Page 1

TM 11-6625-2809-14 & P

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT AND

GENERAL SUPPORT MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS)

FOR

MULTIMETER ME-498/U (HEWLETT-PACKARD

MODEL 34702A) (NSN 6625-00-538-9794)

AND

INDICATOR ID-2101/U (HEWLETT-PACKARD

MODEL 34750A) (NSN 6625-00-538-9758)

HEADQUARTERS, DEPARTMENT OF THE ARMY

JUNE 1979

Page 2

TM 11-6625-2809-14 & P

This manual includes copyright material reproduced by permission of the HEWLETT-PACKARD Company.

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY

No.11-6625-2809-14 & P Washington, DC

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT AND

GENERAL SUPPORT MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS)

FOR

MULTIMETER ME-4981U (HEWLETT-PACKARD MODEL 34702A)

(NSN 6625-00-538-9794)

AND

INDICATOR ID-21011U (HEWLETT-PACKARD MODEL 34750A)

(NSN 6625-00-538-9758)

REPORTING OF ERRORS

You can improve this manual by recommending improvements using DA

Form 2028-2 located in the back of the manual. Simply tear out the self-addressed

form, fill it out as shown on the sample, fold it where shown, and drop it in the mail.

If there are no blank DA Forms 2028-2 in the back of your manual, use the

standard DA Form 2028 (Recommended Changes to Publications and Blank

Forms) and forward to Commander, US Army Communications and Electronics

Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ 07703.

14June1979

In either case a reply will be forwarded direct to you.

This manual is an authentication of the m anufacturer’s commercial literature which, through usage, has been found to

cover the data required to operate and maintain this equipm ent. Since the manual was not prepared In accor dance with

military specifications and AR 310-3, the format has not been structured to consider levels of maintenance.

