Page 1

Operating and Service Manual

Agilent 346A/B/C Noise Source

(Including Options

001, 002, and 004)

Serial Numbers

This manual applies directly to instruments with

serial numbers prefixed 4124A and below.

Instruments with serial prefixes 4124A and above are

supplied with the noise source ENR data preloaded on diskette -

see Chapters 3 & 4.

With changes described in Chapter 2 Manual Changes, this

manual also applies to the following prefixes.

Agilent 346B - 2015A and 1935A

Manufacturing Part Number:00346-90139

July 2001 Supersedes: June 2001

© Copyright 2001 Agilent Technologies

Page 2

Notice

Information contained in this document is subject to change without

notice. Agilent Technologies makes no warranty of any kind with regard

to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent

Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishings,

performance, or use of this material. No part of this document may be

photocopied, reproduced, or translated to another language without the

prior written consent of Agilent Technologies.

Certification

Agilent Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Agilent

Technologies further certifies that its calibration measurements are

traceable to the United States National Institute of Standards and

Technology and/or The United Kingdom National Physics Laboratories,

to the extent allowed by the Institution’s calibration facility, and to the

calibration facilities of other International Standards Organization

members.

Warranty

This Agilent Technologies instrument product is warranted against

defects in material and workmanship for a period of one year from date

of shipment. During the warranty period, Agilent Technologies will at its

option, either repair or replace products which prove to be defective. For

warranty service or repair, this product must be returned to a service

facility designated by Agilent Technologies. Buyer shall prepay shipping

charges to Agilent Technologies and Agilent Technologies shall pay

shipping charges, duties, and taxes for products returned to Aglent

ii

Page 3

Technologies from another country. Agilent Technologies warrants that

its software and firmware designated by Agilent Technologies for use

with an instrument will execute its programming instructions when

properly installed on that instrument. Agilent Technologies does not

warrant that the operation of the instrument, or firmware will be

uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied software

or interfacing, unauthorized modification or misuse , oper ation outside of

the environmental specifications for the product, or improper site

preparation or maintenance. NO OTHER WARRANTY IS EXPRESSED

OR IMPLIED. AGILENT TECHNOLOGIES SPECIFICALLY

DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. AGILENT TECHNOLOGIES SHALL NOT

BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON

CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Safety Notices

This guide uses warnings and cautions to denote hazards.

iii

Page 4

WARNING A warning calls attention to a procedure, practice or the like,

which, if not correctly performed or adhered to, could result in

injury or the loss of life. Do not proceed beyond a warning until

the indicated conditions are fully understood and met.

CAUTION A caution calls attention to a procedure, practice or the like, which, if not

correctly performed or adhered to, could result in damage or the

destruction of part or all of the equipment. Do not proceed beyond a

caution until the indicated conditions are fully understood and met.

iv

Page 5

v

Page 6

Table of Contents

1.General Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Instruments Covered in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Model Characteristics of Individual Noise Sources . . . . . . . . . . . . . . . . . . . . . . . . . 11

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Equipment Available But Not Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Original Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mating Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Storage and Shipping Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Recommended Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operator’s Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operator’s Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Performance Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replaceable Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Returning a Noise Source for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page

2.Manual Changes

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Change A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.Using the ENR Data Diskette

vii

Page 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Loading the ENR Data from Diskette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Saving the ENR Data to the Noise Figure Analyzer’s Internal Memory . . . . . . . . . . 40

Copying the ENR Data to the Noise Figure Analyzer’s Internal Memory . . . . . . . . . 41

4. ENR File F ormat

Format Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Comment Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Header Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ENR Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

A. Caring for Connectors

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Connector Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Handling and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Obvious Defects and Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Mating Plane Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Precision 7 mm Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Sexed Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Compressed Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleaning Alcohol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Precision 7 mm Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cleaning Interior Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Drying Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Mechanical Inspection: Connector Gages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Precision 7mm Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Sexed Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

50 Ohm Type-N Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

75 Ohm Type-N Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Using Connector Gages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Inspecting and Cleaning the Gage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Zeroing the Gage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Making Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Align Connectors Carefully. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

To Make a Preliminary Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Final Connection Using a Torque Wrench. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Disconnection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Principles of Microwave Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

viii

Page 8

1 General Information

1

Page 9

General Information

Introduction

Introduction

This manual contains operating and service information for the Agilent

Technologies model 346A, 346B, and 346C Noise Sources.

Included in the manual is information necessary to operate the noise

sources.

Specifications

The “Specifications - Table 1-1” on page 3, page 4, and page 5 are

performance standards or limits against which the noise source may be

tested. These specifications for the noise source when used with a Noise

Figure Analyzer are ONLY valid if the analyzer has been allowed to meet

its specified warm up time of 60 minutes.

ENR expanded uncertainty analysis and supplemental characteristics

are not specifications but are typical characteristics included as

additional information for the user.

NOTE Specifications are valid at ambient temperature 23 ±1 oCelsius only.

2 Chapter 1

Page 10

Frequency Range

Operating

Temperature

Excess Noise

Ratio (ENR)

Range

1

General Information

Introduction

Specifications - Table 1-1

346A/B 10 MHz — 18 GHz

346C 10 MHz — 26.5 GHz

0 oC to 55 oC

346A 4.5 - 6.5 dB

346B 14- 16 dB

346C 12 - 17 dB

1. ENR values are given at cardinal frequency points over the frequency range of each noise

source. Calibrated values at cardinal frequencies printed on each noise source label and on a

separate report supplied with each Agilent 346 Noise Source. Specificat ions are valid at

calibration temperature only.

Chapter 1 3

Page 11

Maximum

Standing Wave

Ratio (SWR) and

Reflection

Coefficient (r) for

Source ON/OFF

States

General Information

Introduction

Specifications - Table 1-1 Continued

Instrument model Frequency Range

(GHz)

346A/B

1

0.01 - 0.03 <1.3:1 0.13

Maximum

Standing Wave

Ratio (SWR)

Reflection

Coefficient

(Rho) (r)

0.03 - 5.0 <1.15:1 0.07

5.0 - 18.0 <1.25:1 0.11

346C 0.01-18.0 <1.25:1 0.11

18.0 - 26.5 <1.35:1 0.15

1. Maximum change in complex reflection coefficient between source ON

and source OFF at all frequencies for 346A only: 0.01.

4 Chapter 1

Page 12

Impedance

Maximum reverse

power

Power required

General Information

Introduction

Specifications - Table 1-1 Continued

50 ohm nominal

1 Watt

28 ±1 V

346A/B 60 mA peak, 30 mA average for source ON

346C 45 mA

Connectors

1

346 Output

APC-3.5 (male) standard

346 Input Bias: BNC (f)

1. Also mates with female SMA connectors. See option in formation for

other conne ctor styles.

Dimensions

140 x 21 x 31mm (5.5 x 0.8 x 1.2 in)

Net Weight

0.1 kg (3.5 oz.)

