Page 1

Excel Smart I/O

XFC1Axx, XFC1Dxx, XFC2Axx,

XFC2Dxx, XFC3Axx, AND XFC3Dxx MODULES

PRODUCT DATA

FEATURES

• LONMARK™ association-compliant, thus suitable for all

open L

ONWORKS

• Flexible, software-configurable inputs/outputs

• Flash memory for downloading applications (thus

increasing flexibility and facilitating future upgrading)

• 2-wire FTT-10A L

• Easily-accessible service button and a service LED

• Four fast digital inputs configurable for static input or

totalizing (at up to 20 Hz)

• Four relays to which (after software-configuration) e.g.

floating actuators can be directly connected

• Two or (model-dependent) four universal inputs, each

with extra terminal for powering 24 Vac sensors, supporting (model-dependent) different sensor types, also

configurable for voltage-variable or slow digital input

• Two analog outputs, each with extra terminal for

powering 24 Vac actuators, supporting (modeldependent) voltage-variable or current-variable output

• Greater reliability, fewer cables (thus reducing fire

burden), lower installation costs, easy start-up and

servicing, digital communication

• DIN rail (wiring cabinet / fuse box) mounting and wall-

mounting supported

• Easy wiring check using the XILON Handheld MMI

• Fixed or removable terminals (model-dependent)

• 24 Vac, 110 Vac, or 230 Vac power supply (model-

dependent)

• Optional six three-position, software-configurable

manual overrides and corresponding feedback

• Optional terminal protection covers for wall mounting

• Optional swivel label holders for wiring information

®

networks

ONWORKS

®

bus interface

GENERAL

Excel Smart I/O modules are LONMARK association-compliant

devices, and can thus be used in all open L

ments. They feature a variety of software-configurable digital

and analog inputs and outputs and are suitable for installation

at strategic locations throughout your buildings. The modules

convert physical input signals from sensors into network

variables and the network variables into physical output

signals for operating actuators.

The diverse mix of inputs and outputs (flexibly configurable

using Honeywell's LonMaker for Windows™ plug-in) makes

the Excel Smart I/O ideally suited for a wide range of

intelligent, distributed applications.

Table 1 provides a brief overview of the available versions.

See Table 4 on page 10 for details.

® U.S. Registered Trademark

Copyright © 2008 Honeywell Inc. • All Rights Reserved EN0B-0311GE51 R0708

ONWORKS environ-

Table 1. Brief Overview of Excel Smart I/O Versions

Version

XFC1A06001 110 Vac no 4 4 2 4

XFC1D06001 110 Vac yes 4 4 2 4

XFC2A05001 230 Vac no 2 4 2 4

XFC2A06001 230 Vac no 4 4 2 4

XFC3A04001 24 Vac no 4 4 2 4

XFC3A05001 24 Vac no 2 4 2 4

XFC3A06001 24 Vac no 4 4 2 4

XFC2D05001 230 Vac yes 2 4 2 4

XFC2D06001 230 Vac yes 4 4 2 4

XFC3D04001 24 Vac yes 4 4 2 4

XFC3D05001 24 Vac yes 2 4 2 4

XFC3D06001 24 Vac yes 4 4 2 4

power overrides UIs DIs AOs relays

Description

Page 2

EXCEL SMART I/O MODULES

DESCRIPTION

With the Excel Smart I/O, you can choose from among ten

variants featuring different assortments of universal inputs,

digital inputs, analog outputs, and relays for use in conjunction with a wide range of sensor types and actuators. All

module inputs and outputs are protected against overvoltages

of max. 40 Vdc and 24 Vac. An extra power output terminal

accompanying each analog input/output can also be used to

power 24 Vac field devices.

Further, the individual inputs and outputs can be flexibly configured using Honeywell's LonMaker for Windows software

plug-in. Thus, each of the four fast digital inputs can be configured for static input from dry contacts or open collectors or

for totalizing signals having a frequency of up to 20 Hz, while

the universal inputs can be configured for analog signals from

specific sensor types (model-dependent), or for voltagevariable input, or for slow digital input (max. frequency =

0.25 Hz).

The XFC1D06, XFC2D05 and XFC2D06 as well as the

XFC3D04, XFC3D05, and XFC3D06 are equipped with six 3position manual override switches. Using Honeywell's software plug-in, these switches can be configured to override the

individual relays or analog outputs. These modules also

feature ten status LEDs showing the condition of the inputs /

outputs allocated to them.

The XFC2A05, XFC2A06, XFC2D05, and XFC2D06 (long

housing) are equipped with a transformer enabling them to be

powered with 230 Vac (+10%/-15%). The XFC1A06 and

XFC1D06 (long housing) have a transformer enabling them to

be powered with 110 Vac (+10%/-15%). For both the 230 Vac

and 110 Vac models, the standby power consumption (= all

outputs are inactive, all inputs are open, and all LEDs –

except the power LED – are OFF) is less than 10 VA. All

other models (short housings) require 24 Vac (±20%); their

standby power consumption is less than 5 VA.