i

Page 3

Table of Contents TM 11-6625-2809-14 & P

TABLE OF CONTENTS

PART ONE

Section Page

0. INTRODUCTION........................................0-1

I. GENERAL INFORMATION........................1-1

1-1. Description....................................1-1

1-6. Specifications................................1-3

1-8. Options..........................................1-3

1-10. Accessories Available

(See Figure 1-2)............................1-3

1-11. Instrument and Manual

Identification .................................1-3

Section Page

II. INSTALLATION..........................................2-1

2-1. Introduction ...................................2-1

2-3. Initial Inspection.............................2-1

2-5. Power Requirements ....................2-1

2-7. Grounding Requirements .……….2-2

2-10. Environmental Requirements .……2-2

2-12. Instrument Mounting .....................2-2

2-13. Bench Use .…………....................2-2

2-15. Rack Use ......................................2-2

2-17. Repackaging for Shipment .…......2-2

2-21. Power Cords and Receptacles .….2-3

Section Page

III. OPERATING INSTRUCTIONS..................3-1

3-1. Introduction....................................3-1

3-3. Rear Panel Features.....................3-1

3-5. Warm-Up.......................................3-1

3-7. Operation with Plug-On Modules..3-1

Section Page

IV. THEORY OF OPERATION...........4-1

4-1. Introduction.................................................4-1

4-3. Basic Measurement Sequence..................4-1

4-5. Analog Circuits...........................................4-1

4-4. Input Amplifier............................................4-1

4-8. Integrator....................................................4-2

4-10. Zero Detect Circuits....................................4-2

4-12. Auto-Zero Cycle..........................................4-2

4-14. Digital Processing Circuits..........................4-2

4-17. Data Clock (Refer to

Figure 4-8)..................................................4-4

4-19. Timing Generator Circuit (See

Figure 7-8)..................................................4-4

4-21. Zero Detect and Data Transfer

(Refer to Figure 4-10).................................4-4

4-23. Data Accumulator and Storage

(Refer to Figure 7-7)...................................4-6

Section Page

4-25. Data Display and Control Circuits

(Refer to Figure 4-11) .…….......................4-6

4-27. Reset Timing (See Figure 4-12) ................4-7

4-29. Least Significant Digit Blank

(Refer to Figure 7-8) .…….........................4-7

Section Page

V. MAINTENANCE ........................................5-1

5-1. Introduction ...............................................5-1

5-3. Operational Checks ..................................5-1

5-6. Adjustment Procedures..............................5-1

5-8. Cover Removal..........................................5-2

5-10. Adjustment Locator ...................................5-2

5-12. Power Supply Adjustment .…....................5-2

5-13. Input Amp. Offset Adjustment ……............5-2

5-14. Zero Detect Comparator Offset ….............5-2

5-15. Zero Detect Hysteresis

Adjustment .………….................................5-2

5-16. Reference Voltage Adjustments …............5-3

Section Page

VI. IDENTIFICATION OF PARTS ..................6-1

6-1. Introduction .…………................................6-1

6-4. Deleted

6-6. Deleted

6-8. Proprietary Parts .…………….....................6-1

Section Page

VII. CIRCUIT DIAGRAMS AND

TROUBLESHOOTING .………..................7-1

7-1. Introduction .…………................................7-1

7-3. Troubleshooting .………............................7-1

7-4. Troubleshooting Trees .……......................7-1

7-6. Troubleshooting Procedures .....................7-1

7-8. Functional Block Diagram

(Figure 7-4) .………...................................7-1

7-10. Timing Circuits (Figure 7-5) ......................7-1

7-12. Schematic Diagrams (Figures

7-6, 7-7 and 7-8) .……...............................7-1

7-14. Component Location Diagrams ................7-1

APPENDIXES

A. Difference Data Sheet ...............................A-1

B. References ................................................B-1

C. Maintenance Allocation .…………………..C-1

D. Repair Parts And Special

Tools List...................................................D-1

ii

Page 4

Table of Contents TM 11-6625-2809-14 & P

LIST OF TABLES

Table Page

1-1. Specifications................................................ 1-2

1-2. General Information ...................................... 1-3

3-1. 34721B/5055A Output Codes....................... 3-1

5-1. Recommended Test Equipment ................... 5-1

5-2. DC Accuracy ................................................. 5-2

5-3(a). AC Accuracy (45 Hz and 20 kHz................... 5-5

5-3(b). AC Accuracy (100 kHz).................................5-6

5-4. Accuracy Test .............................................. 5-7

6-1. Identification of Parts..................................... 6-3

LIST OF ILLUSTRATIONS

Figure Page

1-1 Instrument Serial Number............................1-1

2-1. Installation of the Model 34702A..................2-1

3-1. Front add Rear Panel Features....................3-0

4-1. Block Diagram..............................................4-0

4-2. ACV/DCV Attenuator....................................4-1

4-3. W Converter.................................................4-2

4-4. AC/DC Converter......................................... 4-3

4-5. Impedance Converter...................................4-4

5-1. Input Impedance Test ..................................5-3

5-2. Effective Common Mode Rejection..............5-3

5-3. Normal Mode Rejection................................5-4

5-4. Removal from Case .....................................5-8

5-5. Adjustment Locator...................................... 5-9

7-1. AC Converter Troubleshooting Tree............7-3/7-4

7-2. W Converter Troubleshooting Tree..............7-3/7-4

7-3. 34702A Schematic.......................................7-5/7-6

iii

Page 5

TABLE OF CONTENTS

PART TWO

TM 11-6625-2809-14 & P

Section Page

I. GENERAL INFORMATION........................1-1

1-1. Description....................................1-1

1-6.Specifications.......................................1-3

1-8. Options..........................................1-3

1-10. Accessories Available

(See Figure 1-2) ...........................1-3

1-11. Instrument and Manual

Identification .……….....................1-3

Section Page

II. INSTALLATION .........................................2-1

2-1. Introduction....................................2-1

2-3. Initial Inspection.............................2-1

2-5. Power Requirements.....................2-1

2-7. Grounding Requirements..............2-2

2-10. Environmental Requirements........2-2

2-12. Instrument Mounting......................2-2

2-13. Bench Use.....................................2-2

2-15. Rack Use.......................................2-2

2-17. Repackaging for Shipment............2-2

2-21. Power Cords and Receptacles......2-3

Section Page

III. OPERATING INSTRUCTIONS..................3-1

3-1. Introduction....................................3-1

3-3. Rear Panel Features.....................3-1

3-5. Warm-Up.......................................3-1

3-7. Operation with Plug-On Modules .3-1

Section Page

IV. THEORY OF OPERATION........................4-1

4-1. Introduction....................................4-1

4-3. Basic Measurement Sequence ....4-1

4-5. Analog Circuits..............................4-1

4-6. Input Amplifier...............................4-1

4-8. Integrator.......................................4-2

4-10. Zero Detect Circuits.......................4-2

4-12. Auto-Zero Cycle.............................4-2

4-14. Digital Processing Circuits.............4-2

4-17. Data Clock (Refer to

Figure 4-8).....................................4-4

4-19. Timing Generator Circuit (See

Figure 7-8).....................................4-4

4-21. Zero Detect and Data Transfer

Circuits (Refer to Figure 4-10).......4-4

4-23. Data Accumulator and Storage

(Refer to Figure 7-7)......................4-6

Section Page

4-25. Data Display and Control Circuits

(Refer to Figure 4-11)...................4-6

4-27. Reset Timing (See Figure4-12)..................4-7

4-29. Least Significant Digit Blank

(Refer to Figure 7-7)..................................4-7

Section Page

V. MAINTENANCE.........................................5-1

5-1. Introduction................................................5-1

5-3. Operational Checks ..................................5-1

5-6. Adjustment Procedures..............................5-1

5-8. Cover Removal .........................................5-2

5-10. Adjustment Locator....................................5-2

5-12. Power Supply Adjustment..........................5-2

5-13. Input Amp. Offset Adjustment ...................5-2

5-14. Zero Detect Comparator Offset ................5-2

5-15. Zero Detect Hysteresis

Adjustment.................................................5-2

5-16. Reference Voltage Adjustments ...............5-3

Section Page

VI. IDENTIFICATION OF PARTS...................6-1

6-1. Introduction................................................6-1

6-4. Deleted

6-6. Deleted

6-8. Parts Changes...........................................6-1

6-10. Proprietary Parts

Section Page

VII. CIRCUIT DIAGRAMS AND

TROUBLESHOOTING...............................7-1

7-1. Introduction................................................7-1

7-3. Troubleshooting.........................................7-1

7-4. Troubleshooting Trees...............................7-1

7-6. Troubleshooting Procedures......................7-1

7-8. Functional Block Diagram

(Figure 7-4)................................................7-1

7-10. Timing Circuits (Figure 7-5).......................7-1

7-12. Schematic Diagrams (Figures

7-6, 7-7 and 7-8)........................................7-1

7-14. Component Location Diagrams.................7-1

Appendix Page

................................6-1

A. Difference Data Sheet.................................A-1

iv

Page 6

Table of Contents

TM 11-6625-2809-14 & P

LIST OF ILLUSTRATIONS

Figure Page

1-1. Plug-On Modules which can be used

with the 34750A Display Module................1-1

1-2. Accessories Available for use with 34750A.. 1-2

1-3. Instrument Serial Number (on rear panel) .1-3

2-1. Voltage Selection........................................2-1

2-2. Rick Mount Kits..........................................2-2

2-3. Power Receptacles....................................2-3

3-1. 34750A Rear Panel....................................3-1

4-1. Basic Block Diagram of 34750A.................4-0

4-2. Simplified Diagram of the

Input Amplifier............................................4-1

4-3. Simplified Diagram of the

Integrator Circuit.........................................4-2

4-4. Simplified Diagram of Zero Detect

Circuits......................................................4-2

4-5. 34750A Circuits shown in Auto-Zero

Mode ......................................................4-3

4-6. Block Diagram of Typical ASM...................4-3

4-7. ASM Simplified Block Diagram...................4-4

4-8. Data Clock..................................................4-4

Figure Page

4-9. 34750A Flow Chart....................................4-5

4-10. Zero Detect and Data Transfer

Timing......................................................4-6

4-11. Data Display Circuits..................................4-6

4-12. Reset Tuning .............................................4-7

5-I. 11456A Readout Test Card.......................5-1

5-2. Cover Removal..........................................5-2

5-3. Zero Detect Comparator Offset

Adjustment.................................................5-2

5-4. Chassis Mounted Component and

Adjustment Locator....................................5-3

7-1. Power Supply Troubleshooting

Tree ................................................7-3/7-4

7-2. Analog Troubleshooting Tree.....................7-5

7-3. Digital Troubleshooting Tree................7-7/7-8

7-4. Functional Block Diagram..................7-9/7-10

7-5. Timing Waveforms...........................7-11/7-12

7-6. Analog Signal Processor..................7-13/7-14

7-7. Digital Signal Processor...................7-15/7-16

7-8. Power Supply...................................7-17/7-18

LIST OF TABLES

Table Page

1-1. 3470A Series Signal Conditioning

Modules.........................................................1-3

1-2. Available Options..............................................1-3

5-1. Recommended Test Equipment.......................5-1

5-2. Operational Checks..........................................5-1

6-1. Identification of Parts........................................6-2

7-1. Troubleshooting Trees......................................7-1

v

Page 7

hp

PART ONE

OPERATING AND SERVICE MANUAL

Binder part No. 34740-90011

(Includes cover sheet)

Manual Part No. 34740-90012 or 34750-90012

(Binder, System Introduction and Display Manual)

MODEL 3470

MEASUREMENT SYSTEM

TM 11-6625-2809-14 & P

IMPORTANT NOTICE

This instruction manual requires no change sheet. Any

change information has already been integrated into the

manual by page revisions. Revised pages have a

revision letter which can be found on the lower corner

of the page. Reference may also be made to Section VIII

of each manual where backdating information for earlier

instruments can be found.

Copyright Hewlett-Packard Company 1972

P.O. Box 301, Loveland, Colorado 80537 U.S.A.

vi

Printed: June 1973

Page 8

TM 11-6625-2809-14 & P

hp

HEWLETT PACKARD

CERTIFICATION

Hewlett-Packard Company certifies that this instrument met its published specifications at the time of

shipment from the factory. Hewlett-Packard Company fur ther certifies that its calibration meas urements

are traceable to the United States National Bureau of Standards, to the ex tent allowed by the Bureau’s

calibration facility, and to the calibration facilities of other International Standards Organization members.

WARRANTY AND ASSISTANCE

This Hewlett-Packard produc t is warranted against defects in materials and work manship f or a period of

one year from the date of shipment, except that in the case of certain components, if any, listed in

Section I of this operating manual, the warranty shall be for the specif ied period. Hewlett-Pack ard will, at

its option, repair or replace products which prove to be defective dur ing the warranty period provided they

are returned to Hewlett-Packard, and provided the proper preventive maintenance procedures as listed in

this manual are followed. Repairs necessitated by misuse of the product are not covered by this

warranty. NO OTHER WARRANTIES ARE EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. HEWLETT-PACKARD IS NOT LIABLE FOR CONSEQUENTIAL DAMAGES.

If this product is sold as part of a Hewlett-Packard integrated instrument system, the above warranty shall

not be applicable, and this product shall be covered only by the system warranty.

Service contracts or customer assistance agreements are available for Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Office, Addresses are

provided at the back of this manual.

vii

Page 9

INTRODUCTION

TM 11-6625-2809-14 & P

The 3470 Measurement System is a series of modules

that may be plugged together to form several different

measuring instrum ents, including both line powered and

battery powered versions.

A mainframe display module is connected to a bottom

plug-on function module to form a complete instrument.

The BCD and/or Battery plug-on module m ay be added

between the display and function modules as desired.

Refer to the Operating and Service Manual of the plugon module to be used with the display module for the

operating instructions, incoming inspection, and adjustment procedures of the instrument as a whole.

Possible Instrument Configurations

viii

Page 10

INTRODUCTION

0-1. SCOPE.

a. This manual in Part 1, describes

Multimeter ME-498/U (fig. 3-1) and provides instructions

for operation and maintenance. Throughout this manual

the ME-498/U is referred to as the Hewlett-Packard

Model 34702A.

SECTION 0

TM 11-6625-2809-14 & P

Improvement Report) as prescribed in AR

70058/NAVSUPINST 4030.29/AFR 71-13/MCOP40

30.29A and DLAR 4145.8.

c.

Discrepancy in Shipment Report

(DISREP) (SF 361). Fill out and forward Discrepancy in

Shipment Report (DISREP) (SF 361) as prescribed in

AR 55-38/NAVSUPINST 4610.33B/AFR 7518/MCO

P4610.19C and DLAR 4500.15.

b. Part 2 describes Indicator ID-2101/U

(fig.1-1, Part 2). This display module is referred to as the

Hewlett-Packard Model 34750A.

0-2. INDEXES OF PUBLICATIONS.

a.

of DA Pam 310-4 to determine whether there are new

editions, changes, or additional publications pertaining to

the equipment.

b.

to determine whether there are modification work orders

(MWO’s) pertaining to the equipment.

0-3. FORMS AND RECORDS.

a.

DA Pam 310-4.

DA Pam 310-7.

Reports of Maintenance and

Unsatisfactory Equipment.

and reports which are to be used by maintenance

personnel at all maintenance levels are listed in and

prescribed by TM 38-750.

b.

Deficiencies.

Report of Packaging and Handling

Fill out and forward DD Form 6 (Pac kaging

Refer to the latest issue

Refer to DA Pam 310-7

Maintenance forms, records,

0-4. REPORTING EQUIPMENT

IMPROVEMENT RECOMMENDATIONS (EIR).

EIR’s will be prepared using SF 368 (Quality Deficiency

Report). Instructions for preparing EIR’s are provided in

TM 38-750, the Army Maintenance Management

System. EIR’s should be mailed direct to Commander,

US Army Communication and Electronics Materiel

Readiness Command, ATTN: DRSEL-ME-MQ, Fort

Monmouth, NJ A reply will be furnished direct to you.

0-5. ADMINISTRATIVE STORAGE.

Administrative storage of equipm ent issued to and used

by Army activities shall be in accordance with TM 74090-1 and paragraph 2-8.

0-6. DESTRUCTION OF ARMY ELECTRONICS

MATERIEL.

Destruction of Army electronics materiel to prevent

enemy use shall be in accordance with TM 750-244-2.

0-1

Page 11

Model 34702A TM 11-6625-2809-14 & P

SECTION I

GENERAL INFORMATION

1-6. Table 1-1 lists specifications for the Model

1-1. INTRODUCTION.

