Page 1

58%

14%

8%

20%

1584

4998

325

425

488

2000

18

C4704A/C4703A

HP DesignJet 2500/2000CP Printer

User’s Guide

Page 2

Printed in Europe

All rights are reserved. No part of

this document may be

photocopied, reproduced, or

translated to another lang ua ge

without the prior written con sent

of Hewlett-Packard Company.

3M™ is a registered trademar k of

3M Company.

Adobe™ is a trademark of Adobe

Systems Incor por at ed wh ic h may

be registered in ce rtain

jurisdictions.

Adobe PageMaker™ and Adobe

Photoshop™ are trademarks of

Adobe Systems Incorporated

which may be registered in

certain jurisdictions.

IEEE-1284 compatible, HP-GL,

and

HP-GL/2 are trad em arks of

Hewlett-Packard Company.

Macintosh is a product of Apple

Computer Inc.

Microsoft® and MS- DO S ® are

registered trademarks of

Microsoft Corporatio n.

Microsoft Windows is a

registered trad emark of Micr osoft

Corporation

PANTONE® and P ANTONE

MATCHING SYSTEM® are

licensed trademarks of Pantone.

Inc. PANTONE®

1

Colors

generated by t h e HP DesignJet

2000CP/2500CP printers are

four-color process simulations

and may not match PANTONEidentified solid color standards.

Use current PANTONE Color

Reference Manu als for accurate

color. PANTONE Color

simulations are only obtain ab le

on this product when driven by

qualified Pantone-licensed

software packag es . Contact

Pantone. Inc. for a current list of

qualified licensees.

1.Pantone. Inc.’s check–

standard trademark for

color. ©Pantone. Inc. 1988

PostScript® is a registered

trademark of Adobe Sys tems

Incorporated.

QuickDraw™ is a trademark of

Apple Computer In c.

UNIX® is a register ed tr ade mark

in the United States and other

countries, Ii censed exclusively

through X/Open Company

Limited.

TM

"WingDings

in TrueType®

format is a product of Microsoft

Corporation. WingDings is a

trademark of Micro s o ft

Corporation and TrueType® is a

registered trademark of Apple

Computer, Inc."

Notice

The informatio n co nt aine d in th is

document is subject to change

without notice and should not be

construed as a commitment by

Hewlett-Packard Company.

Hewlett-Packard assumes no

responsibility for an y errors

that may appear in this

document nor does it make

expressed or implied warranty

of any kind with regard to this

material, including, but not

limited to the implied

warranties of merchantability

and fitness for a particular

purpose.

The Hewlett-Packard Company

shall not be liable for incidental

or consequential damages in

connection with, or arising out of

the furnishing. performance. or

use of this document and the

program material which it

describes.

Safety Symbols

CAUTION

The Caution symbol calls

attention to an operating

procedure, practice, or the like,

which, if not correctly performed

The product is marked w ith this

symbol when it is necessary for

you to refer the instruction

manual in order to protect against

damage to the product.

or adhered to, could re sul t in

damage to or destruction of part

or all of the product. Do not

proceed beyond a Caut ion

symbol until the indicate d

conditions are fully understood

and met.

Hazardous voltage sym bol.

WARNING

The Warning symbol calls

attention to a pr oced ure , p ract ic e,

or the like, which, if n ot c orrec tly

performed or adhered to, could

result in personal injury. Do not

proceed beyond a Warning

symbol until the indicate d

conditions are fully understood

and met.

HP DesignJet Printers - Year 2000 Compliance

All HP DesignJet printer prod uc ts in cl uding all

the HP software, hardware, firmware an d

accessories for the HP DesignJet printers are

Year 2000 Compliant. HP DesignJet printers will

function with all the reliabi li ty and quality

associated with Hewlett-Packard as the transition

is made into the 21st century.

============================== ==

“Year 2000 Compliant Products” are products able to accurately process date

data (including, but not limited to, calculating, comparing and sequencin g

dates, from, into and between the twentieth and twenty-first centuries,

including leap year calculations, when used in accordance with its product

documentation, and provided all other products used in combination with the

product properly exchange data with it.

HP has made every effort to ensure the accuracy of out product testing.

However, because each customer’s enviroment is different from HP’s laboratory test enviroment, it is the customer’s responsibility to validate the

Year 2000 readiness of these products in their own enviroment. Therefore,

information about the Year 2000 staus of HP products is provided “as is”

without warranties of any kind.

HP makes no representation or warranty respecting the accuracy or reliability

of information about non-HP products. Such information, if any, was

provided by the manufacturers of those products and customers are urged to

contact the manufacturer directly to verify Year 2000 readiness.

For further information on how HP is preparing for the approaching

millenium visit the HP Year 2000 Program web site:

http://www.hp.com/year2000/

Page 3

C4704-90241 English

User’s Guide

1

HP DesignJet 2500CP/

2000CP Printer

Page 4

Finding Information

Finding Information

This User’s Guide contains:

n A comprehensive explanation of all the printer’s features and specific

information directly associated with the HP DesignJet CP Ink System (Imaging

ink)

n Specific information directly associated with the H P DesignJet CP Ink System

UV (UV Pigmented ink)

n Information on using the Take Up Reel.

The Assem bly Instruct ions contai n:

Step by step instructions for unpacking the printer and installing the Legs.

The Take Up Reel Setup and Assembly Instructions contain

Step by step instructions for installing and setting up the Take Up Reel.

The Setup Guide contains:

n Detailed information on setting up your printer for the first time, including:

– initial installation of the in k system components

– loading media

– connecting your printer to a computer or network

– setting up your printer software

The Quick Reference Guide contains:

n Information that you are most likely to need at the printer on a

day–by–day basis, such as how to navigate through the front-panel menu, load

media, and replace ink systems.

CD-Rom

When this symbol is displayed it indicates that there is video footage available

which gives you more information on the subject. Refer to the CD “Installing and

using HP DesignJet Printers” or “A User’s Introduction” which is only in English.

ii

Page 5

Finding Information

Where to find the most commonly needed information

To find how to … Go to …

Install the printer ÏThe Setup Guide.

Connect the printer ÏThe Setup Guide.

Choose media ÏPage 3-2, Choosing Media in this guide.

Load media ÏPage 3-13, Loading Roll Media in this guide or the quick

reference guide.

Load the Take Up Reel ÏPage 3-19, Loading Media onto the Take Up Reel accessory

Replace ink system components ÏPage 4-11, Removing and Replacing Ink S ystems in this guide.

See the printer’s current configuration ÏPage 8-5, Viewing the Current Configuration of the Front-

Panel Settings.

Turning on the Take up Reel ÏPage 8-12, Tu rning on the Take Up Reel

Make selections in the front-panel menu ÏPage 2-14, Navigating the Menu System.

Clear a media jam ÏPage 11-44, Clearing a Media Jam

Solve image quality problems ÏPage 11-5, Solving Image-Quality Problems

How to Solve Ink System Problems ÏPage 11-31, Solving Ink System Problems

Interpret a front-panel message ÏChapter 12, Front-Panel Messages.

Order accessories ÏPage 13-18, Ordering Accessories

To find any other information

Go to the index at the back of this manual.

iii

Page 6

Table of Contents

Table of Contents

Welcome 1-1

A Five-Minute Guide To Your Printer 1-2

Your Printer’s Main Features 1-2

Connections 1-7

Memory 1-7

Software Applications and Drivers 1-8

Front View of Printer 1-9

Rear View of printer 1-10

Using the Front Panel 2-1

The Front Panel 2-2

Standby Mode 2-6

Printing the Cu rrent Configuration 2-7

Entering the Menu System 2-8

Printing the Menus 2-9

Printing Other Internal Prints 2-12

Navigating the Menu System 2-14

Menu Graphics Used in This Manual 2-15

Navigation Examples 2-16

Selecting the Full Menu Mode 2-16

Changing the Colo r Calibration Settin g in the Image Quality Menu 2-18

Changing the Merg e Setting in HP-GL/ 2 Settings 2-21

Changing Margins 2-24

Changing the Drying Time 2-26

Other Types of Front-Panel Display Information 2-28

Working with Media 3-1

Choosing Media 3-2

Some Important Points about Media Types 3-3

Supported Media Types 3-4

Using the Ink System UV Outsid e 3-5

Laminating the Media after Printing 3-5

Applying the Overlamin ate to a Finished Print 3-5

Installing the Final Print 3-6

Media Types 3-8

HP Commercial Names of Media Types 3-8

iv

Page 7

Table of Contents

Physical Characteristics of Media Types 3-9

Combinations of Media Type and Print Quality 3-10

Using Coated Paper and Heavy Coated Paper with Normal Mode 3-11

Handling Your Media 3-12

Loading Roll Media 3-13

Loading Media onto the Take Up Reel accessory 3-19

Unloading Media from the Take Up Reel accessory 3-26

Removing a Roll from the Printer 3-30

Installing a New Roll into the Prin ter 3-32

Changing the Core Tube on the Take Up Reel 3-35

Loading sheet media 3-39

Unloading Sheet Media 3-42

Compensating for Badly Cut Media 3-27

Adjusting Skew Tolerance 3-27

Drying time (With a Take Up Reel) 3-44

Drying Time (Without a Take Up Reel) 3-46

Working with Ink Systems 4-1

About the Ink System 4-2

The HP DesignJet CP Ink Systems 4-2

Main Features of the HP DesignJet CP Ink System 4-2

What is an Ink System? 4-3

How to Identify the HP DesignJet CP Ink System UV Components 4-4

Identifying the Ink System in the Printer 4-4

When Does the Ink System Refill the Printheads? 4-5

Obtaining Optimum Refill Performance using non-HP media. 4-6

Refilling the Printhea ds from the Front Panel 4-8

How big a print can I make without a refill? 4-8

Monitoring the Ink Level 4-9

When should I Replace an Ink System? 4-10

Removing and Replacing Ink Systems 4-11

Working with multiple Ink Systems 4-12

Handle Ink Systems with Care 4-12

Replace the Ink System 4-13

After replacing the Ink System 4-23

Removing and Storing Partia ll y Used Ink Syste ms 4-24

Handle the Ink Systems with Care 4-24

Storing the I nk System in the HP DesignJet CP Ink System S torage Container 4-25

