® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc. • All Rights Reserved EN0B-0090GE51 R1200

Distributed I/O

XFL521B, 522B,

523B, AND 524B MODULES

PRODUCT DATA

FEATURES

• LONMARK™ compliant

• 2-wire LONWORKS® bus interface between controller

and I/O

• No additional field terminals required

• May be used with Excel 500 controllers in conjunction

with standard I/O modules

• Automatic binding and commissioning with Excel 500

• Connector module with sliding bus connector (thus

eliminating the need to wire together neighboring

modules)

• Fast connection due to spring clamp terminals

• Module exchange during operation

• Optional manual override with feedback

• Alarm in case of defective module

• Mechanical coding prevents mismatching of modules

• Power LED (L1, green) and L

ONWORKS service LED

(L2, red) on all electronics modules.

• Status LEDs for analog outputs and digital in- and

outputs

• Optional manual override modules for analog and

digital output modules

GENERAL

The XFL521B, 522B, 523B, and 524B modules are LONMARK

compliant digital and analog I/O modules which can be

installed at strategic locations within a building. These

modules convert sensor readings and provide output signals

used for operating actuators via L

ONWORKS standard network

variables (SNVTs). Each Distributed I/O module plugs into a

base terminal block allowing communication with controllers

via the built-in Echelon

®

LONWORKS bus interface. The terminal block provides spring clamp terminals for easy connection of field cables from the various sensors and actuators.

The modular system allows Distributed I/O modules to be

removed from the system without disturbing other modules.

The module with terminal block mounts easily onto a DIN-rail.

The Excel 500 CPU (XC5010C, XC5210C, XCL5010) is

capable of automatically binding and commissioning the Distributed I/O modules via the L

ONWORKS bus. When the

modules are used by other controllers, plug-ins are provided

so that the modules can be commissioned by any LNS or

non-LNS installation or network management tool.

DESCRIPTION

The XFL521B, 522B, 523B, and 524B are Distributed I/O

modules that use a Neuron® chip and an FTT-10A free

topology transceiver for communication on a L

ONWORKS bus.

The modules are compliant with L

ONMARK Application Layer

Guidelines V3.2.

Table 1. Modules and accessories.

Module Description

XFL521B Analog Input module

XFL522B Analog Output module

XFL523B Digital Input module

XFL524B Digital Output module

XSL511 LONWORKS connector module

XSL512 Manual terminal disconnect module

XSL513 Terminal block for XFL521/522/523

XSL514 Terminal block for XFL524

XFR522A Analog Output manual override module

XFR524A Digital Output manual override module

DISTRIBUTED I/O

EN0B-0090 2

INTEROPERABILITY

The Distributed I/O modules are compliant to the LONMARK

Application Layer Interface Guidelines, version 3.2. The

modules contain a L

ONMARK Node Object to allow monitoring

and setting the status of the various Sensor / Actuator Objects, as well as a L

ONMARK Sensor Object for each input or

an Actuator Object for each individual output.

Upon receiving an update to the NViRequest network vari-

able, the NVoStatus network variable is updated. The definition of SNVT_obj_request includes an object ID field to allow

the Node Object to report status conditions for all objects on

a node.

All network variables have the NV names in their self-documentation strings. This allows a network management node

or tool to display meaningful information on a Distributed I/O

module even if it is installed by an EXCEL 5000 controller

and not by the tool itself.

The Distributed I/O modules use the standard 6-byte location

string (see Table 2) in the Neuron® chip’s EEPROM to store

the module address (0...15 as set using the rotary HEX

switch) and the module type.

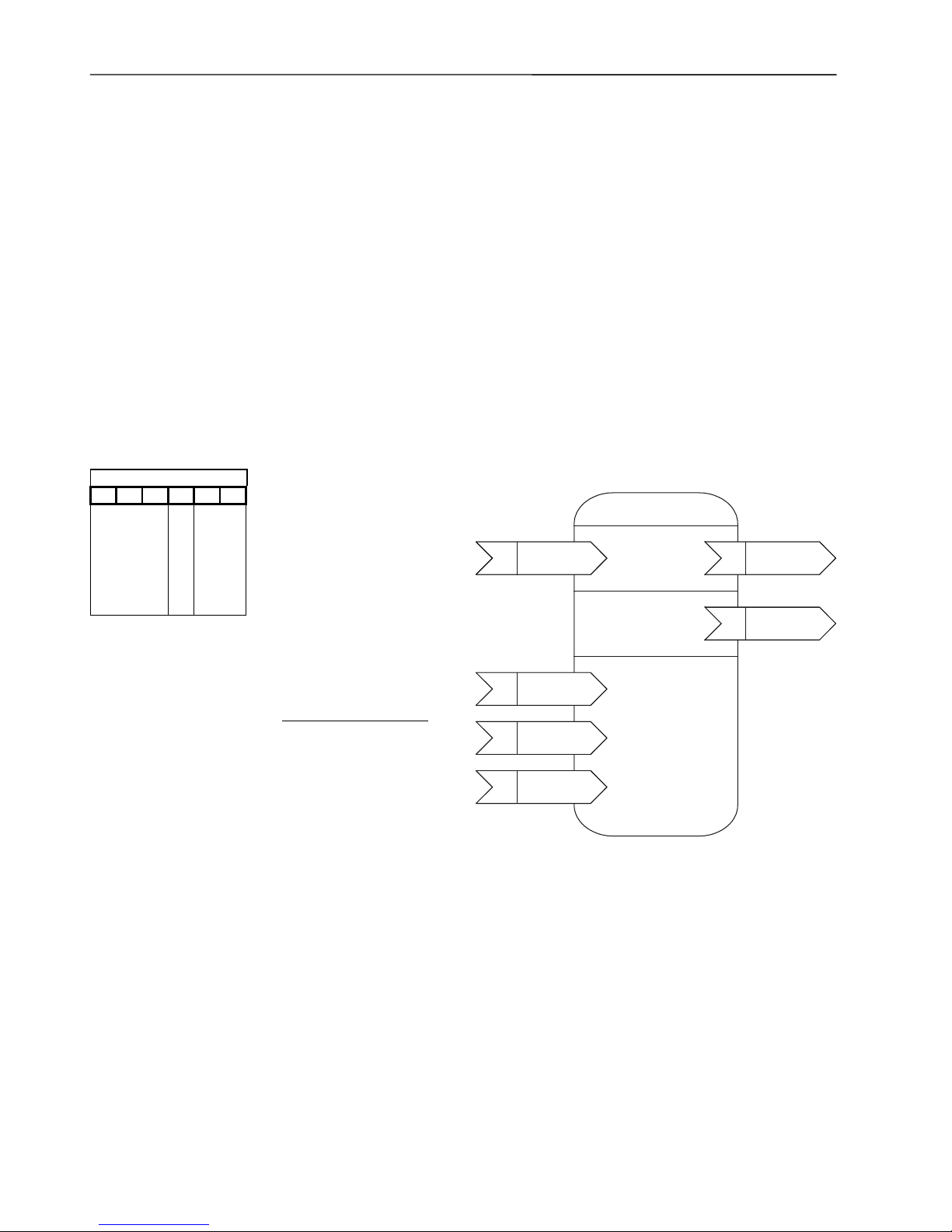

Location String

‘0’ Y Y

Module type

Set to '0'

Module

address

Module Type:

0 = XFL521B Analog Input

1 = XFL522B Analog Output

2 = XFL523B Digital Input

3 = XFL524B Digital Output

Table 2. Location string for storing module address

The node self-documentation string contains the module type

and revision in the optional part after the semicolon.

Example:

#pragma set_node_sd_string &3.2@0,3[6;XDO2_2_00

In this example, the module type is "XDO2" ("2" means that

the 3120E5 chip is used) and the revision is "2.00".

LONMARK Node Object

Setting the Node Object to “DISABLE” via nviRequest

suppresses updating of all output NVs and handling of input

NVs. Setting the Node Object to “ENABLE” via nviRequest

returns the module to normal operation.

The Node Object also contains the optional NV nciNetConfig

which is initialized to “CFG_LOCAL” by default. This allows

the Distributed I/O module to set its location string. If a

network management node commands this nci to

“CFG_EXTERNAL”, then the module will no longer modify its

Location String. This nci is stored in EEPROM and remains

there even in the event of a power failure.

LONMARK Sensor/Actuator Objects

All Actuator Objects (contained in the output modules) have

an output NV showing the actual state of the physical output

and whether it is in the automatic or manual override mode.

Note that the output modules have a manual override panel

which can be plugged on or off.

All Sensor Objects (contained in the input modules) have a

configuration property, MaxSendTime, defining the heartbeat

time, i.e. the interval in which output NVs belonging to the

physical inputs will be sent even if their values do not

change.

All Sensor Objects also have a configuration property,

MinSendTime, defining the minimum time which must elapse

before a changed value of an output NV belonging to a

physical input will be sent. This is to limit the network traffic

when sensor values change rapidly.

Node Object

Type #0

Mandatory

Network

Variables

input

NV 1

nviRequest

SNVT_obj_request

nv1

nviRequest

SNVT_obj_request

input

NV 1

nviRequest

SNVT_obj_request

nv2

nvoStatus

SNVT_obj_status

input

NV 1

nviRequest

SNVT_obj_request

nv8

nvoFileDirectory

SNVT_address

Optional

Network

Variables

Optional

Configuration

Properties

input

NV 1

nviRequest

SNVT_obj_request

nc25

nciNetConfig

SNVT_config_src

input

NV 1

nviRequest

SNVT_obj_request

nc49

SCPTMaxSendTime

SNVT_time_sec

input

NV 1

nviRequest

SNVT_obj_request

nc52

SCPTMinSendTime

SNVT_time_sec

Figure 1. Distributed I/O LONMARK Node Object profile.

DISTRIBUTED I/O

3 EN0B-0090

Table 3. Node Object network variables.

NV Name Type Range Description

nviRequest SNVT_obj_request RQ_NORMAL

RQ_DISABLE

RQ_ENABLE

RQ_UPDATE_STATUS

RQ_REPOPRT_MASK

RQ_SELF_TEST

Upon receiving an update to nviRequest, nvoStatus is

updated.

RQ_SELF_TEST is used only in the XFL522 analog

output module for outputs configured as a motor. In

this case, a synchronization is performed to set the

actuator in the 0% position.

nvoStatus SNVT_obj_status Reports the status of the node upon request through

nviRequest.

nciNetConfig SNVT_config_src CFG_LOCAL (default)

CFG_EXTERNAL

This configuration variable is set to CFG_LOCAL at

the factory and whenever the rotary HEX switch is

reset. If it is set to CFG_EXTERNAL, a network

manager will assign a network address for the node. In

this case, the module will not modify its location string

as long as the rotary HEX switch is not reset.

nvoFileDirectory SNVT_address Points to a file directory in the address space of the

Neuron® chip containing descriptors for the files in the

module. It is used to access the configuration properties stored in configuration parameter files

accessed by network management read/write

messages.