34702A Multimeter. This table supersedes all other

previously printed specifications. Procedures are

1-2. This manual contains installation and operating

instructions as well as maintenance information which

includes performanc e checks for the Model 34702A. A

schematic diagram, theory of operation, and

troubleshooting information are provided for use in

maintaining the 34702A Multimeter Module.

provided in Section V to verify performance of the

instrument to its specifications and to readjust the

instrument if required. T he accuracy specifications apply

for ambient temperatures of 23

0

C+ 50C. For

temperatures outside this range, a temperature

coefficient factor (listed in Table 1-1) must be used.

1-3. DESCRIPTION.

1-4. The Hewlett-Packard Model 34702A Multimeter

is a signal conditioning module that m ay be connected to

a Model 34740A or 34750A Display Module, to measur e

AC Voltage, DC Voltage, or resistance. The AC and DC

volts functions provide four decade ranges from I V to

1000 V. Six resistance ranges from 100 full sc ale to 10

MQ full scale are provided by the "Ω (fy)" function. Each

available range of the Model 34702A has 100%

overranging capability except the 1000 V range which

has 20%.

Overload protection circuits allow up to

1200 V peak to be applied to the INPUT

V terminals without damaging the

instrument. Up to 350 V can be applied

to the INPUT S terminals without

damaging the instrument. No more than

500 V should be applied between LO

and Chassis. Do not apply voltage

between LO and Chassis when using

the 34721A or 34721B BCD Module.

These modules connect LO to Chassis

when attached to the Model 34 702A.

1-7. Table 1-2 lists general information relating to the

instrument.

1-8. INSTRUMENT AND MANUAL

IDENTIFICATION.

1-9. A three-section serial number (xxxxAxxxxx) is

used to identify your Model 34702A. Figure 1-1

illustrates the meaning of the three parts of the number.

1-10. This manual is kept up-to-date with revised

pages. If the serial number of your instrument is lower

than the one on the title page of this manual, refer to the

backdating inform ation in Appendix A which adapts this

manual to your instrument. All correspondence with

Hewlett-Packard Company should include the complete

serial number.

1-5. SPECIFICATIONS AND GENERAL

INFORMATION.

Figure 1-1. Instrument Serial Number.

1-1

Page 12

Model 34702A TM 11-6625-2809-14 & P

Table 1-1. Specifications. (Measured using 34740A or 34750A Display Unit)

DC VOLTAGE

34740A

Performance:

Accuracy (+ 230C t 50C), < 95% RH)

30 days + (0.03% of reading + .01% of range)

90 days + (0.04% of reading + .01% of range)

6 mo. + (0.05% of reading + .02% of range)

1 yr. + (0.06% of reading + .02% of range)

Stability (24 hours, + 230C + 1°C)

+ (0.01% of reading + 0.005% of range)

Temperature Coefficient (00 C to + 500C)

DC voltage: t (0.0035% of reading + 0.001%

of range)/oC.

Input Characteristics:

Input resistance

1 and 10 V ranges: 11.11 M + 0.2%

100 V range: 10.1 M + 0.2%

1000 V range: 10 M + 02%

Effective Common Mode Rejection (1 k unbalance)

DC: > 80 dB.*

Input impedance

1 and 10 V ranges: 11.11 M + 02%/ /80 pF max.

100 V range: 10.1 M ± 0.2%/ /80 pF max.

1000 V range: 10 M + 0.2%/180 pF max.

OHMS

34740A

Performance:

Accuracy (+ 230C ± 50C,< 95% RH)

30 days

10 MO range + (0.25% of reading + 0.02%

of range)

All other ranges + (0.05% of reading + 0.02%

of range)

90 days

10 M range + (0.30% of reading + 0.02%

of range)

All other ranges + (0.06% of reading + 0.02%

of range)

6 mo.

10 M range + (0.35% of reading + 0.03%

of range)

All other ranges + (0.07% of reading + 0.03%

of range)

Normal Mode Rejection

50 Hz (Option 050): >60dB (50 Hz + 0.1%)

60 Hz (Option 060): >60dB (60 Hz + 0.1%)

*Does not apply when BCD Module is used.

AC VOLTAGE

34740A

Performance:

Accuracy (+ 23°C + 50C, <95% RH)

30 days

45 Hz to 20 kHz + (0.25% of reading + .05%

of range)

20 kHz to 100 kHz + (0 75% of reading + .05%

of range)

90 days

45 Hz to 20 kHz + (0.30% of reading + .05%

of range)

20 kHz to 100 kHz + (0.80% of reading + .05%

of range)

6mo.

45 Hz to 20 kHz + (0.35% of reading + .05%

of range)

20 kHz to 100 kHz + (085% of reading + .05%

of range)

1 yr.

45 Hz to 20 kHz + (0.50% of reading + 0.05%

of range)

20 kHz to 100 kHz + (1.0% of reading + 0.05%

of range)

Temperature Coefficient (0°C to + 500C)

AC voltage: ± (0,03% of reading + 0.001%

of range) /0C.

Stability (24 hours, + 23°C + 1°C)

AC voltage: 45 Hz to 20 kHz: ± (0.15% of reading

+ 0.05% of range)

20 kHz to 100 kHz: + (0.4% of reading

+ 0.05% of range)

Response Time: < 2 s within + 0.3% of final value or 20

counts, whichever is greater.

Input Characteristics:

1 yr.

10 M range ± (0.50% of reading + 0.03%

of range)

All other ranges t (0.11% of reading + 0.03%

of range)

Stability (24 hours, 23°C + 10C)

10 Mn range + (0.1% of reading + 0.01%

of range)

All other ranges + (0.02% of reading + 0.02%

of range)

Temperature Coefficient (00C to + 500C)

Ω

10 Ml range: + (0.035% of reading + 0.001%

of range) / C.

All other ranges' t (0.006% of reading + 0.001%

of range) / C.

DC VOLTAGE

34750A

Performance:

Accuracy (+ 23°C + 50C), < 95% RH)

30 days ± (0.025% of reading + .005% of range)

90 days + (0.035% of reading + .005% of range)

6 mo. + (0.045% of reading + .007% of range)

1 yr. + (0.06% of reading + .01% of range)

NOTE: Due to temperature change inside the instrument

between line and battery operation, the references

must be adjusted when changing modes to achieve

these specifications

Stability (24 hours, + 230C + 10C)

DC voltage: + (.008% of reading i .004% of range)

Temperature Coefficient (0°C to + 500C)

DC voltage: ± (0.0025% of reading + 0.0002% of

range) / C

Input Characteristics

Input resistance

1 and 10 V ranges: 11.11 M + 0.2%

100 V range: 10.1 M +.0.2%

1000 V range: 10 M + 0.2%

Effective Common Mode Rejection (1 kO unbalance)

DC: >80 dB.*

*Does not apply when BCD Module is used

Rev. A 1-2

Page 13

Model 34702A TM 11-6625-2809-14 & P

Table 1-1. Specifications (Cont’d).

Normal Mode Rejection

50 Hz (Option 050): >60 dB (50 Hz + 0.1%)

60 Hz (Option 060): >60 dB (60 Hz + 0.1%)

AC VOLTAGE

34750A

Performance:

Accuracy (+ 230 + 5C, A 95% RH)

30 days

45 Hz to 20 kHz +(0.25% of reading + .05%

of range)

20 kHz to 100 kHz + (.75% of reading + .05%

of range)

90 days

45 Hz to 20 kHz + (.3% of reading + .05%

of range)

20 kHz to 100 kHz + (.8% of reading + .05%

of range)

6 mo.

45 Hz to 20 kHz ± (.35% of reading + .05%

of range)

20 kHz to 100 kHz + (.85% of reading + .05%

of range)

1 yr.

45 Hz to 20 kHz + (0.50% of reading + 0.05%

of range)

20 kHz to 100 kHz ± (1.0% of reading + 0.05%

of range)

Stability (24 hours, + 230C ± 10 C)

AC voltage: 45 Hz to 20 kHz: + (0.15% of reading

+ 0.05% of range)

20 kHz to 100 kHz: + (0.4% of reading

+ 0.05% of range)

Temperature Coefficient (0oC to + 50°C)

AC voltage: + (0.03% of reading + 0.001%

of range) /°C

Response Time: < 2 s within + 0.3% of final value or 200

counts, whichever is greater.

Input Characteristics:

Input impedance

1 and 10 V ranges: 11.11 M + 0.2%/1 /80 pF max.

100 V range: 10.1 M + 0.2%1/80 pF max.

1000 V range: 10 M + 0.2%/ /80 pF max.

OHMS

34750A

Performance:

Accuracy (+ 23oC + 5°C, < 95% RH)

30 days

10 M range ±(0.25% of reading + 0.015%

of range)

All other ranges + (0.045% of reading + 0.015%

of range)

90 days

10 M range ± (0.3% of reading + 0.015%

of range)

All other ranges + (0.055% of reading + 0.015%

of range)

6 mo.

10 M range ± (0.35% of reading + 0.02%

of range)

All other ranges + (0.065% of reading + 0.02%

of range)

1 yr

10 M range ± (0.50% of reading + 0.02%

of range)

All other ranges + (0.11% of reading + 0.02%

of range)

NOTE: Due to temperature change inside the instrument

between line and battery operation, the references

must be adjusted when changing modes to achieve

these specifications.

