Page 1

Operating Instructions

Searchpoint Optima Plus

Infrared Point Gas Detector

Page 2

MAN0551 Issue 07 - 09/08

2108M0501

TOTAL ENVIRONMENTAL SOLUTIONS

Ensure that you read and understand these Operating

Instructions BEFORE installing or operating any part of the

Searchpoint Optima Plus.

Please pay particular attention to the Safety Warnings.

WARNINGS

1. For installations in the UK, the Code of Practice

SELECTION, INSTALLATION AND MAINTENANCE

OF ELECTRICAL APPARATUS FOR USE IN

POTENTIALLY EXPLOSIVE ATMOSPHERES should

be strictly observed. General recommendations are

given in BS5345: Part 1: 1989. Specic requirements

for ameproof (Type 'd'), intrinsically safe (Type 'i')

and increased safety (Type 'e') protection are given

in BS 5345: Part 3: 1979, BS 5345: Part 4: 1977 and

BS5345: Part 6: 1978 respectively.

For installations in North America, the National

Electrical Code (NFPA 70 - 1990) or later issues

should be strictly observed.

Elsewhere the appropriate local or national

regulations should be used.

2. The Code of Practice regarding SELECTION,

INSTALLATION, USE AND MAINTENANCE

OF APPARATUS FOR THE DETECTION AND

MEASUREMENT OF COMBUSTIBLE GASES

(OTHER THAN FOR MINING APPLICATIONS OR

EXPLOSIVES PROCESSING AND MANUFACTURE)

must be complied with. Refer to BS6959:1988 in the

UK or the appropriate local or national regulations.

3. Operators must be fully aware of the action to be

taken if the gas concentration exceeds an alarm

level.

2

Page 3

MAN0551 Issue 07 - 09/08

2108M0501

TOTAL ENVIRONMENTAL SOLUTIONS

CAUTIONS

1. Use only approved parts and accessories with the

Searchpoint Optima equipment.

2. To maintain safety standards, a planned maintenance

programme is strongly recommended. This

maintenance programme should take account of all

operational conditions and requirements. Maintenance

and service operations should only be performed by

personnel qualied to work upon Searchpoint Optima

Plus.

3. In order to maintain electrical safety, the unit must

not be operated in atmospheres with more than 21%

oxygen.

IMPORTANT NOTICES

1. Honeywell Analytics Limited can take no responsibility

for installation and/or use of its equipment if this is not

done in accordance with the appropriate issue and/or

amendment of the manual.

2. The user of this manual should ensure that it is

appropriate in all details to the exact equipment to be

installed and/or operated. If in doubt, the user should

contact Honeywell Analytics Limited for advice.

3. If further details are required which do not appear in

this manual, contact Honeywell Analytics Limited or

one of their agents.

4. The Searchpoint Optima System is certied for and

intended for use in potentially hazardous areas.

Install and use the Searchpoint Optima System in

accordance with the latest regulations.

Honeywell Analytics Limited reserve the right to change

or revise the information supplied in this document

without notice and without obligation to notify any person

or organisation of such revision or change.

3

Page 4

MAN0551 Issue 07 - 09/08

2108M0501

HELP US TO HELP YOU

Every effort has been made to ensure the accuracy in the

contents of our documents, however, Honeywell Analytics

Limited can assume no responsibility for any errors or

omissions in our documents or their consequences.

Honeywell Analytics Limited would greatly appreciate being

informed of any errors or omissions that may be found in the

contents of any of our documents and to this end we include

the form opposite for you to photocopy, complete and return

to us so that we may take the appropriate action.

4

Page 5

MAN0551 Issue 07 - 09/08

2108M0501

5

Page 6

MAN0551 Issue 07 - 09/08

2108M0501

CONTENTS

Section Page

1. INTRODUCTION 10

1.1 General 10

2. INSTALLATION VARIATIONS 14

2.1 ATEX Units 14

2.2 UL and CSA Units Only 15

3. INSTALLATION 17

3.1 Unpacking 17

3.2 Siting and Orientation 17

3.3 Installation Guide 18

3.4 Attachments and Options 22

3.4.1 General 22

3.4.2 Standard Weather Protection 22

3.4.3 Sunshade/Deluge Protection 22

3.4.4 Storm Bafe 23

3.4.5 Dust Barrier 23

3.4.6 Calibration Cap 24

3.4.7 Gassing Cover 24

3.4.8 Flow Housing 25

3.4.9 Remote Gassing Cell 26

3.4.10 Junction Box Adaptor Plate 27

3.4.11 European Duct Mounting Kit 28

3.4.12 US Duct Mounting Kit 31

6

Page 7

MAN0551 Issue 07 - 09/08

2108M0501

CONTENTS

Section Page

4. ELECTRICAL CONNECTIONS 35

4.1 General 35

4.2 Analogue Connection 40

4.3 Digital Connection 40

4.4 +24V Power Connection 41

4.5 Earth Connection 41

5. COMMISSIONING 46

5.1 General 46

5.2 Commissioning Procedure using SHC-1

and Multimeter 47

5.2.1 Electrical Commissioning and Tests 47

5.2.2 Gas Response Testing 48

5.2.3 System Level Testing 49

5.2.4 Final Commissioning 51

5.3 Commissioning Procedure with Multimeter

Only 52

5.3.1 Electrical Commissioning and Tests

(Multimeter) Only 52

5.3.2 Gas Response Testing (Multimeter)

Only 54

5.3.3 System Level Testing 55

5.3.4 Final Commissioning (Multimeter) 56

5.4 Control System Setup 57

5.5 Functional Response Checking and

Calibration 57

7

Page 8

MAN0551 Issue 07 - 09/08

2108M0501

CONTENTS

Section Page

6. CALIBRATION 59

6.1 General 59

6.2 SHC-1 Hand-Held Interrogator 60

6.2.1 Connecting the Hand-Held

Interrogator 61

6.2.2 Hand-Held Interrogator Operating

Modes 62

6.2.3 Other Hand-Held Features 66

6.3 Calibrating the Controller 70

6.4 Calibrating the Sensor 73

7. ROUTINE CHECKS 81

7.1 General 81

7.2 Inspection and Functional Response Check

Procedure 81

7.2.1 Response Check Using Gassing Cover

and %LEL Concentration Gas 83

7.2.2 Response Check Using Remote

Gassing Cell & High %VV Gas 87

7.3 Inspection and Testing of Units Installed

in Ducts 92

7.4 Removal and Retting of Flow Housing 94

7.4.1 Removal of Flow Housing 94

7.4.2 Retting of Flow Housing 94

8

Page 9

MAN0551 Issue 07 - 09/08

2108M0501

CONTENTS

Section Page

8. FAULT FINDING 97

8.1 Troubleshooting 97

8.2 Diagnosis of Warning and Fault Messages 103

9. REPLACEMENT OF HAND-HELD

INTERROGATOR BATTERY 111

10. ORDERING DETAILS 113

11. SPECIFICATION 117

11.1 Searchpoint Optima Plus Specication 117

11.2 Cross Interference to Other Gases and

Vapours 124

11.3 Hand-Held Interrogator SHC-1

Specication 125

11.4 SHC Protection Device 126

11.5 Termination Unit DVC100 Specication 127

11.6 DX Termination Units Specication 128

12. CERTIFICATION DETAILS 130

13. WARRANTY 137

9

Page 10

MAN0551 Issue 07 - 09/08

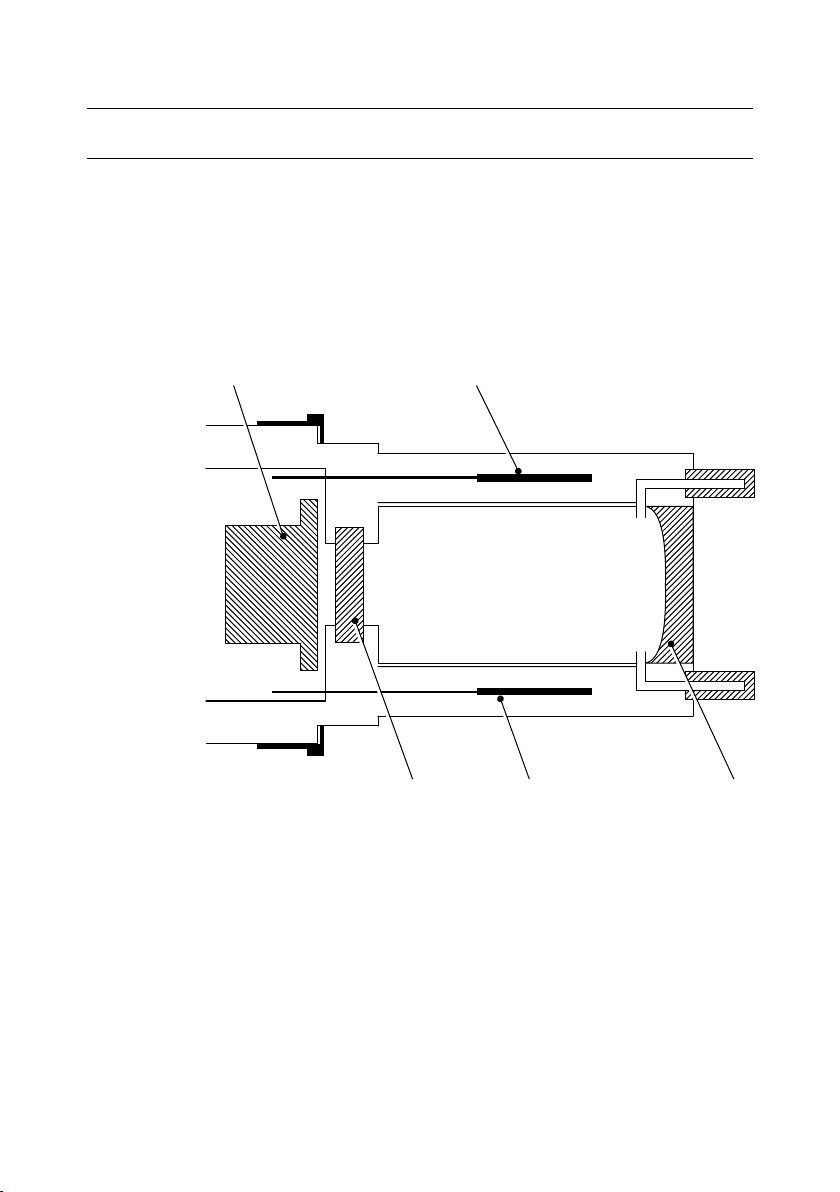

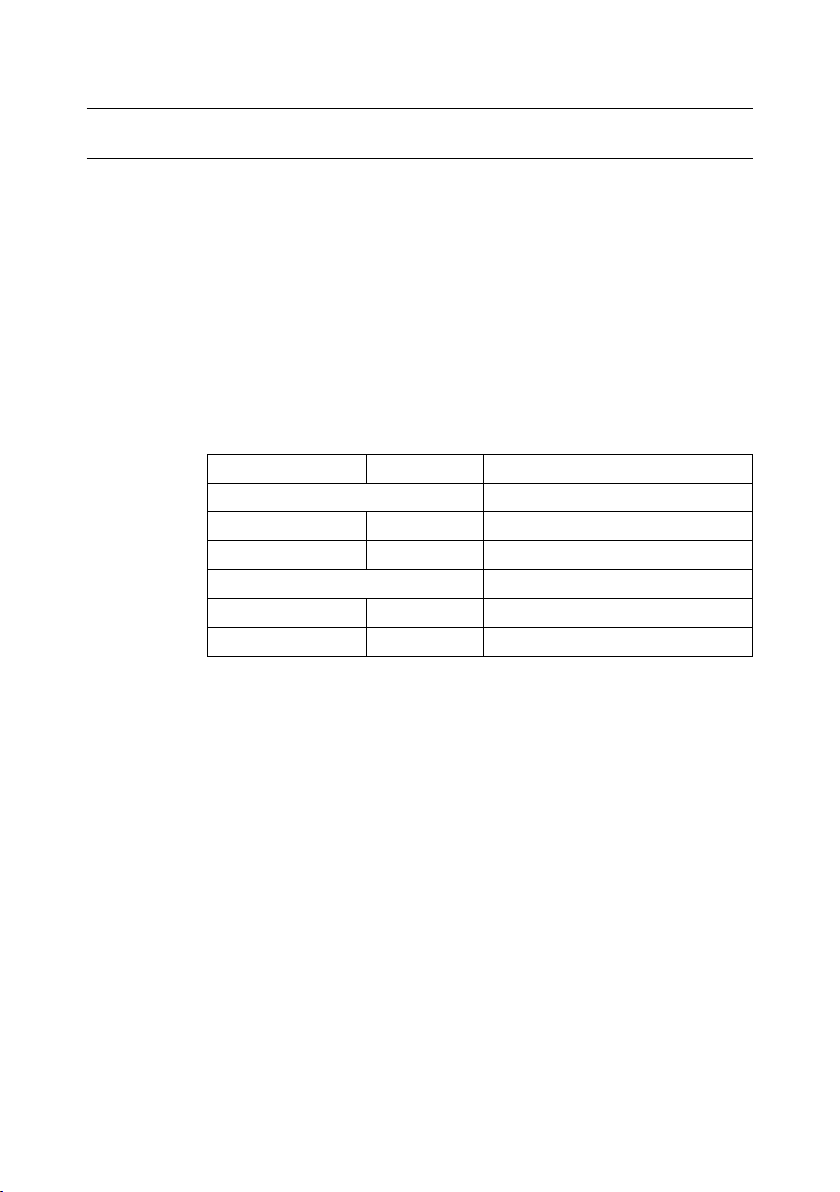

Optical Block

WindowHeaterMirror

Heater

Gas Measuring Path

2108M0501

1. INTRODUCTION

1.1 GENERAL

Searchpoint Optima Plus is designed for use in potentially

hazardous areas where it provides gas and vapour

detection which is free from poisoning and independent

of the presence of oxygen. The gas measuring parts of

Searchpoint Optima Plus are illustrated below.

