Honeywell Sensepoint HT Quick Start Manual

Sensepoint HT

Combustible Gas Sensor

Quick Start Guide

SENSEPOINT HT

COMBUSTIBLE GAS SENSOR

MAN0622 Issu e 01 January 03

2106M052 3

The Sensepoint High Temperature(HT) Combustible GasSensor is a sealed

disposable sensorfor the detection of flammable gases. Itmust be fitted intoa

suitablyapprovedExeor Exdhightemperaturejunctionbox(e.g.Feel Flameproof

Enclosures)fitted withan approvedcable glandfor externalwiring(e.g. Peppers

CableGlands, SeriesA3LF or CR3CROLOCK Series).

The sensor features a Filter Housing thatretains a stainless steel meshfilter. It

employs a catalytic pellistor sensor device which is used as part of a bridge

measuring circuit.

Sensepoint HT is certified for hazardous areas to EN50014/EN50018 and is

protected againstwater and dust ingress to IP66/67. Thesensor is availablein

M20,M25 and3/4 NPTthreadversions.The sensoracceptsaccessoriesfrom a

specifiedrange (see Accessories &Spare Parts).

Information notices

The typ es of info rmation not ices used thro ughout this ha ndbook are as

follows:

WARNINGS

Indicate s hazardous or u nsafe practi ce that coul d result in s evere

injury o r death to pe rsonnel.

Caution: Indicate s haz ardous or unsafe pra ctice which could

result in m inor injury to pers onnel, or pr oduct or

property damage .

Note Provides usefu l/helpfu l/additio nal i nformatio n.

If more informatio n o utside the s cope o f t his te chnical handbook is

required ple ase contact H oneywell Ana lytics.

Associated Documents

Sensepoint GasSensors Technical Handbook Part No:2106M0502

1. INTRODUCTION

1 2

11 12 13 14

8. SPECIFICATIONS 9. ACCESSORIES & SPARE PARTS7. CERTIFICATION

noitallatsnInimargaideeS:snoisnemiD

section.

Operating temperature range: -40 °C to +150°C.

Operating humidity range: 20% to 90% RH contin uous.

10% to 99% RH inter mittent - non

condensing.

Operating pressure ra nge: 75 to 110 k Pa.

.setunim01nahtsseL:emitpumraW

.)Am002ta(egdirbV5.3otV9.2:egnaregatloV

Power consumption: 700mW.

.egdirbVm:tuptuolangiS

Calibration flow rate : Recommended betwee n 1 and

1.5 l/min.

yamstnemelegnisnesehT:gninosioP

become inactive aft er extensive

exposure to silicon es,

halogenated hydrocar bons,

heavy metals or sulph ur

compounds.

Expected operating life: 5 years.

htiw76/66PI;dradnats56PI:gnitarPI

Weather Protection.

htiwseilpmocrosnesehT:EC

relevant CE directive s.

ATEX Certification:

II 2G EEx d II C T3

Tamb -40oC to +150oC

Baseefa02ATEX0242 X

rebmuNtraPnoitpircseD

Complete replacemen t sensor:

0132B6012noisrev02M•

1132B6012noisrev52M•

2132B6012noisrevTPN4/3•

8100-F-08700retlifleetssselniatS

8300-C-08700gnisuoHretliF

High Temperature Ju nction Box 2052D0001

High Temperature We ather Protection 00780-A-0076

Quick Start Guide

MEMBERS OF THE ZELLWEGER ANALYTICS DIVISION

UK AND INTERNATIONAL

ENQUIRIES

ZellwegerAnalytics Ltd

Hatch Pond House

4 Stinsford Road

Nuffield Estate

Poole

Dorset

BH17 0RZ, UK

Tel: +44 (0)1202 676161

Fax: +44(0)1202 678011

Email: sales@zelana.co.uk

ASIAPAC IFIC

ZellwegerAnalytics Ltd

Asia Pacific Regional Office

1 Scotts Road

#25-04 Shaw Centre

Singapore 228208

Tel: +65 6862 7701

Fax: +65 6862 3858

Email:zalasia@singnet.com.sg

BELGIUM

ZellwegerAnalytics NV

Leuvensesteenweg 392a

Chee de Louvain

B-1932 Zaventem

Belgium

Tel: +32 27140311

Fax: +32 27140344

Email: zabl@zelana.com

FRANCE

Zellweger AnalyticsFrance SA

Les Fermes Californiennes

62 avenue de l’Europe

Emerainville

77436 MARNE LA VALLEE

CEDEX 2

France

Tel: 33(1) 60 95 45 46

Fax: 33 (1) 60 95 45 50

GERMANY

ZellwegerAnalytics GmbH

Sollner Strasse 65b

D-81479 Munchen

Germany

Tel: +49 89 791 920

Fax: +49 89 791 9243

Email:

vertriebscenter@zelana.de

ITALY

Zellweger Analyticssrl

Via F.Primaticcio 168

1-20147 Milano

Italy

Tel: +39 0248 3391

Fax: +39 0248 3023 14

Email: zaitaly@zelana.com

MIDDLE EAST

Zellweger Analytics Limited

PO Box 52196

Dubai UAE

Tel: +971 4 3458 338

Fax: +971 4 3458 778

Email:zelana@emirates.net.ae

NETHERLANDS

ZellwegerAnalytics BV

Postbus 157

NL-3740

AD Baarn

Tel: +31 (0)355435646

Fax: +31 (0)355435929

Email: zabl@zelana.com

SPAIN

ZellwegerAnalytics SA

Avda Remolar 31

08820 El Prat de Llobregat

Barcelona

Spain

Tel: +34 93 379 9611

Fax: +3493 379 8551

Email: zellana@jet.es

USA

ZellwegerAnalytics, Inc.

5089BristolIndustrialWay

SuiteB & C

Buford, Georgia 30518

USA

Tel: +1 770 831 4800

TollFree: +1 800 535 0606

Fax: +1678 546 1954

Email: sales@zelana.com

A company o f the Zellw eger Luwa Group

total environmental solutions

This publication is not inte nded to form the basis of a contract, and the compa nyr eserves the right

to amend the design and specification of the instr uments without n otice.