Stability (24 hours, 23°C ± 1oC)

10 M range + (0.1% of reading + 0.009% of range)

All other ranges + (0.2% of reading + 0.015% of range)

Temperature Coefficient (0o C to + 50o C)

10 M range: ± (0.035% of reading + 0.001%

of range) /°C

All other ranges: +(0.006% of reading + 0.001%

of range) /oC

DC VOLTAGE

34740A

Ranges:

Full Scale Maximum

Range Reading Reading

1 V ± 1.0000 V ± 1.9999 V

10 V ± 10.000 V ± 19.999 V

100 V ± 100.00 ±199.99 V

1000 V + 1.0000 V ±1200.0 V

Overrange

1000 V range: 20%.

All other ranges: 100% (19999 max reading)

Range Selection: manual pushbuttons

Performance:

Reading Rate

Option 050 (50 Hz): 8/s fixed

Option 060 (60 Hz): 5/s fixed

Table 1-2. General Information.

Input Characteristics:

Input terminals: floating pair.*

Maximum input voltage

High to low 1200 V

Low to Chassis + 500V*

*Does not apply when BCD Module is used.

AC VOLTAGE

34740A

Ranges:

Full Scale Maximum

Range Reading Reading

1 V 1.0000 V 1.9999 V

10 V 10.000 V 19.999 V

100 V 100.001 199.99 V

1000 V 1.0000 V 1200.0 V

Rev. A 1-3

Page 14

Model 34702A TM 11-6625-2809-14 & P

Table 1-2. General Information (Cont’d).

Overrange

1000 V range: 20%

All other ranges: 100% (19999 max reading)

Range selection- manual pushbuttons

Performance:

Frequency range: 45 Hz to 100 kHz

Input Characteristics:

input terminals: floating pair. *

Maximum input voltage

High to low: 1200 V rms. Except 1 V range.

1 V Range:

1200 V rms maximum 45 Hz - 200 Hz

300 V rms maximum 200 Hz - 100 kHz

Low to Chassis: + 500 V *

* Does not apply when BCD Module is used.

Ω

34740A

Ranges:

Range

100 Ω

1 κΩ

10 κΩ

100 κΩ

1000 κΩ

10 ΜΩ

Full Scale

Reading

100.00 Ω

1.0000 ΚΩ

10.000 ΚΩ

100.00 ΚΩ

1000.0 ΚΩ

10.000 ΜΩ

Maximum

Reading

199.99 Ω

1.9999 ΚΩ

19.999 ΚΩ

199.99 ΚΩ

1999.9 ΚΩ

19.999 ΜΩ

Overrange

1000V range: 20%

All other ranges 100% (199999 max reading)

Range selection: manual pushbuttons

Reading rate

Option 050 (50 Hz): 4/s fixed

Option 060 (60 Hz). 5/s fixed

Input terminals: floating pair *

Maximum Input voltage

High to Low: + 1200 V

Low to Chassis: + 500 V·*

* Does not apply when BCD Module is used.

AC VOLTAGE

34750A

Ranges:

Range

1 V

10 V

100 V

1000 V

Overrange

1000 V range: 20%

All other ranges. 100% (199999 max reading)

Range selection: manual pushbuttons

Full Scale

Reading

1.00000 V

10.0000 V

100.000 V

1000.00 V

Maximum

Reading

1.99999 V

19.9999 V

199.999 V

1200.00 V

Overrange: 100% on all ranges

Range selection: manual pushbuttons

Input Characteristics:

Input terminals: floating pair (different from voltage

input terminals).

Current through measured resistor: 10 mA on 100 Ω

range decreasing one decade per successively higher range.

Effective Common Mode Rejection: same as dc spec-

ifications.

Overload protection: + 350 V peak (248 V rms sine

wave).

Other:

Operating temperature: 0°C to + 50°C.

Storage temperature: - 40oC to + 75oC.

Line requirements: 100/120/220/240 V

- 10%, + 5% switchable:

DC VOLTAGE

34750A

48 Hz to 440 Hz; < 8.7 VA.

Ranges:

Range

1 V

10 V

100 V

!000 V

Full Scale

Reading

+ 1.00000 V

+ 10.0000 V

+ 100.000 V

+ 1000.00 V

Maximum

Reading

+ 1.99999 V

+ 19.9999 V

+ 199.999 V

+ 1200.00 V

Frequency range: 45 Hz to 100 kHz

Input terminals: floating pair

Maximum input voltage

High to Low: 1200 V rms except on 1 V range.

On 1 V range 2.5 x 105 V Hz limit with minimum protection of 300 V rms.

Low Chassis: + 500 V

Ω

34750A

Ranges:

100 Ω 100.000 Ω 199.99 Ω

1 κΩ 1.00000 κΩ 1.99999 κΩ

10 κΩ 10.0000 κΩ 19.9999 κΩ

100 κΩ 100.000 κΩ 199.999 κΩ

1000 κΩ 1000.00 κΩ 1999.99 κΩ

10 ΜΩ 10.0000 ΜΩ 19.9999 ΜΩ

Overrange: 100% on all ranges

Range: selection manual pushbuttons

Input terminals: floating pair (different from voltage

input terminals).

Current through measured resistor: 10 mA on 100 Ω

range decreasing one decade per successively higher range.

Effective Common Mode Rejection: same as dc spec-

ifications.

Overload protection- t 350 V peak (248 V rms sine

wave).

Rev. A 1-4

Page 15

Model 34702A TM 11-6625-2809-14 & P

SECTION II

INSTALLATION

2-1. INTRODUCTION.

2-2. This section contains installation and shipping

information for the Model 34702A.

2-3. INITIAL INSPECTION.

2-4. The Model 34702A should be inspected upon

receipt for damage that might have occurr ed in transit. If

there is damage due to shipping, file a claim with the

carrier. If there are other electrical or mechanical

deficiencies refer to the warranty statement on the back

of the title page. Use the procedures pr ovided in Sec tion

V to check instrument performance.

2-5. CONNECTION TO THE DISPLAY MODULE.

2-6. Referring to Figure 2-1, connect the Model

34702A to the Display Module using the following

procedure:

a. Pull the side locks on the Display Module to the

rear.

b. Pos ition the Display Module and 34702A together

so that the tabs and slots on the sides of the two units

interlock.

c. Push the side locks toward the Display Module.

This pulls the two units together and locks them.

2-7. If a 34720A Battery Module or a 34721B BCD

Module is to be used between the display module and

the 34702A then the side locks on this middle module

hold the 34702A.

2-8. REPACKAGING FOR SHIPMENT.

2-9. If the instrument is to be shipped to HewlettPackard for service or repair, attach a tag to the

instrument describing the work to be accomplished and

identifying the owner of the instrument. Identify the

instrument by serial number, m odel num ber and nam e in

any correspondence. If you have any questions, contact

your local Hewlett-Packard Sales and Service Office.

2-10. If the original shipping container is to be used,

place the instrument in the container with appropriate

packing material and seal the container well with strong

tape or metal bands.

2-11. If an -hp- container is not to be used, use a

heavy carton or wooden box with an inner container.

Wrap the instrument with heavy paper or plastic and

place cardboard strips across the face for protection

before placing the instrument in the inner container. Us e

packing material around all sides of the inner container,

and seal the outer container well with strong tape or

metal bands. Mark the container with "DELICATE

INSTRUMENT" or "FRAGILE."

Figure 2-1. Installation of the Model 34702A

2-1

Page 16

Model 34702A TM 11-6625-2809-14 & P

Figure 3-1. Front and Rear Panel Features.

3-0

Page 17

Model 34702A TM 11-6625-2809-14 & P

SECTION III

OPERATING INSTRUCTIONS

3-1. INTRODUCTION.

3-2. This section contains instructions and info rmation

which will assist you in proper operation of the Model

34702A Multimeter Module. A Model 34740A or 34750A

Display Module is required to operate the Model 34702A.

Included in this section is identification of controls,

indicators and connectors; operating procedures; and

BCD output code information (for use in conjunc tion with

the 34721B BCD Module).

3-3. PANEL FEATURES.

3-4. The panel features of the instrument are

described in Figure 3-1.

3-5. FRONT PANEL OPERATION.

3-6. There are two manual controls; the function

switch and the range switch (See Figure 3-1). Each

range, except the 1000V range, has 100% overranging

capability; e.g. using a four digit display module 1.9999 V

can be measured on the I V range. T he display blanks

at 200% of range, indicating an overload.

Overload protection circuits allow up to

1200 V peak to be applied to the

INPUT V terminals without damaging

the instrument. Up to 350 V can be

applied to the INPUT Ω.

terminals without damaging the instrument. No

more than 500 V should be applied between LO

and Chassis (Grnd. ). Do not apply voltage

between LO and Chassis when using the 34721A or

34721B BCD Module. These modules connect LO

to Chassis when attached to the Model 34702A.

3-7. DC Voltage Measurement.

3-8. Set the Function switch to DCV, select the

required voltage range, and apply the voltage to be

measured to the INPUT V terminals.

3-9. AC Voltage Measurement.