Searchpoint Optima Plus uses the dual wavelength infrared

absorption principle to detect hydrocarbon gases and

vapours in various concentration ranges. The instrument

measures the number of molecules of the target gas in the

light path, which depends on the concentration of the target

gas. In addition to the relatively long and open measuring

chamber, Searchpoint Optima Plus can be tted with a short

enclosed ow through-cell as part of the chassis.

This is tted with separate inlet and outlet ports and

allows the application of high concentrations of gas for

test purposes.

10

Page 11

MAN0551 Issue 07 - 09/08

2108M0501

1. INTRODUCTION

Searchpoint Optima Plus is a micro-processor controlled,

Infrared Gas Detector with comprehensive built-in self-

diagnostic and fault nding facilities. An analogue 4 to

20mA output and digital communications are provided as

standard. Full two way communication allows calibration

and advanced self checking procedures to be used. To take

advantage of these features a Hand-Held Interrogator unit

may be connected to a Termination Unit or via the SHC

Protection Device to other junction boxes.

There are several different types of termination unit available:

Termination Unit Certication Output

DVC Type Termination Units

DVC100 (I) MK2 ATEX Isolated 4-20mA

DVC100 (M) MK2 ATEX Isolated 4-20mA and MODBUS

DX Type Termination Units

DVC100 (I) UL Isolated 4-20mA

DX100 (M) UL Isolated 4-20mA and MODBUS

Searchpoint Optima Plus contains no moving parts and

is available in a robust Stainless Steel explosion proof

enclosure which has a M25 (ATEX) or 3/4 NPT (UL and CSA)

mounting thread. The unit operates over a wide temperature

range and has a high degree of protection against dust

and water ingress. It is designed to operate in the most

arduous conditions and is supplied with a choice of weather

protection assemblies.

Searchpoint Optima Plus can be In-Duct Mounted, used

in Sampling Systems, is easily condence checked and

may easily replace an existing sensor. Provided that

existing cabling has three appropriately rated cores and the

installation is correctly screened and earthed, it should not

be necessary to replace the eld cables or junction boxes. (A

current to bridge converter may be required if the controller

cannot be congured to accept 4-20mA signals).

11

Page 12

MAN0551 Issue 07 - 09/08

2108M0501

1. INTRODUCTION

No special tools are required for installation. Correct

function of the detector as installed can be easily conrmed

using a Hand-Held Interrogator. Maintenance amounts to

occasional cleaning, zeroing and response checking for

condence.

12

Page 13

MAN0551 Issue 07 - 09/08

2108M0501

13

Page 14

MAN0551 Issue 07 - 09/08

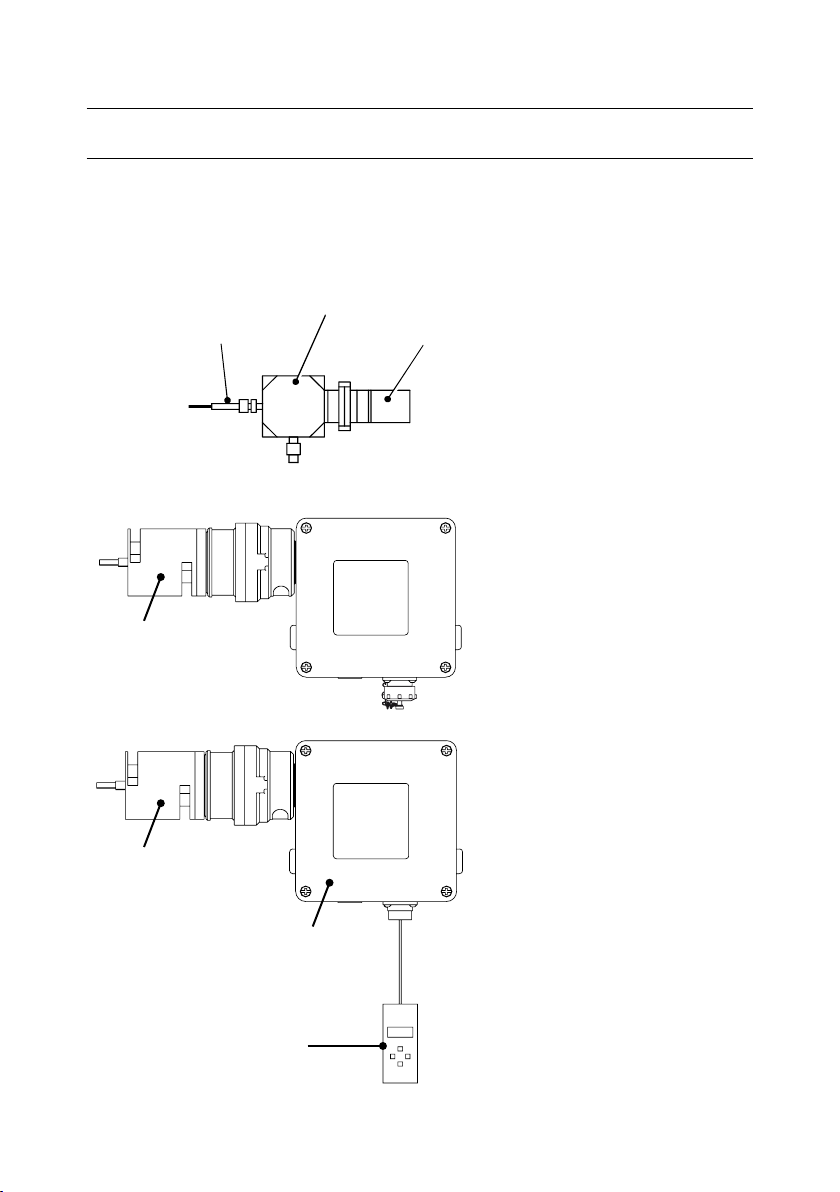

Existing Junction Box

Existing Cable

Optima

2108M0501

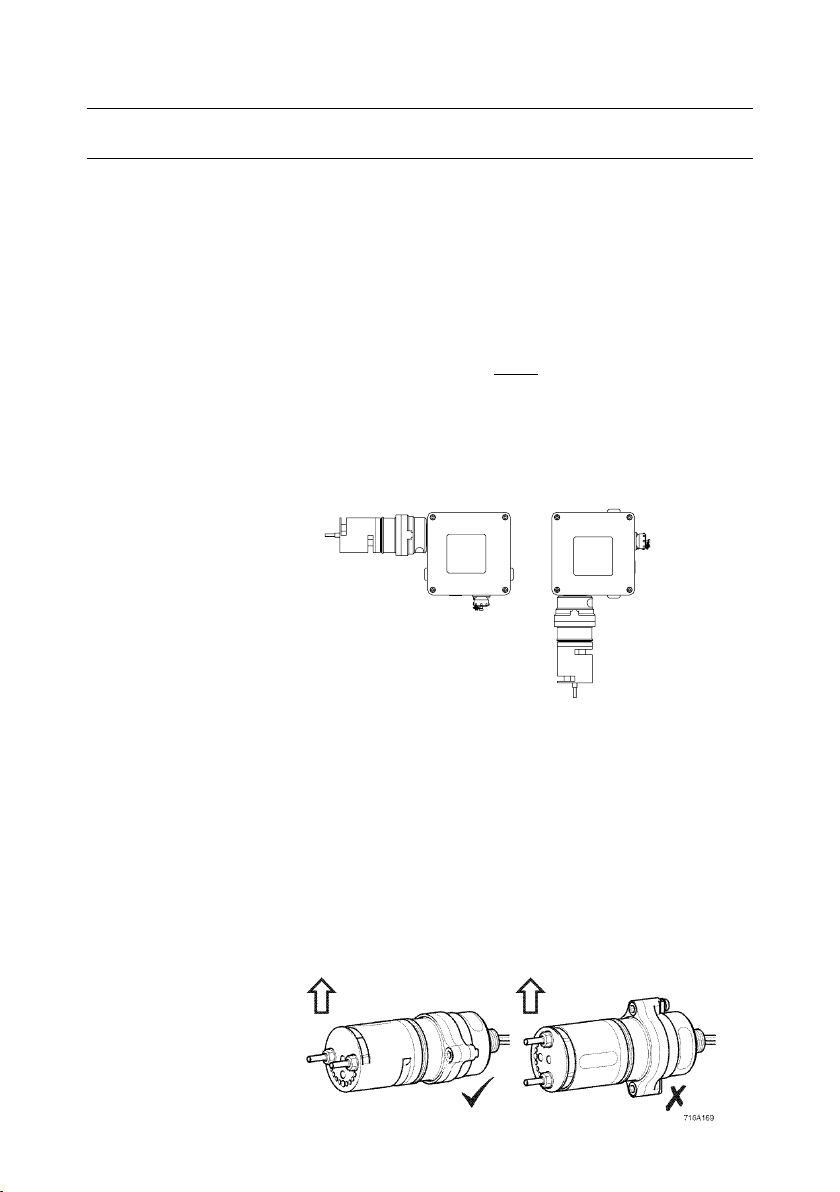

2. INSTALLATION VARIATIONS

2.1 ATEX UNITS

Replacing existing Sensor

using existing Junction Box

and Cable (where suitable).

New Junction Box.

New Installations.

Optima

Optima

DVC Termination Unit

When used for calibration

and diagnostics purposes

the Hand-Held Interrogator

SHC-1 allows digital

communication with the

Optima. It is connected

to the Optima via the IS

Socket on the Termination

Unit DVC100 or via the

SHC Protection Device for

other junction boxes.

SHC-1

14

Page 15

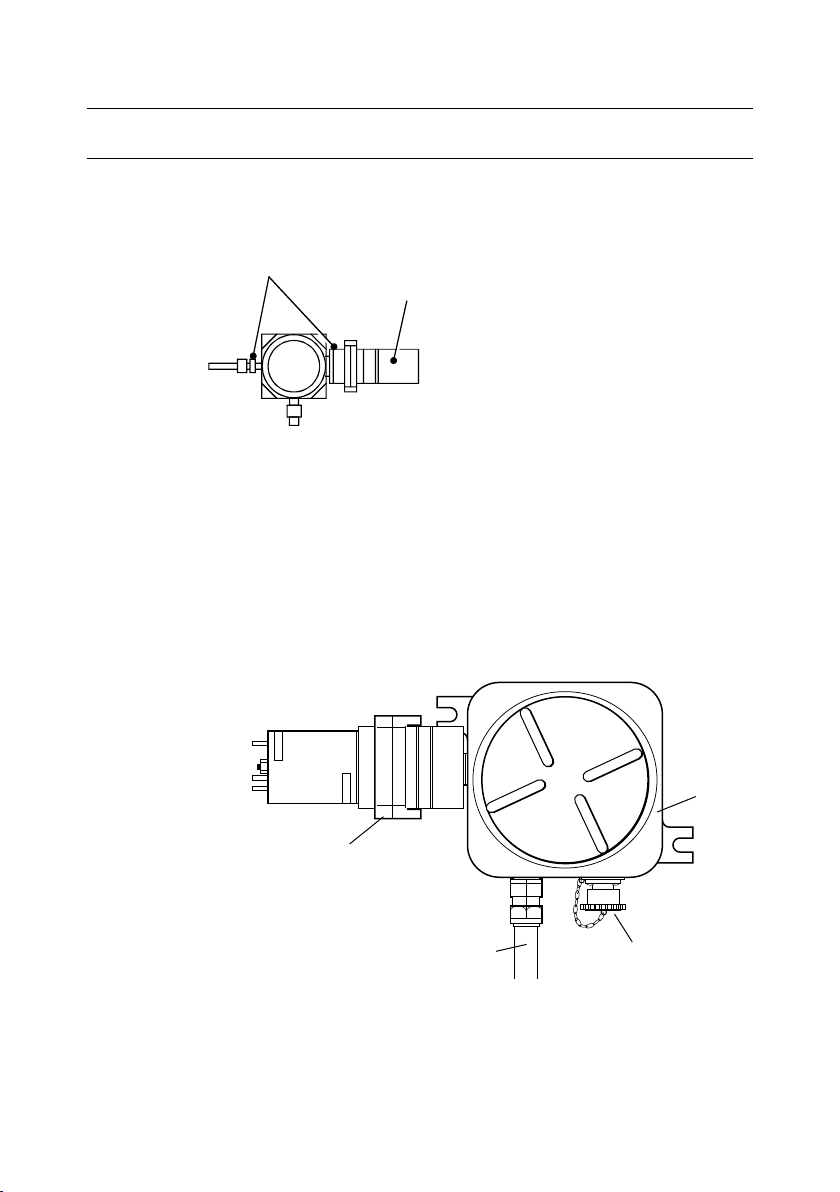

MAN0551 Issue 07 - 09/08

3/4 NPT

Optima

2108M0501

2. INSTALLATION VARIATIONS

2.2 UL AND CSA UNITS ONLY

UL and CSA Installations using

Explosion Proof

Junction Box.

