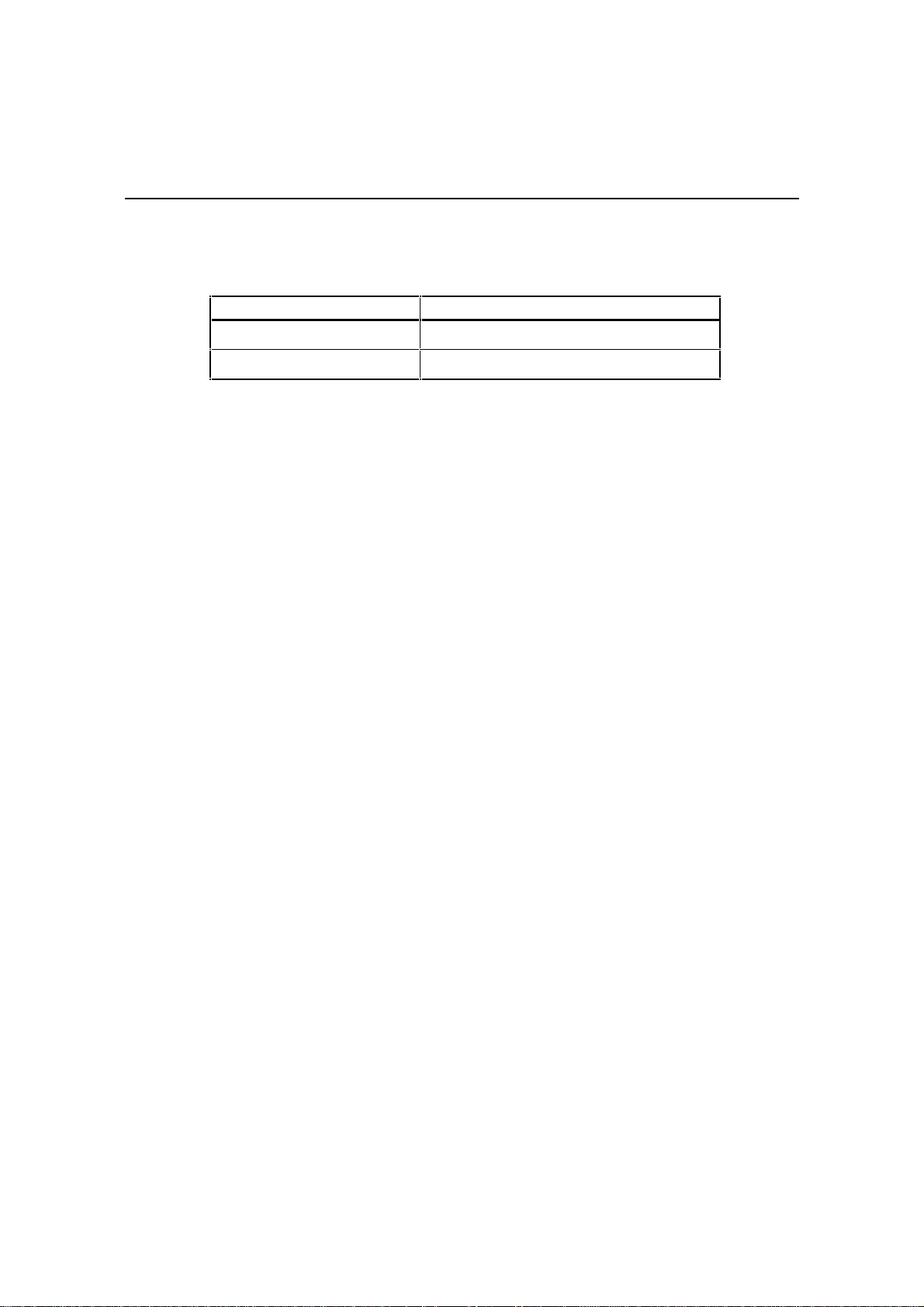

Spe cif i cati ons

Interface Specifications

Category Specifications

Interface Specification

Centronics parallel, IEEE 1284

Compliant with 1284-B

receptacle (ECP)