1. For correct connector usage, refer Table A-2 for the torque settings.

Chapter 1 5

1

Page 13

General Information

Introduction

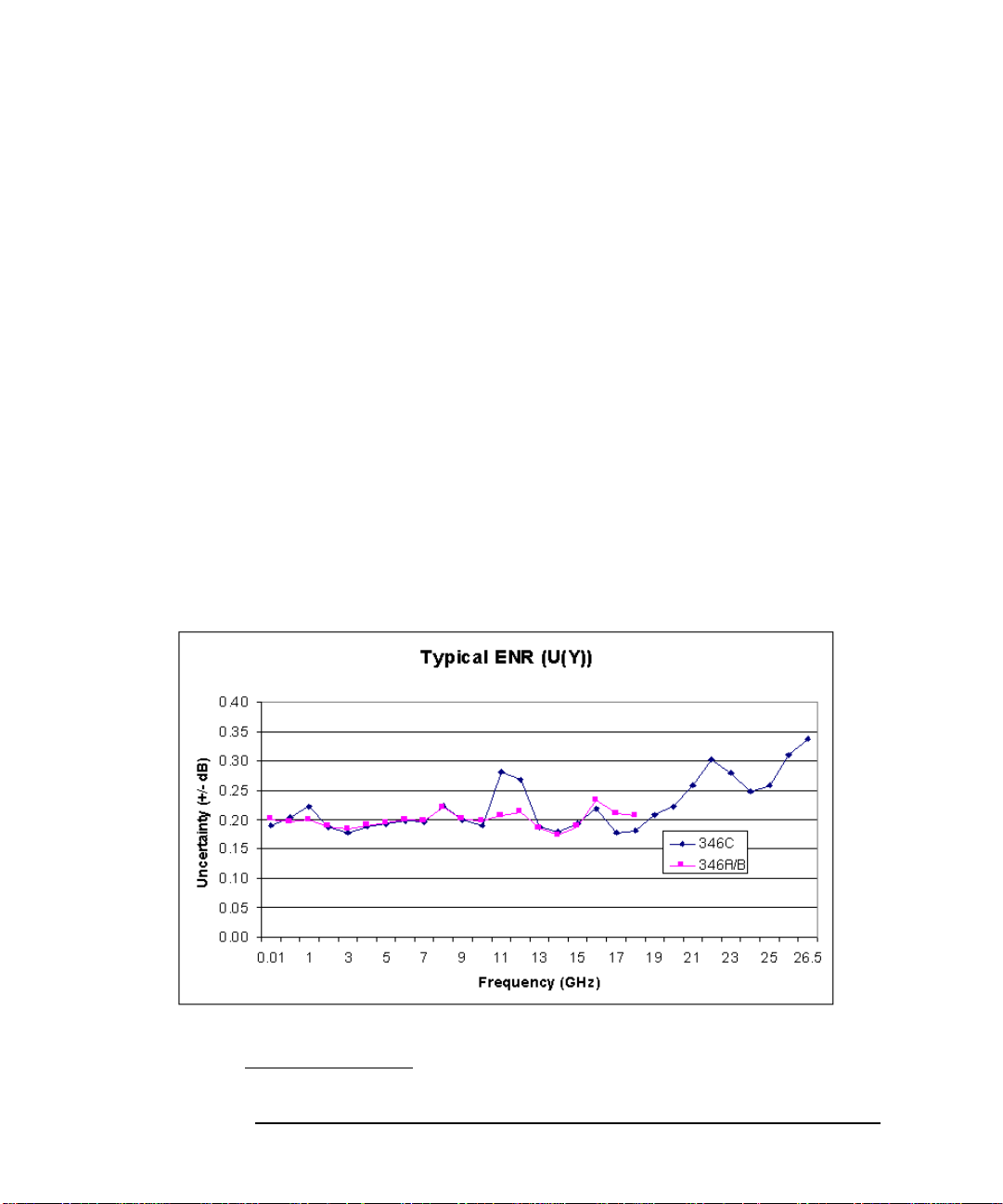

Excess Noise Ratio Expanded Uncertainty (U(Y)) - Table 1-2

ENR values are given at cardinal frequency points over the frequency

range of each noise source. These ENR values are printed on the noise

source label and on a separate printed report supplied with the 346

Noise Source. Included in the printed report is the measurement

uncertainty for each cardinal frequency point.

A significant proportion of the expanded uncertainty (U(Y)) is based on

the uncertainties provided by the United States National Institute of

Standards and Technology (NIST) and/or The United Kingdom National

Physics Laboratories (NPL). Agilent therefore reserve the right to

change the overall expanded uncertainties based on changes in

uncertainty values within the National Standards Institutes.

Uncertainties are valid at ambient temperature 23°C ±1°C (296K) only.

A typical characteristic plot of ENR (U(Y)) versus each cardinal

frequency point is shown in Figure 1-1. the uncertainties given are

typical - refer to the printed calibration report for the actual

uncertainties for your noise source.

Figure 1-1 Characteristic

1

ENR Plot versus Cardinal Frequency Points

1. Characteristic values are met or bettered by 90% of instruments with 90% confidence.

6 Chapter 1

Page 14

Characteristic

ENR (U(Y))

Specification

General Information

Introduction

Excess Noise Ratio Expanded Uncertainty (U(Y)) - Table 1-2

Continued

Instrument model Frequency

ENR Uncertainty (±dB)

(GHz)

346A 0.01- 1.5 0.21

1.5 - 3.0 0.20

3.0 - 7.0 0.20

7.0 - 18.0 0.23

346B 0.01- 1.5 0.20

1.5 - 3.0 0.19

3.0 - 7.0 0.20

7.0 - 18.0 0.23

346C 0.01- 1.5 0.22

1.5 - 3.0 0.19

3.0 - 7.0 0.20

7.0 - 18.0 0.28

18.0 - 26.5 0.34

1

1. Characteristic values are met or bettered by 90% of instruments with

90% confidence.

Chapter 1 7

Page 15

Supplemental

Characteristics

General Information

Introduction

Supplemental Characteristics - Table 1-3

ENR variation with

temperature:

ENR variation with

voltage:

Switching speed:

For repetitive operation (in previous state for less than 5 seconds):

For single-shot operation (in previous state more than 5 seconds):

<0.01 dB/°C for 30 MHz to 26.5 GHz

Internal current regulator for <0.02 dB variation

for 28 ±1 V

Turn-on: < 20 µs

Turn-off: <80 µs

Turn-on: < 3 ms

Turn-off: <80 µs

8 Chapter 1

Page 16

General Information

Instruments Covered in This Manual

Instruments Covered in This Manual

The noise sources covered by this manual have a two-part serial number.

The first four digits and letter constitute the serial number prefix. The

last five digits form a sequential suffix that is unique to each noise

source. The prefix is the same for all noise sources of a particular

configuration. It will change when a design modification occurs. The

contents of this manual apply directly to those instruments having the

same serial number prefixes listed under SERIAL NUMBERS on the

title page.

A noise source manufactured after the printing of this manual may have

a serial number prefix which is not listed on the title page. This unlisted

serial number prefix indicates the noise source is different than those

documented in this manual. If manual changes are needed, the manual

for this newer noise source is accompanied by a Manual Changes

supplement. The supplement contains "change information" that

explains how to adapt this manual to the newer noise source.

In addition to change information, the supplement may contain

information for correcting errors in the manual. The supplement is

identified with the manual print date and part number, both of which

appear on the manu al title page.

For information concerning a serial number prefix that is not listed on

the title page in the Manual Change supplement, contact your nearest

Agilent Technologies office.

Agilent/Hewlett-Packard 346 Noise Sources which were manufactured

before the printing of this manual will have a serial number prefix lower

than the one listed on the title page. Manual changes for these older

models are found in Chapter 2 “Manual Changes”.

NOTE Agilent Te chnologies are migrating t heir existing product serial numbers

to a new format. All new products use this new format. The format is the

first two letters signify the country of manufacture, for ex ample, US

representing the USA, the next four numbers,the serial number prefix,

and the last five numbers form a sequential suffix that is unique to each

product. For example, US123456789, where 1234 is the prefix and 56789

is the suffix. The two letters MY represent Malaysia.

Chapter 1 9

Page 17

General Information

Description

Description

The noise source produces noise output (power-on) when +28 V is

applied. When it is off, there is residual noise due to thermal agitation in

the noise source (power-off). These two noise levels are used to measure

the gain and added noise of the device under test, and consequently, its

noise figure.

The Excess Noise Ratio (ENR) f or each noise source has been measured

at major frequencies and recorded on a label attached to the noise source

(see Figure 1-2). ENR references power-on to the noise power that exists

at 290 Kelvin (17 °C). In addition, a separate calibration sheet showing

the complex reflection coefficient in both the on and off states is included

with each instrument.

All three models are provided with a BNC female connector for power

input. The output connector is a male APC-3.5 on the standard noise

sources. Type-N and APC-7 connectors are available as options for the

Agilent 346A and 346B Noise Sources. In addition to these general

characteristics, certain characteristics apply to the specific models.

These characteristics are listed in Table 1-4.

Figure 1-2 A Partial View of Typical Calibration Label

10 Chapter 1

Page 18

General Information

Model Characteristics of Individual Noise SourcesTable 1-4

Agilent 346A Agilent 346B Agilent 346C

Description

Reflection coefficient differential

between on and off states is specified

to be no greater than 0.01.

Specified output noise spectrum

from 10 MHz to 18 GHz.

Nominal ENR is 6 dB over the

specified frequency range.

Not directly usable for

Agilent/HP 8970A IF attenuator

calibration (Special Function

33). 10 dB of gain is required.