Note: The Junction Box must be suitable for the hazardous

location in which the Optima is installed, check with the

Junction Box manufacturers literature as to suitability of

the box.

Optima

15

Field

Cable /

Conduit

Top

DX

Termination

Unit

Handheld

Interrogator

Socket

Page 16

MAN0551 Issue 07 - 09/08

2108M0501

16

Page 17

MAN0551 Issue 07 - 09/08

2108M0501

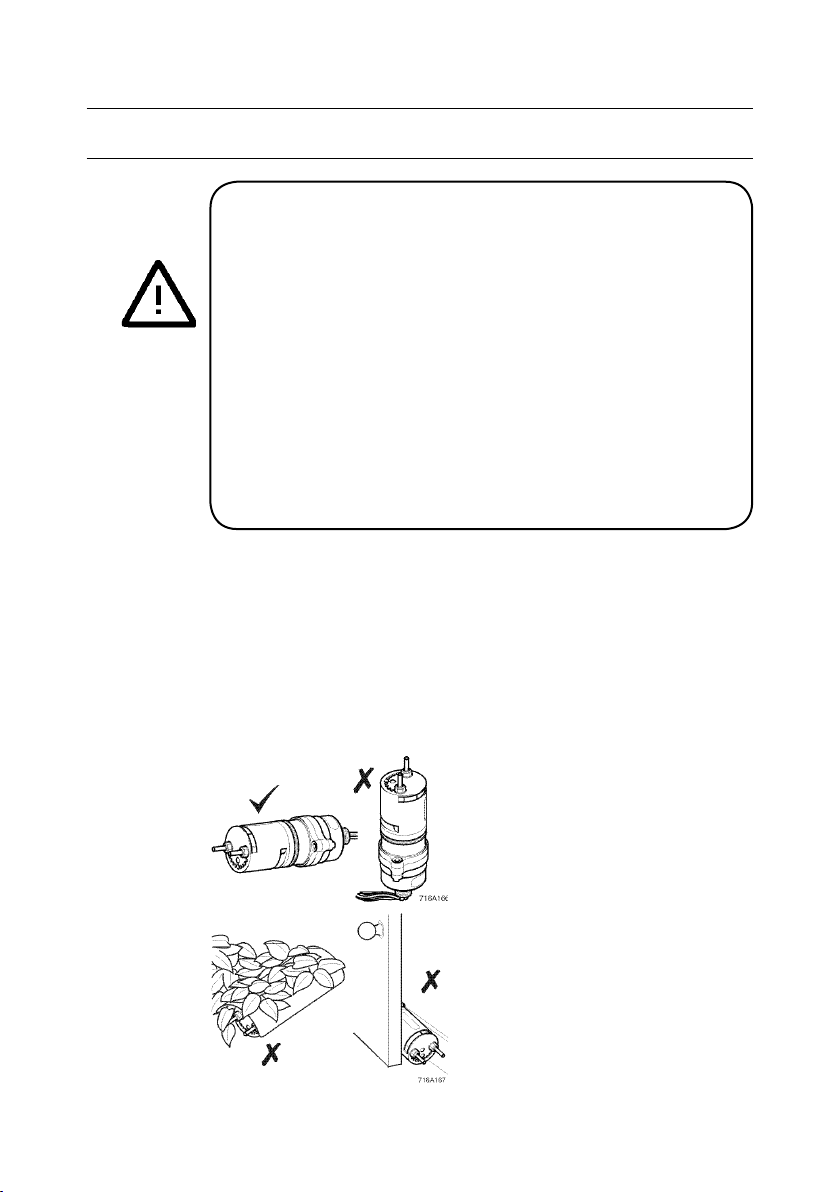

3. INSTALLATION

WARNING

The Code of Practice regarding selection, installation

and maintenance of electrical apparatus for use in

potentially explosive atmospheres must be complied

with at all times.

Notes:1. The flying leads of the Searchpoint Optima Plus

must be mechanically protected and terminated

within a suitable terminal or junction facility.

2. When the detector is terminated in a hazardous

area a suitable UL listed enclosure must be used

(where appropriate).

3.1 UNPACKING

Carefully unpack the equipment, observing any instructions

that may be printed on or contained in the packaging, and

check the contents for transit damage.

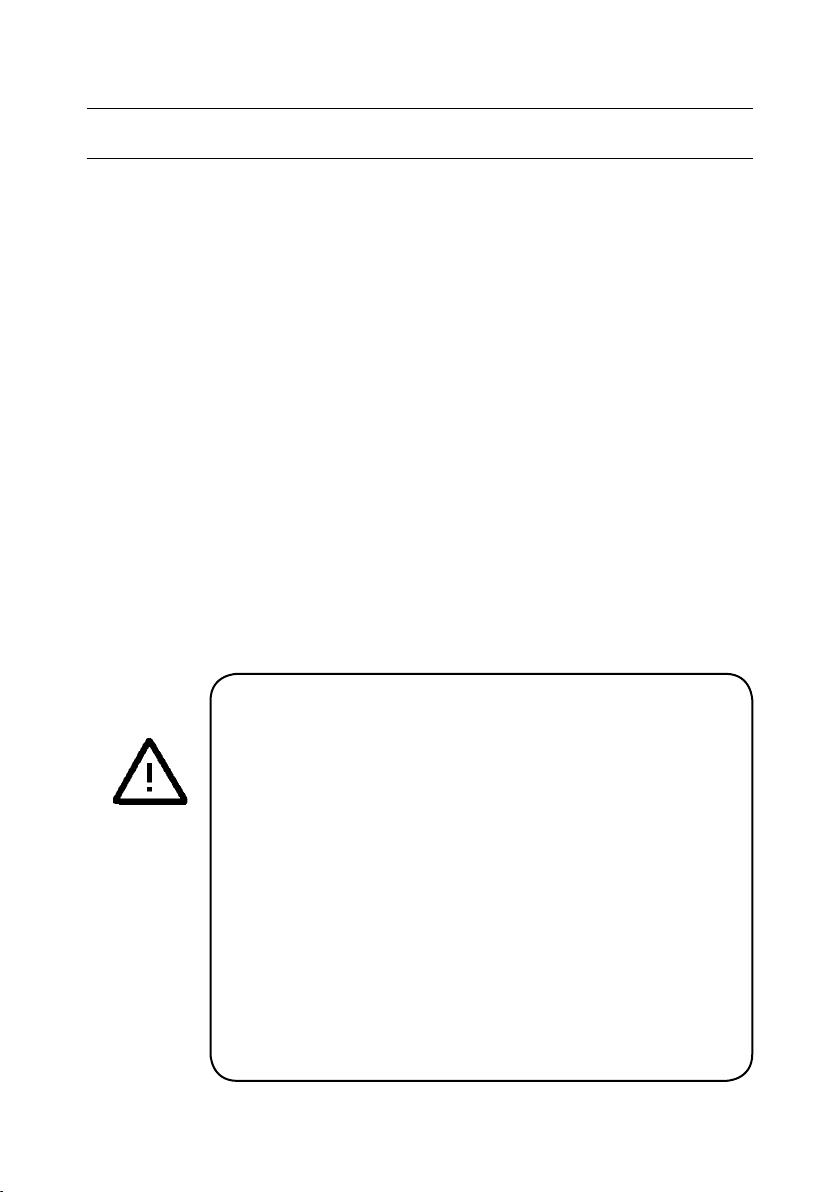

3.2 SITING AND ORIENTATION

Searchpoint Optima Plus must

be mounted horizontally, as

this greatly reduces the risk of

obscuration due to build up of

dirt and moisture on the optical

surfaces.

Ensure the area immediately

surrounding the sensor is free

from objects that could hinder

the free ow of air around it.

17

Page 18

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

For monitoring lighter than air gases, Searchpoint Optima

Plus should be mounted above the area requiring protection.

For monitoring heavier than air gases it should be mounted

below the area to be protected.

When monitoring for heavier than air gases and mounting

the detector close to the oor, give consideration to the

potential of general site debris to build up on the detector.

Whether Searchpoint Optima Plus is installed in a

sheltered or an exposed location, it will require some form

of protection around the optics. The standard weather

protection combined with the sunshade/deluge protection

provides a high degree of protection of the detector, suitable

for many outdoor environments. Detectors operating in very

exposed locations where torrential rain or driven sea-spray

is routinely encountered can benet from the additional

protection provided by the Storm Bafe (2108D0280).

In areas where a high pressure jet may be used at close

range to wash down the surrounding location, it is advisable

to t some means of extra peripheral shielding,

Bafe or a shield plate.

eg. Storm

Accessories and attachments that can be used to improve

ease-of-use, performance and reliability in particular

installations are described in Section 3.4.

3.3 INSTALLATION GUIDE

Note: Installation of Searchpoint Optima Plus does not require

the unit to be opened. There are no user serviceable

parts inside the unit. Do not attempt to open or

dismantle the unit.

(1) Ensure that the correct attachments and accessories

for the application have been tted (see Section 3.4).

18

Page 19

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

(2) Check that the unit's 4-20mA current ouput is of the

correct type for the control card that it is connected to.

(Output type is on a label attached to white lead.)

Control card I/P: SINK Optima O/P: SOURCE

Control card I/P: SOURCE Optima O/P: SINK

(3) Secure the junction box onto the mounting surface,

using the Junction Box Adaptor Plate if required.

Searchpoint Optima Plus must be installed with it's

long axis horizontal in order for the standard weather

protection to operate correctly and to prevent water

from settling on the optical surfaces (see below).

The Optima unit should therefore only be screwed into

a threaded entry that is in a vertical wall of the junction

box.

3 7

(4) Feed the unit's wires carefully through the chosen

junction box entry and offer up it's threaded boss to

the entry. Screw the unit into the junction box until

it is secure and the semi-circular pattern of holes on

the front of the weather protection are on the bottom

(see below). For M25 entries, the boss should go right

through the wall and a locking nut should be tted;

whilst for 3/4 NPT entries, the boss should lock off on

the taper. If getting the holes in the right orientation

requires more rotation than is readily achievable,

remove the weather protection and rotate it through

180 degrees.

19

Page 20

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

(5) Using a multimeter, check that the voltages on the

+24V, and 4-20mA connections with respect to 0V are

less than +32V DC and that there is no 110V or 230V

AC around.

(6) Wire up the unit's electrical connections in

accordance with Section 4, taking note of the general

recommendations upon electrical installation.

(7)

Ensure that all cable entries are either used or plugged

in strict accordance with the relevant certication

requirements and local codes of practice.

(8) Verify the correct installation and operation of the unit

using the SHC-1 handheld interrogator. If a Termination

Unit has been used, testing can be performed without

the need for a hot work permit. Alternatively, if a basic

junction box has been used, electrical connections can

be made to the terminals inside the box using the SHC

adaptor. This will ordinarily require a hot work permit.

CAUTION

1. Searchpoint Optima Plus is certied and specied

for operation in ambient temperatures from -40°C

to +65°C. Operation of the unit outside of this

temperature range invalidates the certication and

the warranty. The unit records a non-erasable fault

log entry if it is operated at temperatures outside of

it's certied range.

If the ambient temperature that the unit could be

exposed to is likely to go outside of the certied

range it is recommended that the unit be located

elsewhere. The use of sampling systems can be

highly effective, especially in applications where

high temperatures are involved.

20

Page 21

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

2. Searchpoint Optima Plus is specied for operation

in environments where the rate of change of unit

temperature is less than 3°C / minute. Exceeding

this rate of change of temperature will cause the unit

to report a fault and may cause permanent damage.