3-10. Set the function switch to ACV, select the

required voltage range, and apply the voltage to be

measured to the INPUT V terminals.

3-11. Resistance Measurement.

3-12. Set the function switch to Ω (92), select the

required resistance range, and connect the device to be

measured to the INPUT Ω terminals.

3-13. 34721B/5055A OUTPUT CODES.

3-14. Output codes obtained from a 34721B BCD

Module when used in conjunction with the Model 34702A

and a display module are listed in Table 3-1. Refer to

the 34721B Operating and Service Manual for further

information regarding the BCD Module

.

Table 3-1. 34721B5055A Output Codes

Polarity

Number

Printed

0 DCV underrange O

1 + 10000 ACV overrange 1

2 1000 1000

3 100 100 3

41010 4

511 5

6.1.1 6

7 7

8 8

9 9

Overload

Column 9

Range

Column 8

Ω

k

Volts

Function

Column 7

Ω

k

3-1

Overrange

Column 6

Digits Columns

1 through 5

2

Page 18

Model 34702A TM 11-6625-2809-14 & P

Figure 4-1. Block Diagram.

4-0

Page 19

Model 34702A TM 11-6625-2809-14 & P

SECTION IV

THEORY OF OPERATION

4-1. INTRODUCTION.

4-2. This section contains a des cription of the Model

34702 Multimeter in simplified form followed by a more

detailed functional description. A detailed circuit

schematic is shown in Figure 7-3.

4-3. BLOCK DIAGRAM DESCRIPTION.

4-4. The circuits of the Model 34702A can be divided

into four major blocks shown in Figure 4-1.

4-5. ACV And DCV Attenuator.

4-6. The ACV/DCV Attenuator reduces the level of

the signal applied to the input so that it can be measur ed

by the 34740A or 34750A Display Module. The signal

can be attenuated by a factor of I, 10, 100 or 1000.

4-7. Current Source.

4-8. Resistance measurem ents are m ade by passing

a known current through the resistor being measured

and then measuring the voltage developed across the

resistor. The current source supplies five different

currents used by the six available ohmmeter ranges.

Resistance of an unknown is measured by connecting it

across the Ω terminals and selecting Ω function.

4-9-. Range/Function Switches

4-10. Range and Function switching is accomplished

by manual selection. Data from the Range and Function

switches is supplied to the Display Module, and to the

BCD Module when it is connected.

4-11. AC Converter.

4-12. The AC Converter accepts ac voltage from the

attenuator and changes it to a dc voltage proportional to

the level of the applied signal.

4-13. DETAILED THEORY OF OPERATION.

4-14 ACV/DCV Attenuator.

4-15. Figure 4-2 shows the ACV/DCV Attenuator with

its AC and DC voltage accuracy adjustments deleted.

Resistors R3, R5, and R7, shown in Figure 7.3 are dc

adjustments. Capacitors C3 through Cl 1, also shown in

Figure 7-j provide ac compensation for the attenuator.

4-16. Ω Converter.

4-17. Current Source. A simplified diagram of the

Ω

meter current source is shown in Figure 4-3a. Zener

diode CRI6 is the voltage reference for the current

source.

Figure 4-2. ACV/DCV Attenuator.

4-1

Page 20

Model 34702A TM 11-6625-2809-14 & P

Amplifier A is connected in a non-inverting configuration

and R

range) is developed across R

is adjusted such that 1 V (.1 V for the 10MIO

b

and R

a

Amplifier B has its

b.

+ input connected to a stable dc voltage of -6.2 V. T he input is connected to the output of Amplifier A through

the range reference resistors R52 - R56. The I V ac ross

and Rb causes the output of Amplifier B to become

R

a

more positive. This allows the current through Qx to vary

such that the - input of Amplifier B becomes

approximately -6.2 V. The input current to Am plifier B is

very small. Consequently the current that flows through

the range reference resistors is the s ame as the current

supplied by the source of Qx. The drain current of Qx is

almost identical to its source current because the gate

current is extremely small. The drain current flows

through Rx and develops a dc voltage which is applied to

the Display Module input. The output current, I

, is

x

changed for different resistance ranges by changing the

value of R

On the 10 M Ω range

a.

Switch Sb is in the 10 M Ω position which reduces the

voltage between points 4 and 5 to .1 V.

4-18. Ohms Protection Circuit. The actual circuit

represented by Qx in Figure 4-3a is shown in Figure 43b. The ohmmeter circuits are protected for voltages

applied to the "Ω (f’)" input up to 350 V peak. Large

negative voltages are blocked by CR12. Large positive

voltages are blocked by the high collector to base

breakdown voltages of Q13 and Q14. CR13 conducts

for positive voltages greater than approximately 2 V,

causing CR14 to conduct.

Figure 4-3. Ohms Converter.

4-2

Page 21

Model 34702A TM 11-6625-2809-14 & P

turning on Q12. This places - 12 V at the collector of

Q12 which turns off transistors QI 1, Q13, and Q14.

419. AC Measuring Circuits.

420. A simplified diagram of the circuits used to

measure ac voltage is shown in Figure 4-4.

The attenuation of the input signal by the Attenuator

for the four ac voltage ranges is:

Range Attenuation Factor

1V X 1

1OV X 0.1

100V X 0.01

1000V X 0.001

The output voltage of the attenuator is buffered by the

Impedance Converter. The voltage gain of the

Impedance Converter is adjustable and is appr oximately

one. Its input impedance is very high to minimize loading

of the Attenuator and its output resistance is low to drive

the Converter Amplifier. T he AC Converter yields a dc

output voltage that is proportional to the average value of

the negative half-wave rectified input signal. The

resulting voltage is filtered and m easured by the Display

Module.

4-21. Impedance Converter. A simplified diagram of

the Impedance Converter is shown in Figure 4-5. The

input transistor Q1 is a sourc e follower. Transistors Q2

and Q3 constitute an amplifier that provides bias c urrent

to Q1 and a high input resistance (load resistance) for

Q1. A positive going voltage at point 1 causes the

voltage at point 2 to increase. This incr eased voltage at

point 2 increases the

Figure 4-4. Ac/DC Converter.

4-3

Page 22

Model 34702A TM 11-6625-2809-14 & P

current through Q2. The increased current causes the

voltage at point 4 to increase. Since Q3 is an emitter

follower, point 3 will also increase and follow very closely

the voltage at point 2. Since the output voltage is taken

at the emitter of Q3, RI3 m ay be increased to make the

gain of the amplifier greater than unity.

4-22. AC Converter. Refer to Figure 4-4 for the

following discussion. Overall ac feedback is supplied

from point 5 back to the inverting input. The voltage at

point 5 is similar in shape to the voltage at point 2,

inverted and about one-half the amplitude. Current for

the negative half of the waveform at point 5 flows

through CR8, R31 and R33. Current for the positive half

of this waveform f lows through CR9, R32 and R33. The

output voltage is taken at the cathode of CR9, filtered by

the Low Pass Filter and measured by the Display

Module. The DC Feedback Amplifier provides a low

frequency feedback path around the Converter Amplifier

to keep the Converter Amplifier biased properly.

Figure 4-5. Impedance Converter.

4-4

Page 23

WARNING

These servicing instructions are for use by qualified personnel

only. To avoid electrical shock, do not perform any servicing

other than that contained in the operating instructions unless

you are qualified to do so.

5-0

TM 11-6625-2809-14 & P

Page 24

Model 34702A TM 11-6625-2809-14 & P

SECTION V.

MAINTENANCE

5-1. INTRODUCTION.

5-2. This section contains information necessary for

maintenance of the -hp- Model 34702A Multimeter.

Included are Performance Tests and Adjustment

Procedures for the 30 day, 90 day, 6 month, and I year

intervals referred to in Table 1-1. To determine the

optimum calibration interval for your instrument, refer to

MIL Specification MILC-45662A. If, after completing the

Performance Checks, you find that the instrument does

not meet its required specifications, refer to the

Adjustment Procedure (Paragraph 5-16). Attempt to

readjust the instrument to bring it into specification. If,

after adjusting the instrument, it is still out of

specification, refer to troubleshooting in Section VII.

5-3. RECOMMENDED TEST EQUIPMENT.

5-4. The test equipment that is recommended for

maintaining the Model 34702A is listed in Table 5-1. If

the recommended model is not available, use equipment

that has specifications equal to or better than those

listed.

5-5. PERFORMANCE TESTS.

5-6. The following tests verify that the Model 34702A

is operating properly and meets the specifications listed

in Table 1-1 of this manual. These tests should be

completed before any attempt is made to adjust the

instrument.

5-7. A Performance Test Record is provided at the

end of this section for recording the results of the

Performance Tests.

5-8. All of the following tests have been written to

include the use of either a 34740A or 34750A Display

Module.

Table 5-1. Recommended Test Equipment.

