Page 1

Xenon™ 1900/1910

Xenon™ 1902/1912

Granit™ 1910i/1911i

Granit™ 1980i/1981i

Area-Imaging Scanner

User’s Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this

document without prior notice, and the reader should in all cases consult HII to determine whether any such changes have been

made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material. HII disclaims all responsibility for the selection and use of

software and/or hardware to achieve intended results.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document

may be photocopied, reproduced, or translated into another language without the prior written consent of HII.

2010-2015 Honeywell International Inc. All rights reserved.

Web Address:

Microsoft® Windows®, Windows NT®, Windows 2000, Windows ME, Windows XP, and the Windows logo are trademarks or

registered trademarks of Microsoft Corporation.

The Bluetooth® word mark and logos are owned by Bluetooth SIG, Inc.

Other product names or marks mentioned in this document may be trademarks or registered trademarks of other companies

and are the property of their respective owners.

For patent information, please refer to www.hsmpats.com.

www.honeywellaidc.com

Page 3

Table of Contents

Chapter 1 - Getting Started

About This Manual ...............................................................................................................1-1

Unpacking Your Device .......................................................................................................1-1

Connecting the Device.........................................................................................................1-1

Connecting with USB .....................................................................................................1-1

Connecting with Keyboard Wedge.................................................................................1-3

Connecting with RS232 Serial Port................................................................................1-6

Connecting with RS485..................................................................................................1-8

Mounting a CCB01-010BT Charge Base.............................................................................1-9

Mounting a CCB02-100BT/CCB05-100BT Base .................................................................1-9

Reading Techniques ..........................................................................................................1-11

Xenon 1900/1902/1910/1912 and Granit 1910i/1911i .................................................1-11

Granit 1980i/1981i........................................................................................................1-12

Menu Bar Code Security Settings......................................................................................1-12

Setting Custom Defaults ....................................................................................................1-13

Resetting the Custom Defaults ..........................................................................................1-13

Chapter 2 - Programming the Interface

Introduction ..........................................................................................................................2-1

Programming the Interface - Plug and Play .........................................................................2-1

Keyboard Wedge .................................................................................................................2-1

Laptop Direct Connect .........................................................................................................2-1

RS232 Serial Port ................................................................................................................2-1

RS485 ..................................................................................................................................2-2

RS485 Packet Mode ......................................................................................................2-2

USB IBM SurePos ...............................................................................................................2-3

USB PC or Macintosh Keyboard..........................................................................................2-3

USB HID ..............................................................................................................................2-4

USB Serial ...........................................................................................................................2-4

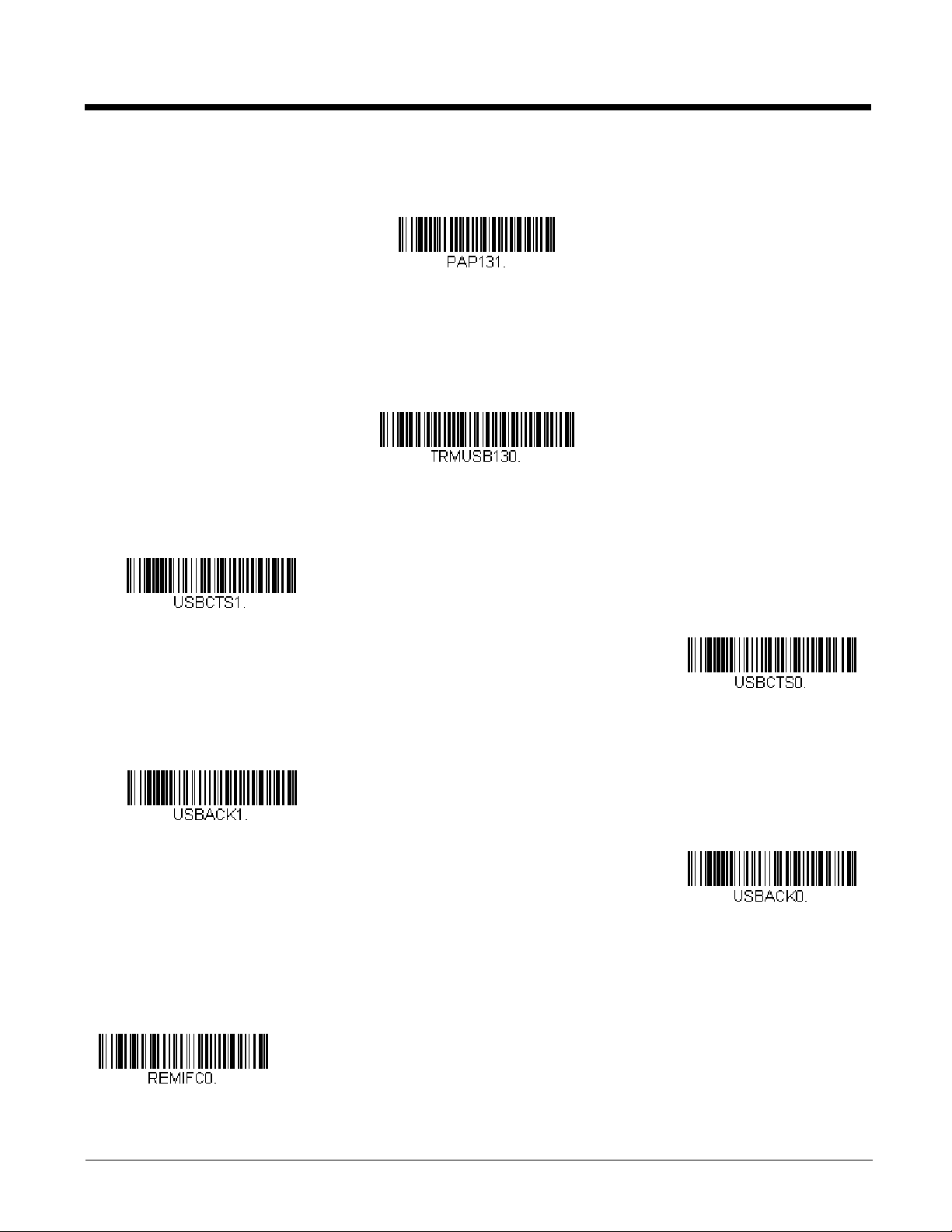

CTS/RTS Emulation.......................................................................................................2-4

ACK/NAK Mode .............................................................................................................2-4

Remote MasterMind™ for USB ...........................................................................................2-4

Verifone

Gilbarco

Honeywell Bioptic Aux Port Configuration ...........................................................................2-5

Datalogic™ Magellan

NCR Bioptic Aux Port Configuration ....................................................................................2-6

Wincor Nixdorf Terminal Default Settings ............................................................................2-6

Wincor Nixdorf Beetle™ Terminal Default Settings .............................................................2-7

Wincor Nixdorf RS232 Mode A ............................................................................................2-7

Keyboard Country Layout ....................................................................................................2-8

Keyboard Style...................................................................................................................2-15

Keyboard Conversion ........................................................................................................2-16

Control Character Output...................................................................................................2-17

Keyboard Modifiers ............................................................................................................2-17

®

Ruby Terminal Default Settings...........................................................................2-5

®

Terminal Default Settings ....................................................................................2-5

®

Aux Port Configuration....................................................................2-6

i

Page 4

RS232 Modifiers ................................................................................................................2-18

RS232 Baud Rate........................................................................................................ 2-18

RS232 Word Length: Data Bits, Stop Bits, and Parity.................................................2-19

RS232 Receiver Time-Out...........................................................................................2-20

RS232 Handshaking....................................................................................................2-21

RS232 Timeout............................................................................................................ 2-21

XON/XOFF ..................................................................................................................2-21

ACK/NAK.....................................................................................................................2-22

Scanner to Bioptic Communication ................................................................................... 2-22

Scanner-Bioptic Packet Mode .....................................................................................2-22

Scanner-Bioptic ACK/NAK Mode.................................................................................2-22

Scanner-Bioptic ACK/NAK Timeout.............................................................................2-23

Chapter 3 - Cordless System Operation

How the Cordless Charge Base/Access Point Works ......................................................... 3-1

Linking the Scanner to a Charge Base................................................................................3-1

Linking the Scanner to an Access Point..............................................................................3-1

Replacing a Linked Scanner................................................................................................3-2

Communication Between the Cordless System

and the Host......................................................................................................................3-2

Programming the Scanner and Base or Access Point ........................................................ 3-3

RF (Radio Frequency) Module Operation ........................................................................... 3-3

System Conditions...............................................................................................................3-3

Linking Process .............................................................................................................3-3

Scanner Is Out of Range ...............................................................................................3-3

Scanner Is Moved Back Into Range ..............................................................................3-3

Out of Range and Back into Range with Batch Mode On.............................................. 3-3

Page Button.........................................................................................................................3-4

About the Battery.................................................................................................................3-4

Charging Information .....................................................................................................3-4

Battery Recommendations ............................................................................................3-4

Proper Disposal of the Battery.......................................................................................3-5

Beeper and LED Sequences and Meaning ......................................................................... 3-5

Scanner LED Sequences and Meaning.........................................................................3-5

Base/Access Point LED Sequences and Meaning........................................................ 3-5

Base Power Communication Indicator...........................................................................3-6

Reset Scanner.....................................................................................................................3-6

Scanning While in Base Cradle ...........................................................................................3-6

Base Charging Modes.........................................................................................................3-6

Paging .................................................................................................................................3-7

Paging Mode..................................................................................................................3-7

Paging Pitch...................................................................................................................3-8

Error Indicators....................................................................................................................3-8

Beeper Pitch - Base Error..............................................................................................3-8

Number of Beeps - Base Error ......................................................................................3-8

Scanner Report ................................................................................................................... 3-9

Scanner Address.................................................................................................................3-9

Base or Access Point Address ............................................................................................ 3-9

ii

Page 5

Scanner Modes ...................................................................................................................3-9

Charge Only Mode.........................................................................................................3-9

Linked Modes ..............................................................................................................3-10

Unlinking the Scanner ....................................................................................................... 3-10

Override Locked Scanner............................................................................................3-11

Out-of-Range Alarm ..........................................................................................................3-11

Alarm Sound Type....................................................................................................... 3-11

Scanner Power Time-Out Timer........................................................................................3-12