Removing the Ink System from the HP DesignJet CP Ink System Storage

Container 4-29

v

Page 8

Table of Contents

Controlling the Page Format 5-1

Page Format 5-2

Do You Need to Adjust the Page Size in the Front Panel? 5-4

Adjusting the Page Size in the Front Panel 5-5

Page Size and Clipped Images 5-7

Page Size and Nesting (Roll Media Only) 5-7

Page Size and Accuracy 5-8

Page Size Using the HP DesignJet CP UV Ink System 5-10

Selecting the Ink Emulation Mode 5-11

Adjusting Margins for Roll and Sheet Media 5-12

Margins and Automatic Cutting 5-14

Print Margins using the HP De signJet CP UV Ink System 5-14

Rotating an Image 5-15

Rotating an Image from the Front Panel 5-15

What is Rotated? 5-16

How Does Rotate Interact with Your Software? 5-17

Printing a Mirror Image 5-19

Changing the Scale of a Printed Image 5-20

Controlling the Overall appearance of a Print 6-1

Ways of Controlling the Print’s Appearance 6-2

Changing Pen Widths and Colors Using the Internal Palettes 6-3

To Select a Palette 6-4

Viewing Current Config. Settings 6-5

Viewing the Colors Availab le For a Palette 6-6

To Change the Palette Settings 6-7

Changing the Treatment of Overlapping Lines

(Merge) 6-9

Printing Color Images in Monochrome 6-10

Switching between Color and Monochrome 6-11

Printing Speeds and Print Quality 6-12

Print quality settings 6-14

Changing th e print quality 6-16

Managing Your Prints 7-1

Managing Pages Currently being Printed or Drying 7-2

Cancelling a Page 7-2

Cutting a Page before Drying is Complete

(Roll Media Only) 7-3

vi

Page 9

Pausing while Printing a Series of Pages 7-4

Managing Pages not yet Printed (the Queue) 7-5

What is the Queue? 7-5

Starting to Print a File that is Waiting for a T ime-out 7-7

Identifying a Job in the Queue 7-8

Viewing the Size of a Page in the Queue

(Non-Postscript) 7-8

Prioritizing a Job in the Queue 7-9

Deleting a Job from the Queue 7-9

Making Copies of a Job in the Queue 7-10

Avoiding Media Waste by Nesting Pages 7-11

When Does the Printer Try to Nest Pages? 7-13

Which Pages Qualify for Nesting? 7-13

Which Pages Cannot be Rotated? 7-13

Turning Nesting On or Off and Choosing the Nesting Method 7-14

What Happens to Nesting if You Turn Queueing Off? 7-14

How Long does the Printer Wait for Another File? 7-15

Getting the Best from Nesting (Nesting and Margins) 7-16

Nesting and the Rotate Feature 7-16

Reconfiguring Your Printer 8-1

Table of Contents

Viewing the Current Overall Configuration of the Printer 8-2

Viewing the Current Configuration of the Front-Panel Settings 8-5

To Change the Front-Panel Settings 8-5

Recalibrating the Printer for Accuracy 8-6

When to Recalibrate the Printer 8-6

To Recalibrate the Printer 8-6

To Restore the Factory’s Calibration 8-7

Changing the Graphics Language 8-8

To Change the Graphics Language S etting 8-8

Graphics Language and Networks 8-9

Changing the Interface Settings 8-10

To Change the I/O Time-out Setting 8-10

Upgrading Your Printer with More Memory 8-11

Turning on the Take Up Reel 8-12

Controlling Image Quality 9-1

Selecting the Ink Emulation Mode 9-2

Calibrating the Color Output 9-3

vii

Page 10

Table of Contents

Comparing Color Outp ut between Im aging and UV Ink Systems 9-3

Performing a Image Quality Test 9-4

Servicing the Printheads 9-5

Aligning Printheads 9-5

Refilling Printheads 9-5

Checking Printheads 9-6

Media Test Print 9-7

How to perform the Media Te st Print 9-8

Changing the Print Quality when Media is Already Loaded 9-10

Maintaining Your Printer 10-1

Cleaning the Printer 10-2

Cleaning the Printer Exterior and Inside the Doors 1 0-2

Lens Maintenance 10-3

Replacing the Lens Cover 10-4

Normal Printer Use 10-6

Storing and Moving Your Printer 10-7

Selecting Transport Mode 10-7

Removing the Printheads 10-8

Removing the Printhead Cleaners 10-9

Removing the Ink Cartridges 10-11

Switching off and Disconnecting the Printer 10-13

viii

Troubleshooting 11-1

A Note About Troubleshooting 11-2

Where to Find Help in Solving Problems 11-3

Finding the Source of Your Problem 11-4

Solving Image-Quality Problems 11-5

How to Proceed with the Image Quality Print Diagnosis 11-5

If the Color is Not as Expected 11-6

Some General Information About the Image Quality Test 11-7

Identifying the Printhead Components 11-7

How to Use the Image Quality Print 11-8

Printing the Image Quality Print 11-8

Analyzing the Image Quality Test Results 11-10

Solving the Problems 11-11

No Printing Defects Found in the Image Quality Print 11-22

Solving Color Accuracy problems 11-23

Color Consistency problems 11-23

Page 11

Table of Contents

Configuration 11-24

Media 11-24

Where to Find Additional Information 11-26

If There are Slightly Warped Lines 11-26

If There are Blurred Lines (Ink “Bleeds” from Lines) 11-26

If there is a horizontal line 2 inches (5.5 cms) from the start of your image. 11-26

There are Smears and/or Scratching on Your Printed Media. 11-27

Solving M edia-Handling Problems 11-28

The Front Panel Keeps Indicating that Media Is Misaligned or Incorrectly

Positioned 11-28

Prints Do Not Feed Out Properly From the Printer 11-28

The Automatic Cutter does not Cut Immediately after a Print has Finished 11-28

The Automatic Cutter do es not Work 11-29

The Cutter is Jammed 11-30

A Sheet is Ejected when You Switch On the Printer 11-30

Solving Ink System Problems 11-31

Missing Ink System 11-31

Ink System Error 11-31

Summary of Ink System Defect Messages 11-32

If the Replace Ink System Key does not Work 11-34

If Brand New Printheads have Problems 11-34

If there is a Failure after Refilling Printheads 11-34

Printhead Alignment Errors 11-35

Printhead Checks 11-37

Using the Replace Ink System Key 11-37

Checking Ink Systems 11-38

If You Have Problems Reseating a Printhead 11-41

Cleaning Electrical Contacts 11-42

Clearing a Media Jam 11-44

Solving Communication Problems 11-45

If there is a Problem Communicating between Your Computer and the Printer 11-

45

Solving Problems wi th Image Position or Content 11-46

If the Print is Completely Blank 11-46

If the Output Contains Only a Partial Print 11-46

If the Image is Clipped 11-47

If a Long-Axis Print Is Clipped 11-47

If the Entire Image is in One Quadra nt of the Correct Printing Area 11-48

If the Image Is Unexpectedly Rotated 11-48

If the Print Is a Mirror Image of Your Graphic 11-48

ix

Page 12

Table of Contents

If the Print Is Inaccurate 11-48

If the Print is Distorted or Unin telligible 11-49

If One Image Overlays Another on the Same Sheet 11-49

If Pen Settings Seem to have No Effect 11-49

If the Printer Produces a Black and White Print When You Expected a Color Print

11-49

If the Printer has Printed a Different Print than the One You were Expecting 11-50

Solving Front-Panel Problems 11-51

If the Replace Ink System Key Does Not Work 11-51

If None of the Front-Panel Keys Work 11-51

If Page Format/Rotate does not Work 11-51

If a Display Message will not Clear 11-51

If a “System Error” Message Is Displayed 11-52

If an “Out Of Memory/Data Was Lost” Message Is Displayed 11-52

Problems with the Take Up Reel 11-53

Solving Miscellaneous Problems 11-54

If the Printer does not Print 11-54

If the Printer Seems Too Slow 11-54

If the Printer Waits Too Long to Print a Nest 11-55

If the Bail (Black Metal Bar) does not Lower All the Way 11-55

The Media coming from the Printer is Fed Back into the Printer causing a Media

Jam. 11-55

Getting Help 11-56

What to Do Before You Call 11-56

Front-Panel Messages 12-1

Message Explanations and Actions 12-2

STATUS Messages 12-17

Reference 13-1

Printer Specifications 13-2

Interface Specifications 13-10

Interface Cables 13-11

Regulatory Notices 13-12

Glossary G-1

Index I-1

x

Page 13

Welcome

1

1

A Five-Minute Guide To Your Printer 1-2

Front View of Printer 1-9

Rear View of printer 1-10

1-1

Page 14

Welcome

A Five-Minute Guide To Your Printer

A Five-Minute Guide To Your Printer

Your Printer’s Main Features

Your printer is an E/A0-size inkjet printer designed for printing high-quality, largeformat color or monochrome images. Some major features of the printer are:

n Large capacity ink system

n True 600 dpi print resolution.

n A choice of HP media designed to provide the best image quality with your

printer.

n An easy-to-use front-panel interface with a two-line display, giving you access

to a comprehensive set of printer functions.

n Available as an optional accessory is the Take Up Reel. This enables long

unattended prints

2500CP Only n Built-in Adobe PostScript Level 3 Raster Image Processor.

n Automatic color calibration to improve color consistency betwe en jobs.

n Ink emulation allowing the printer to print jobs intended for devices using

standard pre-press color gamuts.

n PostScript queueing and nesting to reduce media waste.

n Large and very-complex PostScript file printing.