Instrument

Type

AC Calibrator 1 V, 10 V, 100 V

100 Ω, 1ΚΩ

10ΚΩ, 100ΚΩ

1ΜΩ, 10ΜΩ

standard resistors

DC Standard 1 V, 10 V, 100 V,

Electronic

Counter

Required

Characteristics

1000 V, 45 Hz to

100 kHz

Accuracy: +0.04%

of setting (45 Hz to

20 kHz)

+ 0.15% of setting

(100 kHz)

Accuracy: +0.01%

1000 V Ranges

Accuracy: +0.008%

Capable of measuring the period of

50 Hz or 60 Hz to

within + .01%

Recommended

-hp- Model

745A/746A

General Radio

Model GR 1433-Z

Decade Resistor

-hp- 740B

-hp- Model 5300A/

5302A

34750A

Accuracy (+ 23

o

C + 5oC), <95% RH):

30 days +(0.025% of reading + .005% of range)

90 days ±(0.035% of reading + .005% of range)

6 mo. ±(0.045% of reading + .007% of range)

1 yr. ±(0.06% of reading + .01% of range)

RECOMMENDED TEST EQUIPMENT:

DC Standard, -hp- Model 740B

TEST PROCEDURE:

Model

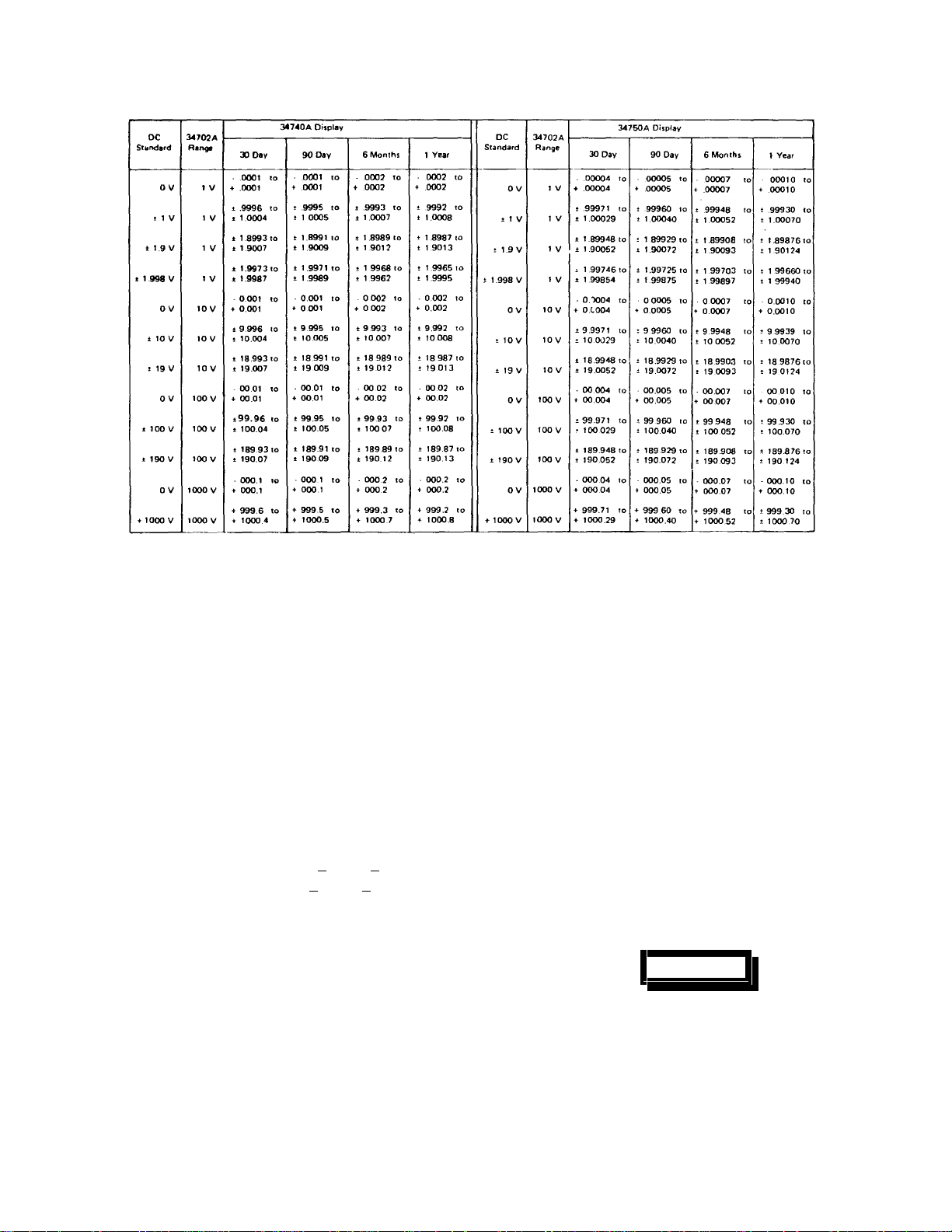

5-9. DC Accuracy Test (DCV Function).

DESCRIPTION:

This test verifies the ability of the Model 34702A to

measure dc voltage accurately within the specification

limits.

SPECIFICATION.

34740A

Accuracy (+ 23o C + 5o C), < 95% RH):

30 days + (0.03% of reading + .01% of range)

90 days + (0.04% of reading + .01% of range)

6 mo. + (0.05% of reading + .02% of range)

1 yr .+ (0.06% of reading + .02% of range)

a. Select the DCV function of the Model 34702A

and connect a dc standard (-hp- Model 740B or

equivalent) to the 34702A INPUT V terminals.

b. Check dc accuracy for both polarities of input

according to Table 5-2. Apply short to 34702A input to

check 0 V reading on all ranges.

NOTE

With 1000 V applied only the positive

polarity is checked due to the possibility

of arcing within the Model 740B.

Rev. B 5-1

Page 25

Model 34702A PERFORMANCE TEST TM 11-6625-2809-14 & P

Table 5-2. DC Accuracy.

5-10. Input Impedance Test (DCV and ACV

Function).

DESCRIPTION:

Input impedance affects the ability of a voltmeter to

accurately measure a given voltage because of loading

effects caus ed by the impedance Nor mally, it is desirable

to achieve as high an input impedance as pos sible. T his

check ensures that the input Impedance of the Model

34702A meets the specifications listed below.

SPECIFIC ATION:

Input Resistance

1 and 10 V ranges: 11.11 ΜΩ + 0.2% <

100 V range: 10.1 ΜΩ + 0.2% <80 pF

1000 V range: 10 ΜΩ ± 0.2% < 80 pF

RECOMMENDED TEST EQUIPMENT:

AC Calibrator, -hp- Model 745A

DC Standard, -hp- Model 740B

Resistance Decade, GR Model 1433-Z

TEST PROCEDURE:

a. Connect the equipment as shown ill Figure 5-1.

The Model 34702A should be set to DCV on the 1 V

range.

80 pF

Rev. B 5-2

b. Set the resistance decade to 10 ΜΩ and then

shunt it with a jumper lead. Set the DC standard for +

1.0000 V (34740A Display) or + 1.00000 V (34750A

Display) as observed on the Display Module.

c. Remove the jumper lead and again observe the

display. It should read between .5258V and .5268V

(34740A) or between .52582 and .52681 (34750A).

NOTE

The 34702A is not checked on the 10 V

range since the input circuit is equiv alent

for both the 1 V and the 10 V ranges.

d. Set the Model 34702A to the 100 V range and

short the resistance box with a jumper lead.

e. Set the dc standard for + 100.00 V (34740A) or

+ 100.000 V (34750A) as observed on the Display

Module.

WARNING

Use extreme cauti

on

when removing or

replacing the jumper in Steps f, g and i

to avoid electrical shock when

performing the input impedance test on

the 100 V’ and 1000 V ranges.

Page 26

Model 34702A PERFORMANCE TEST

Figure 5-1. Input Impedence Test.

f. Turn the dc standard OUTPUT to OFF.

Remove the jumper from the resistance box. Set dc

standard OUTPUT to ON and again observe the display.

It should read 50.20 to 50.30 (34740A) or 50.201 to

50.301 (34750A).

The 34702A display should indicate >.7059 (34740A) or>

.70594 (34750A). This verifies the 34702A input

capacity specification.

TM 11-6625-2809-14 & P

I. Change the ac standard fr equency to 20 kHz.

g. Turn the dc standard OUTPUT to OFF. Set

the Model 34702A to the 1000 V range and short the

resistance box with a jumper lead.

h. Turn the dc standard OUTPUT to ON. Set

the dc standard for + 1000.0 V (34740A) or + 1000.00

V (34750A) as observed on the Display Module.

i. Turn the dc standard OUTPUT to OFF.

Remove the jumper from the resistance box. Turn the

dc standard OUTPUT to ON and again observe the

display. It should read 499.7 to 500.7 (34740A) or

499.75 to 500.75 (34750A).

j. Set the dc standard OUTPUT to zero.

Replace dc standard with the ac standard.

k. Set the Model 34702A to the 1 V range.

Replace the resistance box with a 100 κΩ resistor (-hpPart Number 0757-0465). Connect one end of the

resistor directly to the HI terminal. Set the ac s tandard

frequency to I kHz. Adjust the ac standar d am plitude for

+ 1.0000 V i 1 count(34740A) or + 1.00000 V + 1 c ount

(34750A) as observed on the Display Module.

5-1. DC Effective Common Mode Rejection.

DESCRIPTION:

Effective Common Mode Rejection (ECMR) is a

measure of the eff ect of a com mon mode s ource on the

measured value or readout of the instrument with a

1kohm unbalance. Typically ECMR is measured in

decibels (dB) and can be calculated by the following

formula:

Common Mode Voltage Applied

ECMR (dB) = 20 log10 (

________________________________________

Change in Display Indication

SPECIFICATION

:

Effective Common Mode Rejection (I

κΩ

unbalance): > 80 dB.

