Page 1

Find out more

Contact Honeywell Analytics:

www.honeywellanalytics.com

Europe, Middle East, Africa

Life Safety Distribution AG

Wilstrasse 11-U31

CH-8610 Uster

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell.com

Americas

Honeywell Analytics Distribution, Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8208

detectgas@honeywell.com

www.honeywell.com

Technical Services

ha.emea.service@honeywell.com

Asia Pacific

Honeywell Analytics Asia Pacific

#508, Kolon Science Valley (1)

187-10 Guro-Dong, Guro-Gu

Seoul, 152-050,

Korea

Tel: +82 (0)2 2025 0307

Fax: +82 (0)2 2025 0329

analytics.ap@honeywell.com

INSTALLATION INSTALLATION INSTALLATION

INSTALLATION

6. The earth bonding arrangement must ensure that the maximum

peak voltage between the unit case earth and any eld cable

conductor is less than 350V. Voltages in excess of this can cause

permanent damage to the unit’s RFI protection lters.

7. The use of a single, screened cable for each gas detector ensures

maximum screening and minimum crosstalk. Cabling arrangements

which use a single cable for connecting a number of eld devices

compromise screening, increase the potential for crosstalk and

prevent implementation of true star earthing.

8. Any electrical interference induced onto the 4-20mA loop

conductors by the installation must be kept below the levels

necessary to comply with the general requirements of EN50054.

In practice, this means that peak noise currents induced on the

current loop should be no greater than ± 0.25mA.

9. The 0V rail of the control card

/ control system is often directly

connected to one side of the 4-20mA current sensing resistor.

Electrical noise on such a rail is therefore directly connected to

the 4-20mA input. In order to avoid additional noise being induced

on the 0V rail, it should not be commoned with the safety earth/

ground, which frequently carries a high level of electrical noise.

10. All electrical equipment connected to the system should comply

with EN50081 & EN50082.

11. The 24V supply should be free from large transients and

uctuations.

12. The eld cabling conductors should have sufcient cross sectional

area to ensure that the minimum supply voltage applied to the

system is 18V at a current of 420mA.

This corresponds to a maximum round loop impedance of 14 ohms

for a nominal 24V system supply.

13. Receivers should not be installed in close proximity to the antennae of

high powered radios, radar and satellite communication equipment.

4.3.2 Electrical Installation

1. Isolate all associated power supplies and ensure that they remain OFF

during this procedure.

2. If the units are to be installed with junction boxes other than DVC100/

DX100 junction boxes, ensure that the boxes:

• have M20 cable gland entries for BASEEFA units, or 3/4 NPT for

UL and CSA.

• have terminals for 5 wires and an earth.

3. Remove the M20 blanking plugs (if tted) and attach the Excel

transmitter and receiver cables to their junction box. Fit the locking

rings (if supplied) before terminating the cables in the junction box.

4. Fit approved cable glands to the junction box cable entries, using

sealing washers where necessary to maintain the ingress protection

rating.