SCPTminSendTime SNVT_time_sec 1.0 to 10.0s

(default = 1.0)

Defines the minimum period of time between output

variable transitions. This configuration property is

applicable only to output NVs of the input modules.

SCPTmaxSendTime SNVT_time_sec 1.0 to 6553.4s

(default = 60.0s)

Defines the maximum time period of time before output NVs are automatically updated. It must be set to a

higher number than SCPTminSendTime. This configuration property is applicable only to output NVs of

the input modules.

XFL52xB Module Response Times

The response time of Distributed I/O modules is defined as

the period of time between the updating of the physical signal

and the updating of the NV (or vice versa). The response

time varies somewhat due to certain factors and is also

dependent upon the module type (refer also to Table 4).

The total system response time represents the sum of the

response times of all involved devices. When operating in the

open mode, a fast response time of 40 ms can be achieved,

thus enabling them to be employed in time-critical

applications.

Table 4. Response time (RT)

Module Typical RT

(sec)

Max. RT

(sec)

Min. time between

2 updates

XFL521B 0.8 1.6 SNVTMinSendTime

(default: 1 sec)

XFL522B 0.2 0.4 n.a.

XFL523B 0.3 0.5 SNVTMinSendTime

(default: 1 sec)

XFL524B 0.2 0.4

DISTRIBUTED I/O

EN0B-0090 4

TECHNICAL DATA

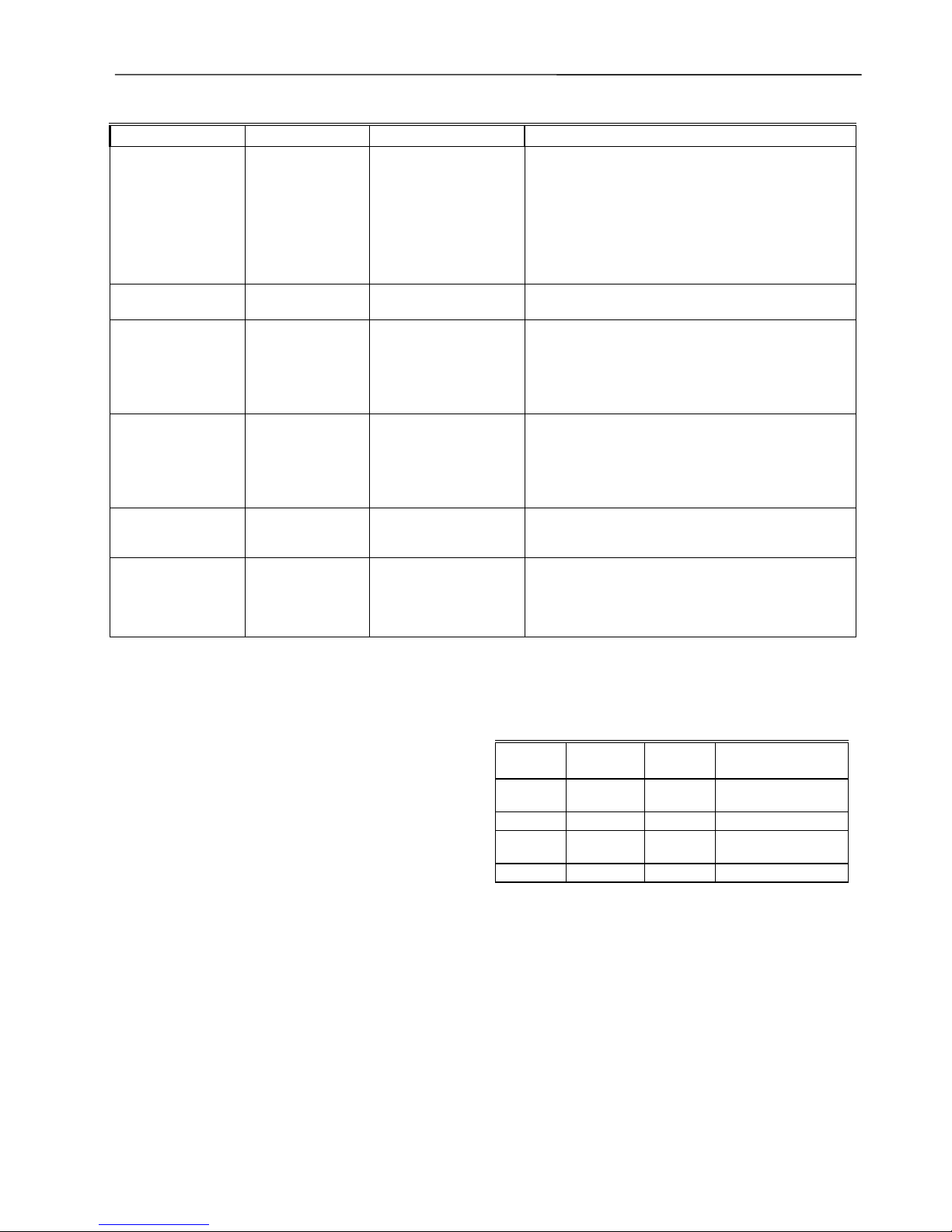

Analog Input Module XFL521B

• Eight inputs (AI1 – AI8)

0 to 10 Vdc (see EN1R-1047 for impedance

information)

0 to 20 mA (via external 500-ohm resistor)

4 to 20 mA (via external 500-ohm resistor)

NTC 20K ohm (-50°C to +150°)

PT1000 (-50°C to +150°C)

• Protected inputs up to 40 Vdc / 24 Vac

• 12-bit resolution

• ± 75 mV accuracy (0 to 10 V)

• 10 Vdc auxiliary voltage supply (9 – 17) , I

max

= 5 mA

• 1 sec polling time with CPU

• Green power LED (L1) and red LONWORKS status LED

(L2)

• Dimensions (WxLxH): 47x97x70 mm

The analog input module has eight input channels which

can be used for connecting sensors or any device providing an analog output. The input values are read by the

CPU and can then be used for monitoring or as parameters for controlling other devices.

The unit plugs into the XSL513 Terminal Block and can be

inserted and removed without disturbing other units on the

bus. Terminals AI1 through AI8 are the analog inputs and

terminals 9 through 17 are wired together and provide an

auxiliary voltage of 10 Vdc. The module address is set

using the rotary HEX switch.

NOTE: When the input is identified as a DI point, the

internal pull-up resistor is disabled.

Open Loop Sensor

Object Type #1

Mandatory

Network

Variables

input

NV 1

nviRequest

SNVT_obj_request

nv1

nvoAiValue

SNVT_volt_f

input

NV 1

nviRequest

SNVT_obj_request

nv1

nvoAiTemp

SNVT_temp_p

Optional

Network

Variables

Optional

Configuration

Properties

input

NV 1

nviRequest

SNVT_obj_request

nc1

UCPTSensorConfig

input

NV 1

nviRequest

SNVT_obj_request

nc2 UCPTSendOnDelta

input

NV 1

nviRequest

SNVT_obj_request

nc3 UCPTWireOffset

Figure 2. LONMARK Object for each analog input.

For each Sensor Object, the XFL521 Analog Input Module

provides an additional output NV, SNVT_temp_p, which

communicates the temperature in °C. This allows this

module to be used as a true temperature sensor in an

open L

ONMARK integration. If the Sensor Object is con-

figured as 0 to 10V, this NV will be invalid (0x7FFF).

DISTRIBUTED I/O

5 EN0B-0090

Table 5. LONMARK Object NVs for the XFL521B.

NV Name Type Range Description

nvoAiValue SNVT_volt_f 0x000 (0.00 mV) to

0x461C4000 (10V)

The value of the input channel connected to a 0

to 10V signal after it has been filtered. Voltage

is transmitted in mV. When configured for a

temperature sensor, the channel transmits the

measured resistance.

nvoAiTemp SNVT_temp_p 0xEC78 (-50°C) to

0x3A98 (150°C)

Invalid = 0x7FFF

The value of the input connected to either an

NTC20 or PT1000 sensor with a resolution of

0.1°C. If the sensor channel is configured as a

voltage input, the temperature value is invalid

(0x7FFF).

UCPTSensorConfig 0 = not used,

9 = 0 to 10V with pull-up resistor

4 = NTC20

5 = PT1000

10 = 0 to 10V without pull-up

resistor (default = 8)

Specifies the type of sensor for a particular

input channel.

UPCTSendOnDelta SNVT_count 0 to 4095 (default = 2) Specifies the difference in the raw value

measured by the A/D converter is required

before the value of the sensor is transmitted.

UCPTWireOffset SNVT_res 0 to 6553.5 ohm (default = 0) Specifies a resistance value to add to the

resistance measured for a temperature sensor.