Flexible Power Management.............................................................................................3-13

Batch Mode .......................................................................................................................3-13

Batch Mode Beep ........................................................................................................3-14

Batch Mode Storage....................................................................................................3-14

Batch Mode Quantity ...................................................................................................3-15

Batch Mode Output Order............................................................................................3-17

Total Records ..............................................................................................................3-17

Delete Last Code......................................................................................................... 3-17

Clear All Codes............................................................................................................3-17

Transmit Records to Host............................................................................................ 3-17

Batch Mode Transmit Delay ........................................................................................3-18

Multiple Scanner Operation ...............................................................................................3-18

Scanner Name...................................................................................................................3-18

Application Work Groups...................................................................................................3-19

Application Work Group Selection............................................................................... 3-20

Resetting the Factory Defaults: All Application Work Groups ...........................................3-20

Resetting the Custom Defaults: All Application Work Groups ...........................................3-21

Using the Scanner with Bluetooth Devices........................................................................3-21

Bluetooth Secure Simple Pairing (SSP) ...................................................................... 3-21

Bluetooth HID Keyboard Connect................................................................................3-22

Virtual Keyboard ..........................................................................................................3-23

Bluetooth HID Keyboard Disconnect ...........................................................................3-23

Bluetooth Serial Port - PCs/Laptops............................................................................ 3-23

PDAs/Mobility Systems Devices..................................................................................3-24

Changing the Scanner’s Bluetooth PIN Code..............................................................3-24

Minimizing Bluetooth/ISM Band Network Activity..............................................................3-24

Auto Reconnect Mode .................................................................................................3-24

Maximum Link Attempts ..............................................................................................3-25

Relink Time-Out...........................................................................................................3-25

Bluetooth/ISM Network Activity Examples...................................................................3-25

Host Acknowledgment.......................................................................................................3-26

Chapter 4 - Input/Output Settings

Power Up Beeper ................................................................................................................4-1

Beep on BEL Character.......................................................................................................4-1

Trigger Click ........................................................................................................................4-2

iii

Page 6

Good Read and Error Indicators..........................................................................................4-2

Beeper – Good Read.....................................................................................................4-2

Beeper Volume – Good Read........................................................................................4-2

Beeper Pitch – Good Read............................................................................................ 4-3

Vibrate – Good Read..................................................................................................... 4-3

Beeper Pitch – Error ......................................................................................................4-4

Beeper Duration – Good Read ......................................................................................4-4

LED – Good Read .........................................................................................................4-4

Number of Beeps – Good Read ....................................................................................4-5

Number of Beeps – Error............................................................................................... 4-5

Beeper Volume Max ......................................................................................................4-5

Good Read Delay ..........................................................................................................4-5

User-Specified Good Read Delay..................................................................................4-6

Manual Trigger Modes.........................................................................................................4-6

LED Illumination - Manual Trigger .................................................................................4-6

Serial Trigger Mode.............................................................................................................4-7

Read Time-Out ..............................................................................................................4-7

Presentation Mode ..............................................................................................................4-7

LED Illumination - Presentation Mode ...........................................................................4-8

Presentation LED Behavior after Decode......................................................................4-8

Presentation Sensitivity .................................................................................................4-8

Presentation Centering.................................................................................................. 4-9

In-Stand Sensor Mode.......................................................................................................4-10

Poor Quality Codes ...........................................................................................................4-11

Poor Quality 1D Codes................................................................................................4-11

Poor Quality PDF Codes .............................................................................................4-11

CodeGate

®

........................................................................................................................4-11

Streaming Presentation™ Mode .......................................................................................4-12

Streaming Presentation In-Stand Programming.......................................................... 4-12

Mobile Phone Read Mode.................................................................................................4-12

Hands Free Time-Out........................................................................................................4-13

Reread Delay.....................................................................................................................4-13

User-Specified Reread Delay ......................................................................................4-13

2D Reread Delay .........................................................................................................4-14

Character Activation Mode ................................................................................................ 4-14

Activation Character .................................................................................................... 4-15

End Character Activation After Good Read................................................................. 4-15

Character Activation Timeout ......................................................................................4-15

Character Deactivation Mode ............................................................................................4-15

Deactivation Character ................................................................................................4-16

Illumination Lights..............................................................................................................4-16

Aimer Delay .......................................................................................................................4-16

User-Specified Aimer Delay.........................................................................................4-17

Aimer Mode ....................................................................................................................... 4-17

Centering...........................................................................................................................4-17

iv

Page 7

Preferred Symbology.........................................................................................................4-19

High Priority Symbology ..............................................................................................4-19

Low Priority Symbology ...............................................................................................4-19

Preferred Symbology Time-out.................................................................................... 4-20

Preferred Symbology Default.......................................................................................4-20

Output Sequence Overview...............................................................................................4-20

Output Sequence Editor ..............................................................................................4-20

To Add an Output Sequence .......................................................................................4-20

Other Programming Selections....................................................................................4-21

Output Sequence Editor ..............................................................................................4-22

Partial Sequence .........................................................................................................4-22

Require Output Sequence ...........................................................................................4-22

Multiple Symbols ...............................................................................................................4-23

No Read ............................................................................................................................4-23

Video Reverse ...................................................................................................................4-24

Working Orientation...........................................................................................................4-24

Chapter 5 - Healthcare Settings

Quiet Operations - Combination Codes...............................................................................5-1

Silent Mode with Flashing LED......................................................................................5-1

Silent Mode with Long LED ...........................................................................................5-1

Very Low Beeper (Nighttime Mode)...............................................................................5-1

Low Beeper (Daytime Mode)......................................................................................... 5-2

Page Button and Presentation Modes.................................................................................5-2

Temporary Streaming Presentation Timeout.................................................................5-2

Quiet Operations - LED and Volume Settings.....................................................................5-3

Linking LED Colors and Sound......................................................................................5-3

Number of LED Flashes ................................................................................................5-3

LED Flash Rate .............................................................................................................5-4

LED Solid (No Flash)..................................................................................................... 5-4

Paging Volume Control..................................................................................................5-4

Out-of-Range Alarm Volume .........................................................................................5-5

Out-of-Range Delay....................................................................................................... 5-6

Chapter 6 - Data Editing

Prefix/Suffix Overview .........................................................................................................6-1

To Add a Prefix or Suffix:............................................................................................... 6-1

To Clear One or All Prefixes or Suffixes........................................................................ 6-2

To Add a Carriage Return Suffix to All Symbologies..................................................... 6-2

Prefix Selections..................................................................................................................6-2

Suffix Selections.................................................................................................................. 6-2

Function Code Transmit ...................................................................................................... 6-3

Intercharacter, Interfunction, and Intermessage Delays......................................................6-3

Intercharacter Delay ......................................................................................................6-3

User Specified Intercharacter Delay.............................................................................. 6-3

Interfunction Delay.........................................................................................................6-4

Intermessage Delay....................................................................................................... 6-4

v

Page 8

Chapter 7 - Data Formatting

Data Format Editor Introduction .......................................................................................... 7-1

Add a Data Format .............................................................................................................. 7-1

Other Programming Selections......................................................................................7-2

Terminal ID Table................................................................................................................ 7-3

Data Format Editor Commands...........................................................................................7-3

Move Commands...........................................................................................................7-6

Search Commands........................................................................................................ 7-7

Miscellaneous Commands.............................................................................................7-9

Data Formatter ..................................................................................................................7-12

Data Format Non-Match Error Tone............................................................................ 7-13

Primary/Alternate Data Formats........................................................................................7-13

Single Scan Data Format Change............................................................................... 7-13

Chapter 8 - Symbologies

All Symbologies...................................................................................................................8-1

Message Length Description...............................................................................................8-1

Codabar...............................................................................................................................8-2

Codabar Concatenation................................................................................................. 8-3

Code 39 ...............................................................................................................................8-4

Code 32 Pharmaceutical (PARAF)................................................................................ 8-5

Full ASCII....................................................................................................................... 8-6

Code 39 Code Page ......................................................................................................8-6

Interleaved 2 of 5.................................................................................................................8-7

NEC 2 of 5...........................................................................................................................8-8

Code 93 ...............................................................................................................................8-9

Code 93 Code Page ....................................................................................................8-10

Straight 2 of 5 Industrial (three-bar start/stop)...................................................................8-11

Straight 2 of 5 IATA (two-bar start/stop)............................................................................8-12

Matrix 2 of 5.......................................................................................................................8-13

Code 11 .............................................................................................................................8-14

Code 128...........................................................................................................................8-15

ISBT 128 Concatenation..............................................................................................8-15

Code 128 Code Page ..................................................................................................8-16

GS1-128 ............................................................................................................................ 8-17

Telepen..............................................................................................................................8-18

UPC-A ...............................................................................................................................8-19

UPC-A/EAN-13 with Extended Coupon Code...................................................................8-21

Coupon GS1 DataBar Output............................................................................................8-21

UPC-E0 .............................................................................................................................8-22

UPC-E1 .............................................................................................................................8-24

EAN/JAN-13 ......................................................................................................................8-24

Convert UPC-A to EAN-13 ..........................................................................................8-24

ISBN Translate ............................................................................................................8-26

EAN/JAN-8 ........................................................................................................................ 8-27

MSI ....................................................................................................................................8-29

GS1 DataBar Omnidirectional ........................................................................................... 8-31

vi

Page 9

GS1 DataBar Limited.........................................................................................................8-31

GS1 DataBar Expanded.................................................................................................... 8-32

Trioptic Code .....................................................................................................................8-32

Codablock A ......................................................................................................................8-33

Codablock F ...................................................................................................................... 8-34

Label Code ........................................................................................................................8-34

PDF417 .............................................................................................................................8-35

MacroPDF417 ................................................................................................................... 8-35

MicroPDF417.....................................................................................................................8-36

GS1 Composite Codes......................................................................................................8-36

UPC/EAN Version........................................................................................................8-37

GS1 Emulation ..................................................................................................................8-37

TCIF Linked Code 39 (TLC39) .......................................................................................... 8-38

QR Code............................................................................................................................8-38

QR Code Page ............................................................................................................8-39

Data Matrix ........................................................................................................................8-40

Data Matrix Code Page ...............................................................................................8-40