1-2

Page 15

Welcome

A Five-Minute Guide To Your Printer

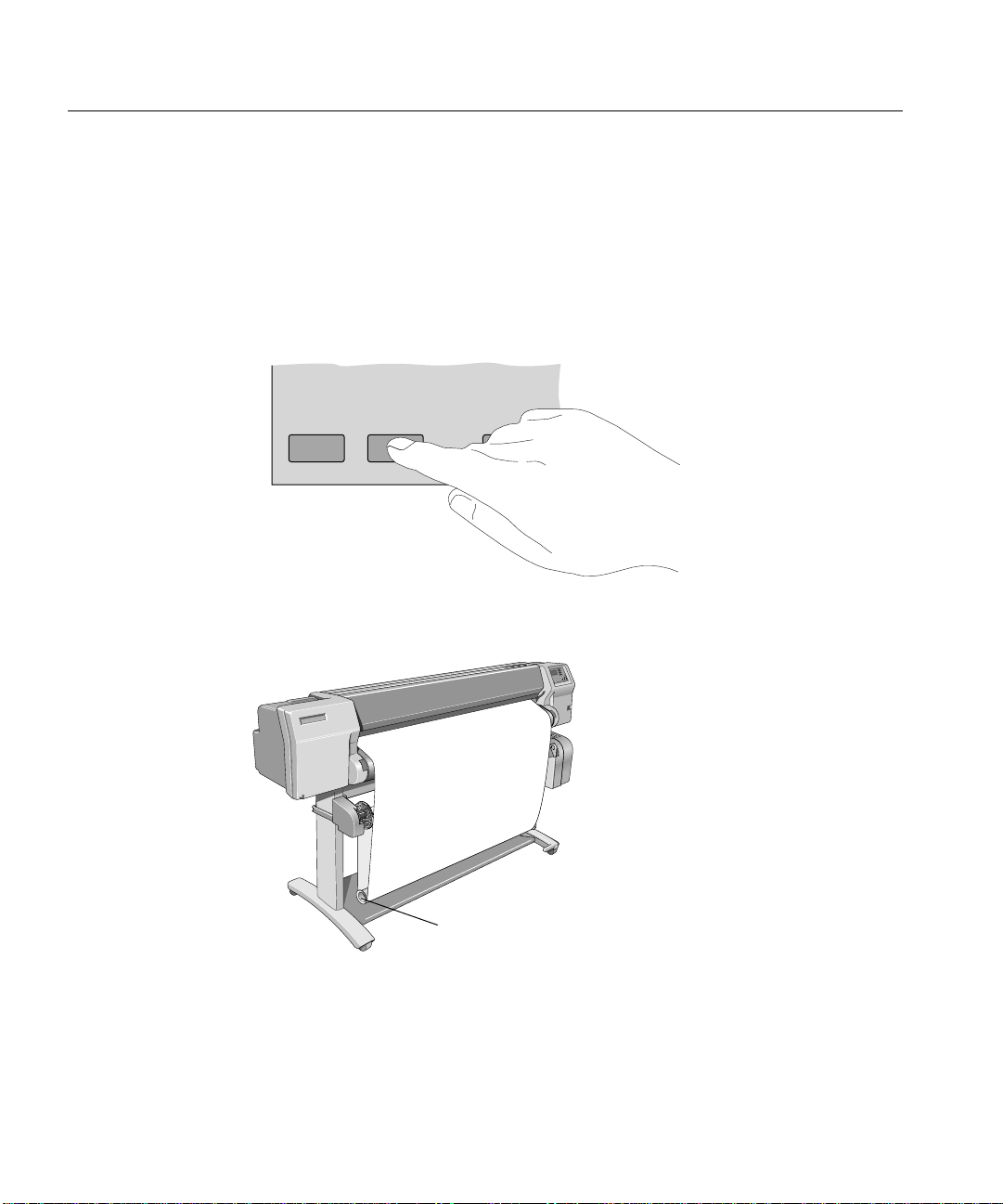

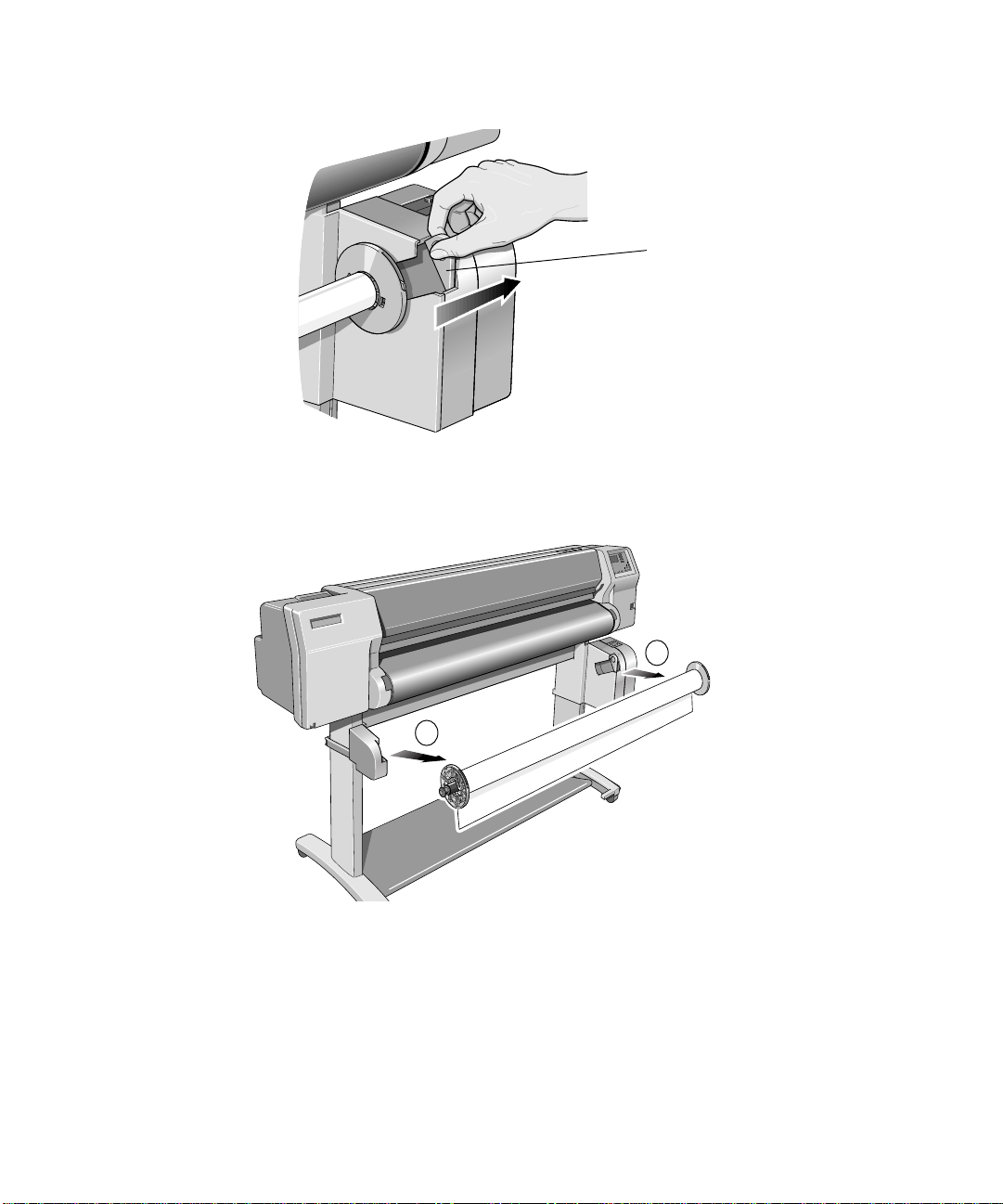

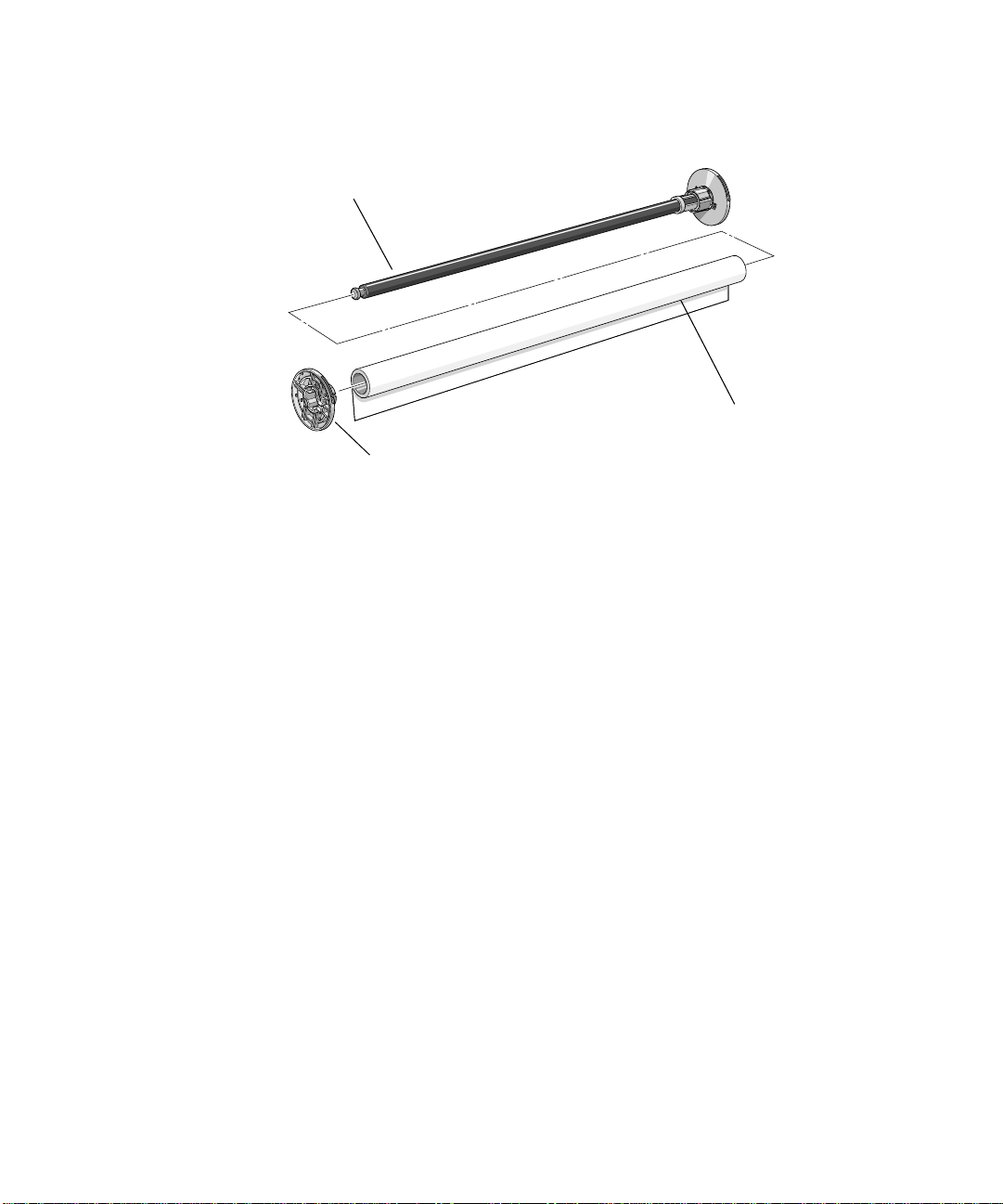

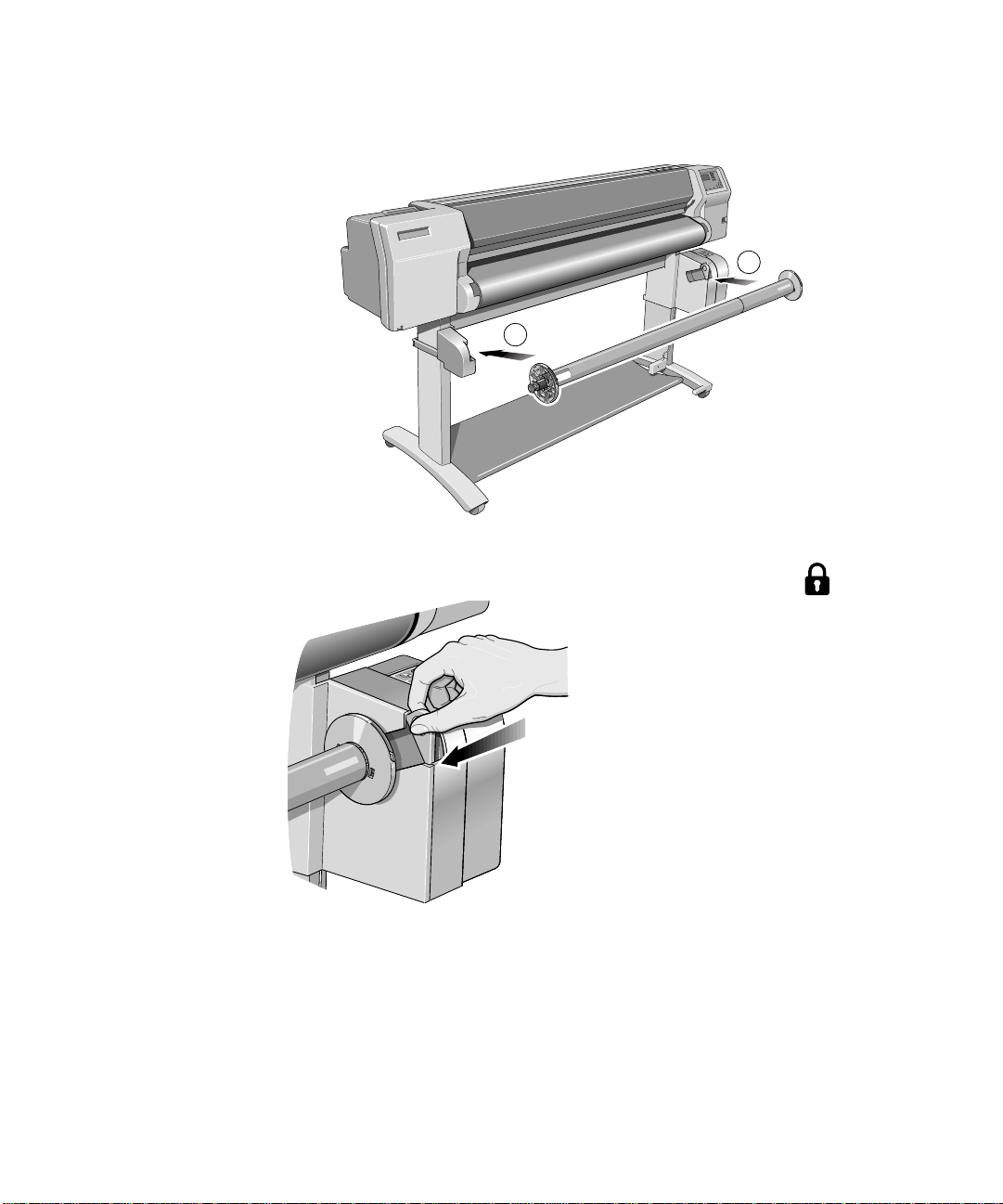

The Take Up Reel Accessory

Available with your printer as an option is the Take Up Reel. The Take Up Reel

consists of the left and right hand assemblies, sensor assembly, spindle assembly,

core tube and a media weight. As the media is fed out of the printer (1) it travels

down the front of the printer, around the Media Weight (2) and then onto the Core

Tube (3). The Core Tube turns, reeling in the printed media.

C472372

1-3

Page 16

Welcome

A Five-Minute Guide To Your Printer

The HP DesignJet CP Ink Systems

There are two HP DesignJet CP Ink Systems designed together with your HP

DesignJet 2500CP or 2000CP printer.

Both Ink Systems include three-components; printhead, printhead cleaner and ink

cartridge to provide large-capacity ink, unattended printing, ease-of-use, reliability

and low-cost. Plus both Ink S yst ems offer true 600 dpi and new advan ced dit her i ng

algorithms for exceptional image quality prints.

Each 600-dpi thermal inkje t printhead applie s ink dropl ets onto t he media an d has a

reservoir which holds enough ink for several prints. The printer automatically refills

the printhead from the ink cartridge whe never the ink volume in the printhead

reservoir becomes low.

The printer uses the printhead cleaners to clean and maintain the printheads, to

ensure best possible image quality, and to seal the printheads when not in use

ensuring the long life.

You can change Ink Systems as easy as 1—2—3 with the modu la r design. If you d o

change one ink set for another, HP offer an Ink System Storage Container to store

partially used printheads and printhead cleaners.

1-4

Main Features of the HP DesignJet CP Ink System

The HP DesignJet CP Ink System is the ink system that you received with your HP

DesignJet CP printer. It is also referred to as Imaging ink. It is designed to deliver

clear, sharp, brilliant images with precise performance every time.

Main Features of the HP DesignJet CP Ink System UV

The HP DesignJet CP Ink UV can be purchased separatel y from your local Hewlet tPackard dealer. It is also referred to as UV Pigmented ink. The HP DesignJet CP

Ink UV prints bright, colorful, outdoor lightfast signs and posters with a HP

Outdoor Durability Warranty.

The HP DesignJet CP Ink UV is designed to work together with the HP DesignJet

CP printers to create clear prints that are lightfast and durable with lamination, even

outdoor in direct sunlight, for up to one year, guaranteed.

The UV Pigmented inks provide resistance to ultra violet light. Protecting your

prints from fading and enhancing the durability of signs and posters.

Page 17

Welcome

A Five-Minute Guide To Your Printer

Color Calibration (2500CP)

Automatic color calibration improves color consistency between prints. The printer

prints a test target image and measure s the image color with a sensor to generate a

color calibration value that is applied to the P ostScript imaging process.

Ink emulation (2500CP)

Ink emulation lets your printer accept CYMK PostScript files that use printing

industry standard color gamuts, enabling the printer to emulate commercial printing

presses for proofing.

PostScript queueing and nesting (2500CP)

PostScript queueing enables files to be reprint ed quickly . PostS cript nesting reduces

media waste by storing jobs and then positioning them to use the maximum width

of the media roll, reducing your printing costs.

Large/Complex PostScript file printing (2500CP)

The printer uses a built-in hard disk drive as extended memory for PostScript

rendering, enabling the printer to process almost any PostScript file yo u want to

print.

Multiple copies of prints (2500CP)

The built-in hard disk drive allows enhanced print management, enabling the

printer to print multiple copies of an image without re-rendering and nesting of

prints.

Print Resolution

Print resolution can be set to true 600 dots per inch (Best print quality) or 300 dots

per inch (Normal or Fast print quality mode). You can choose between the three

levels of print quality- Best, Normal or Fast - either from your software or from the

printer’s front panel.