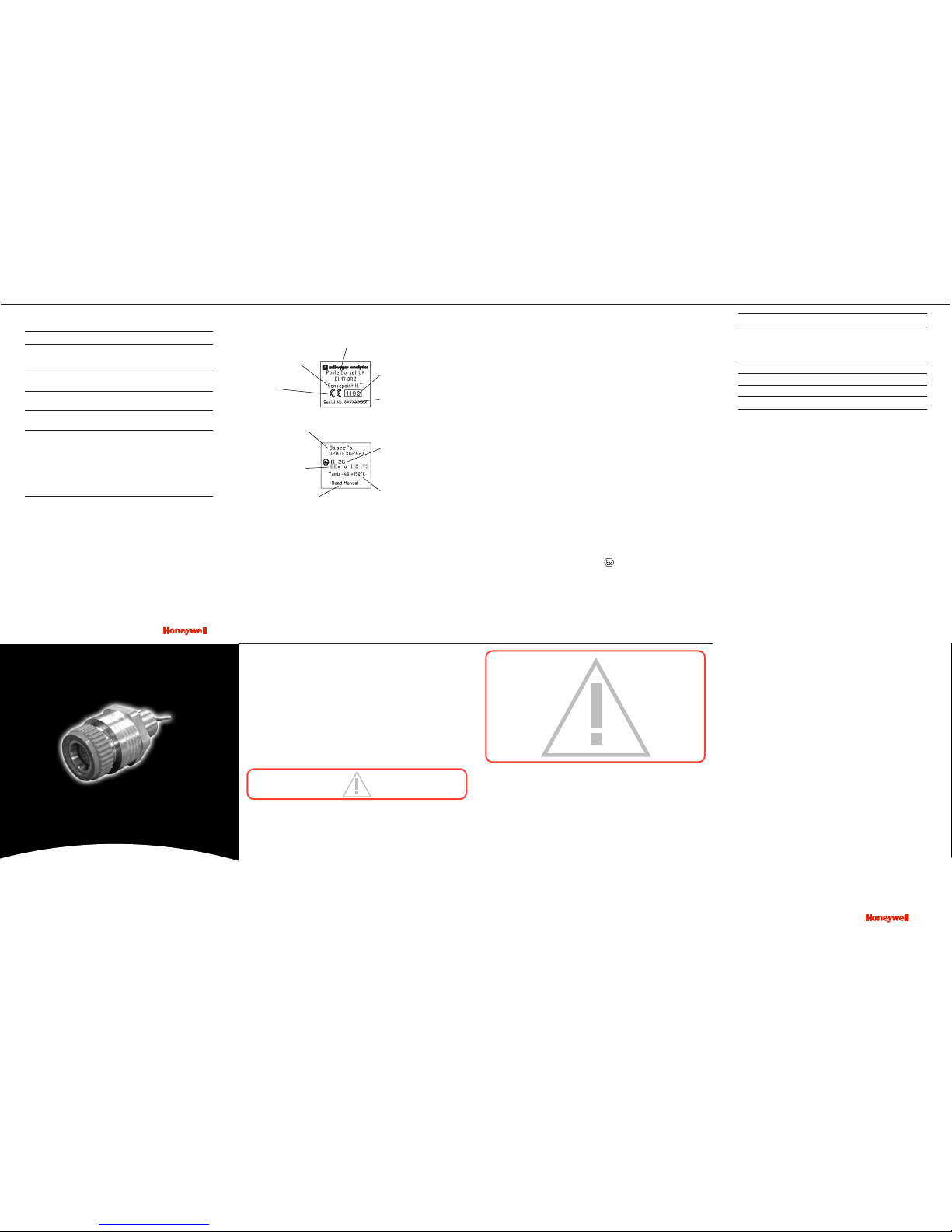

The followi ng BASEEFA certifica tion information is im printed on adjacent

faces in two separate blocks on t he hexagonal part of the sensor body.

CE mark

- conforms to all

applicable European

directives

Manufacturer’s

trademark & address

Identification number

of ATEX notified body

Product name

Year of manufacture/

serial number

Certification number

Explosion protection

mark and equipment

group & category

Certified ambient

temperature range

Certification

code

Caution

6. FAULT FINDING

2. SAFETY

WARNINGS

1. This unit is int ended f or use at a n ormal, or red uced, l evels o f

atmosphe ric oxygen and press ure only, i .e. less th an 21% oxyg en

and less th an 1 .1 b ar. Oxyg en d eficient a tmospheres (less than

10%V/V) may suppr ess the sens or output.

2. Refer to local or n ational reg ulations rel ative t o insta llation at t he

site. Fo r Europe see EN50 073 and EN60 079-14.

3. Operators shou ld be fully awa re of the a ction to be tak en if the gas

concentr ation exceed s the alarm l evel.

4. Installati on should consider not on ly the best placing for gas lea kage

related to p otential l eak points , gas ch aracteristic s and ve ntilation,

but als o where the pot ential of me chanical dam age is mini mized or

avoided .

5. Only asses sed for ATEX for igni tion hazards .

CAUTIONS

1. Atmospheres above 100% LEL may suppress the sensor reading.

2. Do not modify or alter the sensor construction as essential safety

requirements may be invalidated.

3. Install using suitably approved and certified Exe or Exd high temperature

junction box, connectors and glands.

4. Dispose of in accordance with local disposal regulations.

Ma terials used - S tainless Ste el.

The follow ing table provide s a list of possible fa ults related to the s ensor

together wit h possible ca uses and rem edies.

ydemeR/esuaCtluaF

Sensor reads non zero Gas could be present, ensure

all the time there is no combust ible gas in the

atmosphere.

Sensor reads non zero Adjust the control syste m zero

when no gas is pres ent se tting.

Sensor reads low w hen Adjust the con trol system span

gas is applied setting.

Sensor reads high whe n Adjust the control sy stem span

gas is applied setting.

Sensor reads zero w hen 1. C heck the wiring.

gas is applied 2. Check that the pro tective disc

has been removed fr om the

filter housing.

3. Check that the filter is not

dirty/obstructed.

4. Replace the sensor if

poisoning is susp ected.

Issue 1 12/2005

H_MAN0622Z_ 2106M0523_EMEA

07-07

© 2007 Honeywell Analytics

11187

Find out more

Contact Honeywell Analytics:

www.honeywellanalytics.com

Europe, Middle East, Africa

Life Safety Distribution AG

Wilstrasse 11-U11

CH-8610 Uster

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell.com

Americas

Honeywell Analytics Distribution, Inc.