DISTRIBUTED I/O

EN0B-0090 6

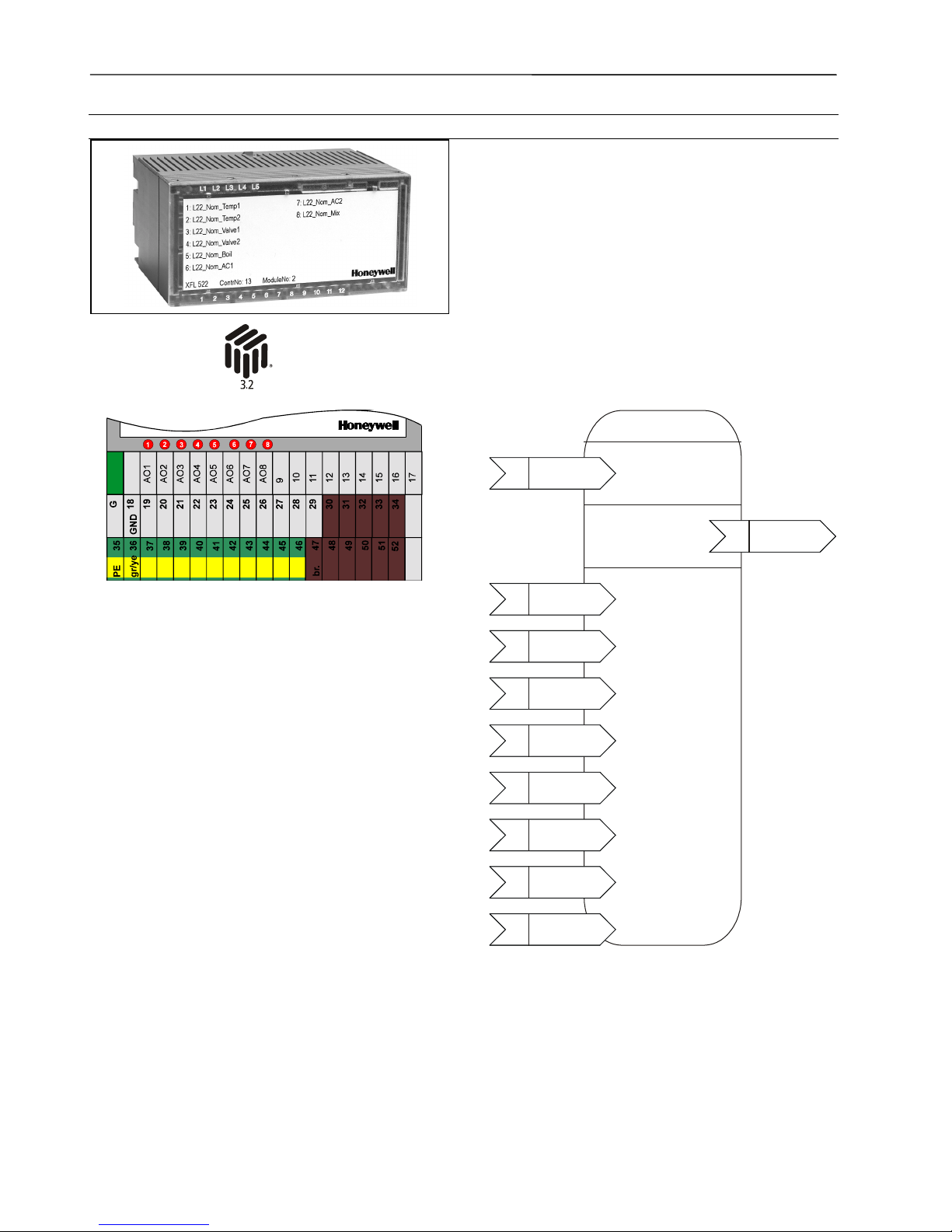

Analog Output Module XFL522B

• Eight outputs (AO1 – AO8), short-circuit proof

• Signal levels 0 to 10 Vdc

U

max

= 11 Vdc, I

max

= +1 mA, -1 mA

• Protected outputs up to 40 Vdc / 24 Vac

• 8-bit resolution

• Zero point < 200 mV

• Accuracy ± 150 mV deviation from output voltage

• One red LED per channel (light intensity proportional to

output voltage)

• Green power LED (L1) and red L

ONWORKS status LED

(L2)

• Control updating every 1 sec with CPU

• Dimensions (WxLxH): 47x97x70 mm

This analog output module has eight output channels

which can be connected to actuators or other suitable

analog devices.

The unit plugs into the XSL513 Terminal Block and can be

inserted and removed without disturbing other units on the

bus. Terminals AO1 through AO8 are the analog outputs.

Terminals 9 through 17 are connected to ground. Eight red

LEDs are located on top of the module. The brightness of

each LED is proportional to the output level of the corresponding channel. The module address is set using the

rotary HEX switch.

Open Loop Actuator

Object Type #3

Mandatory

Network

Variables

input

NV 1

nviRequest

SNVT_obj_request

nv1

nviValue

SNVT_switch

input

NV 1

nviRequest

SNVT_obj_request

nv3

nvoFeedback

SNVT_switch

Optional

Network

Variables

Optional

Configuration

Properties

input

NV 1

nviRequest

SNVT_obj_request

nc1

UCPTSensorConfig

input

NV 1

nviRequest

SNVT_obj_request

nc2

UCPTdriveTimeClose

input

NV 1

nviRequest

SNVT_obj_request

nc3

UCPTdriveTimeOpen

input

NV 1

nviRequest

SNVT_obj_request

nc4

UCPTsyncMin

input

NV 1

nviRequest

SNVT_obj_request

nc5

UCPTsyncMax

input

NV 1

nviRequest

SNVT_obj_request

nc6

UCPTsyncCharge

input

NV 1

nviRequest

SNVT_obj_request

nc88

UCPTminDeltaLevel

input

NV 1

nviRequest

SNVT_obj_request

nc96

UCPTdelayTime

Figure 3. LONMARK Object for each analog output.

DISTRIBUTED I/O

7 EN0B-0090

Table 6. LONMARK Object NVs for the XFL522B.

NV Name Type Range Description

nviValue SNVT_switch Receives the value for the output channel.

nvoFeedback SNVT_switch Transmits the feedback value of the actuator output. If

the manual override switch is set to 0, or if the manual

override module is not plugged in, the feedback output

reflects the value of nviValue. As soon as the manual

override switch is set at the 20% threshold, the

Actuator Objects adopts this manual value. In this

case, the nvoFeedback state field will be 0xFF (invalid)

and the value field will contain the actuator position.

If the actuator is configured as a motor, the position

commanded with the manual override switch will be

reflected in the open/close commands for a floating

actuator.

If the manual override switch is in the automatic position, data is transmitted whenever nviValue is written.

If the manual override switch is in the manual position,

data is transmitted whenever the manual position is

changed.

UCPTSensorConfig none 0 = not used

6 = 0 to 10V (default)

7 = motor (floating)

Specifies the actuator output type for an output

channel.

UCPTdriveTimeClose SNVT_time_sec 10.0 to 1000s

(default = 90.0s)

Specifies a floating actuator’s runtime from 100% to

0%.

UCPTdriveTimeOpen SNVT_time_sec 10.0 to 1000s

(default = 90.0s)

Specifies a floating actuator’s runtime from 0% to

100%.

SCPTdelayTime SNVT_time_sec 0.0 to 10.0s

(default = 5.0s)

Specifies the delay time before a floating actuator

changes its direction. This avoids mechanical

problems that could occur when the run direction

changes due to an update to nviValue while the

actuator is still moving.

SCPTminDeltaLevel SNVT_lev_cont. Specifies the delta level for an update to nviValue to

be exceeded before a new position is calculated for

the floating motor model. This is applicable only if the

actuator is configured as a motor.

UCPTsyncMin SNVT_lev_cont 0 to10%

(default = 2%)

Specifies the lower synchronization threshold. If the

actuator is configured as a motor and the value

commanded through nviValue approaches 0%, the

actuator is synchronized to 0% as soon as nviValue

reaches the percentage specified by UCPTsyncMin.

UCPTsyncMin SNVT_lev_cont 90 to 100%

(default = 98%)

Specifies the upper synchronization threshold. If the

actuator is configured as a motor and the value

commanded through nviValue approaches 100%, the

actuator is synchronized to 100% as soon as nviValue

reaches the percentage specified by UCPTsyncMin.

UCPTsyncCharge SNVT_lev_cont 0 to 127.5%

(default = 100%)

Specifies the additional runtime when an actuator performs a synchronization. This is to ensure that the

actuator reaches the end position even if the actuator

position is not what it should be due to inaccuracy.

For example, with UCPTsyncCharge at 100%, an

actuator with a theoretical current position of 20%

would be forced to run 120% of the runtime specified

by UCPTdriveTimeClose if it starts a synchronization

from this point of operation.

DISTRIBUTED I/O

EN0B-0090 8

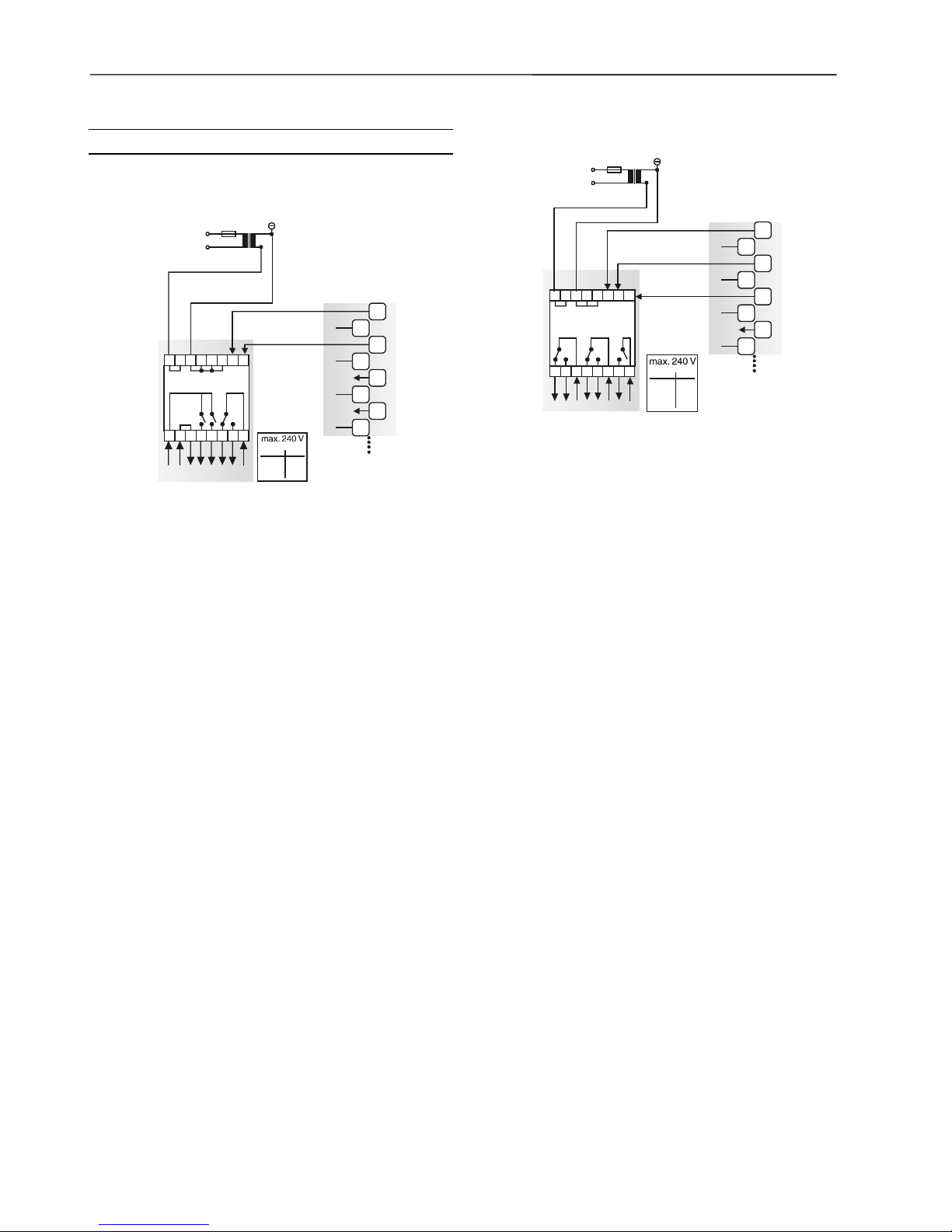

Relay Modules MCD 3 and MCE 3

The relay modules facilitate the control of peripheral devices

with high load via the analog outputs. Figure 4 and Figure 5

present connection examples for the relay modules MCD 3

and MCE 3, respectively.

230 Vac / 12 0 V ac

FUSE

0.2 A

K 1

K 2

K 3

3 A

11121314 15161718

1223K345

K1

LN

678

MCD 3

A

O1

18

A

O2

19

A

O3

20

A

O4

21

00000001

Figure 4. Analog Outputs, Connection of Relay MCD 3.