1-5

Page 18

Welcome

A Five-Minute Guide To Your Printer

Media

You can print on roll media or sheet media up to EA0-size in width-91cm (36

inches).The following media types are supported for HP DesignJet CP Ink (imaging

ink) which is high image quality for indoor use:

n Coated paper

n Heavyweight coated paper

n High-gloss photo paper

n Semi-gloss photo paper

n Imaging film-Backlit

n Opaque vinyl

For detailed information on Hewlett-Packard media, see pages 3-4 of this manual

and the Media Guide for the HP DesignJe t CP Printers provided with your printer.

The following media types are supported for HP DesignJet CP Ink UV

(UVPigmented Ink)

n HP Heavyweight Coated paper

n Opaque Vinyl

1-6

User Interface

The printer’s front pa nel includes an easy-to-use interface with a two-line display,

giving you access to a comprehensive set of printer functions and to a number of

useful internal pr ints. See Chapter 2, Using the Front Panel, for a short tutorial to

teach you how to navigate through the menus and a description of internal prints.

Standby Mode

The printer has a standby mode where, after 15 minutes of inactivity, the printer

goes into a sleep mode (low-power usage mod e). The pri nter “wak es up” whenever

you press the Standby button on the printer or there is any I/O activity such as

receipt of a file. See page1-9, Front View of Printer, for the switch location and

page 2-6, Standby Mode, for more information about this function.

Page 19

Welcome

A Five-Minute Guide To Your Printer

Connections

2500CP Only The 2500CP printer comes with an HP JetDirect network interface card, for LAN

connections, as well as a parallel interface for a direct connec tion to yo ur computer.

See the Setup Guide for information on connecting your printer to a computer or

network.

2000CP Only Your printer comes with a Modular IO (MIO) slot which can be used to connect a

networking card.

Memory

2500CP Only The 2500CP printer comes with 32MB of memory plus 4 MB of internal printing

memory. You can this expand memory up to a maximum of 68 MB by adding 4MB, 8-MB, 16-MB or 32-MB memory SIMMS. In addition to this memory, the

printer has an internal hard disk drive used as extended memory for PostScript

rendering and print management.

For part numbers see page 13-19, Memory Modules

2000CP Only Your printer comes with 4 MB of m emory plus 4 MB of internal printing memory.

You can expand the memory up to a maximum of 68 MB by adding additional 8MB, 16-MB, and 32-MB memory expansion modules.

For part numbers see page 13-19, Memory Modules

1-7

Page 20

Welcome

A Five-Minute Guide To Your Printer

Software Applications and Drivers

To make sure that your printer prints exactly what you were expecting - in terms of

size, position, orientation, color and quality - use the correct driver for the

combination of your application software and your printer, and make sure that it is

configured correctly.

Many software applications include their own drivers. A set of Software

Application Notes is provided wi th this printer for the most popu lar applications. If

you find your own application in these notes, use the information they contain as a

guide to configuring the software for your printer.

Three types of drivers are supplied with the 2500CP printer:

n HP DesignJet PostScript® drivers for Macintosh® (QuickDraw™)

n HP DesignJet PostScript® drivers for Microsoft® Windows™ applications

n AutoCAD Drivers for DOS and Windows

Two types of drivers are supplied with the 2000CP printer:

n HP-GL/2 Windows Drivers

n AutoCAD Drivers for DOS and Windows

1-8

Some printer functions beh ave differen tly when the print er receives a PostScr ipt file

as opposed to files formatted in other printer languages (HP-GL/2 or RTL).

Throughout this manual, references to “PostScript files” mean files sent to the

printer using the HP DesignJet PostScript driver supplied with the printer and

installed by you on your Macintosh or PC.

If you don't know whether your application sends PostScript files consult your

software documentation.

It is strongly recommended that you install and use the AutoCAD drivers to print

from AutoCAD. More CAD-orientated functionality is provided with these drivers,

they are also faster than HP-GL/2 or PostScript windows drivers.

Page 21

Front View of Printer

Window

Ink Cartridges

(inside)

Roll Cover

Storage S h el f

Media Bin

Welcome

A Five-Minute Guide To Your Printer

Printheads (inside)

Front Panel Display

Front Panel

Printhead Cleaners

(inside)

Standby Switc h

Media Lever

Media-Entry Slot

C4704106

1-9

Page 22

Welcome

A Five-Minute Guide To Your Printer

Rear View of printer

Parallel

Interface

Pocket for Quick

Reference Guide

and Media Knife

Network Interface

Power Switch

Socket for

power cord

Slots for

Upgrades

C4704109

1-10

Page 23

Using the Front Panel

The Front Pane l 2-2

Standby Mode 2-6

Printing the Current Configuration 2-7

Entering the Menu System 2-8

1

2

Printing the Menus 2-9

Printing Other Inte rnal Prints 2-12

Navigating the Menu System 2-14

Menu Graphics Used in This Manual 2-15

Navigation Examples 2-16

Other Types of Front-Panel Display Information 2-28

2-1

Page 24

Using the Front Panel

The Front Panel

The Front Panel

The front panel of the printer is made up of four functional areas as shown below:

Display Section

Form Feed

and CutCancel

Replace

Ink System

Previous

Enter

Pause

Color

Mono

Print Quality KeysAction Keys

Receiving

Print Current

Configuration

(Press both Ke y s)

Best

Normal

Fast

Print Quality

Status

Lights

C4704002

2-2

Page 25

Using the Front Panel

The Front Panel

Display Section The display section of the front panel consists of the two-line display and the four

display keys to its right (Previous, ↑, ↓ and Enter).

Previous

Enter

C4704016

n The display can show two lines of text and is used for displaying:

– menus used to configure the printer.

PAGE FORMAT

Mirroring

Menu Title

Menu Option

C4704007

– and messages.

STATUS

Aligning printheads

C4704034

– These messages may concern printer status, required actions or errors.

n You use the display keys to navigate the menu system and select menu options.

You also use the display keys to respond to messages. see chapter 12, Front-

Panel Messages, for detailed descriptions for error and status messages.

Later sections of this chapter give det ailed inst ructio ns for using the di splay keys to

navigate the menu system and select menu options, as well as other uses of the

display keys.

2-3

Page 26

Using the Front Panel

The Front Panel

Action Keys The action keys let you:

n cancel the current printer operation (Cancel).

n advance and cut media (Form Feed and Cut).

n replace ink system components (Replace Ink System).

n pause the printer (Pause).

Form Feed

and CutCancel

Action Keys

Replace

Ink System Pause

C470432a

dddddddy

See chapter 7, Managing Your Prints, for information on the use of these keys.

Print Quality Keys Use the print quality keys to select whether to print in color or monochrome (black

and grayscale) and to select the print quality you want. See chapter 6, Controlling

the Overall appearance of a Print, for information on the use of these keys.

Best

Color

Mono

Print Quality keys

Normal

Fast

C4704033

2-4

Page 27

Using the Front Panel

The Front Panel

Status Lights The status lights provide status information about the current configuration and

state of the printer. These lights are described later in this manual

Receiving

Best

Pause

Color

Mono

Normal

Fast

Print Quality

Status Lights

C4704031

NOTE In most cases, settings in your application software or printer driver override

any settings you make on the front panel of the printer.

2-5

Page 28

Using the Front Panel

Standby Mode

Standby Mode

The printer has a standby mode where, after a period of inactivity, the printer goes

into a sleep mode (low-power usage mode). This is indicated by the front panel

display and status indicators turning off. The indicator light on the Standby switch

is on when the printer is in standby mode. The printer “wakes up” whenever you

press the Standb y switch on the print er or there is any I/O activ ity such as recei pt of

a file.

Standby switch

C4704131a

You can manually place the printer in standby mode by pressing the Standby

switch when the printer is in normal operating mode. When you manually put the

printer in standby mo de, it will not “wake up” until you press the switch again.

n Use the Standby switch to turn the printer off and on, rather t han the Power

switch on the back of the printer.

n Use the Power Switch only when you need to isolate the printer from t he po wer

source, such as, when you are disconnecting or connecting cables, or upgrading

memory.

NOTE To re-initialize the printer, pre ss and hold the Standby switch for three or more

seconds.

2-6

Page 29

Printing the Current Configuration

The display section is used for setti ng the pr i nte r’s configuration. You can print out

a report showing the printer’s current configuration by following the steps below.

1 Make sure that media is loaded. See page 3-13, Lo adi ng Rol l Media, for loading

information.

2 Press the ↑ and ↓ keys simultaneously to print the Current Configuration.

Previous

Using the Front Panel

Printing the Current Configuration

STATUS

Ready

Next

Press These Two

Keys Simultaneously

C4704019

The current configuration print fits on an A4 or US letter-size sheet. Keep this print

for later reference.

2-7

Page 30

Using the Front Panel

Entering the Menu System

Entering the Menu System

1 Make sure a status screen is displayed, as shown in the example below:

STATUS

Ready

2 Press the Enter key.

Either the SHORT MENUS screen

C4704034

SHORT MENUS

Queueing & Nesting

C4704008

Only menus shaded yellow

in front-panel menus print

are accessible in Short Menus

mode. (Shaded gray if printing

in black only).

or the FULL MENUS screen:

FULL MENUS

All menus are accessible.

Queueing & Nesting

C4704008

is displayed, with the Queueing & Nesting option shown.

NOTE You may not be able to access the menu system immedi ately, if the current task

overrides it. If this happens, wait until the task is completed and try again.

2-8

Page 31

Using the Front Panel

Printing the Menus

Printing the Menus

You can see the complete menu structure available on the printer by printing the

Front-Panel Menus print. To help understand the menu structure and its navigation,

print it now:

NOTE The Menus print is printed in the size specified in the Page Format → Size settings

in the front panel. However if sheet media is loaded it will automatically shrink

to fit. Make sure this setting specifies the size you want before printing.

1 Make sure that media is loaded. See page 3-13, Lo adi ng Rol l Media, for loading

information.

2 On the front-panel display, go to

Internal prints, as shown below.

3 Print the menu structure by selecting t he Menu option from the

as follows:

STATUS

Ready

C4704034

a Press Enter.

Note: Your front-panel display may show

SHORT MENUS

Queueing & Nesting

b Press ↓ until

SHORT MENUS

SHORT MENUS

s

Internal prints

C4704034

Internal prints is displayed.

C4704034

FULL MENUS, not SHORT MENUS, depending

on your printer settings. You can print the

internal prints in either mode.

Internal prints menu,

2-9

Page 32

Using the Front Panel

Printing the Menus

c Press Enter.

d Press ↓ or ↑ until

Menu is displayed.

INTERNAL PRINTS

Menu

C4704034

e Press Enter.

The printer prints a menu tree of the entire front-panel menu structure. The

Receiving light flashes while the file is being processed, and then the printer starts

printing.

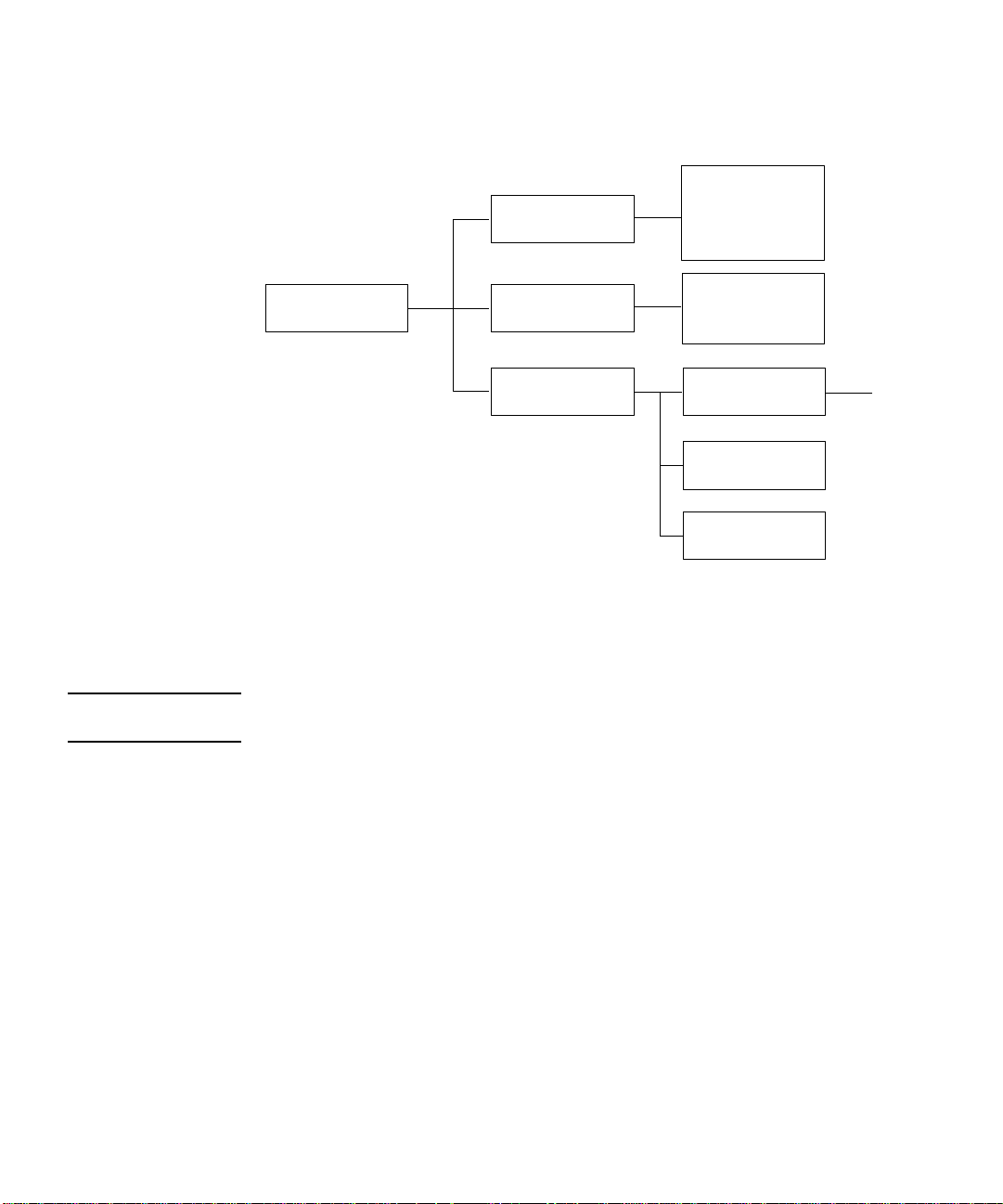

2500CP Only Look at the Front-Panel Menus print. It shows the full menu structure. Here is a

sample section of it concerned with image quality:

There are six columns:

1 contains the highest

level menu options.