If the conditions experienced by the unit are likely

to cause it to exceed this rate of change it is

recommended that additional preventative measures

are taken. The use of sampling systems is highly

effective; whilst shielding the unit from the prevailing

air ow can also be of benet.

3. Searchpoint Optima Plus has been vibration tested

to the levels specied in EN61779. If the vibration

levels on the installation exceed this, the unit's

reliability and integrity of operation will be degraded.

Do not install units in locations where the vibration

exceeds this level.

4. All optical gas detectors are eventually affected by

the build up of contaminants / condensation upon

their optical surfaces, normally resulting in faults

or warnings. In order to minimise the faults and

warnings caused by this it is recommended that

detectors are located as far away as is possible

from sources of airborne contaminants and steam /

condensation. Alternatively, the tting of shields or

the Storm Bafe (2108D0280) should be considered.

Sources of contamination / condensation that have

caused particular problems where appropriate

measures were not taken include generator / turbine

exhausts, steam lines / vents, drilling operation

(oilmist and mud spray) and unltered HVAC

installations. In dusty atmospheres, regularly check

for the build up of dust on the detector (refer to

section 7 Routine Checks).

21

Page 22

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

3.4 ATTACHMENTS AND OPTIONS

3.4.1 General

There are a number of attachments and accessories

available for use with Searchpoint Optima Plus. When

specifying Optima Plus for a particular application, it is

recommended that the user contacts Honeywell Analytics

or their representatives to determine the attachments and

accessories required. Covers, barriers and bafes provide

protection from a wide variety of environmental conditions.

Gassing covers, cells and ow housings provide the means

of applying gas to the detector. Mounting plates and remote

gassing kits enable the detector to be installed in ducts or in

places where obtaining routine access is difcult.

3.4.2 Standard Weather Protection (2108D0276)

Provides the best compromise

between response time and

protection. Suitable for indoor,

outdoor and duct mounting

applications.

3.4.3 Sunshade/Deluge Protection (2108D0275)

Supplied as standard

for all outside

applications. Provides

additional protection

against heavy rainfall,

wash downs and

direct sunlight.

22

Page 23

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

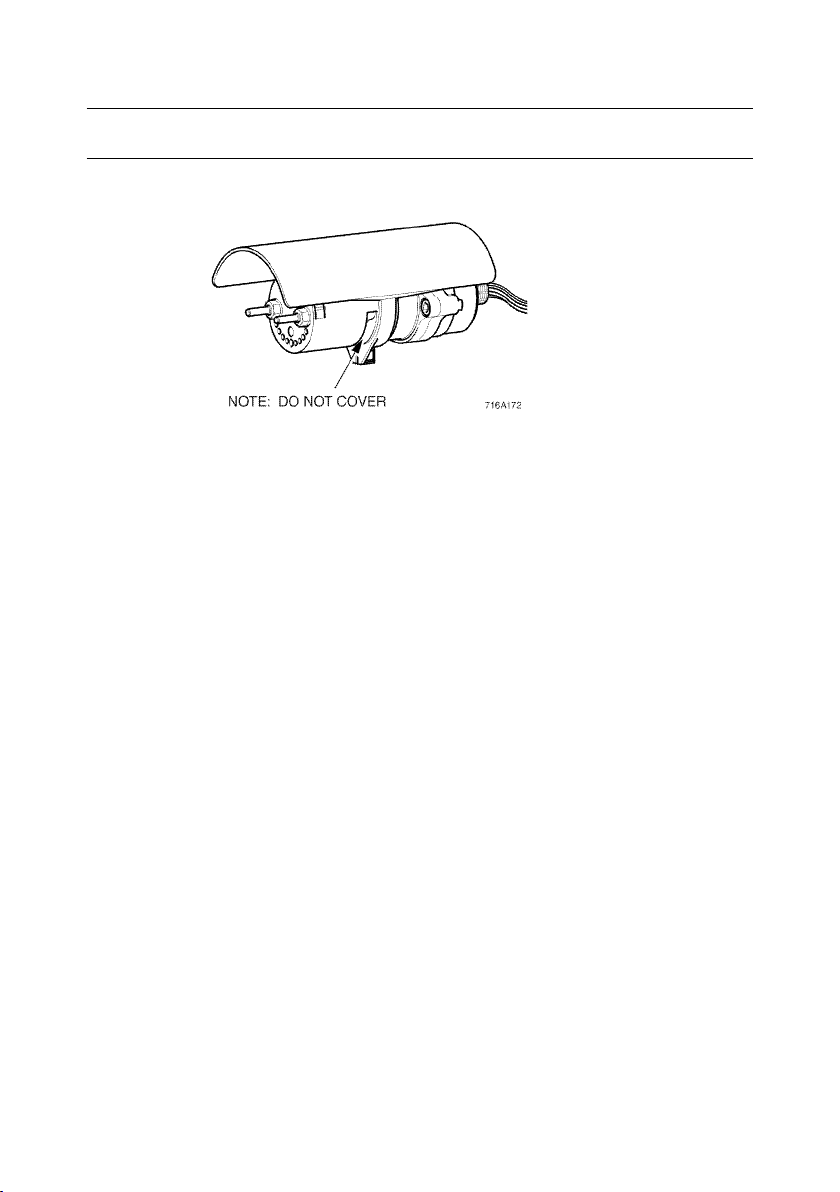

The Sunshade/

Deluge protection

should be clamped

around the base of

the Standard Bafe

Weather Housing with

the longer overhang

extending beyond

the Standard Bafe.

Ensure the clamp

does not cover the

gas venting slot of the

Standard Bafe.

3.4.4StormBafe(2108D0280,NotIllustrated)

The storm bafe provides increased protection against

a variety of environmental conditions and effects. It is

particularly effective against torrential rain and driven

sea-spray and is recommended for exposed installations

in maritime locations or areas where monsoon or tropical

rain conditions are experienced. The storm bafe can be

benecial in installations where steam drifting over the

detector from nearby plant is a problem. The storm bafe

can also be useful in some duct applications where the

inlets are not ltered and where high ow rates result in dirt

build-up or excessive cooling / condensation effects. This

accessory will reduce the detector’s speed of response.

3.4.5DustBarrier(2108D0259,NotIllustrated)

Fits under the standard bafe weather housing to prevent

the ingress of dust or oil mist which could contaminate the

optical surfaces. It also protects the optics in very wet or

exposed locations. This accessory will reduce the detector’s

speed of response.

23

Page 24

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

3.4.6 Calibration Cap (2108D0272)

Used to achieve accurate

calibration of Optima Plus on the

bench. Requires all protective

covers and attachments to be

removed from the measurement

chamber except for the

dust barrier. The calibration

procedures are described in

Section 6.

CAUTION

The Calibration Cap is designed for temporary use on

Optima whilst performing calibration. If the calibration

cap is left tted it will prevent ambient gas from reaching

the detector's measurement chamber. Ensure that

operators are aware that calibration caps must not be

left tted. In order to reduce the likelihood of this mistake

going un-noticed, the calibration caps are coloured red.

3.4.7 Gassing Cover (2108D0258)

Provides a convenient means

of applying gas to Optima Plus

units in the eld. Suitable for

functional test and calibration

purposes. Fits over the standard

weather protection, covering the

gas inlet slots. Gas is introduced

into the weather protection via

an injection tube on the gassing

cover. Injected gas diffuses

through the dust barrier into the

measurement chamber.

The response check procedure

is described in Section 5.4.

24

Page 25

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

CAUTION

The Gassing Cover is designed for eld testing and

calibration operations. If the cover is left tted it will

prevent ambient gas from reaching the detector's

measurement chamber. Ensure that operators are aware

that gassing covers must not be left on detectors.

Gassing covers are coloured red to reduce the likelihood

of this mistake.

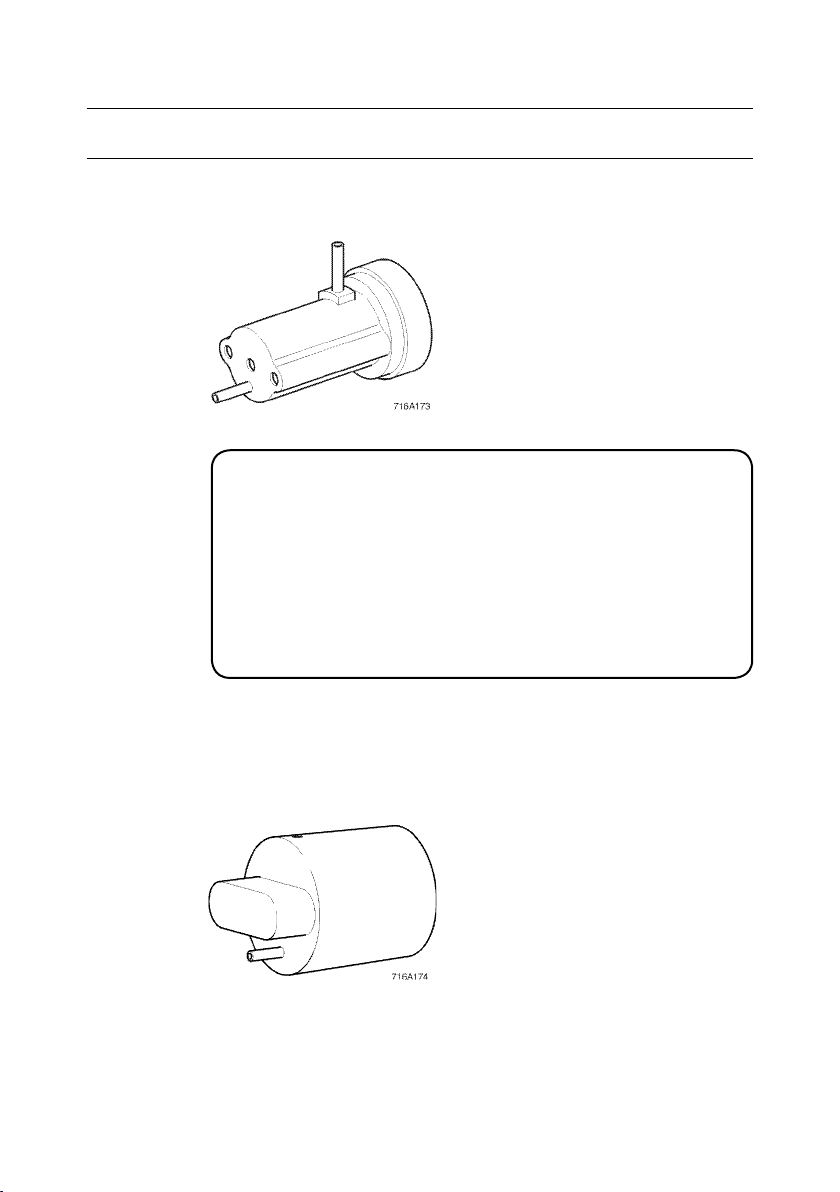

3.4.8 Flow Housing (2108D0282)

For use in sampling system

applications.

The Flow Housing is fabricated

from solvent resistant Anodised

Aluminium.

The nozzles on the Flow Housing

are stainless steel with an outside

diameter of 6mm.

It is advised that sample gases and vapours are sucked

(negative pressure) rather than blown (positive pressure)

through this housing and that sample ow rates do not

exceed 2 litres per minute.

It is recommended that a ow failure indicator is tted

within the sampling system and the minimum ow rates are

suitable for the application and not less than 0.7 litres per

minute.

Note: response time will increase with a decreasing ow

rate.

The commissioning and calibration of an Optima equipped

with a ow housing is described in Sections 5 and 6.

