Page 1

Gas Detection

SEARCHZONE SONIK

Technical Manual

Page 2

1 Preface

1.1Introduction

Searchzone Sonik™ is a hazardous area certified advanced ultrasonic gas leak detector for detecting pressurized gas leaks. It provides

local visual status indication as well as 420 mA with HART® and Modbus® outputs as standard. It has a Bluetooth® interface for

configuration and maintenance using the Searchzone Sonik App on a suitable Bluetooth enabled smartphone or other suitable Android

device (mobile device).

The Searchzone Sonik detector is ATEX and IECEx approved for use in either Zone 1 (gas) or Zone 21 (dust) hazardous areas as well as

being cULus approved for use in Class I Division 1 or Class II Division 1 locations. See Certification and Approvals section of this manual

for a list of certificates.

The Searchzone Sonik detector is available in painted Stainless Steel. It has two cable entries for easy wiring with either M25 or

3/4” NPT cable entries, dependent on the version.

1.2Disclaimer

The Searchzone Sonik detector is designed to detect an airborne acoustic ultrasonic signature produced by escaping high pressure gas.

The detector is not designed to identify the presence of any particular type of gas. It will detect the dangerous release of high pressure

gas, whether toxic or flammable for the purpose of protecting people, plant and the environment. Honeywell shall not be liable to pay

for any gas leak investigation or service call carried out or arranged in response to an alarm. Honeywell Analytics Limited can take no

responsibility for installation and/or use of its equipment if this is not done in accordance with the appropriate issue and/or amendment

of the manual. Please note that product designs may change from time to time and the images in this manual should only be used as a

guide.

21 Preface

1.3Scope

This user manual describes how to install the Searchzone Sonik detector and how to commission and operate it in order to ensure

optimal performance.

1.4How to Use This Manual

The manual is structured to cover the instrument, installation (mechanical and electrical), set-up and commissioning, operating and

maintenance. This manual is available in PDF format .

1.5Copyright & Trademarks

This document is the copyright of Honeywell.

Searchzone Sonik is a Honeywell trademark.

1.6Patents

The Searchzone Sonik advanced ultrasonic gas leak detector uses patented sensing technology. Focus Mode, an operating mode of

Searchzone Sonik is patent pending.

1.7Revision History

Revision Comment Date

Issue 1 A05126 November 2018

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 3

Table of Contents

1 Preface 2

1.1Introduction 2

1.2Disclaimer 2

1.3Scope 2

1.4How to Use This Manual 2

1.5Copyright & Trademarks 2

1.6Patents 2

1.7Revision History 2

2 Safety and Information 8

2.1Warnings and Cautions 8

2.2Important Information 9

2.3Organisational Measures for Functional Safety 9

31 Preface

3 Overview and Introduction 10

3.1Description of Product 10

3.2Description of Function 10

3.3Applications 10

3.4Sensor Technology Description 10

3.5Environmental Factors 10

3.5.1 Introduction to Background Noise and Interference 10

3.6Range and Field of Coverage 11

3.6.1 Standard Mode 11

3.6.2 Focus Mode 12

3.7Description of Gas Leak Detection Using Ultrasound 12

3.8Mounting Accessories and Flexibility 12

3.9Commissioning and Maintenance Tools 13

3.10Available Accessories 14

4 Siting Considerations 15

4.1Safety Case Framework 15

4.2Siting the Detector 15

4.2.1 Mounting Position 16

4.2.2 Mounting Angle 16

4.3Accidental Impact 16

4.4Change in Site Infrastructure 16

4.5Transient Background Noise 16

4.6Location Survey 16

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 4

4.7Bluetooth Considerations 17

5 Mechanical Installation 18

5.1Visual Check after Transportation 18

5.2Description 18

5.3Main Parts 19

5.4Mounting Searchzone Sonik 20

5.5Pole Mount Installation 22

5.6Wall Mount Installation 24

5.7Assemble Cable Glands 25

5.8Connect Cable Glands to the Searchzone Sonik 25

5.9Detector Attachment 26

5.9.1 Detector removal 26

5.10Connect Wires to PCB Terminals 28

5.11Sunshade Installation 30

41 Preface

6 Electrical Installation 31

6.1Power Supply Requirements 31

6.1.1 Internal Battery Cell 31

6.2420 mA Current Loop 31

6.3Relays 32

6.4Connections / Wiring Diagram 32

6.4.1 Terminal Wiring Description 33

6.4.2 Searchzone Sonik Connection for mA loop Configuration as Current Source 34

6.4.3 Searchzone Sonik Connection for mA Loop Configuration as Current Sink 35

6.4.4 Searchzone Sonik Connection for mA Loop Configuration as Isolated Output 35

6.5Cabling Recommendations 35

6.6Earthing Recommendations 36

6.7Modbus 36

7 Commissioning and Configuration 37

7.1First Time Switch On 37

7.1.1 Pre-power Check 37

7.2Operating Function Verification 37

7.3Communication 37

7.3.1 Bluetooth® 37

7.4Settings and Configuration 37

7.5Delay Time 38

7.6Background Noise Rejection 38

7.7Performance Verification 38

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 5

8 Operation 39

8.1Operation 39

8.2Status Signalling 39

8.2.1 Visual Status Indicator 39

8.2.2 mA Loop Status 40

8.2.3 Relay Signalling 40

8.3Normal Operation 40

8.4Operation During Fault 40

8.5Operation During Alarm 41

8.5.1 Pre-alarm 41

8.5.2 Alarm 41

8.5.3 Overload 41

9 Mobile App 42

9.1General User Access 42

51 Preface

9.2Terminology 42

9.3Communications 43

9.3.1 Company Account Management 43

9.3.2 Creating a New Company Account 43

9.4Connecting to Detectors 47

9.4.1 How to Connect to a Searchzone Sonik Detector 47

9.4.2 Making an Ad Hoc Connection to the Detector 49

9.5Detector Overview 50

9.5.1 Detector Status 50

9.5.2 Detector Inhibit 51

9.6Detector Alarm History 52

9.7Detector Maintenance 53

9.7.1 Event Log 53

9.7.2 Set Maintenance Flag 54

9.7.3 Output Test 55

9.7.4 Diagnostics 56

9.8Detector Settings 58

9.8.1 Firmware Version 59

9.8.2 Background Levels 60

9.8.3 Editing Detector Settings 61

9.9How to Change Application Settings 64

9.9.1 Detector Registrations 64

9.10User Management 65

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 6

10 Communications 67

10.1HART® 67

10.1.1 Searchzone Sonik HART Interface 67

10.2Menu Structure 68

10.3Commissioning using HART Communications 72

10.3.1 User Configuration 73

10.3.2 Configure Warning, Inhibit and Over-range Signal Levels 73

10.3.3 Configure Device Identification Information 74

10.3.4 Test 4-20 mA Loop Integrity 75

10.3.5 Configure Internal Alarm Threshold 75

10.3.6 Clear Alarm Latch 75

10.4Maintenance using HART Communications 76

10.4.1 Inspection 76

10.4.2 Proof Test (Gas Leak Challenge) 77

61 Preface

10.4.3 Investigation of Faults or Warnings 77

10.5Modbus 78

10.5.1 Programming the Host 78

10.5.2 Addressing Conventions and Register Values 78

10.5.3 Modbus Cables 78

10.5.4 Modbus Electrical Connections 79

10.5.5 Modbus Termination Resistor 79

10.5.6 Modbus Multi-Drop Mode 79

10.5.7 Modbus Protocol 79

10.5.8 Modbus Registers 80

11 Maintenance 84

11.1Inspection and Cleaning 84

11.2Periodic Proof Test using a Canister of Compressed Air 84

11.3Suggested Maintenance Schedule 84

11.4Response to Fault 85

11.5Product Life Expectancy 85

12 Problem Solving 86

12.1Introduction 86

12.2Problem Solving 87

13 Certification and Approvals 89

13.1Hazardous Locations 89

13.2ATEX Certification 89

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 7

13.3IECEx Certification 89

13.4CSA Certification 90

13.5cULus Certification 90

13.6Labelling 91

13.7EU Declaration of Conformity 91

13.8RoHS 91

13.9China RoHS 92

13.10WEEE 92

13.11EMC 92

13.12RED 92

13.13REACH 92

13.14FCC 92

13.15IC 93

13.16Export Compliance Classification 93

71 Preface

13.17Wireless Approvals 93

13.18Bluetooth® 93

14 Ordering Information 94

15 Specifications 95

15.1Short Form Table 95

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 8

2 Safety and Information

2.1Warnings and Cautions

WARNING

1. Installation must be in accordance with the recognized standards of the appropriate authority in the

country concerned. For Europe see EN 6007914 and EN 60079292.

2. Installation, operation and maintenance of the unit must meet requirements on safety and operation in

hazardous areas.

3. The equipment is NOT intended to be mounted onto surfaces which may act as sources of heating or

cooling.

4. Do NOT operate the unit outside the temperature range stated in the Specification section.

5. Do NOT open the front enclosure. Doing so will invalidate the warranty.

6. Operators should be fully aware of the action to be taken in the event of an alarm.

7. Do NOT modify or alter the construction of the product as essential safety and certification

requirements may be invalidated.

8. Installation, set-up and maintenance must be conducted only by trained personnel. Refer to the

manual at all times.

9. Access to the interior of the product, when carrying out any work, must be conducted only by trained

personnel.

10. In order to maintain electrical safety, the unit must NOT be operated in atmospheres of more than

21% oxygen.

11. The plastic transport cap supplied must be replaced with suitably certified closers (such as glands or

stopping plugs) prior to commissioning. Failure to do so presents a potential source of ignition. One

certified stopping plug is supplied as standard.

12. Do NOT rely on the local visual indicator for safety related purposes.

82 Safety and Information

CAUTION

If the time in which a user logs in to the Searchzone Sonik App in the online mode exceeds 1 year,

it will be necessary to establish an Internet connection to the mobile device and log in to the App in

order to refresh the detector’s security certificate.

Items of Disposal

Enclosure Painted 316 Grade Stainless Steel

Standard Adjustable

Mounting Bracket

Sunshade Plastic / Stainless Steel (optional)

This symbol indicates that this product and/or parts of the product may not be treated as

household or municipal waste. Waste electrical products (end of life) should be recovered/

recycled where suitable specialist WEEE disposal facilities exist. For more information about

recycling of this product, contact your local authority, our agent/distributor or the manufacturer.

Stainless Steel

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 9

2.2Important Information

This manual is for use with the Honeywell Searchzone Sonik advanced ultrasonic gas leak detector only.

Honeywell Analytics can take no responsibility for installation and/or use of its equipment if not done so in accordance with the

appropriate issue and/or amendment of this Manual.

The reader of this Manual should ensure that it is appropriate in all details for the exact equipment to be installed and/or operated. If in

doubt, contact Honeywell Analytics for advice.

The following types of notices are used throughout this Manual.

WARNING

Identifies a hazardous or unsafe practice which could result in severe injury or death to personnel.

CAUTION

Identifies a hazardous or unsafe practice which could result in minor injury to personnel, or product or

property damage.

92 Safety and Information

Note

Identifies useful/additional information.

Every effort has been made to ensure the accuracy of this document, however, Honeywell Analytics can assume no responsibility for any

errors or omissions in this document or their consequences.

Honeywell Analytics would greatly appreciate being informed of any errors or omissions that may be found in the content of this

document.

For information not covered in this document, or if there is a requirement to send comments/corrections about this document, please

contact Honeywell Analytics using the contact details given on the back page.

Honeywell Analytics reserve the right to change or revise the information supplied in this document without notice and without

obligation to notify any person or organization of such revision or change. If information is required that does not appear in this

document, contact the local distributor/agent or Honeywell Analytics.

2.3Organisational Measures for Functional Safety

Refer to the Searchzone Sonik Safety Manual for more information.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 10

103 Overview and Introduction

3 Overview and Introduction

3.1Description of Product

The Searchzone Sonik is an advanced ultrasonic gas leak detector for use in hazardous areas. It detects high pressure gas leaks within

the protection area, in order to provide an early alert to a hazard. While the Searchzone Sonik does not indicate the type of gas, it will

respond to any high pressure gas leak within the coverage area and so will protect against the release of dangerous gases, whether they

be toxic or flammable.

With conventional gas detectors, the escaping gas has to reach the detection point or line between a transmitter/receiver pair. The

Searchzone Sonik ultrasonic gas leak detector recognizes sound emitted by the leak from a distance, without the released gas having to

reach the detector.

3.2Description of Function

The Searchzone Sonik detects pressurised gas leaks by sensing the airborne acoustic ultrasonic sound pressure wave and signature

produced by the escaping gas. The detection method uses a robust patented piezo-based sensor which will function in extreme weather

conditions, on and offshore. With no moving parts and no sensor cover required, the Searchzone Sonik can withstand adverse conditions

including pressure wash-down. The detector does not require field calibration, only periodic bump testing, which can be accomplished

from ground level. Interfacing for set-up, commissioning and maintenance can be achieved wirelessly using the Searchzone Sonik App,

running on a suitable Bluetooth-enabled mobile device.

3.3Applications

The Searchzone Sonik detector is ideal for detecting gas leaks from units such as metering skids, compressors, pumps, valves and

pipework flanges in complex and congested distribution, process and transmission systems.

3.4Sensor Technology Description

The Searchzone Sonik detector employs an advanced ultrasonic sensor module that is robust and reliable even in harsh environmental

and operational conditions. The sensor module has a very long life in these adverse conditions and does not require field calibration.

The sensor detects the ultrasonic sound pressure waves, which are longitudinal vibrations that propagate through the air. Upon entering

the sensor structure, the sound pressure waves create a voltage across the transducer, which is then amplified and processed using

advanced detection algorithms. The patented piezo-based ultrasonic sensor module is robust with minimal failure modes.

3.5Environmental Factors

The leak detection range is limited by the atmospheric absorption of the ultrasound. This absorption increases with frequency. The

Searchzone Sonik will detect specified gas leaks typically up to 20m in all conditions. Background noise levels also have an effect

on the detection range. Process equipment which generates ultrasonic noise will need to be considered when setting the detection

thresholds of the detector, which can cater for high, medium and low levels of background noise. The detection range of the detector will

be maximal at lower levels of background ultrasonic noise. Typical sources of background noise include rotating machinery, clanking

chains, steam whistles and other steam release mechanisms, air horns as well as intentional gas releases.

Note

Ice build-up on the face of the sensor will cause an increase in sensitivity, which may lead to an increase in nuisance alarms. When

mounting in locations where ice build-up is likely, take necessary precautions in protecting the unit against such build-up and/or setting

of alarm levels.

3.5.1Introduction to Background Noise and Interference

The frequency of the noise being produced by the source will also have a bearing on the measurement range since the attenuation

co-efficient of sound in air increases with frequency. This not only affects the sound pattern generated by a gas leak but also that

generated by other sources of ultrasonic noise and they differ. The Searchzone Sonik detection is optimized to detect gas leaks in real

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 11

113 Overview and Introduction

world conditions. The sound pressure level generated by a high pressure gas leak is dependent upon the pressure, the leak diameter, and

upon the gas density. The Searchzone Sonik detector is designed to detect hazardous high pressure leaks.