MaxiCode ..........................................................................................................................8-41

Aztec Code ........................................................................................................................ 8-42

Aztec Code Page.........................................................................................................8-42

Chinese Sensible (Han Xin) Code.....................................................................................8-43

Postal Codes - 2D .............................................................................................................8-44

Single 2D Postal Codes:..............................................................................................8-44

Combination 2D Postal Codes:....................................................................................8-45

Postal Codes - Linear........................................................................................................8-48

China Post (Hong Kong 2 of 5).................................................................................... 8-48

Korea Post...................................................................................................................8-49

Chapter 9 - Imaging Commands

Single-Use Basis ................................................................................................................. 9-1

Command Syntax................................................................................................................ 9-1

Image Snap - IMGSNP........................................................................................................9-1

IMGSNP Modifiers......................................................................................................... 9-1

Image Ship - IMGSHP .........................................................................................................9-3

IMGSHP Modifiers......................................................................................................... 9-4

Intelligent Signature Capture - IMGBOX ...........................................................................9-10

Signature Capture Optimize ........................................................................................9-10

IMGBOX Modifiers.......................................................................................................9-11

RF Default Imaging Device................................................................................................9-14

Chapter 10 - Interface Keys

Keyboard Function Relationships......................................................................................10-1

Supported Interface Keys ..................................................................................................10-3

Chapter 11 - Utilities

To Add a Test Code I.D. Prefix to All Symbologies...........................................................11-1

Show Decoder Revision .................................................................................................... 11-1

vii

Page 10

Show Scan Driver Revision ...............................................................................................11-1

Show Software Revision.................................................................................................... 11-1

Show Data Format.............................................................................................................11-1

Test Menu..........................................................................................................................11-2

TotalFreedom ....................................................................................................................11-2

Application Plug-Ins (Apps) ............................................................................................... 11-2

EZConfig-Scanning Introduction........................................................................................11-3

Installing EZConfig-Scanning from the Web................................................................ 11-3

Resetting the Factory Defaults .......................................................................................... 11-4

Chapter 12 - Serial Programming Commands

Conventions.......................................................................................................................12-1

Menu Command Syntax.................................................................................................... 12-1

Query Commands .............................................................................................................12-1

Responses................................................................................................................... 12-2

Trigger Commands............................................................................................................12-3

Resetting the Custom Defaults..........................................................................................12-3

Menu Commands ..............................................................................................................12-4

Chapter 13 - Product Specifications

Xenon 1900/1910 Corded Scanner Product Specifications .............................................. 13-1

Xenon 1902/1912 Cordless Scanner Product Specifications............................................ 13-2

Granit 1910i Industrial Corded Scanner Product Specifications........................................ 13-3

Granit 1911i Industrial Cordless Scanner Product Specifications ..................................... 13-4

Granit 1980i Industrial Full Range Corded Scanner Product Specifications ..................... 13-5

Granit 1981i Industrial Full Range Cordless Scanner Product Specifications................... 13-6

CCB01-010BT Charge Base Product Specifications......................................................... 13-7

CCB02-100BT/CCB05-100BT Industrial Charge Base Product Specifications................. 13-7

Depth of Field Charts.........................................................................................................13-9

Xenon B&W Scanner Typical Performance................................................................. 13-9

Xenon B&W Scanner Guaranteed Performance .........................................................13-9

Xenon Color Scanner (Model COL) Typical Performance.........................................13-10

Xenon Color Scanner (Model COL) Guaranteed Performance ................................ 13-10

Granit 1910i/1911i Scanner Typical Performance .................................................... 13-11

Granit 1910i/1911i Scanner Guaranteed Performance ............................................ 13-11

Granit 1980i/1981i Scanner Typical Performance (200 lux) ..................................... 13-12

Granit 1980i/1981i Scanner Guaranteed Performance (200 lux) .............................. 13-13

Standard Connector Pinouts ...........................................................................................13-14

Keyboard Wedge....................................................................................................... 13-14

Serial Output.............................................................................................................. 13-14

RS485 Output............................................................................................................ 13-14

USB ...........................................................................................................................13-15

Required Safety Labels ...................................................................................................13-15

Chapter 14 - Maintenance and Troubleshooting

Repairs ..............................................................................................................................14-1

viii

Page 11

Maintenance...................................................................................................................... 14-1

Cleaning the Scanner ..................................................................................................14-1

Cleaning the Window................................................................................................... 14-1

Health Care Housing ...................................................................................................14-1

Inspecting Cords and Connectors ...............................................................................14-2

Replacing Cables in Corded Scanners.............................................................................. 14-2

Replacing a Xenon Interface Cable............................................................................. 14-2

Replacing a Granit Interface Cable..............................................................................14-2

Replacing Cables and Batteries in Cordless Systems ......................................................14-2

Replacing an Interface Cable in a Base ......................................................................14-2

Changing a Xenon Scanner Battery ............................................................................14-3

Changing a Granit Scanner Battery............................................................................. 14-3

Troubleshooting a Corded Scanner...................................................................................14-3

Troubleshooting a Cordless System..................................................................................14-4

Troubleshooting a Base............................................................................................... 14-4

Troubleshooting a Cordless Scanner ..........................................................................14-4

Chapter 15 - Customer Support

Technical Assistance.........................................................................................................15-1

Product Service and Repair...............................................................................................15-1

Chapter A - Reference Charts

Symbology Charts ...............................................................................................................A-1

Linear Symbologies .......................................................................................................A-1

2D Symbologies.............................................................................................................A-2

Postal Symbologies .......................................................................................................A-2

ASCII Conversion Chart (Code Page 1252)........................................................................A-3

Lower ASCII Reference Table.............................................................................................A-4

ISO 2022/ISO 646 Character Replacements ......................................................................A-7

Keyboard Key References.................................................................................................A-10