MCD 3

Relay terminal 17 controls the changeover contact K3. Relay

terminal 18 controls the ON contacts K1, K2. Ground can be

looped through terminals 2/3.

230 Vac / 12 0 V ac

FUSE

A

O1

18

A

O2

19

A

O3

20

A

O4

21

00000002

1112 13 14 15 16 17 18

123

K1 K2

K3

45678

MCE 3

0.2 A

K 1

K 2

2 A

K 3

Figure 5. Analog Outputs, Connection of Relay MCE 3.

MCE 3

Relay terminal 16 controls the ON contact K3. Relay terminal

17 controls the changeover contact K2. Relay terminal 18

controls the changeover contact K1.

Power Supply

Several relay modules can be connected in series via the

bridged terminal pair:

24 Vac: Terminals 11/12 of the relay

24 Vac (-): Terminals 13 to 16 of the relay

DISTRIBUTED I/O

9 EN0B-0090

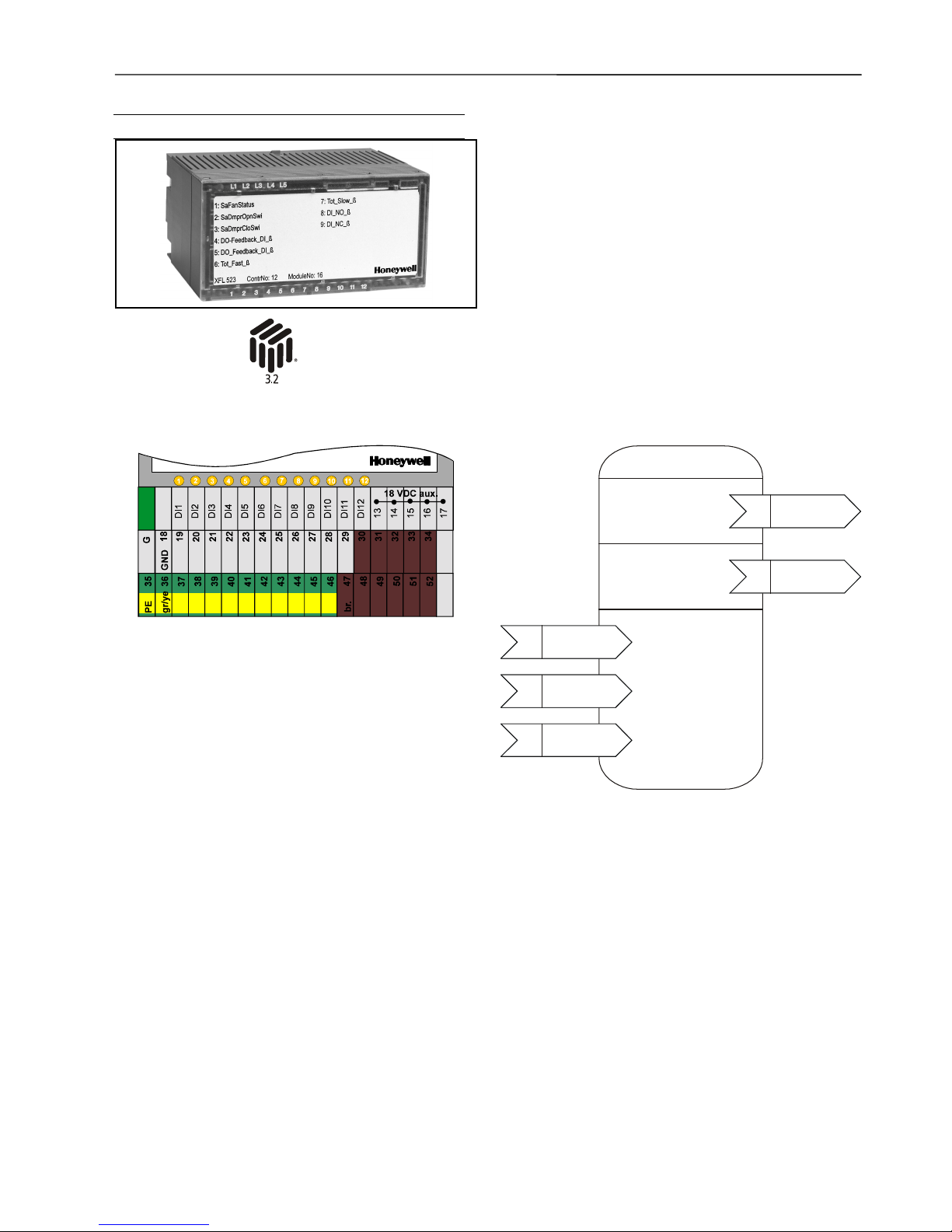

Digital Input Module XFL523B

• Twelve inputs (DI1 – DI12)

• Ri = 10K ohm

• Max. 20 Hz input frequency

• Switching conditions: OFF: Ui ≤ 2.5 V; ON: Ui ≥ 5 V

• Protected switching up to 40 Vdc / 24 Vac

• LED per channel, color selectable in two groups (SW1: DI

1 – 6; SW2 DI: 7 – 12); color combinations: see Table 7

• 18 Vdc auxiliary voltage supply (unregulated)

• 1 sec polling time with CPU

• Green power LED (L1) and red L

ONWORKS status LED

(L2)

• Dimensions (WxLxH): 47x97x70 mm

The digital input module has twelve input channels which can

be used for connecting sensors or any device providing a

digital output. The input values are read by the CPU and can

then be used for monitoring or as parameters for controlling

other devices

The unit plugs into the XSL513 Terminal Block and can be

inserted and removed without disturbing other units on the

bus. Terminals DI1 through DI12 are the digital inputs and

terminals 13 through 17 are wired together and provide an

auxiliary voltage of 18 Vdc. The module address is set using

the rotary HEX switch.

Beginning with V2.04.00 Excel 500 controller firmware, the

online point attribute Normally Open / Normally Closed

(NO/NC) defines the relation between the physical state

(contact position) and its logical status. See Table 7.

Open Loop Sensor

Object Type #1

Mandatory

Network

Variables

input

NV 1

nviRequest

SNVT_obj_request

nv1

nvoDiValue

SNVT_switch

input

NV 1

nviRequest

SNVT_obj_request

nv1

nvoDiValueCnt

SNVT_count

Optional

Network

Variables

Optional

Configuration

Properties

input

NV 1

nviRequest

SNVT_obj_request

nc1

UCPTSensorConfig

input

NV 1

nviRequest

SNVT_obj_request

nc2 UCPTSendOnDelta

input

NV 1

nviRequest

SNVT_obj_request

nc27 SCPTSendOnDelta

Figure 6. LONMARK Object for each digital input.

For each Sensor Object, the XFL523 Digital Input Module

provides an additional output NV, SNVT_switch. For an open

L

ONMARK integration, this offers a more convenient way of

accessing the sensor value compared to using the NV

SNVT_count. If the Sensor Object is configured as

“Totalizer”, this NV is invalid (switch.state = 0xFF,

switch.value = 0).

DISTRIBUTED I/O

EN0B-0090 10

Table 7. Relation between physical state and logical status as defined by the point attribute NO/NC for the XFL523B.

Contact Position NO/NC Attribute Logical Status Input Voltage LED Switch On LED Switch Off

Open NO 0 ≤ 2.5 V Off Green

Closed NO 1 ≥ 5 V Yellow Red

Open NC 1 ≤ 2.5 V Yellow Red

Closed NC 0 ≥ 5 V Off Green

Table 8. LONMARK Object NVs for the XFL523B.

NV Name Type Range Description

nvoDiValue SNVT_switch Transmits the state of the input channel every time

there is a state change or if SCPTMaxSendTime in

the Node Object has expired.

nvoDiValueCnt SNVT_count binary: 0, 1

totalizer: 0 to 65534

(65534 initial value)

Transmits the state of the input channel every time

there is a state change or if SCPTMaxSendTime in

the Node Object is expired. If configured as a

totalizer, this NV transmits the number of transitions

from 0 to 1.

UCPTSensorConfig 0 (not used)

1 = binary (default)

2 = totalizer

Specifies the setting for a sensor channel.

UCPTSendOnDelta SNVT_count 0 to 65535 Specifies the difference in totalizer count required

before a transmission of the value output of the

Sensor Object takes place.

SCPTDirection SNVT_state Used to define the relation between the logical status

of the input and the state of the LED. One bit corresponds to one input channel (bit 4 = input channel

12, bit 15 (MSB) = input channel 1). If a bit is clear,

the LED for the channel will be 0=green and 1=red. If

the bit is set, then 0=red and 1=green.

DISTRIBUTED I/O

11 EN0B-0090

Digital Output Module XFL524B

• Six isolated change-over contacts

• Max. voltage U

max

= 230 Vac per output

• Max. current I

max

= 2 A per output

• LED per channel

OFF: LED off

ON: LED illuminated (yellow)

• Green power LED (L1) and red L

ONWORKS status LED

(L2)

• Cycle time 1 sec with CPU

• Dimensions (WxLxH): 47x97x70 mm

The digital output module has six isolated change-over contacts which can be connected to actuators or other switchable devices.

The unit plugs into the XSL514 Terminal Block and can be

inserted and removed without disturbing other units on the

bus. Terminals 1 through 18 are switched according to the

adjacent figure. Six LEDs are located on top of the module.

The module address is set using the rotary HEX switch.

Beginning with V2.04.00 Excel 500 controller firmware, the

online point attribute Normally Open / Normally Closed

(NO/NC) defines the relation between the physical state

(relay on/off) and its logical status. See Table 9.

NOTE: The digital outputs can be used as status contacts

or as alarm contacts, depending upon how they are

defined in CARE. All outputs from a single module

must be used for the same purpose.

Table 9. Physical state and logical status as defined by

the point attribute NO/NC for the XFL524B.

Relay

On/Off

NO/NC

attribute

Logical

Status

Output

Voltage

LED

Status

On NO 1 24V On

Off NO 0 0V Off

On NC 0 0V Off

Off NC 1 24V On

Open Loop Actuator

Object Type #3

Mandatory

Network

Variables

input

NV 1

nviRequest

SNVT_obj_request

nv1

nviValue

SNVT_switch

Optional

Network

Variables

input

NV 1

nviRequest

SNVT_obj_request

nv1

nvoDiagnose

SNVT_count

1

1

input

NV 1

nviRequest

SNVT_obj_request

nv3

nvoFeedback

SNVT_switch

input

NV 1

nviRequest

SNVT_obj_request

nv1

nvoManCnt

SNVT_count

User-Defined

Network

Variables

input

NV 1

nviRequest

SNVT_obj_request

nc1

UCPTSensorConfig

Optional

Configuration

Properties

This output NV appears only once for the node.

Figure 7. LONMARK Object for each digital output.