All modules are equipped with a power LED as well as with a

L

ONWORKS service button and corresponding service LED.

Matching terminal protection covers and swivel label holders

are available for all modules.

• four LONMARK open-loop sensor objects (Obj#1-4) (one for

each universal input),

• four L

ONMARK open-loop sensor objects (Obj#5-8) (one for

each digital input),

• two L

ONMARK open-loop actuator objects (Obj#9-10) (one

for each analog output), and

• four L

ONMARK open-loop actuator objects (Obj#11-14) (one

for each relay).

LONMARK Node Object

The LONMARK node object allows the various different objects

in a node to be monitored. Upon receiving an update to

nviRequest, nvoStatus is updated. The definition of

SNVT_obj_request includes an object ID field to allow the

node object to report status conditions for all objects in a

node. The node self-documentation string lists the names of

the individual L

ment node or tool to display useful information about an Excel

Smart I/O; it also states (in the optional part after the

semicolon) that the node is an Excel Smart I/O, and lists its

version number.

Example:

network input sd_string("@x|y") SNVT_xxx

nvName;

where input can be replaced by output, x refers to the

object x listed within set_node_sd_string, and y is the NV

index within the following L

set_node_sd_string

"&"&3.2@0,1[4AI,1[4DI,3[2AO,3[4DO;SmartIO_01"

SNVT_obj_request

ONMARK objects, allowing a network manage-

ONMARK object definition:

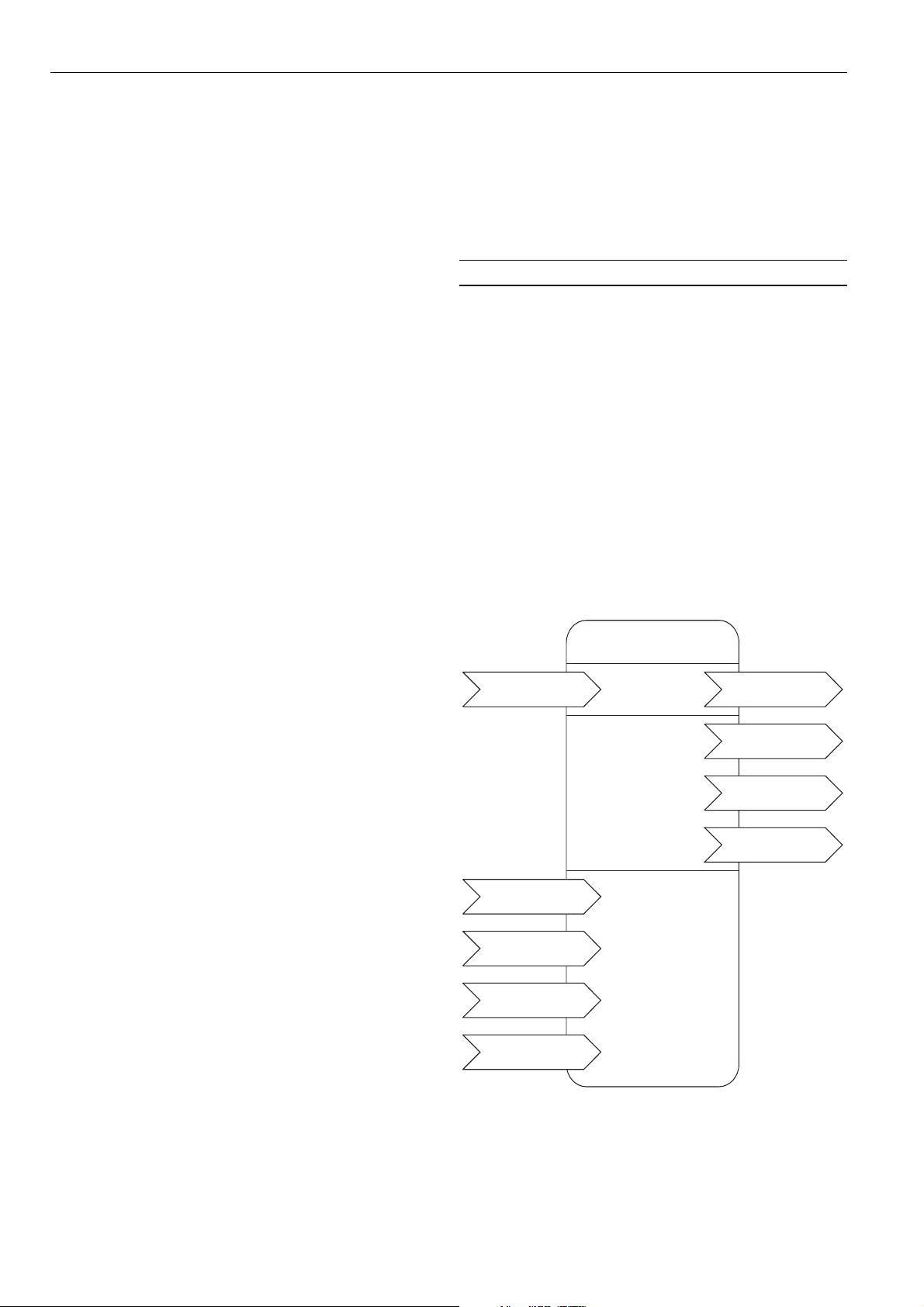

Node Object

(LonMark object type no. 0)

nviRequest

mandatory

Network

Variables

nvoStatus

SNVT_obj_status

nvoFileDirectory

SNVT_address

INTEROPERABILITY

The Excel Smart I/O is compliant with LONMARK Application

Layer Guidelines V3.2. and thus interoperable with all other

devices in open L

devices). See also section "LonWorks Network Interface."

Excel Smart I/O Module Response Times

The response time is defined as the interval between the

updating of the physical signal and the updating of the

corresponding NV (or vice versa). Response times vary

somewhat due to various factors. Assuming that only a single

digital input changes at any given time, the corresponding

response times will typically amount to approx. 1 sec. Thus,

depending upon your specific circumstances, the Excel Smart

I/O may be suitable for rapid-response applications.

LONMARK Objects

The Excel Smart I/O features a total of 15 LONMARK objects:

• one LONMARK node object (Obj#0) to allow monitoring and

setting the status of the various sensor / actuator objects,

EN0B-0311GE51 R0708 2

ONWORKS networks (including third-party

SCPTmaxSendTime

SNVT_time_sec

SCPTmaxRcvTime

SNVT_time_sec

UCPT_Poll

UCPT_Version

Fig. 1. Profile of L

optional

Network

Variables

optional

configuration

properties

ONMARK Node Object

nvoHwType

UNVT_HWType

nvoHwIdentify

UNVT_HWIdentify

Page 3

NV Name Type Description

nviRequest

SNVT_obj_request

nvoStatus

SNVT_obj_status

nvoFileDirectory SNVT_address

nvoHwType UNVT_HWType

nvoHWIdentify UNVT_HWIdentify

SCPTmaxSendTime SNVT_time_sec

SCPTmaxRcvTime SNVT_time_sec

UCPT_Poll

UCPT_Version

EXCEL SMART I/O MODULES

Table 2. Node Object network variables

RQ_NORMAL returns the object to the enabled, non-overridden state.

RQ_DISABLED disables the object.

RQ_ENABLE enables the object.

RQ_UPDATE_STATUS posts the current settings of the flags of the specified object.

RQ_REPORT_MASK reports the supported flags of the specified object.

RQ_RESET resets the appropriate LONMARK object: If the digital input object is configured

for totalizing, it resets the totalizer to 65535 (0xFFFF); if associated to the node object, it

resets the node.

RQ_CLEAR_RESET requests that reset_complete be cleared.

All other requests read to an "invalid_request" error.

object_id is the ID of the object within the node.

For invalid_id, a value of "1" means that the requested object ID is not implemented in this

node.

For invalid_request, a value of "1" means that unimplemented function has been

requested.

For disabled, a value of "1" means that the object has been disabled: those I/O objects not

supported by the current hardware type will always be disabled.

For open_circuit, a value of "1" means that an open circuit has been detected.

For unable_to_measure, a value of "1" means that an I/O line has failed.

For comm_failure, a value of "1" means that network communications have failed: one or

more bound input NVs specified for receive heartbeat weren't updated within the

configured receive heartbeat time.

For manual_control, a value of "1" means that the actuator is under local control: this field

applies to the output objects and the node object, only, and notifies whether the

appropriate output was manually overridden.

Not supported.

For in_override, a value of "1" means that the module has been overridden via

nviAoManOvrd or nviDoManOvrd (e.g. using the XILON Handheld MMI)

For report_mask, a value of "1" means that the status is an event mask.

Not supported.

For reset_complete, a value of "1" indicates the execution of the reset sequence. After a

reset sequence, the reset flag goes to TRUE (1) and remains in this state until it is cleared

(acknowledged).

Valid range: Any value within user data memory of Neuron Chip. Points to a file directory

in the address space of the Neuron Chip. Used to access the configuration properties

accessed by network management read/write messages.

Set at factory; stored in coprocessor's EEPROM. Represents the hardware type with

respect to its OS number (e.g. XFC3A014001) and the coprocessor's software version.

The hardware type is passed through the L

Typically polled for diagnostic purposes.