25

Page 26

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

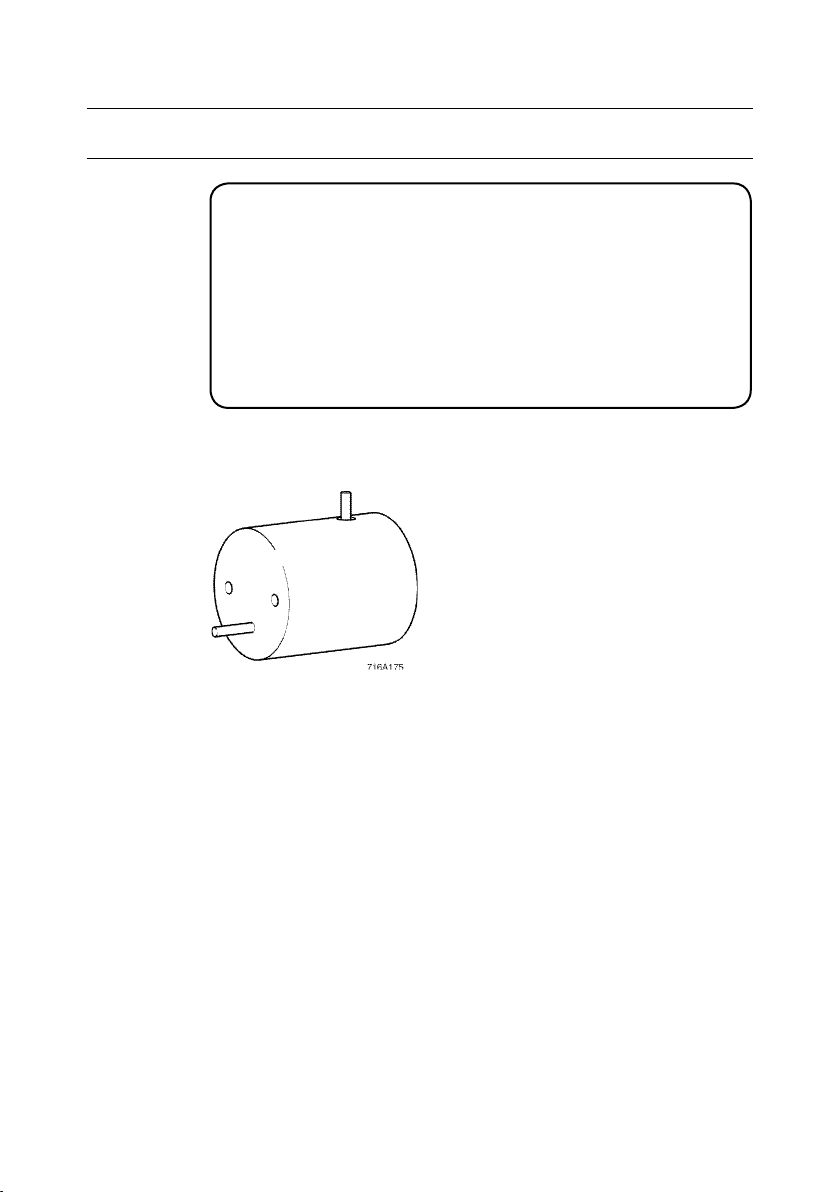

3.4.9 Remote Gassing Cell (2108B0240)

The Remote Gassing Cell (RGC) enables high

%V/V concentration gas to be applied remotely for

performing functional response checks (bump tests).

It is useful for units installed in ducts or in areas

where obtaining access is difcult. The RGC window

can be removed for cleaning.

Note:

During production, Optima Plus units are calibrated

with gas in the main measurement chamber, not in the

RGC. The RGC is not recommended for calibration

or high accuracy calibration testing purposes.

(The only exception to this is where units are being

used to measure high %V/V gases using the RGC as

a flow cell. In this instance, the units are production

calibrated with gas in the RGC.)

In order to avoid pressurisation effects, the ow rate should

be kept below 0.3 litres / minute.

The RGC option is factory tted.

26

Page 27

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

3.4.10 Junction Box Adaptor Plate (04200-A-1040)

The Junction Box Adaptor Plate provides a means of

increasing the spacing between the junction box's gland

entries and the mounting surface. This enables low gland

clearance junction boxes to be used without the Optima

Plus fouling on the wall / mounting surface. Junction boxes

which can be accommodated include the Hawke PL612 and

PJB1.

27

Page 28

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

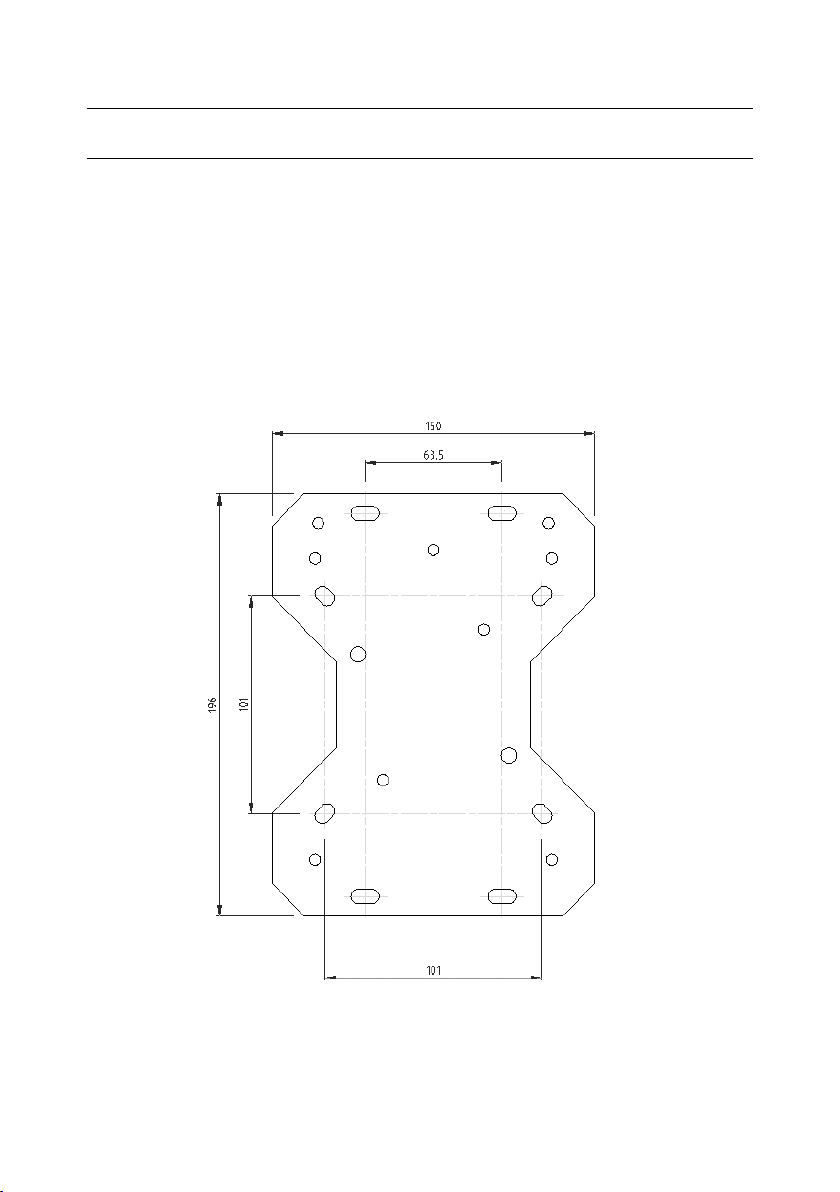

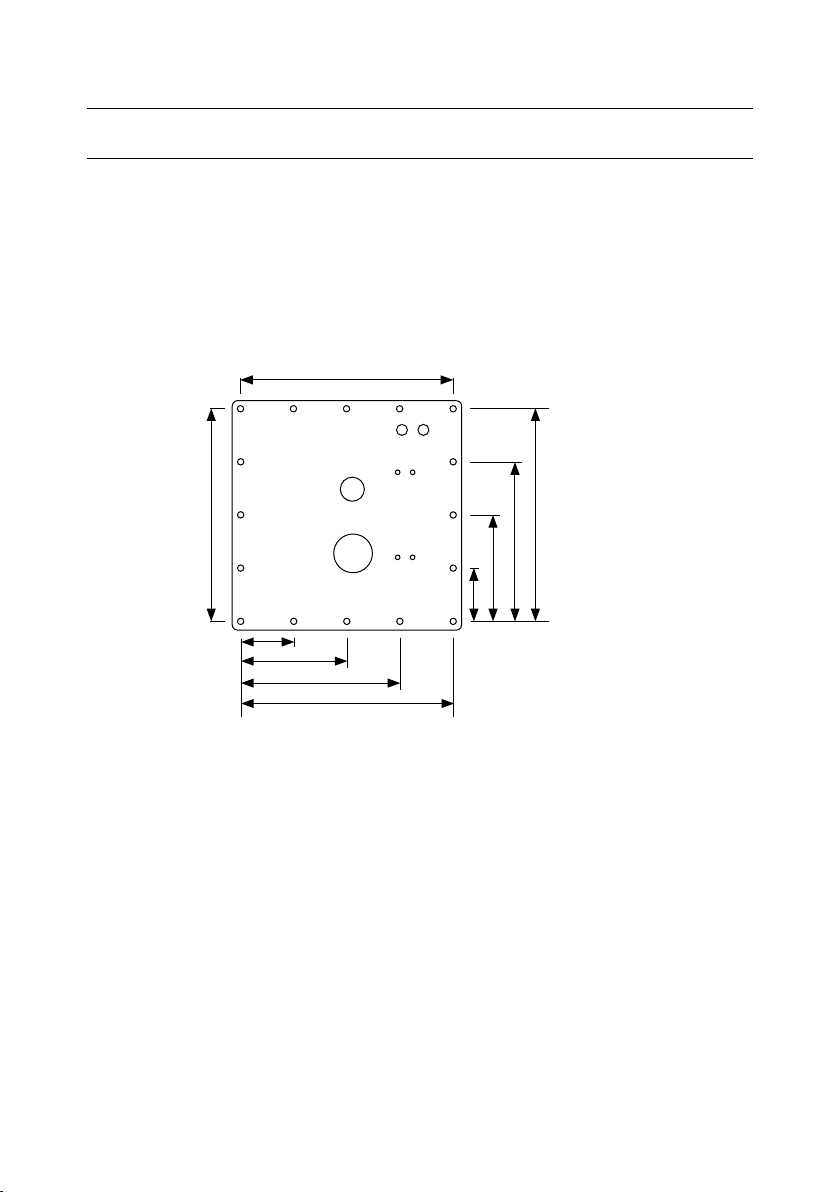

3.4.11 European Duct Mounting Kit (04200-A-1015)

This kit enables Optima Plus to be conveniently mounted

inside a duct. Electrical connections are made to the

detector via a junction box which is mounted outside of the

duct. Using this kit, test gas can be non-invasively applied to

the detector via the gassing points provided.

250

Note 1: Dimensions

shown in mm.

250

125

63

63

125

188

250

Note 2: The cutout

250

in the duct should be

188

230mm x 230mm.

28

Page 29

MAN0551 Issue 07 - 09/08

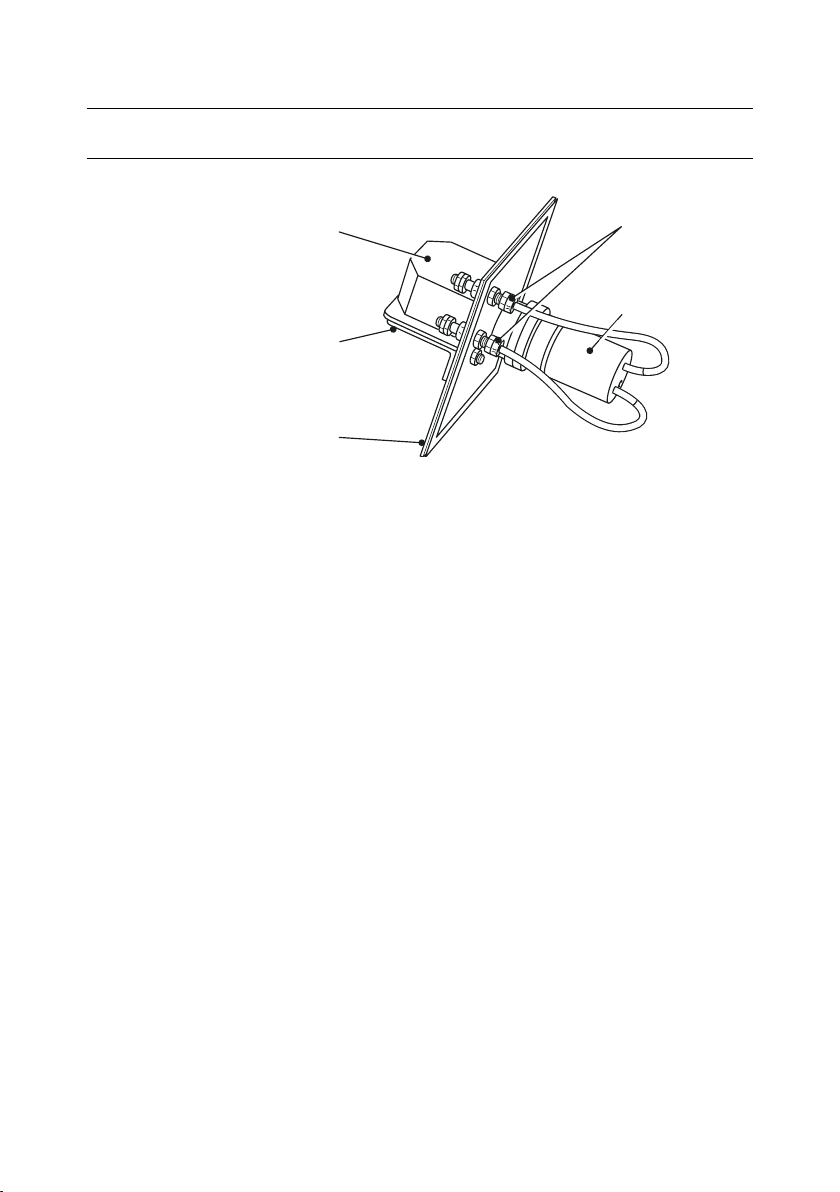

Gassing

Points

Searchpoint

Optima

Duct

Mounting

Junction

Box

Bracket

Junction

Box

2108M0501

3. INSTALLATION

Notes: 1. In order to make use of the gassing points provided,

the Optima unit must be fitted with the Remote Gassing

Cell (2108B0240).

