Page 1

!

SUPER TRADELINE

Thermostat and Q674 Subbase

T874 Multistage

Application

The T874D Thermostat and Q674E Subbase provide 24

to 30 Vac control of standard 2 stage heating and 2 stage

cooling systems.

The Y594D includes the TG504 Thermostat Guard,

field-adjustable range stops and field-adjustable locking

levers.

Operation

The stages of heat make sequentially as the temperature

drops. Make refers to the mercury switch initiating a call for

heat or cool.

There are about 2° F [1° C] between stages so that the

second stage makes only when the first stage cannot handle

the load. This is the interstage differential.

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

1. Disconnect power supply to prevent electrical

shock or equipment damage.

2. To prevent interference with the thermostat

linkage, keep wire length to a minimum and

run wires as close as possible to the subbase.

3. Do not overtighten thermostat captive mounting screws, because damage to subbase threads

can result.

4. Do not short across coil terminals on relay. This

can burn out the thermostat heat anticipator.

Do not install thermostat where it may be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas behind the thermostat,

such as an outside wall.

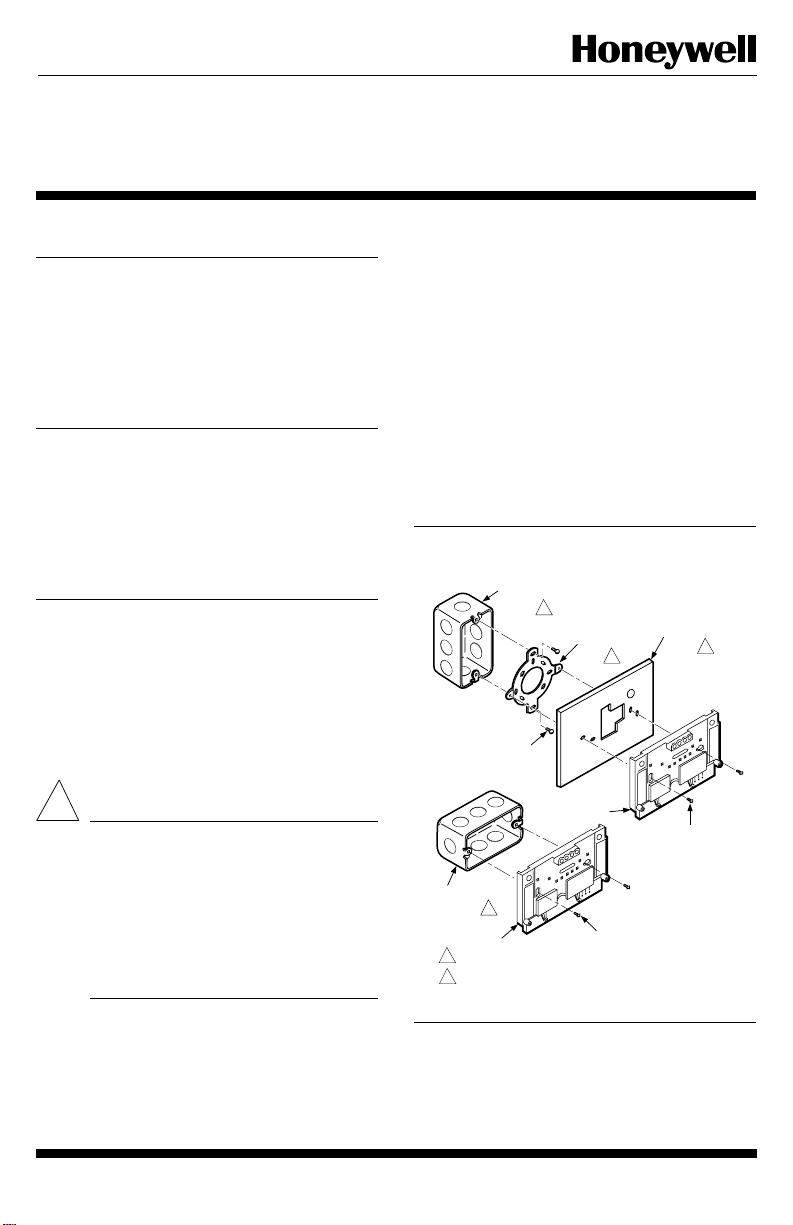

MOUNT SUBBASE

The thermostat subbase can be mounted on a vertical

outlet box, horizontal outlet box or directly on the wall.