DISTRIBUTED I/O

EN0B-0090 12

Table 10. LONMARK Object NVs for the XFL524B.

NV Name Type Range Description

nviValue SNVT_switch Receives the value for the output channel.

nvoFeedback SNVT_switch Transmits the feedback value of the Actuator Object. If

the manual override switch is set to auto, or if the

manual override module is not plugged in, the

feedback output reflects the value of nviValue. As

soon as the manual override switch is set to either

manual position, the Actuator Object adopts this

manual value. In this case, the nvoFeedback state

field will be 0xFF (invalid) and the value field will

contain the actuator position.

If the manual override switch is in the automatic position, data is transmitted whenever nviValue is written.

If the manual override switch is in the manual position,

data is transmitted whenever the manual position is

changed.

nvoManCnt SNVT_count 0 to 65535 Transmits the number of manual switching operations.

Each transition from the state auto/manual on/manual

off to any other statue is counted by incrementing this

NV.

nvoDiagnose SNVT_count 0 to 65535 Counts the number of times the internal filter for

smoothing the signal from the manual override switch

board has been active.

UCPTSensorConfig 0 = not used

1 = binary (default)

Specifies whether an Actuator Object is processed or

not. If set to 0, the value is not updated.

DISTRIBUTED I/O

13 EN0B-0090

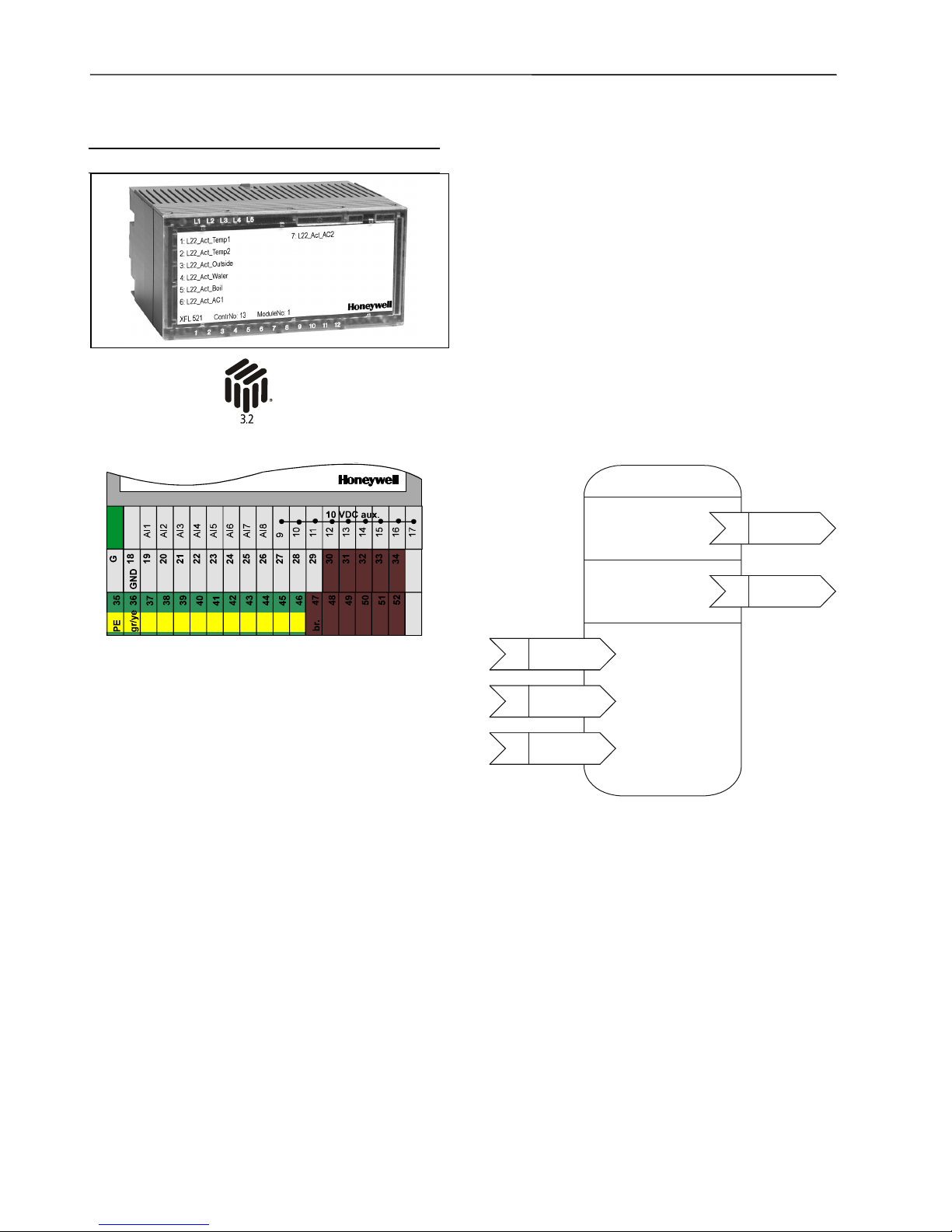

Terminal Block XSL513 for XFL521B/522B/523B

• Mechanical coding prevents mounting of improper

modules

• Mounts on a DIN-rail (top-hat rail)

• Spring-clamp terminals

• Safety latch secures XFL module in its position

The XSL513 Terminal Block has three rows of terminals:

Top row: 18 signal terminals (gray); function depending

upon the electronics module used (see the

respective Distributed I/O module descriptions).

Middle row: Twelve signal ground terminals (gray), con-

nected internally to electronics modules. Five

interconnected auxiliary terminals (brown)

Bottom row: Twelve PE terminals (green/yellow), connected

together to the DIN-rail. Six interconnected

auxiliary terminals (brown)

NOTE: Both rows of brown terminals are connected

internally but are not connected to the module.

Terminal Block XSL514 for XFL524B

• Mechanical coding prevents mounting of improper

modules

• Mounts on a DIN-rail (top-hat rail)

• Spring-clamp terminals

• Safety latch secures XFL module in its position

The XSL514 Terminal Block is intended for use only with the

XFL524B Digital Output module. It has three rows of

terminals.

Top row: 18 signal terminals (gray); function as

described for XFL524B.

Middle row: Eight interconnected auxiliary terminals

(brown), not connected to the module. Eight

interconnected auxiliary terminals (blue), not

connected to the module.

Bottom row: Seven PE terminals (green/yellow), connected

together to the DIN-rail.

DISTRIBUTED I/O

EN0B-0090 14

Manual Override Module XFR522A for XFL522B (Analog Output)

• Mounts on top of the XFL522B module

• Potentiometer settings

automatic or variable 0 – 100%

• XFL 522 LEDs remain visible

• Dimensions (WxLxH): 47x97x20 mm

• Feedback signal including point name, status (manual,

auto), and point value provided to CPU

The XFR522A manual override module mounts directly on

top of the XFL522B. Eight potentiometers on top of the

module can be used to independently vary the output of each

channel from 0 to 100%. Each potentiometer also has an

automatic setting which causes the channel to operate

normally. The LEDs of the XFL522B are also visible.

The manual override module works even if the CPU

XC5010C or XCL5010 is not working.

An optional label is available showing the functional

description generated by CARE.

Manual Override Module XFR524A for XFL524 (Digital Output)

• Mounts on top of the XFL524B module

• Switch settings:

automatic, off (0) and on (1)

• XFL524B LEDs remain visible

• Dimensions (WxLxH): 47x97x20 mm

• Feedback signal including point name, status (manual,

auto), and point value provided to CPU

The XFR524A manual override module mounts directly on

top of the XFL524B. Six switches on top of the module can

be used to independently switch each of the digital outputs

OFF (0) or ON (1). Each switch also has an automatic setting

which causes the channel to operate normally. The LEDs of

the XFL524B are also visible.

The manual override module works even if the CPU

XC5010C or XCL5010 is not working.

An optional label is available showing the functional description generated by CARE.

LONWORKS Connector Module XSL511

• LONWORKS network connection to CPU

• 24 Vac voltage supply for distribution to connected

modules

• Electronic fuse for 24 Vac

• Connection to Distributed I/O modules via sliding bus

connector (L

ONWORKS bus and voltage supply for ten

Distributed I/O modules)

• Bus data: speed: 78 Kbaud; length: depending on cable

type, e.g. 1,200 m, free topology 500 m, node-to-node 300

m

The XSL511 L

ONWORKS connector module provides ter-

minals for connecting to the L

ONWORKS bus wiring, as well as

terminals for the 24 Vac supply voltage for the other

modules. The part number for the L

ONWORKS bus termination

module is 209541B.

DISTRIBUTED I/O

15 EN0B-0090

Manual Terminal Disconnect Module XSL512

• Mounts between terminal blocks and Distributed I/O

modules

• Manual terminal disconnect switches

• 18 disconnect switches

• Dimensions (WxLxH): 58x97x55 mm

• Safety latch secures XFL module in its position

The XSL512 Manual Terminal Disconnect module allows

each of the input connections of the Terminal Block to be

manually disconnected from the plugged-in module. This is

particularly useful for troubleshooting and installation.

Terminal Block Connection

Figure 8. Dimensions of XSL511 LONWORKS connector

module in inches (mm).

NOTE: The terminal blocks are to be mounted on 1.5-inch

(35-mm) DIN-rails (DIN/EN 50 022 35x15). The

mounting panel should have a minimum thickness of

0.08 inch (2 mm) to provide reference potential for

proper grounding and shielding. The maximum

distance between the fastening points of the rail

should be 5.9 inches (150 mm).

The L

ONWORKS connector module is required as an interface

between the L

ONWORKS bus and the Distributed I/O modules.

See section "L

ONWORKS Connector Module XSL511" for

information on determining how many Distributed I/O

modules can be connected to each L

ONWORKS connector

module. The terminal blocks may be fitted alongside one

another.

IMPORTANT

The L

ONWORKS transceiver can be affected by

electromagnetic fields generated by frequency

converters. If possible, locate frequency converters

in a different cabinet, or allow a minimum distance of

18 inches (50 cm) between frequency converters

and their respective cabling, and Distributed I/0

Modules.

Terminal blocks XSL513 and XSL514 can be combined in

any order on the rail.

1. Mount the DIN-rail at the desired location (vertically or

horizontally).

NOTE: It is recommended that when mounting vertically,

the XSL511 L

ONWORKS connector module be

mounted at the bottom to insure a good connection

of the bus in case any slippage occurs on the DINrail.

2. Install the 3

rd

-party DIN-rail end bracket onto the left end

of the rail.

3. Install the connector module onto the left end of the rail

next to the end bracket by first hooking the terminal end of

the module onto the rail and snapping it into place.

4. Install the first terminal block onto the rail.

NOTE: To avoid damage, ensure that the sliding bus con-

nector does not extend past the left edge of the

module.

DISTRIBUTED I/O

EN0B-0090 16

Figure 9. Terminal blocks with LONWORKS connector.