2. In offshore HVAC ducts or ducts without inlet

filtering, the use of the Storm Baffle (2108D0280) is

recommended.

3. CSA approval only applies for flow rates less than 5

m/s and does not cover the use of the Storm Baffle.

The duct mounting kit is assembled and installed onto a duct

as below:-

(1) Cut a square 230mm * 230mm hole in the duct wall. Drill

the holes required to attach the mounting plate to the duct

wall.

(2) Place the Optima unit on the side of the mounting plate

where the threaded bushes protrude and feed the wires

through the central hole.

29

Page 30

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

(3) Locate the unit's boss in the central hole and feed the

unit's wires through the chosen cable entry on the junction

box.

(4) Screw the unit into the junction box until the assembly is

secure with the mounting plate trapped between the box and

the Optima.

(5) Cut off the seals on the ends of the gassing cell inlet

tubes.

(6) Attach the gassing tubing to the ends of the gassing cell

inlet tubes.

(7) Fasten the mounting plate to the wall of the duct,

ensuring that the seal is compressed.

(8) Wire up the unit in accordance with the electrical

connection details in Section 4.

(9) Ensure that all cable entries are either used or plugged in

strict accordance with the relevant certication requirements

and local codes of practice.

30

Page 31

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

3.4.12 US Duct Mounting Kit

This kit enables Optima Plus to be conveniently mounted

inside a duct. Electrical connections are made to the

detector via a junction box which is mounted outside of the

duct. Using this kit, test gas can be non-invasively applied to

the detector via the gassing points provided.

Note 1: Dimensions shown in inches.

31

Page 32

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

The duct mounting kit is assembled and installed onto a duct

as below:-

(1) Cut a square 6" x 6" hole in the duct wall. Drill the holes

required to attach the mounting plate to the duct wall.

(2) Remove the cover from the junction box.

32

Page 33

MAN0551 Issue 07 - 09/08

2108M0501

3. INSTALLATION

(3) Feed the wires from the Searchpoint Optima Plus through

the weldment into the junction box. DO NOT SECURE THE

WIRES TO THE TERMINALS AT THIS TIME.

(4) Secure the sensor to the weldment.

(5) Attach the both tubing assemblies.

(6) Secure the mounting plate to the duct.

33

Page 34

MAN0551 Issue 07 - 09/08

2108M0501

34

Page 35

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

CAUTION

The reliability and performance of instrumentation

installed at industrial and petrochemical facilities can

be strongly inuenced by the design and quality of the

electrical installation. It is strongly recommended that

before designing an electrical installation for Searchpoint

Optima Plus the electrical installation design authority

reads Section 4.1.

4.1 GENERAL

Searchpoint Optima Plus complies with the European EMC

requirements set out in standard EN50270:1999. In order

to maintain compliance with these standards it is essential

that the electrical installation of Searchpoint Optima Plus is

engineered appropriately.

Electrical installation standards and practices vary for

different countries, companies and hazardous area

approvals. It is the responsibility of the electrical installation

design authority to determine the applicable standards

/ practices and ensure compliance with them. When

designing electrical installations for Searchpoint Optima

Plus it is recommended that the design authority considers

the following:-

a. Ideally, the cases of units should not be connected

to electrically noisy (dirty) metalwork or conductors.

Preferably, the case (internally connected to the unit’s

green / yellow GND wire) should be connected to a

low noise instrument (clean) earth.

b. Preferably, the eld cable screen should be connected

to the unit’s green / yellow GND wire, providing a

single, continuous earth screen connected to a low

noise instrument (clean) earth. This connection must

35

Page 36

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

not be allowed to complete an earth loop or connect

instrument earth to safety earth.

c. If armoured cable is being used it is necessary to

prevent safety (dirty) earth from becoming connected

to instrument (clean) earth via the continuity plate in

the eld junction box. This is most easily achieved by

the use of insulating cable glands for the eld cable

entry.

d. For UL / CSA certied installations it is not practical to

isolate the unit’s case from safety (dirty) earth. The unit

and its junction box should be earthed in a manner

that complies with the certication requirements.

e. Any earth / ground bonding arrangement employed

should ensure that the maximum peak voltage

between the unit’s case earth and any eld cable

conductor is less than 350V. This includes conditions

where transient surge voltages are generated

by lightning or the switching of heavy electrical

plant. Surge voltages in excess of 350V can cause

permanent damage to the unit’s RFI lters and such

damage is not covered by warranty.

f. Earthing / grounding arrangements that employ

multiple protective earths or earth grids signicantly

increase the likelihood of large transient surge voltages

being generated between a unit’s case earth and the

eld cable conductors.

g. If it is suspected that the earth / ground bonding

arrangement employed will not prevent voltages

between the unit’s case earth and any eld cable

conductor from exceeding 350V it is strongly

recommended that surge suppression devices be

installed close to the unit. Suitable, certied surge

suppression devices include MTL’s TP-48-I-NDI and

36

Page 37

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

Pepperl & Fuchs’ FN-LB-1. Two of these devices are

sufcient to provide protection of the +24V, 0V,

4-20mA and RS485 (A) connections to a unit.

h. In general, correctly engineered star earthing

arrangements minimise earth current crosstalk and

noise, improving the reliability and performance of

instrumentation.

i. Low noise instrument (clean) earth should only be

connected to safety earth (usually dirty) at a single

point on a site / installation. This connection should

be made in such a manner that it does not introduce

noise onto the instrument earth.

j. The entire length of the eld cabling connected to

a unit should be screened / shielded. This screen /

shield should be connected to a low noise instrument

(clean) earth at a single end. (The screen / shield can

be connected to the unit’s earth in the junction box,

provided that this is isolated from all other earths /

grounds.)

k. For installations where the eld cable conductors run

through conduit or armour connected to safety (dirty)

earth, the conduit or armour should not be considered

as a sufcient screen / shield. A separate cable screen

/ shield, connected to a low noise instrument earth

should be employed.

l. The screens / shields of eld cabling should not be

connected in a manner that creates earth loops or

that will result in the screens / shields carrying large

currents from heavy plant or equipment.

m. The use of a single, screened / shielded cable for

each eld device ensures good screening / shielding

and reduces crosstalk. Cabling arrangements that use

a single cable to connect a number of eld devices

37

Page 38

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

compromise screening and increase the potential

for crosstalk. Such arrangements should only be

employed if the electrical installation design authority

is condent that this will not adversely affect the

reliability or performance of the system.

n. Any electrical interference induced onto the

conductors of a 4-20mA loop by the installation must

be kept below the levels necessary to comply with the

general requirements of EN61779 or other applicable

gas detector performance requirements / standards.

In practice, this means that peak noise currents

induced on the current loop should be no greater than

+/- 0.25mA. If peak noise currents larger than this are

induced on the current loop it is possible that spurious

gas readings, alarms and faults will be reported by the

control system monitoring the current loop.

o. The 0V rail of a control card / control system is often

connected directly to one side of the 4-20mA input’s

current sensing resistor. In such instances, any

electrical noise on the 0V rail can be considered to

be directly connected to the 4-20mA input. In order

to reduce the likelihood of such noise adversely

affecting the performance of a gas detection system it

is desirable to keep noise on the 0V rail to a minimum.

Safety earth / ground frequently carries a high level

of electrical noise and it is therefore advisable not to

connect the 0V rail to safety earth / ground. If the 0V

rail cannot be isolated from earth it is advisable to

either connect it to a low noise instrument (clean) earth

or through a path that presents a high impedance to

noise on the earth.

p. For installations in Europe, all electrical equipment

connected to the system should comply with

EN50270. For non-European installations, electrical

equipment connected to the system should comply

with applicable national or international EMC

standards.

38

Page 39

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

q. Searchpoint Optima Plus is designed to operate

correctly with supply voltages down to 18V. When

supplied with 18V, the maximum current drawn

by a single Searchpoint Optima Plus unit will be

250mA. The eld cabling conductors should have

sufcient cross sectional area to ensure that when

a unit is drawing 250mA the voltage reaching it does

not fall below 18V. For a control room voltage of 24V,

the maximum round loop cable resistance must

therefore be 24 Ohms. Round loop cable resistances

greater than those necessary to ensure that units

always receive at least 18V may result in unreliable

operation.

r. Ideally, the 24V supply reaching units should be free

from large transients, uctuations or high frequency

noise. Transients or uctuations which take the

supply voltage outside of the 18-32V range may

result in units switching off and re-booting.

s. In order to reduce the likelihood of radio frequency

interference affecting the operation of units it is

recommended that neither units nor their cabling are

installed in close proximity to the antennae of high

powered radio, radar or satellite communication

equipment.

39

Page 40

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

4.2 ANALOGUE CONNECTION

The unit’s analogue 4-20mA output is non-isolated and

shares the 0V return (black wire) connection with the DC

supply to the unit. The 4-20mA output is factory congured

for current source or current sink. The conguration is

identied by a label on the white 4-20mA output wire. The

connections to the unit are shown in the following gures.

Note: If using Searchpoint Optima Plus to replace an existing

catalytic sensor, a Current to Bridge converter must be

used.

4.3 DIGITAL CONNECTION

Searchpoint Optima Plus has a built-in RS485 digital

communications link. When using Termination Units, this link

can be connected to using the IS socket. For other junction

boxes, this link can be connected to using the SHC

Protection Device between the junction box terminals and

the SHC-1 Handheld Interrogator.

40

Page 41

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

The RS485 communications link is connected to the unit’s

orange (RS485(A)) and blue (RS485(B)) wires. If not used,

these wires must be separately terminated in a suitable

terminal or junction facility.

4.4 +24V POWER CONNECTION

The +24V DC power supply feed should be connected to the

unit via the red (+24V) and black (0V return) wires.

4.5 EARTH CONNECTION

An earth connection can be made to the unit in a number of

ways. When deciding how to earth the unit, consideration

should be given to the recommendations in section 4.1.

Physically, the earth connection can be made either via

the unit’s green/yellow earth wire, a metal nut between the

unit and the junction box’s earth continuity plate or a wire

connected to the unit’s external earthing point.

41

Page 42

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

42

Minimum Configuration for Retrofit Application (Optional Current to Bridge Converter)

Page 43

MAN0551 Issue 07 - 09/08

Optional Modbus Output

(M version only)

IS

Socket

SHC-1

Termination Unit

(refer to indicidual Terminal Unit manuals

for specific electrical connections

2108M0501

4. ELECTRICAL CONNECTIONS

Configuration for Termination Unit with IS Socket and Hand-Held Interrogator

43

Page 44

MAN0551 Issue 07 - 09/08

2108M0501

4. ELECTRICAL CONNECTIONS

44

Standard Configuration for Retrofit Application (With SHC Protection Device and Hand-Held Interrogator Option.)

Page 45

MAN0551 Issue 07 - 09/08

2108M0501

45

Page 46

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

5.1 GENERAL

WARNINGS

1. Alarm level signals may be intentionally generated

during the commissioning procedure. Ensure

that appropriate steps are taken to prevent the

unintended sounding of alarms or executive

actions. It is recommended that the control card

corresponding to the detector is isolated or inhibited

during the majority of the commissioning procedure.

2. In order to commission units installed with basic

junction boxes (i.e. not DVC100 or DX100), it will be

necessary to open the junction boxes under power.

This will require the appropriate safe operating

procedures to be employed.

3. The Optima Plus commissioning procedure

is best performed using an SHC-1 Handheld

Interrogator and a digital multimeter. Use of the

SHC-1 interrogator in combination with a multimeter

enables more comprehensive checks and testing

(Section 5.2). If however, an SHC-1 interrogator

is not available, basic commissioning can be

performed using just a multimeter (Section 5.3).

IMPORTANT

Searchpoint Optima Plus is supplied calibrated and

ready for use. It does not require calibration during

commissioning. Reference is made in this section to

a Gas Response Test. This is not a full calibration of

the sensor where zero and span values are set, but a

response test using a known concentration of gas to

validate the calibration of the sensor.

46

Page 47

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

5.2 COMMISSIONING PROCEDURE USING

SHC-1 AND MULTIMETER

5.2.1 Electrical Commissioning and Tests

(SHC-1 & Multimeter)

The procedure for verifying the electrical installation of the

unit is described below:-

(1) Before applying power to the unit, ensure that the eld

wiring is correct and all electrical connections are in

accordance with Section 4.