1. If you must mount the subbase on a vertical outlet

box, order Honeywell part no. 193121A Adapter Assembly. See Fig. 1. The assembly includes an adapter ring, two

screws and a cover plate to conceal any holes or blemishes

on the wall. Install the ring and cover plate on the vertical

outlet box.

Fig. 1—Installation of Q674 Subbase on outlet

box.

VERTICAL

OUTLET

1

BOX

ADAPTER

RING

MOUNTING

SCREWS (2)

SUBBASE

HORIZONTAL

OUTLET

BOX

1

SUBBASE

1 NOT INCLUDED WITH UNIT.

2 ACCESSORY PARTS AVAILABLE (193121A).

MOUNTING

SCREWS (2)

COVER

PLATE

2

2

MOUNTING

SCREWS (2)

M925

IMPORTANT: An incorrectly leveled subbase will cause

the temperature control to deviate from setpoint. It is

not a calibration problem.

LOCATION

Install the thermostat about 5 ft [1.5 m] above the floor

in an area with good air circulation at average temperature.

For a wall installation, hold subbase in position and

mark holes for anchors. See Fig. 2. Wall anchors must be

obtained from local hardware store. Be careful that the

wires do not fall back into the wall opening. Set aside

subbase. Drill four 3/16 in. [4.6 mm] holes and gently tap

anchors into the holes until flush with the wall.

1 69-0753J. H. • 11-92 • ©Honeywell Inc. 1992 • Form Number 69-0753

Page 2

2. Pull electrical wires through the cover plate (if

(2)

used) and subbase cable opening. See Fig. 3.

3. Secure the cover plate (if used) and subbase with the

screws provided. Do not fully tighten the subbase screws.

4. Level the subbase using a spirit level, see Fig. 3, and

firmly tighten subbase mounting screws. The subbase mounting holes provide for minor out-of-level adjustments.

IMPORTANT: An incorrectly leveled subbase will cause

the temperature control to deviate from setpoint. It is

not a calibration problem.

Fig. 2—Installation of Q674 Subbase on wall.

Fig. 3—Subbase components and leveling

procedure.

SPIRIT LEVEL

TOP MOUNTING HOLES (2)

WIRING

TERMINAL

THERMOSTAT

CABLE OPENING

WALL

WIRES THROUGH

WALL OPENING

WALL

ANCHORS

(2)