5. Push the sliding bus connector to the left until it locks onto

the matching circuit board section on the adjacent connector module (see Figure 10).

6. Lock in all other modules and connect them using the

sliding bus connector. Slide each sliding bus connector as

far to the left as possible.

NOTE: The electronics module or the manual terminal dis-

connect module will not fit properly on the terminal

block if the sliding bus connector is not on the left

side.

7. Fit the end cover included with the XSL511 onto the last

module.

8. Install 3

rd

-party DIN-rail end bracket close to end cover of

the last module.

NOTE: It is recommended to use solid standard 3

rd

-party

DIN-rail end brackets on both ends of the terminal

block to prevent any movement of the terminal

blocks. Terminal blocks must abut each other to

insure proper contact at the sliding bus connector.

1

2

3

4

5

6

Connector Module

XSL 511

Honeywell AG

Made in Germany

123

LON

shield shield

LON4

5

6

DIN RAIL

END BRACKET

DIN RAIL

END BRACKET

Figure 10. Sliding bus connector connects adjacent modules.

9. Insert clamps provided with electronics modules into slots

as shown in Figure 11 to provide extra assurance that

adjacent terminal blocks will not become separated.

NOTE: If the manual disconnector XSL512 is installed per-

manently in all terminal blocks, the clamps are to be

inserted into the respective XSL512 slots.

DISTRIBUTED I/O

17 EN0B-0090

Figure 11. Clamps hold adjacent terminal blocks

together.

DISTRIBUTED I/O

EN0B-0090 18

Coding the Terminal Block

Figure 12. Coding comb patterns.

The terminal block is coded with pins to prevent mixing the

module types during commissioning or servicing.

CAUTION

Mixing the modules can destroy them.

Coding the terminal block is achieved by inserting pins into

designated location holes on the terminal block in the base.

This codes the electronics modules to their respective

terminal blocks.

1. Break off the coding pins on the coding comb such that

the comb is left with the coding combinations shown in

Figure 12.

2. The comb side corresponding to the respective terminal

block is inserted into the location holes in the terminal

block and broken off (positions 1 to 9 are printed on the

circuit board of the terminal block for alignment).

Figure 13. Inserting coding comb into terminal block.

3. Next, the other side of the comb is inserted into the elec-

tronics module location holes and likewise broken off. If

one or more opposing location holes both contain pins,

then the module cannot be mounted onto the terminal

block. The module can be mounted only if the single

coding pin corresponds to the missing pin in the terminal

block.

Figure 14. Inserting coding comb into I/O module.

DISTRIBUTED I/O

19 EN0B-0090

Setting the Module Address

All modules will report the setting of the 16-position rotary

HEX switch as a 2-byte ASCII number in the lowest 2 bytes

of the Neuron® chip’s location string. Changing the rotary

HEX switch setting causes the module to reset its application

configuration (sensor selection, output selection, motor

runtime, etc.) and go unconfigured. Modules will run their

application in the unconfigured state so that another change

of the DIP switch will be recognized.

To remove the cover or a manual override module from the

Distributed I/O module, do the following:

1. Insert the opening tool XAL2 into the corresponding slots

in the electronics module to release the locking tabs. The

tool should be inserted such that the marking is on the

right-hand side.

Figure 15. Inserting opening tool.

2. Lift off the cover as is depicted in Figure 16.

Figure 16. Lifting the cover off.

IMPORTANT

Always use the XAL2 tool to remove the cover or a

manual override module from an output module. Lift

off manual override modules carefully to avoid

tearing the attached flat strip cable.

Figure 17. Rotary HEX switch location.

3. The module address is set by turning the HEX switch to

the appropriate address code using a screwdriver.

CAUTION

Do not plug an XFL module without a cover or manual

override module into the terminal block.

Installing the I/O Modules

locking procedure locked latch

Figure 18. Safety latch type A

locking procedure locked latch

Figure 19. Safety latch type B

The electronic I/O modules can be installed either on top of

the terminal blocks or on top of the manual terminal disconnect modules.

1. Make sure the sliding bus connector on the terminal block

is on the left side.

2. Mount the module onto the terminal block (or the manual

terminal disconnect module if installed) and make sure the

spring clip snaps on the little hook on the module housing.

3. Lock the safety latch on the terminal block (type A) (and

the manual terminal disconnect module, if installed; for the

safety latch on the manual disconnect module (type B) it is

recommended to use a screwdriver or similar for locking)

as is shown in the figure.

Installing the Manual Override Modules

XFR522A and XFR524A

The manual override modules are installed on top of their

respective output modules. The XFR522A and XFR524A are

connected to the output modules via flat strip cable; this

allows opening the housing and setting the rotary HEX switch

under power without disconnecting the manual override

module.

The manual override modules are installed using the

following procedure:

DISTRIBUTED I/O

EN0B-0090 20

1. Switch off the power to the output module or, unlock the

safety latch and unplug the module from the terminal block

as described in “Removing Modules and Terminal Blocks”.

2. Remove the standard cover of the module housing

(XFL522A/XFL524A) as is described in "Setting the

Module Address".

3. Plug the manual override connector situated at the end of

the flat strip cable into the socket in the output module.

NOTE: By mechanical design, the plug can be inserted in

only one orientation, thus preventing wrong connection.

Figure 20. Manual override connector socket location.

1. Slightly push back the locking tabs with the XAL2 tool to

bring them behind the edge of the module housing.

Figure 21. Pushing back locking tabs.

2. Snap the override module onto the electronics module

housing such that the power, L

ONWORKS service, and out-

put LEDs in the electronics module are aligned with their

respective view windows on the manual override face

plate. Make sure that all tabs of the manual override

module are snapped into the slots of the output module.

Figure 22. Snap override module into place.

IMPORTANT

Avoid tearing on the flat strip cable if you need to

remove a manual override module. Always use a

cover release tool XAL2 to remove the manual

override module and disconnect the plug carefully

(see also "Setting the Module Address"

3. Remount the module as is described in the previous

section.

Installing the Manu al Terminal Disconnect

Module XSL512

Figure 23. Installing the manual terminal disconnect

module.

The manual terminal disconnect module is installed between

the terminal block and the electronics module. If the right

side of the XSL512 is accessible (no other modules are

mounted to the right), then the end cover provided with the

XSL512 must be used.

1. Remove the electronics module as described in

"Removing Modules and Terminal Blocks"

2. Mount the XSL512 module onto the terminal block with the

switches on the terminal side of the terminal block as

depicted and lock the safety latch as described previously.

3. Mount the electronics module onto the top of the XSL512

and lock the safety latch as described in "Installing the I/O

Modules".

The individual inputs to the electronics module can now be

connected and disconnected manually.

DISTRIBUTED I/O

21 EN0B-0090

Applying CARE Printout Labels

Figure 24. XAL1 swivel label holder.

Normally, CARE labels can be used on electronics modules.

When using electronics modules with manual override units,

CARE labels cannot be applied to the face of the manual

override unit. In this case, the XAL1 swivel label holder is required (package of 10). The XAL1 swivel label holder is

mounted to the terminal block as shown in Figure 24.

Removing Modules and Terminal Blocks

The electronics modules and terminal blocks can be removed

by carrying out the following steps:

1. Unlock the safety latch(es) as is depicted in Figure 25.

on terminal blocks on XSL512

Figure 25. Unlocking the safety latches.

2. Remove the electronics module from the terminal block (or

manual terminal disconnect module) by pushing a screwdriver between the electronics module and the spring clip

on the terminal block (or manual terminal disconnect

module).

Figure 26. Unlocking the module spring clip.

3. Unlock the spring clip by lightly bending upwards with the

screwdriver.

4. Unplug the electronics module.

5. When installed, dismount the manual terminal disconnect

module as is described for the electronics module.

6. Disconnect the power to the connector module before

removing the terminal block.

Figure 27. Releasing the sliding bus link.

7. Now release the sliding bus link with a screwdriver and

push the sliding bus link to the right into its terminal block.

Make sure that it is drawn back completely!

NOTE: Do not dismount the terminal block until both sliding

bus links are drawn back completely.

8. The sliding bus link of the terminal block to the right (if one

exists) can be released without removing the electronics

module by pushing a screwdriver into one of the notches

of the sliding bus link and sliding it backwards into its

home position (terminal block) with small sideways movements.

Figure 28. Removing the terminal block.

9. Lift the terminal block from the rail by inserting a screw-

driver tip into the two mounting feet - one after the other and lifting up the terminal block with small levering movements.

LONWORKS Network Interface

Distributed I/O modules contain an FTT-10A Free Topology

Twisted Pair Transceiver allowing communication with other

devices on a L

ONWORKS network. FTT-10A transceivers

communicate at 78 Kbaud and provide transformer isolation

so that the bus wiring does not have a polarity; that is, it is

not important which of the two bus terminals are connected

to each wire of the twisted pair.

FTT devices can be wired in daisy chain, star, loop or any

combination thereof as long as the maximum wire length requirements given below are met. The recommended configuration is a daisy chain with two bus terminations. This

layout allows for maximum bus length, and its simple structure presents the least number of possible problems, particularly when adding on to an existing bus.

NOTE: A doubly-terminated bus may have stubs of up to

10 ft (3 m) from the bus to each node.

DISTRIBUTED I/O

EN0B-0090 22

Table 11. Doubly-terminated bus specifications.

Cable Type Max. bus length

Belden 85102 8,900 ft (2,700m)

Belden 8471 8,900 ft (2,700m)

Level IV, 22 AWG 4,600 ft (1,400m)

JY (St) Y 2x2x0.8 3,000 ft (900m)

TIA568A Categ. 5 24AWG, twisted pair 3,000 ft (900m)

NOTE: The cable types listed above are as recommended

by Echelon® in their FTT-10A User Guide. The

cable recommended by Honeywell is the level IV, 22

AWG, solid core, nonshielded cable. Belden part

numbers are 9H2201504 (plenum) and 9D220150

(non-plenum).

TERMINATION

MODULE

DEVICE

DEVICE DEVICE DEVICE

DEVICE

TERMINATION

MODULE

Figure 29. Doubly-terminated bus configuration

(recommended).

Free topology requires only one bus termination and allows a

variety of bus configurations (see Figure 30):

TERMINATION

MODULE

DEVICE

DEVICE DEVICE DEVICE

DEVICE

DEVICE

SINGLY TERMINATED

DEVICE

DEVICE

TERMINATION

MODULE

DEVICE

DEVICE

STAR

Figure 30. Possible bus configurations

DEVICE

DEVICE

DEVICE

DEVICE

DEVICE

DEVICE

DEVICE

TERMINATION

MODULE

DEVICE

DEVICE

DEVICE

MIXED

TERMINATION

MODULE

DEVICE

DEVICEDEVICE

DEVICEDEVICE

LOOP

Figure 31. Free topology examples.