6 contains the lowest

level menu options.

123456

C4704039

2-10

Row associated with

first level menu

(Image Quality).

Area expanded for use

in the navigation example

in this chapter .

Page 33

Using the Front Panel

Printing the Menus

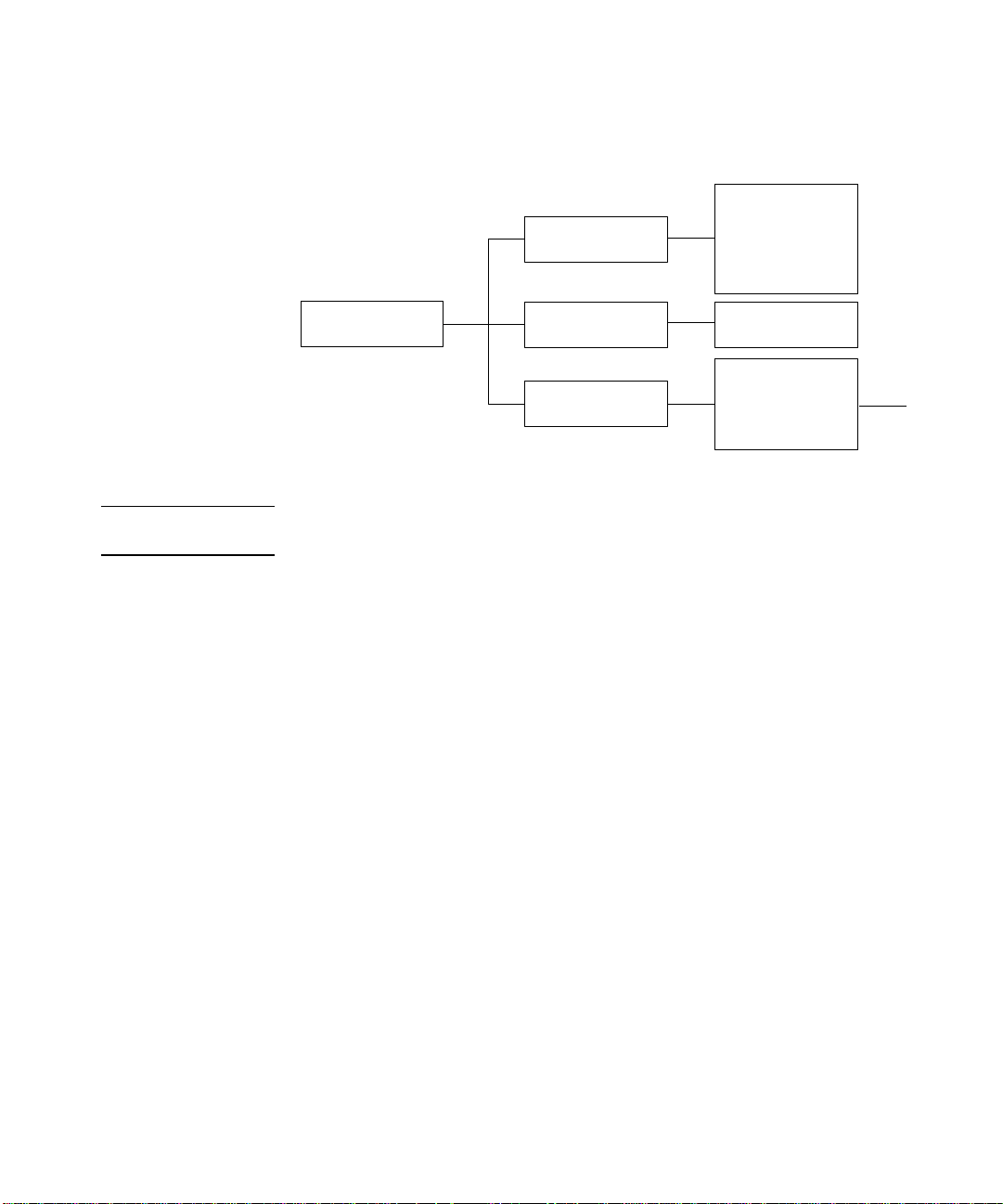

2000CP Only Look at the Front-Panel Menus print. It shows the full menu structure. Here is a

sample section of it (concerned with pen settings):

There are six columns:

1 contains the highest

level menu options.

6 contains the lowest

level menu options.

Row associated with

first level menu

(HP-GL/2).

123456

C4704005

Area expanded for use

in the navigation exa mp le

in this chapter.

2-11

Page 34

Using the Front Panel

Printing Other Internal Prints

Printing Other Internal Prints

In addition to the current confi gurati on print and menu pr int, there are several othe r

internal prints availab le in the printer. The internal prints are listed belo w:

2500CP Only PostScript demo

Demonstrates the image quality capabilities of the printer.

PostScript config

The PostScript Configuration print shows the current configuration status of the

printer’s PostScript features.

PostScript fonts

The Fonts print shows all resident Post Script fonts (inter nal and downloaded) wi th a

printed sample of each font.

2-12

HP-GL/2 config

The HP-GL/2 Configuration print shows the current settings for the printer’s HPGL/2 features.

Usage report

The Printer Usage Information print shows the status of the printer’s usage

counters. This information includes the total nu m ber of prints, number of prints b y

media size, number of prints by media type, number of prints per print mode, and

total amount of ink used per color. The counts in this report are estimates.

Image quality print

The Image Quality print can be us ed to help di agnose whethe r the pri nter has imag e

quality problems, and if problems exist, help determine the cause of image quality

problems see chapter 11, Troubleshooting, for more information about this print.

Page 35

2500CP Only

Using the Front Panel

Printing Other Internal Prints

Service print

The Service print provides information needed for printer servicing, such as the

current configuration, operating conditions (temperature and humidity), ink levels,

and other statistics about printer usage.

n Menu

The Menu print shows the complete menu structure available on the printer to help

you in locating menu options in the front panel.

HP-GL/2 pa lette

The HP-GL/2 Palette print shows the color or grayscale definitions in the currentlyselected color palette.

Where to Find Internal Prints

The following internal prints are located under the Internal Prints menu:

n PostScript demo

n PostScript config

n PostScript fonts

n HP-GL/2 config

n Usage report print

n Menu print

n HP-GL/2 Palette print

The following internal prints are located under the

Utilities menu:

n Image Quality print

n Service print

Service Tests option in the

2-13

Page 36

Using the Front Panel

Navigating the Menu System

Navigating the Menu System

Once in the first-level menu, you can navigate the menu system using the display

keys.

Press Previous to display the previous menu level,

without changing any menu selections (equivalent

to moving left [ ←]

Menus print).

Press ↑ to scroll up, or ↓ to scroll down

through the options in a menu (equival e nt

to moving up [↑] or down [↓] a column

in the Front-Panel Menus print).

The option list is continuous, allowing you

to move from the bottom to the to the top

by pressing ↓ or from the top to the bottom

by pressing ↑.

1

one column in the Front-Panel

Previous

Enter

Press Enter to:

a. select an option and move to the next menu level,

when in the menu system (equivalent to moving one

column to the right [→] in the Front-Panel Menus print).

b. Change the printer’s configuration to the displayed choice

to the configuration, that is, selecting an option from the

the lowest level menu [↵].

1

The colored arrows ↑↓← →↵, shown in square brackets above,

are used to repres ent pressing the rel ev a nt keys once,

in the following navigation example.

C4704006

NOTE A → character in a menu option box indicates that another level of menu is

available.

2-14

Page 37

Menu Graphics Used in This Manual

At the end of this chapter, there are some examples of navigating the menu system,

showing all the menu displays available. In the rest of this manual, a menu graphic

is displayed in the left margin when y ou need to use the menu system. This menu

graphic gives a concise explanation of how to navigate to the exact place.

The graphics look similar to this, but further levels may be shown:

Using the Front Panel

Menu Graphics Used in This Manual

First level selection

Represents pressi ng Enter key

Menu mode required,

and other useful information

Second level

selection

Full menu mode

Default: 0

Affects next file sent

Stays after power off

C4704018

Currently selected options are displayed with a * in the fro nt-panel display.

2-15

Page 38

Using the Front Panel

Navigation Examples

Navigation Examples

Use the following examples to practice navigating the menu system. All examples

assume that you have entered the menu system from the STATUS screen shown

below.

Ready

Selecting the Full Menu Mode

u Make sure the STATUS display level is shown on the front panel:

Ready

STATUS

C4704034

STATUS

C4704034

2-16

1 Press Enter.

SHORT MENUS

Queueing & Nesting

2 Press ↓ or ↑ until

SHORT MENUS

Utilities

3 Press Enter.

UTILITIES

Menu mode=Short

C4704008

Utilities is displayed.

C4704034

→

C4704034

If FULL MENUS is displayed

instead of SHORT MENUS,

press the Previous key and

skip the following steps.

Page 39

4 Press Enter.

MENU MODE

Short*

C4704034

Using the Front Panel

Navigation Examples

5 Press

↓.

MENU MODE

Full

C4704034

6 Press Enter.

UTILITIES

Menu mode=Full →

C4704034

7 Press Previous.

FULL MENUS

Utilities

→

C4704034

8 Press Previous again to return to the

ST ATUS

Ready

ST ATUS screen in the front-panel display.

C4704034

2-17

Page 40

Using the Front Panel

Navigation Examples

2500CP Only

Changing the Color Calibration Setting in the Image Quality Menu

In this example, you will change the

Color Calibration setting in the Image Quality

menu. The arrows on the excerpt from the Front-Pa nel Menus print on page 2-20

correspond to the numbered instructions. From the previous example, you should

now have the STATUS screen displayed on the front panel, with

FULL MENUS

mode selected.

STATUS

Ready

C4704034

1 Press the Enter key to enter the front-panel menu. You are now at the first level

shown in the menu print.

FULL MENUS

Queueing & Nesting

C4704034

2 Press the

↓ key until IMAGE QUALITY is displayed.

FULL MENUS

Image quality

→

C4704034

2-18

3 Press the Enter key to select the option and move t o the

second-level menu. The

Ink emul. option is displayed.

IMAGE QUALITY

Ink emul.=Euroscale→

C4704034

4 Press the

↓ key once to display the Color calibration option.

IMAGE QUALITY

Color calib.=On

→

C4704034

IMAGE QUALITY settings

Page 41

Using the Front Panel

Navigation Examples

5 Press the Enter key to select the option and move to the Co lor calibration third-level

menu. The option currently selected is displayed with a *.

COLOR CALIBRATION

On*

C4704034

6 Change the displayed option by pressing the

↓ or the ↑ key.

COLOR CALIBRATION

Off

C4704034

7 Press the Enter key to set

You will be returned to the

COLOR CALIBRATION to the new dis played setting.

IMAGE QUALITY second-level menu.

IMAGE QUALITY

Color calib.=Off

→

C4704034

8 To exit the menu system, press the Previous key twice.

STATUS

Ready

C4704034

2-19

Page 42

Using the Front Panel

Navigation Examples

If you now reenter the menu system and repeat steps 1 to 4, you will see the option

that you selected displayed with a *.