64KB buffer size

Product Information1-15

Page 22

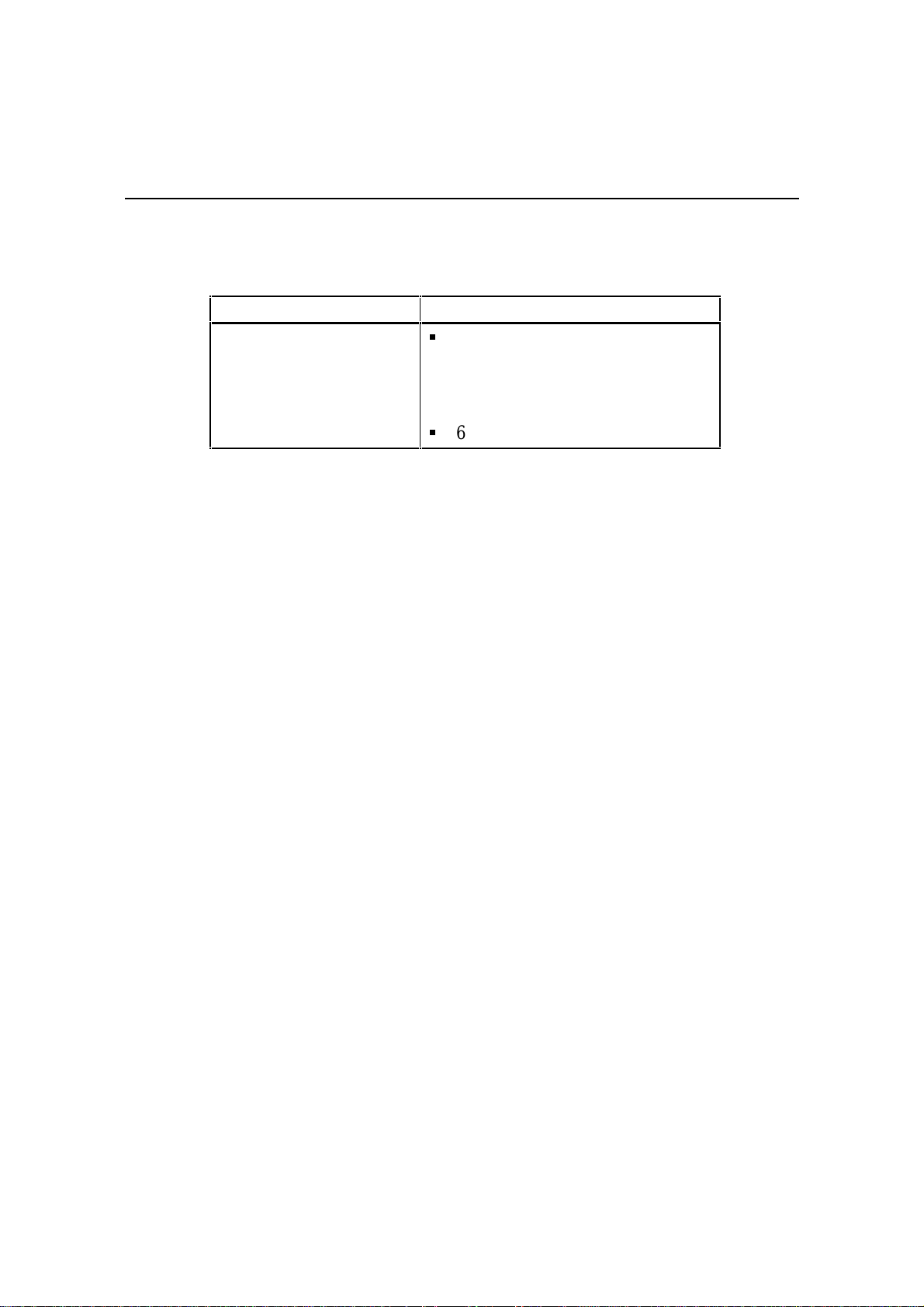

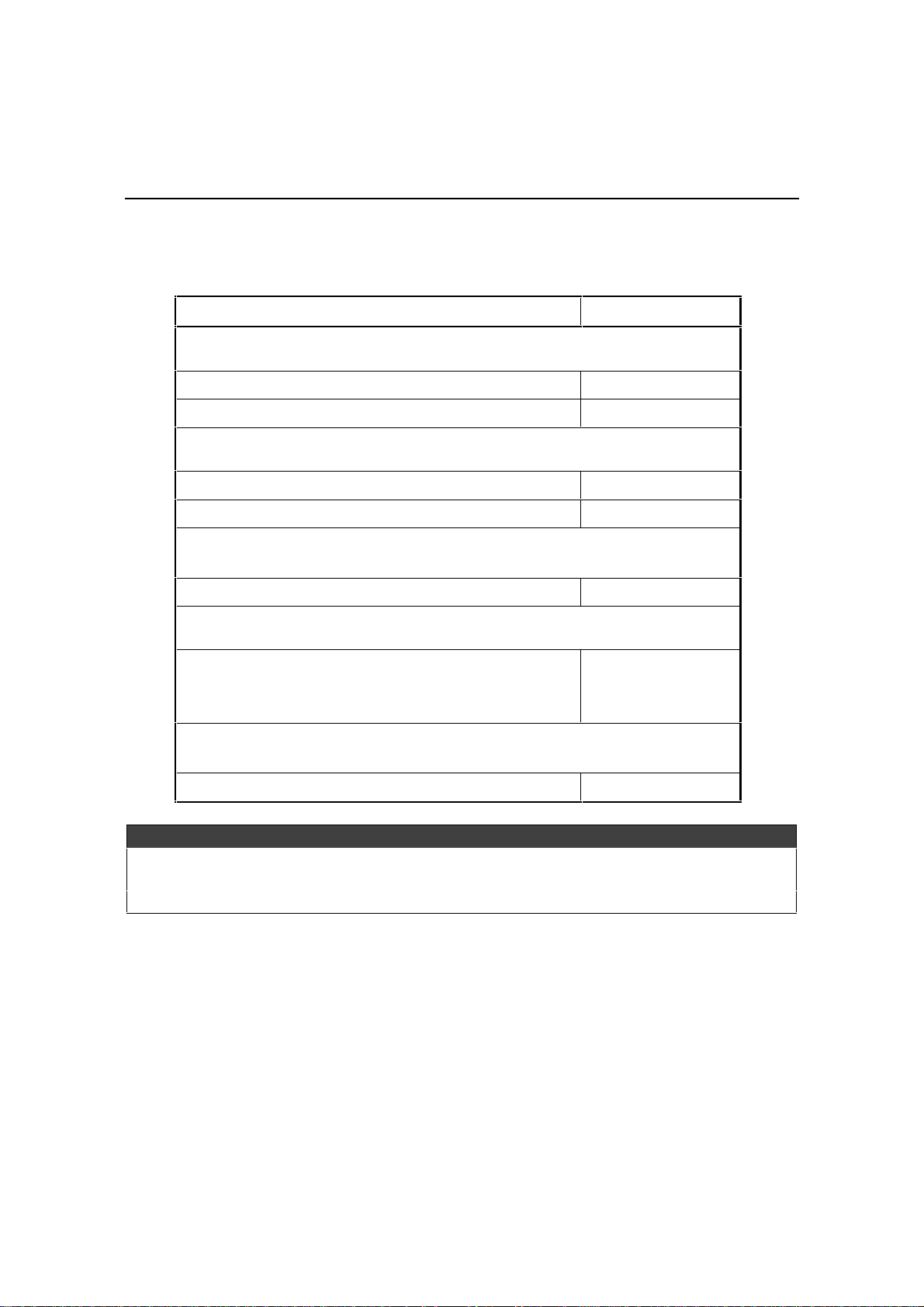

Spe cif ica tion s

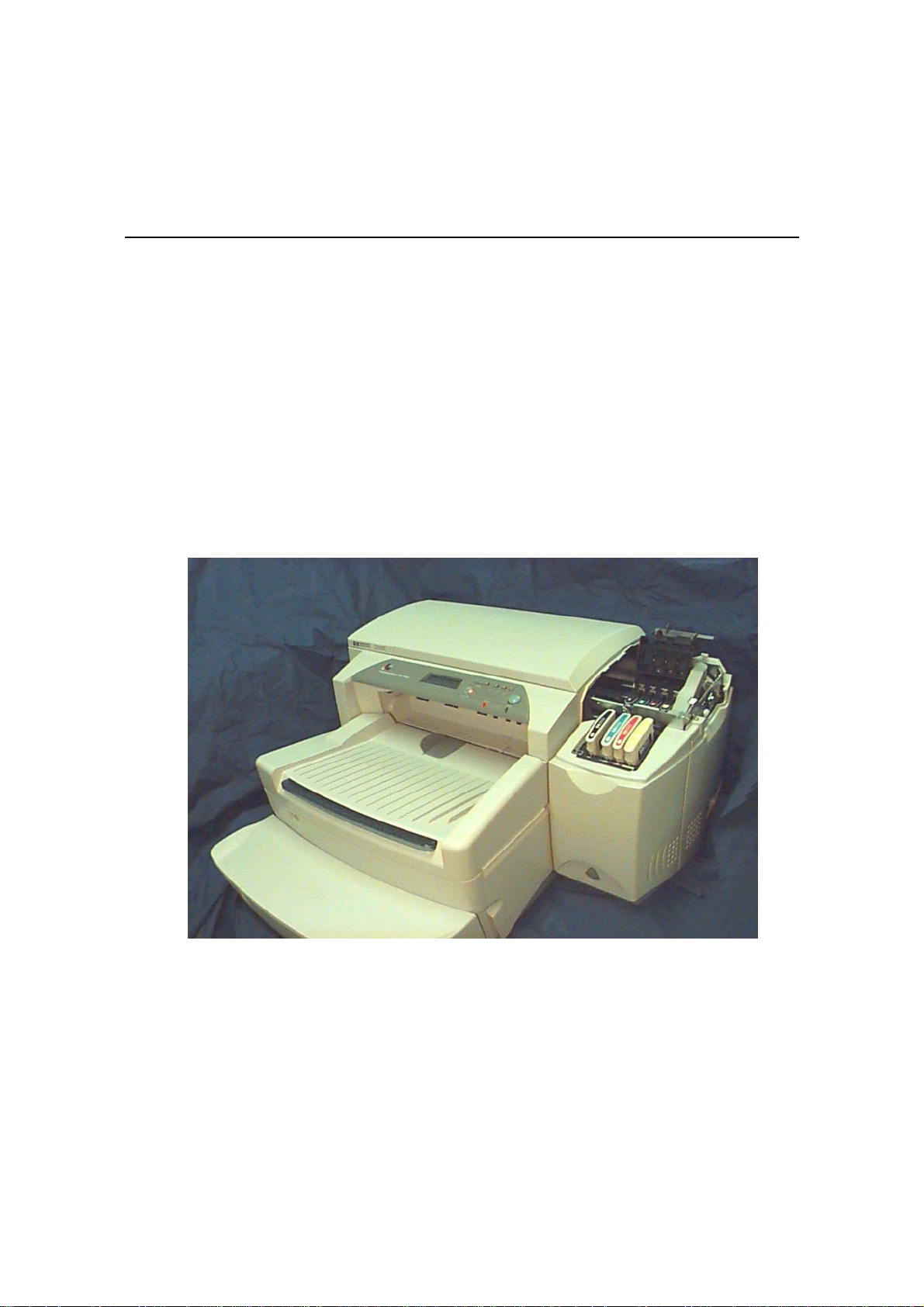

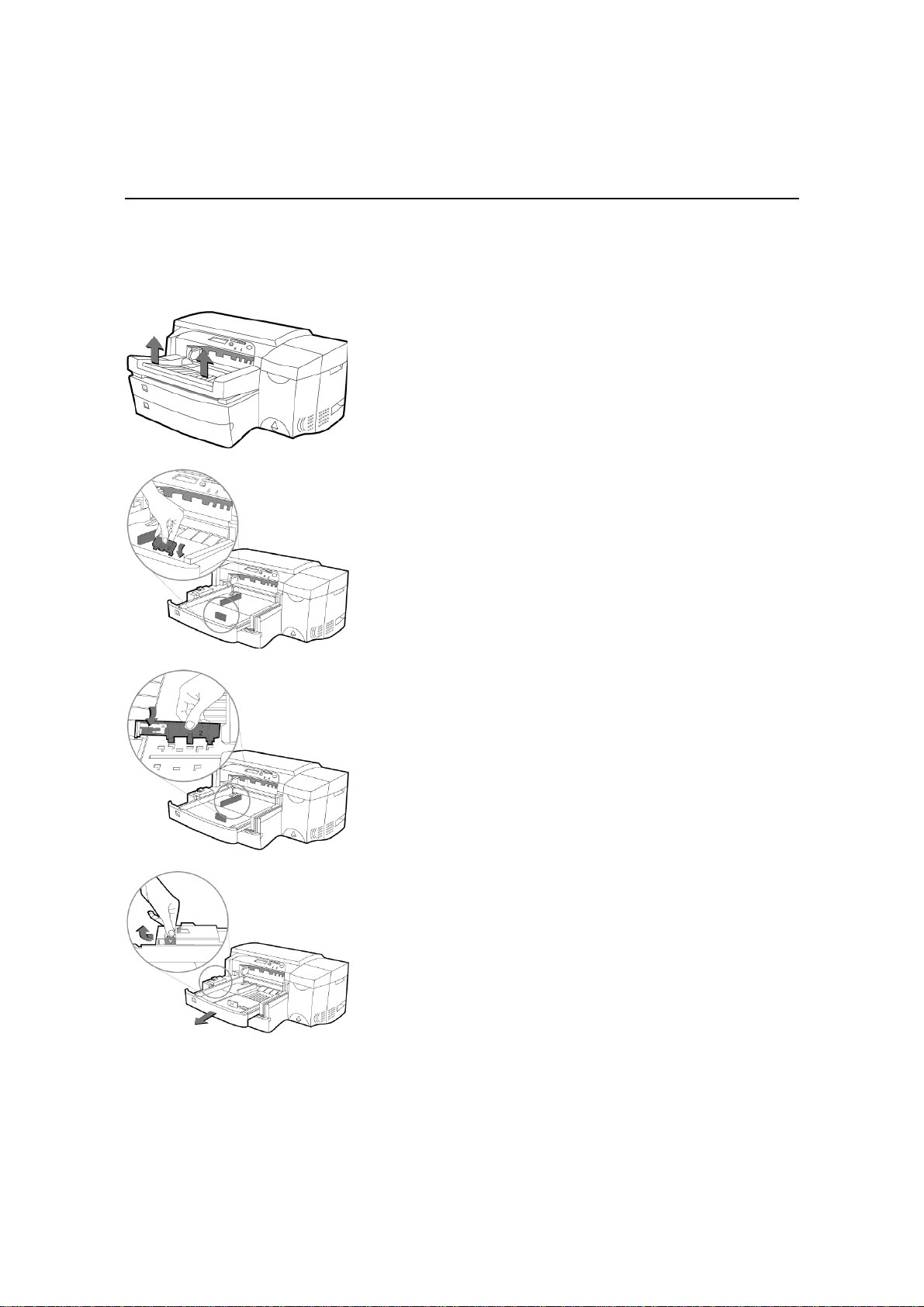

Physical Dimensions

With paper tray closed

(W x D x H )

With paper tray fully extended

(W x D x H )

Weight 26.5 kg (58.48 lb.) without printheads and

Desk space needed

(W x D)