400 Sawgrass Corporate Pkwy

Suite 230

Sunrise, FL 33325

USA

Tel: +1 954 514 2700

Toll free: +1 800 538 0363

Fax: +1 954 514 2784

detectgas@honeywell.com

www.honeywell.com

Technical Services

ha.global.service@honeywell.com

Asia Pacific

Honeywell Analytics Asia Pacific

#508, Kolon Science Valley (1)

187-10 Guro-Dong, Guro-Gu

Seoul, 152-050

Korea

Tel: +82 (0)2 2025 0307

Fax: +82 (0)2 2025 0329

analytics.ap@honeywell.com

Please Note:

While every effort has been made to ensure

accuracy in this publication, no responsibility can

be accepted for errors or omissions. Data may

change, as well as legislation, and you are strongly

advised to obtain copies of the most recently

issued regulations, standards, and guidelines.

This publication is not intended to form the basis

of a contract.

3

5. MAINTENANCE

4 5

CALIBRATION

Table 2 Meter Set tings

* Calibration * Rating of Gas to be Detecte d

Gas

8* 7* 6 * 5* 4* 3* 2* 1*

8* 50 62 76 95 - - - -

7* 40 50 61 76 96 - - -

6* 33 41 50 62 78 98 - -

5* 26 33 40 50 63 79 100 -

4* 21 26 32 40 50 63 80 -

3* - 21 26 32 40 50 64 81

2* - - - 25 31 39 50 64

1* - - - - 25 31 39 50

Note: These settings must only be used with a calibration gas

concentration of 50% LEL. All data at standard temperature and

pressure.

Example

1. Th e target gas to b e detected is B utane.

The calibration gas available is Methane (50% LEL).

2. Look up the star rat ing for each gas from Table 1:

Butane = 4* Methane = 6*

3. Check the meter settings for 50% LEL calibration gas from Table 2.

The reading is 78%.

4. The control card shou ld therefore be set to 78%.

This gives an accurate reading for Butane, using 50% LEL Methan e

as a cal ibration gas .