(2) Check that the unit’s 4-20mA output conguration is

correct for the type of control card that it is connected

to. (Source output for sink input, sink output for source

input. Unit’s output conguration is on label attached

to white wire.)

(3) Apply power to the control card connected to the unit

being commissioned. Wait for 1 minute to allow the

unit to initialise and stabilise. Using a multimeter set

on dc volts, measure the voltage across the red (+24V)

and black (0V return) connections. Nominally, this

voltage should be +24V. Voltages in the range +18V to

+32V are acceptable.

(4) Using either the IS socket on the Termination Unit,

or the SHC Protection Device, connect the SHC-1

Handheld Interrogator to the unit’s RS485 comms

link.(See Section 4.2 for SHC Protection Device

connections.)

(5) Select the DIAGNOSTICS option on the interrogator

menu and instruct the unit to display any ACTIVE

WARNINGS or ACTIVE FAULTS. (Diagnosis of FAULT /

WARNING codes is described in Section 8.)

47

Page 48

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

a. If there are any ACTIVE FAULTS, the cause(s) of

these must be identied and remedied before the

unit will become fully operational.

b. If there are any ACTIVE WARNINGS, the unit can

operate correctly despite the warning(s). However,

for reliable long term operation it is strongly

recommended that problems causing warnings are

xed before a unit is fully commissioned.

5.2.2 Gas Response Testing (SHC-1 & Multimeter)

The procedure for testing gas response as part of the

commissioning process is described below:-

(1) Select the DISPLAY mode on the SHC-1 Handheld

Interrogator. Check that the displayed gas reading

is 0.0% LEL. If the displayed gas reading is not

0.0% LEL, check that their is no background gas

concentration present, the optics are clean and free

from condensation and that the unit has been given

sufcient time to stabilise in it’s intended operating

environment. (For best results, it is recommended

that a unit is left powered up for one hour before

performing zero or span calibration / test activities.)

(2) Using the SHC-1 interrogator, put the detector into

INHIBIT (this will prevent gas readings from being

signalled on the 4-20mA output).

(3) Making use of either the gassing cover, or the remote

gassing cell (where tted), perform a functional gas

test. The procedure for performing functional gas

tests is detailed in Section 5.5. For a nominal 50%

LEL test gas concentration, the displayed reading

should be between 45% LEL and 55% LEL. (If

necessary, test gas concentrations between 20%LEL

and 95%LEL can be used with the same +/- 5% LEL

test tolerance.)

48

Page 49

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

Provided the displayed gas reading falls within the +/-5%

LEL test tolerance range, the functional gas test has been

completed satisfactorily.

CAUTION

If the displayed gas reading is not as expected, do not

proceed to re-calibrate the unit immediately. Instead,

double check the unit’s zero, the test gas and the gassing

technique. (IR gas detectors do not exhibit signicant

span drift and in most instances, any problem will be with

the zero or the test gas / technique.) Only consider

re-calibrating a unit when certain that the zero, test gas

and technique are correct and that the unit’s gas response

is signicantly out. The calibration technique is detailed in

Section 6.3.

5.2.3 System Level Testing (SHC-1 & Multimeter)

Conrmation of correct operation of the complete gas

detection system can be done using either test gas at the

required concentrations (Option B) or by FORCEing the

unit’s 4-20mA output under control of the SHC-1 interrogator

(Option A):-

CAUTION

When performing system level tests, ensure that any

resulting alarms or executive actions will not give rise to

unintended emergency drills or loss of production /

shut-down.

Note: It is assumed that the control system has been set up

for currents of 4mA and 20mA to read 0.0% LEL and

100% LEL respectively. If necessary, the FORCE 4-20mA

option can be used for setting up the control card. Be

aware that a 10 minute timeout applies to FORCE’d

4-20mA outputs.

49

Page 50

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

Option A) System Test Using FORCE’d 4-20mA

(1) The easiest way of performing system level functional

tests is to use the SHC-1 interrogator to FORCE the

4-20mA output to currents that are just above the

relevant alarm thresholds.

(2) The FORCE 4-20mA option is available from the

CALIBRATE menu. Using this option, FORCE the

4-20mA output to a current just above the A1 alarm

threshold. For example, with an A1 of 20% LEL, a

current of 7.5mA should sufce. Verify that the system

reports and responds as intended to this A1 signal.

(3) FORCE the 4-20mA output to a current just above the

A2 alarm threshold. With an A2 of 60% LEL, a current

of 14mA should sufce. Verify that the system reports

and responds correctly to this A2 signal.

(4) RELEASE the 4-20mA output. Conrm that the

system returns to normal, with no active alarms or

faults.

Option B) System Test Using Gas

If system level functional tests must be performed using gas,

test gas concentrations at least 5% LEL (ideally 10% LEL)

above each alarm threshold are required in order to allow for

system tolerances.

(1) Using either the gassing cover or the remote

gassing cell, apply test gas to the detector at the

concentration required to reliably exceed the A1

alarm threshold. For example, with an A1 alarm

threshold of 20% LEL, the minimum nominal test gas

concentration should be 25% LEL (ideally 30% LEL).

Verify that the system responds as intended to an A1

signal generated in this manner.

50

Page 51

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

(2) Apply test gas at the concentration required to reliably

exceed the A2 alarm threshold. With an A2 alarm

threshold of 60% LEL, the minimum nominal test gas

concentration should be 65% LEL (ideally 70%LEL).

Verify that the system responds correctly to an A2

signal generated in this manner.

5.2.4 Final Commissioning (SHC-1 & Multimeter)

The commissioning process is nished off as described

below:-

(1) Remove or disconnect any gas testing equipment

from the unit.

(2) Ensure that any test gas used is fully vented from the

measurement chamber or gassing cell. Verify that the

displayed gas reading returns to zero. (If the remote

gassing cell has been used, ensure that once vented,

it’s inlet tubes are sealed with the protective caps

provided (or a suitable alternative).)

(3) If required, remove the detector from INHIBIT.

(4) Select DIAGNOSTIC mode and verify that the unit has

no ACTIVE FAULTs or ACTIVE WARNINGs.

(5) Disconnect the SHC-1 interrogator. Replace the

junction box lid (where removed).

(6) When all of the relevant steps above are completed

satisfactorily, the unit has been commissioned and is

ready for operational use.

51

Page 52

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

5.3 COMMISSIONING PROCEDURE WITH

MULTIMETER ONLY

5.3.1 Electrical Commissioning and Tests

(Multimeter) Only

The procedure for verifying the electrical installation of the

unit is described below:-

(1) Before applying power to the unit, ensure that the

eld wiring is correct and in accordance with

Section 4.

(2) Check that the unit’s 4-20mA output conguration

is correct for the type of control card that the unit

is connected to. (Source output for sink input,

sink output for source input. The unit’s output

conguration is on a label attached to the white wire.)

(3) Apply power to the control card connected to the unit

being commissioned. Wait for 1 minute to allow the

unit to initialise and stabilise. Using the multimeter

set on dc volts, measure the voltage across the red

(+24V) and black (0V return) connections. Nominally,

this voltage should be +24V. Voltages in the range

+18V to +32V are acceptable.

(4) Remove power from the unit.

(5) Insert the multimeter set to read current (mA) in series

with the 4-20mA loop as follows:-

a. Current Sink Output

Remove the unit’s white 4-20mA output wire from

the terminal for the 4-20mA loop connection.

Connect the multimeter’s negative probe to the

white 4-20mA wire. Connect the multimeter’s

positive probe to either the +24V terminal or the

4-20mA loop terminal.

52

Page 53

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

b. Current Source Output

Remove the unit’s white 4-20mA output wire from

the terminal for the 4-20mA loop connection.

Connect the multimeter’s positive probe to the

white 4-20mA wire. Connect the multimeter’s

negative probe to either the 0V terminal or the

4-20mA loop terminal.

(6) Apply power to the unit and monitor it’s 4-20mA

output to conrm that it executes the correct powerup sequence as below:-

a. Output current of 0.0mA (0.0 to 0.5mA) for a period

of approximately seven seconds.

b. Output current of 2mA (INHIBIT current, 1.8 to

2.2mA) for a period of up to one minute whilst the

unit initialises and stabilises.

c. Output current of 4mA (ACTIVE zero gas current,

3.8mA to 4.2mA), which indicates that the unit is

operational and reading 0.0% LEL gas.

Note: If the unit is powered up in a non-zero

gas concentration, it will output a signal

corresponding to the gas concentration.

53

Page 54

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

5.3.2 Gas Response Testing (Multimeter) Only

CAUTION

Without the SHC-1 interrogator it is not possible to

INHIBIT the gas detector. To avoid unintended executive

actions or alarms, it is recommended to either isolate

the detector itself or inhibit / isolate the corresponding

control card.

Functional gas testing can be performed using the

multimeter to monitor the 4-20mA output:-

(1) Isolate the detector by disconnecting the 4-20mA

output from the loop terminal and connecting the

multimeter to measure the 4-20mA current to either

the +24V (for current sink) or 0V (for current source).

Alternatively, if the control card has been isolated /

inhibited, connect the multimeter in series with the

4-20mA loop.

(2) Making use of either the gassing cover, or the remote

gassing cell (where tted), perform a functional gas

test as detailed in Section 5.5.

CAUTION

If the 4-20mA current is not as expected, double check

the unit’s zero, the test gas and the gassing technique.

(IR gas detectors do not exhibit signicant span drift and

in most instances the problem is with the zero or the

test gas / technique.) Only consider re-calibrating a unit

when certain that the zero, test gas and technique are

correct and that the unit’s gas response is signicantly

out. The calibration procedure is detailed in Section 6.3.

54

Page 55

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

For a nominal 50% LEL test gas concentration, the

4-20mA output current should be between 11mA and 13mA.

If the measured current falls within the correct range, the

functional gas test has been completed satisfactorily.

Note: Zeroing and calibration activities require use of the

SHC-1 interrogator.

5.3.3 System Level Testing (Multimeter)

If it is necessary to conrm the correct operation of the

complete gas detection system during commissioning

(without an SHC-1 interrogator), this can only be done using

test gases at concentrations which are at least 5% LEL

(ideally 10% LEL) above the relevant alarm thresholds.

(1) Remove power from the unit. Reconnect the unit’s

4-20mA output to the appropriate loop terminal (the

multimeter should still be in series to measure current).

(2) Making use of either the gassing cover, or the

remote gassing cell (where tted), introduce gas at

the required A1 test concentration into the unit. For

example, with an A1 alarm threshold of 20% LEL, the

minimum test gas concentration required is 25% LEL.

The corresponding 4-20mA output current should be

between 7.2mA and 8.8mA. Conrm that the correct

current and system responses are observed when the

A1 test gas is introduced into the unit.

(3) Introduce gas at the required A2 test concentration

into the unit. With an A2 alarm threshold of 60% LEL,

the minimum test gas concentration required is 65%

LEL. The corresponding 4-20mA output current should

be between 13mA & 15mA. Conrm that the correct

current and system responses are observed when the

A2 test gas is introduced into the unit.

55

Page 56

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

5.3.4 Final Commissioning (Multimeter)

The commissioning process is nished off as described

below:-

(1) Remove or disconnect any gas testing equipment

from the unit.

(2) Ensure that any test gas used is fully vented from the

measurement chamber or gassing cell. (If the remote

gassing cell has been used, ensure that once vented,

it’s inlet tubes are sealed with the protective caps

provided (or a suitable alternative)).

(3) Verify that after the initialisation and stabilisation

period (approximately 1 minute), the 4-20mA output

returns to 4mA nominal (between 3.8mA and 4.2mA).

(4) Remove power from the unit and disconnect the

multimeter from the 4-20mA loop. Connect the white

4-20mA wire back directly to the loop terminal.

Re-apply power to the unit.

(5) Verify that the unit returns to ACTIVE status and that

the gas reading displayed on the control card is

0.0% LEL.

(6) Replace the junction box lid.

(7) When all of the relevant steps above are completed

satisfactorily, the unit has been commissioned and is

ready for operational use.

56

Page 57

MAN0551 Issue 07 - 09/08

2108M0501

5. COMMISSIONING

5.4 CONTROL SYSTEM SETUP

If the controller is in need of setting up, ie. for a 4 to 20mA

signal to show an equivalent reading eg. 0 - 100% fsd, this

may be done in two ways:

i) By using the Hand-Held Interrogator to FORCE the

required signal to the controller (see Section 6.4 of

this manual)

or

ii) With calibration gas applied to the sensor.

In each of these cases, a known signal is sent to the

controller, and the controller is set to show the equivalent

signal.

5.5 FUNCTIONAL RESPONSE CHECKING AND

CALIBRATION

Searchpoint Optima Plus is supplied factory calibrated and

when commissioning a unit, all that should be required to

verify correct operation is a functional response check.