Not directly usable for

Agilent/HP 8970B IF attenuator

calibration. Refer to

"Calibration, IF Attenuators" in

the Agilent/HP 8970B Operating

Manual.

Reflection coefficient

differential between on and off

states is not specified, but is

less than 0.1 typically.

Specified output noise

spectrum from 10 MHz to

18 GHz.

Nominal ENR is 15 dB over the

specified frequency range.

Suitable for Agilent/HP 8970A

IF attenuator calibration

(Special Function 33).

Suitable for Agilent/HP 8970B

IF attenuator calibration.

Refer to "Calibration, IF

Attenuators" in the Agilent/HP

8970B Operating Manual.

Reflection coefficient

differential between on and off

states is not specified, but is

less than 0.1 typically.

Specified output noise

spectrum from 10 MHz to

26.5 GHz.

Nominal ENR is 15 dB over the

specified frequency ra nge.

Suitable for Agilent/HP 8970A

IF attenuator calibration

(Special Function 33).

Suitable for Agilent/HP 8970B

IF attenuator calibration.

Refer to "Calibration, IF

Attenuators" in the Agilent/HP

8970B Operating Manual.

Chapter 1 11

Page 19

General Information

Description

Warranty

The noise sources are warranted and certified as indicated in this

manual. Connector damage resulting from improper use is not covered

under warranty.

Equipment Available But Not Supplied

The following equipment is available from Agilent Technologies for use

with the noise sources:

• 8710-1766: 3/4" Torque Wrench (APC-7)

• 5060-0344: 9/16" Torque Wrench (APC-3.5)

NOTE Agilent/HP Model 346B Noise Sources with serial prefixes of 2037A and

below, have an APC-3.5 connector of a different configuration (See Figure

1-3). The 9/16" torque wrench will not fit these older models.

Figure 1-3 Agilent/HP Noise source with Older APC-3.5 Connector

Options

The Agilent 346A and 346B Noise Sources are available with the

following output connector options:

• Option 001, Type-N (male)

• Option 002, APC-7

• Option 004, Type-N (female)

Since the APC-7 and Type-N connectors do not operate up to 26.5 GHz,

no output connector options are available for the Agilent 346C.

12 Chapter 1

Page 20

General Information

Installation

Installation

Handling Precautions

CAUTION Do not disassemble the noise source. The diode module is static sensitive

and can be damaged or the calibration can be altered.

CAUTION Do not drop the noise source. Dropping can damage the unit o r alter the

calibration.

Proper connector care is essential. See Operator’s Maintenance in the

Operation section of this manual for more information.

Initial Inspection

Inspect the shipping container for damage. Inspect the noise source for

mechanical damage incurred in transit. If the shipping container or

cushioning material is damaged, it should be kept until the contents of

the shipment have been checked for completeness and the noise source

has been mechanically and electrically checked. If the contents are

incomplete, if there is mechanical damage or a defect, or if the noise

source does not work electrically, notify the nearest Agilent Technologies

office. If the shipping container is damaged, or the cushioning material

shows signs of unusual stress, notify the carrier as well as the Agilent

Technologies office. Keep the shipping materials for the carrier’s

inspection.

Chapter 1 13

Page 21

General Information

Installation

Original Packaging

Container and materials identical to those used in factory packaging are

available through Agilent Technologies offices. If the noise source is

being returned to Agilent Technologies for servicing, attach a tag

indicating the name and address of the company, the technical contact

person, phone number and extension, the model number, serial number,

type of service being requested, and failure symptoms if applicable. Mark

the shipping container FRAGILE. In any correspondence, refer to the

noise sources by model number and serial number.

Mating Connectors

The noise sources can be mated with other instrumentation having the

connectors listed in Table 1-5.

Connectors That Can Be Mated With the Noise SourcesTable 1-5

Configuration Mating Connector

Input: all units

BNC male

1

Output: standard APC-3.5 female

SMA female

Opt.001

Type-N female

1

Opt.002 APC-7

Opt.004

1

Must comply with U.S. Military Standard MII,C-39012

Type-N male

1

Storage and Shipping Environment

The noise sources should be stored in a clean, dry environment. The

following environmental limitations apply to both storage and shipment:

• Temperature: -55 °C to +75 °C

• Humidity: <95% relative

• Altitude: <15300 meters (50000 feet)

14 Chapter 1

Page 22

General Information

Operation

Operation

This section refers to operation with noise figure meters. For more

detailed operating instructions, refer to the operating manual for the

noise figure meter used.

CAUTION Use a dc blocking capacitor to protect the noise source from damage

when connected to any system where a dc voltage is present on the

output center conductor.

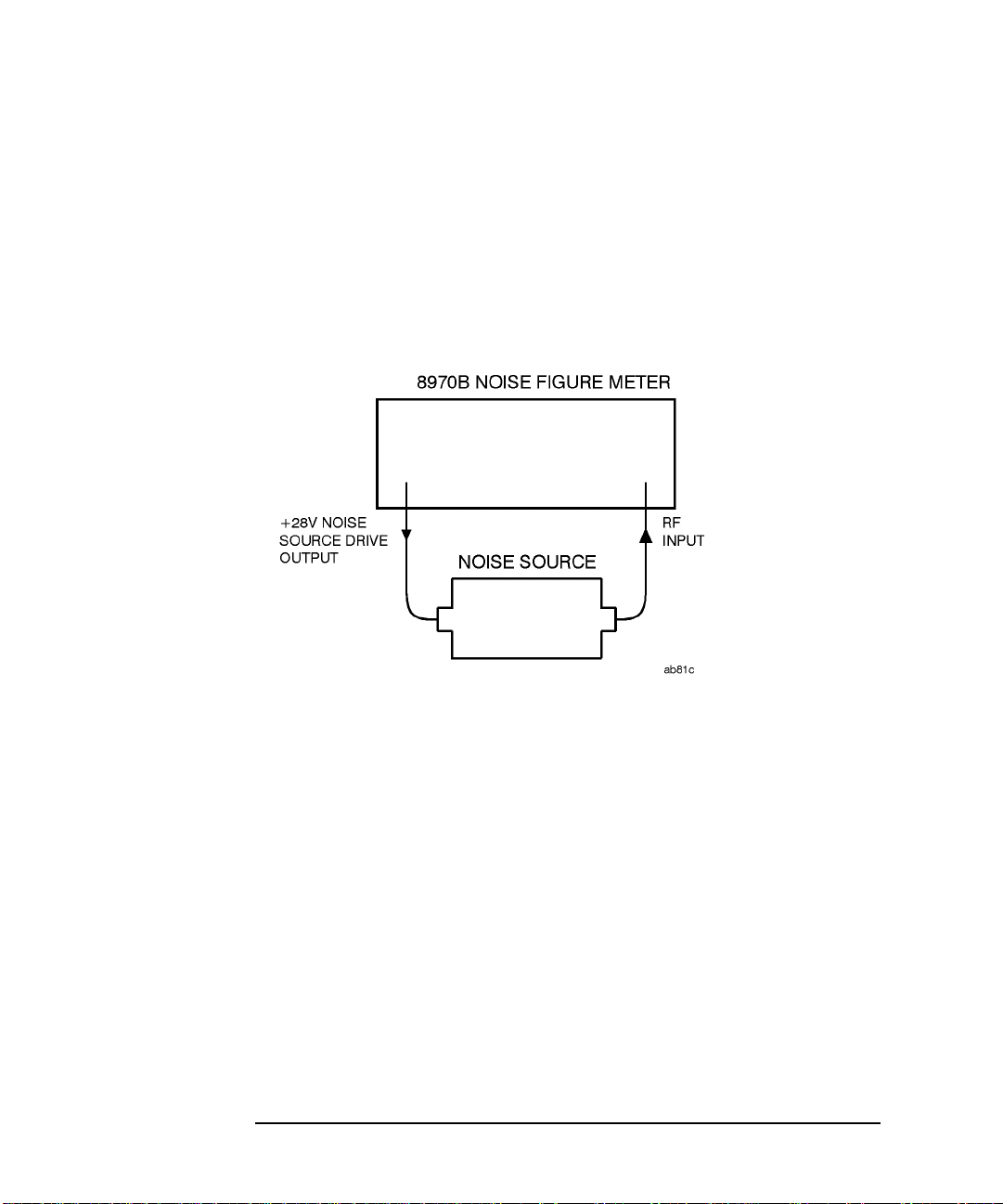

Noise figure measurements of devices (such as amplifiers, mixers,

transistors, and receivers) can be made using the noise source with a

noise figure meter. Figure 1-4 depicts a simple test setup for a noise

figure measurement.

