Page 1

T874 Multistage Thermostats

APPLICATION

These thermostats and subbases provide low voltage control

of multistage heating and cooling systems, including heat

pump systems.

and Q674 Subbases

PRODUCT DATA

FEATURES

• T874 Thermostat has silent, dust-free mercury

switches operated by coiled bimetal elements.

• Heat anticipator(s) are adjustable or fixed cooling

anticipator(s) are fixed.

• Individual heat and cool levers and scales (most

models) for temperature setting located on top of

thermostat case.

• Cover thermometer on most T874 Multistage

Thermostat models.

• Locking cover and locking lever screws available for

T874 Multistage Thermostats.

• Versaguard™ Thermostat Guard or custom key lock

thermostat guards available for T874 Multistage

Thermostats.

• T874 Thermostat requires a Q674 Subbase.

• Q674 Subbase provides system and fan switching,

wiring terminals and mounting base for T874

Multistage Thermostat.

• Adapter plate available for mounting Q674 on wall or

horizontal outlet box.

• Light-emitting diodes (LEDs) located on subbase for

easy reference.

• Up to three stages each of heating and cooling control

possible.

• Models with setpoint restrictions and locking cover

with no thermometer available for Department of

Defense (DoD) and other special applications.

• Outdoor reset used on some models to improve

thermal performance.

Contents

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Understanding Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cross Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

60- 2485- 8

Page 2

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed specifications. This product is tested and calibrated under

closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

Super Tradeline®/Tradeline® Models

SUPER TRADELINE controls offer features not available on

TRADELINE or standard models, and are designed to replace

a wide range of Honeywell and competitive controls.

TRADELINE models are selected and packaged to provide

ease of stocking, ease of handling, and maximum

replacement value. Specifications of SUPER TRADELINE

and TRADELINE controls are the same as those of standard

models except as noted below.

Super Tradeline Models

T874 THERMOSTAT

T874D Thermostat. Provides two stages of heating and two

stages of cooling. Use with Q674A-F Subbases.

Y594D (T874D/Q674E/TG504A) Thermostat/Subbase/key

lock cover package. Provides two stages of heating and

two stages of cooling. Includes a key lock cover for setpoint

protection.

Y594G (T874G/Q674F) Thermostat/Subbase package for

heat pump. Provides two stages of heating and one stage

of cooling. Automatic changeover in heat or cool mode.

Available in beige or Premier White® color.

Y594R (T874R/Q674L) Thermostat/Subbase package for

heat pump. Provides two stages of heating and one stage

of cooling. Manual changeover in heat or cool mode. Available in beige or Premier White® color.

Tradeline Models

T874 THERMOSTAT

• T874 TRADELINE models provide staged heat and/or cool

operation. See Table 1.

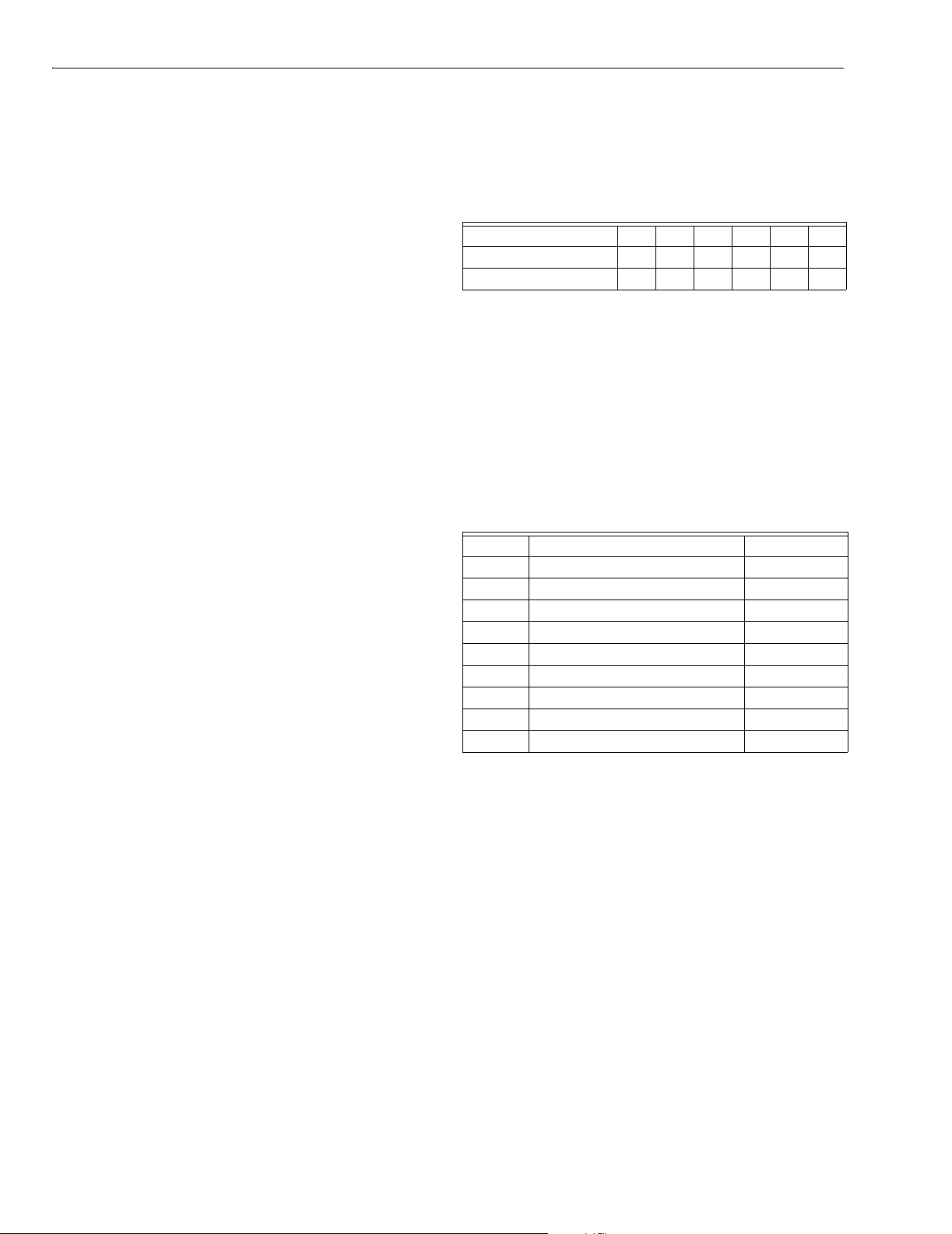

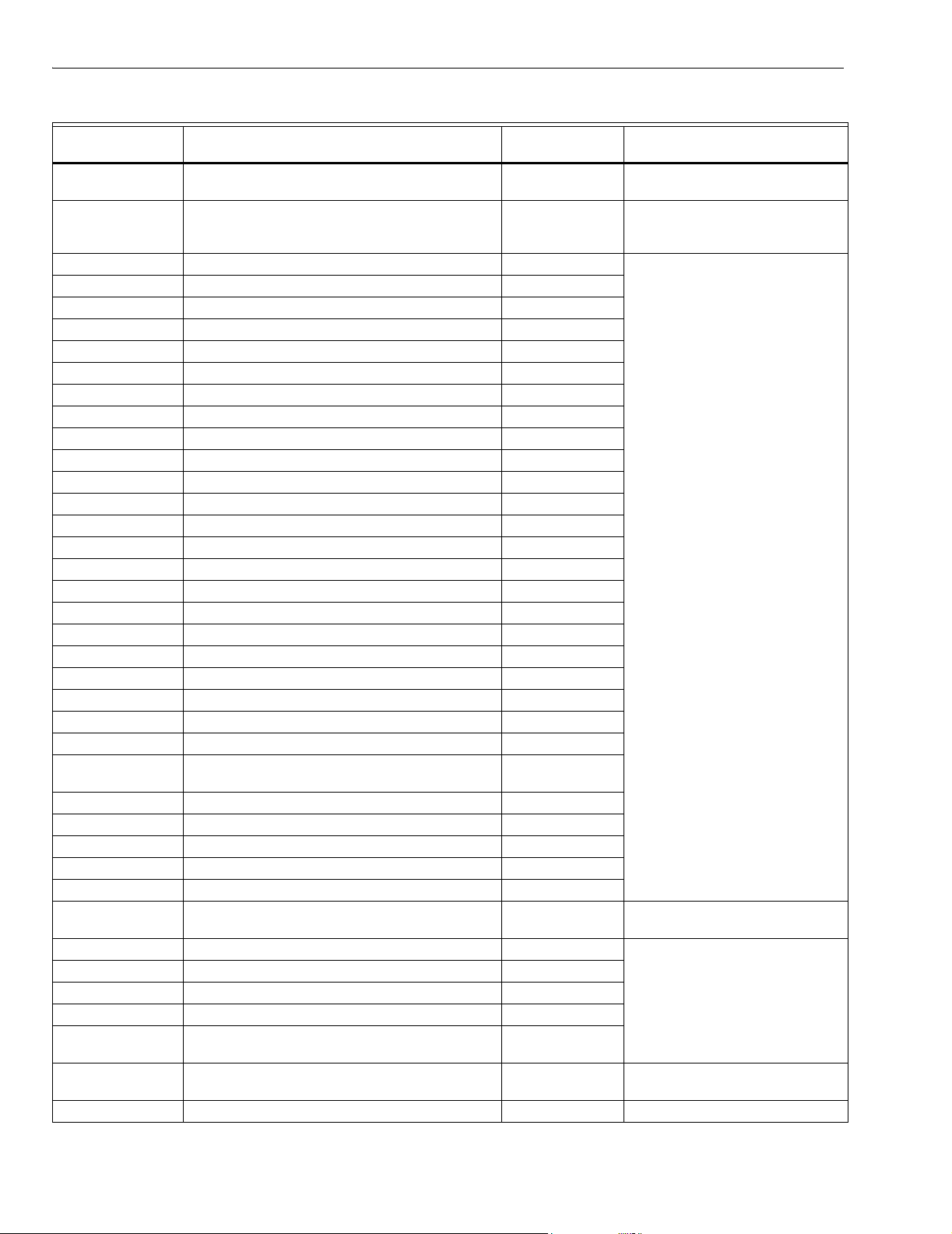

Table 1. Heating and Cooling Stages.

Models ABCDEF

Heating Stages 1122—2

Cooling Stages 12122—

• T874A-F are standard models.

TRADELINE FEATURES:

• TRADELINE package with cross reference label and

special instruction sheet.

• T874A,C model available with factory stops for DoD

applications.

• T874A,C model available with adjustable temperature

locking stops.

Q674 SUBBASE

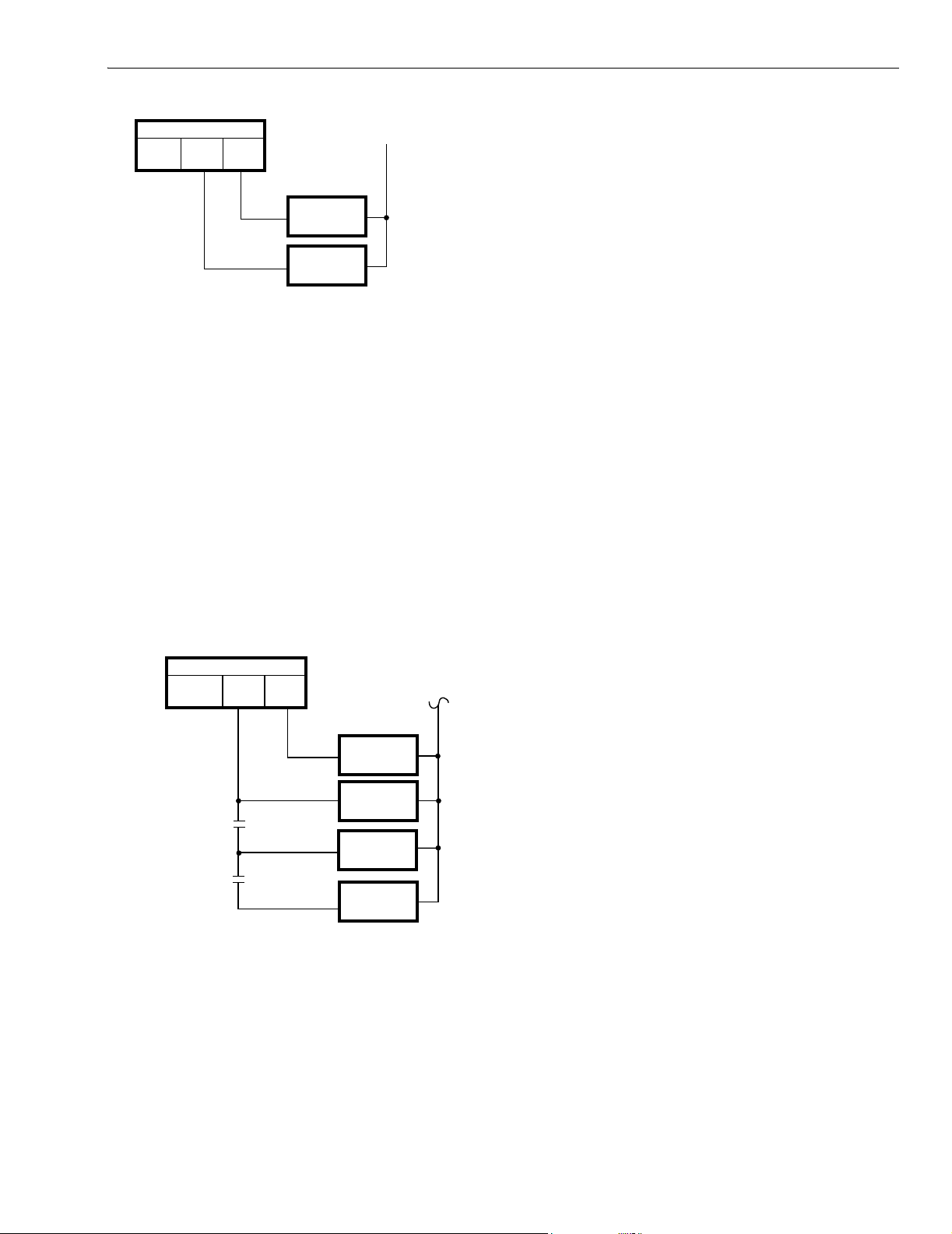

Q674 switching subbases provide system and fan switching.

See Table 2.

Table 2. System and Fan Switching.

Q674 System Fan

A Heat-Auto-Cool Auto-On

B Heat-Off-Cool Auto-On

C Off-Auto Auto-On

D None None

E Off-Heat-Auto-Cool Auto-On

F Em. Ht.-Off-Heat-Auto-Cool Auto-On

G Off-Auto None

J Em. Ht.-Auto-Off Auto-On

L Em. Ht.-Heat-Off-Cool Auto-On

SUPER TRADELINE FEATURES:

• SUPER TRADELINE package with cross reference label

and special instruction sheet.

• SUPER TRADELINE model supplied with locking lever and

locking cover accessories.

• Includes adjustable temperature locking stops.

• T874D replaces T874A-F TRADELINE or standard models.

TRADELINE FEATURE:

• TRADELINE package with cross reference label and

special instruction sheet.

• Q674A-E,G are standard (non-heat pump) models.

Q674F,J,L are heat pump models.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (800) 328-5111

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2485—8 2

Page 3

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

9

Standard Models

T874 THERMOSTATS

Models: See Table 3.

Electrical Rating: 24 to 30 Vac.

Switching: Coiled bimetal elements operate mercury

switches.

Temperature Adjustment: Heating and cooling setting

levers, with separate scales located on top of thermostat

base. Common lever for heating and cooling on T874R;

one cooling lever on T874E,V; and one heating lever on

T874F,Q.

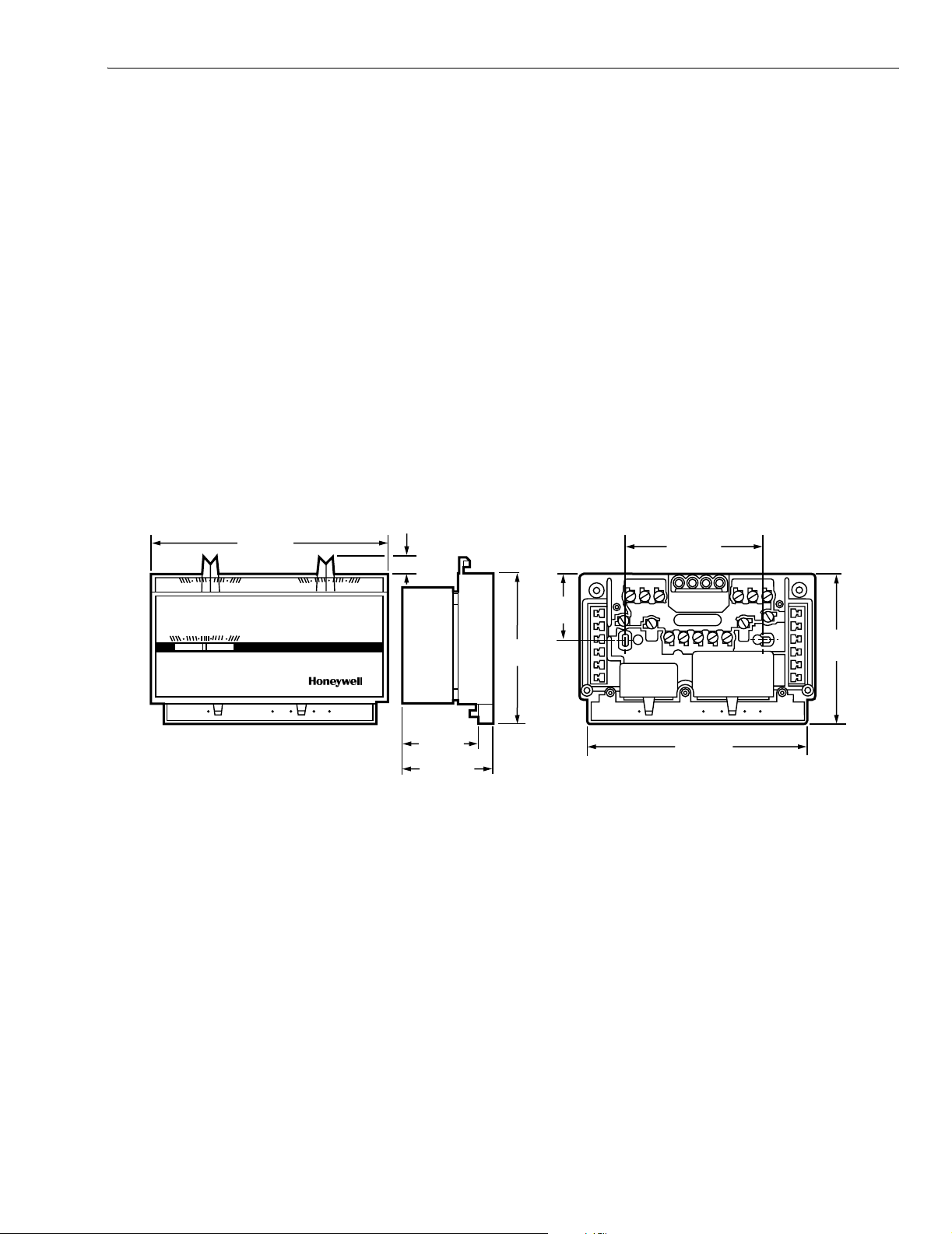

Dimensions: See Fig. 1.

Temperature: Scale Range: 42° to 88°F (6° to 31°C) stan-

dard; optional ranges available.

THERMOSTAT MOUNTED

ON SUBBASE

FRONT

5-5/8 (143)

SIDE

3/8 (10)

Thermometer Range: 42° to 88°F (6 to 31°C)

Changeover Differential: 4°F (2°C) minimum between heat-

ing and cooling (5°F [3°C] on T874W). Levers can be set

apart for greater separation.

Interstage Differential:

Standard Models: Mechanical differential is 1°F (0.6°C)

between heating or cooling stages; operating differential is

approximately 1.9°F (1°C) between stages in heating or

cooling.

Special Models: See Table 3.

Finish: Beige or Premier White

®

finish.

Mounting Means: T874 Multistage Thermostat mounts on

Q674 Subbase. Subbase mounts horizontally on wall or

outlet box. Mounts on vertical outlet box with optional

193121A Adapter Plate Assembly.

SUBBASE

3-9/32 (83)

HEAT COOL

50 60 70 80

50 60 70 80

FAN

AUTO ON

50 60 70 80

OFF

EM. HT. HEAT AUTO COOL

1-7/8 (48)

2-3/16 (56)

Fig. 1. T874 Thermostat and Q674 Subbase dimensions in in. (mm).

Optional Specifications (T874 Only):

Temperature scale ranges are 40° to 75°F (4° to 24°C) heat-

ing and 75° to 90°F (24° to 32°C) cooling with stop; 44° to

68°F (7° to 20°C) heating, 80° to 86°F (27° to 30°C) cooling; 6° to 29°C (43° to 85°F) Celsius scale; 3° to 22°C (38°

to 72°F) and 26° to 32°C (78° to 90°F) cooling with stop.

Nonadjustable factory-added stop limits heating setpoint to

72°F (22°C) maximum and cooling setpoint to 78°F (26°C)

minimum.

OEM customer personalization.

Locking cover and locking lever (see Thermostat Accesso-

ries).