Sample Symbols

Programming Chart

ix

Page 12

x

Page 13

1

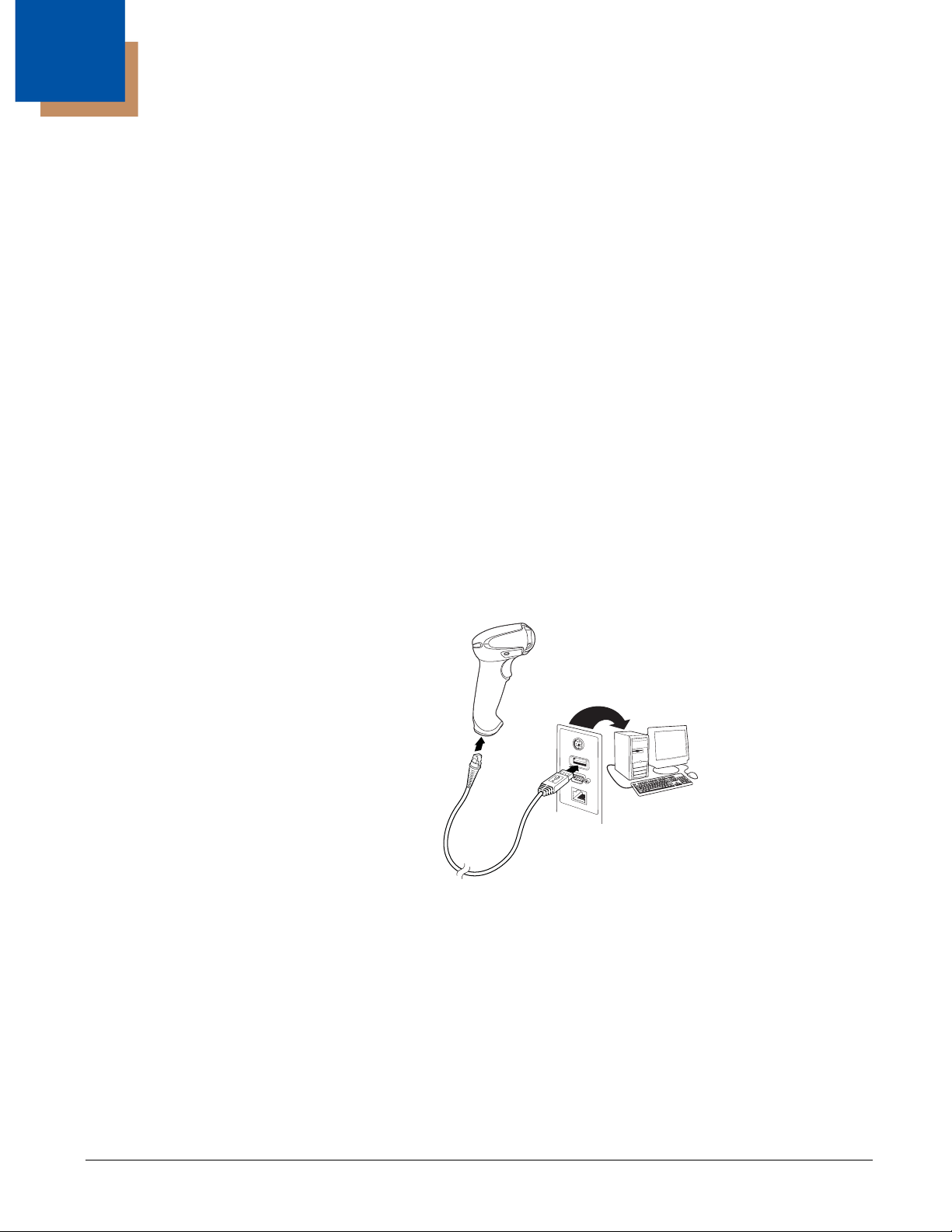

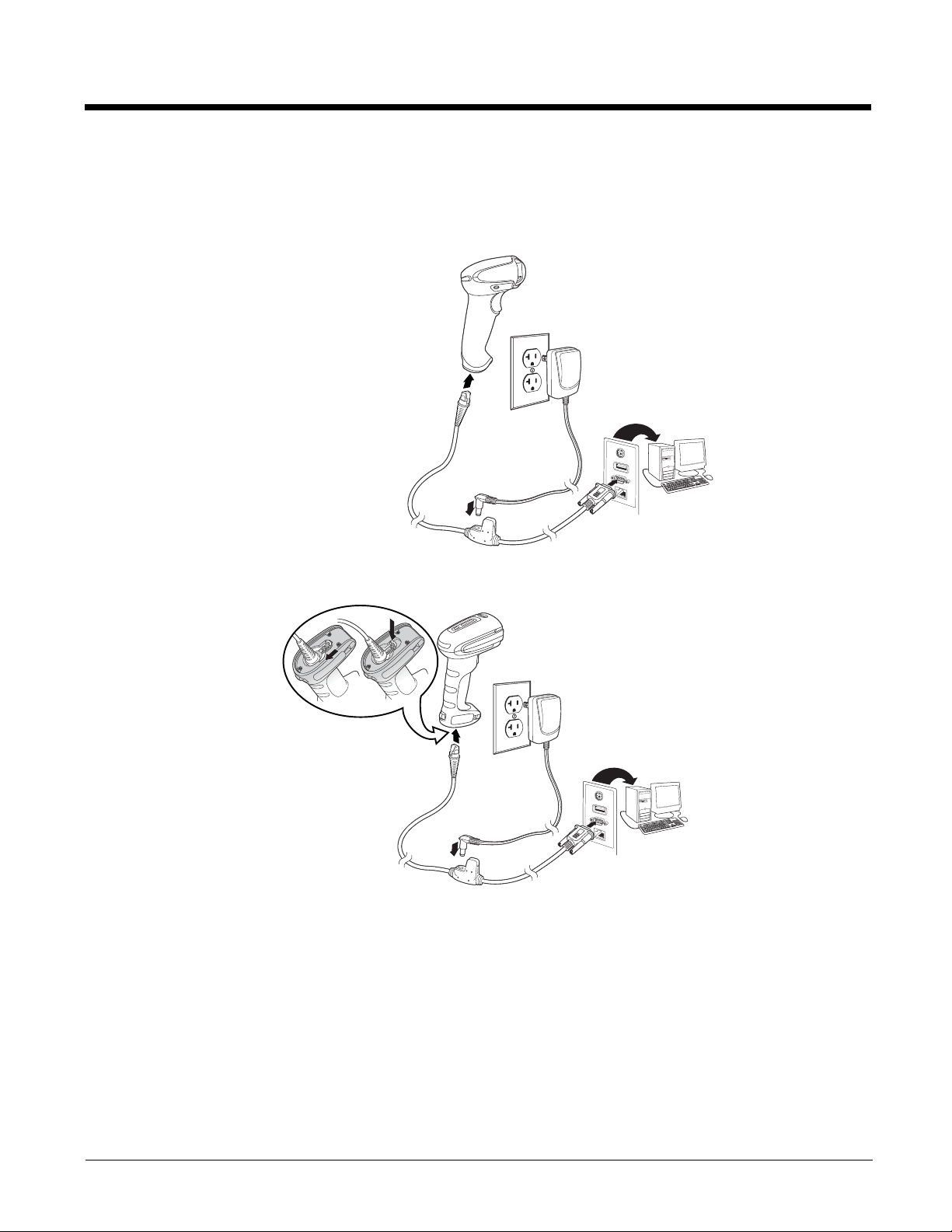

Corded Xenon Scanner

USB Connection:

Getting Started

About This Manual

This User’s Guide provides installation and programming instructions for the Xenon™ 1900 and 1910 corded area-imaging

scanners, the Xenon 1902 and 1912 cordless area-imaging scanners, the Granit 1910i and 1980i corded industrial scanners,

and the Granit 1911i and 1981i cordless industrial scanners. Product specifications, dimensions, warranty, and customer support information are also included.

Honeywell bar code scanners are factory programmed for the most common terminal and communications settings. If you need

to change these settings, programming is accomplished by scanning the bar codes in this guide.

An asterisk (*) next to an option indicates the default setting.

Unpacking Your Device

After you open the shipping carton containing the product, take the following steps:

• Check for damage during shipment. Report damage immediately to the carrier who delivered the carton.

• Make sure the items in the carton match your order.

• Save the shipping container for later storage or shipping.

Connecting the Device

Connecting with USB

A scanner or a cordless base can be connected to the USB port of a computer.

1. Connect the appropriate interface cable to the device first, then to the computer.

1 - 1

Page 14

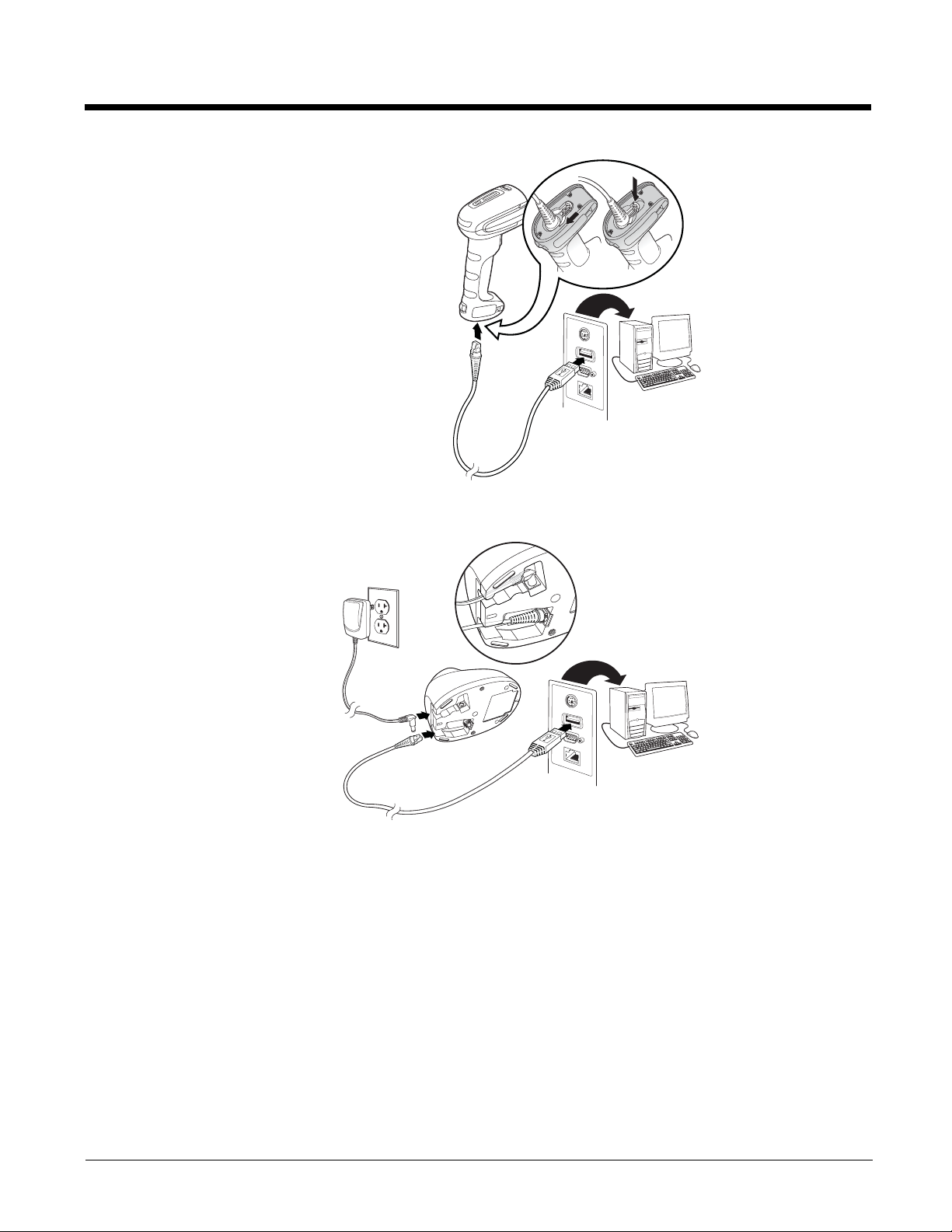

2. If you are connecting a Granit scanner, make sure the cable is pushed tightly into the scanner. Loosen the locking plate

Corded Granit Scanner

USB Connection:

CCB01-010BT Base

USB Connection:

and slide it over the base of the cable connector to lock the cable in place. Tighten the screw.

1 - 2

Page 15

Note: The power supply must be ordered separately, if needed.

CCB02-100BT/CCB05100BT Base USB

Connection:

3. If you are connecting a CCB01-010BT Base, make sure the cables are secured in the wireways in the bottom of the

cordless base and the base sits flat on a horizontal surface. If you are connecting a CCB02-100BT or CCB05-100BT

Base, see Mounting a CCB02-100BT/CCB05-100BT Base on page 1-9.

4. The scanner beeps.

5. Verify the scanner or cordless base operation by scanning a bar code from the Sample Symbols in the back of this

manual.

The unit defaults to a USB PC Keyboard. Refer to page 2-3 for other USB terminal settings.

For additional USB programming and technical information, refer to “USB Application Note,” available at www.honey-

wellaidc.com.