NOTE The noise figure meter must have a +28 ±1 V switched supply.

Figure 1-4 Typical Noise Figure Measurement Test Setup

Chapter 1 15

Page 23

General Information

Operation

Operating Environment

The operating environment of the noise sources should be within the

following limitations:

• Temperature: 0 °C to +55 °C

• Humidity: <95% relative

• Altitude: <4600 metres (15 000 feet)

Recommended T est Equipment

Table 1-6 is a list of equipment that can be used to perform an

operational verification check.

Recommended Test Equipment For Operator’s ChecksTable 1-6

Check

No.

1 Power Meter and Power

Sensor

Power Supply Voltage : 28.0 ±1.0 V

2 Noise Figure Meter Voltage Output: 28.0 ±1.0 V

Instrument Critical Specification Recommended Model

Minimum Sensitivity: 0.1 nW

Frequency Range: 10 MHz to

18 GHz

Current: 100 mA

Input Noise Figure:<7.4 FdB

at 100 MHz

Agilent/HP E4418A

with

Agilent/HP 8481D, or

E4412A, or E9300A

Agilent/HP 6028A

Agilent/HP 8970B

or

Agilent N8972/3/4/5A

16 Chapter 1

Page 24

Operator’s Check

The operator’s checks in this section should be performed if failure of the

noise source is suspected. The checks can be used only to verify that the

noise sources are produci ng a broad band noi se spectrum. They cannot be

used to check th e units against specifi cations. Only one of the checks is

necessary to verify operation. Table 1-6 shows the recommended test

equipment used for each check.

Operator’s Check with Power Meter (Check 1)

Step 1. Connect the equipment as shown in Figure 1-5.

Figure 1-5 Operator’s Check Test Setup 1

General Information

Operation

Step 2. Turn the power supply OFF. Zero the power meter.

Step 3. Turn the power supply ON (+28 V). Measure the power output with the

noise source on.

Step 4. Verify that the result of the measurement is within the following limits

and hence the noise source is operating correctly:

• Agilent 346A Power output = -66 ±4 dBm.

• Agilent 346B Power output = -56 ±4 dBm.

• Agilent 346C Power output = -56 ±4 dBm.

Chapter 1 17

Page 25

General Information

Operation

Operator’s Check with Agilent/HP 8970B Noise Figure Meter (Check 2a)

Step 1. Remove any cables from the noise figure meter input. Press

After 5 seconds, verify the noise figure display shows --FdB and the left

display shows 30 MHz.

Step 2. Connect the equipment as shown in Figure 1-6.

Figure 1-6 Operator’s Check Test Setup 2a

Step 3. Enter a tuned frequency of 100 MHz. (See "Fixed Frequency Tuning" in

the Agilent/HP 8970B Operating Manual).

PRESET.

Step 4. Enter special function 5.3 to enable the instrument for spot ENR entry.

(See "Special Functions" in the Agilent/HP 8970B Operating Manual).

Step 5. Enter the ENR at 100 MHz from the noise source calibration label. (See

"Spot EN R, T

, and T

hot

, in the Agilent/HP 8970B Operating Manual).

Cold

Step 6. Confirm that the noise source is operating correctly.

The noise figure measurement of the noise figure meter will appear in

the noise figure display. If the result of the measurement is less than 7.4

FdB, the noise source is operating.

Step 7. Press

PRESET to return the instrument to preset conditions.

18 Chapter 1

Page 26

General Information

Operation

Operator’s Check with Agilent N8972/3/4/5AB Noise Figure Analyzer (Check 2b)

Step 1. Remove any cables from the NFA input and the noise source drive.

Step 2. Press the

Preset key.

Wait until the preset routine has completed before proceeding.

NOTE The preset condition used is the NFA default of Preset (Factory).

Step 3. Connect the 346A/B/C to the NFA Input port using a BNC cable, as

shown in Figure 1-7.

Figure 1-7 Operator’s Check Test Setup 2b

Step 4. Press the

Step 5. Press the

Step 6. Press the

Step 7. Press the

ENR key.

ENR Table menu key.

Edit Table menu key.

Clear Table menu key.

Step 8. Enter 100 MHz in the Frequency column of the table: Press

numeric keypad followed by the

MHz menu key.

Chapter 1 19

1,0,0 on the

Page 27

General Information

Operation

Step 9. Press the Tab key to highlight the ENR Value column of the table.

Step 10. Enter the ENR value of the 346A/B/C at 100 MHz (0.1 GHz) using the

numeric keypad followed by the

dB menu key.

Step 11. Press the

Step 12. Press the

Step 13. Press the

Step 14. Press the

Enter 100 MHz as a fixed frequency value, by pressing the

numeric keys followed by pressing the

Step 15. Press the

Step 16. Press the

Step 17. Press the

Step 18. Press the

Step 19. Press the

Frequency/Points key.

Frequency Mode menu key.

Fixed menu key.

Fixed Frequency menu key.

1, 0, 0

MHz menu key.

Sweep key.

Manual Meas menu key.

Manual State menu key and set it to Manual State (On).

Noise Source menu key and set it to Noise Source (On).

IF Att menu key and set it to IF Att (Hold).

Step 20. Monitor the power value which appears in the manual measurement

screen. Figure 1-8 shows a typical example of this.

20 Chapter 1

Page 28

General Information

Figure 1-8 Typical example of power reading with Noise Source On

Operation

Step 21. Press the

Noise Source menu key and set it to Noise Source (Off).

Step 22. Monitor the power value which appears in the manual measurement

screen. Figure 1-9 shows a typical example of this.

NOTE The monitored value is only to be used to indicate if the 346A/B/C is

switching the Excess Noise “On” and “Off” by showing a change in power

value.

Chapter 1 21

Page 29

General Information

Operation

Figure 1-9 Typical example of power reading with Noise Source Off

Step 23. If there is not a change in value, return the 346A/B/C to Agilent

Technologies for repair.

Operator’s Maintenance

Proper connector care is a vital part of the maintenance which should be

performed by the user. By following the general connector care practices

outlined below, the life of the connector can be gr eatly extended.

• Connectors should be properly torqued as shown below .

Connector Type Torque Specifications

N 1.3 N m (l2 in.-lb.)

APC-7 1.3 N m (12 in.-lb.)

SMA to APC-3.5 0.9 N m (8 in.-lb.)

APC-3.5 to APC-3.5 0.9 N m (8 in.-lb.)

• Always tighten or loosen a connector by rotating only the nut. Never

rotate the noise source body.

22 Chapter 1

Page 30

General Information

Operation

• Use isopropyl or ethyl alcohol on a swab to clean connectors.

Absorbent, lint-free paper wrapped around the end of tweezers is

recommended. Carefully clean the conductive surfaces and avoid

wetting the plastic parts inside the connector with alcohol. After

cleaning, be sure connector is blown dry before re-assembly.

• It is good practice to inspect a connector after cleaning. During the

inspection, check for contaminants and worn plating. Also check for a

misaligned center conductor or spread fingers on the APC-3.5 or

Type-N connectors.

• Support the cable or component attached to the connector.

• When using APC-7 connectors, the nut of one connector should

always be backed off completely and the nut on the mating connector

should be tightened. Never set an APC-7 connector on its mating

surface. Before storage, always screw the nut out to protect the

surfaces.

• Be sure the connectors are axially aligned before the nut is tightened.

• Use a connector gauge periodically to check the center pin depth. The

shoulder of the center conductor must never extend beyond the plane

of the outer conductor mating surface in an APC-3.5 connector.

• For more information, refer to Appendix A , “Caring for Connectors,”

on page 51.

Chapter 1 23

Page 31

General Information

Performance Tests

Performance Tests

Due to the complex test equipment involved, there are no recommended

performance tests for the user to perform. Return the noise sources to

Agilent Technologies when tests are required to verify its performance

and for periodic re-calibration. The suggested interval before initial

re-calibration is one year.

24 Chapter 1

Page 32

General Information

Adjustments

Adjustments

There are no adjustments that can be made on the noise sources by the

user.