Thermostat cover without thermometer.

Adjustable locking temperature stops.

Voltage heat anticipation for first or second stage heat or both.

See Table 3.

Fast cycling on heating stage(s) for electric heat applications.

C815A Outdoor Thermistor for improved performance on

specified models.

1-1/2

(38)

3-1/2

(89)

FAN

AUTO ON

OFF

EM. HT. HEAT AUTO COOL

5-1/8 (130)

3-7/16

(87)

M584

Thermostat Accessories:

Locking Cover and Locking Lever Assembly: Part no.

194559R with thermometer; 194559S without thermometer. See Fig. 2. Includes cover, screws, and Allen wrench

for locking cover. The screws must be used to assure

proper operation.

Adjustable Lever Stop: Part no. 4074ECK; includes lever stop

and screws.

Universal Versaguard™ Thermostat Guard: Includes wall-

plate, ring base, guard cover, tumbler lock, two keys and

optional Honeywell logo insert. Double-wall construction

provides extra measure of tamper-resistance. Tamperresistant lock; key cannot be removed without being in

locked position. Vents in guard base allow airflow for optimum thermostat performance. See form 68-0104 for more

information.

— TG511A1000: Clear cover.

— TG511B1008: Opaque cover.

— TG511D1004: Painted steel (off-white) cover. See

Fig. 2.

3 60-2485—8

Page 4

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

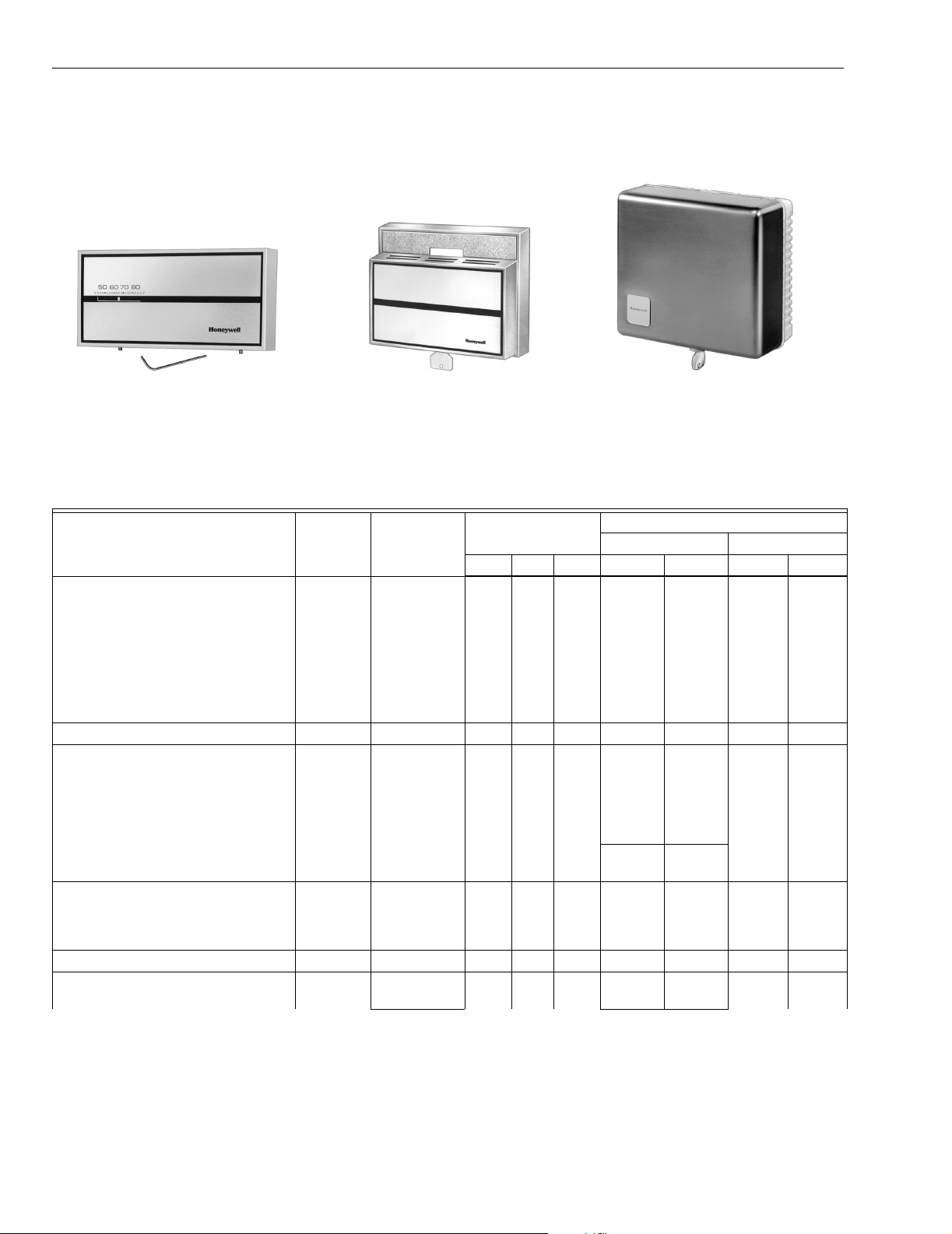

Key Lock Cover: Part no. TG504A replaces existing T874

cover. Mounts on T874 base and covers thermostat settling

— TG504A1025: Blank face, internal thermometer.

— TG504A1033: External thermometer. See Fig. 2.

levers and subbase switches. Includes LED window and

two keys. Should not be used with 193121A Adapter Plate.

194559R Locking Cover

with Thermometer

Allen Wrench

TG504A1033 Key Lock

Cover with External

Thermometer

TG511D1004 Includes

Painted Steel Cover,

Opaque Base and Wallplate

Fig. 2. T874 Thermostat accessories.

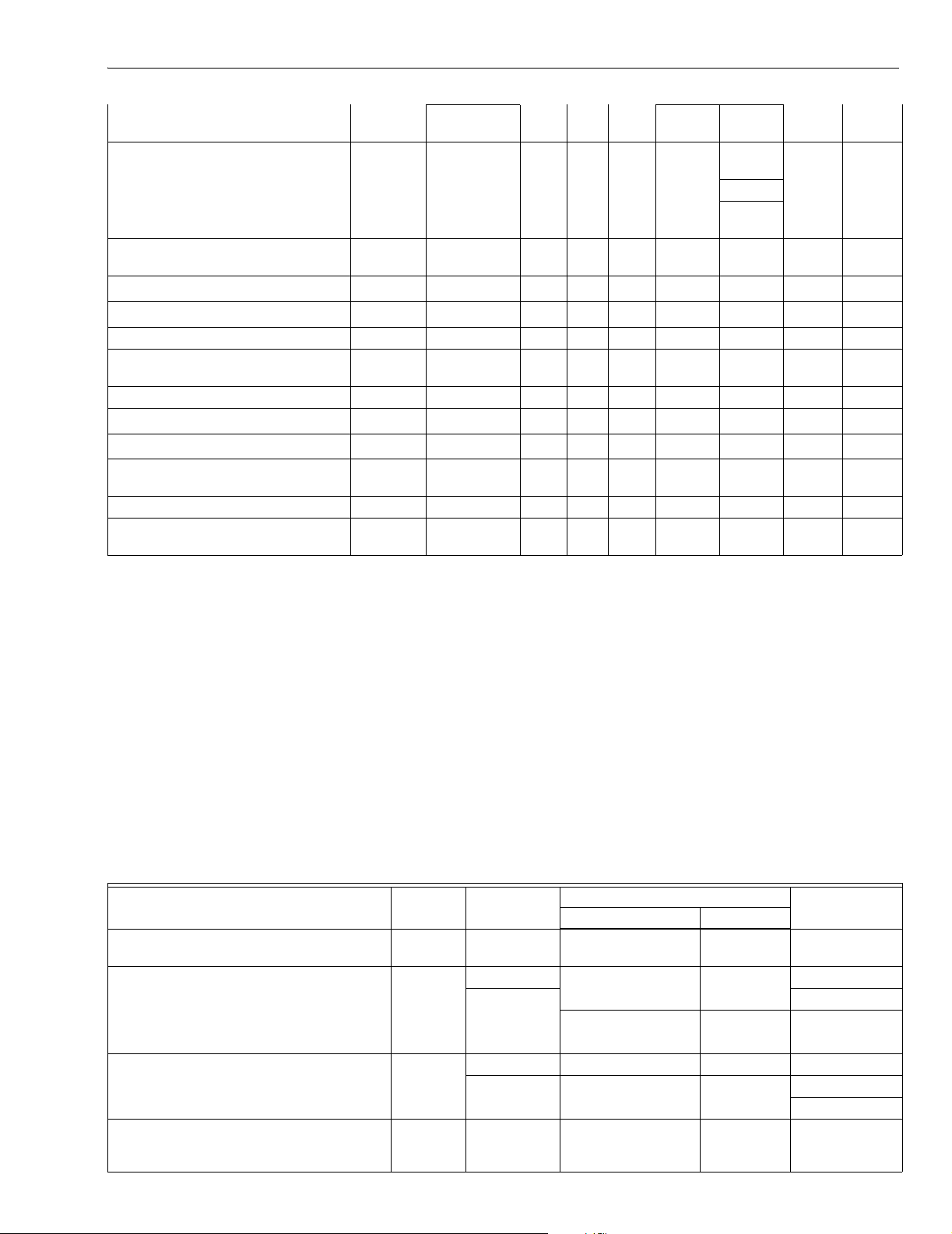

Table 3. T874 Thermostat Specifications.

Anticipation

Models and Options Replaces Applications

T874A—Standard and TRADELINE®.

System Stages

Heat Cool Other Stage 1 Stage 2 Stage 1 Stage 2

T872A Standard 1 1 — 0.1-1.2A — 0-1.5A —

Heating (Adj) Cooling (Fixed)

— 72°F/78°F (22°C/26°C)setpoint

stops with locking cover.

— Adjustable anticipator set 0.4A.

— Adjustable locking temperature

stops (TRADELINE®).

— 72°F/78°F (22°C/26°C) setpoint

stops with locking cover, no

thermometer (for DoD

a

).

T874B—Standard and TRADELINE. T872B Standard 1 2 — 0.1-1.2A — 0-1.2A 0-1.0A

T874C—Standard and TRADELINE.

T872C Standard 2 1 — 0.1-1.2A 0.1-1.2A 0-1.5A —

— 72°F/78°F (22°C/26°C)set stops

with locking cover, no thermometer

(for DoDa).

— 12°F (7°C) differential between

H1 and H2 stages (T874C1125).

— Fast cycling. 0.12-

0.6A

T874D—Standard and SUPER

T872D Standard 2 2 — 0.1-1.2A 0.1-1.2A 0-1.2A 0-1.0A

0.12-

0.6A

TRADELINE®.

— Adjustable locking temperature

stops (SUPER TRADELINE).

T874E—Standard and TRADELINE. T872E 2-Stage Cool — 2 — — — 0-1.2A 0-1.0A

T874F—Standard and TRADELINE.

T872F 2-Stage Heat 2 — — 0.1-1.2A 0.1-1.2A — —

— Locking cover.

a

Department of Defense.

b

Changeover stage operates with heating.

c

Fixed voltage type anticipation.

d

Changeover stage operates with heating; a secondary changeover is provided in cooling switch.

e

Provides night setback used with standard T874 and timer-operated remote switching.

f

Manual changeover stage—use Q674B,L subbase.

g

Changeover stage operates with cooling.Q674 Subbases

60-2485—8 4

Page 5

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

— Fast cycling. Electric Heat 0.12-

0.6A

T874G—Heat pump, cool

changeover, with fast cycling.

T872G Heat Pump or

Standard

21

b

0-1.0A

1

0.12-

0.6A

c

0.1-1.2A 0-1.0A —

— Fixed anticipator for H2. 0.1-1.5A

— Fast cycling. 0.12-

0.6A

T874H—Use with Q674C. T872H Heat Pump or

11

Standard

T874J—Heat pump. None Heat Pump 2 1

T874K—Heat pump. None Heat Pump 2 1

b

1

d

2

b

1

c

0-1.0A

—0-1.0A—

0-1.0Ae0-1.5Ac0-1.0A

0.1-1.2A

0-1.5A

c

0-1.5A —

c

—

T874L—Heat pump. None Heat Pump 2 1 — 0.1-1.2A 0.1-1.2A 0-1.5A —

T874N—Heat pump, heat

changeover.

T872N Heat Pump 2 1

b

0.1-1.2A 0.1-1.2A 0-1.0A —

1

T874P—Heat pump. None Heat Pump 2 1 — 0.1-1.2A 0.1-1.2A 0-1.5A —

e

T874Q—Night setback heating. T872Q Standard

T874R—Heat pump. T872R

T874S—Two-speed compressor heat

None Heat Pump 2 2

Heat Pump

pump.

f

— — 0.1-1.2A — — —

1

21—

g

1

c

0-1.5A

0.1-1.2A 0-1.5A —

0-1.2Ac0-1.2A

c

0-1.2A 0-1.0A

T874V—Standard. None Standard — 1 — — — 0-1.5A —

T874W—Heat pump and standard.

— Night setback heating.

a

Department of Defense.

b

Changeover stage operates with heating.

c

Fixed voltage type anticipation.

d

Changeover stage operates with heating; a secondary changeover is provided in cooling switch.

e

Provides night setback used with standard T874 and timer-operated remote switching.

f

Manual changeover stage—use Q674B,L subbase.

g

Changeover stage operates with cooling.Q674 Subbases

T872W Heat Pump or

Standard

32—

0-1.2A

b

0-1.2A

c,d

0-1.2A 0-1.0A

Models:

See Table 4.

Mounting: Designed to mount horizontally on an outlet box

or the wall. Adapter plate assembly available for mounting

on a vertical outlet box (see Subbase Accessory).

Electrical Ratings:

Switch Contacts: 2.5A at 30 Vac (7.5A inrush).

Finish: Dark brown or gray.

LED Lights (Optional): 30 Vac.

Dimensions in in. (mm): 3-1/2 (89)height; 5-5/8 (143) width;

Switches: Two slide switches (one switch on Q674G and K;

5/16 (8) depth. See Fig. 1.

no switches on Q674D) operated by levers. Switch position

is shown on scaleplate.

Table 4. Q674 Subbase Specifications.

Switch Positions

Models and Options Replaces Application

Q674A—Standard and TRADELINE®.

Q672A Standard HEAT-AUTO-COOL AUTO-ON T874A-D

Use WithSystem Fan

— Indicator LEDs.

Q674B—Standard and TRADELINE. Q672B Standard HEAT-OFF-COOL AUTO-ON T874A-D

— Provision for fan relay operation from Heat Pump T874G,H,L,R

external fan switch (isolate G terminal). OVERRIDE-HEAT- AUTO-ON T874P

— Indicator LEDs. OFF-COOL

Q674C—Standard and TRADELINE. Q672C Standard OFF-AUTO AUTO-ON T874A-H,W

— Indicator LEDs. Heat Pump OVERRIDE-AUTO- AUTO-ON T874K,L,N

OFF T874P

Q674D—Standard and TRADELINE.

Q672D Standard None None T874A-F

— For use when subbase switching is not

required.

5 60-2485—8

Page 6

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

g

Q674E—Standard and TRADELINE. Q672E Standard OFF-HEAT-AUTO-

AUTO-ON T874A-D

COOL

Q674F—Two LED models.

— EM.HT. light.

— Provision for AUTO fan operation in

EM.HT.

Q672F Heat Pump OFF-EM.HT.-HEAT-

AUTO-COOL

OFF-COOL-AUTO-

HEAT-EM.HT.

AUTO-ON T874C,D,G,N,S

AUTO-ON

Q674G—O and B terminals. Q672G Standard OFF-AUTO None T874A-F

Q674J—Provision for AUTO fan operation Q672J Heat Pump EM.HT.-AUTO-OFF AUTO-ON T874A,D,G,J

in EM.HT. EM.HT.-ON-OFF AUTO-ON

— Provision for outdoor thermistor. SUPL.HT.-ON-OFF AUTO-ON

Q674K—Standard. Q672K Standard OFF-HEAT-AUTO-

None T874F

COOL

OFF-WOOD-WOOD/

None

OIL-OIL

Q674L—Provision for AUTO fan operation in

EM.HT.

— Indicator LEDs. SUPL.HT.-HEAT-

Q672L Heat Pump EM.HT.-HEAT-OFF-

COOL

AUTO-ON T874R,W

AUTO-ON

OFF-COOL

Q674N—Standard. Q672N Evaporative

Cooler

Q674P—Standard. Q672P Heat Pump SUPL.HT.-HEAT-

EVAP-COOL-OFF-

HEAT

AUTO-ON T874C

AUTO-ON T874G

COOL

Q674Q—Standard. None Fan Coil HEAT-OFF-COOL LO-MED-HI-

T874A

ON

Q674R—Standard.

— International symbols.

None Fan Coil OFF-COOL LO-HI-

CONT.

T874V

Q674S—Indicator LED. None Standard HEAT-COOL None T874C

Optional Specifications (Q674 Only):