SUBBASE

M926

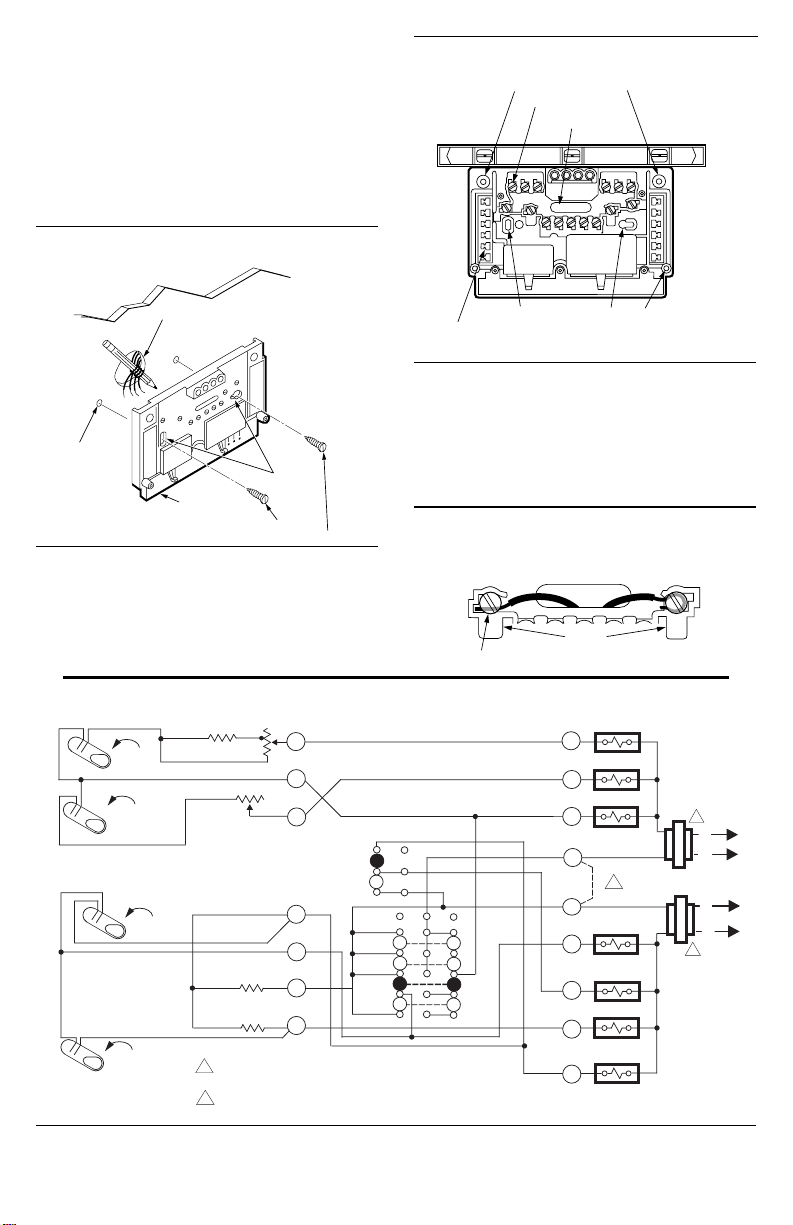

WIRING THE SUBBASE

All wiring must comply with local electrical codes and

ordinances. Follow equipment manufacturer wiring instructions when available. To wire subbase, proceed as follows:

1. Connect the system wires to the subbase as shown in

Figs. 5 through 8. A letter code is located near each terminal

MOUNTING

HOLES

MOUNTING

SCREWS

TO SPRING FINGER CONTACTS

ON THE THERMOSTAT

(UP TO 12)

for identification. The terminal barrier permits straight or

conventional wraparound wiring connection. See Fig. 4.

2. Firmly tighten each terminal screw.

3. Fit wires as close as possible to the subbase. Push

excess wire back into hole.

4. Plug hole with nonflammable insulation to prevent

drafts from affecting the thermostat.

Fig. 4—Barrier configuration.

FOR STRAIGHT

INSERTION–

STRIP 5/16 in. [8 mm]

SUBBASE TERMINAL SCREW

Fig. 5—Schematic and hookup for T874D Thermostat with Q674E Subbase.

FALL

H2

RISE

C2

FALL

H1

RISE

C1

H1 ANTICIPATOR

H2 ANTICIPATOR

FAN

SWITCH

AUTO

ON

SYSTEM

SWITCH

OFF

C1 ANTICIPATOR

C2 ANTICIPATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

JUMPER RC AND RH FOR A SINGLE TRANSFORMER SYSTEM.

HEAT

AUTO

COOL

MOUNTING HOLES (2)

BARRIER

W1

HEAT RELAY 1

W2

HEAT RELAY 2

B

CHANGEOVER

RELAY (HEAT)

RH

RC

O

CHANGEOVER

RELAY (COOL)

G

FAN RELAY

Y2

COMPRESSOR

CONTACTOR 2

Y1

COMPRESSOR

CONTACTOR 1

POST (2) FOR

MOUNTING

THERMOSTAT

FOR WRAPAROUND–

STRIP 7/16 in. [11 mm]

2

M927

M928

1

1

L2

L1

(HOT)

L1

(HOT)

L2

M3203

2

Page 3

TEMPERATURE LEVER STOPS

!

The T874D has factory-installed temperature lever locking screws and stop brackets. See Figs. 6 and 7. These

should be used only if the HEAT and COOL temperature

setpoint lever ranges are to be restricted.

Fig. 6—Location of locking lever screws.

LEVER LOCKING SCREWS

M18680

Fig. 8—Installing locking lever screws and stop

brackets.

HOLES FOR INSULATED

LOCKING LEVER SCREWS

HEAT

LEVER

COOL

LEVER

HOLE WITH

BRASS INSERT

BRACKET

TABS

Fig. 7—Location of lever stop brackets.

LEVER STOP BRACKETS

M18681

INSTALL AND ADJUST LOCKING LEVER

SCREWS

The two screws with insulated heads should be used

only if the HEAT and COOL levers are to be locked in

place at a specific temperature control point. Do not use

standard screws that provide metal-to-metal contact with

the lever brackets.