Table 3 Meter Mul tiplication F actors

Unit calibrated Unit used to detect

to detect

8* 7* 6* 5* 4* 3* 2* 1*

8* 1.00 1.24 1 .52 1.8 9 2.37 2.98 3.78 4.83

7* 0.81 1.00 1 .23 1.5 3 1.92 2.40 3.05 3.90

6* 0.66 0.81 1 .00 1.2 4 1.56 1.96 2.49 3.17

5* 0.53 0.66 0 .80 1.0 0 1.25 1.58 2.00 2.55

4* 0.42 0.52 0 .64 0.8 0 1.00 1.26 1.60 2.03

3* 0.34 0.42 0 .51 0.6 4 0.80 1.00 1.27 1.62

2* 0.26 0.33 0 .40 0.5 0 0.63 0.79 1.00 1.28

1* 0.21 0.26 0 .32 0.3 9 0.49 0.62 0.78 1.00

CALIBRATION

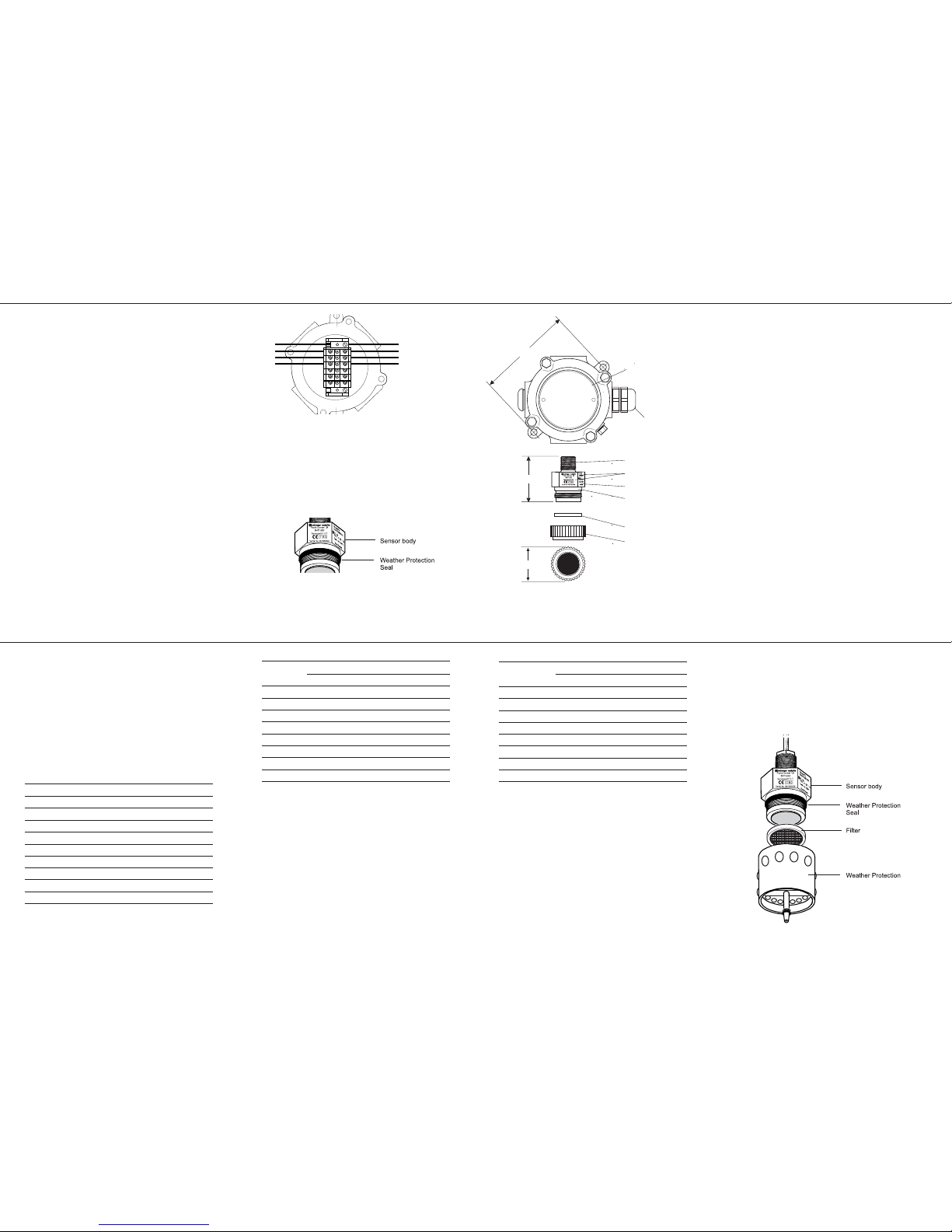

The Sensepoi nt HT Comb ustible Gas Sensor must be fitted into a

suitably ap proved Exe or Ex d high tem perature ju nction box fitt ed with

an approved cable gland for ex ternal w iring. T he s ensor r equires a

200mA curr ent supply, nomi nal 3V, derived fr om a suitable contr ol card.

Only a q ualified inst allation eng ineer should inst all the sens or.

Install the s ensor in a loc ation free fr om direct heat sou rces and fit it so

that it e ither poi nts down wards or horizontally . It is n ot recomm ended

that the senso r po ints upwards. See the Sen sepoint Gas Sensor s

Technica l Handbook f or installat ion in force d air condit ions.

1. Isola teall associated power supplies and ensure that they remain

OFF during the installation procedure. Ensure a gas free

atmospher e.

2. In stall the high temp erature junc tion box.

See the manufacturer’s instructions.

3. Re move the junct ion box lid.

4. Fi t the Sensepoi nt HT sensor t o the junctio n box.

Ensure that the junction box thread and the sensor thread are

compatible. Push the sensor wires through the cable entry in the

junction box and screw the sensor body firmly home into the entry.

Lock the sensor in place with a suitable lock-nut.

5. Co nnect the sens or wiring to the j unction box te rminal strip .

See the subsequent wiring diagram. Use multicore cable, three wire

minimum, of conductor size 2.5mm

2

max.

6. Fi t a suitable gla nd to the box, s ecure the cont rol system cabl e

and conn ect the field w iring to the term inal strip.

See the subs equent wirin g diagram.

7. Re fit the junctio n box lid.

8. Un screw th e filter h ousing f rom the sensor body and rem ove

the filte r from the filt er housing.

Discard the filter housing with protective disc. The filter housing

material cannot withstand high temperatures.

3. INSTALLATION

Sensors sho uld be ca librated at co ncentrations rep resentative of tho se

to be measured . It is al ways recommende d tha t Se nsepoint HT is

calibrat ed with t he target gas i t is to dete ct. If th is is no t possible, th en

cross ca libration can be used .

For ca libration in fast fl ow conditi ons see t he Sensepo int Gas S ensors

Technica l Handbook.

Prior to calibra tion, allow the sensor to warm up for approxim ately

10 minut es. Re-calibra tion should only be at tempted by qualifi ed service

personn el.