27.0 x 24.0 x 13.3 inches

685 x 610 x 337 mm

27.0 x 29.3 x 13.3 inches

685 x 745 x 337 mm

ink cartridges

27.0 kg (59.52 lb.) with printheads and

ink cartridges

27.0 x 21.0 inches

685 x 532 mm

Product Info rmation1-16

Printer with paper tray closed

Printer with paper tray fully extended

Page 23

Spe cif i cati ons

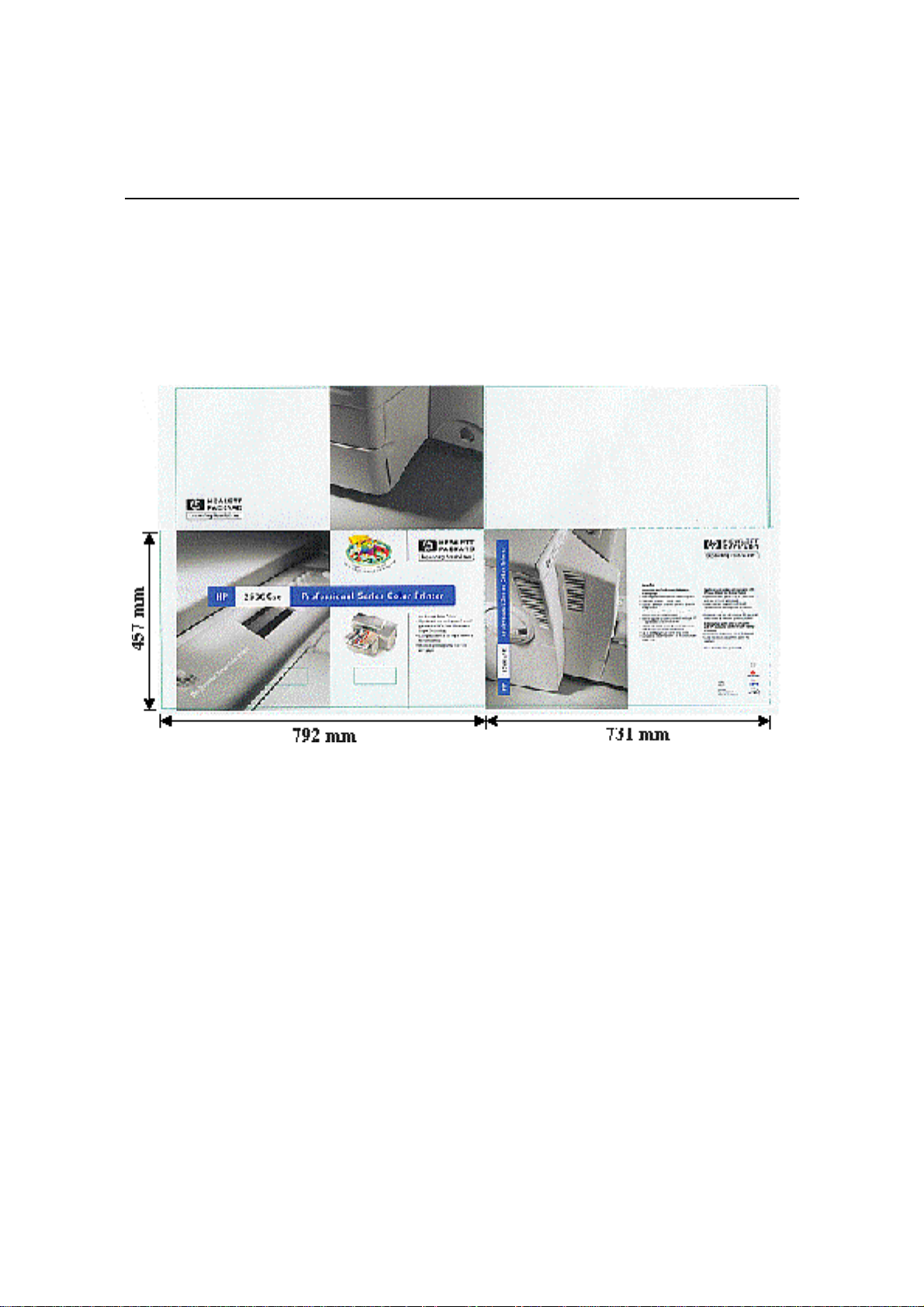

Packaging Dimensions Specifications

792 mm (31.3 in.) W x 731 mm (28.8 in.) D x 457 mm (18.0 in.) H

Product Information1-17

Page 24

Spe cif ica tion s

Electrical Specifications

Category Specification

Input Voltage

Frequency 50/60 Hz (±3 Hz)

Interface

Specification

Power Consumption

Idle

Printing

Transient Spike Immunity

Amplitude

Pulse width

Rise time

100 to 240 Vac (±10%)

Centronics parallel,

IEEE 1284 Compliant with 1284-B recept acle (ECP)

4.4 watts

35 watts max.

1 kV

50 µseconds

1.2 µseconds

Product Info rmation1-18

Page 25

Spe cif i cati ons

Environmental Specifications

Category Specifications

Temperature

Operating

Storage condition

Recommended oper at ing

Humidity

Operating

Storage condition

Recommended oper at ing

Altitude

Operating

Non-operating

5 °C to 40 °C (41 °F to 104 °F)

-40 °C to 60 °C (-40 °F to 140 °F)

15 °C to 35 °C (59 °F to 95 °F)

10%-80% RH non-condensing

10%-80% RH non-condensing

20%-80% RH non-condensing

0 to 3100 meters

0 to 4600 meters

Mechanical Vibration

Freq uency range

Operating (Random)

Non-operating (Random)

Swept Sine

Noise Levels per ISO 9296

Sound power L

pAm

5 to 500 Hz

Approximately 0.21 G rms

Approximately 2.09 G rms

0.5 (0 to peak)

49 dB(A) (By-stander position)

Product Information1-19

Page 26

Spe cif ica tion s

Product Certif ic ations

Safety Certifications EMI Certifications

CCIB (China) C TICK (Australia and New Zealand)

CSA (Canada) VCCI (Japan)

NOM1 (Mexico) CE (European Union)

PSB (Singapore) GOST (Russia)

TUV-GS (Germany) B m a rk (Pol and)

UL (USA) GOST (Russia)

SABS (South Africa) BCIQ (Taiwan)

JUN (Korea) RRL (Korea)

EMI FCC Class B whe n used with a Class B computing

device (USA)

Product Info rmation1-20

Page 27

Spe cif i cati ons

Media Sizes Supported

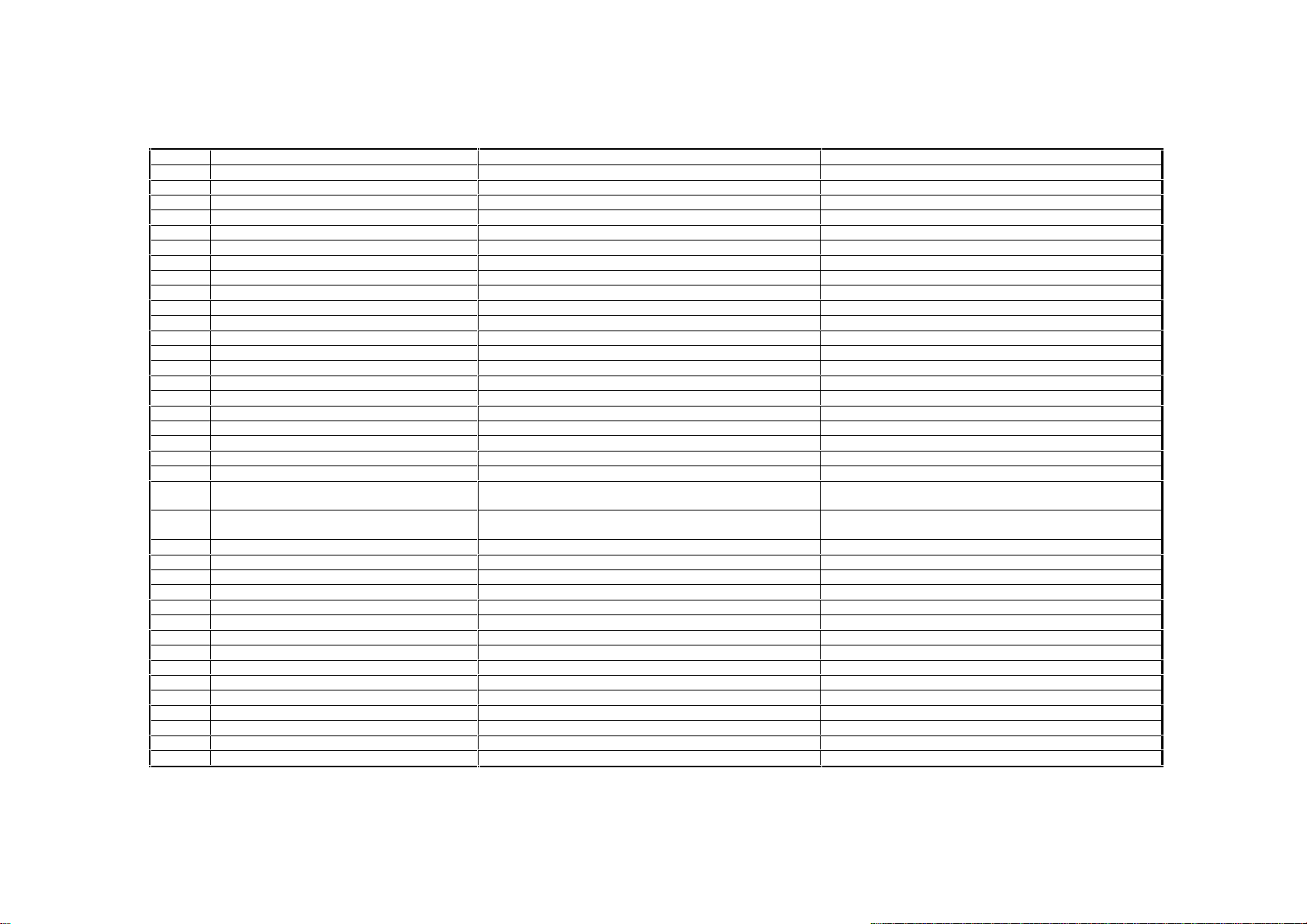

The following are the media sizes supported by the printer.

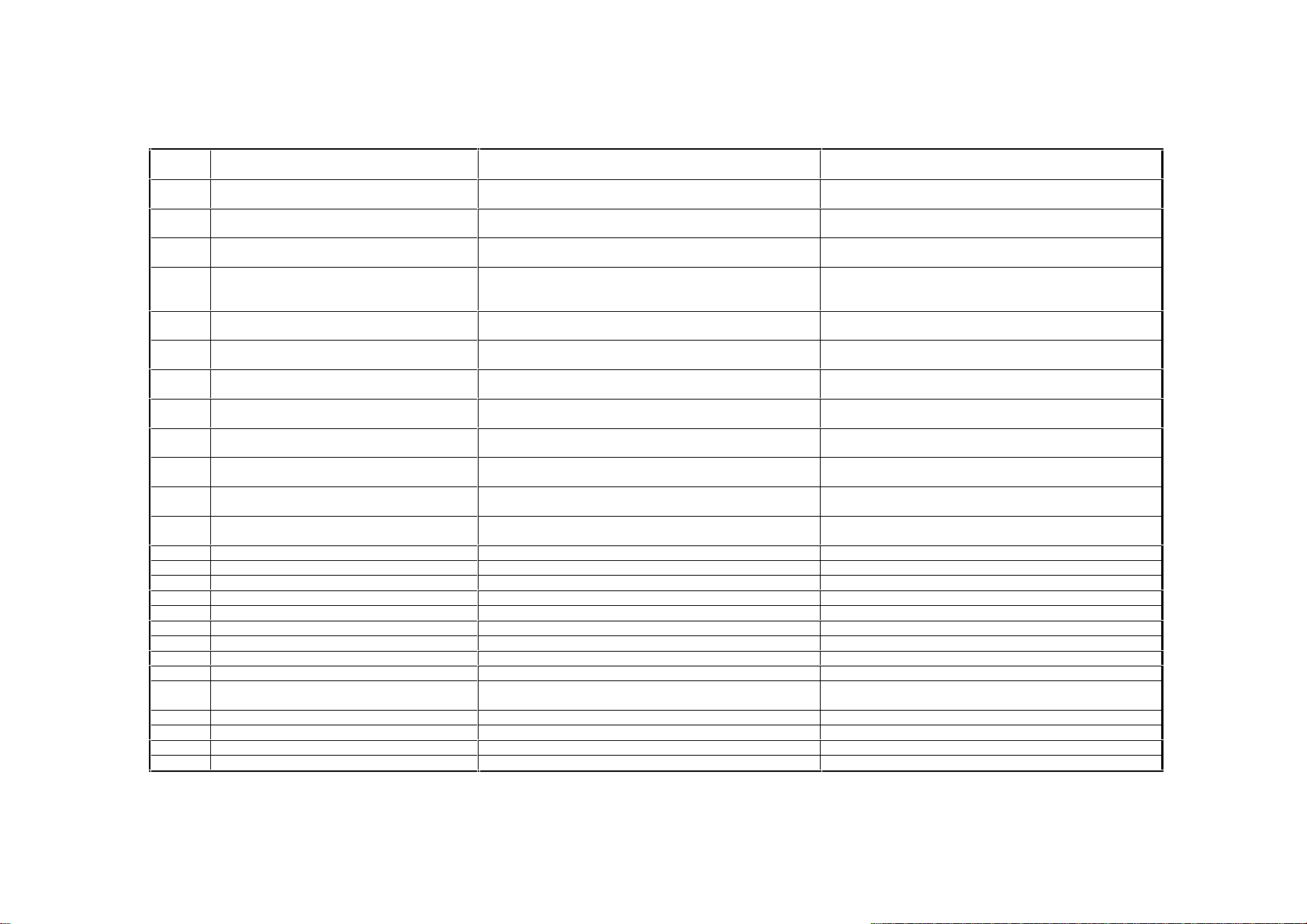

General type Sizes (mm) Sizes (inch) Remarks

Tray 1 (Input / Output Tray)