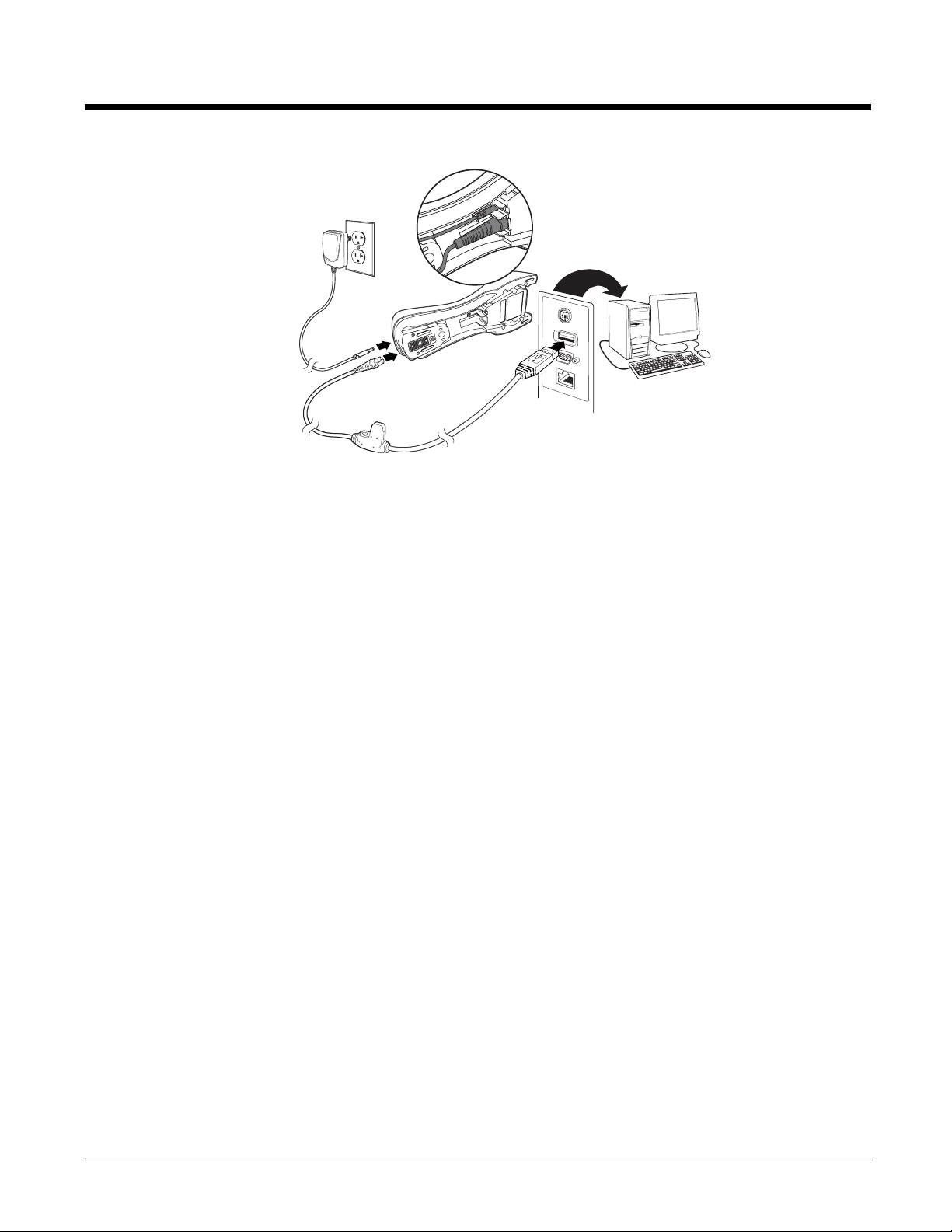

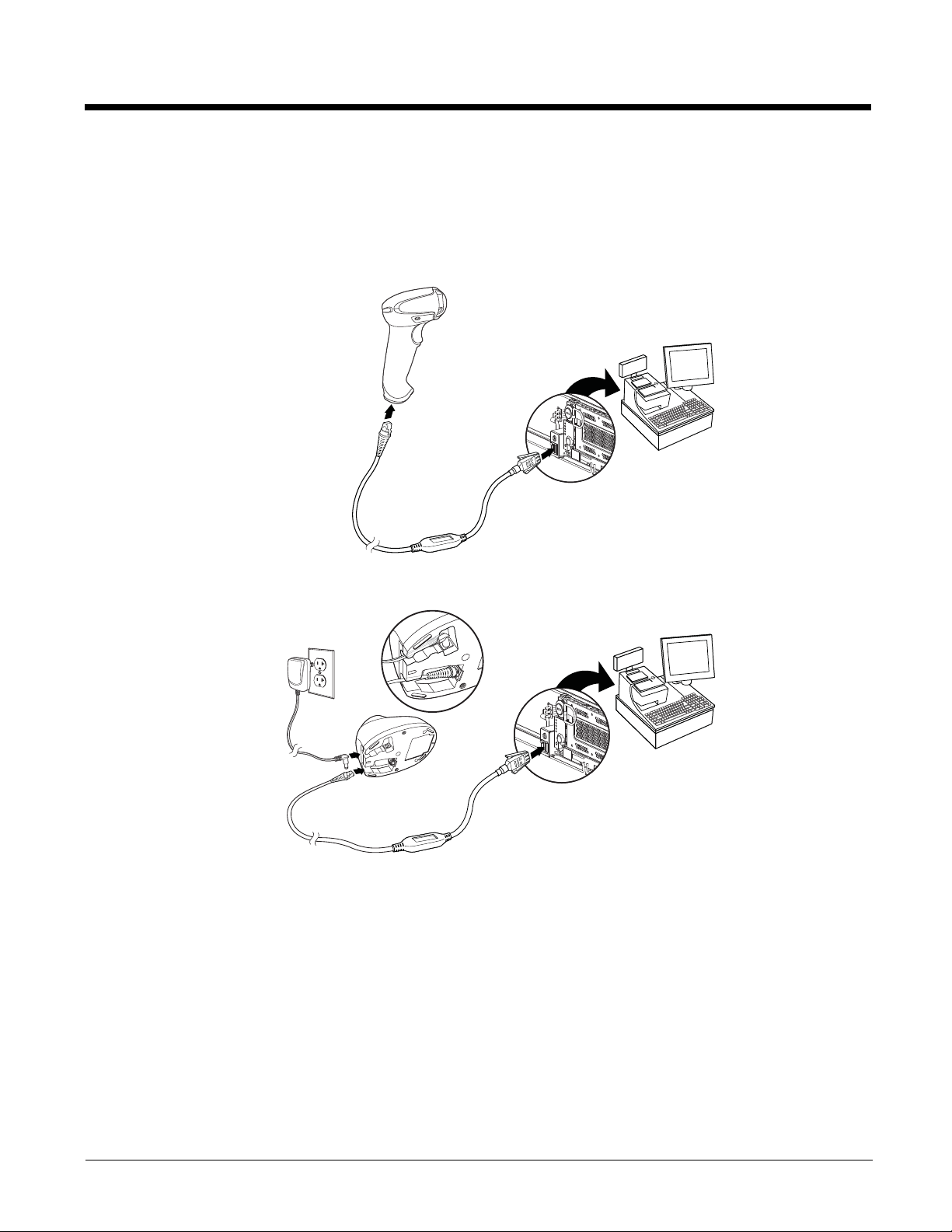

Connecting with Keyboard Wedge

A scanner or cordless base can be connected between the keyboard and PC as a “keyboard wedge,” where the scanner

provides data output that is similar to keyboard entries.

Note: The Granit 1980i does not support the keyboard wedge interface.

The following is an example of a keyboard wedge connection:

1. Turn off power and disconnect the keyboard cable from the back of the terminal/computer.

1 - 3

Page 16

2. Connect the appropriate interface cable to the device and to the terminal/computer.

Corded Xenon Scanner

Keyboard Wedge

Connection:

Corded Granit Scanner

Keyboard Wedge

Connection:

3. If you are connecting a Granit scanner, make sure the cable is pushed tightly into the scanner. Loosen the locking plate

and slide it over the base of the cable connector to lock the cable in place. Tighten the screw.

1 - 4

Page 17

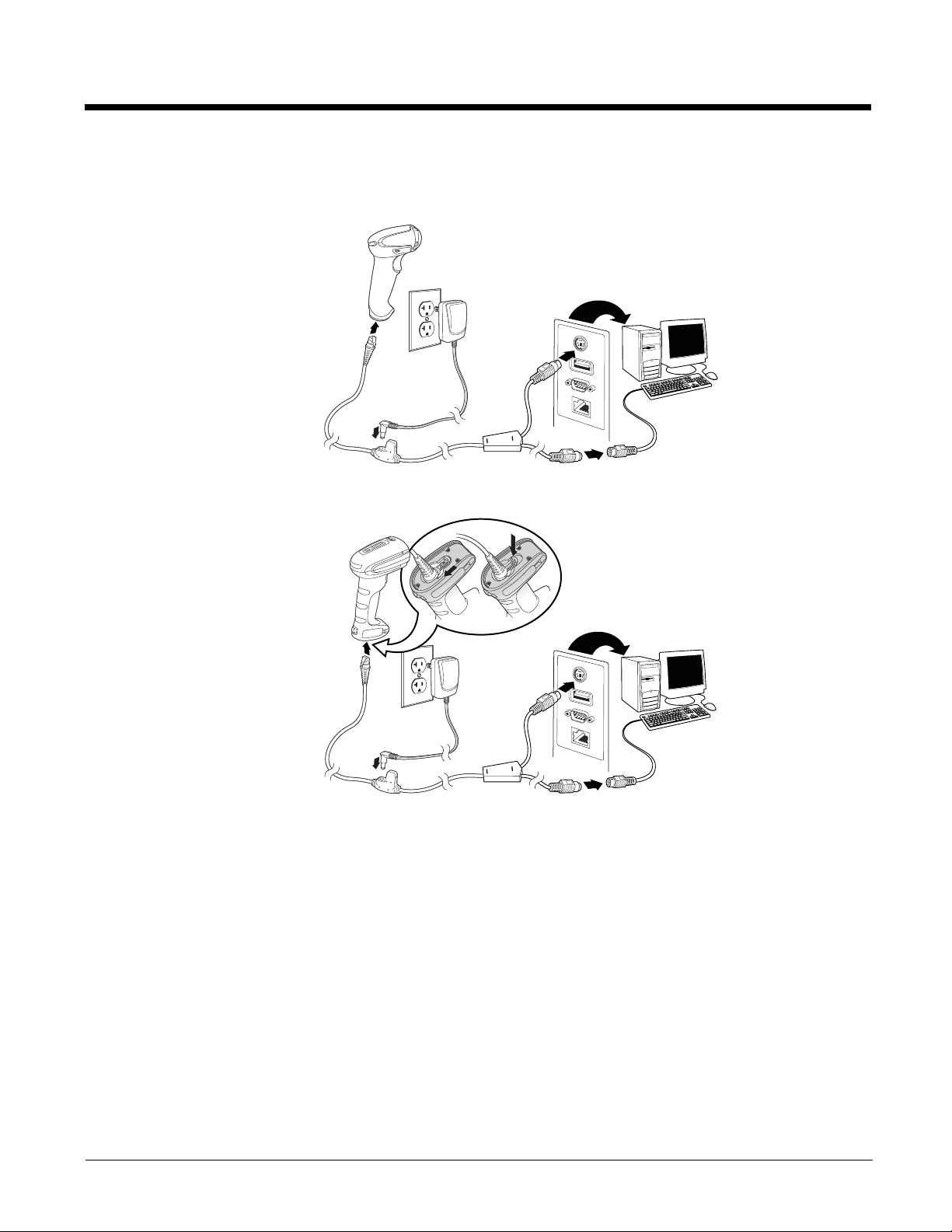

Note: The power supply must be ordered separately, if needed.