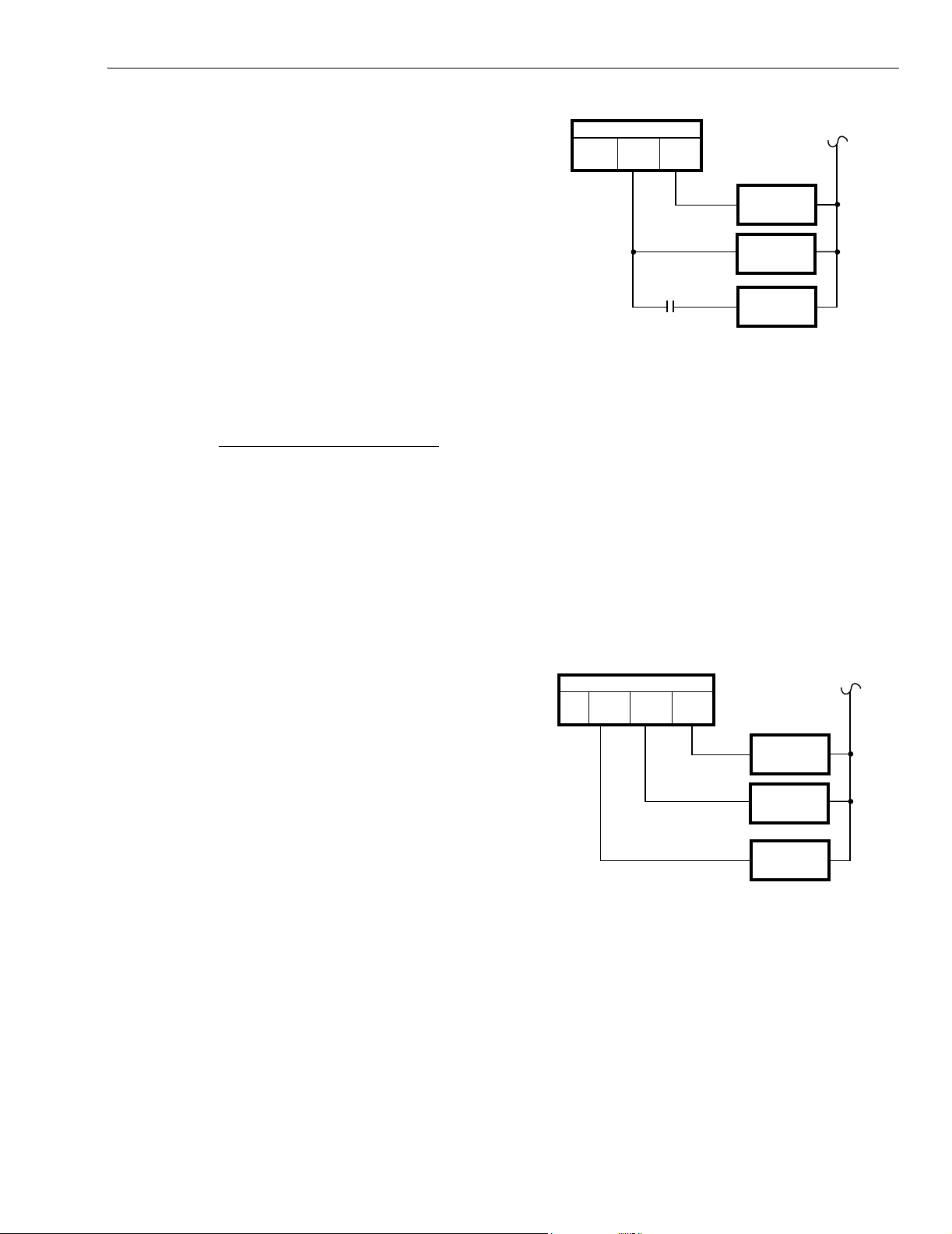

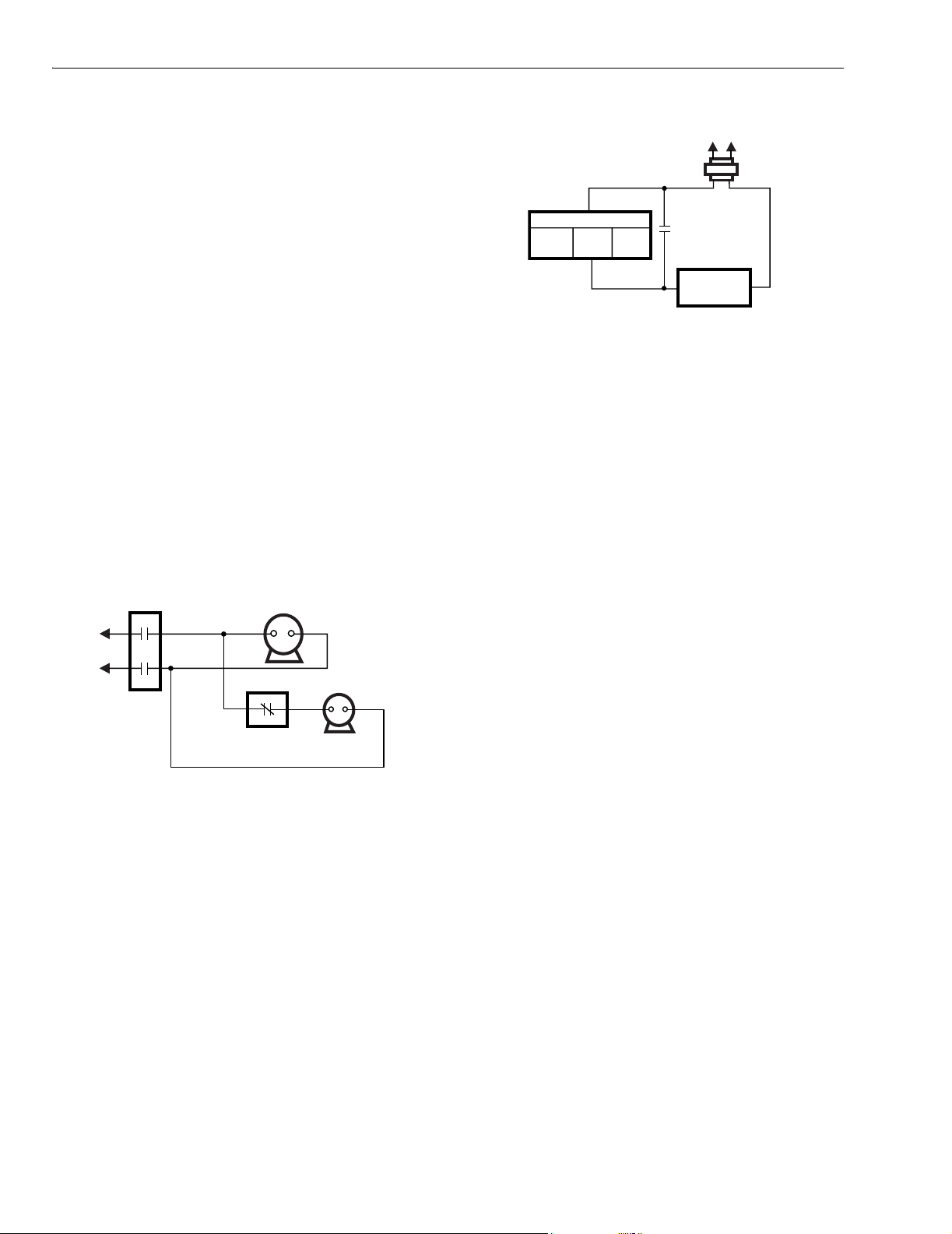

Models available with up to four LEDs; for example, LEDs can

show EM. HT, AUX. HT, SERVICE, CHECK, FILTER, and

LOCKOUT. See Fig. 3.

System switching marked HEAT-OFF/RESET-COOL for sys-

tems requiring impedance relay reset. Available on Q674B

only.

G terminal isolated on heating to provide fan relay operation

from external low voltage fan switch (Q674B only).

Auto fan operation on both heat and cool.

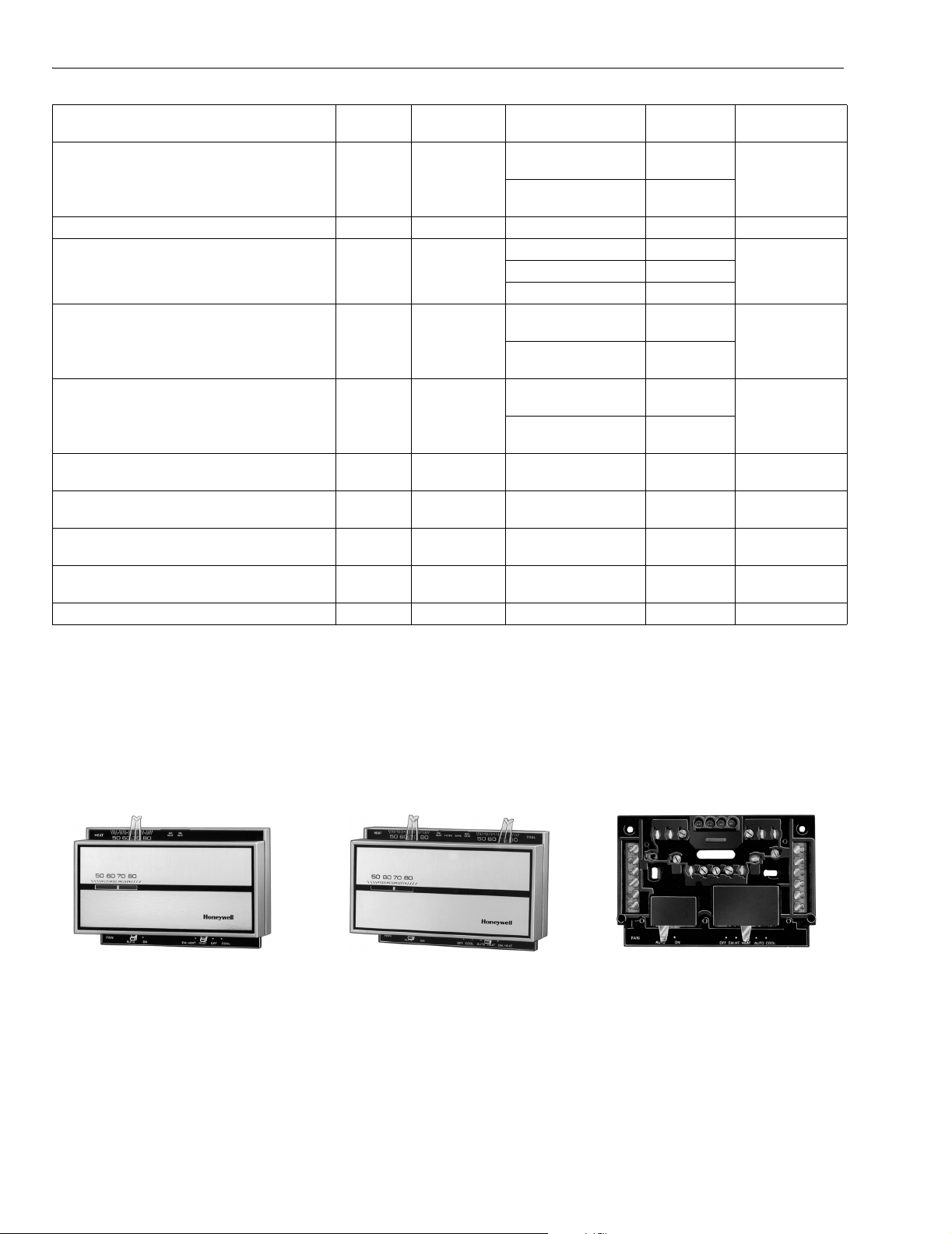

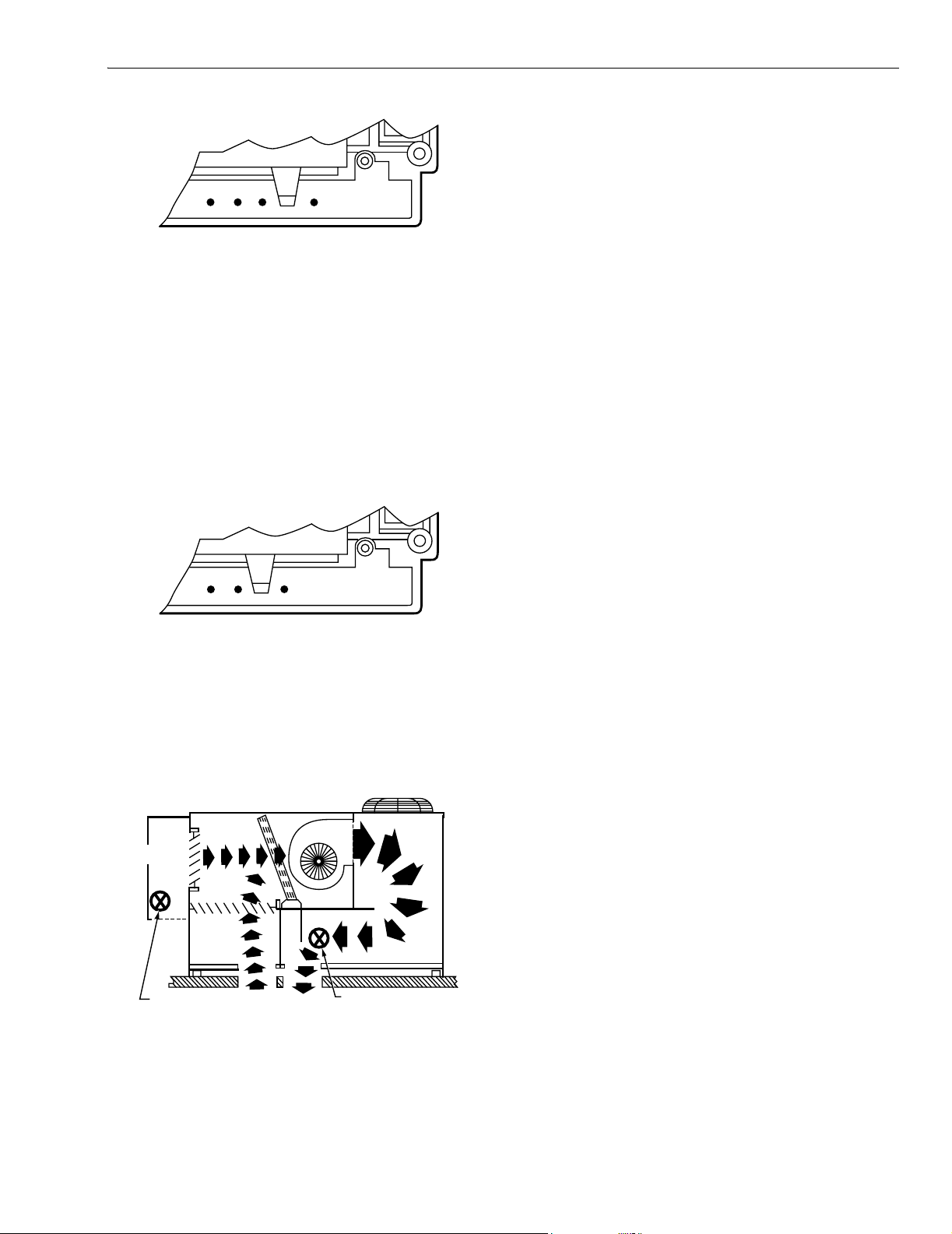

T874 Thermostat with

One Setpoint Lever

T874 Thermostat with

Separate

Heatin

and Cooling Levers

Fig. 3. Heating, cooling levers and system LED indicators.

L terminal is used for system monitoring devices.

Common R terminal for heating/cooling.

Changeover in cool or heat mode for heat pumps.

Auto fan in EM.HT. for heat pumps.

Subbase Accessory: 193121A Adapter Plate Assembly for

mounting on vertical outlet box. Assembly includes adapter

ring and cover plate. Use to cover wall marks from

replaced thermostat.

Q674 Subbase

with Four LEDs

60-2485—8 6

Page 7

MERCURY NOTICE

T

This control contains mercury in a sealed tube. Do not

place control in the trash at the end of its useful life.

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old control

in the trash.

Contact your local waste management authority for

instructions regarding recycling and the proper

disposal of this control, or of an old control containing

mercury in a sealed tube. If you have questions, call

the Honeywell Customer Response Center at

1-800-468-1502.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings given on the product to make sure the

product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

CAUTION

Hazardous Voltage.

Can damage heating/cooling system.

1. Disconnect power supply before beginning instal-

lation to prevent electrical shock or equipment

damage.

2. Do not short across coil terminals on relay. This

can burn out thermostat heat anticipator.

3. To prevent interference with the thermostat link-

age, keep wire length to a minimum and run wires

as close as possible to the subbase.

4. Do not overtighten thermostat captive mounting

screws because damage to subbase threads can

result.

IMPORTANT

An incorrectly leveled thermostat will cause the temperature control to deviate from setpoint. It is not a

calibration problem.

Location

Install the thermostat about 5 ft (1.5m) above the floor in an

area with good air circulation at average temperature.

Do not mount the thermostat where it can be affected by:

— drafts or dead spots behind doors, in corners or under

cabinets.

— hot or cold air from ducts.

— radiant heat from the sun, fireplace, or appliances.

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall behind

the thermostat.

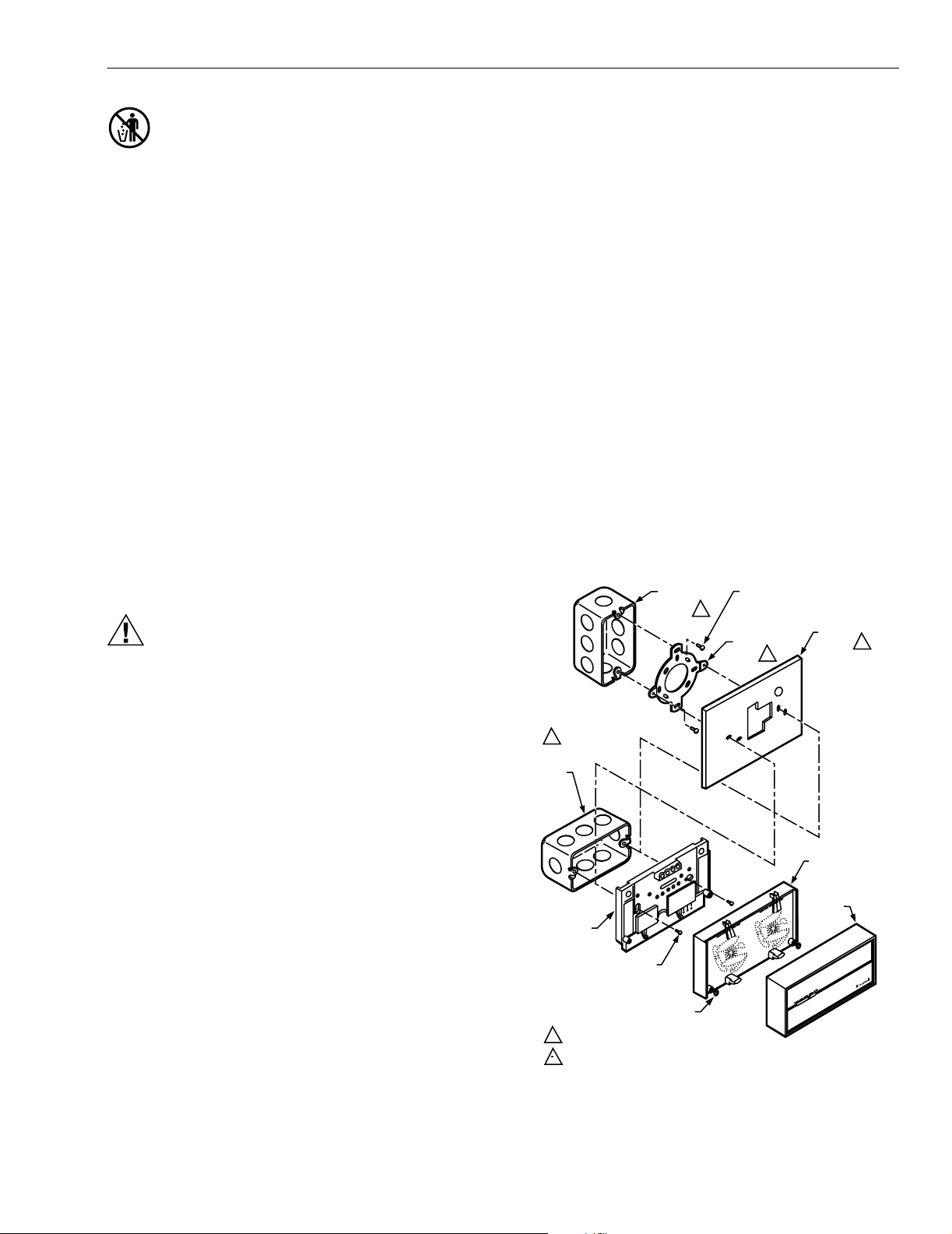

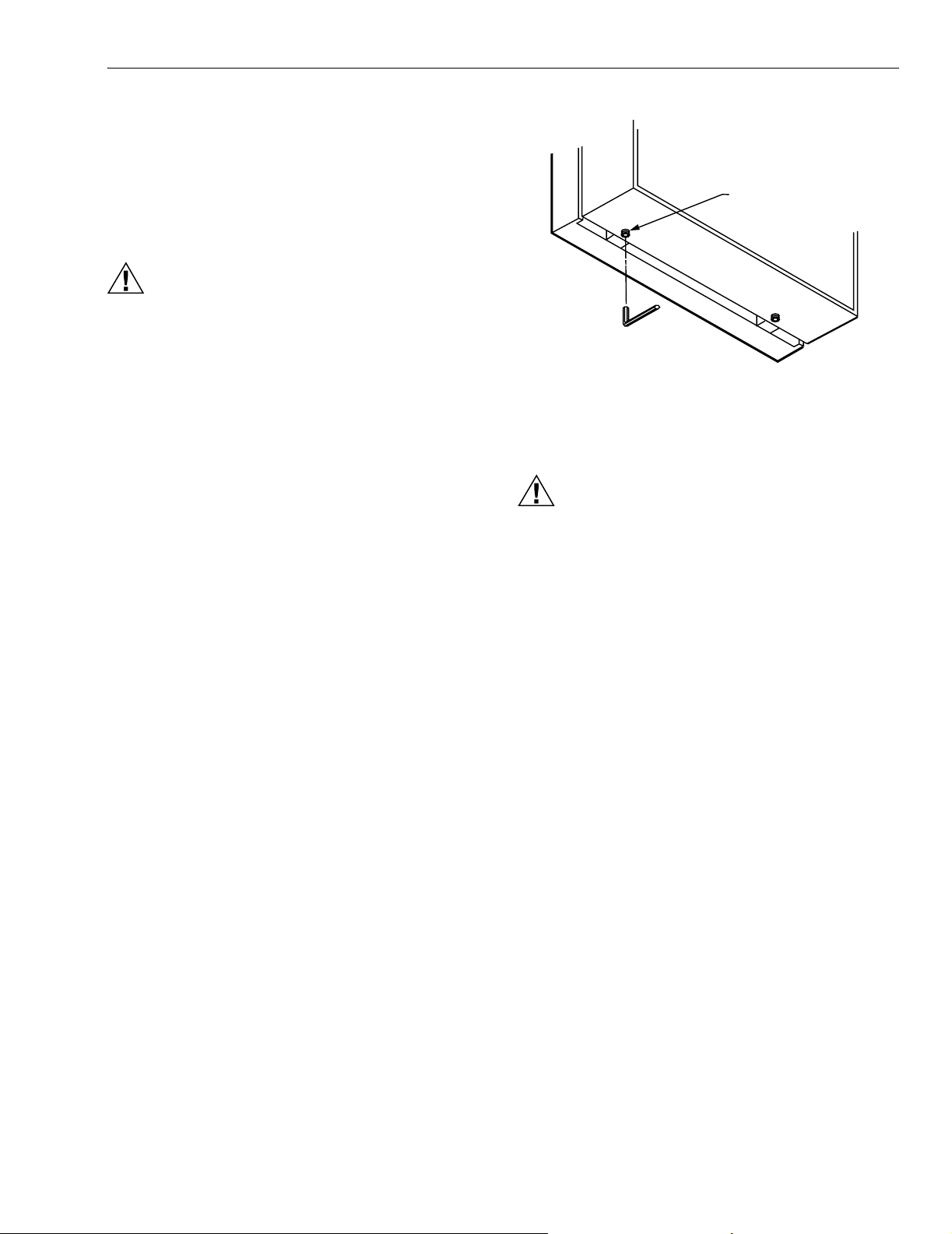

Mount Subbase

The subbase can be mounted on a vertical outlet box,

horizontal outlet box or directly on the wall.

1. If the subbase is mounted on a vertical outlet box, order

Honeywell part no. 193121A Adapter Assembly. See

Fig. 4. The assembly includes an adapter ring, two

screws and a cover plate to cover marks on the wall.

Install the ring and cover plate on the vertical outlet box.

NOTE: For a wall installation, hold subbase in position and

mark holes for anchors. See Fig. 5. Wall anchors

must be obtained from local hardware store. Be careful that the wires do not fall back into the wall opening. Set aside subbase. Drill four

3/16 in. (4.8 mm) holes and gently tap anchors into

the holes until flush with the wall.

2. Pull wires through the cover plate (if used) and subbase

cable opening. See Fig. 6.

3. Secure the cover plate (if used) and subbase with the

screws provided. Do not fully tighten the subbase

screws.