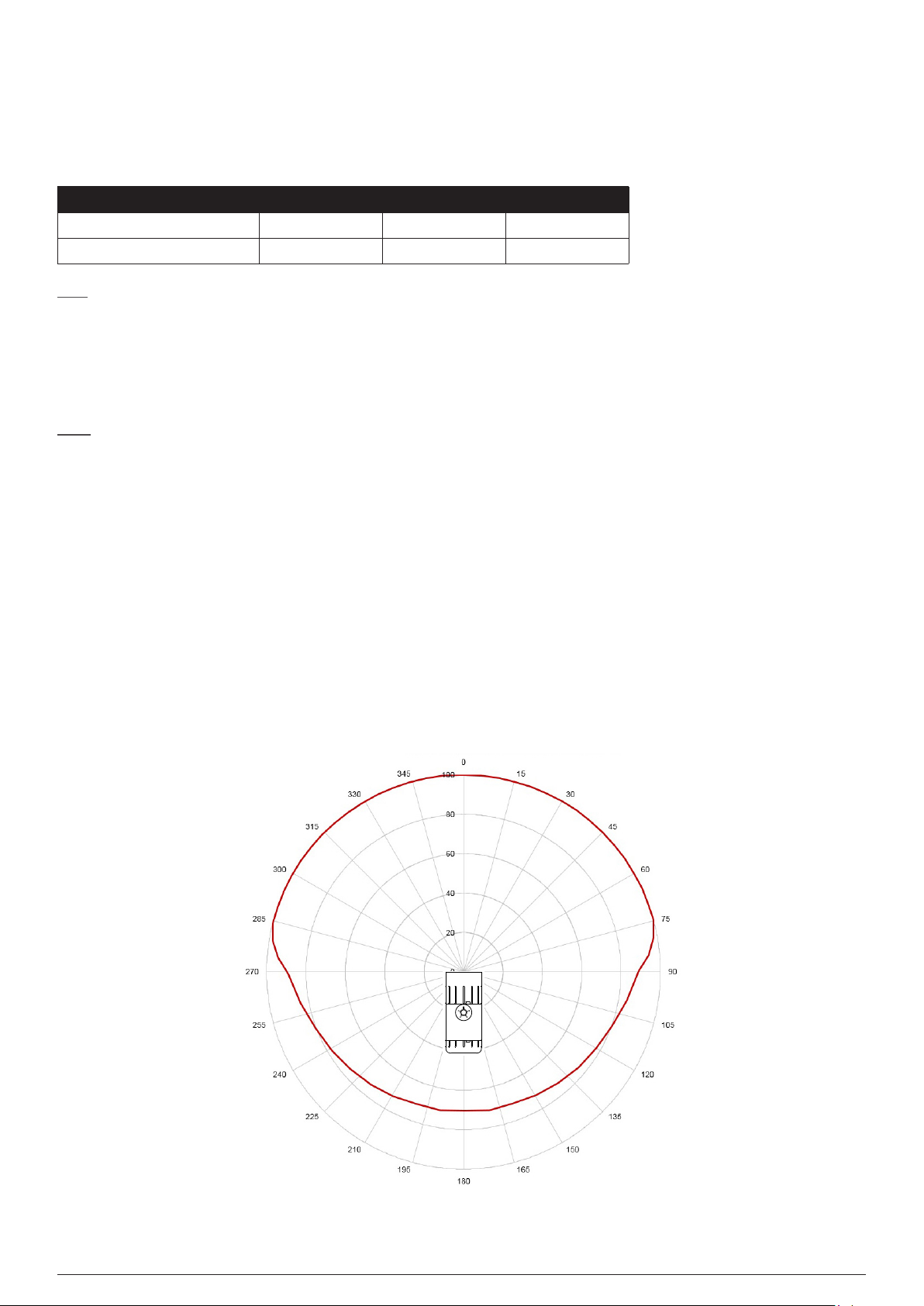

As a guide, the following table indicates typical maximum detection ranges that can be achieved for various levels of background

ultrasonic noise.

Detection Threshold Level 64 dB (Low) 74 dB (Mid) 84 dB (High)

Standard Detection Mode 24 m 12 m 7 m

Focus Detection Mode 7 m 5 m 3 m

Note

Due to variances sound level intensity generated across the measured frequency range and angular positioning of the detector.

The above values may vary up to 50%.

The values in the table above were achieved with a methane leak, mass flow rate of 0.1 kg/s at an environment of 20°C, 50 %RH and a

standard atmospheric pressure of 1013 hPA.

Note

The Background Levels feature, available in the Searchzone Sonik mobile App, can be used to validate and check that the current

detector settings are appropriate. Refer to section 9.9 Detector Settings for more information.

3.6Range and Field of Coverage

The Searchzone Sonik detector has a dynamic range of 40dB to 140 dB giving a detection range of typically 20m on-axis radius

(background noise dependant). The field of detection coverage (FoC) is +/90 degrees in both horizontal and vertical planes measured

on-axis to the face of the detector’s sensor.

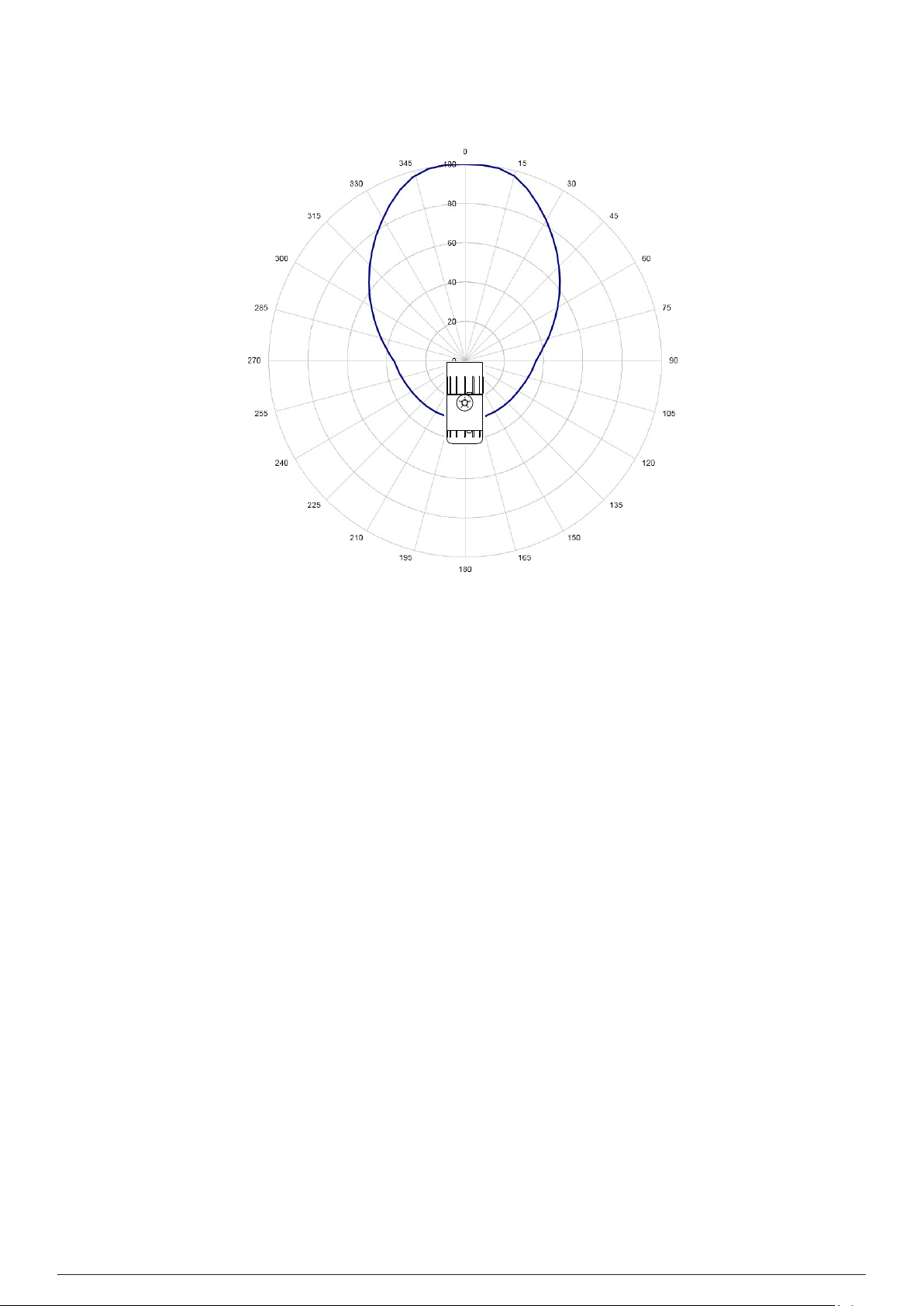

The detection algorithms (Standard or Focus) differentiate between leak signatures and typical noise source signatures in both time and

frequency domains. The polar plots in the Figures 3 and 4 below show the typical detection areas for both Standard and Focus modes.

Refer to the table in section 3.5.1 for typical ranges that can be achieved for both Standard Mode and Focus Mode.

3.6.1Standard Mode

Use Standard Mode for larger areas which are subject to lower levels of background noise and where nuisance alarms sources are not

expected.

Figure 3.Angular Field of Coverage in

Standard Mode (% of Range)

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 12

3.6.2Focus Mode

Use Focus Mode for closer areas which are subject to high levels of background noise and where nuisance alarm sources are expected.

123 Overview and Introduction

Figure 4.Angular Field of Coverage in

Focus Mode (% of Range)

3.7Description of Gas Leak Detection Using Ultrasound

A high pressure gas leak is a broadband continuous phenomenon. This gas leak ultrasound signature is detected in the presence of

other ultrasound noise sources using advanced detection algorithms. The detection algorithms differentiate between leak signatures

and typical noise source signatures in both time and frequency domains.

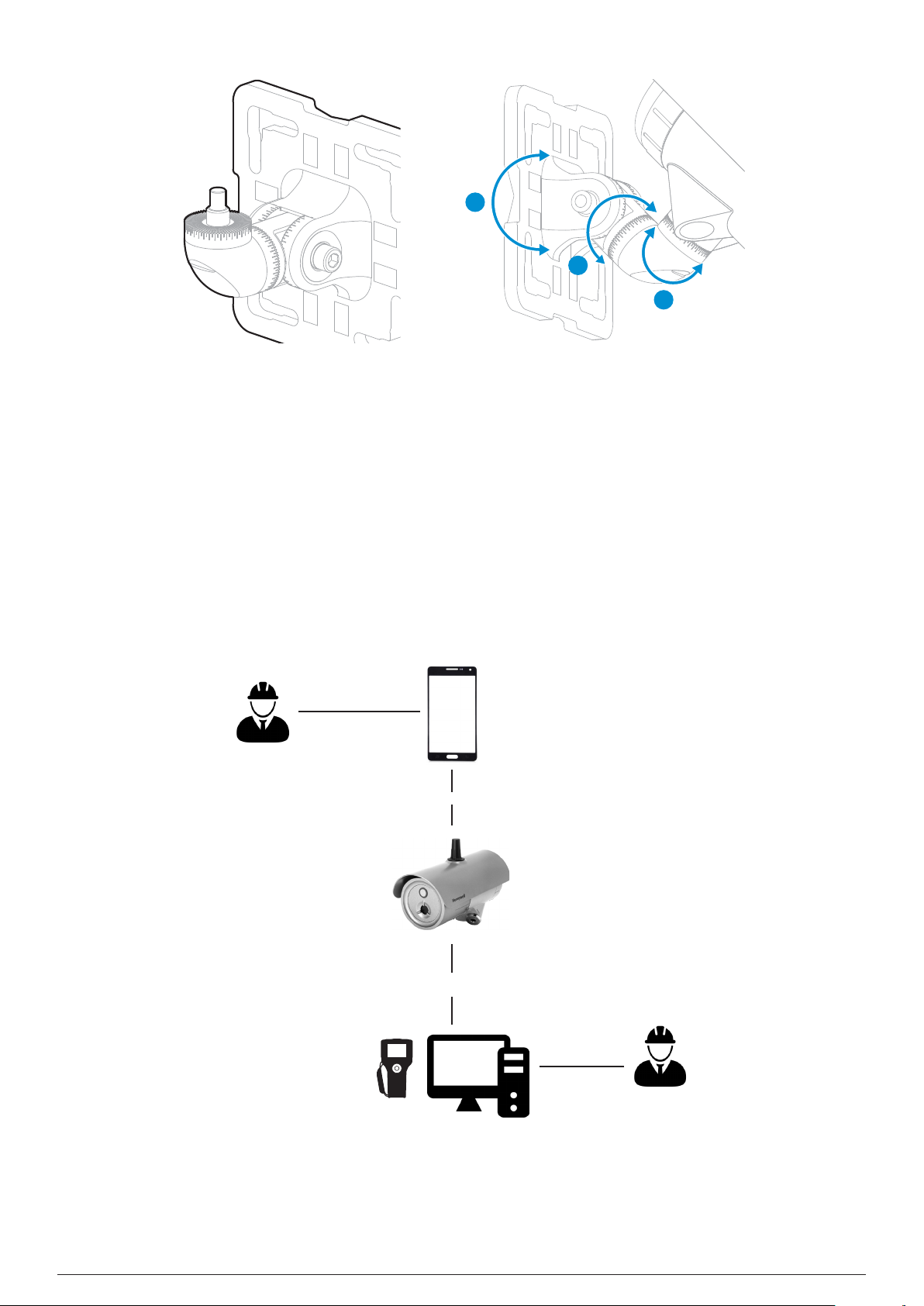

3.8Mounting Accessories and Flexibility

The Searchzone Sonik detector is supplied with the Standard Adjustable Mounting Bracket that can be simply installed prior to the

fitting of a Searchzone Sonik detector. The 3-axis adjustment allows the detector to be aimed precisely and has graduated angles

marked on the adjustments. The Standard Adjustable Mounting Bracket allows simple fixing onto a range of surfaces as well as poles,

struts, plates and other plant infrastructure. It is manufactured from high quality Stainless Steel.

LEGEND:

- Adjusting range in the vertical axis (A) = 0° to 90°

- Adjusting range in the horizontal axis (B) = 45° to +45°

- Adjusting rotational range (C) = 45° to +45°

- Graduated adjustment in 5 degree steps

- Graticule for easy setting

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 13

133 Overview and Introduction

A

C

B

Figure 5.Standard Adjustable

Figure 6.Adjustment ranges

Mounting Bracket

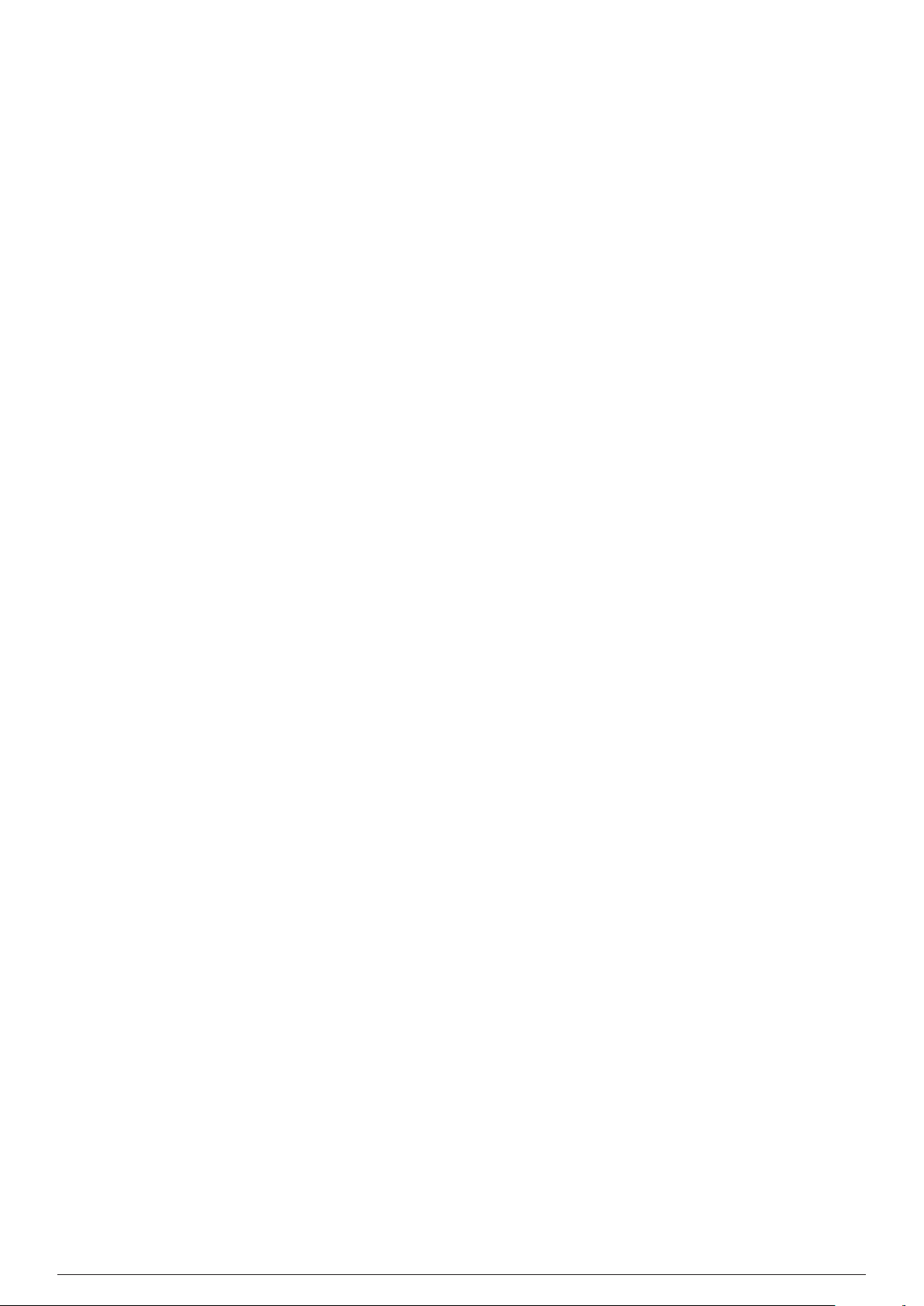

3.9Commissioning and Maintenance Tools

The Searchzone Sonik Mobile App is an Android-based application downloadable from Google Play. It connects via Bluetooth to the

Searchzone Sonik detectors and is the primary tool for installation, commissioning and maintenance.