Set at factory; stored in coprocessor's EEPROM. Used to identify the hardware by the

number and types of I/Os supported by the actual hardware type. This information is

passed through the L

ONWORKS network as a polled output NV. Typically polled for

diagnostic purposes.

Valid range: 10...6553 s; in increments of 1 s (default = 60.0 s). Defines the maximum

period of time before output NVs are automatically updated. Defines the Maximum Send

Time and is accessible using standard L

Valid range: 0...6553 s (default = 0). Defines the max. time that elapses after the last

update to a bound input NV. Defines the Maximum Received Time and is accessible

using standard L

ONMARK mechanisms. Setting to zero disables the receive failure detect

mechanism.

Valid range: Pre-set at factory. Configures the start-up behavior for input NVs with respect

to getting an immediate update through a poll request. If enabled, any input NV bound to

another node will initiate a poll request after reset, thus helping to avoid start-up problems

until the next NV update. Polling based on a time grid of 1 sec, only. If disabled, the input

NVs remain invalid until the next update is sent.

Valid range: Pre-set by application program. Identifies the current application and its

version. Passed through the L

standard L

ONMARK mechanisms.

ONWORKS network as a read-only file. Readable using

ONWORKS network as a polled output NV.

ONMARK mechanisms.

3 EN0B-0311GE51 R0708

Page 4

EXCEL SMART I/O MODULES

LONMARK Sensor/Actuator Objects

All actuator objects have an output NV showing the actual

state of the physical output and whether it is in the automatic

or manual override mode. All sensor objects have a common

configuration property defining the heartbeat time.

LONMARK Open-Loop Sensor Objects for Universal Inputs

The Excel Smart I/O makes use of four LONMARK open-loop

sensor objects (one for each universal input) suitable for use

in applications in which the actuator provides no feedback.

LONMARK Open-Loop Actuator Objects for Analog Outputs

The Excel Smart I/O makes use of two LONMARK open-loop

actuator objects (one for each analog output).

Open-Loop Actuator Object

(LonMark object type no. 3)

mandatory

Network

Var iab les

optional

Network

Var ia ble s

SCPTdirection[x]

SNVT_state

UCPT_AOType[x]

optional

configuration

properties

Fig. 2. Profile of LONMARK sensor object for UIs

LONMARK Open-Loop Sensor Objects for Digital Inputs

The Excel Smart I/O makes use of four LONMARK open-loop

sensor objects (one for each digital input).

Fig. 4. Profile of L

ONMARK actuator objects for AOs

LONMARK Open-Loop Actuator Objects for Relays

The Excel Smart I/O makes use of four LONMARK open-loop

actuator objects (one for each relay) individually configurable

as simple ON/OFF controls or as floating outputs (in order to

drive two physical outputs with configurable runtimes).

Fig. 3. Profile of L

EN0B-0311GE51 R0708 4

ONMARK sensor objects for DIs

Figure 5. Profile of L

ONMARK actuator objects for relays

Page 5

EXCEL SMART I/O MODULES

Table 3. LONMARK sensor/actuator object NVs

NV Name Type Description

nvoAiValuePct SNVT_lev_percent Transmitted immediately when its value has changed by a rate higher than the con-

figured "Send on Delta". Regularly transmitted as a heartbeat output.

nvoAiTemp SNVT_temp_p

nvoAiSwitch SNVT_switch Transmitted immediately when its value has changed. Regularly transmitted as a

UCPT_AIType not applicable Used to define the appropriate input type. Stored in the configuration parameter file

UPCT_AISendDelta not applicable Defines the significant change rate of the associated input which should cause an

UCPT_AIProperty not applicable Used to define some properties associated to the analog input. Stored in the con-

nvoDISwitch SNVT_switch Represents a slow digital input connected to the digital input terminals. According to its

nvoDICount SNVT_count Transmitted immediately when its value has changed more counts than defined in

nvoDiOccupancy SNVT_occupancy Transmitted immediately when the digital input state has changed. Regularly transmitted

UCPT_DIType not applicable Used to set up the type of DI. It is stored in the configuration parameter file accessible

UCPT_DIProperty not applicable Used to define the properties associated with a digital input.

nvoAoActPosnFb SNVT_switch Represents the current status of the analog output, including feedback related to

nviAoSwitch SNVT_switch Used to drive the analog output to 0...100%. Typically bound to a LONWORKS control

nviAoValuePct SNVT_lev_percent Used to drive the AO to 0...100%. Typically bound to a LONWORKS control device

nviAoManOvrd SNVT_switch Used to manually override the analog output to 0...100%. Has priority over nviAoSwitch

SCPTdirection SNVT_state Used to set the actuator sense of rotation and the safety position in case of any failure.