To install:

1. Refer to Fig. 8 for screw hole locations.

2. Install the two screws with insulated heads in the

indicated holes Do not overtighten screws.

3. Set the HEAT lever and the COOL lever at desired

temperature control points.

4. Firmly tighten both screws.

INSTALL AND ADJUST STOP BRACKETS

The stop brackets should be installed only if there is a

need to restrict the adjustable range of the heating and

cooling temperature setpoint levers. See Fig. 6.

To install:

1. Turn over the T874 Thermostat to the back side.

Locate the hole in the plastic base for the brass insert. See

Fig. 9.

2. Push brass insert into the hole with your finger.

3. Turn to front side of the T874 Thermostat.

4. Place the two stop brackets in position with the tabs

in the slot between the HEAT and COOL levers. See Fig. 8.

5. Insert the mounting screws into the two slots in the

stop brackets and attach to the brass insert. Tighten the

screw to pull the brass insert into the back of the thermostat.

6. Loosen the mounting screw enough to slide the stop

brackets for adjustment.

7. Move the HEAT and COOL setpoint levers to the

maximum temperature that is desired.

8. Slide the stop brackets until one rests against the

HEAT lever and the other against the COOL lever.

ADJUSTABLE

LEVER STOP

BRACKETS

BRACKET

SLOTS

MOUNTING

SCREW

M7346

Fig. 9—Installing brass insert.

LED WINDOW

BRASS INSERT

INSERT HOLE

BACK OF

THERMOSTAT

M955A

9. Firmly tighten the mounting screw.

10. If the HEAT and COOL levers are to be locked in

place at a specific temperature, use the two insulated head

screws supplied instead of the two adjustable lever stop

brackets.

CAUTION

Do not use standard screws that provide metal-tometal contact with the stop brackets. Short circuit and potential equipment damage may result.

3 69-0753

Page 4

MOUNT THERMOSTAT

)

1. Remove the thermostat cover by pulling the bottom

edge of the cover upward until it snaps free of the mounting slots.

NOTE: The cover is hinged at the top and must be removed

by pulling up at the bottom.

2. Carefully remove and discard the polystyrene packing

insert that protects the mercury switches during shipment.

3. Turn over thermostat base and note the spring fingers

that engage the subbase contacts. Make sure the spring

fingers are not bent flat, preventing proper electrical contact with the subbase.

4. Note the two tabs on the top inside edge of the

thermostat base. The tabs fit into corresponding slots on top

of the subbase. Mount the thermostat on the subbase.

5. Align the two captive mounting screws in the thermostat base with the posts on the subbase. See Fig. 10.

Tighten both screws. Do not overtighten screws or damage

to subbase posts can result.

Fig. 10—Mounting thermostat on subbase.

THERMOSTAT

MOUNTING SLOTS (2)

THERMOSTAT

MOUNTING POST (2)

COOL

50 60 70 80

50 60 70 80

SUBBASE

THERMOSTAT

M936

HEAT

CAPTIVE MOUNTING

SCREWS (2

Settings

SET THE HEAT ANTICIPATOR

Move the indicator to match the current rating of the

primary control. See Fig. 11. When using the T874 Thermostat with two stages of heating, set each heat anticipator to match its respective primary control current draw. If

you cannot find the current rating on the primary control,

or if further adjustment is necessary, see NOTE below and

use the following procedure to determine the current draw

of each stage.

The current draw of each heating stage must be measured with the thermostat removed and the power on to the

heating system.

1. Connect an ac ammeter of appropriate range between

the heating terminals of the subbase:

Stage 1—between W1 and RH;

Stage 2—between W2 and RH.

2. Move the system switch to HEAT or AUTO.

3. After one minute, read the ammeter and record the

reading:

Stage 1—__________ amperes.

Stage 2—__________ amperes.

4. After mounting the thermostat, set the adjustable

heat anticipator to match the readings measured in Step 3.

NOTE: If equipment cycles too fast, set the indicator to a

higher current rating, not more than one-half division at

a time, and recheck cycle rate. Most conventional two-

stage heating equipment is designed to operate at three

cycles per hour per stage and one-stage heating equip-

ment at six cycles per hour, at 50 percent load condition.

TEMPERATURE SETTING

Move the heating and cooling setpoint levers to the

desired comfort positions. See Fig. 12. One lever controls

all stages of heating, and the other lever controls all stages

of cooling. The minimum differential between heating and

cooling setpoint is 3° F [1.7° C], which means the setting

levers are designed so they cannot be set closer together

than 3° F [1.7° C].