EuroScale*

4

→

TOYO

Enhanced

Native

SWOP

On*

5↑↓6

Now

Off

↵

1

↓

↓

FULL MENUS

Image quality

8

←

2

→

Ink emul.=

3

↓

→

7

←

Color Calib.=

→

Printhead service=

Check=Frequency

Refill Now

Align Now

→

C4704040

NOTE A → character in a menu option box indicates that a lower level of menu is

available.

2-20

Page 43

Using the Front Panel

Navigation Examples

Changing the Merge Setting in HP-GL/2 Settings

In this example, you will change the Merge setting in the HP-GL/2 Settings. The

arrows on the excerpt of the Front-Panel Menus print on the next page correspond

to the numbered instructions. You should now have the STATUS screen displayed

on the front panel, with FULL MENUS mode selected.

STATUS

Ready

C4704034

1 Press the Enter key to enter the front-panel menu. You are now at the first level

shown in the menu print.

FULL MENUS

Queueing & Nesting

C4704034

2 Press the

↓ key until HP-GL/2 settings is displayed.

FULL MENUS

HP-GL/2 settings

→

C4704034

3 Press the Enter key to select the option and move to the

level menu. The

Palette option is displayed.

HP-GL/2

Palette=Software

4 Press the

↓ key once to display the Merge option.

→

C4704034

HP-GL/2

Merge=Off

→

C4704034

HP-GL/2 settings second-

2-21

Page 44

Using the Front Panel

Navigation Examples

5 Press the Enter key to select the option and move to the Merge third-level menu.

The option currently selected is displayed with a *

MERGE

Off*

C4704034

6 Change the displayed option by pressing the

↓ or the ↑ key.

MERGE

On

C4704034

7 Press the Enter key to set

returned to the

Merge second-level menu.

Merge equal to the new displayed value. You will be

HP-GL/2

Merge=On

→

C4704034

8 To exit the menu system, press the Previous key twice.

STATUS

Ready

C4704034

2-22

Page 45

Using the Front Panel

Navigation Examples

If you now reenter the menu system and repeat steps 1 to 4, you will see the option

that you selected displayed with a *.

1

↓

↓

↓

↓

↓

↓

↓

FULL MENUS

HP-GL/2 Settings

8

←

2

Palette=

→

3

↓

→

Merge=

→

4

←

Define Palette=

4

→

Software*

Palette A

Palette B

Factory

Off*

5↑↓6

On

Palette A

Palette B

Factory

↵

C4704009

NOTE A → character in a menu option box indicates that another level of menu is

available.

2-23

Page 46

Using the Front Panel

Navigation Examples

u Make sure the STATUS display level is shown on the front panel:

Changing Margins

This example shows how to adjust the page margins.

STATUS

Ready

C4704034

1 Enter the menu system by pressing the Enter key.

FULL MENUS

Queueing & Nesting

C4704034

Either the

SHORT MENUS screen or t he FULL MENUS scre en is d ispla yed wi th th e

Queueing & Nesting option. If necessary, see page 2-16, Selecting the Full Menu

Mode, to change to full menu mode.

2 Press the ↑ key or the ↓ key until the

Page Format menu is displayed.

FULL MENUS

Page format

→

C4704034

3 Press the Enter key.

PAGE FORMAT

Size=Software

4 Press the ↑ key, or the ↓ key until the

→

C4704034

Margins option is displayed.

PAGE FORMAT

Margins=Extended

C4704034

2-24

Page 47

Using the Front Panel

Navigation Examples

5 Press the Enter key to display the MARGINS menu.

MARGINS

Extended*

C4704034

6 Use the ↑ and ↓ keys to display the available options and, when the desired option

is displayed, press the Enter key to select it as the setting for

Margins.

7 To exit the menu system, press the Previous key twice.

STATUS

Ready

C4704034

2-25

Page 48

Using the Front Panel

Navigation Examples

u Make sure the

Changing the Drying Time

This example adjusts the drying time, a setting used to suit different environmental

conditions, in the

this example.

Ready

1 Press the Enter key to enter the menu system.

FULL MENUS

Queueing & Nesting

DRYING TIME menu. The printer must be in full menu mode for

STATUS display level is shown on the front panel.:

STATUS

C4704034

C4704034

Either the

SHORT MENUS screen or t he FULL MENUS scre en is d ispla yed wi th th e

Queueing & Nesting option. If necessary, see page 2-16, Selecting the Full Menu

Mode, to change to Full Menu mode.

2 Press the ↑ key or the ↓ key until the

Device Setup menu is displayed.

FULL MENUS

Device Setup

→

C4704034

3 Press the Enter key.

DEVICE SETUP

Lang=Automatic

4 Press the ↑ key or the ↓ key until

→

C4704034

DRYING TIME is displayed.

DEVICE SETUP

Drying time=Automatic

→

C4704034

2-26

Page 49

Using the Front Panel

Navigation Examples

5 Press the Enter key to display the DRYING TIME menu.

DRYING TIME

Automatic*

C4704034

6 Use the ↑ and ↓ keys to display the available options and, when the desired option

is displayed, press the Enter key to select it as the setting for Drying time.

7 To exit the menu system, press the Previous key twice.

STATUS

Ready

C4704034

2-27

Page 50

Using the Front Panel

FULL MENUS

Ink level

Full menu mode

Other Types of Front-Panel Display Information

Other Types of Front-Panel Display Information

Other types of messages are also displayed in the front panel, such as those

displayed for selecting media type during media loading:

SELECT MEDIA

Coated Paper

C4704034

or the amount of ink remaining:

Cyan

Yel

Mgnta

Black

C4704041

There are other selection menus which are not part of the main menu system. These

behave in the same way as th e main menus. You scroll through the options u sing t he

↑

and ↓ keys and select a displayed option using the Enter key.

2-28

Page 51

Working with Media

Choosing Media 3-2

Using the Ink System UV Outside 3-5

Handling Your Media 3-12

Loading Roll Media 3-13

1

3

Loading Media onto the Take Up Reel accessory 3-19

Unloading Media from the Take Up Reel accessory 3-26

Removing a Roll from the Printer 3-30

Installing a New Roll into the Printer 3-32

Changing the Core Tube on the Take Up Reel Accessory 3-35

Loading sheet media 3-39

Unloading Sheet Media 3-42

Drying time (With a Take Up Reel) 3-44

Drying Time (Without a Take Up Reel) 3-46

3-1

Page 52

Working with Media

Choosing Media

Choosing Media

Your printer supports several types of media. Choosing the best media type fo r your

needs is an essential step in ensuring good image quality. For best printing results,

use only genuine He wlett-Packard media, whose reliability and pe rformance have

been developed and thoroughly tested. All HP printing components (printer, ink

system, and media) have been designed to work together to give trouble-free

performance and optimal image quality.

For detailed in formation on Hewlett- Packard media, see pag e 3-4, S upported Med ia

Types, and the HP DesignJet Papers and Films catalog supplied with the printer.

HP has tested some media products developed by a non-HP manufacturer. These

tested products are approved by HP as compatible with this printer.

Some non-endorsed media products are listed in the Media Guide for the HP

DesignJet CP Printers provided with your printer. HP has not tested these media

products to ensure their performance or quality.

If you choose to pri nt on a non- endorsed media it is r ecommended that you per form

the Media Test Print see page 9-7, Media T est Pri nt .

CAUTION Use of non-endorsed coated papers when printing with high ink volume may

saturate the coated paper and could result in serious printhead damage.

CAUTION For the Outdoor Durability Warranty, with the Ink System UV you must

always print on the compatible 3M Opaq ue V inyl medi a. Also you must use 3M

Overlaminate film to maintain the print’s luster, depth and quality.

3-2

Page 53

Working with Media

Choosing Media

Some Important Points about Media Types

n This printer supports many media types. However, the quality of some images

may be reduced if you do not use HP media.

n Whenever you load a roll or a sheet, the printer’s front-panel display prompts

you to specify the media type you are loading. It is absolutely essentia l to specify

this correctly for good image quality. The table on page 3-4, Supported Media

Types, gives you all the information yo u need. If med ia is already l oaded and you

are unsure which media type was specified, go to Utilities / Statistics in the

front-panel menu. See page 8-2, Viewing the Current Overall Configuration of

the printer.

n Make sure the appropriate print-quality setting (Best, Normal or Fast) is

selected. You can set the print quality either from your software or from the

printer’s front panel (software driver settings override any print-quality settings

made on the front panel). The combination of media type and print-quality

settings tells the printer how to place the ink on the media - for example, the ink

density, dithering method, and number of passes of the printheads. For more

details, see the table on page 3-10, Combinations of Media Type and Print

Quality.

n Included with this printer is an HP DesignJet Papers and Films catalog which

gives ordering details for Hewlett-Packard med ia supplies. To get the latest

version of this document, contact your local HP Sales and Support office.

NOTE If you are using a third-party Raster Image Processor (RIP) to print with your

printer, the above points may not apply. In this case, consult your RIP vendor

for advice on media and the best settings for your requirements.

3-3

Page 54

Working with Media

Choosing Media

Supported Media Types

Your printer supports several types of media The supported types and their most

common uses are shown in the table below.

The media you choose will de pend on t he ink system you have installed t hat i s, UV

inks or imaging inks.

Media Type on the FrontPanel Display

Coated Paper

High Gloss Photo Paper

Semi Gloss Photo Paper

Imaging Film-Bac klit

Opaque Vinyl

HP Heavyweight Coated

Paper

3M Changeable Opaque

Imaging Media

NOTE:HP Heavyweight Coated Paper is the only media that is compatible with both

the

Description

A specially coated wood-pulp based paper for inexpensive high-quality

color graphics and photographic image prints.

A white Photographic paper with a high -gloss finish for high quality

prints.

A white Photographic paper with a semi-gloss finish for high quality

prints.

A clear polyester film for backlit viewing of images.

Adhesive-backed white opaque vinyl.

A specially coated heavyweight based paper for high quality color

graphics which when combined with the HP DesignJet CP Ink System

UV provide s enhanced light fastness for indoor and outdoor use.

A flexible white opaque film with removable pressure-sensitive adhesive

backing for outdoor use. It is outstanding for outdoor signs, posters and

banners. When printing with this media use the Best print mode.

HP DesignJet CP Ink System and the HP DesignJet CP Ink System UV.

3-4

NOTE:To order the above media types see page 3-8, HP Commercial Names of

Media Types and the pamphlet Media Guide for the HP DesignJet printers.

From time to time, new media types may become available. For up-to-date

information, please contact your HP dealer or local HP Sales and Support Office.

Page 55

Working with Media

Using the Ink System UV Outside

Using the Ink System UV Outside

Laminating the Media after Printing

After you have printed a file using the HP DesignJet CP Ink System UV on 3M™

Changeable Opaque Imaging Media 8522CP and before displaying the print

outdoors, it must b e l ami nat ed with one of the 3M overlaminates (see Table below).

The use of the overlaminate is essential for outdoor use to provide resistance to

water, scratches and tears and to maintain the print’s luster, depth and quality.

Applying the Overlaminate to a Finished Print

NOTE These guidelines provide a general process for laminating prints to help you

maintain consistent results and best quality. The laminating process may vary,

depending on the laminat i ng equi pment that you are usi ng. Always refe r to t he

manufacturer’s documentation for safe operation and additional information.

Before applying the lamin ate to your finished print, make sure it is completely d ry.

The print will feel almost dr y immediatel y after printi ng, but if you are prin ting i n a

particularly cold or humid en vironment, the dryi ng time ma y be longe r than nor mal.

For these situations wait 15 to 30 minutes before applying the overlaminate.

The 3M overlaminates are not heat-activated adhesives; however, heat can be used

to improve the adhesive flow. The temperature should not exceed 68° C (180° F).

The recommended laminator pressure is a minimum of 15 psi , an d must not exce ed

75 psi.

Overlaminate Type Description

3M Lustre Protective Finish

3M Matte Protective Finish

3M High-Gloss Protective

Finish

2mm vinyl overlaminate with pressure sensitive adhesive for outdo or

use.

2mm vinyl overlaminate with pressure sensitive adhesive for outdo or

use.

2mm vinyl overlaminate with pressure sensitive adhesive for outdo or

use.

3-5

Page 56

Working with Media

Using the Ink System UV Outside

Installing the Final Print

Recommendations to Follow When Installing the Final Print

Follow these recommendations when the final print is to be displayed outdoors:

n Installation temperatures

Final graphic installation temperature should range between 28° F and 110°F.

Final graphic removal temperature should range between 28° F and 110°F.

n Installation surfaces

The print must only be installed on flat, vertical surfaces. It is not recommend ed

to install the final prin t over rivets or corrugations.

The surface should not be susceptible to fuel spillage.

The print must be flat, with minimum curvature and mounted in a vertical

position with no more than ±10° tilt.