Chapter 1 25

Page 33

General Information

Replaceable Parts

Replaceable Parts

Table 1-7 lists all replaceable parts available for the Agilent 346A/B/C

Noise Sources. Figure 1-10 shows a typical Noise Source being prepared

for parts replacement at modular level by removing the four end screws

(two at each end).

NOTE If the Agilent 346A/B/C is opened and parts replaced, the Noise Source

will require calibration.

NOTE Due to a parts change, adjustment of the bias current may be necessary

for the product to meet its ENR specifications when parts are replaced in

older units. Installation Note 00346-90137 details the adjustment

process for the 346A and 346B. Installation Note 00346-90140 details the

adjustment process for the 346C. Both are supplied with their

appropriate replacement parts.

To order parts contact your local Agilent Technologies Sales and Service

Office.

26 Chapter 1

Page 34

General Information

Replaceable Parts

Replaceable Parts ListTable 1-7

Agilent Part Numbers

Model/Option Bulkhead RF

Replacement

346A Std

Option 001

Option 002

346B Std

Option 001

Option 002

Option 004

346C Std 00346-60021 00346-60155 00346-60027 00346-60158

00346-60022 00346-60154 00346-60156 00346-60157

00346-60023 00346-60154 00346-60156 00346-60157

00346-60024 00346-60154 00346-60156 00346-60157

00346-60026 00346-60154 00346-60027 00346-60157

00346-60018 00346-60154 00346-60027 00346-60157

00346-60019 00346-60154 00346-60027 00346-60157

00346-60020 00346-60154 00346-60027 00346-60157

Replaceable Labels ListTable 1-8

Part Number Label Descriptions

00346-80006 346A Label Caution

00346-80007 346BA Label Caution

00346-80008 346C Label Noise

Replacement Noise

Cartridge Assy

Replacement

Attenuator Assy

Replacement PC

Board Assy

00346-80012 Label - Blank ENR

Chapter 1 27

Page 35

General Information

Replaceable Parts

Figure 1-10 Preparing for Parts Removal/Replacement

28 Chapter 1

Page 36

General Information

Service

Service

Principles of Operation

Figure 1-11 shows a simplified diagram of the noise source. When driven

by a +28V pulse, the 346 produces an output noise spectrum with an

ENR of approximately 5.0 dB for the 346A and approximately 15.0 dB

for the 346B and 346C. The noise generator is an avalanche diode

positioned into a 50 ohm system. The noise source is divided into a dc

section including a voltage converter and a current regulator, and an RF

section which includes the noise generator, a matching network and an

attenuator.

The +28 volts supplies a 5.6 kHz oscillator which is rectified as the

supply for the constant current source to produce a controlled noise level

output. The current regulator controls through the noise generator diode

producing a known level of broadband noise that is constant for a supply

voltage of 27 to 29 volts.

Figure 1-11 Simplified Diagram of the Noise Source

Matching Network

and Noise Generator

BNC

Input

≈5.6kHz

Oscillator

Voltage

Converter

Current

Regulator

Troubleshooting

Check the connectors. If there is no apparent damage to the connectors,

perform one of the oper ator’ s chec ks describ ed in the Operatio n section of

this manual. If the noise source’s output does not fall within the stated

range, or if the connectors are damaged, return the unit to Agilent

Technologies for repair.

Chapter 1 29

Attenuator

DC Block

Output

Page 37

General Information

Service

Repair

Repair by the user is not recommended because of the complex

equipment required for test and calibration.

Returning a Noise Source for Calibration

When returning a 346 or Noise Source to Agilent Technologies for repair

or calibration, please specify whether an ENR Data Diskette is needed.

When the 346 is used with an Agilent Noise Figure Analyzer NFA, the

ENR Data Diskette is used to automatically load the ENR values into

memory.

When the 346 is used with an 8970A/B Noise Figure Meter, you must

enter the ENR values manually, and the ENR Data Diskette is not

necessary.

30 Chapter 1

Page 38

Agilent Technologies Sales and Service OfficesTable 1-9

UNITED STATES

Agilent Technologies

(tel) 1 800 452 4844

CANADA

Agilent Technologies Canada Inc.

Test & Measurement

(tel) 1 877 894 4414

EUROPE

Agilent Technologies

Test & Measurement

European Marketing Organization

(tel) (31 20) 547 2000

JAPAN

Agilent Technologies Japan Ltd.

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

General Information

Service

LATIN AMERICA

Agilent Technologies

Latin America Region Headquarters, USA

(tel) (305) 267 4245

(fax) (305) 267 4286

AUSTRALIA/NEW ZEALAND

Agilent Technologies Australia Pty Ltd.

(tel) 1-800 629 4852 (Australia)

(fax) (61 3) 9272 0749 (Australia)

(tel) 0-800 738 378 (New Zealand)

(fax) (64 4) 802 6881 (New Zealand)

ASIA PACIFIC

Agilent Technologies, Hong Kong

(tel) (852) 3197 7777

(fax) (852) 2506 9284

Chapter 1 31

Page 39

2 Manual Changes

This chapter contains information for adapting this manual to

Agilent/HP 346B Noise Sources with serial number prefixes of 2015A

and 1935A.

33

Page 40

Manual Changes

Manual Changes

Manual Changes

To adapt this manual to your instrument, refer to Table 2-1. Make all of

the manual changes listed opposite your instrument’s serial number

prefix. Perform these changes in the sequence listed.

Table 2-1 Manual Changes by Serial Number

Instrument Serial Number Prefix Make Manual Changes

346B 1935A, 2015A A

If your instrument (all models) has a serial number prefix which is

higher in value than those listed on the title page of this manual, it may

be documented in a yellow MANUAL CHANGES supplement. For

additional information, refer to "Innnstruments Coverd by Manual" in

the General Information section of this manual.

Change A

Table 1-2 Supplemental Characteristics

Change Switching Speed for both repetitive operation and single shot

operation to read: Turn off <140 µs.

34 Chapter 2

Page 41

3 Using the ENR Data Diskette

35

Page 42

Using the ENR Data Diskette

Introduction

Introduction

The Agilent 346 and 347 series of Noise Sources are supplied with the

noise source ENR data preloaded on diskette to allow eas y downloading

into the Agilent NFA series Noise Figure Analyzers. This eliminates time

consuming and error prone manual keying of the ENR values.

Additionally you can easily open the ENR files using a standard text

editor and the files are easy to interpret and create.

This chapter covers the following:

• Loading the ENR Data from Diskette

• Saving the ENR Data to the Noise Figure Analyzer’s Internal

Memory

• Copying the ENR Data from Diskette to the Noi se Figure Analyzer’s

Internal Memory

NOTE The following procedures do not apply to noise sources used with the

Agilent 8970A/B Noise Figure Meter.

You must enter ENR values manually into the 8970A/B.

36 Chapter 3

Page 43

Using the ENR Data Diskette

Loading the ENR Data from Diskette

Loading the ENR Data from Diskette

To load the ENR data from the diskette and use the data as the current

ENR table, proceed as follows:

Step 1. Power up the Noise Figure Analyze r and w ai t for the power-up sequence

to complete.

Step 2. Insert the diskette into the floppy drive of the Noise Figure Analyzer.

NOTE Do not insert the diskette into the Noise Figure Analyzer until the

power-up sequence is complete.

Step 3. On the Noise Figure Analyzer, press the

File key and press the Load

menu key to access the file system.

Step 4. Press the

Table

ENR menu key and select whether the ENR table is a Meas

(used for measurements) or a Cal Tab le (used for calibration). If you

intend to use the same ENR table for calibration and measurement, then

set the ENR table as

Meas Table.

The Noise Figure Analyzer allows you to use the same or separate ENR

tables for calibration and measurement as required. For more details on

specifying

Meas Table and Cal T able, see the Noise Figure Analyzer User’s

Guide .

Step 5. Press the

Select menu key and use the arrow keys if necessary to

highlight [-A-]. If C: is the currently selected drive use the “..” directory

to reach the A: drive as directed on the screen. Press the

Select menu key

again to read the diskette.

Step 6. Use the down arrow key (↓) to highlight the ENR file and press the

key to load it.

When the file is successfully loaded a message, for example

A:A0100364.ENR file load ed appears on the display.