The HART and Modbus protocols provide additional means of communicating with Searchzone Sonik for the purpose of installation,

commissioning and maintenance.

Searchzone Sonik Mobile App

Installation/

Commissioning

Engineer

Bluetooth

HART

Modbus

Plant Management System

Figure 7.Searchzone Sonik communication diagram

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Plant Operator

Page 14

3.10Available Accessories

The Standard Adjustable Mounting Bracket and a Plastic Sunshade are provided as standard. The following items are available as

optional accessories. Refer to the Ordering Information section of this manual for more information:

1. Large Adjustable Mounting Bracket

2. Stainless Steel Sunshade

3. Hazardous Area Mobile Phone

4. Searchzone Sonik App

143 Overview and Introduction

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 15

154 Siting considerations

4 Siting Considerations

When designing an installation for a Searchzone Sonik detector it is important to give due consideration as to where it is to be located,

what potential sources of problems that may be encountered in the intended location and how the detector is to be mounted.

Users are strongly recommended to consult with experts who are experienced in site mapping and siting of ultrasonic gas leak detectors

when determining final positioning.

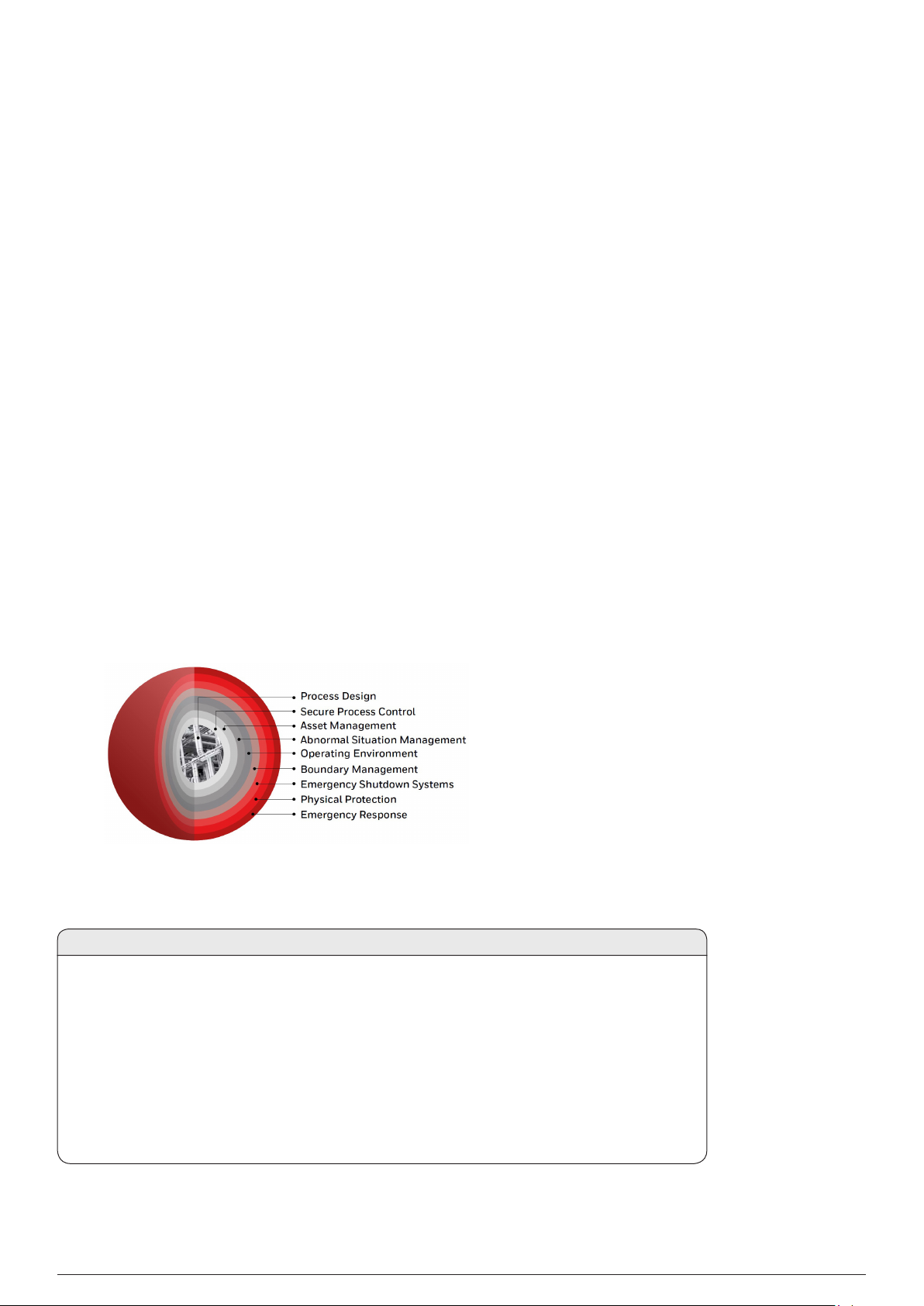

4.1Safety Case Framework

In compliance with IEC 61508, IEC 61511 and EEMUA recommendations, the Safety Case Framework is used as a method of

reducing risks at hazardous installations to acceptable levels. The framework is based on the concept of Layers of Protection which is

widely recognized by the process industry and clearly defined in industry safety standards.

Considering the application of all types of the protection layers − some layers are preventative (e.g., emergency shut down), while

some are there to mitigate the impact of an incident should it occur (e.g., fire and gas protective systems or plant emergency response

systems). Other layers of protection can counter occurrence of incidents in the first place (e.g., plant and physical asset protection,

constraint and boundary management, operator training, and asset management); while others can provide detection and alerting, and

associated guidance (e.g., operator alarms, early event detection, and integrated operator procedures). Layers can either be automated,

such as emergency shut down (ESD) equipment, or require human interaction such as operator responses to process alarms. Some

layers offer easily quantifiable risk-reduction benefits but require that the risks all be identified before. And still others are less tangible

and offer subtler benefits.

An Advanced Ultrasonic Gas Leak Detector will generally be used as part of a Gas Detection and Mitigation layer. Ultrasonic gas leak

detectors complement point and open path gas detectors as they detect the gas leak by sensing the sound pressure level created by a

high pressure gas leak. Ultrasonic gas leak detectors are affected by environmental conditions but not significantly by wind.

4.2Siting the Detector

CAUTION

1. Do NOT install in areas where detector can be struck by falling objects.

2. Do NOT site the detector where maintenance may impact, misalign or damage the detector.

3. Avoid installing on a vibrating infrastructure.

4. Install the detector a minimum of 1 m away from potential source of gas leak. Point the detector

30 degrees away from the potential source of gas leak.

5. A detector installed a minimum of 3 m away from a potential source of gas leak may be aimed directly

at it.

6. Do NOT operate the detector outside of the allowed temperature range. Refer to the Specification

section of this manual for more information.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 16

4.2.1 Mounting Position

It is recommended that Searchzone Sonik is placed close to the area to be protected to maximise the detection performance. For best

performance, use the following location principles when determining final positioning of the detector:

• Avoid situations were a leak plume is presented directly to the face of the detector. For best results, aim the detector at the potential

leak but at an angle of approximately 30 degrees off axis of the resultant plume.

• When monitoring a pipe containing the pressurized gas, mount the detector so that it ‘looks’ along the pipe.

• Avoid mounting the detector directly next to or over sources of ultrasonic noise e.g. compressor, gearbox, turbine, generator, etc.

• Do not install the detector next to pressurized air lines and fittings.

• Positioning the detector away from sources of unwanted ultrasonic noise will significantly reduce the risk of nuisance alarms.

4.2.2Mounting Angle

It is recommended that Searchzone Sonik is mounted pointing downwards by at least 30 degrees when used outdoors to allow the

sunshade to protect the sensor from the adverse environmental conditions.

4.3Accidental Impact

Situations where there is a significant probability of equipment, personnel or moving objects accidentally impacting Searchzone Sonik

detector should be avoided. If such locations cannot be avoided, measures including increase mechanical protection and warning

notices should be considered.

164 Siting considerations

4.4Change in Site Infrastructure

When there are changes in site infrastructure or configuration, which may introduce new sources of ultrasound, the customer should

review the existing configuration of Searchzone Sonik detectors and decide if it needs to be adapted to suit those changes.

4.5Transient Background Noise

Transient background noise from processes that release gas or steam under pressure (e.g., planned release of gas intended by the

operator) can cause unwanted triggering of an ultrasonic gas leak detector. These can be avoided by setting an alarm delay which is

longer than duration of that process operation.

4.6Location Survey

Points of consideration:

1) Assess the Risk Case

a. What is the risk?

b. What is the anticipated gas leak sound pressure level ?

c. What is the protection method?

d. What is the detection method in case of a leak?

e. How best to mitigate the risk?

2) Assess the environmental conditions before installation

3) Assess the potential sources of background noise in the area

If necessary measure these at the proposed ultrasonic gas leak detector install position

4) Assess the area to be covered by an ultrasonic gas leak detector with respect to:

a. Type of working environment

b. Local sources of ultrasounds

5) Choose an appropriate distance of the detector from the monitored area. Avoid installing the detector at or close to maximum range

to allow higher detection thresholds to be set, reducing the risk of false false alarms. See coverage diagrams specified in Overview

and Introduction section of this manual.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 17

174 Siting considerations

6) Choose Standard or Focus Mode with respect to the expected background noise levels and the nature of the risk to be covered.

Refer to the Overview and Introduction section of this manual for more information.

7) Choose the detector’s mounting position and angle, considering

a. Coverage

b. Ease of access

c. The direction of any potential leak. Refer to section 4.2.1 Mounting Position.

8) Ensure that the risk of physical impact, misalignment, or damage of the detector by human factor or uncontrollable events is avoided

4.7Bluetooth Considerations

1. Is use of Bluetooth permitted on the site?

2. Is the mobile device rated for operation in hazardous locations?

3. Is the Searchzone Sonik installed within 20 m from the place where operator will stand?

4. Is there direct visibility ensured between the Searchzone Sonik and the mobile device?

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 18

5 Mechanical Installation

5.1Visual Check after Transportation

The Searchzone Sonik pack includes:

• The Searchzone Sonik Gas Leak Detector

• Standard Adjustable Mounting Bracket

• Plastic Sunshade

• One certified blanking plug

• Tool Kit

To ensure that the Searchzone Sonik unit was not damaged during transport, perform the following checks:

1. Check the packaging for damage before opening. If the packaging shows signs of tearing, breakage or other damage, immediately

inform the transport company and the supplier. Document the damage in an appropriate way (e.g., photographs).

2. Open the packaging carefully to avoid damaging the contents.

3. Examine the Searchzone Sonik detector for damage. If you find the detector to be damaged in any way, immediately inform the

transport company and the supplier. Document the damage in an appropriate way (e.g., photographs).

4. In the case of damage: a) Leave the detector in the original packaging

b) Do not attempt repair, or operate the detector until the damage claim has been resolved with the supplier.

185 Mechanical Installation

CAUTION

1. Installation, set-up and maintenance must be conducted only by trained and authorized personnel.

2. Do NOT open the front enclosure. The warranty of a unit, whose front enclosure has been opened, is invalidated.

3. Do NOT modify the front enclosure or component parts as this will compromise the hazardous location certification and

invalidate the warranty.

4. Do NOT modify the construction of the detector in any way as this will invalidate the warranty.

5. Open and close the wiring compartment cover with care to avoid deformation.

6. Installation, set-up and maintenance must be conducted only by trained and authorized personnel.

7. Avoid water and dust ingress when opening the wiring compartment to protect the unshielded electronic contacts.

8. Secure the detector when loosening bracket bolts. Unwanted release may cause injury.

9. Check mating surfaces prior to assembly (threads, O-rings). Ensure that they are clean and free of contaminants.

10. Check the O-rings prior to assembly, replace if damaged with genuine parts.

11. The Searchzone Sonik is supplied without cable glands. Ensure that all cable entry threads are sealed with an

appropriate plug to eliminate water ingress and thread damage. At installation, the cable entry transportation plugs

must be removed and replaced with suitable cable glands, thread adapters or blanking plugs to meet local hazardous

location requirements.

12. Check suitability of the blanking plug for its end use on site, ensure it meets local and national regulations.

13. Remove power from the Searchzone Sonik detector while installing wiring. Do NOT install wires or set up wiring with

power applied.

5.2Description

The Standard Adjustable Mounting Bracket enables Searchzone Sonik to be fitted to a wide range of plant infrastructure and then

appropriately aimed to cover the area to be protected. It is manufactured in 316L Stainless Steel.

A Large Adjustable Mounting Bracket is available as option to suit installation on larger diameter poles.

Searchzone Sonik cable entries are 2 x M25 or 2 x ¾” NPT dependent on the version.

The two compartment design means that the sensing electronic module and wiring compartment are separate. There are no set-up

switches within the electronics.