UCPT_AOType not applicable Used to set up the various properties associated with an analog output point. Stored in

Transmitted immediately when its value has changed by a rate higher than the configured "Send on Delta". Regularly transmitted as a heartbeat output.

heartbeat output.

accessible using standard LonMark mechanisms. Used by the NEC coprocessor.

immediate NV update to be sent. Stored in the configuration parameter file accessible

using standard L

ONMARK mechanisms. Applies to the universal input type when con-

figured for "Voltage" or "Temperature Sensor", respectively, and will be ignored for other

input types.

figuration parameter file accessible using standard L

ONMARK mechanisms. Used by the

NEC coprocessor.

configuration with respect to a normally open / normally closed contact, the output NV

shows "state=0 / value=0%" for the "disabled" logical state, and "state=1 / value=100%"

for the "enabled" logical state. Regularly transmitted as a heartbeat output as dictated

by nciSndHrtBt.

"Send on Delta". Regularly transmitted as a heartbeat output. After power-up and reset,

the value 0xFFFF=65535 will be sent to the network to indicate to the receiving device

that previous count values have been lost due to a reset.

as a heartbeat output as dictated by nciSndHrtBt.

using standard L

ONMARK mechanisms.

manual override initiated from either nviAoManOvrd or the manual override switches.

Typically used for monitoring purposes at supervisory stations or for diagnostic

purposes. In the case of an override, the state is equal to -1.

device issuing an output level 0...100%. A value of 110% is also possible

(corresponding to a voltage range of 0...11 V).

issuing an output level 0...100%. A value of 110% is also possible (corresponding to a

voltage range of 0...11 V).

and nviAoValuePct. Typically used during start-up and commissioning, supported by the

XILON Handheld MMI, and does not have to be bound. If the relay is at present

manually overridden, this will be reflected in nvoAoActPosnFb, accordingly. The manual

override remains in force until explicitly reset to normal operation via power-up and

reset. This state is therefore stored in EEPROM. If there has been a manual override to

the same output, this will have priority over nviAoManOvrd.

Stored in the configuration parameter file accessible using standard L

ONMARK

mechanisms.

the configuration parameter file accessible using standard L

ONMARK mechanisms.

5 EN0B-0311GE51 R0708

Page 6

EXCEL SMART I/O MODULES

nvoDoActPosnFb SNVT_switch Represents the current status of the relay, including feedback related to manual over-

ride initiated from either nviDoManOvrd or the manual override switches. Typically used

for monitoring purposes at a supervisory station or for diagnostic purposes. In the case

of floating actuator, nvoDoActPosnFb will monitor the actual valve position based on the

calculation of the position within the motor model. In the case of an override, the state is

equal to -1.

nviDoSwitch SNVT_switch Used to drive the relay, which can be configured for different models, such as simple

ON/OFF output, or floating output. Typically bound to a L

issuing an output level ON/OFF or 0...100%, as the case may be.

nviDoValuePct SNVT_lev_percent

nviDoManOvrd SNVT_switch

UCPT_DOType not applicable Used to set-up the type of the relay point. Stored in the configuration parameter file

UCPT_DOProperty not applicable Used to set-up the various properties of a relay. Depending upon the selected output

UCPT_StatusLED not applicable Used to set-up the various properties associated with a status LEDs. Stored in the con-

UCPT_ManOvrdSw not applicable Used to set-up the manual override switches accordingly. Stored in the configuration

Used to drive the relay to 0…100% when configured for floating type. Typically bound to

ONWORKS control device issuing an output level 0…100%. If both nviDoSwitch and

a L

nviDoValuePct receive valid values, nviDoValuePct will have priority.

Used to manually override the relay to ON/OFF. Has priority over nviDoSwitch and

nviDoValuePct. Typically used during start-up and commissioning, supported by the

XILON Handheld MMI, and does not have to be bound. If the relay is at present

manually overridden, this will be reflected in nvoDoActPosnFb, accordingly. The manual

override remains in force until explicitly reset to normal operation via power-up and

reset. This state is therefore stored in EEPROM. If there has been a manual override to

the same output, this will have priority over nviDoManOvrd.

accessible using standard L

type, various different properties can be set-up which are stored in the configuration

parameter file accessible using standard L

coprocessor.

figuration parameter file accessible using standard L

NEC coprocessor.

parameter file accessible using standard L

coprocessor.

ONMARK mechanisms. Used by the NEC coprocessor.

ONMARK mechanisms. Used by the NEC

ONMARK mechanisms. Used by the NEC

ONWORKS control device

ONMARK mechanisms. Used by the

TECHNICAL DATA

General

The Excel Smart I/O is equipped with a 10-MHz 3150

Neuron® Chip (which executes the application program and

implements the LonTalk protocol) and a NEC coprocessor

(for handling the inputs and outputs). It communicates within

the L

ONWORKS network at a rate of 78 kilobaud via an FTT-

10A Free Topology Twisted Pair Transceiver

Each module is equipped with four 230 Vac, 6 A digital

outputs, i.e. relays (including two normally open [N.O.] and

two changeover [C.O.] relays). Floating actuators can be

directly connected to these relays once they have been

configured using Honeywell's LonMaker for Windows plug-in.