Post Card 100x148 3.94x5.83 Minimum Size

Including all media sizes in Tray 2 (Upper Tray) / Tray 3 (Lower Tray)

Tray 2 (Upper Tray) / Tray 3 (Lower Tray)

ISO-A4 210x297 8.27x11.7

US-Letter 215.9x279.4 8.5x11

US-Legal 215.9x355.6 8. 5x14

JIS-B4 257x364 10.11x14.33

US-B (Ledger) 279.4x431.8 11x17

ISO-A3 297x420 11.69x16.53

Super B 330.2x482.6 13x19 Maximum Size

Note

1. There are sensors mounted on Tray 2 (Upper Tray) and Tray 3 (Lower Tray) of the

printer to detect the sizes of paper in use on each tray.

2. The printer is capable of printing on custom-sized media provided that its

dimensions conform to the mini mum and maximum siz e definition.

3. Envelopes are not supported on the HP DesignJet ColorPro CAD/GA Printer.

Product Information1-21

Page 28

Spe cif ica tion s

Recommende d Media Weight

Paper

Cardstock 110 to 200 g/m2 (110 lb. Index)

60 to 135 g/m2 (16 to 36 lb. Bond)

(up to 0.012 in. or 0.3 mm thickness for straight paper path)

Product Info rmation1-22

Page 29

Spe cif i cati ons

Paper Ha ndling

Tray 1 (Input / Output Tray)

Sheets 10

Cards 4

Tray 2 (Upper Tray)

Sheets 150

Cards 60

Tray 2 (Upper Tray)

Sheets 250

Media Type Capacity (Pages)

Rear Manual Feed

All media sizes from 4x6 inches (101.6x152.4mm)

to 13x19 inches (330.2x482.6mm) and maximum

thickness of 0.3mm (0.012 inches)

Output Tray

Sheets (face-up) 150

Note

1. There is a sensor mounted on t he bypass paper feed to indicat e whet her it is in use.

1

Product Information1-23

Page 30

Spe cif ica tion s

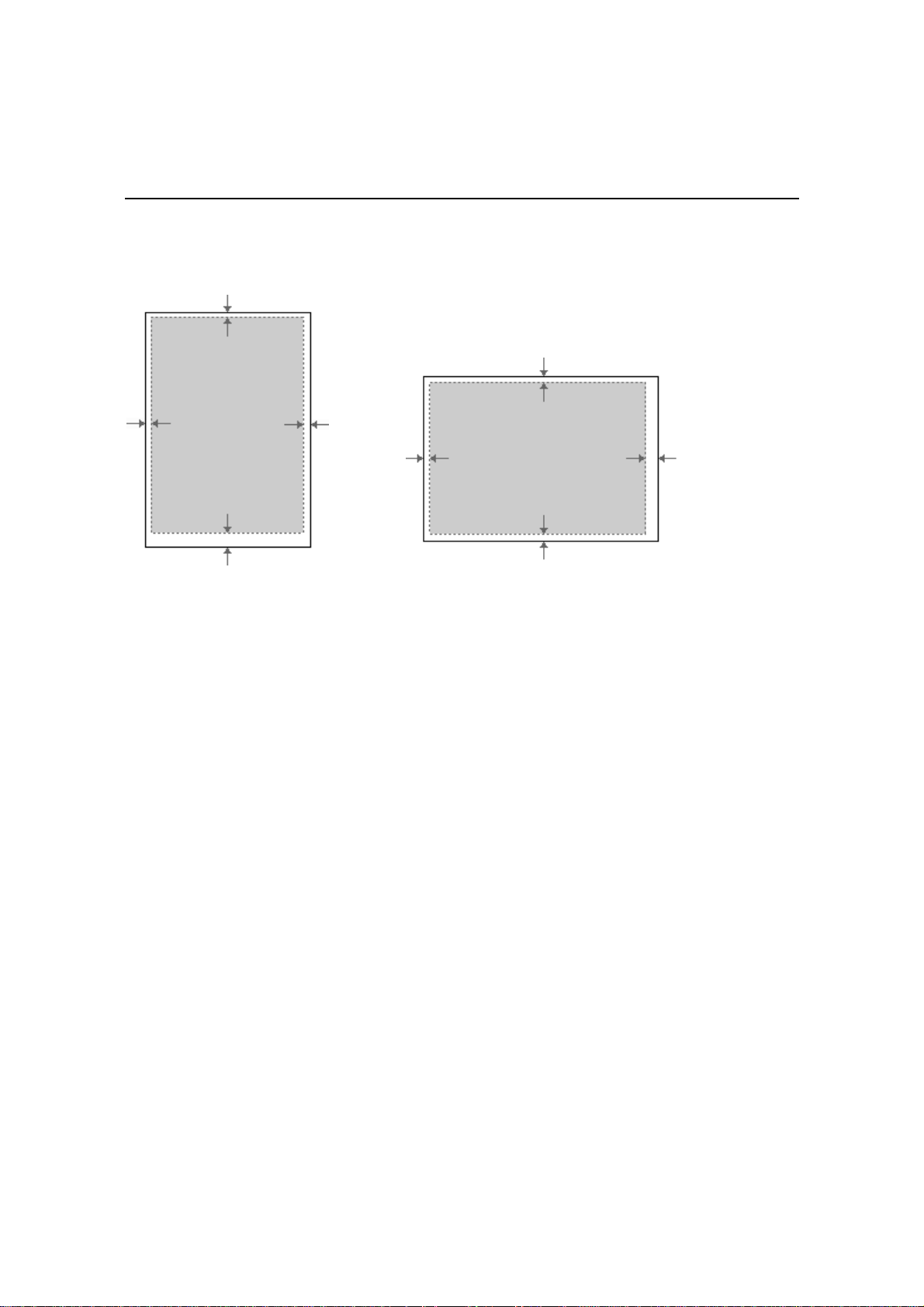

Printable Area

Printable area

(Portrait

orientation)

The table as follows will show the minimum margin of each media type (portr ait

orientatio n) for the HP DesignJet ColorPro Series Printer.

Please note that the printable area is smal ler than that of HP LaserJets. However in the

HP DesignJet ColorPro pr inter driver so ftware t here is a new utility that can

automatically ad just the margins of LaserJet formatted documents so t hat the y can be

printed without the loss of any formatting.

Printable area

(Landscape orient ation)

Product Info rmation1-24

Page 31

Spe cif i cati ons

Media Margins (in portrait orientation)

Media Type

US Letter

8.5 x 11 in.

215.9 x 279.4 mm

Tabloid / Ledger

11 x 17 in.

279.4 x 431.8 mm

A4

8.27 x 11.69 in.

210.00 x 296.9 mm

A3

11.69 x 16.53 in.

296.9 x 419.9 mm

B4

10.12 x 14.33 in.

257.0 x 364.0 mm

Legal

8.5 x 14 in.

215.9 x 355.6 mm

Executive

7.25 x 10.50 in.

184.2 x 266.7 mm

A5

5.83 x 8.27 in.

148.0 x 210.0 mm

B5

7.16 x 10.12 in.

181.9 x 257.0 mm

4x6 Index Card

4.00 x 6.00

101.6 x 152.4

5x8 Index Card

5.00 x 8.00

127.0 x 203.2

Left Right Top Bottom Comments

0.25 in.

6.4 mm.

0.20 in.

5.1 mm.

0.13 in.

3.4 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.25 in.

6.4 mm.

0.25 in.

6.4 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.25 in.

6.4 mm.

0.20 in.

5.1 mm.

0.13 in.

3.4 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.25 in.

6.4 mm.

0.25 in.

6.4 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

Margins

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

Landscape

Orientation

Product Information1-25

Page 32

A6 Card

4.13 x 5.83

105.0 x 148.0

Hagaki Card

3.94 x 5.83

100.0 x 148.0

Super B

13.00 x 19.00

330.2 x 482.6

Statement

5.50 x 8.50

139.7 x 215.9

C Size

17.00 x 22.00

431.8 x 558.8

A2

16.53 x 23.38

419.9 x 593.9

Hagaki

7.87 x 5.83

200.0 x 148.0

A3 Nobi

13.00 x 19.00

330.2 x 482.6

Custom

3.94 to 13.00 x 5.83 to 19.00

100 to 330 x 148 to 482

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.40 in.

10.2 mm.

0.40 in.

10.2 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.40 in.

10.2 mm.

0.40 in.

10.2 mm.

0.51 in.

13.0 mm.

0.51 in.

13.0 mm.

0.50 in.

12.7 mm.

*NEC only

*NEC only

Note

For the printable regions o f landscap e orientation, just reverse t he matrix on the t able

above. For example, the matr ix for US Letter size in portrait is 8.5 x 11 inches, so in

landscape the matrix is 11 x 8.5 inches.

Product Info rmation1-26

Page 33

Spe cif i cati ons

Hewlett-Packard Ink Cartridge Specifications

Category Specification

Type

Printhead Nozzles

Black Resolution

Color Resolution

Ink Drop V o lume

Print Speed1 Blac k Black Text

Plain paper drop on-demand thermal inkjet printing

304 black, 912 color (304 per color printhead)

Up to 600x600 dpi

PhotoREt II for photo quality

35ng black, 8ng color drop volume for high resolution print ing

Econofast Mode

Normal Mode

Best Mo d e

Letter / A4

9 ppm

7 ppm

7 ppm

11x17 / A3

5 ppm

3 ppm

3 ppm

Print Speed1 Color

Color Highlights

Econofast Mode

Normal Mode

Best Mo d e

Mixed Text & Graphics

Econofast Mode

Normal Mode

Best Mo d e

Full Page Color Highlights

Econofast Mode

Normal Mode

Best Mo d e

1

Approximate figures. The exact speed is dependent on the

system configuration, software progr am and document

complexity.