1. Ze ro the contro l system with no g as present on the s ensor.

If combustible gas is suspected to be in the vicinity of Sensepoint HT

flow clean air over the sensor using a flow housing (see below).

2. Fi ta flo wh ousing and connect a cyli nder of either air, for a zero,

or a known concentrat ion of gas in a ir, at approxi mately th e

alarm po int (e.g. 50% LEL) , to the flow ho using.

3. P ass the gas throu gh the flow h ousing a t a flow rat e of

approxim ately 1 litre to 1. 5 litre/min.

4. Al low the sensor to st abilise.

5. Wh en gassing wi th air, adjus t the control card to in dicate zero.

6. Fo r span, the c ontrol card should be adjusted to ind icate t he

concentr ation of the t arget gas bei ng applied.

Remove the flow housing and the gas supply.

Cross Cal ibration Pro cedure

When cali brating the Sen sepoint HT sens or with a gas whic h is different

to the gas/vapour to be detected, the following cross calib ration procedure

should b e followed.

Table 1 lists gases accordin gto the rea ction they produce at the detector.

An eigh t star (8*) ga s produces the high est output whil e a one st ar (1*)

gas produces the lo west o utput. (These are not applic able at p pm

levels.)

4. CALIBRATION

7 8 9 10

6

INSTALLATION

CALIBRATION

To calibrat eth eS ensepoint HT sensor car ry out the following proce dure:

1. Ob tain the star r ating f or both the tes t gas an d the g as to be

detected from Tabl e 1 .

2. Us e the v alues in Table 2 to ob tain the r equired m eter sett ing

when a 5 0% LEL test ga s is applied t o the detecto r.

If a sensor is to be used to detect a gas other than that for which it

was calibrated, the required correction factor may be obtained from

Table 3 . The meter reading should be multiplied by this number in

order to obtain the true gas concentration.

Important Notes:

1. Since combustible sensors require oxygen for correct operation,

a mixture of gas in air should be used for calibration purposes.

2. Assuming an average sensor performance, the sensitivity

information in Tables 1 to 3 is normally accurate to ± 20%.

Table 1 Star Rating o f Gases

Gas StarRat ing Gas Star Rati ng

Acetone 4* Hexane 3*

Ammonia 7* Hydrog en 6*

Benzene 3* Methane 6*

Butane 4* Octane 3*

Diethyl ether 4* Propan-2-ol 4*

Ethane 6* Propane 5*

Ethanol 5* Styre ne 2*

Ethyl acetate 3* Tetra hydrafuran 4*

Ethylene 5* Xylene 2*

Sensitive (S)

Non-Sensitive (NS)

Common

Earth

Brown

Blue

White

Green

dleifmetsyslortnoCgniriwrosneS

wiring

Note: Inaddition to the sensor's integral earth conductor, earth

equipotential bonding may be maintained via the sensor rear

mounting thread if required.

9. If the sens or is install ed:

• ind oors - discar d the filter.

• out doors - fi t the previously removed filter (if required) to

the Hig h Tem pera ture We ather Pr otec tion acc esso ry

(Part No : 00780-A-007 6) and fit the a ccessory to th e sensor.

Fit the seal supplied with the Weather Protection accessory to

the sensor body. Screw the accessory firmly onto the sensor until

it seats against the sensor body hexagon.

10. Pow er-up the syst em and check for c orrect operat ion.

INSTALLATION

High Temperature

Junction Box

Exe/Exd gland

Threads available:

M20, M25, 3/4 NPT

38mm across flats

Sensepoint

Combustible

Gas Sensor 0-100%LEL

Filter

Filter Housing

High

Temperature

Certification data (on

adjacent faces)

58mm

42mm

125mm

Only a qu alified insta llation engin eer should se rvice the sen sor. Ensure

power is off befo re carrying o ut any mainte nance proced ures.

The only maintena nce required is sensor replacem ent and filter changing

(if fi tted to an a ccessory). To re place the c omplete s ensor refe r to th e

Sensepoi nt Gas Sen sors T echnical Handbook . To replac e the filte r

carry ou t the followi ng procedure:

1. Re move the High T emperature We ather Protecti on accessory.

2. Re move the old fi lter and repla ce with a fre sh filter.

3. Re place the Weat her Protectio n accessory.

Ensure the Weather Protection seal is in place. Screw the accessory

firmly onto the sensor until it seats against the sensor body hexagon.

Loading...

Loading...