INSTALL OR REMOVE TG504A KEY LOCK

COVER

To install the TG504A:

—hang the upper edge of the cover on the thermostat

subbase.

—swing cover downward.

Spring-loaded locking mechanism will automatically

engage mounting posts and secure cover in final position

without use of key provided.

To remove the TG504A:

— insert the key provided.

— rotate the key clockwise until locking mechanism

releases from thermostat posts.

— swing cover upward and off.

Fig. 11—Adjustable heat anticipator scales.

.12

.15

.2

.3

.4

.5

.6

.8

1.2

.10

.12

.15

.2

.3

.4

1.2

.8

.6

STAGE TWO

ANTICIPATOR

HEATING CONTROL

MOVE INDICATOR TO

MATCH CURRENT RATING

OF PRIMARY CONTROL

4

STAGE ONE

ANTICIPATOR

HEATING CONTROL

M5069

Page 5

Fig. 12—Location of external components.

!

HEATING SET

POINT LEVER

HEAT

M3459

50 60

70 80

.3

.4

.6

1.2

.8

FAN

COOLING SET

POINT LEVER

HEAT

.12

1.5

.2

.3

.4

.6

.8

1.2

1.5

.2

ON

AUTO

FAN

SWITCH

50 60

70 80

AUTO

HEAT

COOL

OFF

SYSTEM

SWITCH

SUBBASE SETTING

The subbase switching positions control the system

operation as follows (see Fig. 12):

SYSTEM SWITCH (some subbase do not have all of the

following functions):

OFF—both the heating and cooling systems are off. If

the fan switch is in AUTO position, the cooling fan is

also off.

HEAT—heating system is automatically controlled by

the thermostat. Cooling system is off.

AUTO—thermostat automatically changes between

heating and cooling system operation, depending on

the indoor temperature.

COOL—cooling system is automatically controlled by

the thermostat. Heating system is off.

FAN SWITCH

ON—fan operates continuously.

AUTO—fan operates with cooling equipment as con-

trolled by the thermostat or with the heating equip-

ment as controlled by the plenum switch.

To move the subbase switches to the desired control

positions, use thumb and index finger to slide lever. Lever

must stop over desired function indicator position for

proper circuit operation.

Checkout

HEATING

Move the system switch on the Q674 to HEAT or

AUTO, and the fan switch to AUTO. Move the heating

setpoint lever on the T874 about 10° F [6° C] above room

temperature. Heating equipment should start and the fan

should run. Move the heating lever about 10° F [6° C]

below room temperature. The heating equipment and fan

should shut off.

NOTE: In heat pump applications, a minimum off-timer

provides a five-minute time delay before starting compressor when the thermostat last turned off the compressor, or when the system first received power. This delay

prevents compressor short cycling.

COOLING

CAUTION

If outside air or heat exchange medium (water) is

below 50° F [10° C], do not operate cooling.

Move the system switch on the Q674 to COOL or AUTO,

and the fan switch to AUTO. Move the cooling setpoint

lever on the T874 about 10° F [6° C] below room tempera-

ture. The cooling equipment should start (see Note). Move

the cool lever about 10° F [6° C] above room temperature.

The cooling equipment and fan should shut off.

NOTE: If using a Control Module Mark IV, there are

time delays built-in. Check your Mark IV instructions

for specifics.

FAN

Move the subbase system switch to OFF, and the fan

switch to ON. The fan should run continuously. Move the

fan switch to AUTO. In this position, fan operation is

controlled by the heating or cooling system control circuit.

INSTALL OR REMOVE TG504A KEY LOCK

COVER

To install the TG504A:

—hang the upper edge of the cover on the thermostat

subbase.

—swing cover downward.

Spring-loaded locking mechanism will automatically

engage mounting posts and secure cover in final position

without use of key provided.

To remove the TG504A:

— insert the key provided.

— rotate the key clockwise until locking mechanism

releases from thermostat posts.

— swing cover upward and off.

Calibration

THERMOSTAT

T874 Thermostats are accurately calibrated at the fac-

tory. They do not have provision for field calibration.

5 69-0753

Page 6

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

Printed in U.S.A. www.honeywell.com/yourhome

6

QUALITY IS KEY

Loading...

Loading...