Letter / A4

9 ppm

6 ppm

5 ppm

Letter / A4

7 ppm

3.5 ppm

1.2 ppm

Letter / A4

3.5 ppm

1.8 ppm

0.4 ppm

11x17 / A3

5 ppm

3 ppm

2 ppm

11x17 / A3

4 ppm

2 ppm

0.5 ppm

11x17 / A3

1 ppm

0.8 ppm

0.2 ppm

Product Information1-27

Page 34

Spe cif ica tion s

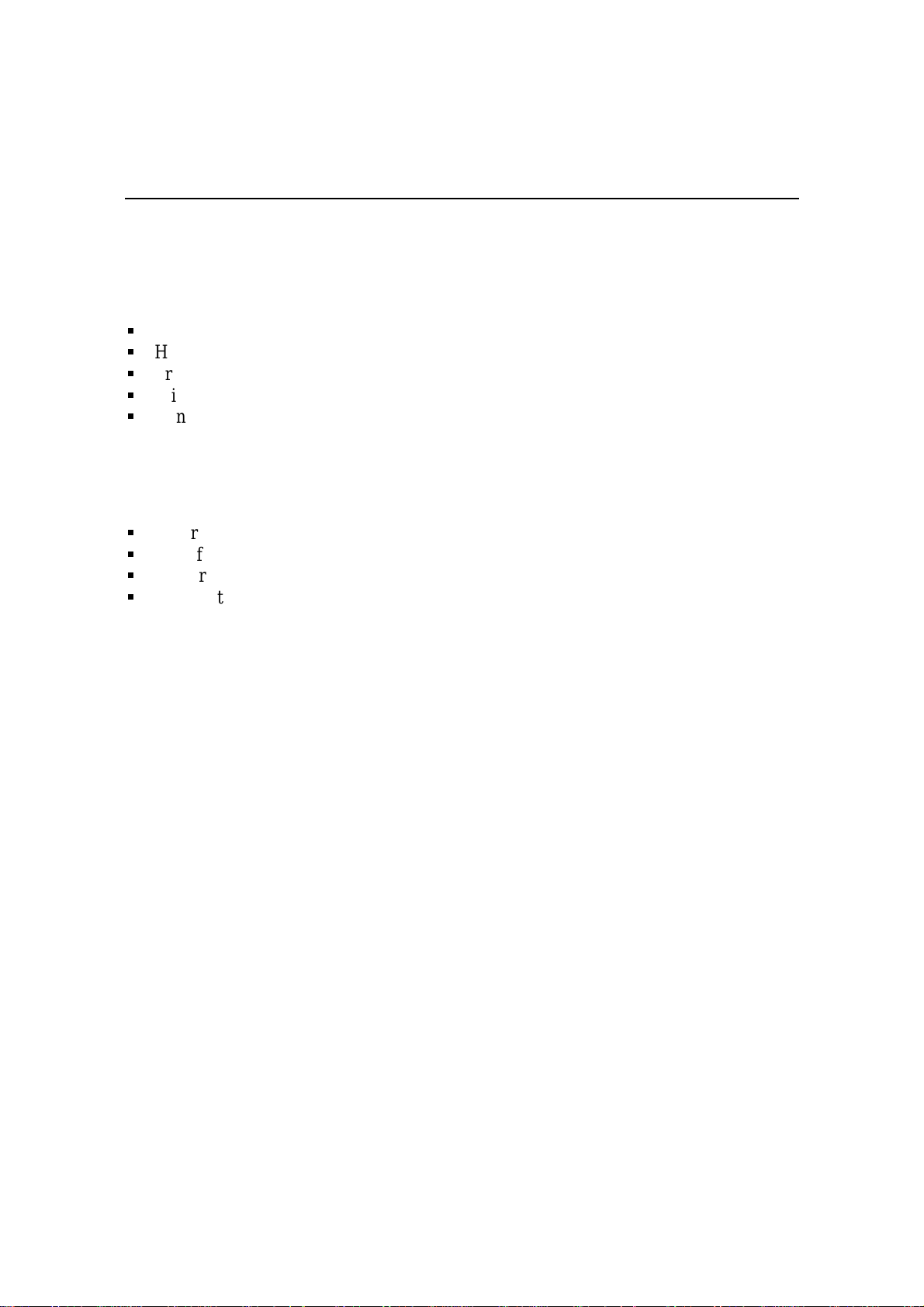

System Requirement

The following CPUs and memory are required :

Minimum: Windows 3.1x: 486DX-66, 8 Mb RAM

Windows 95/98: 486DX-100, 8 Mb RAM

Windows NT 4.0/5.0: 486DX-66, 16 Mb RAM

Macintosh System 7.5.3 or later: 68040 – 8 Mb RAM

Recommended: Windows 3.1x: Pentium 150/166, 16 Mb R AM

Windows 95/98: Pentium 150/166, 16 Mb RAM

Windows NT 4.0/5.0: Pentium 150/166, 32 Mb RAM

Macintosh System 8 or later: Power PC – 16 Mb RAM

50 Mb free hard disk space for 11x17 or A3 size print ing.

Graphics intensive files may require more disk space.

Product Info rmation1-28

Page 35

Product Overview

Printer External View

Model and Seri al Number

The serial number of the HP DesignJet ColorPro Series Printers can be found on the

labels at the back of each printer and at the top of the main case (concealed by the top

cover). The figure below shows how t he serial number is interpreted.

Serial Number = CCYMDVL###

CC (Country) T he co unt r y show where the printer was manufact ur ed.

Y (Year) The year the printer was manufactured.

M (Mont h) The mo nth t he printer was manufactur ed.

D (Day) The day the printer was manufactured.

V (Version) The printer model version 1 indicates HP DesignJet ColorPro, other

version numbers will be assigned as needed. Contact a technical support

engineer if you need to know which version a new number refers to.

L (Line) The factor y assembly line which manufact ur ed t his printer.

### These three digits allow a maximum of 27,000 unique serial numbers per

line per day. This unit number is in base 30.

Product Information1-29

Page 36

Supplies and Accessories

Pr oduct Structur e

The following it e ms will be shipped in the box:

Basics

Printer

Extended Tray Cover (a)

Driver Kit

Starter CD (b)

HP JetDirect CD (HP DesignJet ColorPro GA

printer only)(b)

User’s Guide (d)

Hardcopy Kit

Setup Poster (c)

Getting Started Guide (Not available in U.S.)

Quick Reference Guide (e)

User ’s G uide (Ava ilable in U.S . only)

Accessory Ki t

Power Cord (f)

Four HP No. 10 Ink Cartridges (h)

(Black, Cyan, Magenta and Yellow)

Four HP No. 10 Printheads (g)

(Black, Cyan, Magenta and Yellow)

Product Info rmation1-30

Page 37

Supplies and Accessories

Power Cord

US 8120-6805 #ABB, #ABM, #AC4, #AKY, #A2L, #ABA

Europe 8120-6802 #ABS, #AKB, #ACB, #ABT, #AKC, #ACT,

#AB7, #ABB, #ARG, # ARP, # AKY

Australia 8120-6803 #ABG, #AKY

Singapore / Malaysia 8120-6809 #AB4

SA 8120-6808 #ACQ

UK 8120-6801 #ABU

Product Information1-31

Page 38

Supplies and Accessories

Network Interface

The following cards have been tested with the HP DesignJet ColorPro Series Printers.

JetDirect MI O print ser ver card

(Bundled with HP HP DesignJet

ColorPro GA)

JetDirect MI O print ser ver card

300X Print Server J3263A Ethernet

J4100A Ethernet

RJ-45 (10/100 base-TX)

BNC

J2556B Ethernet

RJ-45 (10/100 base-TX)

J2550B Ethernet

RJ-45 (10 Base-T)

J2552B Ethernet

BNC (Thin Coax)

RJ-45 (10 Base-T)

LocalTalk System 7

J2555B To ken Ring

DB9, RJ-45

RJ-45 (10/100 base-TX)

Parallel Port

Product Info rmation1-32

Page 39

Supplies and Accessories

Print Cartridge

No. 10 Cyan Ink Cartridge C4841A

No. 10 Magenta Ink Cartridge C4842A

No. 10 Yellow Ink Cartridge C4843A

No. 10 Hi Capacity Black Ink Cartridge C4844A

No. 10 Cyan Pen C4801A

No. 10 Magenta Pen C4802A

No. 10 Yellow Pen C4803A

No. 10 Black Pen C4800A

Note

The HP DesignJet Co lorP ro S er ies Printer s are shipped w ith a Low Capacity Black Ink

Cartridge (C4840A).

Product Information1-33

Page 40

Supplies and Accessories

Media

HP Bright White Paper (500 / A size) C1824A

HP Bright White Paper (500 / A4 size) C1825A

HP Bright White Paper (200 / 11x17 size) C1857A

HP Bright White Paper (200 / A3 size) C1858A

HP Premium InkJet Coated Paper (200 / A) 51634Y

HP Premium InkJet Coated Paper (200 / A4) 51634Z

HP Premium InkJet Coated Paper (100 / 11x17) C1855A

HP Premium InkJet Coated Paper (100 / A3) C1856A

HP Premium InkJet Heavyweight Paper (100 / A) C1852A

HP Premium InkJet Heavyweight Paper (100 / A4) C1853A

HP Premium Photo Paper (20 / 11x17) C6058A

HP Premium Photo Paper (20 / A3) C6059A

HP Premium Photo Paper (15 / A) C6039A

HP Premium Photo Paper (15 / A4) – European C6040A

HP Premium Photo Paper (15 / A4) – Asian C6043A

HP Premium InkJet Transparency Film (20 / A) C3828A

HP Premium InkJet Transparency Film (20 / A4) C3832A

HP Premium InkJet Transparency Film (50 / A) C3834A

HP Premium InkJet Transparency Film (50 / A4) C3835A

HP Premium InkJet Rapid-Dry Transparency Film (A) C6051A

HP Premium InkJet Rapid-Dry Transparency Film (A4) C6053A

HP Iron-On T-Shirt Transfers (10 / A) C6049A

HP Iron-On T-Shirt Transfers (10 / A4) C6050A

HP Greeting Card Paper C1812A

HP Greeting Card Paper (Europe Only) C6042A

HP White Labels 1”x2.5/8” Addressing Labels 92296A

HP White Labels 1.1/3”x4” Addressing Labels 92296B

HP White Labels 1”x4” Addressing Labels 92296C

HP White Labels 2”x4” Shipping Labels 92296D

HP White Labels 3.1/3”x4” Shipping Labels 92296E

HP White Labels 1/2”x1.3/4” Return Address Labels 92296F

HP White Labels 8.1/2”x11” White Full Sheet Labels 92296K

HP White Labels 99.1x38.1mm Addressing Labels 92296L

HP White Labels 99.1x38.8mm Addressing Labels 92296M

HP White Labels 63.5x38.1mm Addressing Labels 92296N

HP White Labels 100x51mm Addressing Labels 92296P

HP White Labels 199.6x289mm Full Sheet Labels 92296R

HP White Labels 99.1x67.7mm Parcel Labels C4296A

HP White Labels 63.5x46.6mm Addressing Labels C4297A

Product Info rmation1-34

Page 41

Supplies and Accessories

Other Accessories

HP 64MB (2x32MB) 60ns EDO SIMM D4543A

HP 32MB (2x16MB) 60ns EDO SIMM D3648B

HP 16MB (2x8MB) 60ns EDO SIMM D3647B

HP DesignJet ColorPro CAD Po stscript 3

Upgrade Kit

Customer Replaceable Parts

Note

The following parts ar e custo mer replaceable parts. Replacing these part s r equire no

technical expert ise. These parts can be sent directly to the customer by the Customer

Care Centers after qualification. This process is based on the pre mise that customers

agree to replace the parts themse lves.