Two pluggable connectors are provided within the wiring compartment. The connectors feature mechanical retention.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 19

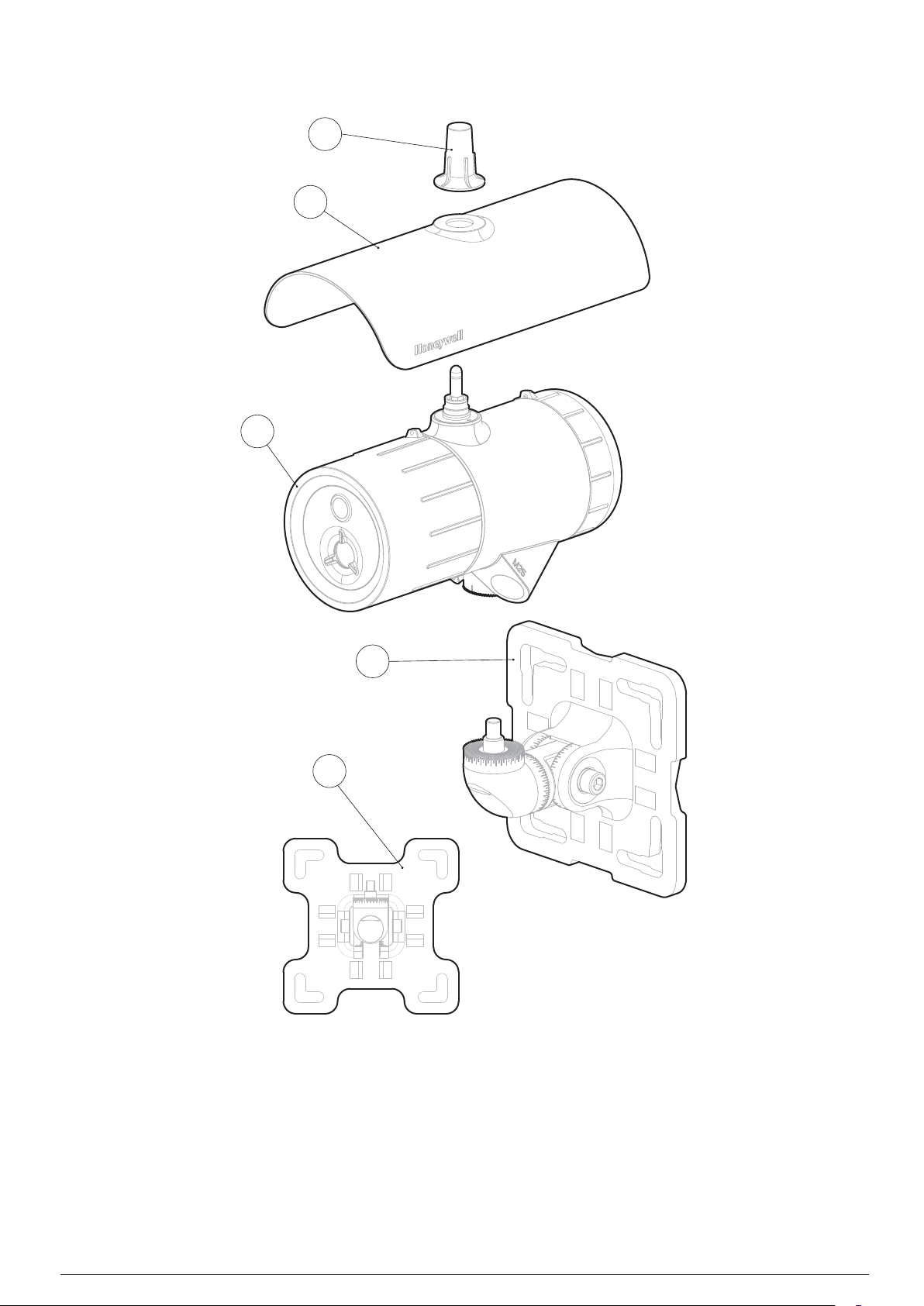

5.3Main Parts

195 Mechanical Installation

4

3

1

2

5

Figure 8.Searchzone Sonik general view

LEGEND:

1. Searchzone Sonik Advanced Gas Leak Detector

2. Standard Adjustable Mounting Bracket to fit on a plate, pole or plant infrastructure

3. Sunshade

4. Antenna cover

5. Large Adjustable Mounting Bracket (optional)

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 20

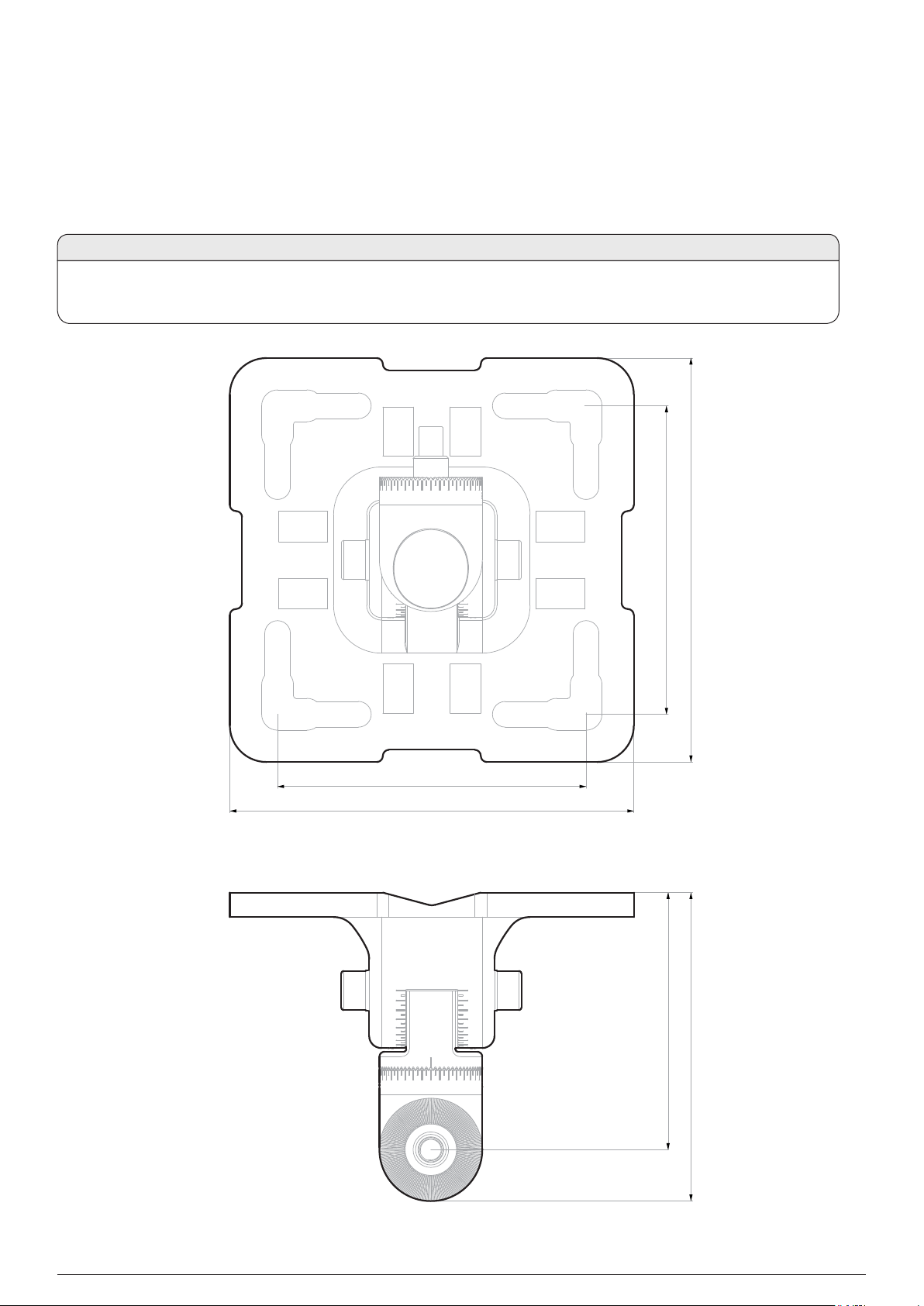

5.4Mounting Searchzone Sonik

Searchzone Sonik will normally be mounted at height, typically secured to a pole using the UBolts or Worm Drive Clips supplied in the

Pole Installation Kit (optional).

The supplied Standard Adjustable Mounting Bracket allows mounting on a plate, pole or other plant infrastructure. All bolts are captive

to avoid accidental loss during installation.

CAUTION

IMPORTANT: When tightening the pivot bolts, first, tighten the left-facing horizontal M10 bolt to fix the pivot in

its horizontal position. Second, tighten the right-facing horizontal M10 bolt. Tighten these bolts to a final torque of

30 Nm/22 lb.ft.

205 Mechanical Installation

126 mm (4.95")

165 mm (6.5")

165 mm (6.5")

126 mm (4.95")

105 mm (4.15")

Figure 9.Standard Adjustable Mounting Bracket general view and dimensions

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

126 mm (4.95")

Page 21

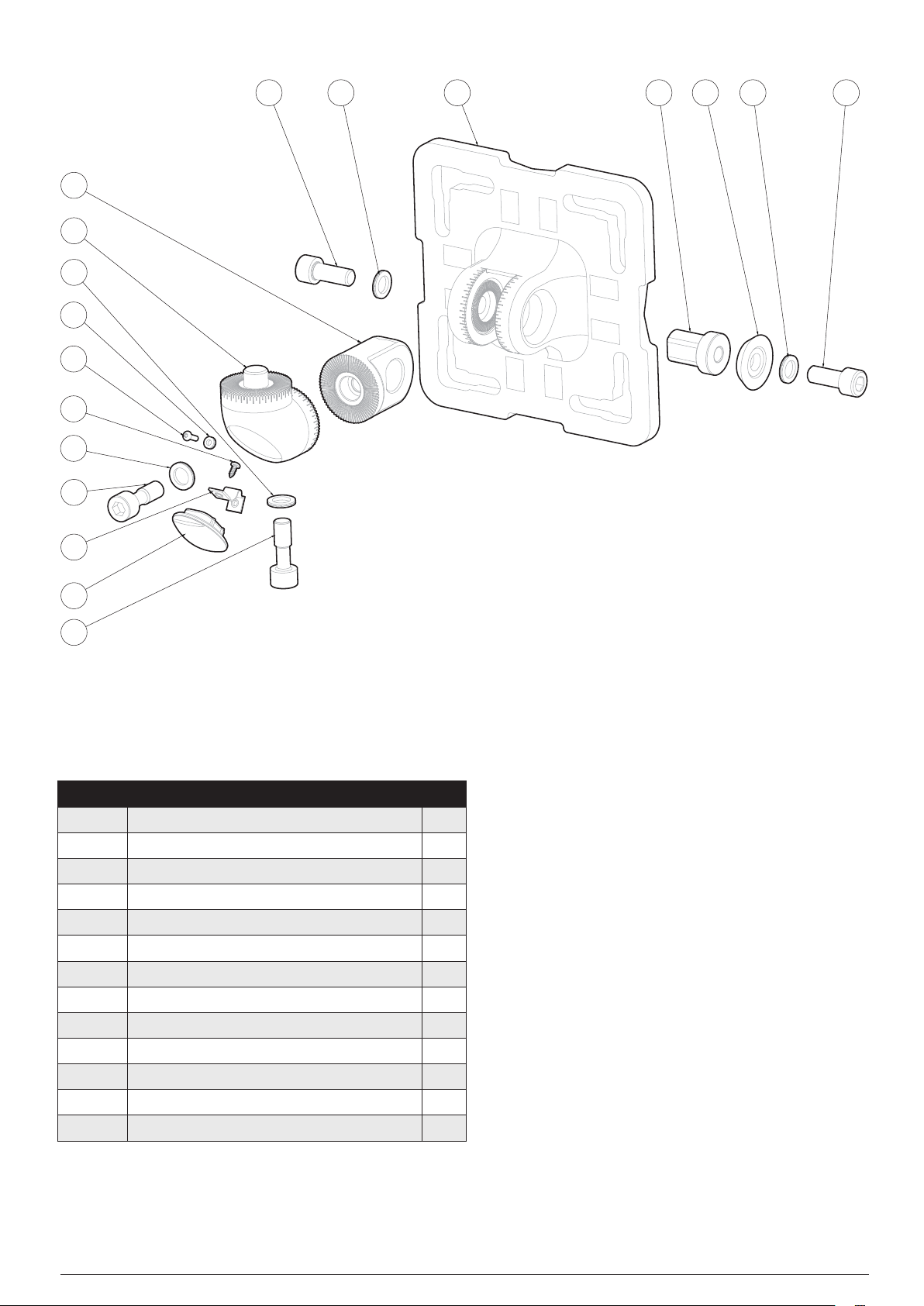

215 Mechanical Installation

12

11

13

6 1

2

3

8

8

7

8 8

4 5 6

10

9

7

Figure 10.Standard Adjustable Mounting Bracket exploded view

LEGEND:

Position Description Pcs.

1 Standard Adjustable Mounting Bracket flange 1

2 Vertical pivot 1

3 Horizontal pivot 1

4 Keyed insert 1

5 Conical washer 1

6 Bolt M10x25 2

7 Captive Bolt M10x30 2

8 Nord lock washer M10 4

9 Bolt cover plate 1

10 Plate retention strap 1

11 Bolt M3x10 1

12 Nord lock washer M3 1

13 Retention strap screw 1

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 22

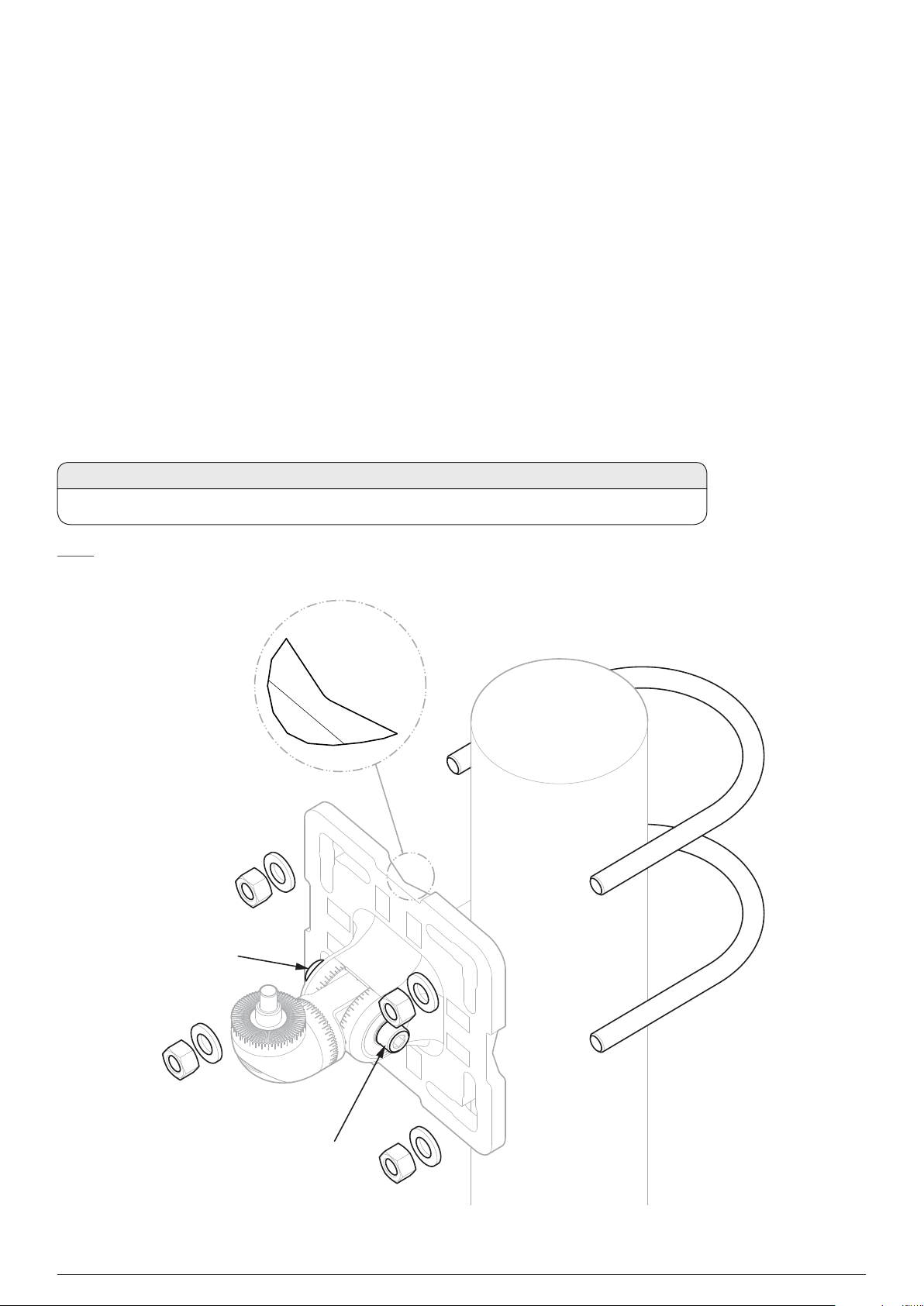

5.5Pole Mount Installation

For pole installation, use the optional Pole Mount Fixing Kit. Refer to the Ordering Information section of this manual.