Level the subbase using a spirit level, see Fig. 7, and firmly

tighten subbase mounting screws. The subbase mounting

holes provide for minor out-of-level adjustments.

VERTICAL

OUTLET

BOX

1

HORIZONTAL

OUTLET

BOX

SUBBASE

SUBBASE

MOUNTING SCREWS (2)

CAPTIVE

MOUNTING SCREWS (2)

1 NOT INCLUDED WITH UNIT.

2 ACCESSORY PART AVAILABLE (193121A).

Fig. 4. Installing Q674 Subbase on outlet box.

MOUNTING

SCREWS (2)

1

THERMOSTAT

COOL

COVER

50 60 70 80

COVER

PLATE

2

THERMOSTA

M6009

HEAT

ADAPTER

RING

50 60 70 80

2

50 60 70 80

7 60-2485—8

Page 8

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

SUBBASE

SCREWS (2)

G

(UP TO 12)

F

I

S

)

WALL

WIRES THROUGH

WALL OPENING

WALL

ANCHORS

(2)

M926

MOUNTING

HOLES

MOUNTING

Fig. 5. Installing Q674 Subbase on wall.

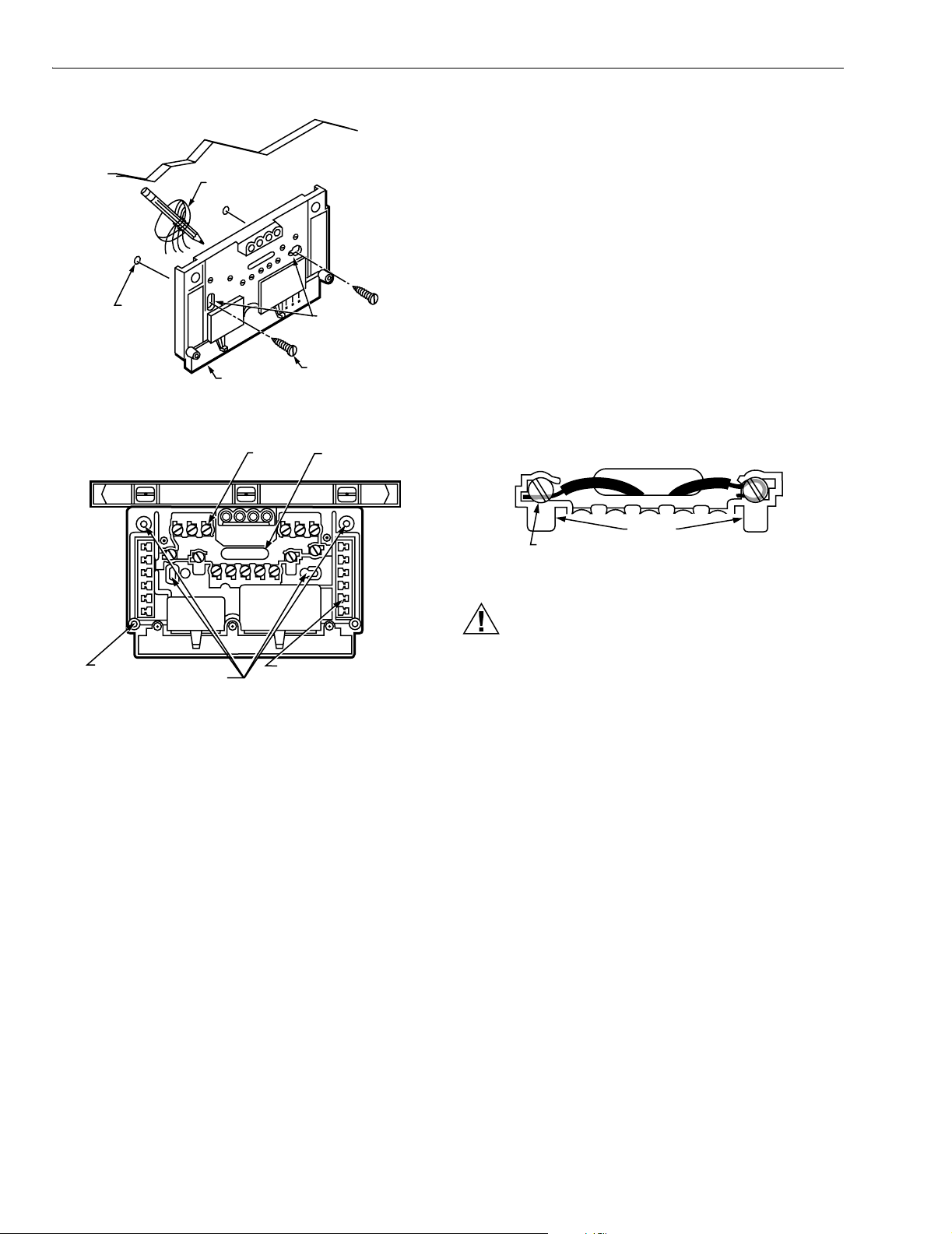

All wiring must comply with local electrical codes and

ordinances.

IMPORTANT

Use 18 gauge, solid-conductor wire whenever possible. If using 18 gauge stranded wire, no more than

10 wires can be used. Do not use larger than

18 gauge wire.

Follow equipment manufacturer wiring instructions when

available. To wire subbase, proceed as follows:

1. Connect the system wires to the subbase as shown in

the applicable diagram. A letter code is located near

each terminal for identification. Typical terminal designation and wiring connections are listed in Table 5. The

terminal barrier permits straight or wraparound wiring

connection. See Fig. 7. The subbase can require one or

more jumpers that may or may not be factory-supplied.

See Fig. 8 and the wiring diagrams for specific terminals

to be jumpered.

SPIRIT LEVEL

POST FOR

MOUNTING

THERMOSTAT (2)

MOUNTING

HOLES (4)

WIRING

TERMINAL

THERMOSTAT

CABLE OPENIN

TO SPRING FINGER

CONTACTS ON

THE THERMOSTAT

M927

Fig. 6. Subbase components and leveling procedure.

Wire Subbase

Disconnect power supply before beginning installation to

prevent electrical shock or equipment damage.

OR STRAIGHT

NSERTION–

TRIP 5/16 IN. (8 MM)

SUBBASE TERMINAL SCREW

BARRIER

FOR WRAPAROUND–

STRIP 7/16 IN. (11 MM

M928

Fig. 7. Barrier configuration.

CAUTION

Equipment Damage Hazard.

Never install more than one wire per terminal unless

using factory-supplied jumper with spade terminal.

2. Firmly tighten each terminal screw.

3. Fit wires as close as possible to the subbase. Push

excess wire back into the hole.

4. Plug hole with nonflammable insulation to prevent drafts

from affecting the thermostat.

60-2485—8 8

Page 9

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

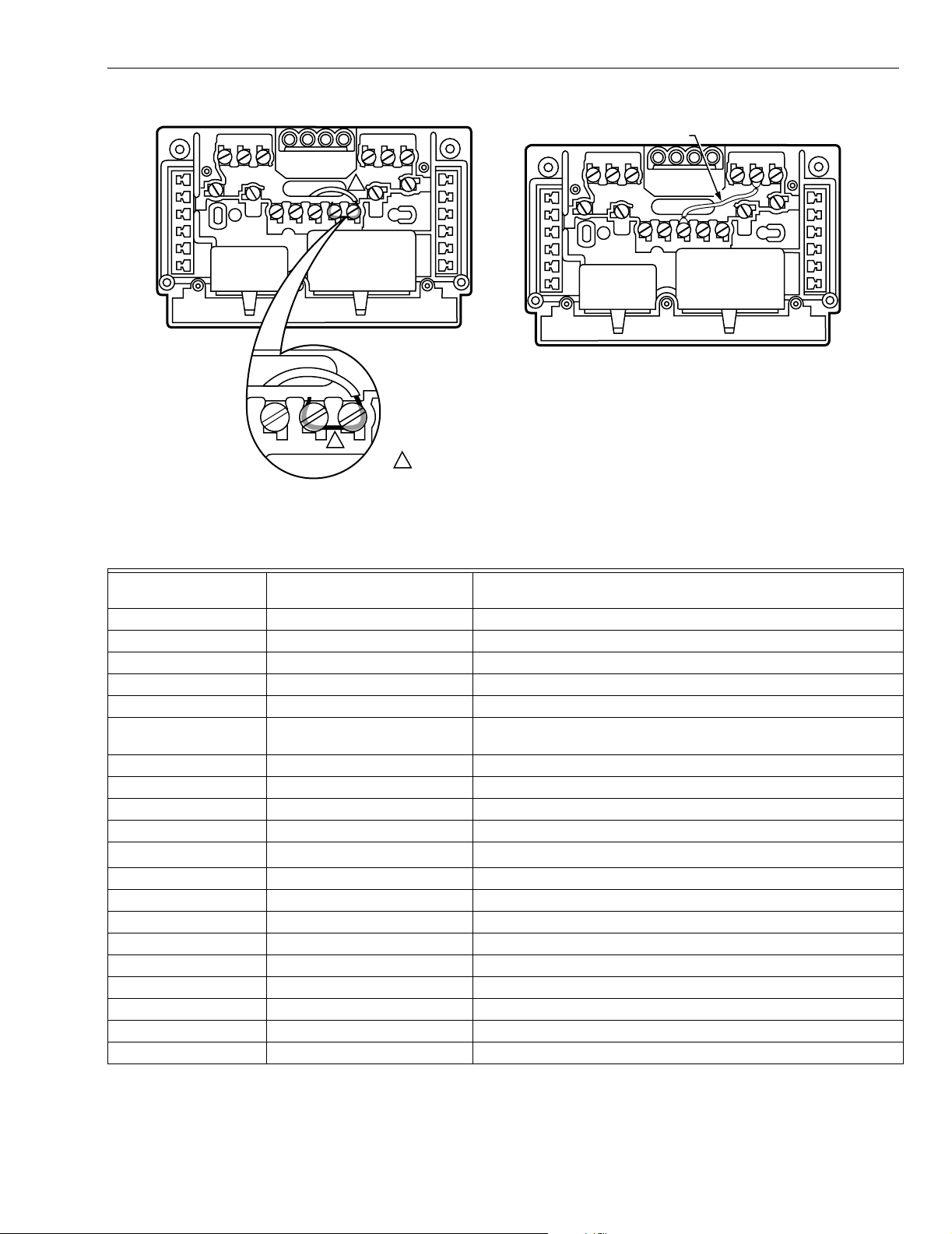

JUMPER WIRE

(SUPPLIED WITH SOME MODELS)

1

1

1 TWO ADJACENT TERMINALS SHOWN JUMPERED ARE FOR EXAMPLE ONLY. COMPARE WIRING

DIAGRAM AND SUBBASE TO IDENTIFY TERMINALS TO BE JUMPERED.

M5899

Fig. 8. Jumper adjacent terminals for special system hookup using stripped wire 3/4 in. (19 mm).

For nonadjacent terminals and using jumper wire supplied with subbase.

a

Standard Terminal

Designation

Table 5. Terminal Designations

Alternate Designations or

Customer Specials Typical Connection

B Heating damper motor; changeover valve

E K Emergency heat relay

G F Fan relay coil

L System monitor

O R Cooling damper motor; changeover valve

R V Power connection to transformer (internally connected for heating

and cooling)

RC Power connection to cooling transformer

RH Power connection to heating transformer

W1 H1, R3 Stage 1 heating control

W2 H2, Y, R4 Stage 2 heating control

W3

Stage 3 heating control

b

Y1 C1, M Stage 1 cooling control

Y2 C2 Stage 2 cooling control

Y3 Stage 3 cooling control

X X1,X2,C Clogged filter switch or common connection

T A Outdoor thermistor

L, C, H HSII control panel

PDefrost

O Momentary circuit, changeover

A, A1, A2, Z, C, L LEDs

a

Other terminal designations can be used that are not listed on this table. Refer to the hookup drawing and internal schematic

for exact connections.

b

W3 controls the auxiliary heat like W2, and allows adding additional stages of auxiliary heat with outdoor thermostats while

maintaining the proper second stage anticipation.

9 60-2485—8

Page 10

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

78°F (26°C) MIN. COOL

a

Standard Terminal

Designation

Table 5. Terminal Designations

Alternate Designations or

Customer Specials Typical Connection

T External temperature readout, T relay

R1, R2 LO and HI speed fan relays

RS Cooling contactor

Y M Compressor contactor

a

Other terminal designations can be used that are not listed on this table. Refer to the hookup drawing and internal schematic

for exact connections.

b

W3 controls the auxiliary heat like W2, and allows adding additional stages of auxiliary heat with outdoor thermostats while

maintaining the proper second stage anticipation.

Outdoor Disconnect

The National Electrical Code requires the installation of a

disconnect switch within sight of the outdoor unit of an air

conditioner or heat pump. The switch is for the safety of any

technician working on the unit. The technician can assure that

the unit remains unpowered.

mounting screw and two locking screws with insulated heads.

When installed, the stop brackets limit the movement of the

T874 HEAT and COOL levers.

TO INSTALL:

1. Remove the thermostat cover by pulling the bottom

edge of the cover upward until it snaps free of the

mounting slots.

Install and Adjust Stop Brackets

The stop brackets should be installed only if there is a need to

restrict the adjustable range of the heating and cooling

temperature setpoint levers. If adjustable lever stops are

desired, order 4074ECK Envelope Assembly, which contains

two adjustable lever stop brackets, one brass insert, one

2. Turn to the back of the T874 Thermostat. Locate the

hole for the brass insert in the plastic base below the

LED window.

3. Push the brass insert into the hole with finger.

4. Turn to the front of the T874 Thermostat.

5. Place the two stop brackets in position with the tabs in

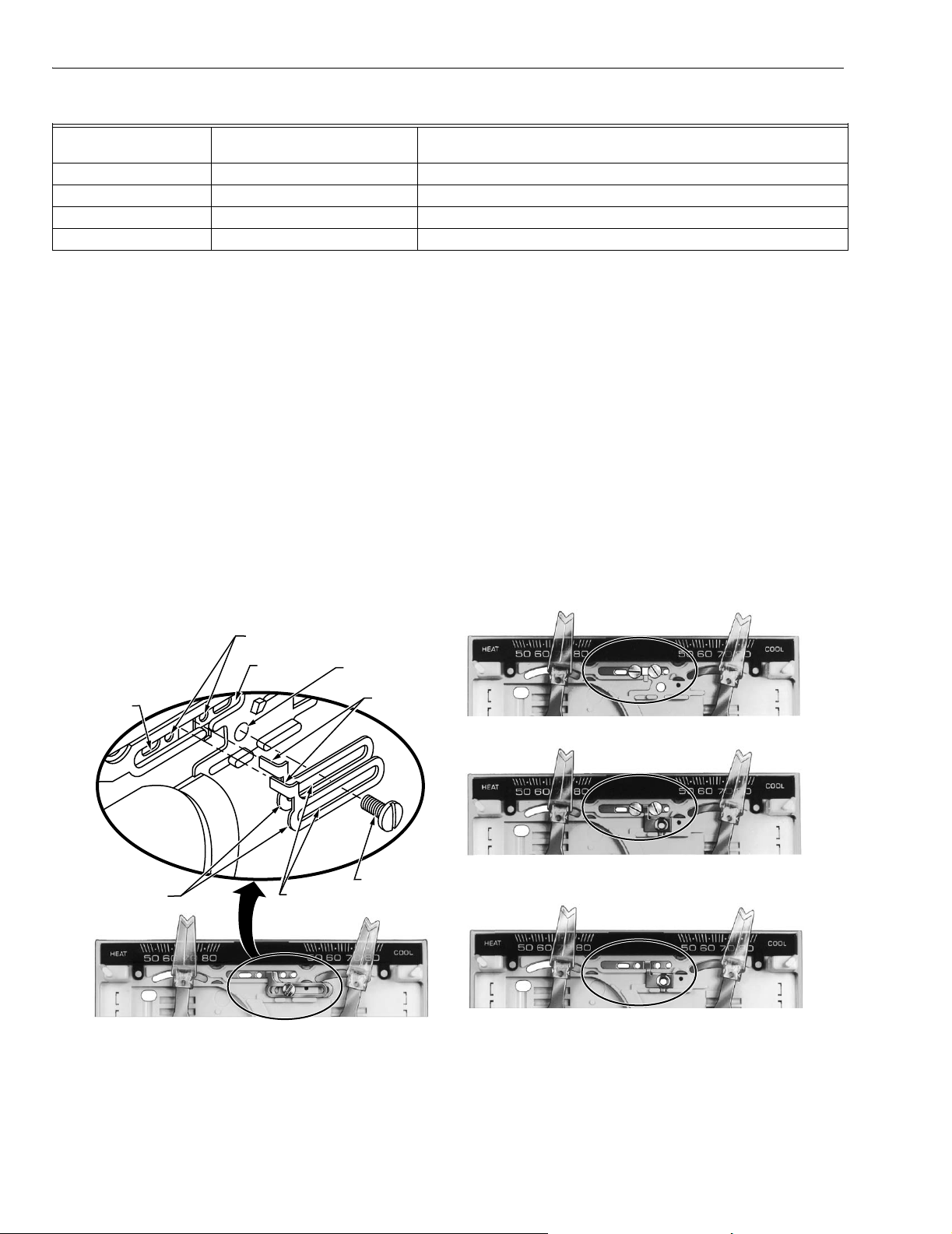

the slot between the HEAT and COOL levers. See

Fig. 9.

HEAT

LEVER

ADJUSTABLE

LEVER STOP

BRACKETS

HOLES FOR INSULATED

LOCKING LEVER SCREWS

COOL

LEVER

BRACKET

SLOTS

ADJUSTABLE STOPS

Fig. 9. Range limiting and lever locking methods.

HOLE WITH

BRASS INSERT

BRACKET

TABS

MOUNTING

SCREW

ADJUSTABLE LOCKING LEVERS

NONADJUSTABLE STOPS

WITH LOCKING LEVER SCREWS

75°F (24°C) MAX. HEAT

75°F (24°C) MIN. COOL

NONADJUSTABLE D.O.D. STOPS

72°F (22°C) MAX. HEAT

M7626

6. Insert the mounting screw into the two slots in the stop

brackets and attach to the brass insert. Tighten the

screw to pull the brass insert into the back of the ther-

60-2485—8 10

mostat.

7. Loosen the mounting screw enough to free the stop

brackets for adjustment.

Page 11

8. Move the HEAT and COOL levers to the maximum tem-

M956

perature desired.

9. Slide the stop brackets until one rests against the HEAT

lever and the other against the COOL lever.

10. Firmly tighten the mounting screw.

11. If the HEAT and COOL levers are to be locked in place

at a specific temperature, use the two insulated head

screws supplied instead of the two adjustable lever stop

brackets.

CAUTION

Equipment Damage Hazard.

Do not use standard screws that provide metal-tometal contact with the stop brackets. Short circuit and

potential equipment damage can result.

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

ALLEN

RETAINING

SCREWS (2)

Mount Thermostat

1. Remove the thermostat cover by pulling the bottom

edge of the cover away from the base until it snaps free

of the cover clip.

NOTE: The cover is hinged at the top and must be removed

by pulling up at the bottom.

2. Carefully remove and discard the polystyrene packing

insert that protects the mercury switches during shipment.

3. If LED indication (EM.HT., CHECK, etc.) is to be used

with the Q674 Subbase, install the preprinted insert

under the thermostat setpoint scale. To install, push

both thermostat setpoint levers to the far ends of the

thermostat. Use index finger to gently pull out the plastic

setpoint scale about 1/4 in. (6 mm). Position the desired

preprinted insert in the space above the LED lights.

Reposition setpoint levers.

4. Turn over the thermostat base and note the spring fingers that engage the subbase contacts. Make sure the

spring fingers are not bent flat, preventing proper electrical contact with the subbase.

5. Set the heat anticipator indicator(s) to the respective

current setting of each stage. See Set The Heat Anticipator section.

6. If the thermostat provides optional locking cover assembly, start the Allen locking screws in the cover with the

wrench provided. See Fig. 10.

7. Note the two tabs along the top inside edge of the thermostat base. The tabs fit into corresponding slots on top

of the subbase. Mount the thermostat on the subbase.

8. Align the two captive mounting screws in the thermostat

base with the posts on the subbase. Tighten both

screws. Do not overtighten screws or damage to subbase posts can result.

Fig. 10. Installation of locking cover assembly.

SETTINGS

CAUTION

Equipment Damage Hazard.

On systems using a gas valve, never apply a jumper

across the valve coil terminals, even temporarily. This

can burn out thermostat heat anticipator(s).

Set the Heat Anticipator

Move the indicator to match the primary control current draw.

When using a T874 Thermostat with two stages of heating,

set each heat anticipator to match its respective primary

control current draw. If you cannot find the current rating on

the primary control, or if further adjustment is necessary, see

NOTE and use the following procedure to determine the

current draw of each stage.

The current draw of each heating stage must be measured

with the thermostat removed and power on to the heating

system.

1. Connect an ac ammeter of appropriate range between

the heating terminals of the subbase:

a. Stage 1—between W1 and RH or R;

b. Stage 2—between W2 and RH or R

c. Stage 3—between W3 and RH or R.

2. Move the system switch to HEAT or AUTO.

3. After one minute, read the ammeter and record the

reading:

a. Stage 1—__________A;

b. Stage 2—__________A;

c. Stage 3—__________A.