The FTT specification includes two components that must be

met for proper system operation. The distance from each

transceiver to all other transceivers and to the termination

must not exceed the maximum node-to-node distance. If

multiple paths exist, the maximum total wire length is the total

amount of wire used.

Table 12. Free topology (singly-terminated)

specifications.

Cable type Maximum node-

to-node distance

Maximum total

wire length

Belden 85102 1,650 ft (500m) 1,650 ft (500m)

Belden 8471 1,300 ft (400m) 1,650 ft (500m)

Level IV, 22AWG 1,300 ft (400m) 1,650 ft (500m)

JY (St) Y 2x2x0.8 1,050 ft (320m) 1,650 ft (500m)

TIA568A Category 5

24AWG, twisted pair

825 ft (250m) 1,500 ft (450m)

IMPORTANT

Do not use different wire types or gauges on the

same L

ONWORKS network segment. The step

change in line impedance characteristics would

cause unpredictable reflections on the bus.

DISTRIBUTED I/O

23 EN0B-0090

Examples of free topology schemes (1 allowed, 2 not

allowed) for cable JY (St) Y 2x2x0.8 are shown below.

Device

Device

Device

CPU

Termination

module

ALLOWED

Node-to-node = 656 ft (200m)

Total wire length = 328 ft (400m)

NOT ALLOWED

Node-to-node = 1287 ft (400m)

Total wire length = 1640 ft (500m)

Device

656 ft

(200m)

656 ft

(200m)

Device

Device

Termination

module

328 ft

(100m)

328 ft

(100m)

328 ft (100m)

328 ft (100m)

328 ft (100m)

Figure 32. Free topology examples (max. node-to-node

320 m, max. wire length 500m)

NOT ALLOWED

Node-to-node = 656 ft (200m)

Total wire len

g

th = 1969 ft (600m

)

Termination

module

328 ft

(100m)

328 ft

(100m)

Device Device

Device

Device

Device

656 ft

(200m)

Figure 33. Additional free topology example (max. node-

to-node: 320 m, max. wire length: 500 m)

NOTE: In the event that the limit on the total wire length is

exceeded, then FTT physical layer repeaters

(FTT 10A) can be added to interconnect segments

and increase the overall length by an amount equal

to the original specification for that cable type and

bus type for each repeater used. For example,

adding repeaters for a doubly-terminated bus using

JY (St) Y 2x2x0.8 cable increases the maximum

length 3000 ft (900m) for each repeater.

LONWORKS Bus Termination

One or two Termination Modules, part no. 209541B, are required for a L

ONWORKS bus with FTT devices on it, de-

pending upon the configuration. The maximum lengths described in "L

ONWORKS Network Interface" must be adhered to

for either a daisy chain or free topology L

ONWORKS bus

layout. See Figure 34 and Figure 35 for connection details for

the 2095401B Termination Module.

Figure 34. Termination Module connections for doubly-

terminated FTT network.

Figure 35. Termination Module connections for a singly-

terminated FTT network.

DISTRIBUTED I/O

EN0B-0090 24

Commissioning Distributed I/O Modules

Previous to V2.04.x controller firmware, Distributed I/O

modules were used only on a local L

ONWORKS bus con-

nected to a single Excel 500 controller. Concurrent with the

release of V2.04.x firmware is the release of the XFL52xB

Distributed I/O modules with updated firmware and with a

new Neuron chip which make them fully L

ONMARK compliant.

This means that multiple Excel 500 controllers, each with its

own Distributed I/O modules, as well as third-party L

ONMARK

compliant devices, can coexist and interoperate on the same

L

ONWORKS bus. Furthermore, the XFL52xB modules can be

used as third-party devices with other L

ONMARK compliant

products, independently of an Excel 500 controller.

IMPORTANT:

Full L

ONMARK functionality requires an Excel 500

controller with V2.04.x firmware, a 3120E5 Neuron

chip, and Distributed I/O modules XFL52xB.

An Excel 500 controller with V2.4.x firmware and

3120E5 Neuron chip will commission earlier versions of Distributed I/O modules (XFL52x,

XFL52xA), but only in the local mode (max 16

modules per CPU and no other controllers on the

L

ONWORKS bus).

Distributed I/O modules XFL52xB can be used with

older versions of Excel 500 that support Distributed

I/O, but only if the modules are switched into a

different mode. This is accomplished by pressing the

service pin while simultaneously turning the HEX

address switch. This mode can be cancelled by

pressing the service pin for more than three

seconds.

Table 13. Controller compatibility.

Operating mode

2

of

Distributed I/O modules

Controller type CPU / Application modules Controller

firmware

Open LONWORKS

functionality?

XFL52x XFL52xB

Excel 500 XC5010C / XCL5010 V2.0.x to V2.3.x not possible local local

Excel 500 XC5010C / XCL5010 V2.4.x not possible local local/shared

Excel 500 XC5010C1 / XCL50101 / XC5210C1V2.0.x to V2.3.x not possible local local

Excel 500 XC5010C1 / XCL50101 / XC5210C1V2.4.x in use --- shared/open

Excel 500 XC5010C1 / XCL50101 / XC5210C1V2.4.x not in use local local/shared

1

When bearing the LONMARK™ logo on the module/CPU.

2

The term "local" refers to an operating mode in which a maximum of 16 modules are assigned (automatically) to each controller and only a single controller is connected to each L

ONWORKS bus.

The term "shared" means that a maximum of 16 modules are assigned (manually) to each controller, but that multiple controllers can be connected to a single L

ONWORKS bus.

The term "open" refers to an open L

ONWORKS system, i.e. the use of CARE to generate a LONMARK compliant network

interface file (XIF) capable of providing NVs which can be bound to other devices (Excel 50 or Excel 10 controllers, thirdparty devices); further, the limitation of max. 16 modules per controller can also be exceeded.

Table 14. Distributed I/O module compatibility.

L

ONWORKS Functionality, by Controller Firmware VersionDistributed I/O modules

V2.0.x to V2.3.x V2.4.x

XFL521

XFL522A

XFL523

XFL524A

One controller to which Distributed I/O modules

are assigned on a single L

ONWORKS bus

One controller to which Distributed I/O modules

are assigned on a single LONWORKS bus

XFL521B

XFL522B

XFL523B

XFL524B

One controller to which Distributed I/O modules

are assigned on a single L

ONWORKS bus (press

the L

ONWORKS service pin while turning HEX

switch to enable this backwards-compatible

mode)

1

Full LONWORKS functionality: Multiple

Distributed I/O modules and multiple controllers

possible on a single L

ONWORKS bus

2

1

To cancel the backwards-compatible mode for Distributed I/O modules (allowing full LONWORKS functionality), press and hold

down the L

ONWORKS service pin for at least 3 seconds.

2

Excel 500 controller with Neuron 3120E5 chip required!

NOTE: Compatibility of XFR522A and XFR524A Manual Override modules is affected by neither firmware nor Neuron chip

version.

DISTRIBUTED I/O

25 EN0B-0090

Operating Modes

It is important to remember the following definitions:

Local

The term "local" refers to an operating mode in which a max.

of 16 Distributed I/O modules are connected to a single host

Excel 50/500 controller via a L

ONWORKS bus, and in which no

other devices co-exist on that bus. In this mode, the Distributed I/O modules are assigned to their host Excel 50/500

controller automatically, and autobinding is performed.

Shared

The term "shared" means that, aside from the host Excel 500

controller and its Distributed I/O modules, other devices

(which may include other Excel 500 controllers with their own

Distributed I/O modules, Excel 50 or Excel 10 controllers, or

3

rd

-party devices) co-exist on the LONWORKS bus. In the

shared mode, autobinding may still be used for the NVs of a

maximum of 16 Distributed I/O modules assigned (manually)

exclusively to the host Excel 500 controller.

NOTE: It is recommended that you use CARE to assign the

Distributed I/O modules to the host Excel 500 controller (i.e. to enter the Distributed I/O modules'

Neuron IDs). The alternative is to assign them using

the MMI.

Open

The term "open" refers to an interoperable LONWORKS sys-

tem in which CARE has been used to generate a L

ONMARK

compliant network interface file capable of providing NVs

which can be bound to other devices (which may include

other Excel 500 controllers with their own Distributed I/O

modules, Excel 50 or Excel 10 controllers, or third-party

devices). In the open operating mode, the NVs of the Distributed I/O modules exceeding 16 must be bound manually

using a L

ONWORKS network management tool (an LNS-based

tool capable of using Honeywell plug-ins is recommended).

Combined Shared and Open Mode

The shared and the open operating modes can be in effect

simultaneously. In this case, autobinding is performed for the

NVs of a maximum of 16 Distributed I/O modules, while the

data points of additional Distributed I/O modules must be

mapped with shared NVs, and the NVs of the additional Distributed I/O modules must be bound manually (e.g. using an

LNS-based tool).

Autobinding

When Distributed I/O modules are used exclusively by

Honeywell Excel 500 controllers, it is possible to automatically bind their NVs to the controller. This is referred to

as "autobinding." In autobinding, each controller on the bus

finds the Distributed I/O modules assigned to it and binds the

required NVs.

IMPORTANT:

Autobinding does not work across routers. Distributed I/O modules must be located within the

same router segment as the controller to which their

NVs are to be bound. However, autobinding is

possible across repeaters.

IMPORTANT:

The autobound NVs of a controller are not visible to

a L

ONWORKS network management tool, and there is

hence no danger that a careless user will attempt to

re-bind them. However, the NVs of the Distributed

I/O modules are visible to a L

ONWORKS network

management tool. Any attempt to re-bind the autobound NVs of Distributed I/O modules will corrupt

the autobindings. In such a case, the Excel 500 controller will restore the autobindings automatically, but

there will be numerous system and application

alarms as a result.

If, prior to autobinding, the Distributed I/O modules

have been accessed by a L

ONWORKS network

management tool, the modules will remain in the

“configured” mode. In this state, they cannot be

found by the controller during autobinding, and they

do not appear in the list of modules on the controller

MMI. Such modules must be decommissioned using

the L

ONWORKS network management tool, or the

L

ONWORKS service pin must be pressed for at least

three seconds.

If an Excel 500 controller in the shared/open mode is deleted

from the LonMaker project, all of its bindings will also be

deleted. In this case, the Excel 500 controller will restore all

of the autobindings (if any) automatically after 3 minutes

(provided no bindings are performed or changed in LonMaker

in the meantime), but there will be numerous system and

application alarms as a result.

Assignment

There are two methods of assigning Distributed I/O modules

to a particular Excel 500 controller.

Recommended assignment method

The Ideal approach is to know the Neuron IDs of the Distributed I/O modules when engineering the application using

CARE, thus enabling you to enter the Neuron ID during the

CARE terminal assignment. When this is done, every module

will be fully identified and assigned automatically by the Excel

500 controller after the application is downloaded.