1. For poles 50 to 101 mm (2 to 4 inches) in diameter use the supplied Standard Adjustable Mounting Bracket.

2. For larger poles 101 to 152 mm (4 to 6 inches) in diameter use the Large Adjustable Mounting Bracket (optional; Refer to

section 14 Ordering Information of this manual.)

3. Attach the assembled Standard Adjustable Mounting Bracket (or Large Adjustable Mounting Bracket) to the pole. Align the bracket

flange V-groove with the pole for a good fit. Fix the bracket with two U-bolts and four nuts with washers. Alternatively, fix the bracket

using the Worm Drive Clips. Refer to the figure below.

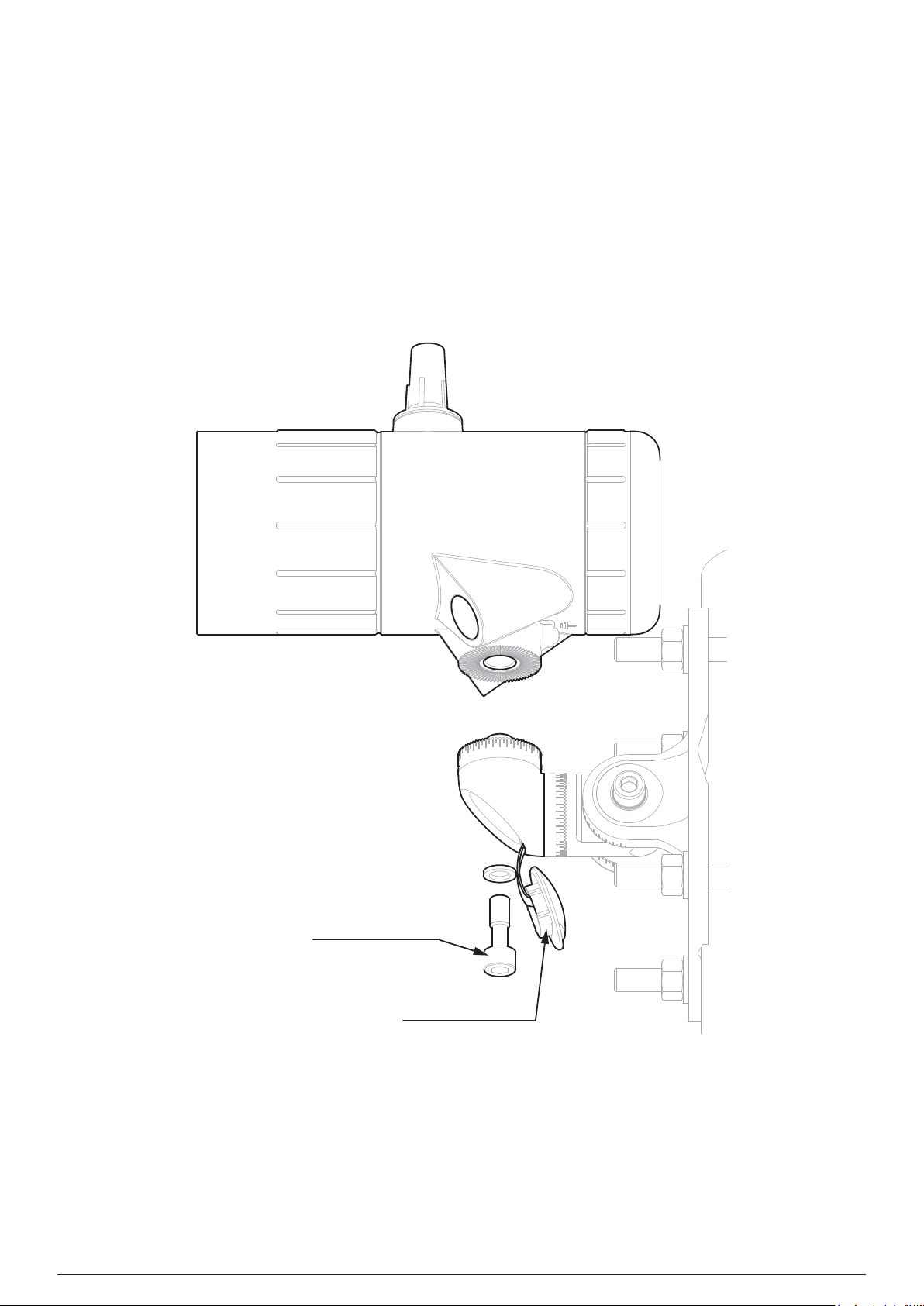

4. Unscrew both horizontal M10 bolts by 23 turns.

5. Adjust the pivot in horizontal position.

6. IMPORTANT: First, tighten the left-facing horizontal M10 bolt (refer to the figure below) to fix the pivot in horizontal position

(torque 30 Nm/22 lb-ft).

7. IMPORTANT: Second, tighten the right-facing horizontal M10 bolt (refer to the figure below) to fix the pivot in horizontal position

(torque 30 Nm/22 lb-ft).

CAUTION

225 Mechanical Installation

Use of the Worm Drive Clips is NOT recommended for installation on moving objects, e.g., gas carriers.

NOTE

All Mounting Bracket bolts are captive to ensure that they are not accidentally dropped during installation.

V-GROOVE

DETAIL

Left-facing

horizontal

M10 bolt

Right-facing

horizontal

M10 bolt

Figure 11.Standard Adjustable Mounting Bracket fitment to pole with U-bolts

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 23

235 Mechanical Installation

Horizontal M10 bolts

Figure 12.Standard Adjustable Mounting Bracket fitment using Worm Drive Clips

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 24

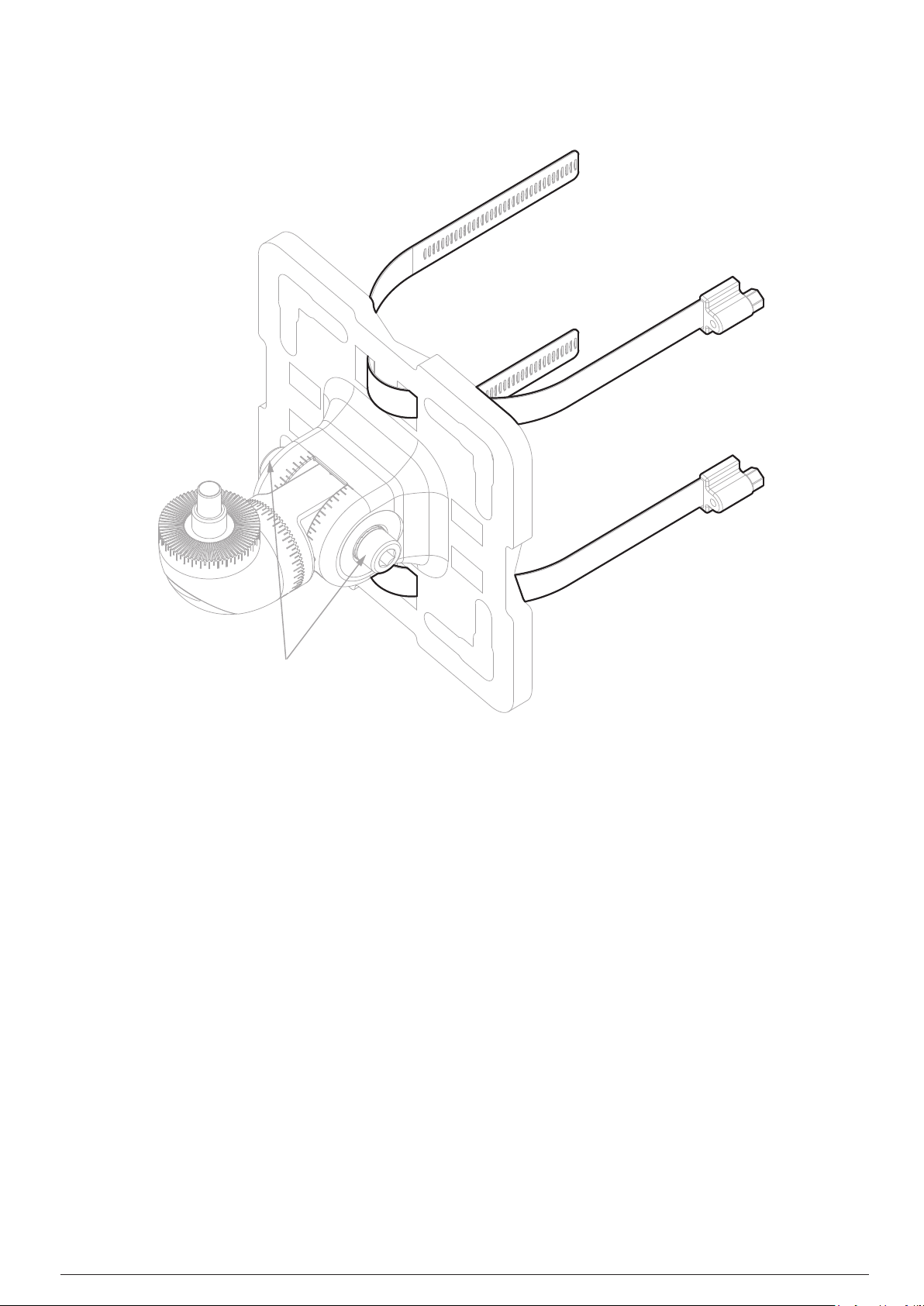

5.6Wall Mount Installation

For installation onto a wall, use M8 or M10 mounting bolts with washers (not supplied).

245 Mechanical Installation

Figure 13.Wall mount installation

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 25

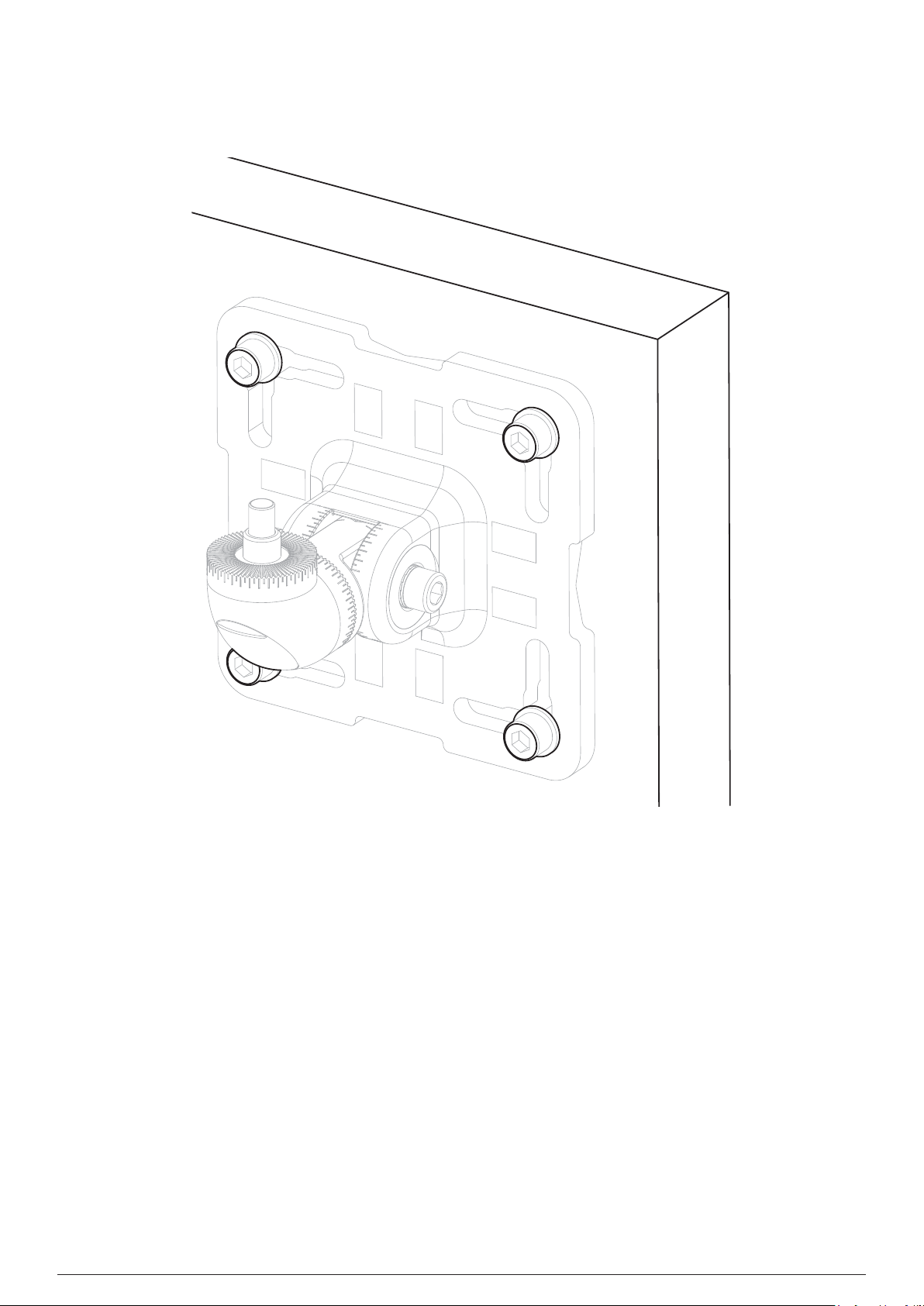

5.7Assemble Cable Glands

Refer to the original manufacturer’s assembly instructions for the particular cable gland type. The wiring compartment is certified to be

able to use EX d or Ex e glands to suite local requirements. Leave a service loop in the cable as per site standard procedures.

NOTE

Use certified cable glands and blanking plugs as per local standards.