RECOMMENDED TEST EQUIPMENT:

DC Standard, -hp- Model 740B

Resistor, I κΩ t 1% (resistance decade may be used for

this)

)

Figure 5-2. Effective Common Mode Rejection

Rev. C 5-3

Page 27

Model 34702A PERFORMANCE TEST TM 11-6625-2809-14 & P

TEST PROCEDURE

a. Disconnect all previous connections to the

Model 34702A input and connect the equipment as

-2.

shown in Figure 5

Set the dc standard for a +10 V

output. Set the 34702A to the I V range.

b. Observe the voltmeter display. It should read

less than 10 counts (34740A Display) or 100 counts

(34750A Display). This verifies an effective common

mode rejection at dc of > 80 dB.

5-12. Normal Mode Rejection.

DESCRIPTION:

Normal Mode Rejection (NMR) is a measure of the ability

of the Model 34702A to reject ac signals applied to the

INPUT V terminals while the instrument is operating in

DCV function. NMR is measured in decibels (dB) and

can be calculated by the following formula:

Peak Normal Mode Voltage

____________________________________

NMR (dB) = 20 log

(

10

)

Peak Display Indication

SPECIFICATION:

Normal Mode Rejection: Greater than 60 dB (at 50 Hz

t 0.1%or 60 Hz ± 0.1%).

RECOMMENDED TEST EQUIPMENT:

AC Calibrator, -hp- Model 745A

Electronic Counter, -hp- Model 5300A/5302A

TEST PROCEDURE:

a. Disconnect all previous connections to the

34702A input and connect the equipment as

shown in Figure 5-3. Set the Model 34702A to

DCV and the 1 V range.

b. Adjust the ac calibrator output for .707 V rms (1V

peak).

c. Set the counter controls to meas ure period and

adjust the ac calibrator frequenc y for a counter indic ation

between 16.650 ms and 16.683 ms (19.980 ms to

20.020 ms for Option 050). The Display Module should

read <10 counts (34740A Display) or <100 counts

(34750A Display).

5-13. AC Accuracy.

DESCRIPTION:

This test verifies the ability of the Model 34702A to

measure ac voltage accurately to within the specification

tolerances.

SPECIFICATION:

34740A

Accuracy (+ 23°C ± 5°C, <95% RH)'

30 days

45 Hz to 20 kHz +(0.25% of reading +

.05% of range)

5%

20 kHz to 100 kHz +(0.7

of reading +

.05% of range)

90 days

45 Hz to 20 kHz +(0.30°c of reading +

.05% of range)

20 kHz to 100 kHz +(0.80% of reading +

.

05% of range)

6 mo.

45 Hz to 20 kHz +(0.35% of reading +

.05% of range)

20 kHz to 100 kHz +(0.85% of reading +

.05% of range)

I yr.

45 Hz to 20 kHz +(0.50% of reading +

0.05% of range)

20 kHz to 100 kHz +(1.0% of reading +

0.05% of range)

Figure 5-3. Normal Mode Rejection.

Rev. A 5-4

Page 28

Model 34702A PERFORMANCE TEST TM 11-6625-2809-14 & P

34750A

Accuracy (+ 23

30 days

45 Hz to 20 kHz +(0.25% of reading +

20 kHz to 100 kHz +(.75% of reading +

90 days

45 Hz to 20 kHz ±(.3% of reading +

20 kHz to 100 kHz +(.8% of reading +

6 mo.

45 Hz to 20 kHz +(.35% of reading +

20 kHz to 100 kHz +(.85% of reading +

1 yr.

45 Hz to 20 kHz ±(0.50% of reading +

20 kHz to 100 kHz ±(1.0% of reading +

o

C + 5°C, < 95% RH):

.05% of range)

.05% of range)

.05% of range)

.05% of range)

.05% of range)

.05% of range)

0.05% of range)

0.05% of range)

AC Calibrator/High Voltage Amplifier, -hp- Model

745A/746A or equivalent.

TEST PROCEDURE:

a. Set the Model 34702A function switch to ACV

and select the I V range. Apply short to 34702A input

and check 0 V reading on all ranges.

b. Using an ac calibrator and a high voltage

amplifier (-hp- Model

745A/746A

recommended), check

the accuracy of the Model 34702A for inputs other than 0

V at 45 Hz and 20 kHz using Table 5-3(a). Also check

the accuracy for these inputs at 100 kHz using Table 53(b). All readings should be within the limits specified by

the tables.

514. Response Time.

DESCRIPTION:

This test verifies the ability of the Model 34702A to

respond quickly to changes in input voltage.

SPECIFICATION:

34740A

RECOMMENDED TEST EQUIPMENT:

Response time: < 2 s to within + 0.3% of final value or 20

counts, whichever is greater.

Table 5-3. (a). AC Accuracy (45Hz and 20 kHz).

Rev. B 5-5

Page 29

Model 34702A PERFORMANCE TEST TM 11-6625-2809-14 & P

Table 5-3(b). AC Accuracy (100 kHz).

34750A

Response time: <2 s to within t 0.3% of final value or 200

counts, whichever is greater.

RECOMMENDED TEST EQUIPMENT:

AC Calibrator, -hp- Model 745A or equivalent

TEST PROCEDURE:

a. Set the ac calibrator output to 10 V at I k Hz. Set

the 34702A to ACV on the 10 V range.

b. Connect the output of the ac calibrator to the

34702A INPUT V terminals while observing the

34740A/34750A Display Module. The display indication

should read within 30 counts (34740A) or 300 counts

(34750A) of its final value within two seconds after the

34702A is connected to the ac calibrator.

5-15. Ohms Accuracy.

DESCRIPTION:

This test verifies the ability of the Model 34702A to

accurately measure resistance to within the limits of the

specification given below.

SPECIFICATION:

34740A

Accuracy (+ 23

o

C + 5°C, < 95% RH):

Rev. A 5-6

30 days

90 days

6 mo.

1 yr.

34750A

Accuracy (+ 23

30 days

10 ΜΩ range +(0.25% of reading +

0.02% of range)

All other +(0.05% of reading +

ranges 0.02% of range)

10 ΜΩ range +(0.30% of reading +

0.02% of range)

All other +(0.06% of reading +

ranges 0.02% of range)

10 ΜΩ range +(0.35% of reading +

0.03% of range)

All other ±(0.07% of reading +

ranges 0.03% of range)

10 ΜΩ range +(0.50% of reading +

0.03% of range)

All other +(0.1 1% of reading +

ranges 0.03% of range)

o

C + 5°C, <95% RH):

10 ΜΩ range +(0.25% of reading +

0.015% of range)

All other +(0.045% of reading +

ranges 0.015% of range)

Page 30

Model 34702A PERFORMANCE TEST TM 11-6625-2809-14 & P

90 days

10 ΜΩ range +(0.3% of reading +

0.015% of range)

All other ±(0.055% of reading +

ranges 0.015% of range)

6 mo.

10 ΜΩ range +(0.35% of reading +

0.02% of range)

All other +(0.065% of reading +

ranges 0.02% of range)

1 yr.

10 ΜΩ range ±(0.50% of reading +

0.02% of range)

All other +(0.1 1% of reading +

ranges 0.02% of range)

RECOMMENDED TEST EQUIPMENT:

Resistance Decade, GR Model 1433-Z or equivalent.

Due to temperature change inside the

instrument between line and battery

operation, the voltage references in the

Display Module must be adjusted when

changing modes to achieve these

specifications.

TEST PROCEDURE:

a. Connect a resistance decade with 100 f through

ΜΩ

steps to the INPUT i2 terminals of the Model

34702A.

b. Refer to Table 5-4 and check the accuracy of the

34702A on the 100 Ω through 10 ΜΩ ranges.

Table 5-4. Ohms Accuracy Test.

NOTE

5-7

Page 31

Model 34702A ADJUSTMENT PROCEDURES TM 11-6625-2809-14 & P

5-16. ADJUSTMENT PROCEDURE.

5-17.The following is a complete adjustment procedure

for the Model 34702A.

NOTE

Before proceeding, it should be

ascertained that the display module is

operating properly and is calibrated.

5-18. Cover Removal.

5-19. Disconnect the power cord. Separate the 34702A

from the display module by pulling the two side locks at

the back of the instrument rearward and lifting the

mainfram e f rom the 34702A. Separate the 34702A main

assembly from its c over by spreading apart two sets of

plastic fingers, as shown in Figure 5-4, and r em oving the

cover. After removing the c over reconnect the 34702A

to the mainframe and attach the power cord.

RECOMMENDED TEST EQUIPMENT:

DC Standard, -hp- Model 740B or equivalent

CALIBRATION PROCEDURE:

WARNING

1000 V is used in the following

procedure. Contact with this voltage can

cause death or serious injury.

a. Selec t the 10 V range of the 34702A and connec t

a dc standard to the INPUT V terminals.

b. Set the output of the dc standard to 10 V and

adjust 41R3 for a 10.000V readout (34740A), or a

10.0000 V readout (34750A).

c. Select the 100 V range of the 34702A and set the

dc standard to 100 V output. Adjust R5 to obtain a

100.00 V readout (34740A) or a 100.000 V readout

(34750A).

d. Select the 1000 V range of the 34702A and set

the dc standard to 1000 V output. Adjust R7 to give a

1000.OV readout (34740A), or a 1OOO.00V readout

34750A).