Further, each Excel Smart I/O is equipped with four fast digital

inputs. Each fast digital input can be reconfigured (using the

Honeywell plug-in) to accept static input (from dry contacts or

open collectors) or to totalize input signals (having a

frequency of up to 20 Hz).

Depending upon the given model, each module is also

equipped with a varying number of different universal inputs

and analog outputs (see section "Universal Inputs and Analog

Outputs" below), each of which has an extra power output

terminal for supplying 24 Vac power to field devices.

Certain models also feature six 3-position manual override

switches and ten status LEDs (see section "Manual Overrides

and Status LEDs" below).

Optional accessories include swivel label holders and terminal

protection covers (see "Optional Accessories" below).

A power LED, a L

ponding L

ONWORKS service button (see sections "LONWORKS

Service LED" and "L

ONWORKS service LED, and a corres-

ONWORKS Service Button" below) are

located on the top of each module.

There are two standard module sizes: the long module (with a

built-in 230 Vac transformer) and the short module (which

requires 24 Vac power). See section "Long and Short

Housings" below.

Universal Inputs and Analog Outputs

Further, depending upon the given model, the modules are

equipped with a variable number of different universal inputs

and analog outputs.

Universal Inputs

The term "universal inputs" refers to analog inputs for

temperature-sensor signals which can also be reconfigured

(using the Honeywell plug-in) as voltage-variable or slow

digital inputs (e.g. for dry-contact/open-collector signals).

Each module is equipped with universal inputs of one of the

following three types:

EN0B-0311GE51 R0708 6

Page 7

EXCEL SMART I/O MODULES

• The first type can be configured for analog signals from

NTC20k sensors or for 0...10 Vdc/2..10 Vdc voltage

signals or for slow digital input (max. frequency = 0.25 Hz).

• The second type can be configured for analog signals from

three-wire PT100 sensors or for 0...10 Vdc/2..10 Vdc

voltage signals or for slow digital input (max. frequency =

0.25 Hz). The XFC3A04001 and XFC3D04001 are

equipped with two universal inputs of this type, the

reconfiguration of which yields four voltage-variable or slow

digital inputs.

• The third type can be configured for analog signals from

PT1000, Ni1000, and Ni1000TK5000 sensors or for

0...10 Vdc/2..10 Vdc voltage signals or for slow digital input

(max. frequency = 0.25 Hz).

The universal inputs of all models have an individually

configurable offset.

The universal inputs of the XFC3A06001, XFC3D06001,

XFC2A06001, and XFC2D06001 have a 10-bit resolution,

with a typical accuracy of ±0.1 V and an impedance of

> 100 kOhm to GND for voltage input.

The universal inputs of the XFC3A04001 and the

XFC3A05001 have a 12-bit resolution, with a typical accuracy

of ±0.075 V and an impedance of > 100 kOhm to GND for

voltage input.

Each universal input features an extra power output terminal

for supplying 24 Vac power to active sensors.

Analog Outputs

Each module is equipped with two analog outputs providing

either 0...11 VDC, 0…±1.1 mA signals or 0..20 mA/4..20 mA

signals (model-dependent). Each analog output features an

extra power output terminal for supplying 24 Vac power to

actuators.

The analog outputs have a permissible load of > 10 kOhm,

and a typical accuracy of ±0.2 V.

Other Module-Specific Features / Options

Manual Overrides and Status LEDs

The XFC1D06, the XFC2D05 and XFC2D06, as well as the

XFC3D04, 3D05, and 3D06 are each equipped with six 3position (ON, OFF, AUTO) manual override sliding switches

with which the individual digital/analog output signals can be

overridden. The manual override switches can be configured

using Honeywell's plug-in.

These same modules are each equipped with a total of ten

colored status LEDs:

• The four 3-color software-configurable LEDs can be used

to test whether signals from e.g. digital inputs are

changing. They can also indicate whether the hardware is

defective.

• The four yellow software-configurable LEDs are ordinarily

used for relays.

• The two red variable-intensity LEDs are connected to the

analog outputs; their brightness varies according to the

strength of the corresponding signal (i.e. 0 volts / 0 mA =

dark LED, 10 volts / 20 mA = bright LED)

See also the section of the plug-in's on-line help on status

LED configuration.

Long and Short Housings

The XFC2A05 and XFC2A06 as well as the XFC2D05 and

XFC2D06 are each equipped with a transformer enabling

them to be powered with 230 Vac, and they thus feature long

housings (W x L x H = 180 x 76 x 110 mm). The XFC1A06

and XFC1D06 have a transformer enabling them to be

powered with 110 Vac, and likewise feature long housings. All

other models require a 24 Vac power supply and are

enclosed in short housings (W x L x H = 126 x 76 x 110 mm).