5. Fit approved blanking plugs to all unused cable entries.

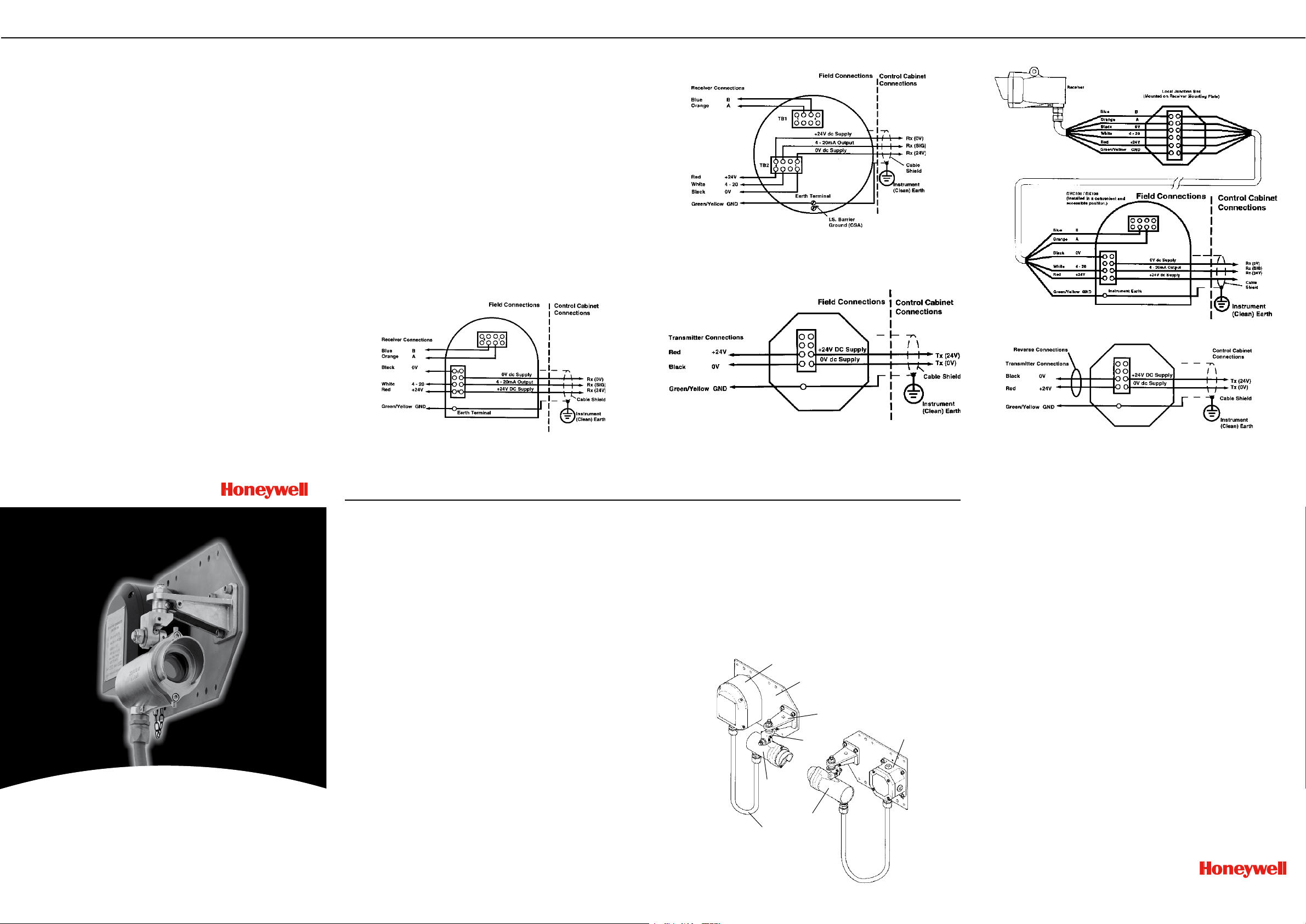

6. Make appropriate electrical connections as shown in the following

diagrams.

4.3.3 Receiver Connections via DVC100

4.3.4 Receiver Connections via DX100

4.3.5 Transmitter Connections

4.3.6 Remote Installation Receiver Connections

4.3.7 Transmitter Connections - Turbo Heating Disabled

11 12 13 14

Installation Guide

Searchline Excel

Open Path Infrared Gas Detector

CONTENTS

1. Introduction 2

2. Safety 3

3. Mechanical assembly 4

3.1 General 4

3.2 Transmitter 4

3.3 Receiver 4

3.4 Adjustable Mountings 5

4. Installation 6

4.1 General 6

4.2 Mechanical Installation 6

4.3 Electrical Installation 10

4.3.1 Electrical Connections 10

4.3.2 Electrical Installation 12

4.3.3 Receiver Connections via DVC100 12

4.3.4 Receiver Connections via DX100 13

4.3.5 Transmitter Connections 13

4.3.6 Remote Installation Receiver Connections 14

4.3.7 Transmitter Connections - Turbo Heating Disabled 14

1 2

1. INTRODUCTION

This guide provides the installation personnel with the basic information

necessary to mechanically install the Searchline Excel system units and

make the necessary electrical connections.