NOTE: If equipment cycles too fast, set the indicator to a

higher current rating, but not more than one-half division at a time, and recheck the cycle rate. Most conventional two-stage heating equipment is designed

to operate at three cycles per hour per stage, and

one-stage heating equipment at six cycles per hour,

at 50 percent load conditions. When using the T874

Thermostat in heat pump systems, set the heat anticipator at 140 percent of the actual primary control

current draw to reduce the cycling rate. See Fig. 11.

11 60-2485—8

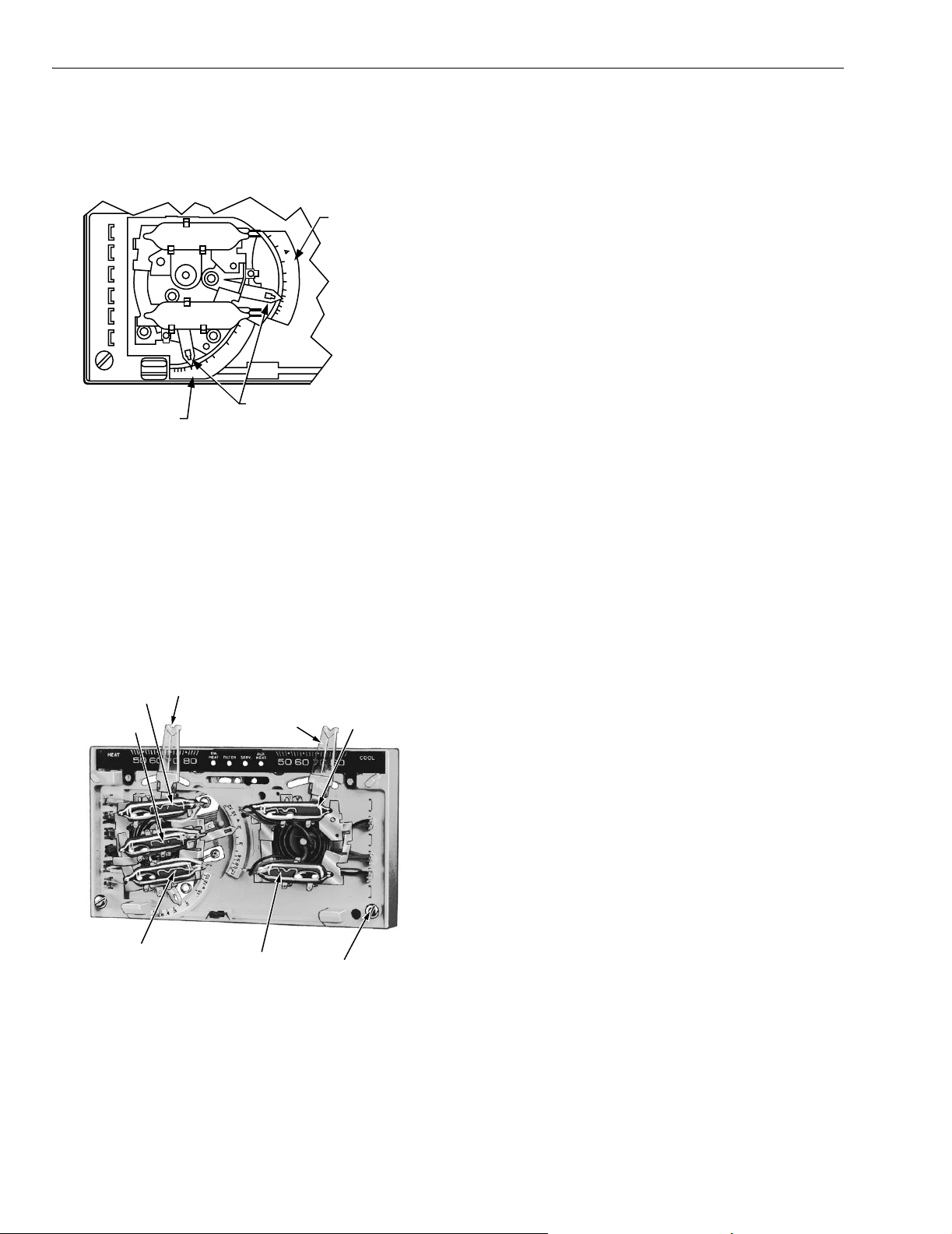

Page 12

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

9

G

Most heat pump systems should cycle 2-1/2 to 3 times per hour.

4. Hang the upper edge of the thermostat cover on top of

the thermostat base and swing the cover downward

until it engages with the cover clip.

STAGE ONE

.5

.6

.2

.3

.4

ANTICIPATOR

HEATING

CONTROL

M506

STAGE TWO

ANTICIPATOR

HEATING CONTROL

.12

.15

.8

1.2

.10

.12

.15

.2

.3

.4

1.2

.8

.6

MOVE INDICATOR TO

MATCH CURRENT RATING

OF PRIMARY CONTROL

Fig. 11. Adjustable heat anticipator scales.

Temperature Setting

Move the heating and cooling levers to the desired comfort

positions. See Fig. 12. On some models with two stages of

heating or cooling, the same lever controls both stages. The

minimum differential between heating and cooling setpoints is

4°F (2°C) (5°F [3°C]) on T874W.

If model has optional screws to lock temperature control

levers, loosen these screws before making temperature

adjustment; tighten the screws when levers are set at desired

position.

STAGE 1

HEATING

STAGE 3

HEATING

HEATING

LEVER

COOLING

LEVER

STAGE 1

COOLIN

HEAT—heating system is automatically controlled by the

thermostat. Cooling system is off.

AUTO—thermostat automatically changes between heat-

ing and cooling system operation, depending on the

indoor temperature.

COOL—cooling system is automatically controlled by the

thermostat. Heating system is off.

EM.HT.—emergency heat relay is automatically controlled

by the thermostat. Cooling system is off. Compressor is

de-energized.

SUPL.HT.—supplemental heat relay is energized. Cooling

system is off. Compressor is de-energized.

WOOD—heating system is operating with only the wood-

burning stage.

OIL—heating system is operating with only the oil-burning

stage.

WOOD/OIL—wood and oil stages operate sequentially;

first the WOOD stage operates, then the OIL stage

operates if the WOOD stage cannot handle the load.

EVAP—controls cooling system by water evaporation; see

equipment instructions for further information.

OVERRIDE—night setback is disabled.

ON—heating system is controlled by the thermostat. EM.

HT. or SUPL. HT. relay is not energized.

FAN SWITCH positions control fan operation as follows:

ON or CONT.—fan operates continuously.

AUTO—fan operates as controlled by the thermostat in

heat pump systems or conventional cooling mode; fan

operates as controlled by the plenum switch in conven-

tional heating mode.

LO—fan operates constantly at low speed.

MED—fan operates constantly at medium speed.

HI—fan operates constantly at high speed.

To move the subbase switches to the desired control

positions, use thumb and index finger to slide the lever. The

lever must stop over desired function indicator position for

proper circuit operation.

Spring return momentary position switching feature is

available on selected subbase models. On these models, the

fan switch is positioned to the right of the system switch. By

moving the fan switch to the far right and releasing it, the ON

position circuit makes. The lever springs back on release. This

position is not marked on the subbase.

STAGE 2

HEATING

STAGE 2

COOLING

CAPTIVE

MOUNTING

SCREWS (2)

M7625

Fig. 12. Internal view of T874W (three stages of

heating, two stages of cooling).

Subbase Setting

The subbase switching positions control the system operation

as described below.

SYSTEM SWITCH (see subbase for positions):

OFF—both the heating and cooling systems are off. If the

fan switch is at the AUTO position, the cooling fan is

also off.

60-2485—8 12

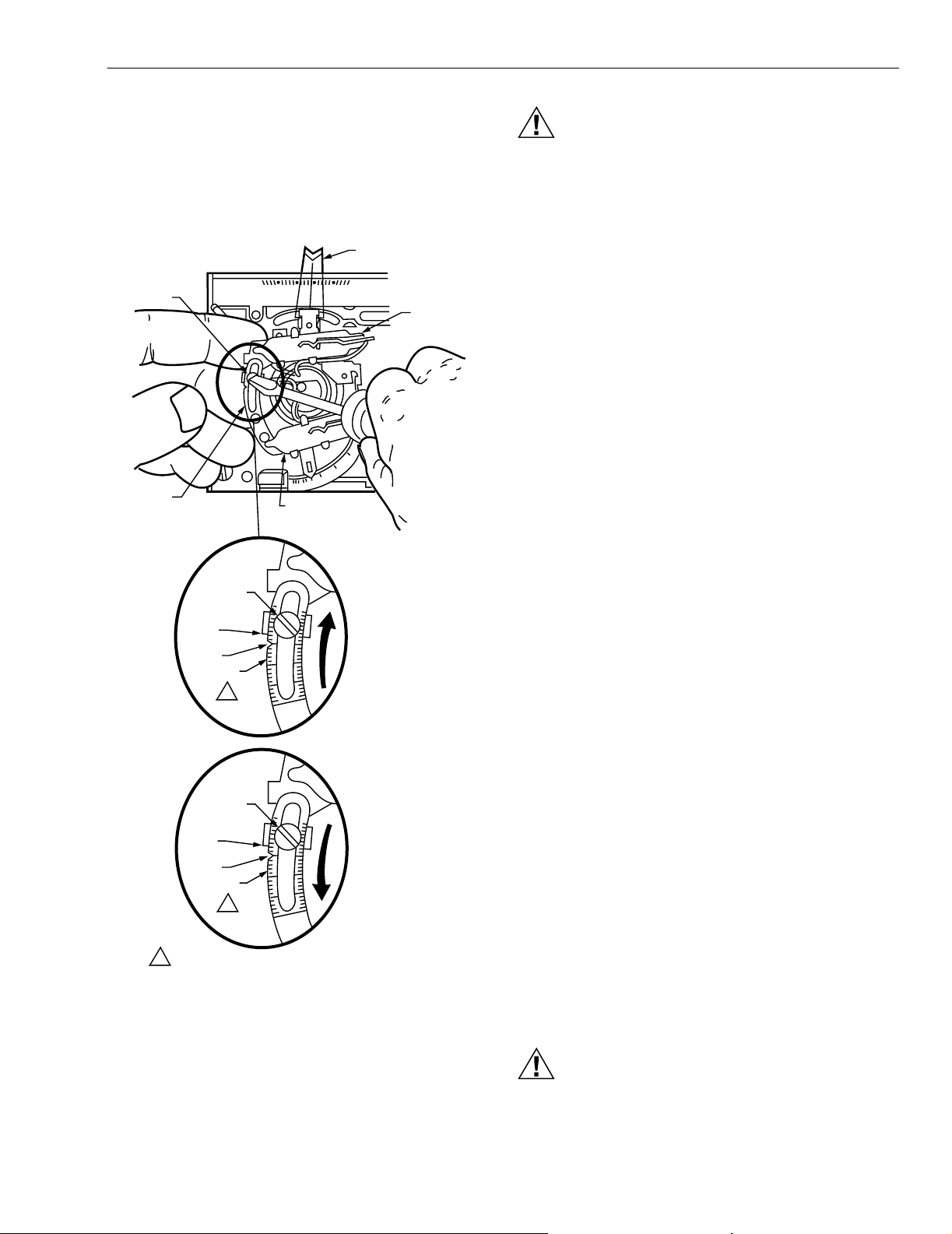

Setting the Adjustable Differential

The adjustable interstage differential feature, on a selected

T874D model only, can be identified by the scale and tension

screw near the heating and cooling mercury switches. See

Fig. 13. On this model, the number of degrees between the

making of the first and second stage mercury bulbs is

adjustable. This feature is especially useful if the first stage

controls the comfort temperature, and the second stage

controls the energy savings temperature. Timers, such as the

S6005, for insertion between the first and second stage

control points must be ordered separately.

Each mark on the scale represents 1°F (0.6°C) The

differential is factory set at 2°F (1°C) the differential can be set

as high as 12°F (7°C) To set the adjustable interstage

differential, loosen the tension screw. See Fig. 13. Slide the

adjustable scale to align with the number of degrees desired

between stages. Use the lower edge of the tension screw

bracket as a guide for alignment. In heating, slide the lever

wider apart for a larger differential, or closer together for a

Page 13

smaller differential. In cooling, slide the lever closer together

M937

for a larger differential, or wider apart for a smaller differential.

While supporting the scale with hand, tighten the tension screw.

IMPORTANT

Support the scale with hand while tightening tension

screw. See Fig. 13. Failure to do so can result in

twisting and damaging bimetal coil.

HEATING SETPOINT LEVER

TENSION

SCREW

SCALE

HEATING

HEAT

TENSION

SCREW

ALIGN LOWER

EDGE WITH

SCALE

NOTCH

10°F

SCALE

1

50 60

1.2

.8

SECOND STAGE

(ADJUSTABLE)

SWITCH

70 80

.3

.4

.6

1.5

.2

SLIDE LEVER

WIDER APART

FOR LARGER

DIFFERENTIAL

FIRST

STAGE

SWITCH

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

CAUTION

Equipment Damage Hazard.

When the thermostat is used to control a two-stage

heating or cooling system, the second stage mercury

bulb must never make before the first stage bulb, or

severe equipment damage could result. To prevent

this problem, provide at least 2°F (1°C) differential

between stage-one and stage-two make points.

Example: in heating, if stage-one makes at 70°F (21°C)

stage-two should make at 68°F (20°C) or lower.

Verify the Adjustment

Heating

Start with the heating setpoint lever all the way to the left.

Slowly move the lever to the right, just until the first stage bulb

makes (mercury rolls to the right side of the bulb). Note the

setting on the temperature scale. Slowly move the lever to the

right until the second stage bulb makes. Note the setting on

the temperature scale. The difference between the two

temperatures is the interstage differential, which should match

the number set on the scale with the tension screw.

Cooling

Start with the cooling setpoint lever all the way to the right.

Slowly move the lever to the left, just until the first stage bulb

makes (mercury rolls to the left side of the bulb). Note the

setting on the temperature scale. Slowly move the lever to the

left until the second stage bulb makes. Note the setting on the

temperature scale. The difference between the two

temperatures is the interstage differential, which should match

the number set on the scale with the tension screw.

CHECKOUT

COOLING

TENSION

SCREW

ALIGN LOWER

EDGE WITH

SCALE

NOTCH

4°F

SCALE

1

1 EACH MARK ON THE SCALE REPRESENTS 1°F (0.6°C).

SLIDE LEVER

CLOSER TOGETHER

FOR LARGER

DIFFERENTIAL

Fig. 13. Set adjustable interstage differential.

Heating

Move the system switch on the Q674 Subbase to HEAT or

AUTO. Move the heat lever on the T874 about 10°F (6°C)

above room temperature. See Fig. 12. Heating system should

start and the fan should run after a short delay. Move the heat

lever about 10°F (6°C) below room temperature. The heating

equipment should shut off, and the fan should run for a short

time, then shut off.

In heat pump applications, sometimes time delays are

involved before the compressor and auxiliary heat are

activated. This is due to a minimum-off timer, which prevents

the compressor from restarting for five minutes from when the

thermostat last turned off the compressor, or from when the

system first received power.

Cooling

CAUTION

Equipment Damage Hazard.

Do not operate cooling if outdoor temperature is below

50°F (10°C). Refer to manufacturer recommendations.

13 60-2485—8

Page 14

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

0

TEMPERATURE OF THERMISTOR (°F)

M1590A

Move the system switch on the Q674 Subbase to COOL or

AUTO. Move the cool setting lever on the T874 Multistage

Thermostat about 10°F (6°C) below room temperature. See

Fig. 12. The cooling equipment and fan should start. If the

system has two stages of cooling, both stages should start.

Move the cool lever about 10°F (6°C) above room

temperature. The cooling equipment and fan should stop.

Fan

Move the system switch to COOL, OFF, or AUTO. If

necessary, position both temperature setting levers so that the

heating and cooling equipment are off. Move the fan switch to

ON or CONT. The fan should run continuously. When the fan

switch is in AUTO, LO, MED, or HI position, fan operation is

controlled by the heating or cooling system.

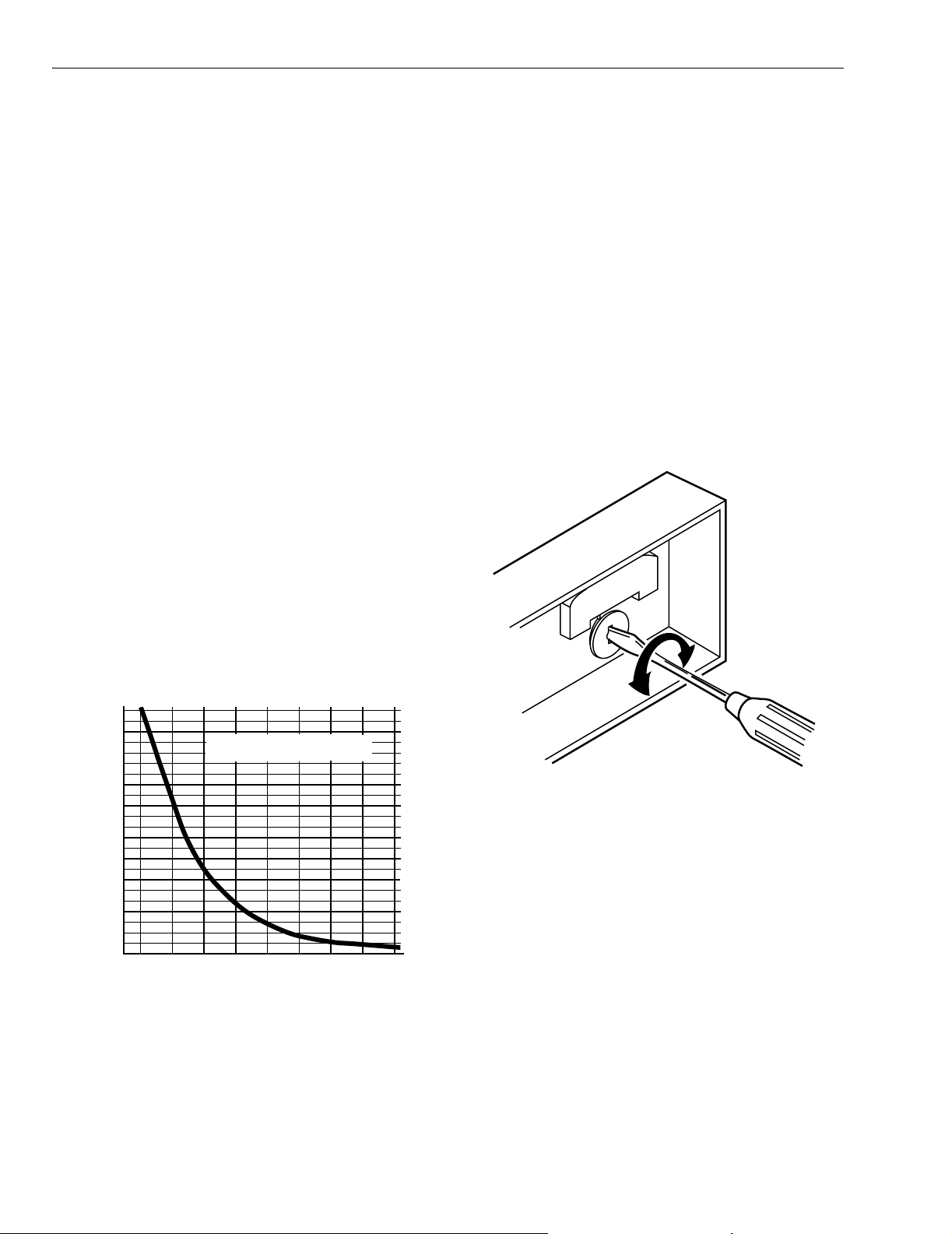

Outdoor Reset Thermistor (Where Applicable)

If the system is supplied with a thermistor, it must be used; if

not used, thermostat performance deviates radically from

proper operation.

The proper thermistor operation must be verified to ensure the

correct operation of the thermostat. Check thermistor

operations as follows:

1. Disconnect the T wire on the subbase.

2. Use an ohmmeter to measure resistance between the

T wire and the A subbase terminal.