The exceptions to th is process are t he PCA Log ic and Service Station. These two parts

require some technica l capa bilit y and w ill only be sent to customers that have the

capabilities to replace t hese t wo modu les.

C3289A

PCA-Logic C2684-60200

CAD NamePlate (ColorPro CAD Printer) C7777-40001

GA NamePlate (ColorPro GA Printer) C7778-40001

Cover Main PCA C2684-60206

Side Cover Service Station C2684-60210

Assembly Secondary Access Door C2684-60212

Assembly Output Tray C2684-60214

Removable Trough C2684-60215

Assembly Dual Bin Tray C2684-60224

Adjuster Width Dual Bin C2684-60225

Adjuster Length Dual Bin C2684-60226

Media Plate C2684-60227

Adjuster Length I/O C2684-60232

Adjuster Width I/O C2684-60233

Tray Cover C2684-60108

CAD Front Cover (ColorPro CAD Printer) C7777-40002

GA Front Cover (ColorPro GA Printer) C7778-40002

Service Station C2684-60273

Plate Media 2 C2684-60274

Foot C2684-60275

Product Information1-35

Page 42

Warranty and Support

The warranty for HP DesignJet ColorPro Series Printers varies depending on the product,

the date and the country of purchase.

For products returned under warranty, Hewlett-Packard may :

Provide on-s ite repair,

Replace the product with a remanufactured unit,

Replace the product with a product of equal or greater functionality or

Refund the purchased price.

Product Info rmation1-36

Page 43

Warranty and Support

Hewlett-Packard Limited Warranty Statement

HP Product Duration of Limited Warranty

Software 1 year

Print Cartridges 90 days

Printer 1 year

Printheads 1 year

Extent of L imited Warranty

1. Hewlett-P ackar d (HP) war r ant s to the end user customer that HP products will be free

from defects in materials and workmanship, for a specified time after the date of

purchase by the customer. The duration of this limited warranty is stated above.

Certain additiona l condit io ns and limitations of HP’s warranty are stated in the user’s

guide. Those conditions and limitations include:

a. For software products, the warranty applies only to the media upon which the

product is recorded; and

b. H P does not w arrant the operation of any product to be unint errupte d or error fr e e.

2. HP’s limited warrant y covers onl y those de fects which arise as a result of normal use

of the product, and do not apply to any:

a. Improper or inadequate maintenance;

b. So ftware or interfacing not supplied by HP;

c. Unauthorized modificat ion or misuse;

d. Operation outside the product’s environment specifications, including duty cycle

abuse or use of a mechanical switch-box without a designated surge protector;

e. Use of non-supported printing media or memory boards; or

f. Improper site preparation or maintenance.

3. For HP printer products, the use of a non-HP print cartridge or a refilled print

cartridge does not affect either the warrant y to the customer or any HP support

contract with the customer; pr int cart r idge includes bot h toner cartr idges and ink

cartridges. However, if printer failure or damage is attributable to the use of a nonHP or refilled print cartridge, HP will charge its standard time and materials charges

to service the printer for the particular failure or damage.

4. If any software media product or print cartridge product proves defective during the

applicable warranty period, and if the product is covered by HP’s warranty, the

customer shall retur n the product for replacement.

Product Information1-37

Page 44

5. If HP receives, during the applicable warrant y period, not ice o f a defect in a hardware

product which is covered by HP ’ s warr anty, HP shall either repair or replace the

product, at its option. Any replacement product may be either new or like-new,

provided that it has functionality at least equal to that of the product being replaced.

6. If HP is unable to repair or replace, as applicable, a defective product which is

covered by HP’s w a rranty, HP shal l within a reasonable time after being notified of

the defect, refund the purchase price for the pro duct, provided t he custo mer ret ur ns

the product.

7. The warranty is valid in any country where this product is distributed by Hewlett-

Packard. Contract s for additional ser vice s suc h as o n-s ite ser vic e ar e avai lable from

any authorized HP service facility in countries where this product is distributed by HP

or an authorized importer.

8. This limited Warrant y Statement gives the customer specific legal rig ht s. The

customer may also have ot her legal rig ht s which vary from state to state in the United

States, from province to pro vince in Canada, and from country to country elsewhere

in the world.

Limitations of Warr anty

1. NEITHER HP NOR ANY OF ITS THIRD PARTY SUPPLI E RS MAKES ANY

OTHER WARRANTY OF ANY KIND, WHETHER EXP RE SS OR IMPLIED,

WITH RESPECT TO HP PRODUCTS . HP AND ITS THI RD PARTY SUPPLI E S

SPECIFICALLY DISCLAIM THE IMPLIED WARRANTIES OF

MERCHANT ABILI TY AND FITNESS FOR A PARTI CUL AR P U RP OS E .

2. To the extent that this Limited Warranty Statement is inconsistent with the law of the

locality where the customer uses the HP product, this Limited Warranty Statement

shall be deemed modified to be consistent with such local law. Under such local law,

certain limitations of this Limited Warranty Statement may not apply to the customer.

For example, some states in the United States, as well as some governments outs ide

the United States (including pro vinces in Canada), ma y:

a. Preclude the disclaimers and l imitations in this Warranty Stat ement fro m limiting

the statutory rights of a customer (e.g. Australia and the United Kingdom);

b. Otherwise restrict the ability of a manufacturer to make such disclaimers or

impose such limitations; or

c. Grant the customer additional warranty rights, specify the duration of implied

war ranties which the manufactur er cannot discla im, o r not allow li mitations on

how long an implied warra nty la s ts.

3. To the extent allowed by local law, the remedies provided in this Warranty Statement

are the customer’s so le and exclusive re med ies.

Product Info rmation1-38

Page 45

Limitations of Li ability

1. EXCEPT FOR THE OBLIGATIONS SPECIFICALLY SET FORTH IN THIS

WARRANTY STATEMENT, IN NO EVENT SHALL HP BE LIABLE FOR ANY

DIRECT, INCIRECT, SPECIAL, INCIDENT AL, OR CONSE QUE NTIAL

DAMAGES, WHETHE R BASED ON CONT RACT, T ORT, OR ANY OTHER

LEGAL THEORY AND WHETHER ADVISED OF THE POSSIBI LIT Y OF SUCH

DAMAGES.

Product Information1-39

Page 46

Warranty and Support

Obtaining Printer Drivers

The HP DesignJet ColorPro Series Printer Driver Software is updated periodically. T he

latest versions can be obt ained from authorized Hewlett-Packar d dealers or any of the

sources listed below.

24-hour Modem Access

Internet

HP DesignJet ColorPro Series Printer drivers and product support information can be

obtained through the World Wide Web at:

http://www.designjet-online.hp.com

HP BBS Library

The HP DesignJet ColorPro Series Printer dr ivers ca n also be obtained at HP’s electronic

bulletin board library service. Refer to HP BBS Library under Service and Support

Resources for the list o f phone numbers.

Set modem communications software to: no parity, 8 bits, and 1 stop bit.

Product Info rmation1-40

Page 47

Warranty and Support

Service Support Contracts

In the U.S.

HP SupportPack

The HP SupportPack is an enhancement to the cust omer’s original one-year warranty

repair service. The HP SupportPack provides next business day on-site support for the

duration of an additional two years of warra nty. This service enhancement provides

customers with a cost-effective and timely way to achieve quality support. The HP

SupportPack (ordered like any other HP product) is sold exclusively through resellers and

is not available direct ly from Hewlett-Packard. Customers MUST purchase this service

enhancement within 30 days of purchasing the printer. The HP SupportPack is not

transferable fro m one piece of equipment to anot her. Additional information on HP

SupportPack and the prices for the service upgrade are available through HPNN and the

In-Touch newsletter.

Non-U.S.

HP SupportPack

The HP SupportPack enhances the service offering during the warranty period by

upgrading warranty repair service to a next day exchange service. This service

enhancement prov ides customers with a cost-effective and t imely wa y to achieve qualit y

support. HP SupportPack is sold exclusively through resellers (ordered like any other HP

product) and is not available directly from Hewlett-Packard. Additional information on

HP SupportPack and the prices for the service upgrade is available through HPNN.

For other service and support contracts, contact the Hewlett-Packard office or Response

Center for that count r y.

Product Information1-41

Page 48

Warranty and Support

Service and Support Resources

Hewlett-Pac kard News Network (HPNN)

HPNN is an electronic bullet in board service available only to HP authorized resellers.

This s erv ic e pro vides the fo llowing info rmation:

Presales Informat ion

Printer D rivers

HP SupportPack Information

Software Notes

Postsales Informat ion

For more information, call 1 (408) 553-7303.

HP Customer Informati o n Center

The HP Customer Informat ion Cent er pro v ides presa les product information. This

service is available for resellers and end-users.

For more information, call 1 (800) 752-0900, Monday – Friday, 6:00 AM – 5:00 PM U.S.

Pacific Time.

HP Reseller Response Line

The HP Reseller Response Line provides pre-sales and post-sales technical support for

HP authorized resellers.

For more information, call 1 (800) 544-9976, Monday – Friday, 8:00 AM – 4:00 PM U.S.

Pacific Time.

Product Info rmation1-42

Page 49

Warranty and Support

HP BBS Library

The HP electronic bulletin board library service, whic h is availa ble 24 hours a day, 7

days a week, contains drivers and support infor mation which can be downloaded to your

PC via modem.