Optional Accessories

Optional accessories include matching terminal protection

covers (available in packs of 8) and swivel label holders

(available in packs of 8).

Those Excel Smart I/O modules featuring override switches

require swivel label holders onto which the labels containing

customer-specific wiring information can be applied. The

swivel label holders are snapped into place on the housing.

LONWORKS Network Interface

The Excel Smart I/O communicates within the LONWORKS

network at a rate of 78 kilobaud via an FTT-10A Free

Topology Twisted Pair Transceiver. This transceiver provides

transformer isolation so that the bus wiring does not have a

polarity.

Devices equipped with this transceiver can be wired in daisy

chain, star, loop, or any combination thereof as long as the

max. wire length requirements are met. The recommended

configuration is a daisy chain with two termination modules.

This layout allows for maximum bus length, and its simple

structure presents the least number of possible problems,

particularly when adding on to an existing bus. For more

information, please refer to http://www.echelon.com

Configuration and Binding

The network variables of the Excel Smart I/O are configured

and bound using Honeywell's LonMaker for Windows™ plugin.

Wiring Check

The XILON Handheld MMI is used to check the wiring of the

modules.

7 EN0B-0311GE51 R0708

Page 8

EXCEL SMART I/O MODULES

No knowledge of LONWORKS is necessary to use XILON.

Refer also to XILON Handheld MMI for L

User Guide (EN2B-0214GE51) for more information.

ONWORKS Networks

LONWORKS Service Button

All models feature a LONWORKS service button accessible

from the outside on the top of module for use in installation

and troubleshooting. When the service button is pressed, the

following actions take place:

• The service pin message is issued on the network.

• When the service button has been pressed longer than 30

sec, the node reverts to normal mode.

The service pin message is broadcast:

• whenever the service button has been pressed;

• after each reset due to power-up, software reset;

• when changing the mode from offline to online.

See also Excel Smart I/O Installation Instructions (EN1B0180GE51) for more-detailed information.

LONWORKS Service LED

All models feature a LONWORKS service LED connected to the

Neuron® Chip service LED output. The service LED displays

numerous different behaviors indicating various module states

for use in troubleshooting.

See also Excel Smart I/O Installation Instructions (EN1B0180GE51) for a complete description of these behaviors.

For more information on standard service LED behavior, refer

to Motorola L

page AL-190.

ONWORKS Technology Device Data Manual,

Accessories, Standards, Ratings, and

Literature

Accessories

• Swivel label holders; short and long variants (required for

modules equipped with manual override switches).

24 Vac models, order number: XAL_LAB_S

230 Vac models, order number: XAL_LAB_L

• 209541B Termination Module (one or two required,

depending on L

Installation Instructions, EN1R-1047 for details).

• Terminal protection covers; short and long variants

(required for wall/ceiling mounting).

24 Vac models, order number: XAL_COV_S

230 Vac models, order number: XAL_COV_L

Approvals and Standards

• CE and EN 50081-1

ONMARK Application Layer Guidelines Version 3.2

• L

Housings

• IP20 or IP30 (standard housing)

Environmental Ratings

• Operating temperature: 32...122 °F (0...50 °C)

• Shipping/storage temperature: -22...158 °F (-30...70 °C)

• Relative humidity (operation and storage): 5...90%, non-

condensing

Applicable Literature

• XILON Handheld MMI for LONWORKS Networks User

Guide (EN2B-0214GE51)

• Excel Smart I/O Installation Instructions (EN1B-

0180GE51)

• Excel 50/500 L

• Excel 10 FTT/LPT 209541B Termination Module

Installation Instructions, form 95-7554

• Honeywell's Excel Smart plug-in help file

ONWORKS bus layout; see Excel 500

ONWORKS Mechanisms (EN0B-0270GE51)

EN0B-0311GE51 R0708 8

Page 9

DIMENSIONS

swivel label

holder (optional)

terminal protection

cover (optional)

manual override switches

(specific modules)

swivel label

holder (optional)

terminal protection

cover (optional)

EXCEL SMART I/O MODULES

long housing (with built-in transformer): 180 m (7-7/8 in.)

short housing (without transformer): 126 mm (4-15/16 in.)

manual overrides

(specific modules)

leverage slot

LonWorks

service button

red LEDs

(specific modules)

yellow LEDs

(specific modules)

3-color LEDs

(specific modules)

power LED

LonWorks

service LED

ventilation slits

cut-out tabs

(to expose terminal pins)