Detergent-and-water application methods should not be used.

The surfaces that give easy print removal include; aluminum, painted metal

(with good paint adhesion), Sintra board, acrylic, PVC banners and glass.

However all surfaces should be tested before applying the print.

If the surface has poor paint adhesion, paint may be pulled off when the final

graphic is removed. Aged surfaces with surface oxidation or chalking may result

in adhesive residue when the final print is removed.

n Installing on glass surfaces

The use of dark colors on your print may increase the risk of glass breakag e. All

glass has a tendency to absorb heat when exposed to sunlight. The ability of

glass to resist breakage due to temperature stress is affected by size, thickness,

quality of cut, edge treatment, tinting of the glass, and the frame design.

3-6

NOTE: Do not use very dark colors in window appl icat io ns. Large areas of dark

opaque colors could greatly increase the risk of glass breakage.

Page 57

Working with Media

Using the Ink System UV Outside

CAUTION Always apply the final print to the surface by hand or using a squeegee with a

low friction paper sleeve .

1 Position the final print on the surface. Measure the final print placement relative to

the sides of the substrate.

2 Tape the full leading e dge of the final print in the correct position. Two-inch wide

masking tape is recommended for this.

If the final print is less than 50 inches long:

a Lift the final print up from the trailing edge. You can roll the final print up for

easier handling, if desired.

b Strip back some of the backing from the final print holding it away from the

surface with one hand.

c Starting at the leading edge (the taped edge), use your other hand to squeegee

down the front surface of the final print. Use loose, easy motions to avoid

stretching the final print.

d Remove the masking tape when you have finished.

If the final print is more than 50 inches long:

a Using two people, tape the middle of the final print to the surface and then lift it

up from the trailing edge.

b Strip back some of the backing from the final print holding it away from the

surface.

c Apply one half of the final print from its outer edge.

d Strip back some of the backing from the other side of the final print. Again

holding it away from the surface, continue applying the final print from where

you left off.

e Remove the masking tape when you have finished.

3-7

Page 58

Working with Media

Media Types

Media Types

HP Commercial Names of Media Types

The following table lists the common and HP commercia l names of the media types

supported by your printer.

Media Type on the

Front-Panel Display

Commercial Name of Media as

described in the Media Guide for

Also Known As

printers

Coated paper

Heavy coated paper

High-gloss photo

Semi-gloss photo

Imaging film-backlit 3M C lear Imaging Media Clear polyester film

Opaque vinyl Ch angeable Opaque Imaging Media

UV Opaque Vinyl Opaque Imaging Vinyl

HP Coated Paper

HP Heavyweight Coated Paper

HP High-Gloss Photo Paper

HP Semi-Gloss Photo Paper

(for Imaging inks)

(for UV inks)

*

*

*

*

Color inkjet paper

Matte paper

Presentation

Heavyweight coated paper

Heavyweight inkjet paper

Heavyweight color inkjet paper

Heavyweight matte paper

High-gloss photo paper

High-gloss paper

Semi-gloss photo paper

Semi-gloss paper

Backlit media

3M Opaque vinyl

3M Opaque vinyl

*HP DesignJet CP Ink Systems are not compatible with media designed for previous HP DesignJet

printer models and inks. Make sure your media is designed for HP DesignJet CP Ink Systems. See the

Media Guide for the HP DesignJet CP Printers provided wit h your p rinte r fo r inf ormatio n on c ompat ible

media.

3-8

Page 59

Working with Media

Media Types

Physical Characteristics of Media Types

The following table lists the physical characteristics of the different supported

media types.

Media Type on the Front-panel

Physical Characteristics

Display

Opacity Matte or Glossy

Coated paper Opaque Matte

Heavy coated paper Opaque Matte

High-gloss photo Opaque Glossy

Semi-gloss photo Opaque Semi-Gloss

Imaging film-backlit Clear Glossy

Opaque vinyl Opaque Glossy

UV Opaque Vinyl Opaque Semi-Gloss

NOTE:When loading media into the printer , make sure the coa ted side of the media

is facing downwards.

NOTE:To order the above media types see page 3-8, HP Commercial Names of

Media Types and the pamphlet Media Guide for the HP DesignJet printers.

3-9

Page 60

Working with Media

Media Types

Combinations of Media Type and Print Quality

The table below shows possible combinations of media type and print quality.

Media Type on the

Front-Panel Display

Coated paper Yes Yes Yes

Heavy coated paper Yes Yes Yes

High-gloss photo Yes Yes Yes

Semi-gloss photo Yes Yes Yes

Imaging film-backlit

Opaque vinyl Yes Yes Yes

UV Opaque Vinyl Yes Yes Yes

Print Quality

(Set either on the Front Panel or in the Software)

Fast Normal

Yes

b

Yes Yes

Best

a

a.Use Best mode to ensure that your print is the best quality possible.

b.Fast print mode is the same as Normal print mode for backlit media.

NOTE:If you are using a third-party R aster Image Processor (RI P) to print with your

printer, the above table may not apply. In this case, consult your RIP vendor for

advice on the best settings for your requirements.

3-10

Page 61

Working with Media

Using Coated Paper and Heavy Coated Paper with Normal Mode

Using Coated Paper and Heavy Coated Paper with Normal

Mode

You should always select the media type in the front-panel menu that matches the

media type you have loaded in the printer, with the following one exception:

Printing on Coated Papers Using Normal Mode

n If you are loading Coated paper or Heavy coated pap er , and you intend to print in

Normal mode, you can select either Coated paper or Heavy coated paper in

the front-panel menu selection.

– For Faster Printing; select Coated paper media type in the front panel,

although this is not recommended for images containing gradient fills.

– For Better Print Quality; select Heavy coated paper media type in the front

panel.

You should print images in both modes t o see whi ch gi ves the best resu lts on coated

paper for your images. The difference in print quality between the two modes may

not be noticeable for some images.

3-11

Page 62

Working with Media

Handling Your Media

Handling Your Media

n Handle film and glossy media by the edges or wear cotton gloves. Skin oils can

interact with the ink a nd cause it to smear.

n Although the standard ink systems supplied with this printer have excellent

lightfastness, colors will eventually fade or change if exposed to sunlight over a

long period of time.

n Handle 3M

scratching and abrasions, especially after printing.

n When applying the final print avoid the application of excessive pressure and

keep sharp objects well away. After printing, the print image is susceptible to

scratching before the overlaminate is applied.

n Rewrap partially used rolls if they are not being used and do not stack rolls.

n Always keep unused rolls wrapped in the plastic wrap to prevent discoloration.

™

Changeable Opaque Imaging Media 8522CP carefully, avoid

3-12

Page 63

Working with Media

Loading Roll Media

Loading Roll Media

To start this procedure you need to have a roll of media installed on to the printer

spindle. See page 3-32, Installing a New Roll into the Printer.

1 Check the leading edge as it unwind s from t he spool . If i t is not eve nl y cut o r if it i s

skewed (not perpendicular to the guides), continue with the next procedure. If the

media is cut correctly go to step 3.

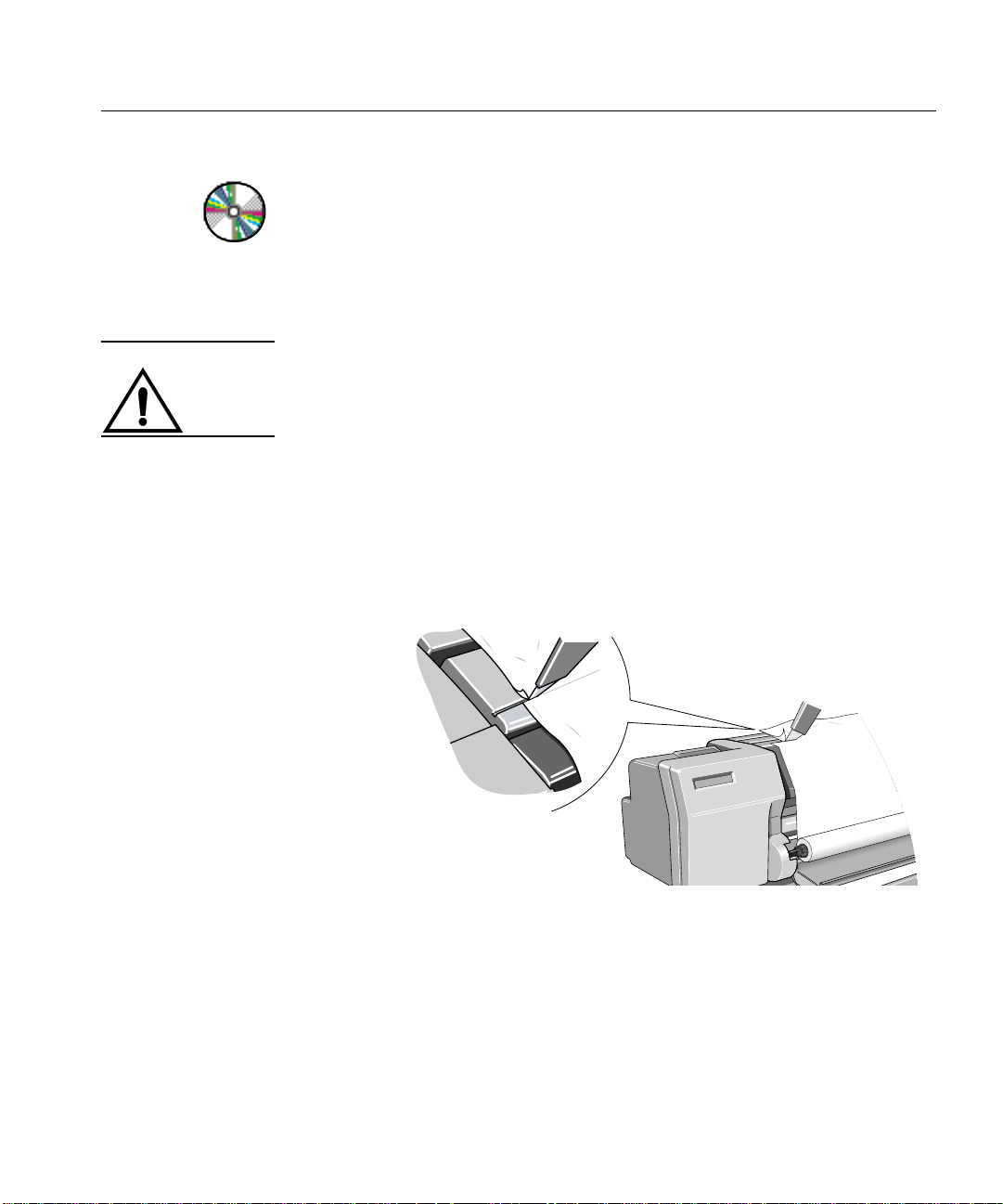

WARNING The knife used in the next step is sharp. Be sure the printer’s wheels are locked.

Keep fingers clear of the cutting path. Keep the knife away from children.

2 Trim the leading edge of the media roll only if it is not straight:

a Pull the media over the top of the machine and lay it over the cutting track.

b Use the knife in the pocket located on the back of the printer to cut off the first

few inches of the media.

c Retract the blade and return the knife to its pocket.

3-13

Page 64

Working with Media

Loading Roll Media

NOTE:Make sure the media leve r is in the raised position.