Country Number Baud Rates

Austria + 43 (222)251658 2400 to 28800 or ISDN

Belgium + 32 ( 2) 778-3819 1200 to 28800

Denmark + 45 (45) 991905 300 to 28800

Finland (9600) 7280 2400 to 28800

France 3616 HP MICRO 1200 to 28800 (Service Minitel)

Italy + 39 (2) 9210-4244 Up to 28800

Netherlands + 31 (20) 647-5433 2400 to 28800

Norway + 47 (2) 273-5697 2400 to 28800

Sweden + 46 (8) 750-6262 2400 to 28800

Switzerland + 41 ( 64) 560200 Up to 28800 or ISDN

United Kingdom + 44 (1344) 361891 Up to 28800

Worldwide Int Code + 1 (208) 344-1691 300 to 28800

Set the modem for no parity, 8 data bits and 1 stop bit (N,8,1).

Product Information1-43

Page 50

Warranty and Support

HP FAXback on Demand – HP FIRST

You can use this service to select documents, such as pro duct descriptions and technical

information. To access this service, use the handset o n your fax machine and dial the

appropriate number fro m the table in this section.

Use the following steps to use HP FIRST :

1. Call the system. You will need to use a to uch-tone t elephone o r the phone set of your

fax machine. A voice prompt will welcome you and guide you to the infor mation you

need. You will also need to give the phone number of the fax machine where you

wish to receive the documents you se lect.

2. We sug gest you initially reques t t he index which lists all available documents .

3. Once you receive the HP FIRST index, choose the documents you need.

4. Call HP FIRST again. A voice prompt will ask you for the index number of the

do cuments you have s elected and would like to have f axed to you.

5. Selected documents will be sent immediat ely to t he fax number you have specified.

Note

To obtain documents in English from outside the UK, dial your internat ional access

code and then (31) 20 681 5792 (international toll rates applicable).

Product Info rmation1-44

Page 51

Warranty and Support

HP FIRST Telephone Numbers

Country Telephone Number

For US and Canada

For Custo mers in Europe:

U.K. 0800 96 02 71

For service in English outside U.K. + 31 20 681 5792

Austria 0600 8128

Belgium (Dutch) 0800 11906

Belgium (French) 0800 17043

Denmark 800 10453

Finland 800 13134

France 0800 905900

Germany 0130 810061

Italy 1678 59020

Norway 800 11 319

Portugal 05 05 31 33 42

Spain 900 993123

Sweden 020 795743

Switzerland (French) 0800 551 526

Switzerland (German) 0800 551 527

Netherlands 0800 022 2420

(800) 333-1917

For Customers in Asia-Pacific:

Australia 613 9272 2627

China 86 10 6564 5735

Hong Kong 2506 2422

India 9111 622 6420

Indonesia 21-352 2044

Korea 822 769 0543

Malaysia 03 298 2478

New Zealand 64 09 356 6642

Philippines (65) 275 7251

Singapore 275 7251

Taiwan (02) 719 5589

Thailand 662 661 3511

Product Information1-45

Page 52

Warranty and Support

HP Telephone Support

Technical Phone Support for Customers

The HP Customer Support Center provides free technical assistance for peripherals

within the hardware warranty period.

For the product under warranty, call (208) 323-2551.

For the product out of warranty, call :

1 (900) 555-1500 at $2.50 per minute, or

1 (800) 999-1148 at $25.00 per call using VISA / MasterCard.

(The above prices are subject ed to change wit hou t notice)

To ensure the call is dealt with quickly, have the following informat ion read y:

The product model number and serial number.

The operating system version and the co nfigurat ion.

A description of the softwar e inst alled and the accessories used.

HP North American Customer Support Center

Assistance from the Hewlett-Packard Nort h American Customer Support Center is

available Monday to Friday, 7:00 AM to 6:00 PM Mountain Time, except Wednesday,

(7:00 AM to 4:00 PM).

1 (303) 635-1000

HP European Customer Support Center

Assistance from the Hewlett-Packard European Custo mer Support Center is available in

English, Monday to Friday, 8:30 AM to 6:00 PM Central European time, except

Wednesday, (8:30 AM to 4:00 PM).

Int Code + 31 (20) 682-8291

HP provides free telephone support during the warranty period. After the warranty has

expired, support is available through the same telephone number for a fee. The fee is

charged on a per incident basis. When calling HP, please have the following infor mat ion

ready:

The product model number and serial number.

The operating system version and the co nfigurat ion.

A description of the softwar e inst alled and the accessories used.

Product Info rmation1-46

Page 53

Warranty and Support

Warranty and Out-of-Warranty Support Telephone Numbers

Country (Language) Telephone Number

Austria (German) 0660-6386

Belgium (Dutch) 02 626 8806

Belgium (French) 02 626 8807

Denmark (Danish) 3929 4099

Finland (Finnish) 0203 47288

France (French) 04 50 43 9853

Ireland 01 622 5525

Germany (German) 0180 5 25 81 43

Italy (Italian) 02 26410350

Netherlands (Dutch) 020 606 8751

Norway (Norwegian) 22 11 6299

Portugal 01 441 7199

Spain (Spanish) 902-321 123

Sweden (Swedish) 08 619 2170

Switzerland (French) 0848 80 11 11

Switzerland (German) 0848 80 11 11

UK 0171 512 5202

English language support for other European countries +44 171 512 5202

Product Information1-47

Page 54

Warranty and Support

Contacting Hewlett-Packard

To contact HP, check your local telephone directory for the HP Sales and Service Office

near you. If you cannot find an HP office, contact one of the major HP Sales and Service

Offices or one of the following Worldwide Marketing Headquarters.

Asia Far East Sales Region Headquarter s

Hewlett-Packar d Asia Ltd.

22/F Peregrine Tower

Lippo Centre

89 Queensway, Central

Ho ng Kong

Canada Hew lett-Packard Ltd.

6877 Goreway Drive

Mississauga

Ontario L4V 1M8, Canada

Europe Euro pean Operations Headquarters

Hewlett-Packar d S.A.

150, route du Nant-d’Avril

PO Box 1217

Meyrin 2/ Geneva, Swit z erla nd

Latin America Hewlett-Packard Latin Am. Headquarters

Monte P elvoux 111

Lomas de Chapultepec

11000 Mexico D.F.

Middle East / Asia Middle East / Central Africa Sales Headquarters

Hewlett-Packar d S. A.

Rue de Veyrot 39

CH-1217 Meyrin 1/Geneva, Switzerland

U.S. Intercon Operations Headquarters

Hewlett-P ackar d Co mpany

3495 Deer Creek Road

PO Box 10495

Palo Alto, CA 94303-0896, USA

Product Info rmation1-48

Page 55

Warranty and Support

Worldwide Customer Support Numbers

Customer Support Centers provide technical information via telephone directly with

online agents who are trained to assist with setup, configuration, startup and

troubleshooting of HP products.

Customer Support Center assistance can be obtained by calling one of the following

country-specif ic t elephone nu mbers:

Note

Check the world wide web at http://www.designjet-online.hp.com for t he most up-todate customer support telephone numbers.

Country Telephone Number

For U.S .

For Latin A merica

Argentina (541) 787 4061/69

Brazil 55 11 709 1444

Chile 562 800 360999

Mexico City 01-800-22147000/1-800-9052900

Mexico Guadalajara (525) 264 2075

Mexico Monterey 91800 22147

Venezuela 582 239 5664

(208) 323-2551

Product Information1-49

Page 56

Fo r E urope

Africa/Middle East 41 22/780 71 11

Austria 0660 6386

Belgium (Dutch) 02 6268806

Belgium (French) 02 6268807

Czech Republic 42 ( 2) 471 7327

Denmark 3929 4099

Finland 203 47288

France 01 43 62 34 34

Germany 180 5258 143

Greece 0168 96 411

Hungary 36 (1) 252 4505

Ireland 01662 5525

Italy 02 264 10350

Norway 22 11 6299

Poland 48 22 37 50 65

Portugal 01 441 7199

Russia 7095 923 50 01

Spain 902 321 123

Sweden 08 619 2170

Switzerland 0848 80 11 11

Netherlands 020 606 8751

Turkey 90 1 224 59 25

United Kingdom 0171 512 5202

Product Info rmation1-50

Page 57

For Asia-Pacific

Australia (61-3) 9272-8000

China 86 10 6564 5959

Hong Kong 800 96 7729

India 9111 682 6035

Indonesia 21 350 3408

Korea (82-2) 3270-0700

Malaysia 03 295 2566

New Zealand 09 356-6640

Philippines 2 867 3551

Singapore 272 5300

Taiwan 866-2-7170055

Thailand 02 661 4011

Vietnam 8823 4530

Product Information1-51

Page 58

Product Info rmation1-52

Page 59

Chapter 2 Operating Overview

Using t he Control Pa nel

Th e Contr ol Pane l allo ws yo u to per f orm most major tasks w ith th e prin ter, includin g

controlling print status, resetting from recoverable error s and changing the printer’s

default settings.

Control Panel Lay out

The Control Panel on the front of the printer consists of six buttons on the panel, two

LEDs and a LCD multi-function display panel:

Operating Overview 2-1

Page 60

Using t he Control Pa nel

The functions of each of the buttons are as follows :

Control Panel Key Function

[ GO ]

[ Cancel Job ]

[ Menu ]

[ Item ]

[ Value ]

[ Select ]

Puts the printer either online or offline.

Allows the printer to resume printing after going

offline. Also clears most printer messages and puts

the print er online.

Allo ws the pr inter to co ntinue printing afte r a no n-

critical warning message such as UNEXPECTED

PAPER SIZE

Exits the control pa nel menus. (To s ave the contro l

panel select ion, press the [ S elect ] butt on firs t.)

Displays unrecoverable error codes.

Press this only once to cancel t he print job that the printer

is processing. The duration requ ired to cancel the job will

depend on the size of the print job. Pressing the Cancel

Job butt on re peat e dly wi ll not canc el the next job o n the

print queue.

Press this to cycle t hro ugh the contro l panel menus.

To print a menu map from the control panel :

1. Press [ Menu ] until SELF TEST MENU appears.

2. Press [ Item ] unt il PRINT MENU MAP appears.

3. Press [ Select ] to print the menu map.

For more i nfor mation on eac h menu it em, se e Control

Panel Menus (Chapter 2).

Press this to cycle through selected menu items.

Press this to cycle through selected menu item’s values.

Saves the value for t he se lect ed item. An asterisk (*)

will appear next to the value, indicat ing that it is the

new default. Default settings will remain when the

printer is powered off, or until reset when you choose

to reset factory defaults from the [ RESETS ] menu.

Prints the selected printer infor mat ion page from the

control panel.

or TRAY x LOAD [ TYPE ] [ SIZE ].

Operating Overview2-2

Page 61

Using t he Control Pa nel

Indicator Lights

There are two LEDs (lights) on the pr inter :

LED Indicators Color Function

Ready LED Green Lit up when the printer is printing

OR in normal state

OR when it is online.

Attent ion LED Red Blinks when the printer is in an error stat e

OR requires attention.

Error LED Green + Red

blinking rapidly

Both LEDs blink when the printer detects an

error. Power cycle the printer to correct. If the

error persists, push the on-line button once to

see the error message.