The procedure for functional response checking is described

in Section 7 Routine Checks.

Where local regulations or working practices require gas

detectors to be calibrated when they are commissioned,

this should be performed in accordance with the procedure

described in Section 6 Calibration.

57

Page 58

MAN0551 Issue 07 - 09/08

2108M0501

58

Page 59

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

6.1 GENERAL

Searchpoint Optima Plus is supplied factory calibrated for

a particular hydrocarbon gas (approximately 100 different

gas calibrations are currently available). Properly installed

and maintained, Optima Plus does not require routine

calibration. This operational benet is made possible

by the inherent stability of the IR absorption process

and the fully compensated optical conguration used.

In order to maintain condence in the continued correct

operation of elded Optima Plus units it is recommended

that a functional gas test is incorporated into the planned

maintenance procedure for the unit. In most applications

and installations, a planned maintenance / service interval

of 1 year is appropriate, although this will depend upon

site conditions and requirements. EN50073 and national

regulations should be observed.

Where site operating procedures or regulations require

routine calibration of gas detectors, this is possible using

the SHC-1 Handheld Interrogator and the gassing cover.

Care needs to be taken in order to ensure that routine

eld calibrations do not reduce the calibration accuracy

compared to the original factory calibration. (Factory

calibration is performed in more controlled conditions than

are readily achievable in the eld.)

Functional gas testing and calibration are made considerably

easier by use of the SHC-1 Handheld Interrogator. If an

SHC-1 is not available, basic functional gas testing can be

performed using just a multimeter to monitor the 4-20mA of

the unit being tested.

CAUTION

Searchpoint Optima Plus is a robust, ammable gas

detector, it is not an analyser. Where the performance or

features of an analyser are required, an analyser should

be used.

59

Page 60

MAN0551 Issue 07 - 09/08

LCD Display

Push Buttons

Hand-Held

Interrogator

Type SHC-1

2108M0501

6. CALIBRATION

6.2 SHC-1 HANDHELD INTERROGATOR

The SHC-1 Handheld Interrogator is a portable, Intrinsically

Safe (IS) device which can be used to calibrate, test and

commission all of Honeywell Analytics Searchpoint and

Searchline optical gas detection products. The SHC-1

interrogator communicates with detectors via a digital RS485

link. Electrically, this link can be made either by using the IS

socket on the DVC100 / DX100 or by connecting the ying

leads on the SHC Protection Device (04230-A-1025) to the

appropriate junction box terminals.

WARNING

The IS certication of the SHC-1 Handheld Interrogator

only remains valid if it is used in conjunction with the

Termination Unit or the SHC Protection Device. Do not

attempt to connect the SHC-1 interrogator directly to

units, always use either the Termination Unit or the SHC

Protection Device.

Press ↵ and hold for three

seconds to switch on.

Press ↵ and esc together

and hold to switch off.

Unit powers down

auto-matically after

10 minutes to prolong

battery life.

60

Page 61

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

6.2.1 Connecting the SHC-1 Hand-Held Interrogator

6.2.1.1 Termination Units

When using a Termination Unit, the SHC-1 Handheld

Interrogator can be directly connected to the IS socket on

the bottom of the Termination Unit.

Termination Unit

Optima

IS Socket

SHC1

6.2.1.2 Other Junction Boxes

(Use of SHC Protection Device)

WARNING

The SHC Protection Device can only be used in a safe

area. ie. When a local safe area is achieved using a hot

work permit or other appropriate gas free permit.

Interrogator connections to units mounted on junction boxes

other than the DVC100 / DX100 can be made using the

SHC Protection Device. The procedure for using the SHC

Protection Device is as follows:-

(1) Remove the cover to the respective junction box.

61

Page 62

MAN0551 Issue 07 - 09/08

To Optima

Communications

Link Connections

in Junction Box

brown

blue

SHC Protection Device

To Hand-Held

Interrogator

SHC-1

2108M0501

6. CALIBRATION

(2) Connect the brown lead of the SHC Protection Device

to the orange lead of the Optima communications link.

(3) Connect the blue lead of the SHC Protection Device to

the blue lead of the Optima communications link.

(4) Connect the Hand-Held Interrogator SHC-1 to the

SHC Protection Device connector.

Note: When transporting the SHC Protection Device in a

hazardous area, the SHC Protection Device must be

disconnected from the Hand-Held Interrogator.

6.2.2 Hand-Held Interrogator Operating Modes

The Hand-Held Interrogator version 4v0 is compatible

with Searchpoint Optima, Searchpoint Optima Plus and

Searchline Excel. To work with a specic product the correct

operating mode has to be selected as follows:

(1) Press ↵ to switch on the power.

(2) The display will rst show a title screen:

Z - SHC 1 Optima

Interrogator 4v0

The current operating mode is shown in the top right

of the display.

(3) Press esc and the display will show:

Z - SHC 1 Optima +

Interrogator 4v0

62

Page 63

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

(4) Press esc again and the display will show:

Z - SHC 1 Excel

Interrogator 4v0

If esc is pressed again the operating mode will

change to Optima and the different modes can be

stepped through again.

(5) When the display shows Optima + as the operating

mode wait three seconds for the main menu to be

displayed:

Main

Note: 1. The current operating mode is remembered when

the Hand-Held is switched off.

2. The operating mode can also be changed by

selecting the change mode option on the main menu.

Display

(6) Press

Main

(7) Press and the display will show:

Main

(8) Press and the display will show:

Main

and the display will show:

Calibrate

Diagnose

Gas Tables

63

Page 64

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

(9) Press and the display will show:

Main

(10) Press and the display will show:

Main

(11) Press and the display will show:

Main

Congure

Change Mode

Power Off

64

Page 65

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

Power Off

Main

Gas Tables

Main

Diagnose

Main

Calibrate

Main

Main

Show Gas

Gas Tables

Active Faults

Diagnose

Display

Calibrate

Congure

Main

Show Library

Gas Tables

Active Warns

Diagnose

Cal Sensor

Calibrate

Change Mode

Select Gas

Gas Tables

Self Test

Diagnose

Calibrate

Diagnose

Force 4-20

Calibrate

Soft Reset

This diagram shows all the Hand-held Interrogator

Software features. Use of the and keys to display

Normal 4-20

the individual menu options. The options are selected

by pressing ↵ and exited by press esc.

SHC-1 Hand-held Calibrator Menu Structure

Interrogator 4v0

Z- SHC1 Optima +

Display

Main

65

Page 66

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

6.2.3 Other Hand-Held Features

6.2.3.1 Display

Selecting this option from the main menu displays:

Optima + Methane

xx.x % LEL

The display shows the gas type, the gas reading and in the

bottom right a status indicator:

Rotating bar indicates a healthy active unit.

F indicates an active fault condition.

W indicates an active warning.

A indicates a gas concentration in excess of

the units internal alarm threshold

O indicates an active overrange.

I indicates inhibit condition.

Pressing

or ↵ changes the display to show:

Optima + S/W

4v0

The version of software currently installed within the

Searchpoint Optima Plus unit.

Pressing

, or ↵ will return the display to showing the

current gas reading.

Pressing esc exits the display option to the main menu.

66

Page 67

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

6.2.3.2 Calibrate

Display

The Display option on the Calibrate menu provides the same

information as the Display option on the Main menu except

the analogue output will be inhibited. This function is useful

if a response check is to be carried out and you do not wish

the gas reading to be reported on the analogue output.

Note: The rotating bar will not be shown on the gas reading

display when the analogue output is inhibited.

Normal 4-20

This action releases the analogue output. It should be

used if a communication error occurs while performing an

operation with the Hand-Held which Inhibited the analogue

output.

Note: The unit will release its analogue output automatically 10

minutes after it was Inhibited if no digital communication

occurs.

6.2.3.3 Diagnostics

Active Faults/Active Warning

Selecting one of these actions displays any fault or warning

conditions which are present in the unit. If more than one

condition is simultaneously present, these may be scrolled

through by pressing the

or keys.

FAULT conditions prevent the unit from working as a gas

detector and are always signalled on the analogue output as

0mA.

67

Page 68

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

WARNING conditions indicate that the unit is operating

close to the limits of its specied operating envelope. The

unit may go into fault in the near future. If a fault condition

is present in the unit while the active warnings are being

displayed, the top line of the display will show Fault Present.

Correct the Fault condition rst.

A list of fault and warning conditions and the actions

which should be taken to correct the problem are given

in section 8.

Self Test

This action instructs the unit to complete a self test cycle. If

a fault or warning condition was found in the unit, the HandHeld display will show:

Error 13

Error in Unit

Details of the fault or warning can be viewed by selecting

the Active Fault/Active Warning menu option.

Soft Reset

Selecting this option forces the unit to reboot. It is

equivalent to switching the power to the unit off and

then on.

6.2.3.4 Gas Table

The Show Gas menu option displays the current gas type.

The Show Library action displays the part number and issue

of the data base within the unit which contains the details of

the diferent gasses which can be detected.

The Select Gas menu option allows the gas type of the unit

to be changed. The gas types available on the standard

unit are listed in Section 11.1.

The unit is inhibited while this action is performed. The unit

should be calibrated after the gas type is changed.

68

Page 69

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

6.2.3.5Cong

The Show Cong option on the Cong menu shows the

values of a number of key paramaters in the Searchpoint

Optima Plus. These may be scrolled through by pressing the

or keys.

OptimaPlusCongurationParameters

Conguration

Parameters

Auto Zero

Alarm

Threshold

Inhibit

Current

Warning

Current

Overrange

Current

Protocol

Address

Parameter

Title

Zero

Tracking

Alarm

Threshold

Inhibit mA

Warning mA

Overrange mA

Digital

Address

Purpose

Enables automatic zero tracking

function within the unit. Used only

in specialist applications, function

is normally disabled.

Sets a gas concentration thresh-

old (adjustable over the range

10% to 50% full scale, default

25%) beyond which the unit

considers a dangerous level of

gas is present. A fault will be

signaled if the output current can

not be driven to a value in excess

of this threshold.

Denes the output current for

Inhibit condition.

Denes the output current when a

warning is present.

Denes the output current when

the gas concentration exceeds

full scale.

Denes the protocol address of

the unit when connected into a

multi-drop digital network.

Used only in specialist

applications.

6.2.3.6 Power Off

Entering this menu and pressing ↵ turns off the Hand-held

Interrogator to preserve battery life.

69

Page 70

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

6.3 CALIBRATING THE CONTROLLER

This procedure allows the user to calibrate the controller by

FORCE’ing a known current out of the unit’s 4-20mA output.

Use of this technique enables calibration of the controller’s

0-100% fsd scale without the need for gas. The output can

be forced in the range 1.0 to 21mA (0.1mA resolution).

It is recommended that calibration of the controller is

performed at two points, ideally 4mA (0.0% fsd) and 12mA

(50% fsd). Provided that no background gas concentration

is present, the unit’s 4mA (0.0% fsd) output can be used to

calibrate the control cards zero point. The span calibration

of the controller can then be calibrated by FORCE’ing the

required current as follows:-

(1) Connect the Hand-Held Interrogator to the unit.

(2) Press ↵ to switch the power on, ensure the Hand-held

is in Optima + mode and wait ve seconds.

The display will show:

Main

(3) Press and the display will show:

Main

(4) Press ↵ and the display will show:

Calibrate

Display

Calibrate

Display

70

Page 71

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

(5) Press and the display will show:

Calibrate

(6) Press and the display will show:

Calibrate

This selects the FORCE'd 4-20mA routine which can

be used to calibrate the controller.

(7) Press ↵ and the display will show:

O/P 4-20 current

Cal Sensor

Force 4-20

4.0 mA

(8) Press

or to change the displayed mA value in

0.1mA steps:

O/P 4-20 current

12.0 mA

Choose the desired value.

(9) Press ↵ and the display will show:

Fixed: nn.nn mA

Press enter

where nn.nn is the current measured by the Optima

Plus diagnostic function. The analogue output is now

set to the selected value set in step (8). Specied

accuracy is ±1% FS (±0.2mA).

71

Page 72

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

(10) Calibrate the controller to display the correct reading

for the current being FORCE'd on the 4-20mA output.

(11) Press ↵ and the display will show:

Press Enter To

Release 4 - 20

Note: The unit will return to normal operation after 10 minutes

if no key is pressed.

(12) Press ↵ and the display will show for 3 seconds:

4 - 20 Released

The analogue output has now returned to normal

operation.

(13) Wait and the display will show:

Calibrate

Force 4-20

Returns to the Calibrate Menu.

(14) Press esc twice to return to the Main Menu:

Main

Display

(15) The Hand-Held Interrogator may be switched off by

pressing esc and ↵ together.

72

Page 73

MAN0551 Issue 07 - 09/08

2108M0501

6. CALIBRATION

6.4 CALIBRATING THE SENSOR