Note that ENR files with a large number of frequency points (for

example, up to 50 GHz) may take a few seconds to load.

Enter

Chapter 3 37

Page 44

Using the ENR Data Diskette

Loading the ENR Data from Diskette

ENR filename

format

The ENR filename of the ENR file st ored on the diskette, for example

A0100123.enr, has the following format:

• The first letter shows the noise source type and can be:

— A = 346A

— B = 346B

— C = 346C

— R = R347A

— Q = Q347A

• The next four digits, for example 0100, show the calibration date. For

example0100 shows a calibration date of January 2000.

• The last three digits, for example 123, are the last 3 digits of the

serial number of the Noise Source.

• The file extension is .enr to indicate ENR file format.

Once the ENR file is loaded from diskette, to verify that the ENR data is

correct, press the

ENR key, then press the ENR Table> menu item to

display the ENR table.

Confirm that the Noise Source Serial Number and the Noise Source

38 Chapter 3

Page 45

Using the ENR Data Diskette

Loading the ENR Data from Diskette

Model ID are correct and compare the Frequency and ENR values with

the supplied Calibrat ion Sheet or the data printed on the body of the

Noise Source.

Chapter 3 39

Page 46

Using the ENR Data Diskette

Saving the ENR Data to the Noise Figure Analyzer’s Internal Memory

Saving the ENR Data to the Noise Figure

Analyzer’s Internal Memory

To save the current Noise Source ENR data from the diskette (A: drive)

to the Noise Figure Analyzer’s internal memory (C: drive) proceed as

follows:

Step 1. Load the ENR table as described in “Loading the ENR Data from

Diskette” on page 37.

Step 2. Press the

File key and press the Save menu key.

Step 3. The ENR menu key indicates whether the file is currently loaded as a

measuremnet table (

ENR menu key and select whether you w ant to store the ENR table as

the

Meas Table or a Cal Table . If you intend to use the same common ENR

a

table for calibration and measurement, then set the ENR table as

Table

.

Meas Table) or a calibration table (Cal Table). Press

Meas

The Noise Figure Analyzer allows you to use the same or separate ENR

tables for calibration and measurement as required. For more details on

using ENR tables see the Noise Figure Analyzer User’s Guide .

When the ENR table is selected, the

Alpha Editor is now presented to you,

allowing you to specify a name for the file. If required you can use the

numeric keypad to enter numbers in the filename. Note that you can also

use the default filename which is in the format TSTxxxx where x is a

sequentially allocated number. For details of the filename format used

for the ENR data supplied on the disk ette , see “ENR filen ame format” o n

page 38.

Step 4. Input the name of the ENR table using the

keypad. Use the

Tab key to move to the “..”: field.

Step 5. If the To: Path: field is currently A:, pre ss t he

the arrow key to highlight [-C-], then press the

With the To: Path: field set to C: press

Alpha Editor and numeric

Select menu key and use

Select menu key again.

Enter to save the file with the

specified filename.

When the file is successfully saved, a message, for example:

C:A0100364.ENR file save d appears on the status line of the display.

40 Chapter 3

Page 47

Using the ENR Data Diskette

Copying the ENR Data to the Noise Figure Analyzer’s Internal Memory

Copying the ENR Data to the Noise Figure

Analyzer’s Internal Memory

To copy the Noise Source ENR data from the diskette (A: drive) to the

Noise Figure Analyzer’s i nternal memory (C: drive) proceed as follows:

Step 1. Power up the Noise Figure Analyze r and w ai t for the power-up sequence

to complete.

Step 2. Insert the diskette into the floppy drive of the Noise Figure Analyzer.

NOTE Do not insert the diskette into the Noise Figure Analyzer until the

power-up sequence is complete.

Step 3. Press the

Step 4. Press the

The file system is now presented to you.

Step 5. Press the

Step 6. Set the From: Path: field to A:, use the down arrow key (↓) to highlight

the ENR file and the

The filename you are going to copy now appears in the From: Name:

field.

Step 7. Press the

to C:

Step 8. Press the

Noise Figure Analyzer’s internal memory (C:).

When the file is successfully copied a message, for example

A:A0100364.ENR f ile copied appears on the status line of the display.

For details on the ENR filename format, see “ENR filename format” on

page 38.

File key and press the File Manager menu key.

Copy> menu key.

ENR menu key to set the file type and format to ENR.

Select key to select it for copying.

Tab key to navigate to the To: Path: field and ensure it is set

Enter key to copy the selected file from the diskette (A:) to the

Chapter 3 41

Page 48

4 ENR File Format

43

Page 49

ENR File Format

Format Details

Format Details

An ENR file:

• includes all data currently supplied on the printed noise source

Calibration Certificate

• can be viewed and edited using a standard text editor (for example

Notepad)

• is simple to create and interpret

• is easily printable

• is easily imported into Excel

The ENR file is read line by line. Each line is terminated by either a

linefeed character, or a carriage-return, linefeed pair. Each line must be

less then 100 characters long, excluding the terminator.

Lines containing only whitespace (tab or space character) are ignored.

Each line is interpreted as one of three types of record:

• Comment

•Header Field

•ENR Data

Comment Records

A comment record must have either a '#' or '!' as the first character in the

line. The entire line is ignored. Comment records can appear at any

point within the file.

Header Fields

General form Header fields must have a '[' as the first character in the line. Each

header field has the general form:

• [FieldName OptionalValue]

• The '[' must be the first character on the line.

• The fieldname and optionalvalue, if present, must be separated by

44 Chapter 4

Page 50

ENR File Format

Format Details

whitespace.

• Whitespace following the ']' is ignored.

• The file must start with one or more header fields (ignoring

comments and blank lines).

All header fields must appea r at the beginni ng of the file before the ENR

data records. Mixing header fields and ENR data is not permitted.

Mandatory header

fields

Certain header fields must be present. These are:

Table 4-1 Mandatory header fields

Fieldname Description OptionalValue Description Example

Filetype Indicates the type of

file.

Version Indicates the version

of the file format

which applies to this

file.

NOTE All mandatory fields must appear in the file before any optional header

fields.

Optional header

fields

The following header fields are also allowed. Note that only the first two,

Serialnumber and Model are currently used by the Noise Figure

Analyzer.

ENR Onl y ’E NR’ i s

allowed for ENR

data files.

versionnumber

(formatted as

major.minor)

Allows for future

changes in the file

format.

[Filetype ENR]

[Version 1.0]

Table 4-2 Optional header fields

Fieldname Description Optional-

Value

Serialnumber the serial

number of the

noise source

Chapter 4 45

serialtext a string

Description Example

[Serialnumber 3318A14223]

containing the

serial number

Page 51

ENR File Format

Format Details

Table 4-2 Optional header fields

Fieldname Description Optional-

Value

Model ident ifies the

noise source

model number

Option Identifies any

model code

option

Caldate date of

calibration of

noise source

Calduedate indicates date

when next

calibration of

noise source is

due

Temperature calibration

temperature

modelcode model code

optioncode option code

date&time formatted date

date&time formatted date

value number

Description Example

[Model 346B]

string

[Option 001]

string

[Caldate 19991202.09:15:30]

and optional

time

[Calduedate 20001225]

and optional

time

[Temperature 24C]

followed by

unit. Valid units

are C,F,K

Humidity calibratio n

relative

humidity

The format of date&ti me parameters is YYYYMMDD[.hh :mm:ss], i.e. a

four digit year, two digit month a nd two dig it date , optiona lly foll owed by

a ’.’ then two digit hour ’:’ two digit minutes ’:’ two digit seconds.

Unknown header fields are ignored by the Noise Figure Analyzer. This

allows for future expansion.

value number

followed by

optional ’%’

[Humidity 40%]

ENR Data

ENR data records must be ordered from lowest to highest frequency.

General form The Noise Figure Analyzer attempts to interpret lines which are not

46 Chapter 4

Page 52

ENR File Format

Format Details

comments or header fields as ENR data. ENR data has the general form:

Freq [Funit] ENR [Eunit] [Euncert [on_mag on_phase

off_mag off_phase [Runcert]]]

Note that the square brackets denote optional fields.

Field separator Each field is separated by whitespace. A single ’,’ is allowed within or

instead of the whitespace.