3. Take outdoor temperature at thermistor location and find

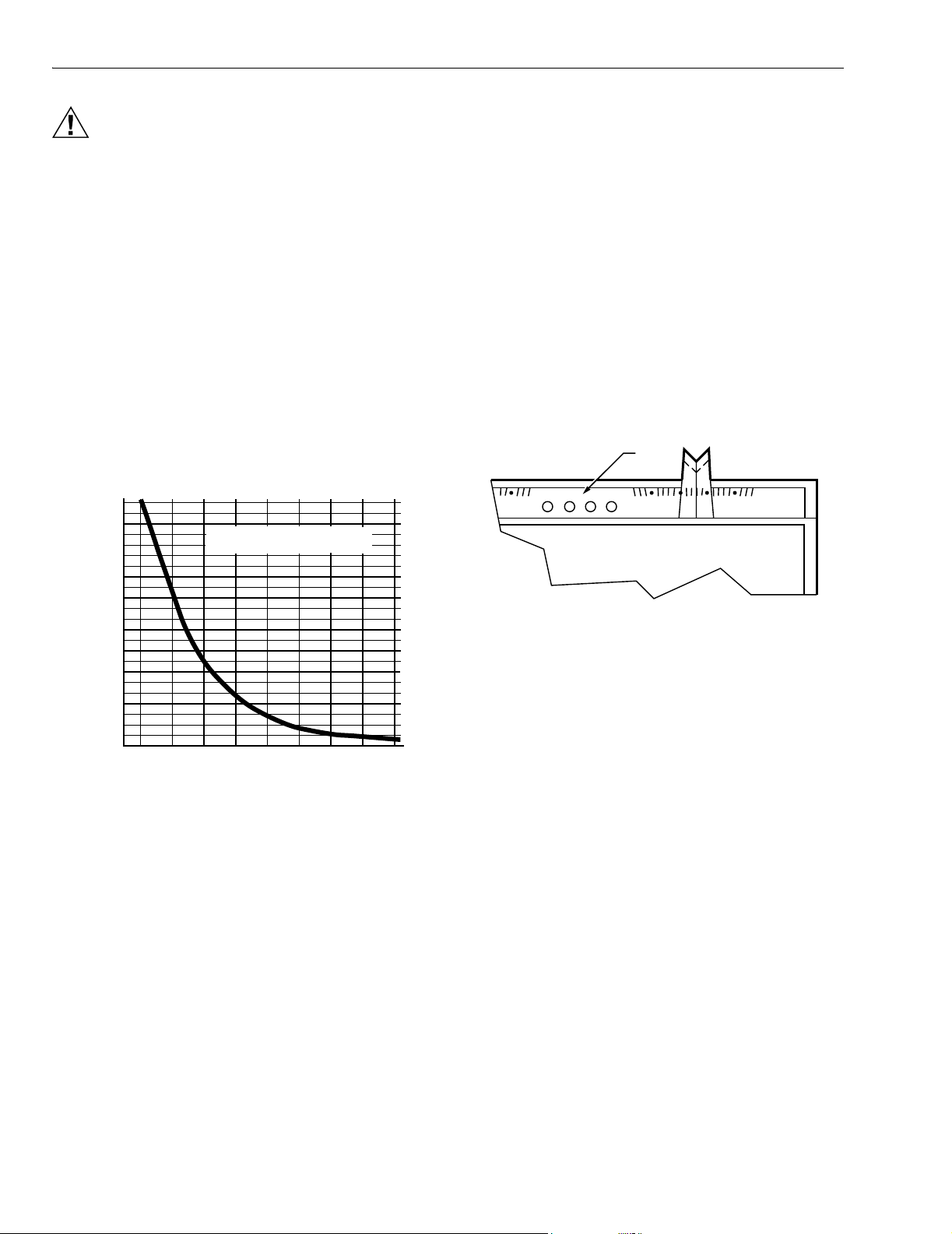

the correct thermistor resistance on the Fig. 14 chart.

4. If the resistance measured in step 2 and the calculated

resistance in step 3 vary by more than 15 percent, the

thermistor requires replacement. Contact Honeywell or

installing dealer for replacement packaged outdoor thermistor, part no. C815A1005.

Thermometer

The thermometer in your thermostat has been accurately

calibrated at the factory. The thermometer should only need

adjustment if it has been dropped or shifted due to mishandling.

If the setpoint lever and the thermometer reading do not

agree, use the following procedure:

1. Remove the thermostat cover by pulling up from the

bottom edge of the cover away from the base until it

snaps free of the cover clip.

2. Set the thermostat cover on a table near an accurate

thermometer.

3. Allow ten minutes for cover thermometer to sense area

temperature; compare the readings. Be careful not to

touch thermometer or breathe on it.

4. If the readings are the same, replace cover and put the

system into operation.

5. If the readings are different, insert a small screwdriver in

the thermometer slot and turn it until the thermometers

have the same reading. See Fig. 15.

6. Replace thermostat cover and put the system into operation.

4600

4400

4200

4000

3800

3600

3400

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

THERMISTOR RESISTANCE (ohms)

1200

1000

800

600

400

200

0

-20 0 20 40 60 80 100 120 14

C815A THERMISTOR RESISTANCE

R = 400 ohms ± 10% AT 77°F (25°C)

Fig. 14. Thermistor resistance chart.

CALIBRATION

Thermostat

T874 Thermostats are accurately calibrated at the factory.

They do not have provision for field calibration.

M5070

Fig. 15. Thermometer calibration.

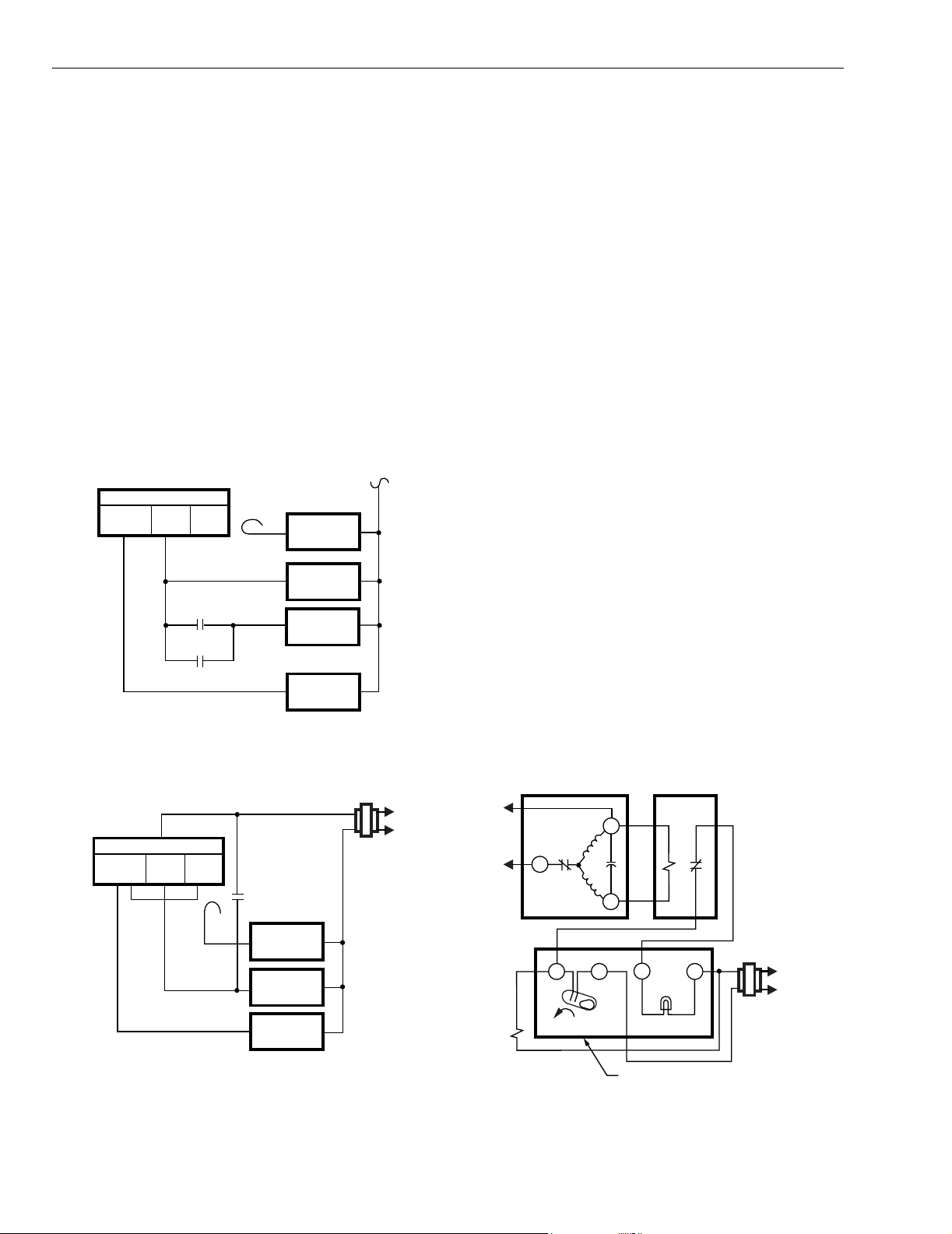

UNDERSTANDING CIRCUITS

To understand wiring diagrams, it is important to know what all

the symbols mean and how to trace the path of the circuits

from the transformer. See Fig. 16 through 25.

Circuit descriptions and terminology are defined as follows:

For standard heating-cooling circuits:

Auto changeover—refers to the presence of an AUTO

position in the system switching (EX: Q674E with OFFHEAT-AUTO-COOL switching). The thermostat automatically changes between heat and cool modes as

indoor temperature changes.

Manual changeover—requires a system switch movement

to change mode (EX: Q674B with HEAT-OFF-COOL

switching). T874D Multistage Thermostats with 2 heat

or 2 cool switches are shown on most standard circuits.

Most standard or TRADELINE® subbases (Q674A-E,G)

can be used with T874A-F standard or TRADELINE

60-2485—8 14

Page 15

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

8

S

R

thermostats. The schematics can be field-modified as

required (EX: if T874C is being used, eliminate second

stage of heat).

For heat pump circuits:

Cool changeover valve—operates on cooling. The revers-

ing valve or relay is activated either by moving the system switch to COOL (manual changeover) or by a

mercury switch that makes on a temperature rise (auto

changeover).

Heat changeover valve—operates on heating. The revers-

ing valve or relay is activated either by moving the system switch to HEAT (manual changeover) or by a

mercury switch that makes on a temperature fall (auto

changeover).

System monitor relay—optional equipment on some heat

pumps includes an R4222P1065 or equivalent. This

system monitor relay detects a malfunction in the compressor and indicates the malfunction by activating the

EMERGENCY HEAT LED on the Q674 Switching Subbase. The system monitor relay is usually wired into the

L terminal on the Q674.

Each mercury switch is identified by function:

H1—Stage 1 Heating.

H2—Stage 2 Heating.

H3—Stage 3 Heating.

C1—Stage 1 Cooling.

C2—Stage 2 Cooling.

C3—Stage 3 Cooling.

C/O—Changeover (heat pumps).

perature rise. Fixed anticipation is represented by a zigzag line and adjustable anticipation is a zigzag with an

arrow. The resistance of the fixed anticipator is so large

it limits current so that a system relay cannot be pulled

in from a circuit path going through the fixed anticipator.

The relay can be pulled in through an adjustable anticipator because its resistance is generally 0 to 5 ohms.

5. The center portion (the subbase) contains the switches.

The fan switch is above the system switch. The small

circles on the switch represent the maximum possible

contacts available on the Q674 Subbase. The larger circles represent the switch positions available on this particular Q674, with the solid circle representing where it

is actually switched on the diagram.

NOTE: Solid circles are not interconnected electrically.

At the right, the relays and contactors are shown, attached to

the proper terminals. The terminals are represented by large

circles with terminal designations in capital letters. See Table

3 for the meaning of each lettered terminal.

Sometimes power for a fixed anticipator is brought through an

off system relay like the changeover relay shown in Fig. 20.

This current is kept low by the high resistance of the fixed

anticipator so that relay does not pull in.

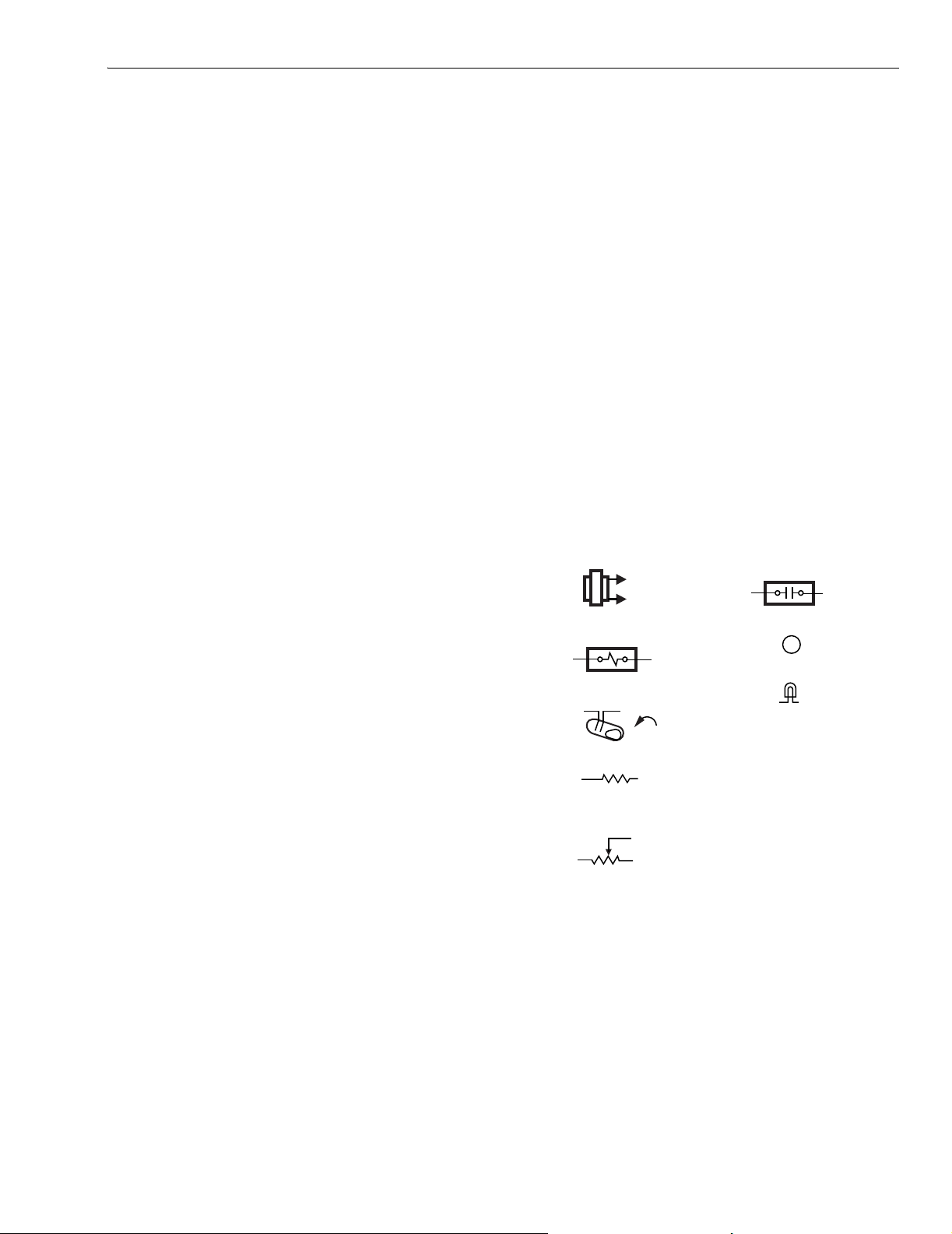

KEY TO HOOKUP SYMBOLS

Each anticipator is identified and each switch affected is

named (EX: H1 anticipator, C1 anticipator).

All T874 Multistage Thermostats use mercury switches. Each

schematic indicates switch operation by being drawn in the

open position with an arrow indicating operation with a

temperature RISE or FALL.

One circuit has been selected that is typical of various models

used with heat pumps. This circuit has been traced to illustrate

the functions performed by these control systems.

Tracing Method:

1. Always begin at the system transformer or R terminal.

You may want to draw the switch contacts in each

switch position to aid in tracing. Colored pencils are

helpful when only one copy of the circuit is available.

See Fig. 16 for a description of the hookup symbols and

Fig. 17 through 25 for typical hookups.

2. Completely trace only one circuit at a time (for example:

heat or cool).

3. Connections are indicated by small dots at the point of

intersection. If there is no dot, there is no connection.

4. The left portion of the circuit (the thermostat) contains

TRANSFORMER

(24 VAC SECONDARY)

ELAY OR CONTACTOR COIL

MERCURY SWITCH

FIXED ANTICIPATOR

HIGH RESISTANCE

(TYPICALLY 5 KILOHMS)

ADJUSTABLE ANTICIPATOR

LOW RESISTANCE

(TYPICALLY 0 TO 5 OHMS)

Fig. 16. Key to hookup symbols.

RELAY/CONTACTOR CONTACT

B

TERMINAL

LED

ODT

OUTDOOR THERMOSTAT

EHR

EMERGENCY HEAT RELAY

RTD

TIME DELAY RELAY

RD

DEFROST RELAY

CHP

PRESSURE SWITCH

LACO

LOW AMBIENT CUTOFF

M584

the mercury switches. The heat switches make on a

temperature fall, and the cool switches make on a tem-

15 60-2485—8

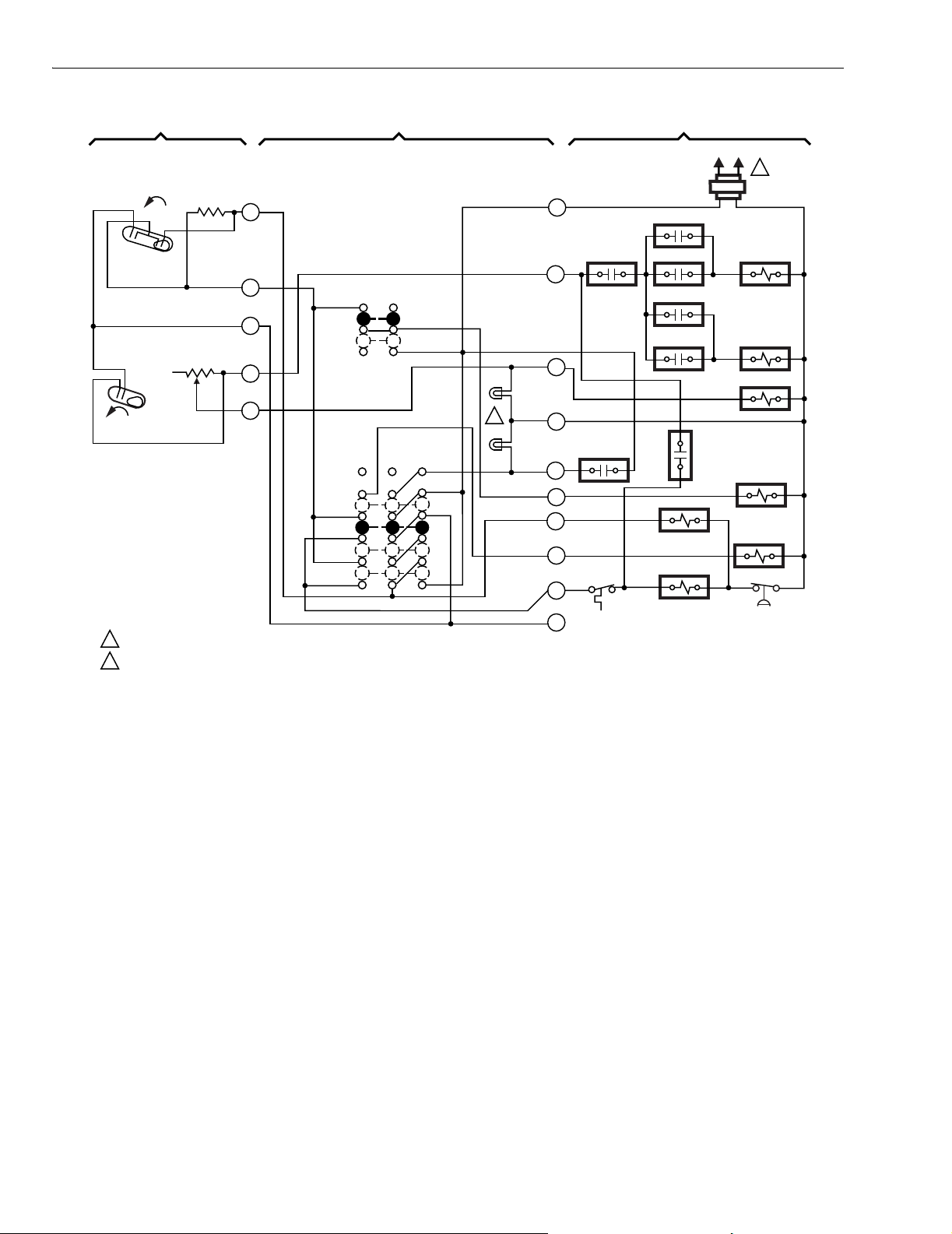

Page 16

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

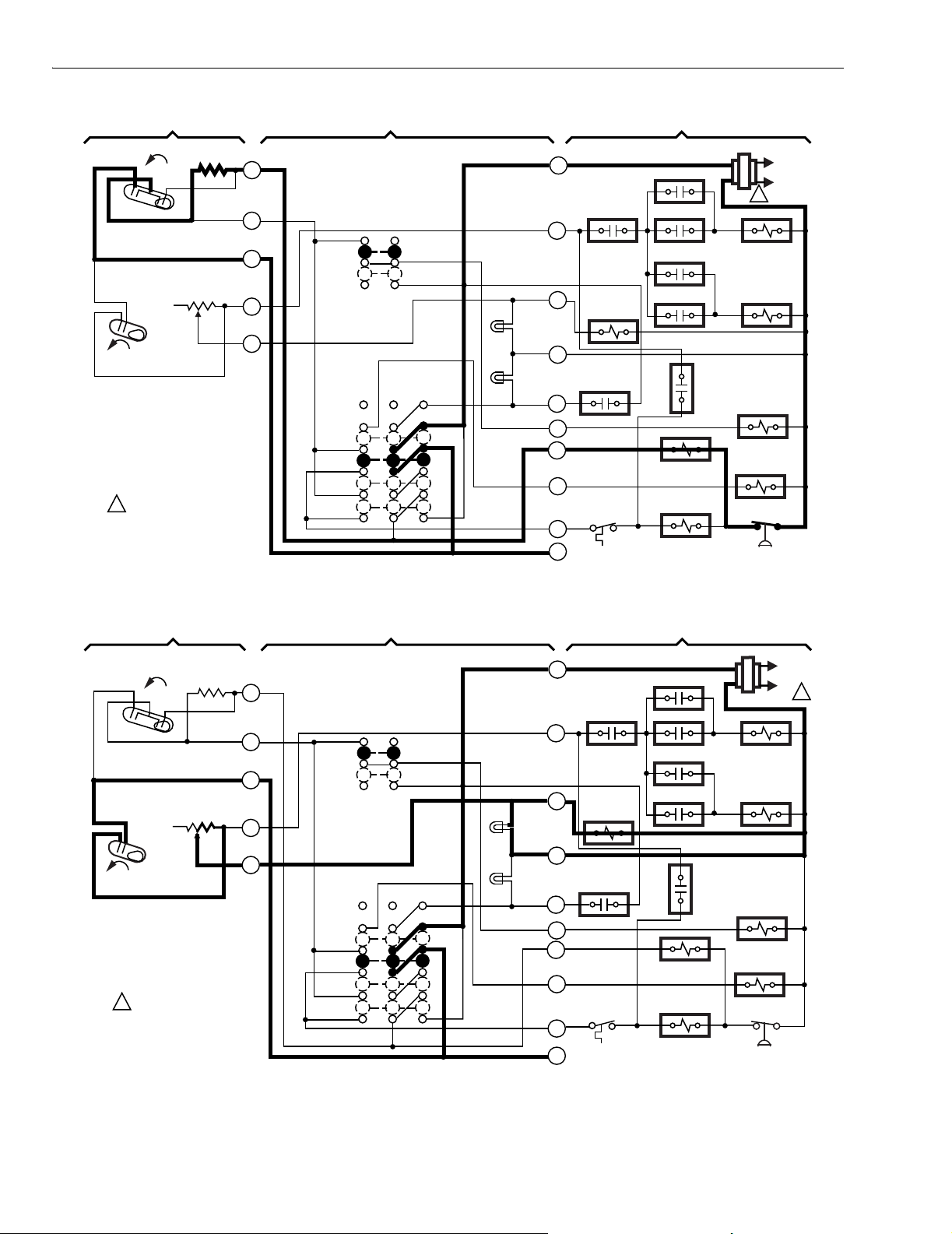

THERMOSTAT

H1/C1

ANTICIPATOR

FALL

H1

C1

H2

ANTICIPATOR

H2

FALL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

AUXILIARY HEAT LED AVAILABLE ON SOME MODELS.