CCB01-010BT Base Keyboard

Wedge Connection:

CCB02-100BT/CCB05-100BT

Base Keyboard Wedge

Connection:

4. If you are connecting a CCB01-010BT Base, make sure the cables are secured in the wireways in the bottom of the

cordless base and the base sits flat on a horizontal surface. If you are connecting a CCB02-100BT or CCB05-100BT

Base, see Mounting a CCB02-100BT/CCB05-100BT Base on page 1-9.

5. Turn the terminal/computer power back on. The scanner beeps.

6. Verify the scanner or cordless base operation by scanning a bar code from the Sample Symbols in the back of this

manual. The scanner beeps once. If using a Granit scanner, it also vibrates.

The unit defaults to an IBM PC AT and compatibles keyboard wedge interface with a USA keyboard. A carriage return (CR)

suffix is added to bar code data.

1 - 5

Page 18

Connecting with RS232 Serial Port

Corded Xenon Scanner

RS232 Serial Port

Connection:

Corded Granit Scanner RS232 Serial

Port Connection:

1. Turn off power to the terminal/computer.

2. Connect the appropriate interface cable to the scanner.

Note: For the scanner or cordless base to work properly, you must have the correct cable for your type of terminal/computer.

1 - 6

Page 19

3. If you are connecting a Granit scanner, make sure the cable is pushed tightly into the scanner. Loosen the locking plate

CCB01-010BT Base

RS232 Serial Port Connection:

CCB02-100BT/CCB05/100BT Base

RS232 Serial Port Connection:

and slide it over the base of the cable connector to lock the cable in place. Tighten the screw.

Note: The power supply must be ordered separately, if needed.

4. If you are connecting a CCB01-010BT Base, make sure the cables are secured in the wireways in the bottom of the

cordless base and the base sits flat on a horizontal surface. If you are connecting a CCB02-100BT or CCB05-100BT

Base, see Mounting a CCB02-100BT/CCB05-100BT Base on page 1-9.

5. Plug the serial connector into the serial port on your computer. Tighten the two screws to secure the connector to the

port.

6. Once the scanner or cordless base has been fully connected, power up the computer.

This interface programs 115,200 baud, 8 data bits, no parity, and 1 stop bit.

1 - 7

Page 20

Connecting with RS485

Corded Xenon Scanner

RS485 Connection:

CCB01-010BT Base

RS485 Connection:

A Xenon scanner or cordless base can be connected for an IBM POS terminal interface. (This interface is not available in

the Granit devices.)

1. Connect the appropriate interface cable to the device, then to the computer.

Note: The power supply must be ordered separately, if needed.

2. Make sure the cables are secured in the wireways in the bottom of the cordless base and the base sits flat on a

horizontal surface.

3. Turn the terminal/computer power back on. The scanner beeps.

4. Verify the scanner or cordless base operation by scanning a bar code from the Sample Symbols in the back of this

manual. The scanner beeps once. If using a Granit scanner, it also vibrates.

For further RS485 settings, refer to RS485, page 2-2.

1 - 8

Page 21

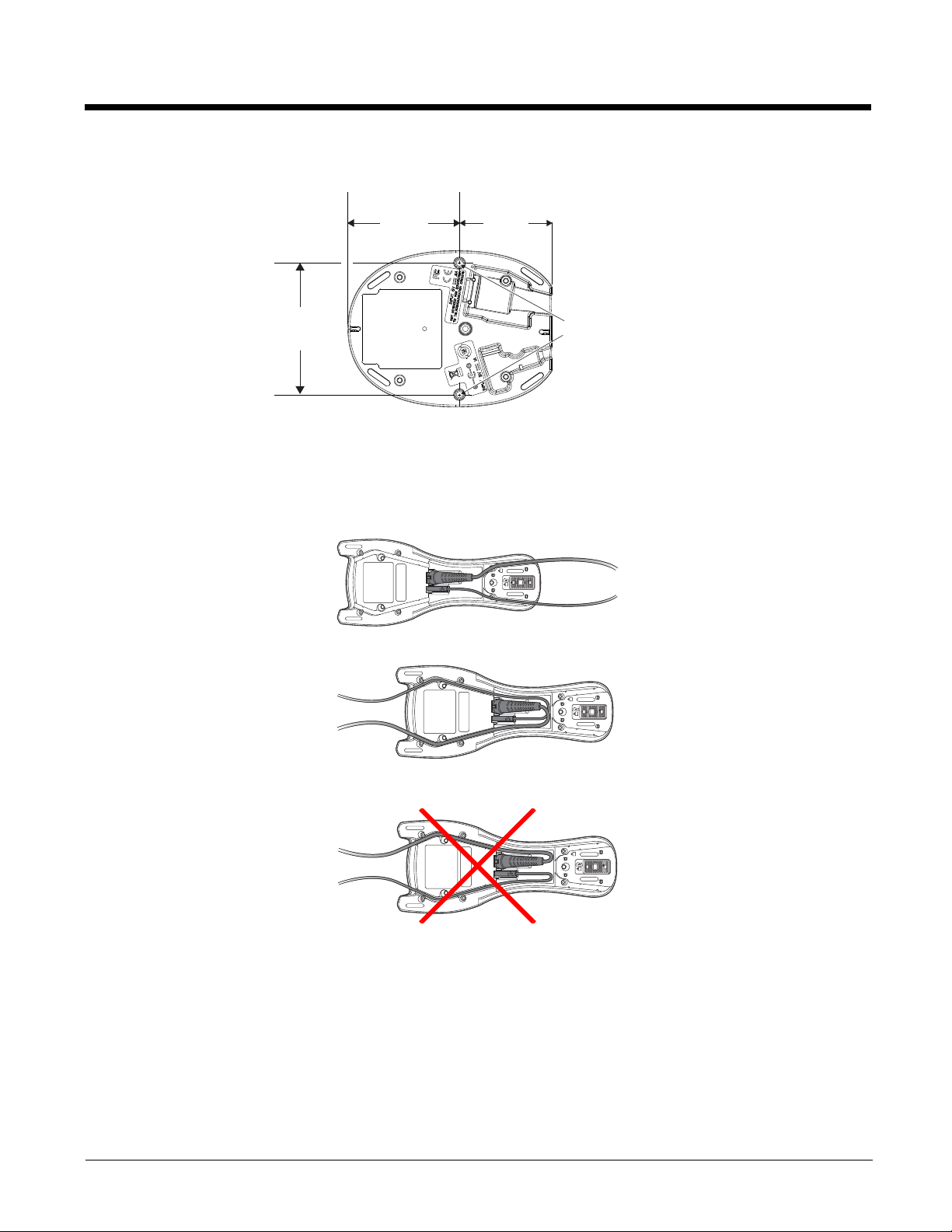

Mounting a CCB01-010BT Charge Base

2.8 in.

72.1mm

3.35 in.

85.09mm

2.36 in.

59.84mm

8x32 thread

x .39 in. (10mm) deep

Mounting a CCB02-100BT/CCB05-100BT Base

The CCB02-100BT or CCB05-100BT Base can be mounted on either a horizontal or vertical surface. The cables can be routed

through either the top or the bottom of the base.

The cables can be routed down through the bottom of the base, securing the cables in the wireways.

The cables can also be routed up through the top of the base, crossing them over and securing the cables in the wireways.

When routing the cables up through the top of the base, be sure to cross the cables over before placing in the wireways. If not,

too much strain is placed on the cable connectors.

1 - 9

Page 22

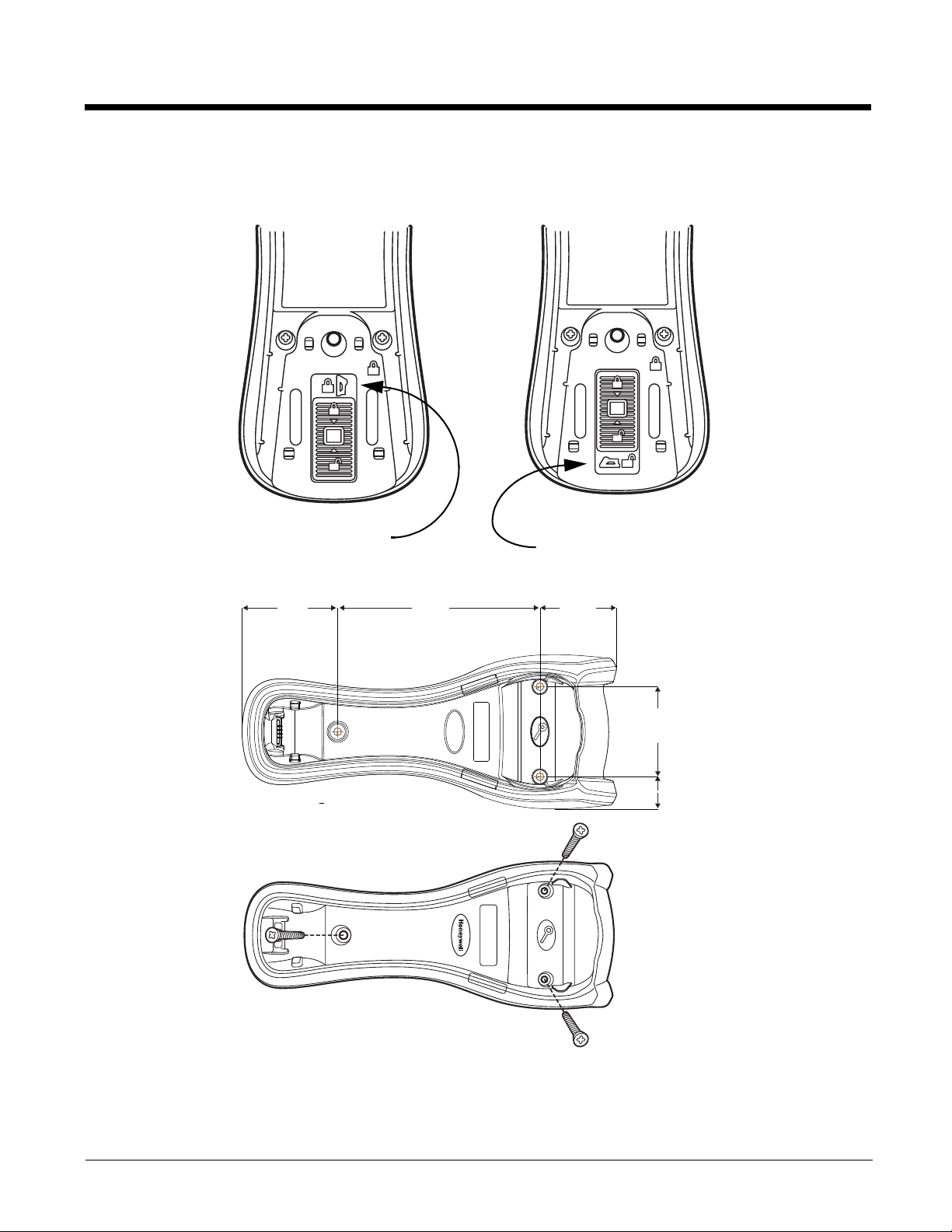

When mounted on a vertical surface, a locking system is used to secure the scanner when it is in the stand. When mounted on

Locked position

for vertical mount

Unlocked position

for horizontal mount

a horizontal surface, the locking mechanism should be set to unlocked (pushed up). When mounted on a vertical surface, the

locking mechanism should be set to locked (pushed down).