Numeric fields With the exception of the two optional unit fields, the other fields are

numeric. Numbers are formatted as an optional sign, followed by a

sequence of one or more digits (which can include a single decimal point

within the sequence), follow ed by an optional exponent. The exponent

consists of the ’e’ or ’E’ followed by an optional sign followed by between

one and three digits.

Frequency fields The frequency field (Freq) is the frequency at which the ENR amplitude

was measured.

The frequency unit field (Funit) is optional. The default unit is Hz.

Valid units are Hz, kHz, MHz, GHz, THz. Units are not case sensitive.

ENR fields The ENR amplitude (ENR) is the measured ENR at the specified

frequency.

The ENR unit field (Eunit) is optional. The default unit is dB. Currently,

the only allowed unit is dB. Note that units K, C, F (temperature) are

reserved for possible future use, but are not supported by the Noise

Figure Analyzer at this time.

The uncertainty fiel d for the ENR amplitude (Euncert) is optional.

However , this field must be present if reflection coefficient data is

supplied.

Chapter 4 47

Page 53

ENR File Format

Format Details

Reflection

coefficient data

The reflection coefficien t data is optional and is formatted as four fields

(on_mag, on_phas e, off_m ag, off_ phase):

• reflection magnitude with noise source on

• reflection angle (in degrees) with noise source on

• reflection angle with noise source off

• reflection angle (degrees) with noise source off

If any reflection coefficient data is supplied, then all four fields must be

present. Note that the file format requires that the ENR uncertainty

field must be present before any reflection data.

The reflection coefficien t uncertainty (Runcert) is an optional parameter .

Reflection coefficient data must be present if this field is suppl ied.

48 Chapter 4

Page 54

ENR File Format

Examples

Examples

Example 1 This first example shows a simple ENR file where the Freque ncy and

ENR values have been entered manually into the Noise Figure Analyzer:

# ENR Data File

# Created by N8973A Agilent NFA Series Noise Figure

Analyzer

# Serial Number US00000012 Firmware Revision A.00.01

# 13:37:07 Mar 28, 2000

# Format is: Frequency (Hz), ENR (dB)

[Filetype ENR]

[Version 1.0]

10000000, 15.3500

100000000, 15.4230

1000000000, 15.2280

2000000000, 15.0900

3000000000, 14.9600

4000000000, 14.8400

5000000000, 14.7890

6000000000, 14.7500

7000000000, 14.7720

8000000000, 14.8570

9000000000, 14.9580

10000000000, 15.0600

11000000000, 15.0830

12000000000, 15.1950

13000000000, 15.2710

14000000000, 15.3430

15000000000, 15.4800

16000000000, 15.6750

17000000000, 15.8400

18000000000, 15.8940

Chapter 4 49

Page 55

ENR File Format

Examples

Example 2 The second example is a typical ENR file supplied on diskette with a

Noise Source:

[Filetype ENR]

[Version 1.0]

[Serialnumber 3318A15364]

[Model 346B]

[Caldate 20000110.13:53:54]

[Temperature 24C]

[Humidity 40%]

! Frequency ENR Unc Refl. Coef. On Refl. Coef. Off

! MHz dB dB Mag Phase Deg Mag Phase Deg

10 MHz 15.281 .193 .0450 -136.0 .0330 -66.0

100 MHz 15.291 .190 .0358 +168.0 .0110 -24.6

1000 MHz 15.118 .151 .0398 +39.6 .0107 +164.5

2000 MHz 14.999 .168 .0377 -85.7 .0266 +.9

3000 MHz 14.879 .172 .0267 +150.6 .0390 -129.2

4000 MHz 14.795 .173 .0130 -18.1 .0313 +106.0

5000 MHz 14.818 .179 .0359 +169.5 .0104 -99.3

6000 MHz 14.846 .181 .0556 +63.7 .0451 +104.3

7000 MHz 14.895 .180 .0430 -37.0 .0579 -2.3

8000 MHz 15.016 .198 .0232 -160.3 .0491 -123.8

9000 MHz 15.134 .201 .0122 +71.4 .0407 +107.3

10000 MHz 15.253 .194 .0080 +116.2 .0248

11000 MHz 15.249 .243 .0241 +65.7 .0259 +144.5

12000 MHz 15.349 .240 .0196 +8.8 .0457 +32.2

13000 MHz 15.383 .188 .0217 -5.4 .0362 -61.9

14000 MHz 15.355 .178 .0228 -66.6 .0075 +151.2

15000 MHz 15.367 .187 .0141 +141.6 .0136 -13.2

16000 MHz 15.421 .182 .0251 +6.4 .0030 -127.2

17000 MHz 15.418 .174 .0242 -100.5 .0148 -29.7

18000 MHz 15.464 .179 .0183 +124.4 .0198 -149.1

-15.4

50 Chapter 4

Page 56

A Caring for Connectors

The material contained in this appendix may not be apply to the

connector you are using on the instrument.

51

Page 57

Caring for Connectors

Introduction

Introduction

Recent advances in measurement capabilities have made connectors and

connection techniques more important than ever before. Damage to the

connectors on calibration and verification devices, test ports, cables, and

other devices represent an increasing burden in downtime and expense.

This Appendix will help you get the best performance from all coaxial

microwave connectors:

• To know what to look for whe n cleaning and inspecting the m, in order

to preserve their precision and extend their life.

• To make the best possible microwave connections, improving the

accuracy and repeatability of all of your measurements, saving both

time and money.

Connector Pa rt Numbers

Refer to the latest edition of the HP RF & Microwave Test Accessories

Catalog for connector part numbers.

Handling and Storage

Microwave connectors must be handled carefully, inspected before use

and when not in use, stored in a way that gives them maximum

protection. Avoid touching the connector mating plane surfaces and

avoid setting the connectors contact-end down, especially on a hard

surface.

Never store connectors with the contact end exposed. Plastic end caps

are provided with all Agilent connectors and these should be retained

after unpacking and placed over the ends of the connectors whenever

they are not in use. Extend the threads of connectors that have a

retractable sleeve or sliding connecto r nut, then put the plastic end cap

over the end of the connector.

Above all, never store any devices loose in a box or in a desk or a bench

drawer. Careless handling of this kind is the most common cause of

connector damage during storage.

52 Appendix A

Page 58

Caring for Connectors

Visual Inspection

Visual Inspection

Visual inspection and, if necessary, cleaning should be done every time a

connection is made.

Metal and metal by-product particles from the connector threads often

find their way onto the mating plane surfaces when a connection is

disconnected and even one connection made with a dirty or damaged

connector can damage both connectors beyond repair.

Magnification is helpful when inspecting connectors, but it is not

required and may actually be misleading. Defects and damage that

cannot be seen without magnification generally have no effect on

electrical or mechanical performance. Magnification is of great use in

analyzing the nature and cause of damage and in cleaning connectors,

but it is not required for inspection.

Obvious Defects and Damage

Examine the connectors first for obvious defects or damage: badly worn

plating, deformed threads or bent, broken, or misaligned center

conductors. Connector nuts should move smoothly and be free of burrs,

loose metal particles, and rough spots.

Immediately discard, or mark for identification and send away for repair,

any connector that has obvious defects like these.

Mating Plane Surfaces

Flat contact between the connectors at all points on their mating plane

surfaces is required for a good connection. Therefore, particular attention

should be paid to deep scratches or dents, and to dirt and metal or metal

by-product particles on the connector mating plane surfaces.

Also look for bent or rounded edges on the mating plane surfaces of the

center and outer conductors and for any signs of d amage due to exces sive

or uneven wear or misalignment.

Appendix A 53

Page 59

Caring for Connectors

Visual Inspection

Light burnishing of the mating plane surfaces is normal, and is evident

as light scratches or shallow circular marks distributed more or less

uniformly over the mating plane surfa ce. Other small defects and

cosmetic imperfections are also normal. None of these affect electrical or

mechanical performance.

If a connector shows deep scratches or dents, particles clinging to the

mating plane surfaces, or uneven wear, clean it and inspect it again.

Damage or defects like dent s or scratches, which are deep enough to

displace metal on the mating plane surface of the connector, may indicate

that the connector itself is damaged and should not be used. Try to

determine the cause of the damage before making further connections.

Precision 7 mm Connectors

Precision 7mm connectors, among them APC-7 connectors, should be

inspected visually with the center conductor collets in place, and

whenever the collet has been removed. See Figure A-1.