Figure 5-4. Removal From Case

It will be necessary to turn the

instrument upside down to obtain access

to the 34702A adjustments. Figure 5-5

shows the location of all adjustments in

the Model 34702A.

5-20. DC Adjustments.

DESCRIPTION:

NOTE

5-21. 34702A AC Adjustments

DESCRIPTION:

These adjustments affect ac accuracy of the Model

34702A.

RECOMMENDED TEST EQUIPMENT:

AC Calibrator, -hp- Model 745A

High Voltage Amplifier, -hp- Model 746A

CALIBRATION PROCEDURE:

WARNING

1000 V ac is used in the following

procedure Contact with this voltage can

cause death or serious injury.

a. Selec t the ACV function of the Model 34702A and

set it to the I V range.

b. Apply I V at 10 kHz from the ac calibrator to the

34702A INPUT V terminals and adjust AIR13 for a

1.0000 V readout (34740A), or a 1.00000 readout

(34750A).

c. Select the 1000 V range of the Model 34702A and

apply 1000 V from the ac calibrator/high voltage amplifier

to the 34702A.

These adjustments affect dc accuracy of the Model

34702A.

5-8

Page 32

Model 34702A ADJUSTMENT PROCEDURES TM 11-6625-2809-14 & P

d. Adj ust AIC5 (coarse adj.) for a IO0O.OV readout

(34740A), or a 1000.00 V readout (34750A).

e. Select the IOV range of the Model 34702A and

set the ac calibrator to the 10 V range.

f. Adjust AIC6 for a 10.000 V readout (34740A), or

a 10.0000 V readout (34750A).

g. Selec t the 100 V range of the Model 34702A and

set the ac calibrator for 100 V output.

h. Adj ust A1C9 for a 100.00 V r eadout (34740A), or

a lO0.000 V readout (34750A).

i. Select the 1000V range of the Model 34702A and

apply 1000 V from the ac calibrator/high voltage

amplifier.

j. Adjust AICII (fine adj.) for a I000.OV readout

(34740A), or a 1000.00 V readout (34750A).

WARNING

To avoid possible electrical shock, turn

off the high voltage amplifier before

disconnecting it from the Model 34702A.

5-22. 34702A Ohms Adjustments

DESCRIPTION:

These adjustments affect the Ω Accuracy of the Model

34702A.

RECOMMENDED TEST EQUIPMENT:

Decade Resistor, General Radio Model 1433-Z or

equivalent.

CALIBRATION PROCEDURE:

a. Connect the resistance decade to the 34702A

INPUT Ω terminals using two short lengths of copper

wire. Set the resistance decade to 10 κΩ.

b. Select the Ω function of the Model 34702A and

set it to the 1OκΩ range. Adjust AIR64 to give a 10.000

kt readout (34740A), or a 10.0000Okf readout (34750A).

c. Set the resistance decade to 10 Mt. Select the 10

ΜΩ

range of the 34702A and turn AIR59 to give a

10.000 ΜΩ readout (34740A) or a 10.0000 ΜΩ readout

(34750A).

Figure 5-5. Adjustment Locator.

5-9

Page 33

TM 11-6625-2809-14 & P

PERFORMANCE TEST CARD

Hewlett-Packard Model 34740A/34702A Tests Performed By_______________

Multimeter

Serial Number____________________ Date___________________________

Paragraph

Number Test Minimum Actual Maximum

5-9 DC Accuracy

(30 Days)

1 V

Range

10V

Range

100 V

Range

1000 V

Range

(90 Days)

1 V

Range

10 V

Range

.0001

+ .9996

+ 1.8993

+ 1.9973

- 0.001

+ 9.996

+ 18.993

- 00.01

+ 99.96

+ 189.93

- .000.1

+ 999.6

- .0001

+ .9995

+ 1.8991

+ 1.9971

- 0.001

+ 9.996

+ 18.993

Results

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

+ .0001

+ 1.0004

+ 1.9007

+ 1.9987

+ 0.001

+ 10.004

+ 19.007

+ 00.01

+ 100.04

+ 190.07

+ .0001

+ 1.0004

+ .0001

+ 1.0005

+ 1.9009

+ 1.9989

+ 0.001

+ 10.004

+ 19.007

100 V

Range

1000 V

Range

(6 months)

1 V

Range

10 V

Range

100 V

Range

1000 V

Range

5-10

- 00.01

+ 99.96

+ 189.93

- 000.1

+ 999.5

- .0002

+ .9993

+ 1.8989

+ 1.9968

- 0.002

+ 9.993

+ 18.989

- 00.02

+ 99.93

+ 189.89

- 000.2

+ 999.3

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

+ 00.01

+ 100.04

+ 190.07

+ 000.1

+ 1000.5

+ .0002

+ 1.0007

+ 1.9012

+ 1.9992

+ 0.002

+ 10.007

+ 19.012

+ 00.02

+ 100.07

+ 190.12

+ 000.2

+ 1000.7

Page 34

Paragraph

Number Test Minimum

5-9 (Cont’d)

5-10

5-11

5-12 Normal Mode

5-13

(1 Year)

1 V

Range

10 V

Range

100 V

Range

1000 V

Range

Input Impedence

1 V and 10 V Ranges

100 V Range

1000 V Range

Capacitance

DC Effective

Common Mode

Rejection _____________

Rejection

AC Accuracy

45 Hz to 20 kHz

(30 Days)

1 V

Range

10 V

Range

100 V

Range

1000 V

Range

(90 Days)

1 V

Range

10 V

Range

100 V

Range

- .0002

+ .9992

+ 1.8987

+ 1.9966

- 0.002

+ 9.992

+ 18.987

- 00.02

+ 99.92

+ 189.87

- 000.2

+ 999.2

.5258

50.20

499.7

. 9970

1.8948

1.9845

9.970

18.948

99.70

189.48

000.5

997.0

.9965

1.8938

1.9835

9.965

18.938

99.65

189.38

TM 11-6625-2809-14 & P

Results

Actual Maximum

_____________

_____________

_____________

_____________

_____________

___

_____________

_____________

_____________

____________

_____________

_____________

_____________

____________

_____________

_____________

_____________

_____________

_____________

_____________

_____________

_____________

_____________

_____________ <10 counts

_____________

_____________

_____________

_____________

_____________

___

_____________

_____________

_____________

____________

_____________

_____________

_____________

____________

_____________

_____________

________

_____________

_____________

_____________

_____________

_____________

___

_____________

_____________

_____________

____________

_____________

_____________

+ .0002

+ 1.0008

+ 1.9013

+ 1.9994

+ 0.002

+ 10.008

+ 19.013

+ 00.02

+ 100.08

+ 190.14

+ 000.2

+ 1000.8

.5268

50.30

500.7

<80 pF

<10 counts

.0005

1.0030

1.9053

1.9955

0.005

10.030

19.053

00.05

100.30

190.53

000.5

1003.0

.0005

10.035

1.9062

1.9965

0.005

10.035

19.062

00.05

100.35

190.62

Rev. A 5-11

Page 35

TM 11-6625-2809-14 & P

Paragraph

Number Test Minimum Actual Maximum

5-13 (Cont’d)

100 V

Range

(6 Months)

1 V

Range

10 V

Range

100 V

Range

1000 V

Range

(1 Year)

1 V

Range

10 V

Range

100 V

Range

1000 V

Range

AC Accuracy

100 kHz

(30 Days)

1 V

Range

10 V

Range

100 V

Range

1000 V

Range

(90 Days)

1 V

Range

996.5

.9960

1.8929

1.9825

9.960

18.929

99.60

189.29

994.5

.9945

1.8900

9.945

18.900

99.45

189.00

994.5

.9920

1.8853

9.920

18.853

99.20

188.53

992.0

.9915

1.8839

Results

_______________

_______________

____

_______________

_______________

_______________

_______________

________

_______________

_______________

_______________

______

_______________

_______________

_______________

______

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

______

_______________

_______________

_______________

_______________

_______________

_______________

_______________

____

_______________

_______________

_______________

______

_______________

_______________

_______________

_______________

000.5

1003.5

.0005

1.0040

1.9072

1.9975

0.005

10.040

19.072

00.05

100.40

190.72

000.5

1005.5

.0005

1.0055

1.9100

0.005

10.055

19.100

00.05

100.55

191.00

000.5

1005.5

.0005

1.0080

1.9148

0.005

10.080

19.148

00.05

100.80

191.48

000.5

1008.0

.0005

1.0085

1.9162

5-12

Page 36

TM 11-6625-2809-14 & P

Paragraph

Number

5-13 (Cont’d)

Test Minimum Actual Maximum

10 V

Range

100 V

Range

1000 V

Range

(6 Months

1 V

Range

10 V

Range

100 V

Range

1000 V

Range

(1 Year)

1 V

Range

9.915

18.839

99.15

188.39

991.5

.9910

1.8819

9.910

18.829

99.10

188.29

991.0

.9895

1.8801

Results

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________