2

3

4

5

6

FAN SWITCH

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

SUBBASE

ON

2

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

W3

W2

X

L

G

O

E

R

Y

B

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

RTD 1 EHR 1

ODT 2

EHR 2 RTD 3

RD

COOL CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

(HOT) L1

L2

1

RTD 2

RTD 1

FAN RELAY

EM. HT.

RELAY

CHP

M5072A

Fig. 17. Internal schematic and typical hookup of a T874R Thermostat and Q674L Subbase in a heat pump application.

The thermostat provides two-stage heating and one-stage cooling manual changeover operates on cooling.

60-2485—8 16

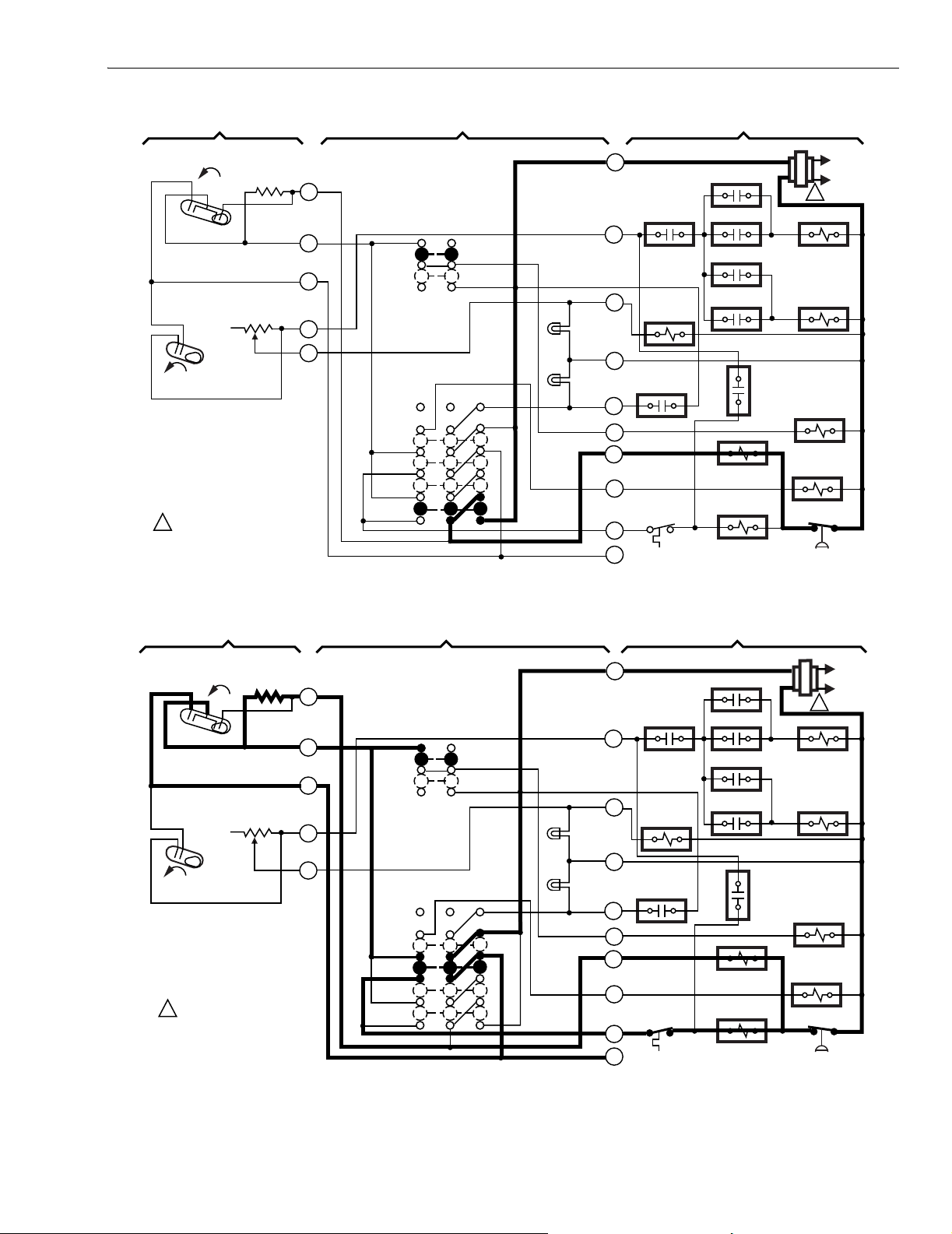

Page 17

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

0

)

THERMOSTAT

H1/C1

C1

H2

ANTICIPATOR

ANTICIPATOR

FALL

H1

H2

FALL

1

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

SUBBASE SYSTEM COMPONENTS

L1

R

2

X

L

G

O

E

Y

B

SYSTEM

MONITOR

LACO

RTD 1 EHR 1

RTD 1

FAN SWITCH

3

4

5

6

AUTO

ON

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

W3

W2

ODT 1

ODT 2

EHR 2 RTD 3

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

(HOT)

1

RTD 2

FAN RELAY

EM. HT.

RELAY

CHP

L2

M584

Fig. 18. Tracing the changeover relay circuit.

THERMOSTAT SUBBASE

H1/ C1

ANTICIPATOR

FALL

H1

C1

H2

ANTICIPATOR

H2

FALL

1

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

2

FAN SWITCH

3

4

5

6

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

ON

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

W3

W2

R

X

L

G

O

E

Y

B

RTD 1

RTD 1

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

EHR 1

ODT 2

EHR 2 RTD 3

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

1

RTD 2

FAN RELAY

EM. HT.

RELAY

CHP

L1

(HOT

L2

M5841

Fig. 19. Tracing the heat 1 and anticipation circuit.

17 60-2485—8

Page 18

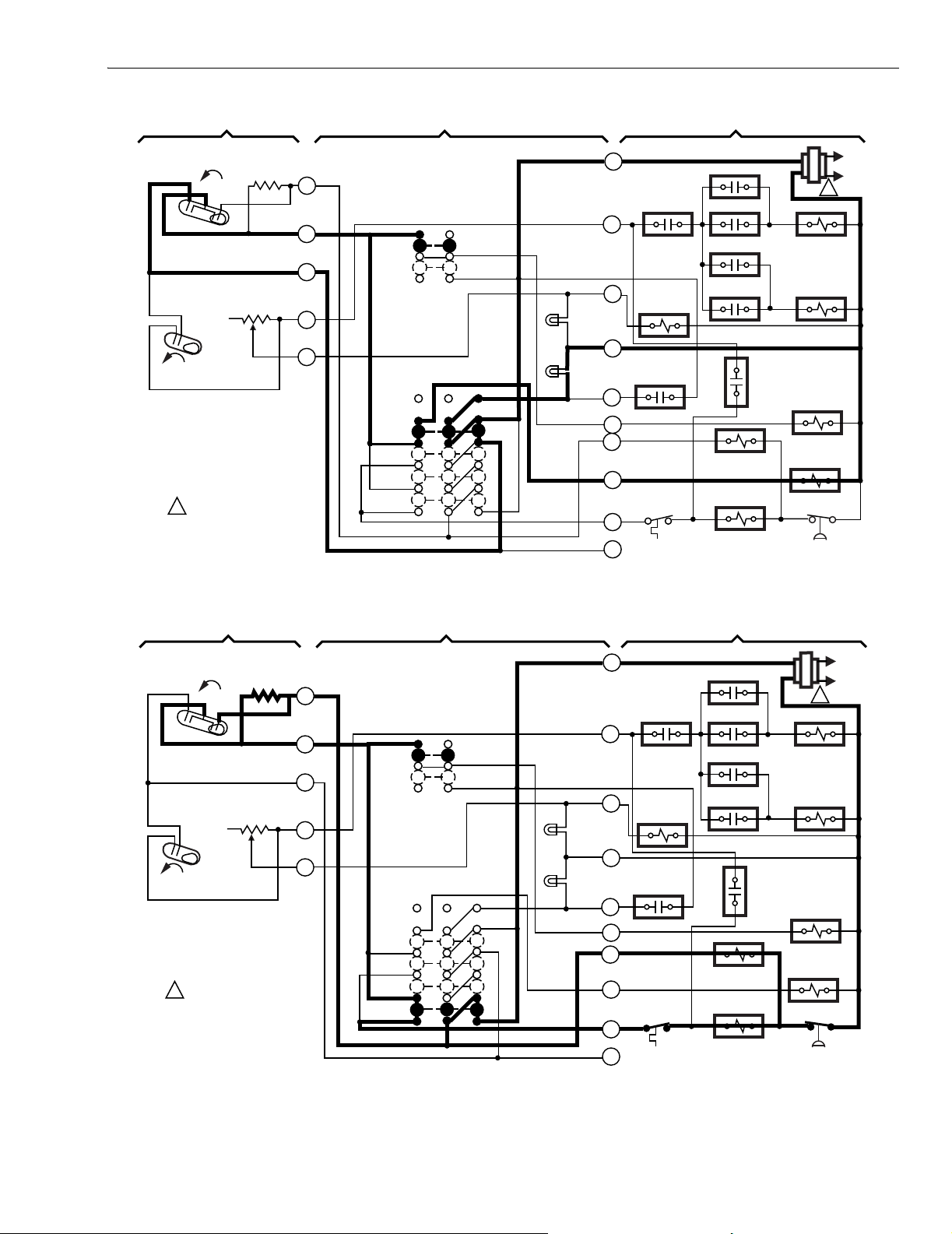

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

M5842

)

THERMOSTAT SUBBASE

H1/ C1

ANTICIPATOR

FALL

H1

FALL

1

C1

H2

ANTICIPATOR

H2

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

2

3

4

5

6

FAN SWITCH

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

ON

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

W3

W2

R

X

L

G

O

E

Y

B

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

RTD 1 EHR 1

ODT 2

EHR 2 RTD 3

RTD 1

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

1

RTD 2

FAN RELAY

EM. HT.

RELAY

CHP

L1

(HOT)

L2

Fig. 20. Tracing the heat 1 anticipation circuit.

THERMOSTAT SUBBASE

H1/C1

ANTICIPATOR

FALL

H1

FALL

1

C1

H2

ANTICIPATOR

H2

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

2

FAN SWITCH

3

4

5

6

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

COOL

ON

OFF

W3

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

W2

R

X

L

G

O

E

Y

B

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

RTD 1 EHR 1

ODT 2

EHR 2 RTD 3

RTD 1

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

FAN RELAY

EM. HT.

RELAY

RTD 2

CHP

L1

(HOT

L2

M5843

1

Fig. 21. Tracing the heat 2, anticipation and AUX. HT. LED circuit.

60-2485—8 18

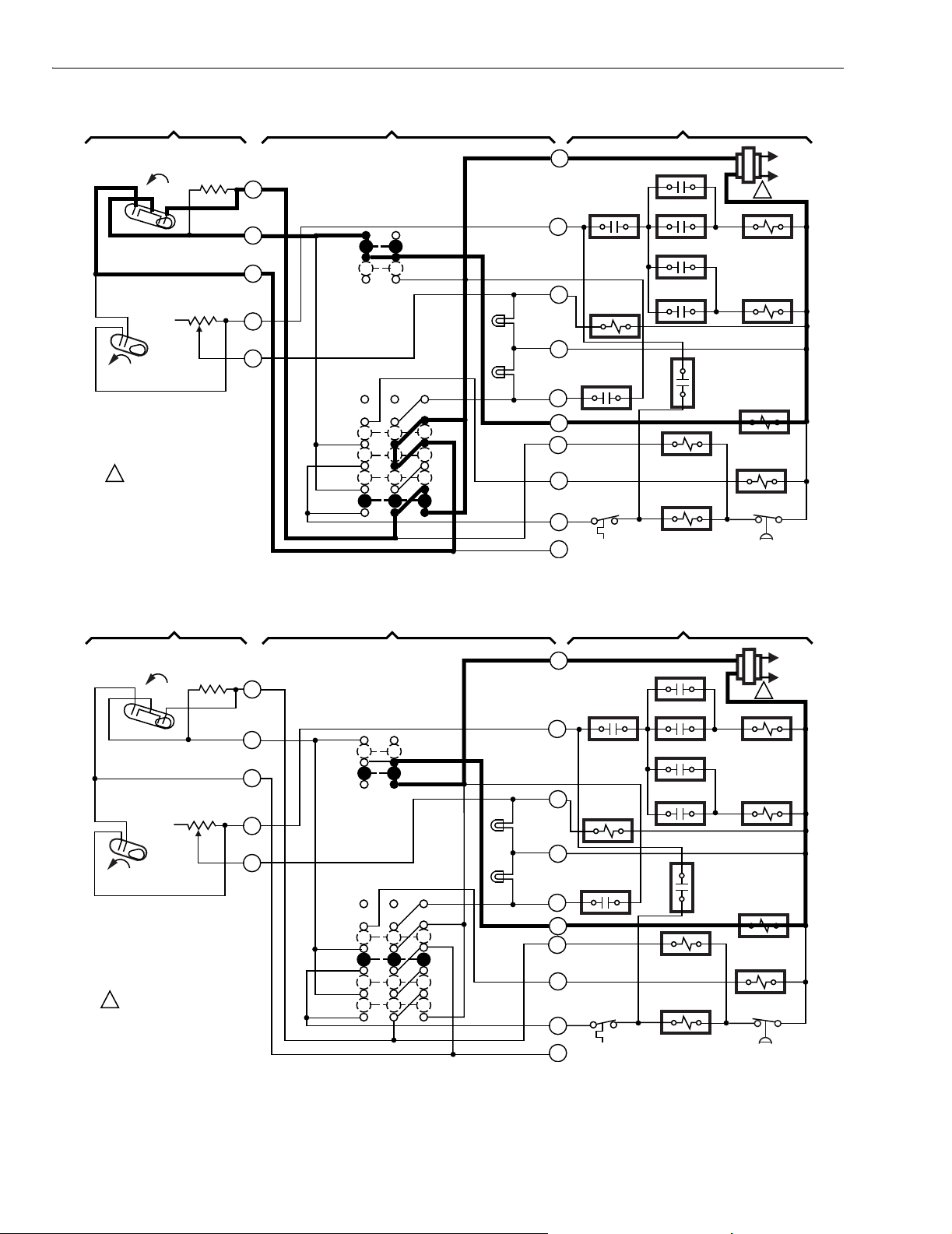

Page 19

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

)

M5845

)

THERMOSTAT SUBBASE

H1/C1

ANTICIPATOR

FALL

H1

FALL

1

C1

H2

ANTICIPATOR

H2

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

2

FAN SWITCH

3

4

5

6

AUTO

ON

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

W3

W2

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

R

X

L

G

O

E

Y

B

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

RTD 1 EHR 1

ODT 2

EHR 2 RTD 3

RTD 1

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

1

RTD 2

FAN RELAY

EM. HT.

RELAY

CHP

M5844

L1

(HOT

L2

Fig. 22. Tracing the emergency heat and EM. HT. LED circuit.

THERMOSTAT SUBBASE

H1/C1

ANTICIPATOR

FALL

H1

FALL

1

C1

H2

ANTICIPATOR

H2

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

2

FAN SWITCH

3

4

5

6

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

ON

W3

W2

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

R

X

L

G

O

E

Y

B

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

RTD 1 EHR 1

ODT 2

EHR 2 RTD 3

RTD 1

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

L1

(HOT

L2

1

RTD 2

FAN RELAY

EM. HT.

RELAY

CHP

Fig. 23. Tracing the cooling circuit.

19 60-2485—8

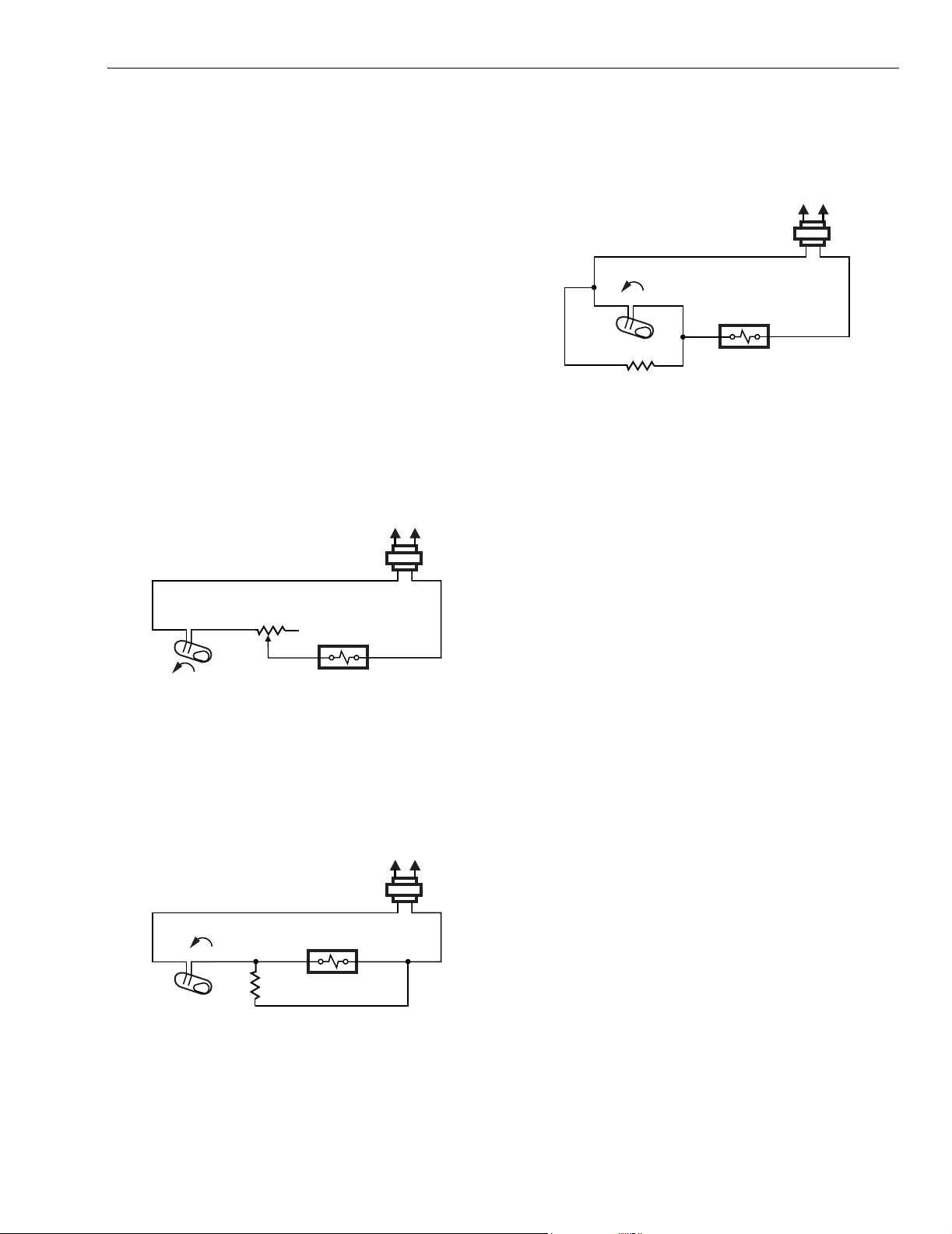

Page 20

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

)

)

THERMOSTAT SUBBASE

H1/C1

ANTICIPATOR

FALL

H1

FALL

1

C1

H2

ANTICIPATOR

H2

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

2

FAN SWITCH

3

4

5

6

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

ON

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

W3

W2

O

R

X

L

G

E

Y

B

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

RTD 1 EHR 1

ODT 2

EHR 2 RTD 3

RTD 1

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

1

RTD 2

FAN RELAY

EM. HT.