Use 30mm screws, appropriate for the mounting surface material, to mount the base securely.

2.51 in.

63.7mm

5.31 in.

134.92mm

2 in.

51.17mm

2.36 in.

60mm

.84 in.

21.42mm

1 - 10

Page 23

Reading Techniques

Linear bar codes

with aiming beam

2D Matrix symbol

with aiming beam

Linear bar codes

with aiming pattern

2D Matrix symbol

with aiming pattern

Xenon 1900/1902/1910/1912 and Granit 1910i/1911i

The Xenon 1900/1902 scanners have a view finder that projects a bright red aiming beam that corresponds to the scanner’s horizontal field of view. The Xenon 1910/1912 and Granit 1910i/1911i scanners have an aiming pattern. The aiming

beam or pattern should be centered over the bar code, but it can be positioned in any direction for a good read.

1 - 11

Page 24

Granit 1980i/1981i

Near distance scanning

less than 11.8 in/30 cm

Far distance scanning

up to 50 ft/15.2 m

The Granit 1980i/1981i scanners use a laser aimer (red dot) and a red LED (red box) to locate bar codes. Use the red LED

when scanning at a near distance (less than 11.8 inches / 30 cm) and center the box over the bar code. The laser aimer

(red dot) appears to the right of the center of the bar code. Use the laser aimer (red dot) when scanning at a far distance

(up to 50 feet / 15.2 meters) and aim at the center of the bar code. At far distances the red box may not be apparent. For

both near distance and far distance, the aimers can be positioned in any direction for a good read.

The aiming beam or pattern is smaller when the scanner is closer to the code and larger when it is farther from the code.

Symbologies with smaller bars or elements (mil size) should be read closer to the unit. Symbologies with larger bars or elements (mil size) should be read farther from the unit. To read single or multiple symbols (on a page or on an object), hold

the scanner at an appropriate distance from the target, pull the trigger, and center the aiming beam or pattern on the symbol. If the code being scanned is highly reflective (e.g., laminated), it may be necessary to tilt the code up 15° to 18° to prevent unwanted reflection.

Menu Bar Code Security Settings

Honeywell scanners are programmed by scanning menu bar codes or by sending serial commands to the scanner. If you want

to restrict the ability to scan menu codes, you can use the Menu Bar Code Security settings. Please contact the nearest technical support office (see Technical Assistance on page 15-1) for further information.

1 - 12

Page 25

Setting Custom Defaults

Set Custom Defaults

Save Custom Defaults

Activate Custom Defaults

You have the ability to create a set of menu commands as your own, custom defaults. To do so, scan the Set Custom Defaults

bar code below before scanning the menu commands for your custom defaults. If a menu command requires scanning numeric

codes from the back cover, then a Save code, that entire sequence will be saved to your custom defaults. When you have

entered all the commands you want to save for your custom defaults, scan the Save Custom Defaults bar code.

Note: When using a cordless system, the Custom Defaults settings apply to all workgroups. Scanning the Save Defaults bar

code also causes both the scanner and the base or Access Point to perform a reset and become unlinked. The scanner

must be placed in its base to re-establish the link before any setup codes are entered. If using an Access Point, the linking

bar code must be scanned. See Cordless System Operation beginning on page 3-1 for additional information.

You may have a series of custom settings and want to correct a single setting. To do so, just scan the new setting to overwrite

the old one. For example, if you had previously saved the setting for Beeper Volume at Low to your custom defaults, and decide

you want the beeper volume set to High, just scan the Set Custom Defaults bar code, then scan the Beeper Volume High

menu code, and then Save Custom Defaults. The rest of the custom defaults will remain, but the beeper volume setting will be

updated.

Resetting the Custom Defaults

If you want the custom default settings restored to your scanner, scan the Activate Custom Defaults bar code below. This is

the recommended default bar code for most users. It resets the scanner to the custom default settings. If there are no custom

defaults, it will reset the scanner to the factory default settings. Any settings that have not been specified through the custom

defaults will be defaulted to the factory default settings.

Note: If using a cordless system, scanning this bar code also causes both the scanner and the base or Access Point to perform

a reset and become unlinked. The scanner must be placed in its base to re-establish the link. If using an Access Point,

the linking bar code must be scanned. See Cordless System Operation beginning on page 3-1 for additional information.

1 - 13

Page 26

1 - 14

Page 27

2

IBM PC AT and Compatibles with

CR suffix

Laptop Direct Connect

with CR suffix

RS232 Interface

Programming the Interface

Introduction

This chapter describes how to program your system for the desired interface.

Programming the Interface - Plug and Play

Plug and Play bar codes provide instant scanner set up for commonly used interfaces.

Note: After you scan one of the codes, power cycle the host terminal to have the interface in effect.

Keyboard Wedge

If you want your system programmed for an IBM PC AT and compatibles keyboard wedge interface with a USA keyboard, scan

the bar code below. Keyboard wedge is the default interface.

Note: The Granit 1980i does not support the keyboard wedge interface.

Note: The following bar code also programs a carriage return (CR) suffix.

Laptop Direct Connect

For most laptops, scanning the Laptop Direct Connect bar code allows operation of the scanner in parallel with the integral

keyboard. The following Laptop Direct Connect bar code also programs a carriage return (CR) suffix and turns on Emulate

External Keyboard (page 2-16).

Note: The Granit 1980i does not support Laptop Direct Connect.

RS232 Serial Port

The RS232 Interface bar code is used when connecting to the serial port of a PC or terminal. The following RS232 Interface

bar code also programs a carriage return (CR) and a line feed (LF) suffix, baud rate, and data format as indicated below. It also

changes the trigger mode to manual.

Option Setting

Baud Rate 115,200 bps

Data Format 8 data bits, no parity bit, 1 stop bit

2 - 1

Page 28

RS485

IBM Port 5B Interface

IBM Port 9B

HHBCR-1 Interface

IBM Port 17 Interface

IBM Port 9B

HHBCR-2 Interface

* Packet Mode Off

Packet Mode On

Scan one of the following “Plug and Play” codes to program the scanner for an IBM POS terminal interface.

Note: This interface is not supported in Granit devices.

After scanning one of these codes, you must power cycle the cash register.

Each bar code above also programs the following suffixes for each symbology:

Symbology Suffix Symbology Suffix

EAN 8 0C Code 39 00 0A 0B

EAN 13 16 Interleaved 2 of 5 00 0D 0B

UPC A 0D Code 128 * 00 0A 0B

UPC E 0A Code 128 ** 00 18 0B

MaxiCode 00 2F 0B

* Suffixes programmed for Code 128 with IBM 4683 Port 5B, IBM 4683 Port 9B HHBCR-1, and IBM 4683 Port 17 Interfaces

**Suffixes programmed for Code 128 with IBM 4683 Port 9 HHBCR-2 Interface

RS485 Packet Mode

The following selection allows you to break up large bar code data into smaller packets on an IBM POS terminal. To break

up large bar codes into small packets, scan the Packet Mode On bar code below. Scan the Packet Mode Off bar code if you

want large bar code data to be sent to the host in a single chunk. Default = Packet Mode Off.

2 - 2

Page 29

RS485 Packet Length

Packet Length

USB IBM SurePos

(USB Handheld Scanner)

Interface

USB IBM SurePos

(USB Tabletop Scanner)

Interface

U

S

B

K

e

y

b

o

a

r

d

(

P

C

)

USB Keyboard (Mac)

USB Japanese Keyboard (PC)

If you are using Packet mode, you can specify the size of the data “packet” that is sent to the host. Scan the Packet

Length bar code, then then the packet size (from 20 - 256) from the Programming Chart inside the back cover of this

manual, then Save. Default = 40.

USB IBM SurePos

Scan one of the following “Plug and Play” codes to program the scanner for an IBM SurePos (USB handheld scanner) or IBM

SurePos (USB tabletop scanner) interface.

Note: After scanning one of these codes, you must power cycle the cash register.

Each bar code above also programs the following suffixes for each symbology:

Symbology Suffix Symbology Suffix

EAN 8 0C Code 39 00 0A 0B

EAN 13 16 Interleaved 2 of 5 00 0D 0B

UPC A 0D Code 128 00 18 0B

UPC E 0A Code 39 00 0A 0B

USB PC or Macintosh Keyboard

Scan one of the following codes to program the scanner for USB PC Keyboard or USB Macintosh Keyboard. Scanning these

codes also adds a CR suffix.

2 - 3

Page 30

USB HID

USB HID Bar Code Scanner

USB Serial

CTS/RTS Emulation On

* CTS/RTS Emulation Off

ACK/NAK Mode On

* ACK/NAK Mode Off

ReM Off

Scan the following code to program the scanner for USB HID bar code scanners.