9 EN0B-0311GE51 R0708

Page 10

EXCEL SMART I/O MODULES

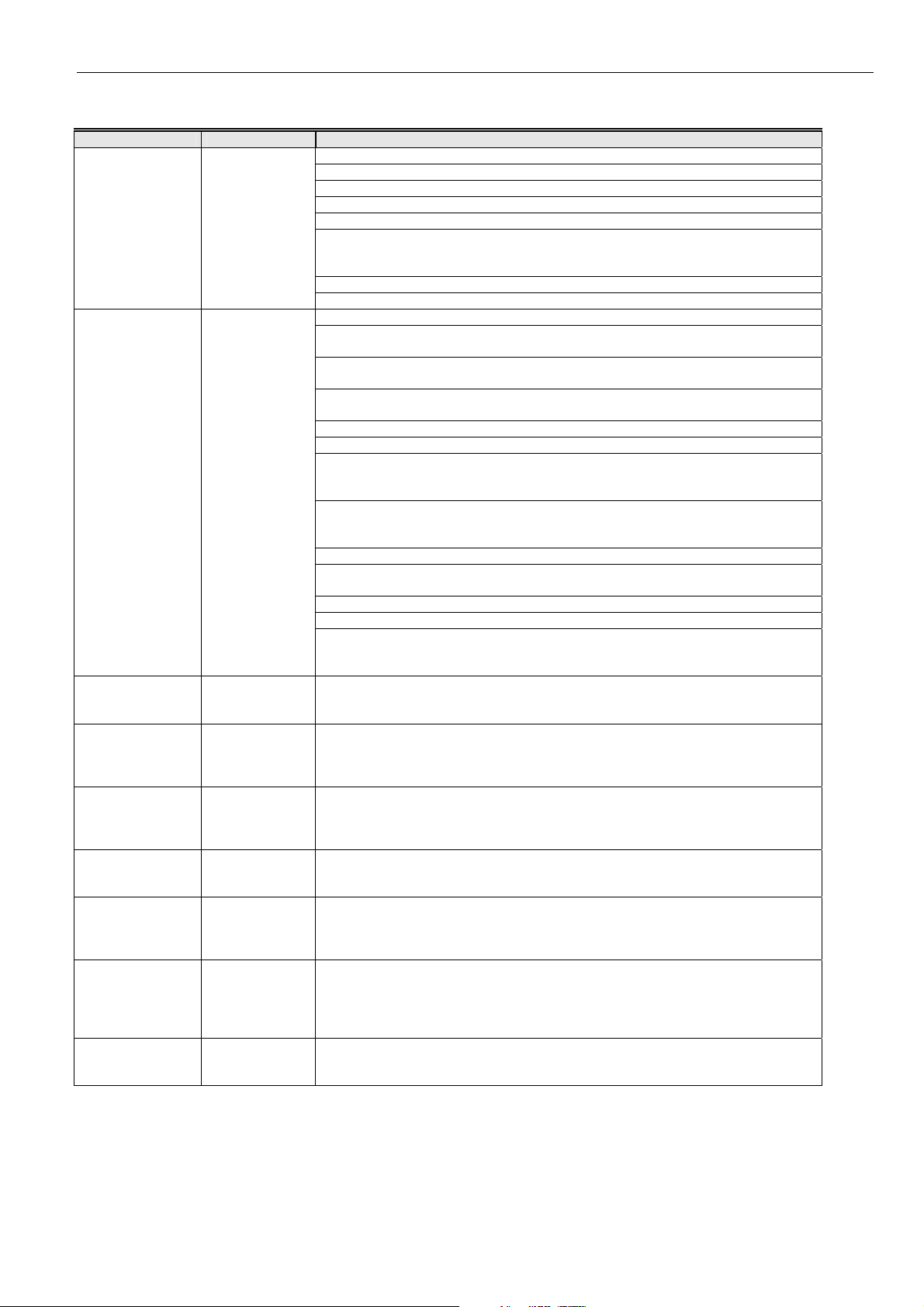

Table 4. Detailed Overview of Excel Smart I/O Versions

XFC1A06001

XFC1D06001

XFC2A05001

XFC2A06001

XFC3A04001

XFC3A05001

XFC3A06001

XFC2D05001

XFC2D06001

XFC3D04001

XFC3D05001

XFC3D06001

housing long long long long short short short long long short short short

power supply (Vac) 110 110 230 230 24 24 24 230 230 24 24 24

fixed (F) / removable

(R) terminals

F R F F F F F R R R R R

manual overrides -- six -- -- -- -- -- six six six six six

status LEDs -- ten -- -- -- ten ten ten ten ten

PT1000* -- -- two -- two -- two -- -- two --

UIs

NTC20k four four -- four -- four -- four -- -- four

PT100 -- -- -- -- two** -- -- -- -- two** -- --

fast DIs four four four four four four four four four four four four

0...10 V two two two two two two two two -- two two

AOs

0...20 mA -- -- -- -- two -- -- -- -- two -- --

N.O. / C.O. relays 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0311GE51 R0708 / 74-3671

Loading...

Loading...