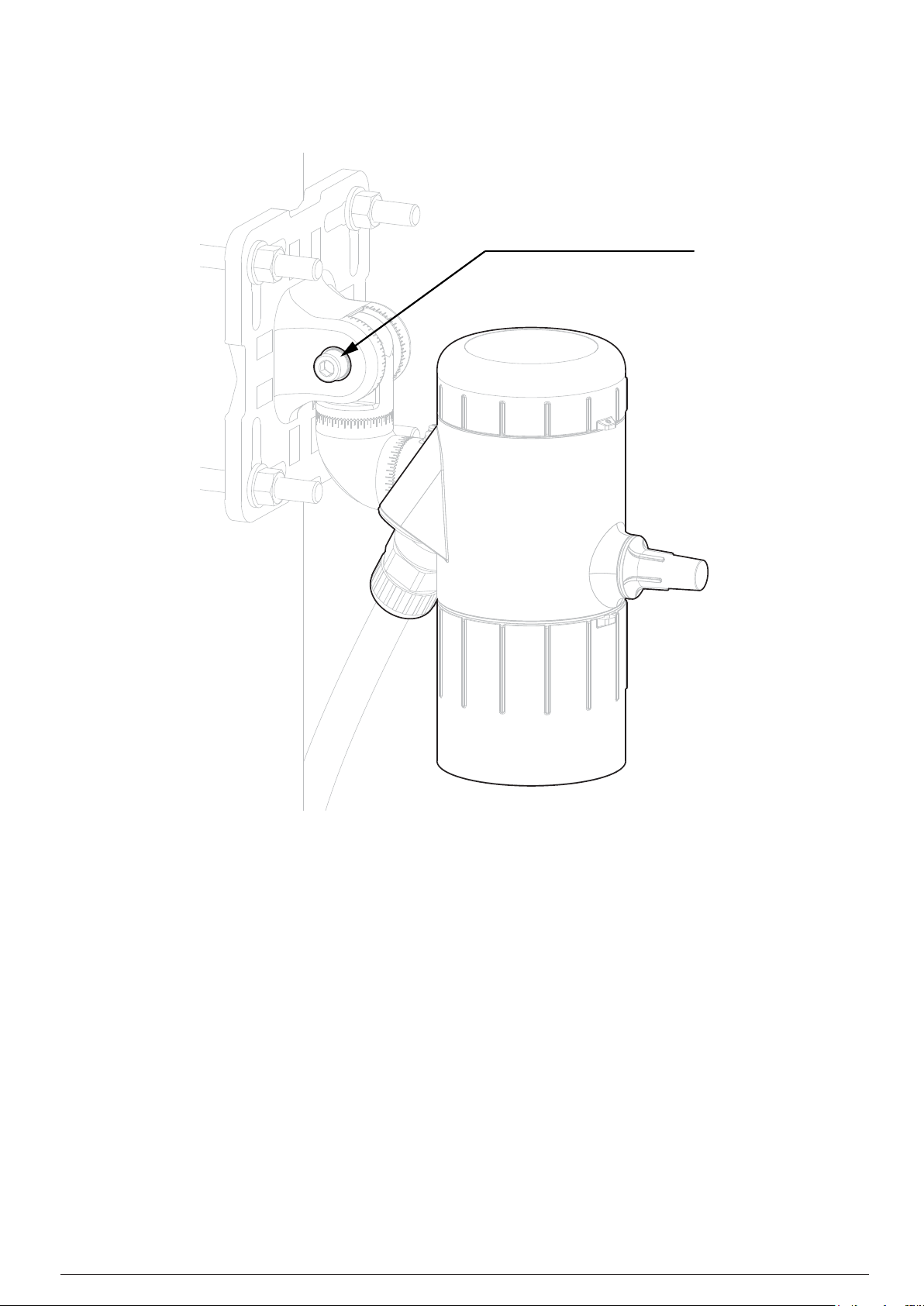

Figure 14.Example of cable gland

255 Mechanical Installation

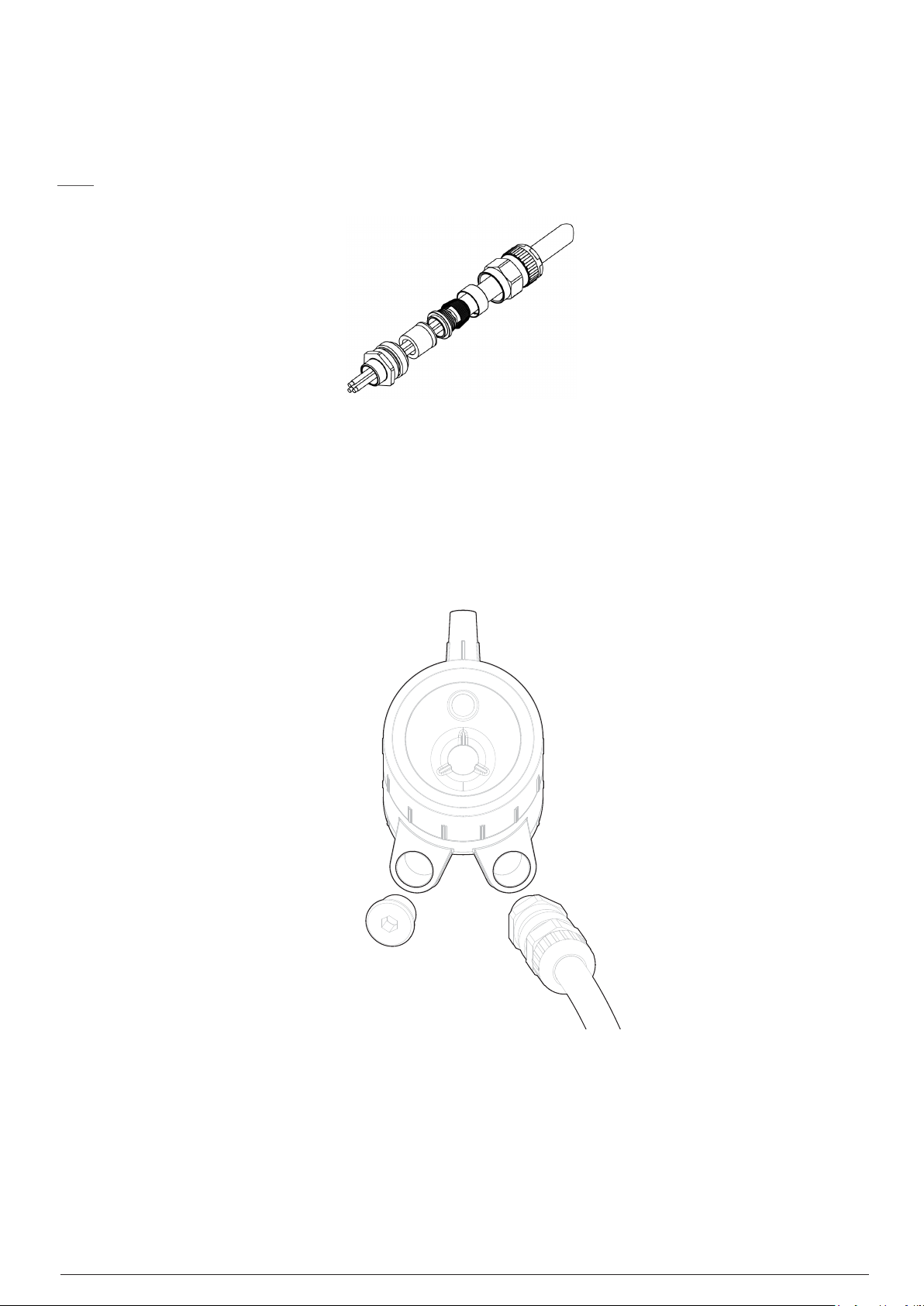

5.8Connect Cable Glands to the Searchzone Sonik

1. Fit the cable glands to the Detector.

2. Fit a Stopping Plug to any unused cable entry.

3. Tighten the gland nuts and Stopping Plugs as per the manufacturer’s instructions.

Figure 15.Connect cable glands to the Detector

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 26

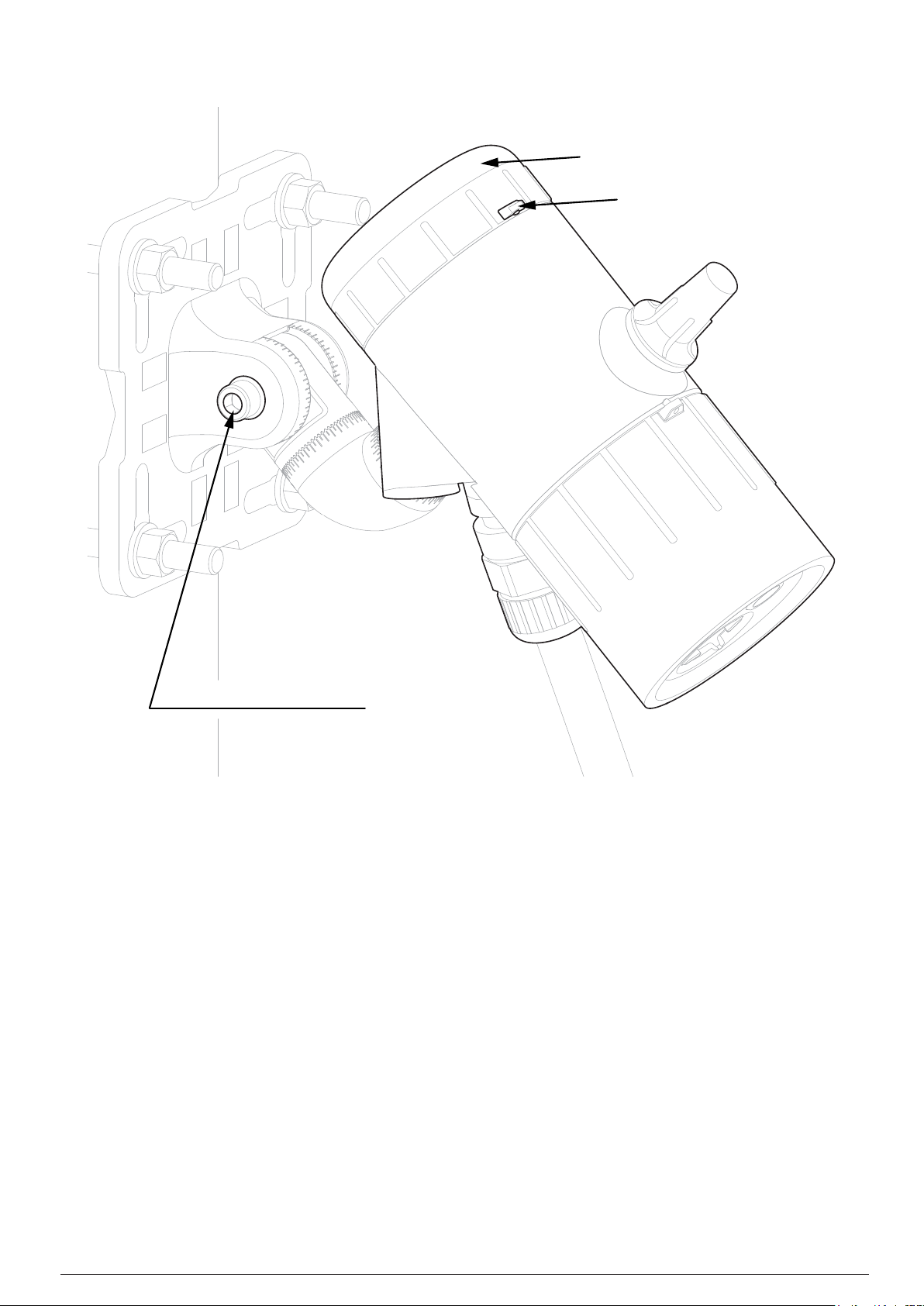

5.9Detector Attachment

1. Remove the bolt cover plate (refer to the figure below).

2. Attach the Searchzone Sonik to Standard Adjustable Mounting Bracket.

3. Hold in place and hand-tighten the vertical M10 bolt with washer. The Standard Adjustable Mounting Bracket is designed so that

Searchzone Sonik sits on the top spigot and is balanced to aid installation.

4. Aim the detector in the desired direction and hand-tighten the left-facing horizontal M10 bolt. Only hand fit the right-facing

horizontal M10 bolt at this stage.

5. Check the final positioning of the detector and make adjustments if necessary.

6. Tighten only the left-facing horizontal M10 bolt to a final torque of 30 Nm (22 lb ft).

7. Tighten the remaining bolts to a final torque of 30 Nm (22 lb ft).

8. Push home the bolt cover plate.

265 Mechanical Installation

Vertical M10 bolt

Bolt cover plate

Figure 16.Detector attachment

5.9.1Detector removal

1. IMPORTANT: First, loosen the right-facing horizontal M10 bolt by 23 turns.

2. IMPORTANT: Second, loosen the left-facing horizontal M10 bolt by 23 turns.

3. Set the vertical position of Detector to 0°.

4. Hold the detector body and loosen the vertical M10 bolt.

5. Remove the Searchzone Sonik from Standard Adjustable Mounting Bracket.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 27

Left-facing horizontal M10 bolt

275 Mechanical Installation

Figure 17.Set the vertical position of Detector to 0°

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 28

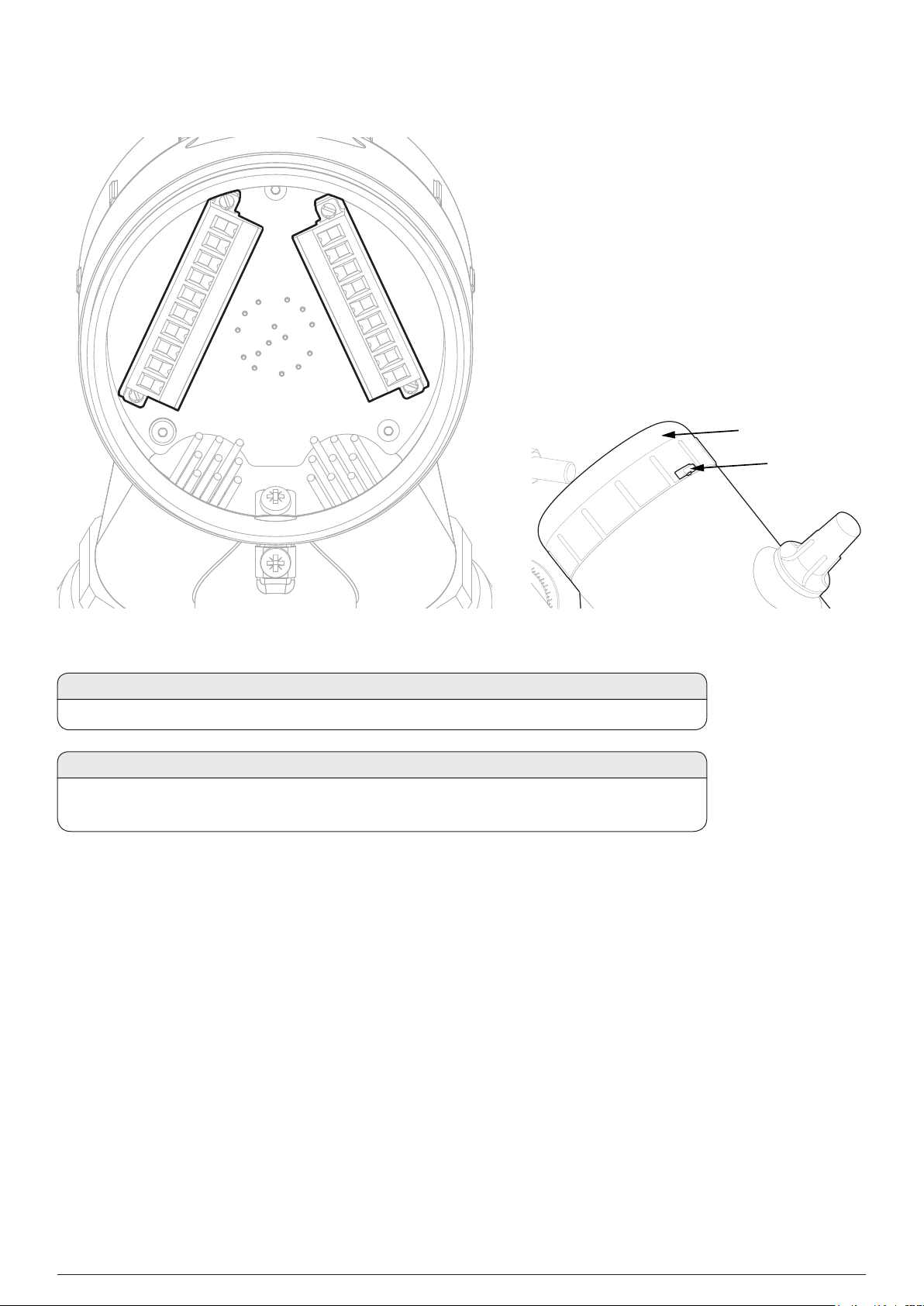

5.10Connect Wires to PCB Terminals

285 Mechanical Installation

Wiring Compartment

Cover

Grub screw

Figure 18.PCB Terminals

CAUTION

Remove power from Searchzone Sonik before performing any electrical installation or maintenance.

CAUTION

The equipment features pluggable connectors that are mechanically locked into position. These are

not accessible by the user during normal operation.

1. Loosen the grub screw.

2. Unscrew the Searchzone Sonik wiring compartment cover.

3. Unscrew and remove the pluggable connectors.

4. Connect wires as per local procedures. The connectors are clearly identified. Refer to the diagrams and tables in the

Electrical Installation section of this manual for information on wiring.

5. Ensure that the O-rings on the detector body and in the end cap are properly fitted and not damaged.

6. Ensure that the threads of the wiring compartment cover are clean of dust and lubricated with a suitable anti-seize compound.