RELAY

CHP

L1

(HOT

L2

M5846

THERMOSTAT SUBBASE

H1/C1

ANTICIPATOR

FALL

H1

FALL

1

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

H2

C1

H2

ANTICIPATOR

2

FAN SWITCH

3

4

5

6

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

COOL

Fig. 24. Tracing the auto fan circuit.

W3

ON

W2

AUX. HT.

LED

(GREEN)

EM. HT.

LED (RED)

OFF

R

X

L

G

O

E

Y

B

SYSTEM

MONITOR

LACO

SYSTEM COMPONENTS

ODT 1

RTD 1 EHR 1

ODT 2

EHR 2 RTD 3

RTD 1

RD

CHANGEOVER

VALVE

COMPRESSOR

CONTACTOR

FAN RELAY

1

RTD 2

EM. HT.

RELAY

CHP

L1

(HOT

L2

M5847

Fig. 25. Tracing the fan on circuit.

60-2485—8 20

Page 21

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

3

4

5

OPERATION

Heat Anticipation/Cool Anticipation

When controlling a heating unit with a thermostat, the

temperature does not remain exactly at the thermostat

setpoint, but varies within a certain temperature range. Heat

anticipation is added to the thermostat to reduce this range.

The anticipator is a small resistive heater in the thermostat

that heats when the system is on (heat mode) or off (cool

mode). The heat produced by the anticipator raises the

internal bimetal temperature slightly faster than the

surrounding room temperature. The thermostat anticipates the

need to shut off the heating system sooner than it would if

affected by room temperature only.

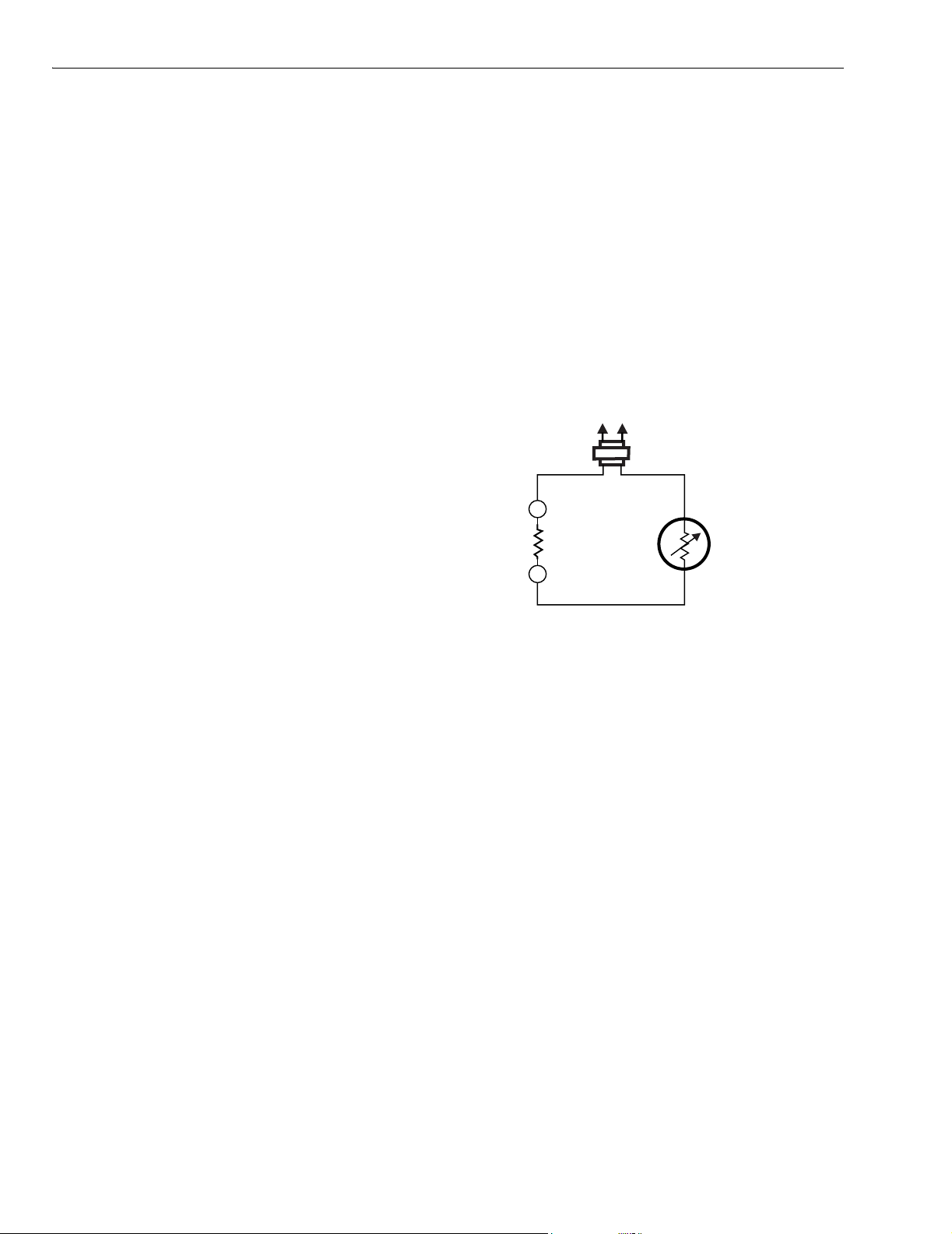

There are two types of heat anticipation, adjustable and fixed.

Adjustable anticipation is also called current anticipation. See

Fig. 26. The heater is in series with the mercury switch and

heating primary. The pointer is adjusted to match the current

draw of the primary control, and the correct amount of heat is

added for proper cycle rates.

L1

L2

(HOT)

Heat anticipators add heat during the call for heat. Cooling

anticipators are activated while the air conditioner is off. See

Fig. 28. This heater makes the thermostat think it is warmer than

it really is, and brings it on sooner than the bimetal alone would.

L1

L2

(HOT)

RISE

C1

C1 ANTICIPATOR

STAGE 1

COOL RELAY

M582

Fig. 28. Internal cooling anticipation schematic.

Interstage Differential

The mercury switch of each stage of heat makes at a slightly

different temperature; that is, the mercury makes the contacts

of the first stage bulb at one temperature, and the second

stage bulb at another temperature. The difference between

these two temperatures is the interstage differential.

H1 ANTICIPATOR

H1

FALL

STAGE 1 HEAT RELAY

M582

Fig. 26. Adjustable anticipation heater in series with load.

Fixed anticipation is also called voltage anticipation. See

Fig. 27. The heater is in parallel with the primary control and is

not affected by the current draw of the primary. It establishes

the proper cycle rate for any application.

L1

L2

(HOT)

STAGE 1

FALL

H1

HEAT RELAY

H1 ANTICIPATOR

M582

Fig. 27. Fixed anticipation heater in parallel with load.

Interstage differential is the difference between the two make

points when the bulbs are controlled by the heating of the

bimetal and the action of the heat anticipator. The interstage

differential is 1.9°F (1°C) between the stages of heating or the

stages of cooling for most models.

Mechanical differential is the difference between the make

and break points of each switch. The mechanical differential

for the T874 is 1°F (0.6°C) between the stages of heating or

between the stages of cooling for most models.

Droop

The addition of anticipator heat to the bimetal causes a control

factor called droop.

As the weather grows colder, the heating appliance must

operate longer and more frequently. More heat must be added

to the bimetal. The bimetal now thinks it is warmer than it

really is, and actual room temperature is controlled at a lower

temperature than the setpoint indicates. At 100 percent heat

load, this droop can be significant.

The C815A Outdoor Reset Thermistor is used in heat pump

systems to minimize droop. Without some method of

countering this situation, the occupant could notice the

temperature offset.

Outdoor Reset

Some T874/Q674 models are intended for use with the

C815A Outdoor Thermistor. The outdoor thermistor provides

significantly improved thermostat performance when

compared to conventional multistage thermostats. The C815A

is usually located in the heat pump condensing unit outdoors.

21 60-2485—8

Page 22

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

0

0

CAUTION

Equipment Damage Hazard.

Due to calibration techniques used for T874

Thermostats with outdoor reset, the C815A Thermistor

must be wired into the system at all times. Failure to

do so will result in serious degradation of performance.

Service and Replacement of C815A Outdoor Thermistor

To check and verify thermistor operation, perform the

following steps:

1. Disconnect wire from T terminal on subbase.

2. Measure resistance with ohmmeter across the T sub-

base wire and X subbase terminal.

3. Take outdoor temperature measurement at thermistor

location and find correct thermistor resistance on the

chart in Fig. 29.

4. Compare resistance on the chart with measured resistance. Replace C815A if resistance varies more than 15

percent. Contact installing dealer for packaged replacement outdoor thermistor.

4600

4400

4200

4000

3800

3600

3400

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

THERMISTOR RESISTANCE (ohms)

1200

1000

800

600

400

200

0

-20 0 20 40 60 80 100 120 14

C815A THERMISTOR RESISTANCE

R = 400 ohms ± 10% AT 77°F (25°C)

TEMPERATURE OF THERMISTOR (°F)

M1590A

A strip of four inserts is included with TRADELINE T874. Drop

a strip into the recessed area behind the scaleplate so

selected LEDs show. Make sure insert is completely seated in

recessed area. Let scaleplate pop back; then set levers to

desired position.

• FILTER LED lights when the filter is clogged and needs

replacement.

• CHECK LED lights when something needs to be checked

or done to maintain efficient operation of system. See

heating system instructions for CHECK LED meaning.

• EM. HT. LED lights when the emergency heat is operating.

• SUPL. HT. LED lights when the supplemental heat is

operating.

• LOCKOUT LED lights when the system is shut down and

needs maintenance.

• AUXILIARY HEAT LED lights when the auxiliary heat is

operating.

• SERVICE or MALFUNCTION LED can have several

meanings. Consult heating system instructions.

LEDs cannot be replaced or added in the field.

LEDS

80

EM.

HEAT

FILTER SERV.

AUX

HEAT

50 60 70 80

COOL

M583

Fig. 30. T874/Q674 LED location.

Restricted Setpoint (DoD)

The Department of Defense (DoD) models are equipped with

a restricted setpoint feature for fuel efficiency.

Fixed stops are factory-set so setpoint levers cannot be set

above 72°F (22°C) on heating, or below 78°F (26°C) on cooling.

Fig. 29. Thermistor resistance chart.

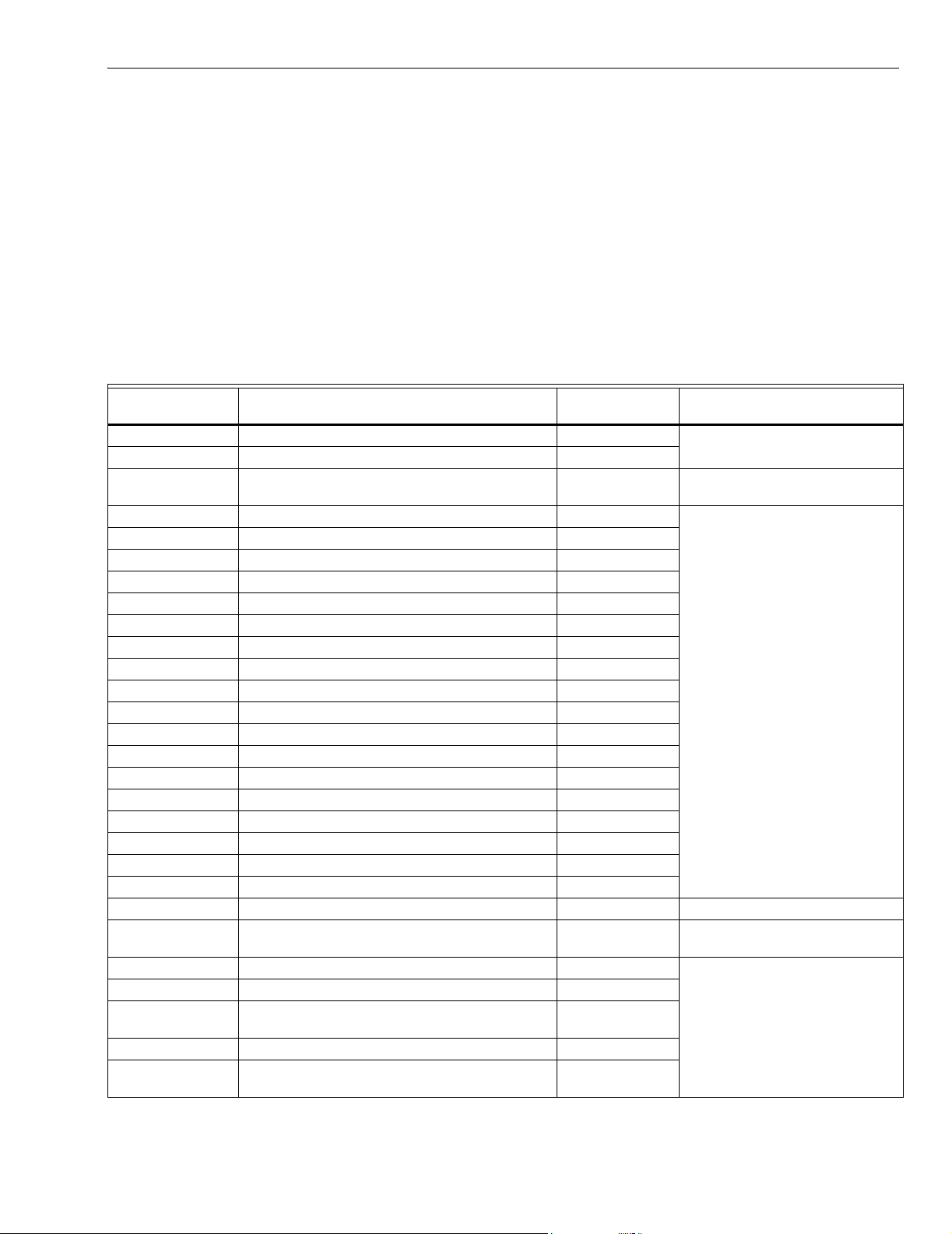

Features

Two of the features of the T874/Q674 include LED indicators

and restricted setpoint.

LED Indicators

The light-emitting diodes (LED) indicators on the subbase

light on command when something specific happens in the

system. See Fig. 30.

Up to four different LEDs are available. The thermostat has a

clear lens window for viewing each LED. On TRADELINE

models, a small insert is used so the LED function desired can

be selected. This must be done during installation.

A blank insert is factory-installed in some T874 models. To

remove it, push both temperature setting levers to the far ends

of the thermostat. Use index fingernail to gently pull out the

scaleplate a fraction of an inch. Turn thermostat upside-down,

and the blank insert falls out.

60-2485—8 22

Applications

The T874/Q674 can be applied to standard residential

systems for automatic or manual changeover, to commercial

rooftop applications, or to heat pump applications.

Changeover on Standard Residential Systems

In a standard residential heating-cooling circuit, changeover

between heating and cooling can be done either automatically

or manually.

Automatic changeover is done by an AUTO position on the

subbase system switch. See Fig. 31. When the switch is in the

AUTO position, the thermostat automatically changes between

heat and cool modes, depending on the indoor temperature.

Page 23

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

8

M5829

E

When enthalpy is low enough, the thermostat and a sensor tell

the economizer damper to open to let in cool air from the

outside. When enthalpy is high, the thermostat and sensor tell

the damper to close. No more outside air comes in, so the air

conditioner is used instead.

OFF EM. HT. HEAT

AUTO COOL

M582

Fig. 31. System switching for automatic changeover.

Automatic changeover is frequently used in areas where there

are large temperature differences in 24 hours. Some uses for

the automatic changeover feature are in the southern states

(cool in the morning and hot in the afternoon) and in

commercial applications.

Manual changeover requires a system switch movement to

change the mode. See Fig. 32. Most manual changeover

switches consist of HEAT-OFF-COOL choices. For heating,

switch to HEAT. For cooling, switch to COOL. It is not automatic.

Manual changeover is often used in areas where the

temperature is relatively stable between day and night.

OFF EM. HT. HEAT

COOL

Fig. 32. System switching for manual changeover.

Commercial Rooftop Application

The T874 can be used as part of a commercial rooftop

application to run mechanical cooling.

An economizer is often used as part of a rooftop application to

save on air conditioning. See Fig. 33.

Heat Pump Application

A heat pump system operates much like an air conditioner.

However, the heat pump is capable of moving heat in two

directions; from inside the home to outdoors for cooling, or

from outdoors to inside for heating.

The heat pump can be controlled by separate relay/contactor

components, which are energized or de-energized by the T874.

Changeover between heating and cooling for heat pump

circuits can be accomplished either manually or automatically.

Manual changeover control requires a system switch

movement to change the mode. The reversing valve is

activated by moving the system switch to COOL for cooling or

to HEAT for heating operation.

Automatic changeover is accomplished by one of the mercury

bulb switches in the thermostat. On a system with automatic

changeover on cooling, the changeover valve is energized by

a mercury switch that makes on a temperature rise. On

heating, the changeover valve is energized by a mercury

switch that makes on a temperature fall.

A description of the methods used to control heat pumps

follows.

Space Temperature Sensing Low Voltage Controls

Control systems for heat pumps usually utilize low voltage

control circuits. The variety of control functions required and

the relative complexity require a versatile and economical

method of control. There are several interlocks and indication

functions that would be more difficult and expensive to wire in

line voltage circuits. Low voltage controls have the precision

and flexibility needed.

OUTDOOR

AIR

H205 OR H705

ENTHALPY

CONTROL

RETURN

AIR

DISCHARGE AIR SENSOR

DOWNSTREAM FROM TH

EVAPORATOR COIL

M5827A

Fig. 33. Typical commercial rooftop economizer

application.

Enthalpy is the temperature and humidity of the air. A more

accurate analysis of the suitability for free cooling can be

made by monitoring the enthalpy.

The thermostat used is a low voltage device that has good

temperature sensitivity and several manual and automatic

switching capabilities.

Two-Stage Thermostat

In most installations, the heat pump itself requires auxiliary

heat, usually in the form of electric strip heaters, to carry the

building heating load at design conditions. Since the heat

pump is usually more efficient, the control strategy is to run

the heat pump whenever possible and the auxiliary heat only

when necessary—during very cold weather or if the heat

pump fails. Usually the auxiliary heat is used only below the

balance point (temperature at which the heat pump cannot

handle heating load by itself).

A two-stage thermostat makes this possible. The two stages

make sequentially as the temperature drops. There is a

degree or two between stages so that the second stage (the

23 60-2485—8

Page 24

T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

R

6

one controlling the auxiliary heat) makes only when the heat

pump alone cannot handle the load. That is how the strategy

of using the most economical heat first is implemented.

Cycling Rate

Normally, thermostat anticipation is set to cycle a fossil fuel

furnace about five or six times an hour (at 50 percent load).

This provides a reasonable balance between comfort, stability

and economy.

A heat pump, being a mechanical refrigeration system, should

be cycled at a rate of 2-1/2 to 3 times an hour. With a T874,

this is accomplished by setting the anticipator at the total

current draw of the controlled device (the contactor and

possibly the changeover relay or valve). Most likely, the

compressor operates from the first stage of the thermostat.

The second stage normally controls the auxiliary heaters. This

heat anticipator can be set for the current draw of the electric

heat primary, and produces good control.

Voltage Anticipation

Although not a specific requirement for heat pumps, several

models of the T874 have voltage heat anticipation instead of

current anticipation.

With voltage anticipation, the amount of heat added to the

thermostat is constant no matter which load is connected to it.

The anticipator realizes a constant voltage and produces a

constant amount of heat during the ON cycle. This allows the

cycling rate to be designed into the thermostat. The heat

pump manufacturer is assured of correct performance

independent of later thermostat adjustments.

This is particularly important on the 3-stage T874. The

additional stage means that more droop is introduced when

the system is in operation. That is the reason the TRADELINE

T874W is sold in a package with the outdoor sensor and the

correct subbase.

Outdoor Reset—How it Works

The heater in the thermostat is connected in series with a

thermistor sensor that measures outdoor temperature. See

Fig. 34. In warm weather, the thermistor has very low

resistance, permitting a large current flow in the heater, which

generates a relatively large amount of heat in the thermostat.

In cold weather, the outdoor sensor has high resistance,

which results in low current flow and little or no heat being

added to the thermostat. This raises the control point,