Operating Overview 2-3

Page 62

Using t he Control Pa nel

Settings and Defaults

These are the various possible menu settings. The facto r y defaults, where applicable, are

indicated in bold. Other additional menu items may also appear, depending on which

hard ware modules have be en installe d in t he printer.

For more information on these settings, refer to Control Panel Menus (Chapter 2).

Paper Handling Menu

TRAY 2 TYPE =

TRAY 3 TYPE =

PLAIN

HP INKJET/HEAVY

HP PHOTO

TRNSPRNCY/IRON

RAPID TRNSPRNCY

PLAIN

HP INKJET/HEAVY

HP PHOTO

TRNSPRNCY/IRON

RAPID TRNSPRNCY

Diagnostics Menu

ALIGN PRNT –HD

CLEAN PRNT -HD LEVEL 1

CLEAN PRNT -HD LEVEL 2

CLEAN PRNT -HD LEVEL 3

PERFORM TRAY2 PAPER PATH TEST

PERFORM TRAY3 PAPER PATH TEST

PERFORM TRAY1 PAPER PATH TEST

Information Menu

BASE FW VER

PS FW VER (Available if PS installed)

MIO FW VER (Available if MIO installed)

CHECK TOTAL RAM SIZE

CHECK INK LEVELS

SERVICE ID

Operating Overview2-4

Page 63

Self Test Menu

PRINT MENU MAP

PRINT PS FONT LI ST (Available if P S installed)

PRINT MARKETING DEMO (Available if Demo DI MM installed)

PRINT DIAGNOSTIC PAGE

PERFORM TRAY2 PAPER PATH TEST

PERFORM TRAY3 PAPER PATH TEST

PERFORM TRAY1 PAPER PATH TEST

Print Quality Menu

PRINT QUALITY =

NORMAL

ECONOFAST

BEST

Printing Menu

PAPER =

ORIENTATION =

APPEND CR TO LF =

LETTER

LEGAL

13X19

A4

A3

11X17

JISB4

PORTRAIT

LANDSCAPE

NO

YES

I/O Menu

(5 - 300 secs)

IN JOB TIMEOUT =

OUT JOB TIMEOUT =

I/O CHANNEL TIMEOUT =

45

(0 - 300 secs)

0

(0 - 300 secs)

0

Resets Menu

RESET TO FACTORY SETTINGS

RESET ACTIVE I/O CHANNEL

RESET ALL I/O CHANNELS

RESET MIO TO FACTORY SETTINGS (Available if MIO installed)

Operating Overview 2-5

Page 64

Configuration Menu (Available if DIMM installed)

PERSONALITY =

AUTO

PCL

PS

(Available if PS installed)

MIO Me n u (Available if MIO installed)

CONFIGURE

MIO

(The remaining options will appear

depending on the type of MIO card installed.)

Postscrip t Menu (Available if PS installed)

PRINT PS ERRORS =

JAM RECOVERY =

COPIES =

OFF

ON

AUTO

ON

OFF

(1 – 99 pages)

1

Operating Overview2-6

Page 65

Using t he Control Pa nel

Restoring Factory Def a ults

To restore t he default factory settings, press [ MENU ] till the Reset s Menu appears. Then

press [ ITEM ] until RESET TO FACTORY SETTINGS is shown in the LCD displa y.

Press [ SELECT ] to restore the facto r y defaults. T h is action will also clear the input

buffer for the active I/O channel.

Operating Overview 2-7

Page 66

Using t he Control Pa nel

ColorPrinter

Control Panel Menus

The following is a summary diagram of all the menus available in the HP DesignJet

ColorPro Series Print er :

DesignJet

ColorPro Series

Operating Overview2-8

Page 67

Using t he Control Pa nel

Paper Ha ndling Menu

Item Value Explanation

TRAY 2 TYPE=PLAIN PLAIN

HP INKJET/HEAVY

HP PHOTO

TRNSPRNCY/IRON

RAPID TRNSPRNCY

Set this value to correspond with the

paper type currently loaded in Tray 2.

PLAIN: Plain paper

HP INKJET/HEAVY: HP Premium

Inkjet Paper or HP Premium Inkjet

Heavyweight Paper

HP PHOTO: HP Premium Photo Paper

TRNSPRNCY/IRON: HP Premium

Transparency Film or HP Iron-on T-Shirt

Transfer

TRAY 3 TYPE=PLAIN PLAIN

HP INKJET/HEAVY

HP PHOTO

TRNSPRNCY/IRON

RAPID TRNSPRNCY

RAPID TRNSPRNCY: HP Premium

Inkjet Rapid-Dry Transparencie s.

Note:

It is not advisable to load the following

combination of paper types in Tray 2 and Tray 3

at the same time:

HP Premium Inkjet Paper and HP Pr emium

Inkjet Heavyweight Paper

HP Premium Tr ansparency Film and HP

Iron-on T-Shirt Transfer

Set this value to correspond with the

paper type currently loaded in Tray 3.

PLAIN: Plain paper

HP INKJET/HEAVY: HP Premium

Inkjet Paper or HP Premium Inkjet

Heavyweight Paper

HP PHOTO: HP Premium Photo Paper

TRNSPRNCY/IRON: HP Premium

Operating Overview 2-9

Page 68

Transparency Film or HP Iron-on T-Shirt

Transfer

RAPID TRNSPRNCY: HP Premium

Inkjet Rapid-Dry Transparencie s.

Note:

It is not advisable to load the following

combination of paper types in Tray 2 and Tray 3

at the same time:

HP Premium Inkjet Paper and HP Pr emium

Inkjet Heavyweight Paper

HP Premium Tr ansparency Film and HP

Iron-on T-Shirt Transfer

Operating Overview2-10

Page 69

Using t he Control Pa nel

Diagnostics Menu

Item Explanation

ALIGN PRNT-HDS

CLEAN PRNT-HD:

LEVEL 1

CLEAN PRNT-HD:

LEVEL 2

CLEAN PRNT-HD:

LEVEL 3

PERFORM TRAY 2 PAPER

PATH TEST

PERFORM TRAY 3 PAPER

PATH TEST

PERFORM TRAY 1 PAPER

PATH TEST

This item aligns the printheads to ensure printout of the best

po ssible p rint quality.

This item cleans the printheads. Level 1 is the basic level and

should be performed first. This option will cause the printer to

perform a dry wipe and spitting.

This item cleans the printheads. Level 2 is more thorough than

Level 1, but it should be performed only when Level 1 cleaning

do e s not solve the pr int qu a lity proble m. This opt ion wil l caus e

the printer to perform a wet wipe, followed by a dry wipe and

spitting.

This item cleans the printheads. Level 3 is most thorough, but it

should be performed only when Levels 1 and 2 cleaning do not

solv e the print quality problem, a s it use s the most ink . This

option will cause the printer to perform 3 wet wipes followed

by dry wipes and spitting. The maximum amount of ink used is

less than 0.1 cc.

This item performs a paper path test on Tray 2. When this is

selected, the printer will pick paper from Tray 2 until all the

paper has been ejected.

This item performs a paper path test on Tray 3. When this is

selected, the printer will pick paper from Tray 3 until all the

paper has been ejected.

This item performs a paper path test on Tray 1. When this is

selected, the printer will pick paper from Tray 1 until all the

paper has been ejected.

Note

1. The “PRNT-HD NOT ALIGNED” message will ap pear if the Secondary Access Door has been

opened even though the print heads have not been changed.

Operating Overview 2-11

Page 70

Using t he Control Pa nel

Information Menu

Item Ex planation

CHECK INK LEVEL

BASE FW VER

This item displays t he amount of ink remaining in each ink

cartridge. The following screen appears on the LCD:

B C M Y

60% 80% 80% 80%

B, C, M and Y represent the black, cyan, magenta and yellow

cartridges respectively. The co r r esponding percent age under

each letter indicates the amount of ink left (fro m 0% to 99%).

This item displays t he firmw a re version of t he print er. Example:

VERSION=5.10

PS FW VER

MIO FW VER

CHECK TOTAL RAM

SIZE

SERVICE ID

This it e m displays the PostScript firmware version of the

printer. Example:

FIRMWARE VERSION=5.10

This item displays t he M IO print s e rver firmwar e vers ion.

Example:

MIO VERSION=3.10

This item displays the total amount of RAM available in the

printer. Example:

TOTAL RAM SIZE=6118K

This item displays t he Serv ice Id entification Number of the

printer. This number is used by HP Custo mer Care Cent er s for

support. The format taken is:

SERVICE ID=YYDDD

Where YY indicates the last two digits of the year of

manufacture and DDD indicates the number of days since the

printer was first used by the customer.

Operating Overview2-12

Page 71

Using t he Control Pa nel

Self-Tes t Menu

Item Explanation

PRINT MENU MAP

PRINT PS FONT LI ST

PRINT DIAGNOSTIC PAGE

PRINT EXT DIAGNOSTIC

PAGE

The Menu Map sho ws the layout of the Co ntrol Panel

menu it e ms .

The PS Font List sho w s all the PS fonts curr e nt ly

available to the printer. This option is act ivated o nly if

PS P e rsonality module h as bee n in s ta l l e d .

The Diagnostic Page shows general printer information

and current network parameters. See Diagnostic Page

(Chapter 2).

The Extended Diagnostic Page shows printer

information which is used for troubleshooting. See

Extended Diagnostic Page (Chapter 2).

Operating Overview 2-13

Page 72

Using t he Control Pa nel

Print Quality Menu

Item Value Explanation

PRINT QUALITY=

NORMAL

NORMAL

ECONOFAST

BEST

NORMAL: Normal mode delivers high

quality output and is the recommended setting

for speed and quality. Normal mode is the

default setting for most paper types.

ECONOFAST: Draft quality printing.

EconoFast mode prints faster than Normal

mode and delivers comparable output.

Using EconoFast will also cut down on the

frequency of replacing your ink car tr idges

because it uses less ink. EconoFast printing is

available only when you select plain paper or

transparency as the paper type.

BEST: High quality printing. Best mode

produces the highest print quality for all paper

types and eliminates the banding effect that

some time s occu rs in solid areas. However,

Best mode prints more slo w ly than Normal

mo de for most docume nts.

Note

2. When printing in either Normal or Econofast mode, the printer will print bi-directionally (that is,

from left to r ight and right to left).

3.

4. However in wh en printing in Best mode, the printer will print uni-directionally (that is, only from

right to left). Printing in Best mode will result in slower printing, but this can solve ban ding

problems.

Operating Overview2-14

Page 73

Using t he Control Pa nel

Printing Menu

Item Value Explanation

PAPER=

LETTER

ORIENTATION=

PORTRAIT

APPEND CR TO LF=NONO

LETTER

LEGAL

13X19

A4

A3

11X17

JISB4

PORTRAIT

LANDSCAPE

YES

Sets the paper size.

Determine the default orientation of print

on the page.

Note:

It is best to set the page orie nt ation from