3 Open the roll cover and in se rt the media into the printer.

C4704124a

4 Holding the media at the sides, align its right edges with the perforated line on the

entry platen

3-14

C472357

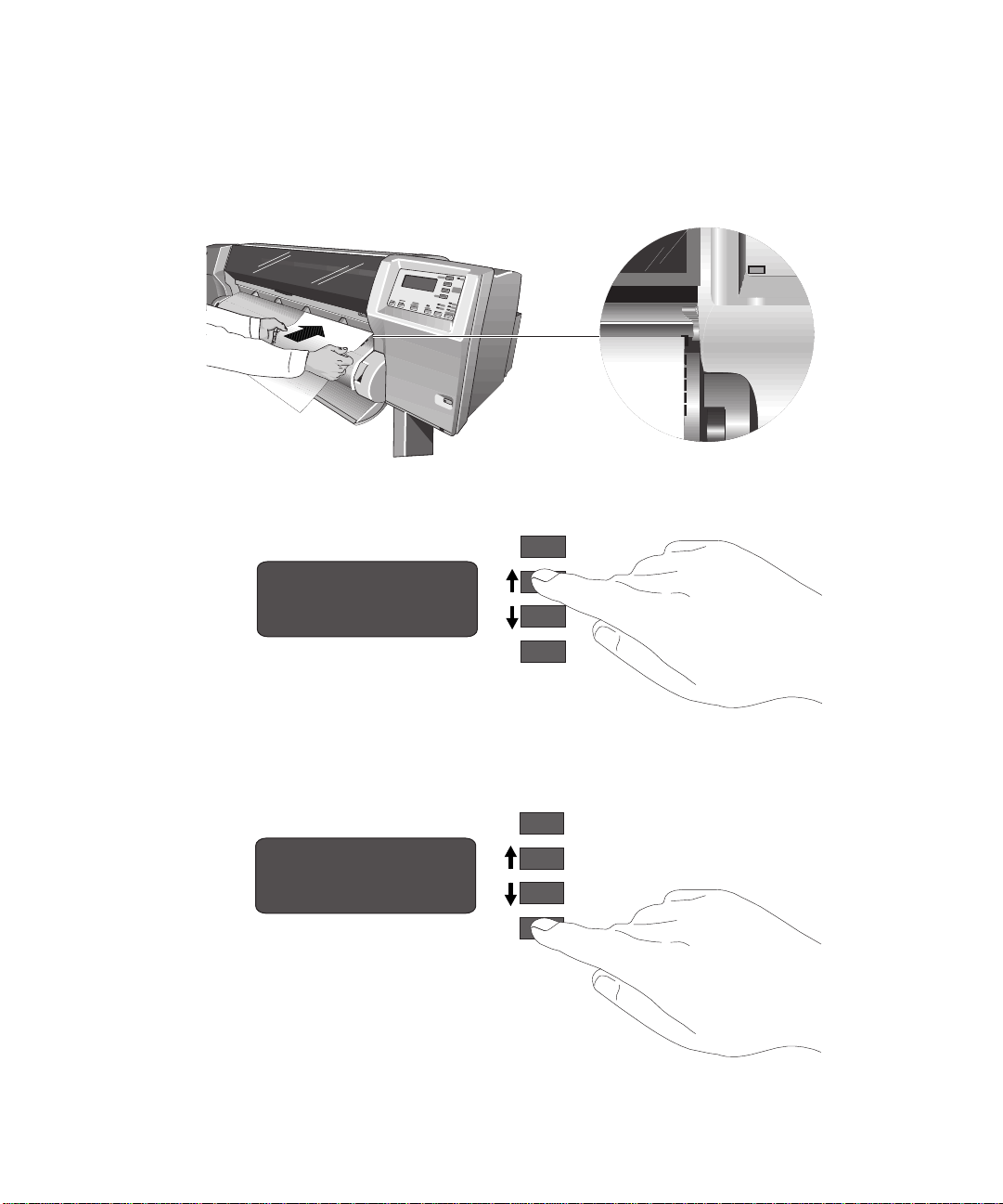

5 Press the ↓ key next to the front-panel display to indicate you are loading a roll.

Previous

Sheet load --------->

Roll load ------------>

Enter

C4704029

Page 65

Working with Media

Loading Roll Media

6 Use the ↑ and ↓ keys until the display shows the type of media you are lo adi ng and

then press the Enter key.

Previous

SELECT MEDIA

Coated paper

Enter

C4704030

3-15

Page 66

Working with Media

Loading Roll Media

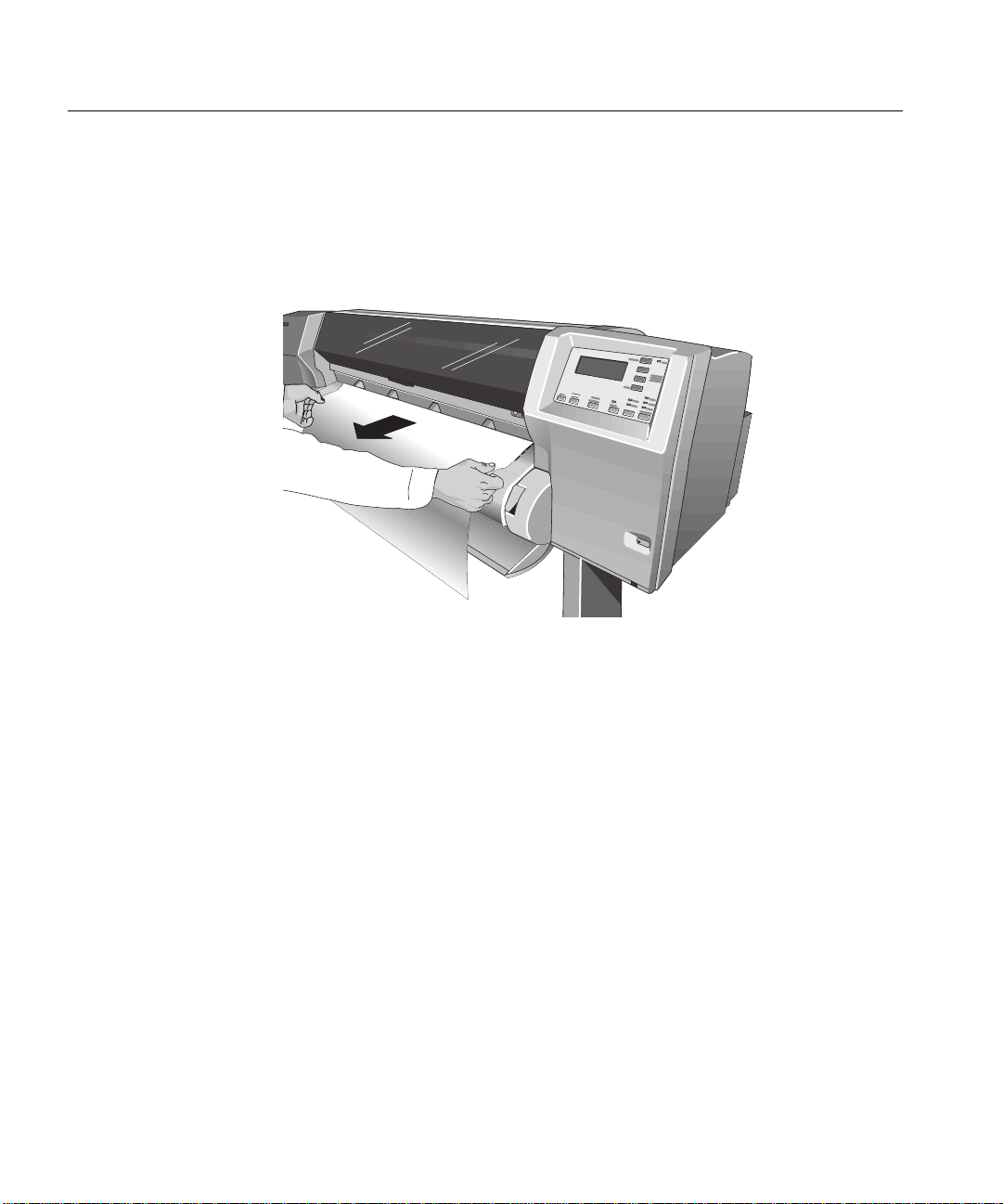

7 Align the media.

a When the front panel displays “Lower Lever”. Lower the media lever.

Lower Lever

C4704034

C4704130

b The front panel displays:

Pull/Align

edges to roll

C4704034

3-16

c Take hold of the edges of th e media now extend ing from the exit slot and pull the

media toward you until taut. Then align the left and right edges of the media, so

that they are flush with the edges of the roll.

I

m

p

o

m

I

m

p

o

m

io

u

i

itr

u

y

I

m

p

o

m

io

u

i

it

r

u

y

C4723127

Page 67

Working with Media

Loading Roll Media

d W ind the media stop in the direction of the arrow shown below. This is to take up

any slack in the roll before closing the roll cov er.

Impom

Impomui

ioitruy

Impomui

ioitruy

roll cover

ue ---------->

C4723128a

e When you have aligned the media lift the lever.

Lift lever

after aligning

after aligning

C4704016

f The printer checks that the media is aligned properly. If the alignment is

successful the front panel displays:

Close roll cover

Continue--------->

C4704131

3-17

Page 68

Working with Media

Loading Roll Media

8 Close the roll cover and press the ↓ key.

9 When the ↓ key is pressed the next step depends on the type of printer you have:

a If you do not have a Take Up Reel installed the printer disp lays:

Ready to print

C4704016

b If you do have a Take Up Reel installed and it is set to ON. Proceed to the next

procedure.

NOTE:If you want to turn on or off the Take Up Reel, see page

Take Up Reel.

8-12, Turning on the

3-18

Page 69

Working with Media

FULL MENUS

Move Media

Loading Media onto the Take Up Reel accessory

Loading Media onto the Take Up Reel accessory

T o sta rt this pr ocedur e you need to have a roll of media instal le d into the pri nter see

page 3-32, Installing a New Roll into the Printer and 3-13, Loading Roll Media.

CAUTION Using Back-lit media with a separate slip sheet is not recommended for use with

the Take Up Reel.

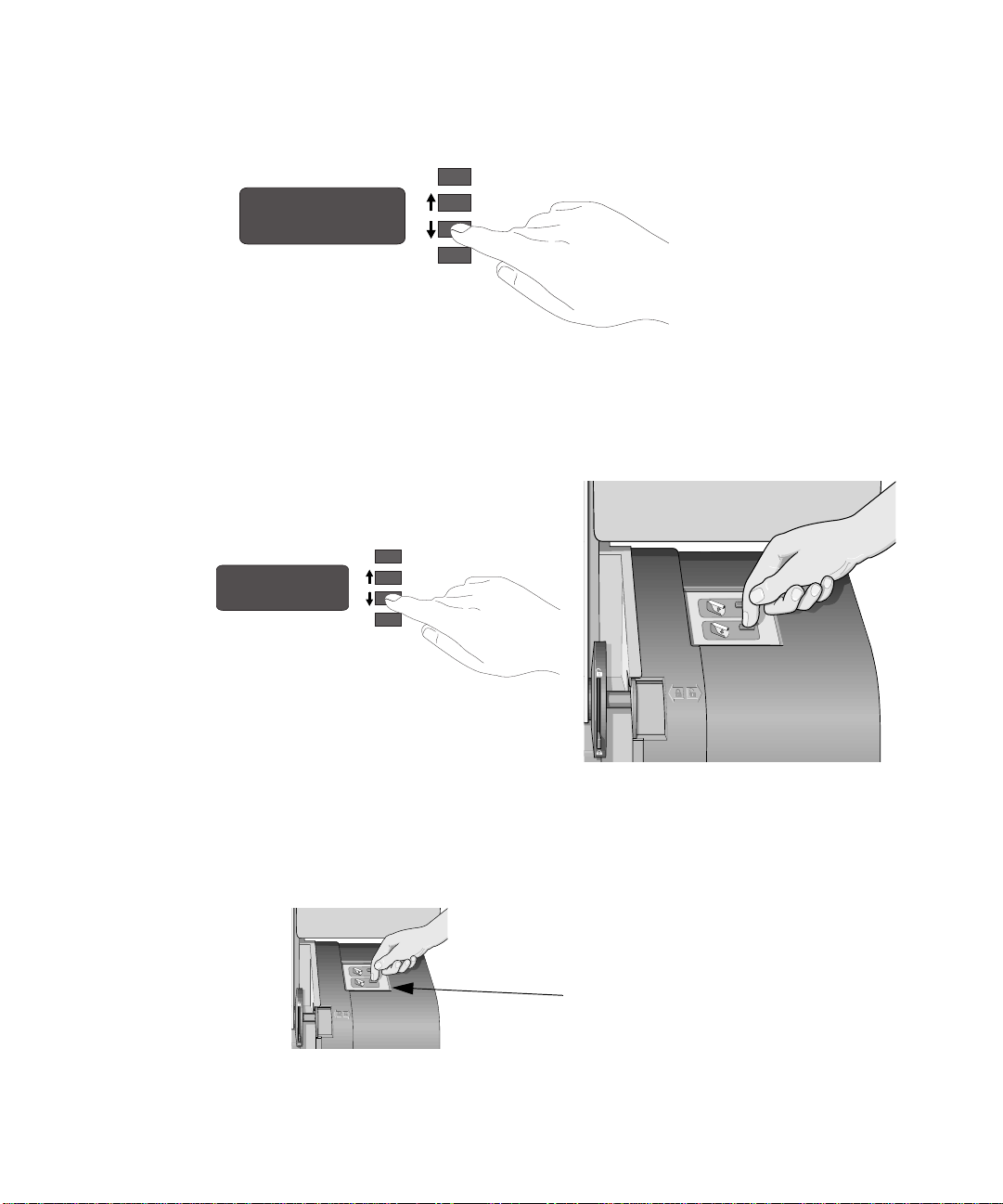

1 Move the leading edge of the media to half way down the Core Tube. To move the

media down use the ↓ key as shown below. If the media has gone too far (i.e. passed

the Core tube) use the ↑ key to move the media back up.

Back Media --------->

Forward Media ---->

FULL MENUS

FULL MENUS

C4704016

C472334C

NOTE:The Back Media/Forward Media display has a time-out of ten minutes. To

return to this display go to Move Media in the front panel display.

3-19

Page 70

Working with Media

Loading Media onto the Take Up Reel accessory