The collet itsel f should be inspected for edge or surface damage and for

any signs that the spring contacts are bent or twisted. If they are, replace

the collet. When the collet has been re-inserted, verify that it springs

back immediately when pressed with a blunt plastic rod or with the

rounded plastic handle of the collet removing tool. Never use a pencil or

your finger for this purpose.

54 Appendix A

Page 60

Figure A-1 Precision 7mm Connector

Outer Conductor Center Conductor

Dielectric

Support bead

Sexed Con n ectors

Caring for Connectors

Visual Inspection

Collet

Outer

Conductor

Mating Plane

On sexed connectors, especially precision 3.5mm and SMA connectors,

pay special attention to the female center conductor contact fingers

(Figure A-2 and Figure A-3). These are very easily bent or broken, and

damage to them is not always easy to see. Any connector with damaged

contact fingers will not make good electrical contact and must be

replaced.

Figure A-2 Precision 3.5mm connectors

FEMALE

Appendix A 55

MALE

Outer Conductor

Mating Plane

Page 61

Caring for Connectors

Visual Inspection

Figure A-3 SMA connectors

FEMALE

MALE

Outer Conductor

Mating Plane

56 Appendix A

Page 62

Caring for Connectors

Cleaning

Cleaning

Careful cleaning of all connectors is essential to assure long, reliable

connector life, to prevent accidental damage to connectors, and to obtain

maximum measurement accuracy and repeatability . Yet it is the one step

most often neglected or done improperly. Supplies recommended for

cleaning microwave connectors are as follows:

• Compressed Air.

•Alcohol.

• Cotton Swabs.

• Lint-Free Clea ning Cloth.

Compressed Air

Loose particles on the connector mating plane surfaces can usually be

removed with a quick blast of compressed air. This is very easy to do and

should always be tried first using compressed air from a small

pressurized can. The stream of air can be directed exactly where it is

wanted through a plastic (not metal) nozzle. No hoses or other

connections are needed. Hold the can upright, to avoid spraying liquid

along with the vapor.

Cleaning Alcohol

Dirt and stubborn contaminants that cannot be removed with

compressed air can often be removed with a cotton swab or lint free

cleaning cloth moistened with alcohol.

NOTE Use the least amount of alcohol possible, and avoid wetting any plastic

parts in the connectors with the alcohol.

Appendix A 57

Page 63

Caring for Connectors

Cleaning

Alcohol should be used in liquid rather than spray form. If a spray must

be used, always spray the alcohol onto a cloth or swab, never directly into

a connector.

Very dirty connectors can be cleaned with pure alcohol. Other solutions

that contain additives should not be used.

Carefully avoid wetting the plastic support bead (which is easily

damaged by alcohol) inside the connector and blow the connector dry

immediately with a gentle stream of compressed air.

Precision 7 mm Connectors

When precision 7mm connectors have been cleaned with the center

conductor collet removed, insert the collet and clean the mating plane

surfaces again.

When the connector is attached to a small component, or to a cable,

calibration, or verification standard, the easiest way to do this is to put a

lint-free cleaning cloth flat on a table and put a couple of drops of alcohol

in the center of the cloth. It should be noted that it is not necessary to

remove the collet to use this cleaning method.

Retract the connector sleeve threads so that the connector interface is

exposed. Gently press the contact end of the connector into the cloth

moistened with alcohol, then turn the connector.

Dirt on the connector interface will be scrubbed away by the cloth

without damaging the connector. Blow the connector dry with a gentle

stream of compressed air.

This cleaning method can be adapted even for fixed connectors such as

those attached to test ports. Simply fold the cloth into several layers of

thickness, moisten it, press it against the connector interface, and turn it

to clean the connector. Blow the connector dry with a gentle stream of

compressed air.

58 Appendix A

Page 64

Cleaning Interior Surfaces

Interior surfaces, especially on precision 3.5mm connectors, are very

difficult to reach, and it is easy to damage connectors in trying to clean

them. The openings ar e very small, and genera lly the center conductor is

supported only at the inn er end, by a plastic di electric supp ort bead. T his

makes it very easy to bend or break the center conductor.

One suitable method (Figure A-4) is to cut off the sharp tip of a round

wooden toothpick, or a smaller diameter wooden rod, and then to wrap it

with a single layer of lint-free cleaning cloth.

Figure A-4 Cleaning interior surfaces

Caring for Connectors

Cleaning

NOTE Metal must never be used (it will scratch the plated surfaces), and in

cleaning precision 3.5mm connectors the diameter must not exceed 0.070

in. (1.7 mm). The wooden handle of a cotton swab, for example, is too

large for this purpose. Even though the handle can sometimes be

inserted into the connector, even when wrapped in lint-free cloth,

movement of the handle against the center conductor can exert enough

force on the center conductor to damage it severely.

Appendix A 59

Page 65

Caring for Connectors

Cleaning

Moisten the cloth with a small amount of alcohol and carefully insert it

into the connector to clean the interior surfaces. Use an illuminated

magnifying glass or mi crosc ope to se e c le arly the ar eas yo u wi sh to clea n.

Drying Connectors

When you have cleaned a connector, always be sure that it is completely

dry before reassembling or using it. Blow the connector dry with a gentle

stream of clean compressed air and inspect it again under a magnifying

glass to be sure that no particles or alcohol residues remain.

60 Appendix A

Page 66

Caring for Connectors

Mechanical Inspection: Connector Gages

Mechanical Inspection: Connector Gages

Even a perfectly clean, unused connector can cause problems if it is

mechanically out of specification. Since the critical tolerances in

microwave connectors are on the order of a few te n-thousandths of an

inch, using a connector gage is essential.

Before using any connector for the first time, inspect it mechanically

using a connector gage. How often connectors should be gag ed after that

depends upon usage.

In general, connectors should be gaged whenever visual inspection or

electrical performance suggests that the connector interface may be out

of specification, for example due to wear or damage. Connectors on

calibration and verification devices should also be gaged whenever they

have been used by someone else or on another system or piece of

equipment.

Precision 3.5mm and SMA connectors should be gaged relatively more

often than other connectors, owing to the ease with which t he center pins

can be pulled out of specification during disconnection.

Connectors should also be gaged as a matter of routine - after every 100

connections and disconnections initially, more or less often after that as

experience suggests.

Table A-1 Recommended connector gages

Connector gage kits containing all of the items required are included in many

Agilent calibration kits. They are also available separately. Part numbers are as

follows.

Ty pe Part Number/Ordering Information

Precision 7mm

(APC-7)

Precision 3.5mm 11752D

Precision 2.4mm 11752E

Type-N 85054-60047

Appendix A 61

85050-80012

Page 67

Caring for Connectors

Mechanical Specifications

Mechanical Specifications

The critical dimension to be measured, regardless of connector type, is

the position (generally, the recession or setback) of the center conductor

relative to the outer conductor mating plane.

Mechanical specifications for connectors specify a maximum distance

and a minimum distance that the center conductor can be positioned

behind (or, in female Type-N connectors, in front of) the outer conductor

mating plane. Nominal specifications for each connector type exist, but

the allowable tolerances (and sometimes the dimensions themselves)

differ from manufacturer to manufacturer and from de vice to device.

Therefore, before gaging any connector, consult the mechanical

specifications provided with the connector or the device itself.

Precision 7mm Connectors

In precision 7mm connectors, contact between the center conductors is

made by spring-loaded contacts called collets. These protrude slightly in

front of the outer conductor mating plane when the connectors are apart.

When the connection is tightened, the collets are compressed into the

same plane as the outer conductors.

For this reason, two mechanical specifications are generally given for

precision 7mm connectors: the maximum recession of the center

conductor behind the outer conductor mating plane with the center

conductor collet removed; and a minimum and maximum allowable

protrusion of the center conductor collet in front of the outer conductor

mating plane with the collet in place.

The center conductor collet should also spring back immediately when

pressed with a blunt pl astic rod or wit h the ro unded pl astic h andle of the

collet removing tool. Never use a pencil or your finger for this purpose.

With the center conductor collet removed, no protrusion of the center

conductor in front of the outer conductor mating plane is allowable, and

sometimes a minimum recession is required. Consult the mechanical

specifications provided with the connector or the device itself.

62 Appendix A

Page 68

Caring for Connectors