7. Screw on the wiring compartment cover.

8. Tighten the grub screw to a final torque of 1.1 Nm (0.81 lb-ft)

9. Ensure the horizontal M10 bolts are loosened by 23 turns.

10. Use the graduated adjustment and angle scale to aim the Detector to the required position.

11. IMPORTANT: First, tighten the left-facing horizontal M10 bolt to a final torque of 30 Nm (22 lb-ft).

12. IMPORTANT: Second, tighten the right-facing horizontal M10 bolt to a final torque of 30 Nm (22 lb-ft).

13. Fit the sunshade in place. Refer to section 5.11 Sunshade Installation for instructions.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 29

Wiring Compartment

Cover

Grub screw

295 Mechanical Installation

Left-facing horizontal M10 bolt

Figure 19.Example position of 45°

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 30

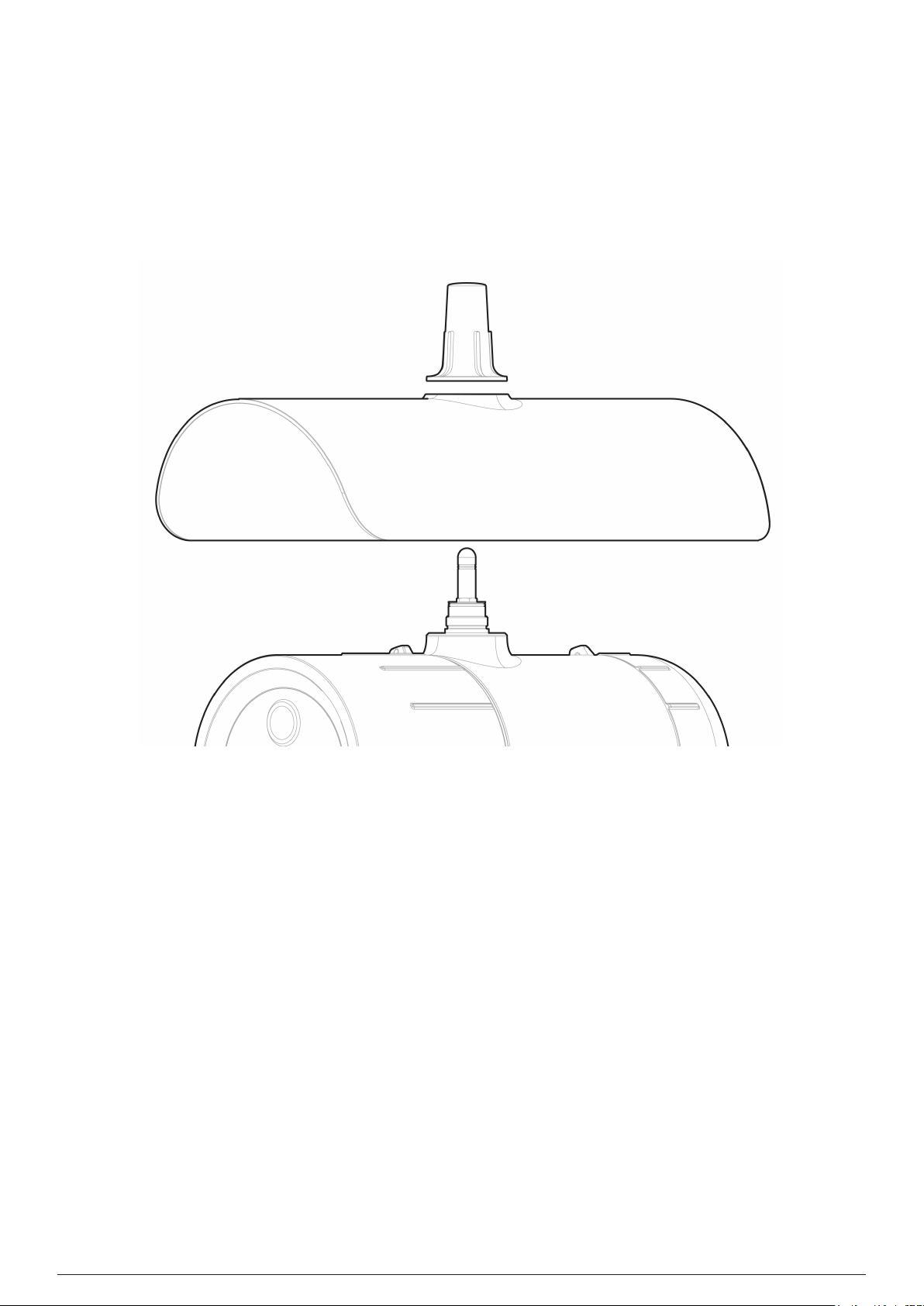

5.11Sunshade Installation

1. Unscrew the antenna cover from the top of the detector.

2. Fit the standard (supplied) or stainless steel sunshade (optional) onto Searchzone Sonik.

3. Ensure the O-ring around the antenna is not damaged and is properly fitted.

4. Screw the antenna cover back onto the antenna.

5. Tighten the antenna cover to a final torque of 5 Nm (7 lb-ft).

305 Mechanical Installation

Figure 20.Sunshade and antenna cover

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 31

6 Electrical Installation

CAUTION

Remove power from the Searchzone Sonik before performing any electrical installation or

maintenance.

6.1Power Supply Requirements

The Searchzone Sonik detector requires a voltage supply of 18 - 32 Vdc (nominal 24 Vdc). Power consumption is 4 W maximum when

the internal heater is not active, i.e. for ambient temperatures above 30°C. At lower ambient temperature the internal heater is active

and power consumption may reach up to 15 W.

Ensure that the minimum required supply voltage 18 VDC is present at the detector, taking into account the voltage drop due to cable

resistance.

Note

Make allowance for the insertion loss resistance.

316 Electrical Installation

The maximum loop resistance in the field cable is calculated as follows:

As an example, V

the connected power supply or control system. Consult the manual of that equipment for this information.

CAUTION

The detector 24 V power supply and 420 mA current loop power supply must be of an isolating type

(galvanic isolation from mains, providing basic insulation) but does not need to be a Class II (SELV)

power supply.

CAUTION

If mains voltage is connected to more than one relay, all relays must be connected to the same phase

of the mains network. Using different phases is not allowed.

detector min

= 18 V; P

= 4 W or 15 W (dependent on environmental conditions) V

max

6.1.1Internal Battery Cell

will depend upon

controller

A primary cell featuring an expected operating life of 10 years is fitted internally. This is not accessible and replacement must only be

conducted by an authorized service centre.

6.2420 mA Current Loop

The Detector provides a 420 mA current loop with HART Communication which can be user configured as a Sink, Source (3Wire) or

Isolated (4Wire) electrical interface, based on installation requirements.

Depending on configuration, the 420 mA current loop output can provide:

• discrete indication of operating modes (Normal operation, Pre-alarm, Alarm) and special states (Fault, Warning, Inhibit, Over-range)

• proportional output to ultrasound pressure level (dB SPL) and a discrete indication of special states (Fault, Warning, Inhibit, Overrange).

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 32

326 Electrical Installation

Ø=78 mm

THIS DOCUMENT HAS BEEN GENERATED USING ADOBE

INDESIGN AND MUST ONLY BE UPDATED BY INDESIGN

The Searchzone Sonik features HART communications to provide access to the detector from a control system or hand-held device for

the purpose of configuration and to provide status and diagnostic information.

The total load resistance for the 420 mA current loop shall be less than 600 Ω, including the resistance of the 420 mA cable and

input impedance of the equipment to be connected. To ensure reliable HART communications, the minimum loop resistance is 250 Ω.

If HART communications is not required, the minimum loop resistance is 100 Ω.

If the 420 mA current loop is not used, a jumper must be connected between 420 mA+ (terminal 5) and 24V DC+ (terminal 8) and a

load resistor must be connected between 420 mA (terminal 6) and 0V DC (terminal 9). It is recommended to use a 470 Ohm, 1/4 W

resistor (250 to 400 Ω if HART is required). With the 420mA current loop configured this way the HART facility can still be used with a

HART hand held unit using terminals 20 and 21 inside the wiring compartment.

CAUTION

The maximum permissible mA loop voltage is 32 VDC and the maximum current is 22 mA.

6.3Relays

The Searchzone Sonik detector features 3 SPDT relay outputs for alarm and fault indication. Relay 1 is for alarm level 1, relay 2 is for

alarm level 2, and relay 3 indicates faults. The fault relay is normally energized and when energized indicates proper operation (no faults

present).

In the event of power failure or fault, the COMNO connection will open (the fault relay may be user configured as normally deenergized.)

6.4Connections / Wiring Diagram

Note

24 V pins number 7 & 8 and 0 V pins number 9 & 10 are internally linked.

10 0V DC

9 0V DC

8 24V DC

7 24V DC

6 420mA 5 420mA +

4 RS485 D

3 RS485 D

2 RS485 B

1 RS485 A

Registration

Serial Number:

1234567890

Activation Key:

ABCDEFGHIJKLM

11 A2 COM

12 A2 NC

13 A2 NO

14 A1 COM

15 A1 NC

16 A1 NO

17 FLT COM

18 FLT NC

19 FLT NO

20 HART +

21 HART -

QR CodeQR Code

Figure 21.Terminal Connector Label

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 33

336 Electrical Installation

External earth connection

Figure 22.Terminal Wiring Compartment

6.4.1Terminal Wiring Description

Number Marking Description

1 RS485 A RS485 A (positive)

2 RS485 B RS485 B (negative)

3 RS485 D RS485 D (cable shielding)

4 RS485 D RS485 D (cable shielding)

5 420mA+ mA signal +

6 420mA mA signal 7 24V DC Input power +

8 24V DC Input power +

9 0V DC Input power 0V

10 0V DC Input power 0V

Internal earth connection

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 34

Number Marking Description

11 Alarm 2 COM Alarm Relay 2 COM contact

12 Alarm 2 NC Alarm Relay 2 NC contact

13 Alarm 2 NO Alarm Relay 2 NO contact

14 Alarm 1 COM Alarm Relay 1 COM contact

15 Alarm 1 NC Alarm Relay 1 NC contact

16 Alarm 1 NO Alarm Relay 1 NO contact

17 Fault COM Fault Relay COM contact

18 Fault NC Fault Relay NC contact

19 Fault NO Fault Relay NO contact

20 HART+ HART hand-held temporary

connection (positive)

21 HART HART hand-held temporary

connection (negative)

Unused conductors must be suitably terminated. Wiring must be in accordance with local, national and company regulations.

Exposed or bare conductors must be avoided.

346 Electrical Installation

CAUTION

The maximum permissible mA loop voltage is 32 VDC and the maximum current is 22 mA.

Note

Searchzone Sonik is protected against accidental reversed polarity in wiring.

6.4.2Searchzone Sonik Connection for mA loop Configuration as Current Source

CAUTION

Ensure that jumper wires are installed applicable for the selected mA current loop configuration.

Figure 23.mA loop configuration as current source

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 35

6.4.3Searchzone Sonik Connection for mA Loop Configuration as Current Sink

Figure 24.mA loop configuration as current sink

356 Electrical Installation

6.4.4Searchzone Sonik Connection for mA Loop Configuration as Isolated Output

Figure 25.mA loop configuration as isolated output

6.5Cabling Recommendations

The cable used must be appropriate for the hazardous area classification and must meet local, national and company regulations. The

use of industrial grade, screened field cable is recommended.

An example may be a 3-core copper cable with screen (minimum 90% coverage) and suitable mechanical protection (e.g. steel wire

armour) to suit an M25 or 3/4” NPT gland entry or conduit, suitable when mA loop and Modbus are used while relay outputs are not

utilized.

The allowable conductor size for the terminals is 0.25 – 2.5 mm² (24 - 12 AWG). The Searchzone Sonik terminals will accept only wire

sizes (solid-core or stranded) in this range. The temperature rating of the conductors and cable glands should be greater than 80°C. The

terminals should be torqued between 0.5 Nm to 0.6 Nm (0.3680.442 lb.ft).

Ensure that the cable gland is installed correctly and fully tightened. All unused cable/conduit entries must be sealed with a suitable

certified blanking plug. Use appropriate and certified cable glands, adapters and/or cable fittings to meet local standards.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 36

6.6Earthing Recommendations

CAUTION

Any earthing regime employed must avoid earth loops.

The following information is provided to assist with proper earthing of the Searchzone Sonik:

• The Searchzone Sonik has both INTERNAL and EXTERNAL earth points provided (see Electrical Connections). This is to facilitate

connection of the detector to protective earth.

The INTERNAL earth point is marked with ground symbol in circle It shall be used for the equipment grounding connection.

Internal earth must be at least equal in mm2 to the incoming power conductors.

The EXTERNAL earth point is marked with ground symbol without circle It provides a supplementary bonding connection, which

provides facility for connection of field wiring conductors of at least 4mm2.

• Field cable screens should be connected to instrument earth at the control room. The other end of the field cable screen should be

suitably terminated or isolated. It should not be connected to internal earth point.

6.7Modbus

366 Electrical Installation

Refer to the Communications section of this manual for more information on Modbus.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 37

7 Commissioning and Configuration

7.1First Time Switch On

7.1.1Pre-power Check

1. Check that the working environment temperature is within the range given in the Specifications section of this manual.

2. Check that the Searchzone Sonik detector is mounted correctly and secured in its position. Refer to the Mechanical Installation and

Electrical Installation sections of this manual for more information.

3. Check that the Searchzone Sonik unit is wired correctly. Refer to the Electrical Installation section of this manual for more

information.

7.2Operating Function Verification

Check that the Searchzone Sonik detector safety outputs are working properly.

Check that the Searchzone Sonik detector is positioned correctly so as to cover the risk being monitored.

Perform a functional test where appropriate.

377 Commissioning / First Time Operation / Configuration

7.3Communication

NOTE

The prerequisite to commissioning using Bluetooth is to have the Searchzone Sonik Mobile App installed to a suitably-approved mobile

device and that the user be fully registered to the Honeywell User Management Server (UMS).

7.3.1Bluetooth®

The Searchzone Sonik detector features a Bluetooth interface that allows non-intrusive connection using a mobile device running the

Searchzone Sonik App. The Bluetooth interface is accessed by the mobile device that supports Bluetooth.

Refer to the Mobile App section of this manual for more information on Bluetooth communication link.

The Searchzone Sonik detector supports Bluetooth point-to-point mode of operation. While there is a connection between the

Searchzone Sonik and a mobile device, the detector cannot be scanned or accessed by another mobile device.

If there is no active Bluetooth communication for 10 minutes, the Searchzone Sonik detector will terminate the Bluetooth connection

automatically.

The communication range will vary depending on the field situation and installation location of Searchzone Sonik. Optimal range will be

achieved when line-of-sight between the Searchzone Sonik detector and the mobile device is achieved.

7.4Settings and Configuration

The Searchzone Sonik Mobile App is the primary tool for configuring the detector. The configurable settings are as follows:

Detector ID

Operation mode

Algorithm mode

Inhibit level

Alarm set point

Warning level

Fault level

Over-range level

Alarm 1 level

Alarm 2 level

Alarm delay

Proof test interval

Relay 1, Relay 2, Relay 3

LED mode

LED intensity

Inhibit timeout period

Set access PIN

Refer to the Mobile App section of this manual for more instructions and guidance on installation, commissioning and maintenance.

NOTE

When used with a Touchpoint Pro controller, the positive and negative suppression values must be set correctly otherwise the controller

will report a detector fault. Similarly, when used with a Touchpoint Plus controller, the upper and lower deadband values must be set up.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 38

7.5Delay Time

A delay time is used to minimize the possibility nuisance alarms and/or when immediate response is not required.