Alternate assignment method

If the Neuron ID is not available when engineering the

application using CARE, it will be possible to correctly assign

the Distributed I/O modules to their controller(s) only after

having downloaded the application. In this case, assignment

is performed via the MMI as described in detail in the

XI581/XI582 User Guide, EN2B-0126.

IMPORTANT:

It is essential that Distributed I/O modules not be

assigned simultaneously via different MMIs. When

using the alternative assignment method, work on

only one MMI at a time so as to avoid competing

network accesses. Disregarding this will result in

contradictory and unreliable assignments. There will

be incomplete Distributed I/O module lists displayed,

and there is the danger that one controller will take

away an existent assignment from another

controller.

DISTRIBUTED I/O

EN0B-0090 26

Regardless of which of these two methods is employed,

assignment requires that the modules' rotary HEX switches

be set according to the CARE terminal assignment.

Priority of Distributed I/O Module Assignments

Assignments made via an MMI always have priority over

assignments made using CARE. Thus, in the event of a conflict (e.g. when the Neuron ID entered using CARE differs

from the Neuron ID entered via the MMI), the assignment

carried out using the MMI will have priority.

Flashing of Distributed I/O Module Assignment

The Distributed I/O module assignment that was made in

CARE or via the controller MMI has to be saved to Flash

memory manually. When Distributed I/O module assignment

has been made during the test mode, the assignments are

saved in Flash memory automatically. These assignments

can be reused for the application after the application has

been downloaded.

Controller Reset

IMPORTANT:

Resetting a controller will erase the Distributed I/O

module assignment. After a reset, one of the

following procedures must be performed.

— Restore the application (including the assignments) from

Flash (this is the simplest method).

— Restore the assignments during the "start-up" sequence

(this requires somewhat more effort).

— Download the application and re-assign the Distributed

I/O modules (this method requires the most effort).

Manual Binding

There are several cases in which it is necessary to manually

bind the NVs of the Distributed I/O modules to their

respective controller(s). This is done using a L

ONWORKS

network management tool (e.g. LonMaker).

More than 16 modules per Excel 50/500

Autobinding can be used to bind the NVs of a maximum of 16

Distributed I/O modules per controller, only. If the application

requires more than 16 Distributed I/O modules per controller,

you must use CARE to allocate those additional NVs

requiring mapping with data points, and you will also have to

use a L

ONWORKS network management tool to bind the NVs

of the additional modules to the controller.

Binding of NVs of other devices to Distributed I/O modules

(Using XFL52xB Modules as 3

rd

-Party Devices)

When the NVs of other devices on the LONWORKS bus (other

than the host Excel 50/500 controller) require binding to

Distributed I/O modules, autobinding cannot be used. A

L

ONWORKS network management tool (e.g. LonMaker) is

required to (manually) bind all of the Distributed I/O modules'

NVs.

Double-mapping a data point

It is possible to preserve the autobinding by mapping the

data point with a second NV. However, the second NV must

then be bound (using a L

ONWORKS network management

tool) to another L

ONWORKS device. While this method

preserves autobinding, it does require one controller NV

more than if all binding is performed using a L

ONWORKS

network management tool (e.g. LonMaker).

Troubleshooting (Autobinding, only)

Wiring Check

Beginning with controller firmware V2.04.x, Distributed I/O

modules can be checked out without even having an

application loaded in the controller using a special test mode

previously active only for internal I/O modules. This test

mode, accessible through the “Data Point Wiring Check”

option on the second screen of the Start-up sequence, allows

manually setting outputs and reading inputs to verify the I/O

wiring. The procedure is described in detail in the XI581/582

User Guide, EN2B-0126.

Figure 36. Distributed I/O module faceplate and LEDs.

Each Distributed I/O module has a green Power ON LED (L1)

and a red L

ONWORKS service LED (L2) at the upper left of the

faceplate. The L

ONWORKS service LED (L2) is used for

diagnosing the state of the Distributed I/O module (see

below).

Figure 37. Distributed I/O module troubleshooting

example.

If you have more than one module connected to one XSL511,

you should check the modules to the left and to the right of

the defect module (status of green power LED L1 and red

L

ONWORKS status LED L2). A module is "working" in Table 15

if L1 illuminates green and if the L

ONWORKS communication

is working.

DISTRIBUTED I/O

27 EN0B-0090

Table 15. Troubleshooting of Distributed I/O modules.

Modules to the left side

working

Modules to the right

side working

Possible Causes

no no

• Power OFF

• CPU not working

• Incorrect wiring

• Sliding bus connector on XSL511 not closed properly

• Defective hardware → contact your Honeywell dealer

yes no

• Sliding bus connector on the left side not closed properly

• Defective hardware → contact your Honeywell dealer

yes yes

• Wrong LONWORKS address (HEX switch setting)

• Defective hardware → contact your Honeywell dealer

In case of problems, check if the behavior is changed if you:

1. Push the LONWORKS service button to reconfigure the

Distributed I/O module. The L

ONWORKS service LED will

light as long as you push the L

ONWORKS service button.

The hardware is defective if this is not the case.

2. Switch the power ON / OFF.

3. Set the HEX switch to an unused address for a few

seconds and select the correct address afterwards. This

procedure will cause a reset of the Distributed I/O module.

Please contact Honeywell if the above actions do not solve

the problem.

Service Pin and LED

A service pin message is sent when

— powering-up or resetting,

— transitioning to the configured/online state, or

— turning the DIP switch.

In the case of a power-up or reset, the service pin message

is delayed a random time between 1 and 5 seconds to avoid

an overload of a network management node receiving these

messages when a large number of Distributed I/O modules

are powered up simultaneously.

The service LED indicates the status of the Neuron® chip.

Normally, the LED will blink a few times during the powerup/reset phase and then remain off. During normal commissioning, the LED will stay on briefly and then flash briefly

before remaining off. The time required for commissioning is

variable, lasting from approximately 10 to 60 seconds, depending upon the amount of network information being downloaded from the installation tool and the installation tool itself.

For additional information on LED behavior, see Table 16

and Figure 38.

LONWORKS Service LED L2

This LED is used to diagnose the state of the Distributed I/O

module. In general:

• The module is applicationless if the LED illuminates con-

tinuously.*

• The module has an application but it is not configured if

the LED is blinking.

• The module is running normally if L2 is off.

*Pushing the L

ONWORKS service button will force a new

commissioning of the module. While commissioning, LED L2

continuously illuminates red for less than 1 minute and then

returns to the normal state (L2 = OFF).

A more detailed diagnosis can be carried out by observing

the duration of the ON and OFF states of the service LED in

connection with power ON / OFF. Figure 38 illustrates the

different service LED behaviors. These are the most common

behaviors, but others are possible since the state of the

service LED is under firmware control and can be affected

both by hardware and software anomalies.

IMPORTANT

In Table 16, the words ”configured”, “unconfigured”,

“application”, and “applicationless” refer only to the

communication layer running on the Neuron® chip and not to

the controller application.

1 sec

1

2

3

4

5

6

7

S

ervice L

E

D Behavior

2 sec 3 sec 4 sec 5 sec

Time

(at 10 MHz,

approx.)

Power

applied

to node

Continuous

* Does not scale with the Neuron chip.

Continuous

Continuous

Continuous

Repeated

Repeated*

see table

= ON = OFF

see table

Figure 38. Service LED behavior.

DISTRIBUTED I/O

EN0B-0090 28

Table 16. Service LED behavior descriptions.

Behavior Context Likely Explanation

1 Power-up of the node Bad node hardware. For Distributed I/O modules, perform the tests shown in

the previous section.

2 Power-up of the node Bad node hardware. For Distributed I/O modules, perform the tests shown in

the previous section.

3 Power-up / Reset of the node The module is applicationless. May be caused by the Neuron chip firmware

when a mismatch occurs on application checksums. This behavior is normal if

the application was exported to come up applicationless.

4 Anytime Possible corrupt EEPROM. For a Neuron 3150 Chip-based node, use a newly

programmed PROM, or EEBLANK and follow bring-up procedure.

5 Anytime The module is unconfigured.

Connect the Distributed I/O module to the CPU. The CPU will configure the

Distributed I/O module.

6 First power-up, Applicationless

firmware state exported

The OFF duration is approximately 1 second. Service LED should then turn

ON and stay on indicating an applicationless state.

6 First power-up, Unconfigured

firmware state exported

The OFF duration is 1-15 seconds depending on the application size and

system clock. Service LED should then begin flashing as in behavior 5,

indicating an unconfigured state.

Connect the Distributed I/O module to the CPU. The CPU will configure the

Distributed I/O module.

6 First power-up, Configured

firmware state exported

The OFF duration is indefinite (1-15 seconds to load internal EEPROM; stays

OFF indicating configured state.) The module is configured and running

normally.

7 Anytime The module is configured and running normally.

DISTRIBUTED I/O

29 EN0B-0090

Accessories, Standards, Rating s, and Literature

Accessories:

— XAL 1 Swivel Label (required for Manual Override

Modules).

— 209541B Termination Module (one or two required,

depending on L

ONWORKS bus layout; see Excel 500

Installation Instructions, EN1R-1047 for details).

— XAL 2 Cover Release Tool (required for opening the

module housing to set the module address using the

rotary HEX switch).

Approvals and Standards:

• CE and EN 50082-1

Environmental Ratings:

• Operating temperature: 32° to 122°F (0° to 50°C)

• Shipping/storage temperature: -13° to 150°F (-25° to

65°C)

• Relative humidity (operation and storage): 5% to 90%,

non-condensing

Applicable Literature:

• EN0B-091 Excel 100/500/600 System Overview

• EN1R-1047 Excel 500/600 Installation Instructions

• EN0B-270 Excel 50/500 LONWORKS Mechanisms

Figure 39. Terminal block XSL513/514 (top view) Figure 40. Terminal block XSL513/514 (side view)

DISTRIBUTED I/O

Home and Building Control Home and Building Control Home and Building Control Products

Honeywell Inc. Honeywell Limited-Honeywell Limitee Honeywell AG

Honeywell Plaza 155 Gordon Baker Road Böblinger Straβe 17 Manufacturing

P.O. Box 524 North York, Ontario D-71101 Schönaich location certif i ed t o

Minneapolis, MN 55408-0524 M2H 3N7 Germany

USA Canada http://europe.hbc.honeywell.com

EN0B-0090GE51 R1200 printed in Germany Subject to change without notic e

ELECTRONIC MODULE

XFL 521, 522,

523, 524

XSL512

X

FR522,

XFR524

4-41/64

(118)

5-43/64 (144)

WITH MANUAL DISC ONNECT MODULE

6-27/64 (163)

WITH MANUAL DISCONNECT MODULE

AND OVERRIDE MODULE

XSL511

1

1

Figure 41. Outside dimensions of XSL513/514 terminal blocks and mounted modules in inches (mm) (side view).

Maximum length is with XSL511 LON Connector

module attached.

Loading...

Loading...