USB Serial

Scan the following code to program the scanner to emulate a regular RS232-based COM Port. If you are using a Microsoft®

Windows® PC, you will need to download a driver from the Honeywell website (www.honeywellaidc.com). The driver will use

the next available COM Port number. Apple® Macintosh computers recognize the scanner as a USB CDC class device and

automatically use a class driver.

Note: No extra configuration (e.g., baud rate) is necessary.

CTS/RTS Emulation

ACK/NAK Mode

Remote MasterMind™ for USB

When using a USB interface, you may wish to configure your scanner to communicate with Remote MasterMind Scanner Management Software (ReM). Scan the ReM On bar code to communicate with ReM. To disable this capability, scan ReM Off.

2 - 4

Page 31

Verifone® Ruby Terminal Default Settings

ReM On

Verifone Ruby Settings

Gilbarco Settings

Honeywell Bioptic Settings

Scan the following Plug and Play code to program the scanner for a Verifone Ruby terminal. This bar code sets the baud rate to

1200 bps and the data format to 8 data bits, mark parity bit, 1 stop bit. It also adds a line feed (LF) suffix and programs the following prefixes for each symbology:

Symbology Prefix

UPC-A A

UPC-E A

EAN-8 FF

EAN-13 F

Gilbarco® Terminal Default Settings

Scan the following Plug and Play code to program the scanner for a Gilbarco terminal. This bar code sets the baud rate to 2400

bps and the data format to 7 data bits, even parity, 2 stop bits. It also adds a carriage return (CR) suffix and programs the following prefixes for each symbology:

Symbology Prefix

UPC-A A

UPC-E E0

EAN-8 FF

EAN-13 F

Honeywell Bioptic Aux Port Configuration

Scan the following Plug and Play code to program the scanner for a Honeywell bioptic scanner auxiliary port configuration. This

bar code sets the baud rate to 38400 bps and the data format to 8 data bits, no parity, 1 stop bit.

2 - 5

Page 32

Datalogic™ Magellan® Aux Port Configuration

Datalogic Magellan Settings

NCR Bioptic Settings

Wincor Nixdorf Terminal Settings

Scan the following Plug and Play code to program the scanner for a Datalogic Magellan auxiliary port configuration. This bar

code sets the baud rate to 9600 bps and the data format to 8 data bits, no parity, 1 stop bit.

NCR Bioptic Aux Port Configuration

Scan the following Plug and Play code to program the scanner for an NCR bioptic scanner auxiliary port configuration. The following prefixes are programmed for each symbology:

Symbology Prefix Symbology Prefix

UPC-A A Interleaved 2 of 5 b

UPC-E E0 Code 128 f

GS1 DataBar

Omnidirecitonal

EAN-8 FF GS1 DataBar

Expanded

EAN-13 F Codabar N

Code 39 a Code 32

Pharmaceutical

(PARAF)

r

r

a

Wincor Nixdorf Terminal Default Settings

Scan the following Plug and Play code to program the scanner for a Wincor Nixdorf terminal. This bar code sets the baud rate

to 9600 bps and the data format to 8 data bits, no parity, 1 stop bit.

2 - 6

Page 33

Wincor Nixdorf Beetle™ Terminal Default Settings

Wincor Nixdorf Beetle Settings

Wincor Nixdorf RS232 Mode A

Settings

Scan the following Plug and Play code to program the scanner for a Wincor Nixdorf Beetle terminal. The following prefixes are

programmed for each symbology:

Symbology Prefix Symbology Prefix

Aztec Code V Interleaved 2 of 5 I

Codabar N MaxiCode T

Code 93 L MicroPDF417 S

Code 128 K PDF417 Q

Data Matrix R QR Code U

EAN-8 B Straight 2 of 5 IATA H

EAN-13 A UPC-A A0

GS1 DataBar E UPC-E C

GS1-128 P All other bar codes M

Wincor Nixdorf RS232 Mode A

Scan the following Plug and Play code to program the scanner for a Wincor Nixdorf RS232 Mode A terminal. This bar code sets

the baud rate to 9600 bps and the data format to 8 data bits, odd parity, 1 stop bit. The following prefixes are programmed for

each symbology:

Note: This setting is not supported in Granit devices.

Symbology Prefix Symbology Prefix

Code 128 K EAN-13 A

Code 93 L GS1-128 K

Codabar N Interleaved 2 of 5 I

UPC-A A0 Plessey O

UPC-E C Straight 2 of 5 IATA H

EAN-8 B GS1 DataBar E

All other bar codes M

2 - 7

Page 34

Keyboard Country Layout

* United States

Albania

Azeri (Cyrillic)

Azeri (Latin)

Belarus

Belgium

Bosnia

Brazil

Brazil (MS)

Bulgaria (Cyrillic)

If your interface is USB Keyboard or Keyboard Wedge, your keyboard layout default is a US keyboard. To change this layout,

scan the appropriate Keyboard Country bar code below. By default, national character replacements are used for the following characters: # $ @ [ \ ] ^ ‘ { | } ~. Refer to the "ISO 2022/ISO 646 Character Replacements" on page A-7 to view the

character replacements for each country.

Keyboard Countries

2 - 8

Page 35

Keyboard Countries (Continued)

Bulgaria (Latin)

Canada (French legacy)

Canada (French)

Canada (Multilingual)

Croatia

Czech

Czech (Programmers)

Czech (QWERTY)

Czech (QWERTZ)

Denmark

Dutch (Netherlands)

2 - 9

Page 36

Keyboard Countries (Continued)

Estonia

Faroese

Finland

France

Gaelic

Germany

Greek

Greek (220 Latin)

Greek (220)

Greek (319 Latin)

Greek (319)

2 - 10

Page 37

Keyboard Countries (Continued)

Greek (Latin)

Greek (MS)

Greek (Polytonic)

Hebrew

Hungarian (101 key)

Hungary

Iceland

Irish

Italian (142)

Italy

Japan ASCII

2 - 11

Page 38

Keyboard Countries (Continued)

Kazakh

Kyrgyz (Cyrillic)

Latin America

Latvia

Latvia (QWERTY)

Lithuania

Lithuania (IBM)

Macedonia

Malta

Mongolian (Cyrillic)

Norway

2 - 12

Page 39

Keyboard Countries (Continued)

Poland

Polish (214)

Polish (Programmers)

Portugal

Romania

Russia

Russian (MS)

Russian (Typewriter)

SCS

Serbia (Cyrillic)

Serbia (Latin)

2 - 13

Page 40

Keyboard Countries (Continued)

Slovakia

Slovakia (QWERTY)

Slovakia (QWERTZ)

Slovenia

Spain

Spanish variation

Sweden

Switzerland (French)

Switzerland (German)

Tatar

Turkey F

2 - 14

Page 41

Keyboard Countries (Continued)

Turkey Q

Ukrainian

United Kingdom

United States (Dvorak)

United States (Dvorak left)

United Stated (Dvorak right)

United States (International)

Uzbek (Cyrillic)

* Regular

Caps Lock

Keyboard Style

This programs keyboard styles, such as Caps Lock and Shift Lock. If you have used Keyboard Conversion settings, they will

override any of the following Keyboard Style settings. Default = Regular.

Regular is used when you normally have the Caps Lock key off.

Caps Lock is used when you normally have the Caps Lock key on.

2 - 15

Page 42

Shift Lock is used when you normally have the Shift Lock key on (not common to U.S. keyboards).

Shift Lock

Automatic Caps Lock

Autocaps via NumLock

Emulate External Keyboard

* Keyboard Conversion Off

Convert All Characters

to Upper Case

Convert All Characters

to Lower Case

Automatic Caps Lock is used if you change the Caps Lock key on and off. The software tracks and reflects if you have Caps

Lock on or off . This selection can only be used with systems that have an LED that notes the Caps Lock status (AT keyboards).

Autocaps via NumLock bar code should be scanned in countries (e.g., Germany, France) where the Caps Lock key cannot be

used to toggle Caps Lock. The NumLock option works similarly to the regular Autocaps, but uses the NumLock key to retrieve

the current state of the Caps Lock.

Emulate External Keyboard should be scanned if you do not have an external keyboard (IBM AT or equivalent).

Note: After scanning the Emulate External Keyboard bar code, you must power cycle your computer.

Keyboard Conversion

Alphabetic keyboard characters can be forced to be all upper case or all lowercase. So if you have the following bar code:

“abc569GK,” you can make the output “ABC569GK” by scanning Convert All Characters to Upper Case, or to “abc569gk” by

scanning Convert All Characters to Lower Case.

These settings override Keyboard Style selections.

Note: If your interface is a keyboard wedge, first scan the menu code for Automatic Caps Lock (page 2-16). Otherwise, your

output may not be as expected.

Default = Keyboard Conversion Off.

2 - 16

Page 43

Control Character Output

Control Character Output On

* Control Character Output Off

Windows Mode Control + X

Mode On

* Control + X Mode Off

DOS Mode Control + X Mode On

Windows Mode Prefix/Suffix Off

This selection sends a text string instead of a control character. For example, when the control character for a carriage return is

expected, the output would display [CR] instead of the ASCII code of 0D. Refer to ASCII Conversion Chart (Code Page

1252) on page A-3. Only codes 00 through 1F are converted (the first column of the chart). Default = Off.

Note: Control + X (Control + ASCII) Mode overrides this mode.

Keyboard Modifiers

This modifies special keyboard features, such as CTRL+ ASCII codes and Turbo Mode.

Control + X (Control + ASCII) Mode On: The scanner sends key combinations for ASCII control characters for values 00-1F.

Windows is the preferred mode. All keyboard country codes are supported. DOS mode is a legacy mode, and it does not support all keyboard country codes. New users should use the Windows mode. Refer to Keyboard Function Relationships, page

10-1 for CTRL+ X Values.

Windows Mode Prefix/Suffix Off: The scanner sends key combinations for ASCII control characters for values 00-1F, but it

does not translate prefix or suffix information.

Default = Control + X Mode Off.

2 - 17

Page 44

Turbo M o d e: The scanner sends characters to a terminal faster. If the terminal drops characters, do not use Turbo Mode.

Turbo Mode On

* Turbo Mode Off

Numeric Keypad Mode On

* Numeric Keypad Mode Off

Automatic Direct Connect Mode

On

* Automatic Direct Connect

Mode Off

300

600

Default = Off.