The delay time setting should be assessed with regards to the following:

• Searchzone Sonik proximity to monitored object/area or to the source of ultrasonic noise

• The gas type being monitored and the potential severity of a resultant leak

• Existing site protocols and local regulations

The Searchzone Sonik raises two types of alarm:

1) Alarm 1 − suspected alarm activated instantaneously after the measured sound pressure level exceeds the alarm threshold, and

is maintained above the Alarm 1 level. At this point, the delay time is applied. If Alarm 1 is still active after the delay time has passed,

Alarm 2 is activated.

2) Alarm 2 − confirms Alarm 1. Following activation of Alarm 1, the delay timer starts. If an alarm signal is still present after this time

then Alarm 2 is activated.

The delay time is set by user within range from 1 to 600 seconds. Refer to the Mobile App section of this manual for more instructions.

7.6Background Noise Rejection

387 Commissioning / First Time Operation / Configuration

Use the Searchzone Sonik Mobile App to select between Standard and Focus background noise rejection algorithms.

Refer to the Mobile App section of this manual for more instructions.

7.7Performance Verification

Note

Be aware of other ultrasonic gas leak detectors that may be within range before performing any performance verification. To minimize

the risk of nuisance alarms, inhibit those detectors where appropriate.

Testing Using Air Cylinder

Use a small canister of compressed air, operated in the vicinity (maximum 5 m of the Searchzone Sonik detector) to test the operation of

the detector.

WARNING

Manipulation of compressed gas cylinders is potentially hazardous and should only be performed by trained

personnel.

Ensure safety measures are taken in the workplace.

Ensure compliance to local regulations and laws.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 39

8 Operation

8.1Operation

This chapter describes the operation of Searchzone Sonik in different states (Normal, Alarm, Fault, Periodic Test).

8.2Status Signalling

Searchzone Sonik utilizes several outputs to indicate its status, namely the high visibility indicator, the mA Loop, relays and digital

communication interfaces (Bluetooth, HART and Modbus). The following sections describe the instrument behaviour.

8.2.1Visual Status Indicator

NOTE:

The visual status indicator is not considered a safety output. Its behaviour is configurable and may indicate different states than other

outputs.

Searchzone Sonik is equipped with a high visibility LED status indicator the function of which is to visually indicate the status of the

instrument. See the following table for behaviour configuration information:

398 Operation

Operation without

Bluetooth

Fault Yellow Yes Default

Inhibit Yellow No Default

Warning Yellow Yes Default

Normal Green No Default

Normal Green Yes Optional

Normal None No Optional

Alarm Red Yes Default

Over-range Red Yes Default

Operation with

Bluetooth

Fault Yellow Yes Default

Inhibit Yellow No Default

Warning Yellow Yes Default

Normal Blue No Default

Normal Blue Yes Optional

Alarm Red Yes Default

Over-range Red Yes Default

Connecting Blue Yes Default

Connected Blue No Default

Warning Blue alternating No Default

Colour Flashing Setting

Colour Flashing Setting

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 40

408 Operation

8.2.2mA Loop Status

The Searchzone Sonik is equipped with a 420 mA loop output which can operate in source or sink mode. Source and sink modes are

configured by wiring. For more information see the wiring diagram in Electrical Installation section. This output is a safety-related output

and is compatible for use in SIL 2 applications. Normal operation and alarm conditions are indicated between 4 to 20 mA, depending

on configuration.

The mA Loop offers two modes of operations:

1) Proportional to the detected sound pressure level.

2) Discrete, where the output will switch between distinct levels, based on detector status.

Fault and Inhibit indications are signalled with values lower than 4 mA, Over-range indications are signalled with value higher than

20 mA. Output levels of the 420 mA loop are configurable,

See the following table for output levels:

Mode Default Value (mA) Min Value (mA) Max Value (mA)

Discrete Mode Proportional Mode

Fault 1 0 3.6

Inhibit 2 1 3.6

Warning 3 1 4

Normal 4 Proportional to

sound pressure

level

Pre-alarm 16 Not available 4 20

Alarm 20 Not available 4 20

Over-range 21 20 22

4 20

8.2.3Relay Signalling

The Searchzone Sonik is equipped with three independent relays, designated for Fault, Alarm1 and Alarm2. These relays are safetyrelated outputs and are compatible for use in SIL1 applications. The Fault relay is used for indication of various fault conditions; the

Alarm1 and Alarm2 relays are used to indicate alarm conditions. All the relays are configurable, giving an option of Normally Energised

/ De-energised and latching / non-latching of events.

CAUTION

Fault relay will be triggered when user performs Inhibit operation.

8.3Normal Operation

During normal operation, the 420 mA output represents 0 100% sound pressure level range, depending on the selected mode and

the SPL level.

The output is:

1) Linear within the range of SPL in Proportional mode

2) 4 mA in Discrete mode

Analog outputs lower than 4 and higher than 20 mA represent diagnostic information. The fault relay in this mode is normally energized

and the visual indicator is lit steady green.

8.4Operation During Fault

If Fault is indicated the visual indicator starts to flash in yellow, the fault relay is de-energized and 420 mA loop is set to 1 mA.

NOTE:

HART communication requires >1 mA current output to support transmission. If the fault level is configured to be below 1 mA, HART

communications will cease.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 41

418 Operation

8.5Operation During Alarm

Searchzone Sonik features three levels of alarm. PreAlarm, Alarm and Overload.

8.5.1Pre-alarm

During PreAlarm, the Alarm1 relay is energized/de-energized depending on its configuration. The 420 mA loop is set to 16 mA in

Discrete mode. It is proportional to the sound pressure level (SPL) in Proportional mode. The visual indicator flashes red.

8.5.2Alarm

During Alarm, the Alarm2 relay is energized/de-energized depending on its configuration. The 420 mA loop is set to 20 mA in Discrete

mode. It is proportional to SPL in Proportional mode. The visual indicator flashes red.

8.5.3Overload

Searchzone Sonik indicates Overload when an exceptionally high SPL is detected (>140 dB). During Overload, the Fault relay is

additionally energized/de-energized depending on its configuration. The 420 mA loop is set to >20 mA in both Discrete mode and

Proportional mode. The visual indicator flashes red.

Searchzone Sonik indicates Fault for thirty seconds after the Overload condition is no longer detected.

Note

Searchzone Sonik logs 10 minutes of recording for each of the last 5 verified alarms. The 10 minutes are divided into 5 minutes before

and 5 minutes after the alarm.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 42

9 Mobile App

9 Mobile App

The Searchzone Sonik App is an Android-based mobile application that is used to configure and commission

Searchzone Sonik detectors.

CAUTION

The Searchzone Sonik App has been designed and tested to run on the Ecom SmartEX 01

mobile phone. Operation on other mobile devices is possible.

9.1General User Access

There are three methods of accessing detector from the mobile device:

1) Normal access. The user is registered and associated with the company account to which the detector is registered,

and has Internet access.

2) Off-line access. The user is registered and associated with the company account to which the detector is registered,

but has no Internet access at the time of connection. The user must periodically log in to the App when Internet

access is available, to maintain the security certificate.

3) Ad-hoc access. The user is registered, but not with the company account associated with the detector. The user

must have access to the detector Serial Number and Activation Key in order to access the detector. This access is

only available when no Internet connection is available, or the device’s Internet access has been disabled. This type

of access is not intended for normal day-to-day use.

42

Access should be granted only to suitably trained and accredited engineers.

A user of the system is able to:

1) Commission (set-up) the Searchzone Sonik – the App connects to the detector using Bluetooth and takes the user

to the commissioning work flow.

2) Create and manage other users. The App allows user to access the user management features after successful

authentication and login.

9.2Terminology

Admin User The user who initially creates a Company account and registers

a detector to that account is created as an Admin user for the

company.

An Admin user can invite further individuals as users, using the

App. The new users will become Admin users once they have

been validated.

Visitor A user who creates an account but does not register a detector

remains a Visitor.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 43

9 Mobile App

9.3Communications

User creation requires the Sonik Searchzone App to be installed on a suitable Android device featuring Bluetooth and

an Internet connection.

9.3.1Company Account Management

The Initial Admin User is considered the first user who is registered that will go on to create a Company group. Once

done, they will then be able to create and invite subsequent users to that Company group.

In order to create this initial Admin user, they will need to register at least one Searchzone Sonik detector with their

account. The account creation will not be completed until this is done.

Note

It is not possible for an existing user to be added to a new Company Group. Please use the Add User function in the

User Management section of the App to add additional users to the Company group, using a new email address.

Note

Once the user is registered on ums.honeywell.com, they can use the same credentials (and Company Group) to access

other Honeywell Industrial Safety products.

43

9.3.2Creating a New Company Account

Use the following method to create a new Company Account and Administrator. To add a new user to an existing

account, use the method described in section 9.3.2.3 Adding Further Users to Company Account

To create a new Company Account, you will be required to provide an email address, which will become your unique

user name for the account.

Enter the following data:

• First name

• Last name

• Email address

• Password

The password must contain:

- at least 8 characters

- at least 1 upper case character (AZ)

- at least 1 lower case character (a-z)

- at least 1 digit (09)

- at least 1 special character

The password must NOT contain:

- the account name itself

- a consecutive string of three or more repeated characters (e.g.,

AAA1111)

- the names (or abbreviations) of months or the weekdays (e.g., JAN,

MON, etc.)

After you have entered all the required information, tap on ‘CREATE ACCOUNT‘ button. This will trigger the

Verification Email to be sent to the email address that was given for that user.

A verification email will be sent to the given email address within 15 minutes. You must respond to the email within

24 hours before it expires.

Open this email and click on the verification link on any suitable device (i.e., PC, tablet or smartphone). You will then be

directed to a web page where you will need to re-enter the password chosen on the Account Creation page. Click or tap

on OK.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 44

9 Mobile App

Return to the Searchzone Sonik App. The UMS will automatically complete the account verification process.

Note

The verification link will expire after 24 hours. After this has passed, repeat the steps in section 9.3.2 and a new

verification link will be sent to the nominated email address.

44

9.3.2.1First Detector Registration

If the Company Account being created is the Initial Admin User for a company group, you must register

at least one Searchzone Sonik detector in order to complete the User Registration. Refer to section

9.4 Detector Registration on how to do this.

9.3.2.2Security Certificates

Each user requires a valid certificate to be loaded on each mobile device used to access Searchzone Sonik

detectors. The certificate is valid for 365 days. A new certificate is automatically downloaded each time

you log into the App as long as there is a connection to the Internet.

Once the certificate is downloaded, you will then be

prompted to register a detector to fully enable the

features of the Searchzone Sonik App.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 45

9.3.2.3Adding Further Users to Company Account

When authenticated, new users will have the same administrative rights as the Initial User and will be able

to access all detectors already registered, in addition to being able to register further detectors.

Advise the new user that they will receive an authentication email, and ensure that they are able to respond

to the email within 24 hours. Agree an initial password.

Navigate to the ‘SETTINGS’ menu, go to ‘User Management’ screen in the Searchzone Sonik App and tap

on the ‘+’ button in the top right-hand corner.

Enter the user’s email address, First Name, Last Name and the initial password. Tap on the ‘ADD USER’

button. The user will receive a confirmation email, normally within 15 minutes.

They will need to click on the link in that e-mail and they be directed to a web page where you will need to

re-enter the password chosen on the Account Creation page. Tap on ‘OK’.

That user will then be able to log in to their account.

Repeat this process to add further users.

Refer to section 9.11 User Management for more information.

9.3.2.4Completing the Account Setup

Once you have successfully set up the account, you and

the users that you have added will be able to access all of

the detectors that you have registered against it.

9 Mobile App

45

9.3.2.5Logging In to Searchzone Sonik App (with Internet Connection)

Connect to the Internet and log in to the App. Open the App on your mobile device and enter the email

address and password for your account.

Your certificate will be automatically updated and a confirmation message shown.

You will be presented with the Home Page with three key options:

Search for detectors (DETECTORS)

View and manage reports (REPORTS)

View and manage app settings (SETTINGS)

Navigate to the required function by simply tapping on it.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 46

9.3.2.6Logging In to Searchzone Sonik App (without Internet Connection)

If your mobile device is not connected to the Internet, you can still log in to the Searchzone Sonik App and

access registered detectors. You must have previously carried out at least one normal login (see section

9.3.2.5), with an Internet connection.

Your security certificate will remain valid for 365 days, allowing you to login off-line. When this period

expires you will need to log in again with an Internet connection to update your security certificate. You

will not be able to access settings or detectors until the security certificate has been updated.

9.3.2.7Forgotten Password

Go to the login screen.

Tap on ‘Forgot your password?’.

Enter the email address provided during the creation of the

account and tap on ‘Continue’.

Check your email inbox for the password reset link and

instructions.

9 Mobile App

46

Follow the instructions and reset your password.

9.3.2.8Changing Password

Go to the main menu and tap on the avatar icon to access

account details.

Alternatively, choose Settings / User Management /

Account Details.

Tap on ‘CHANGE PASSWORD’.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 47

9.3.2.9Detector Registration

To register a detector:

• Ensure that you have an Internet connection.

• Ensure that you have the serial number of the detector you wish to register together with either the

Activation Key or the activation QR code.

The Activation Key and QR code may be obtained from:

• The Registration Sheet supplied with detector

• Site records

• The label inside detector wiring compartment

• By contacting your Honeywell Customer Support

Tap on the preferred method for entering this information

and then either enter the Serial Number and Activation

Key manually or scan the QR code as applicable.

Your security certificate will then be updated and you will

now be able to access this detector.

To register further detectors, tap on ‘SETTINGS’ from the

home screen and tap on ‘Detector Registrations’. Tap on

the ‘+’ icon in the top right-hand-corner of the screen and

repeat the process above.

9 Mobile App

47

Note

If the registration of the Searchzone Sonik detector fails, it may be for several reasons:

1) the detector is already registered to another company

2) the detector does not exist

3) the Activation Key is already in use

4) the Activation Key and/or Serial Number is not valid

9.4Connecting to Detectors

9.4.1How to Connect to a Searchzone Sonik Detector

This section assumes that the Searchzone Sonik detector has been already registered to the company

account. If it has not, then read section 9.4.2 Making an Ad-Hoc Connection to the Detector.

After logging into the Searchzone Sonik mobile App, you

can use Bluetooth to search for Searchzone Sonik detectors

that are in range. If Bluetooth is not switched on, the App

will prompt the user to switch it on.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 48

The App lists only Searchzone Sonik detectors positioned

within range. Other Bluetooth devices are ignored.

Tap on ‘DETECTORS‘.

9 Mobile App

48

To sort the list of detectors, tap on the MENU icon and then

tap on ‘Detector List’.

Select one of the detectors in the list to establish a

connection to it.

You can sort the detector list based on:

• Detector status

The selected detector’s high visibility status indicator will be

flashing blue, indicating that it is establishing a connection

to the Searchzone Sonik mobile App.

Tap on the ‘CONFIRM DETECTOR’ button to complete the

connection process.

Note

If the connection process is not completed within 30

seconds, the connection to the detector will be terminated.

Restart the connection process and try again.

Searchzone Sonik − Technical ManualPN 2331M1220 Issue 1 11/2018

Page 49

After successfully connecting to the detector, you will be

prompted to enter a 4-digit access PIN .

CAUTION

If logging in for the first time, you must set a new

PIN by clicking on ‘set new access PIN’.

9.4.2Making an Ad Hoc Connection to the Detector

9 Mobile App

49

If normal connection to a detector is not possible, a temporary ad-hoc connection can be established as

follows:

1. Obtain the Activation Key and Serial Number of the detector. The Activation Key may be obtained from:

The registration sheet supplied with that detector

Site records

The label inside detector wiring compartment

By contacting your Honeywell Customer Support

2. Ensure the mobile device is NOT connected to the Internet. Disconnect it from WiFi and from the mobile

data. The easiest way to do this is to place the mobile device into Airplane Mode.

3. Switch on Bluetooth on the mobile device.

4. Log in to the Searchzone Sonik mobile App.

5. Tap on ‘DETECTORS’ to search for Searchzone Sonik detectors in range.

6. Select the desired Searchzone Sonik detector.