This guide is not intended to replace the associated Searchline Excel

Technical Handbook (2104M0505) which contains the full safety,

installation, commissioning, maintenance and fault nding instructions.

These procedures assume that consideration of the location and

mounting of the system units has already been taken into account in

accordance with the guidelines in the Technical Handbook.

The following diagram shows a typical system conguration and

identies the main parts.

DVC100 / DX100

(or other junction box)

Mounting Plate

Mounting Bracket

PL612

(or other junction box)

Path

5 - 200m

Receiver

Transmitter

Flexible Conduit

Pivot Block

Issue 02 12/2005

H_MAN0558_ 2104M0510

09-07

© 2007 Honeywell Analytics

11063

Page 2

2. SAFETY 3. MECHANICAL ASSEMBLY

MECHANICAL ASSEMBLY

4. INSTALLATION

Ensure that you read and understand these instructions BEFORE

handling or operating the equipment.

Please pay particular attention to the Safety Warnings.

WARNINGS

The Searchline Excel System is certied for and intended

for use in potentially hazardous areas. Install and use the

Searchline Excel System in accordance with the latest

regulations.

For installations in the UK, the Code of Practice

SELECTION, INSTALLATION AND MAINTENANCE OF

ELECTRICAL APPARATUS FOR USE IN POTENTIALLY

EXPLOSIVE ATMOSPHERES should be strictly observed.

General recommendations are given in BS5345:Part 1:1989.

Specic requirements for ameproof (Type ‘d’), intrinsically

safe (Type ‘I’) and increased safety (type ‘e’) protection are

given in BS 5345: Part 3: 1979, BS 5345:Part 4:1977 and

BS 5345: Part 6:1978 respectively.

For installations in North America, the national Electrical

Code (NFPA 70 - 1990) or later issues should be strictly

observed.

Elsewhere, the appropriate local or national regulations

should be used.

The Code of Practice regarding SELECTION,

INSTALLATION, USE AND MAINTENANCE OF APPARATUS

FOR THE DETECTION OF COMBUSTIBLE GASES (OTHER

THAN FOR MINING APPLICATIONS OR EXPLOSIVE

PROCESSING AND MANUFACTURE) must be complied

with. Refer to BS6959:1988 in the UK or the appropriate

local or national regulations.

3.1 GENERAL

This section details the mechanical assembly information and important

dimensions necessary for installing the system units. Adjustable parts

which form part of the mounting assemblies are also shown.

3.2 TRANSMITTER

3.3 RECEIVER

160mm (SR)

211mm (MR/LR)

291 (SR) 353 (MR/LR)

Approximately 300mm

417mm

417 (SR)

433 (MR/LR)

160mm

291mm

3.4 ADJUSTABLE MOUNTINGS

Clamp Nut

Mounting Bracket

adjusting screws (2 off)

Adjustment Clamp

lock screw (2 off)

Pivot Block

adjusting screw (2 off)

Adjustment Clamp

lock screw (2 off)

Clamp Nut

4.1 GENERAL

Searchline Excel is designed to allow installation to be performed by a

single operator.

The installation procedure is split into mechanical installation and

electrical installation. Each unit needs to mounted to a supporting

structure before making the electrical connections. The diagrams show

different ways of orientation for the mountings.

4.2 MECHANICAL INSTALLATION

This mechanical installation procedure applies to both the receiver and

the transmitter.

1. Ensure that the equipment to be

installed is correct for the type

Mounting

Plate

of installation required (i.e. short/

medium/long range).

2. Fit the mounting bracket to the

mounting plate for the unit, as

shown.

Mounting

Bracket

Isolation Kit

3. Fit the mounting plate to the

supporting structure in one of the

following ways:

• by through bolts directly to a at surface.

• by U-bolts (2 off) to a single 150mm diameter pipe/pole.

• by U-bolts (4 off) to two 55mm diameter pipes/poles,

166mm apart.

Honeywell Analytics Limited reserve the right to change or revise the

information supplied in this document without notice and without

obligation to notify any person or organisation of such revision or

change. If further details are required that do not appear in this

document, contact Honeywell Analytics Limited or one of their agents.

3

INSTALLATION

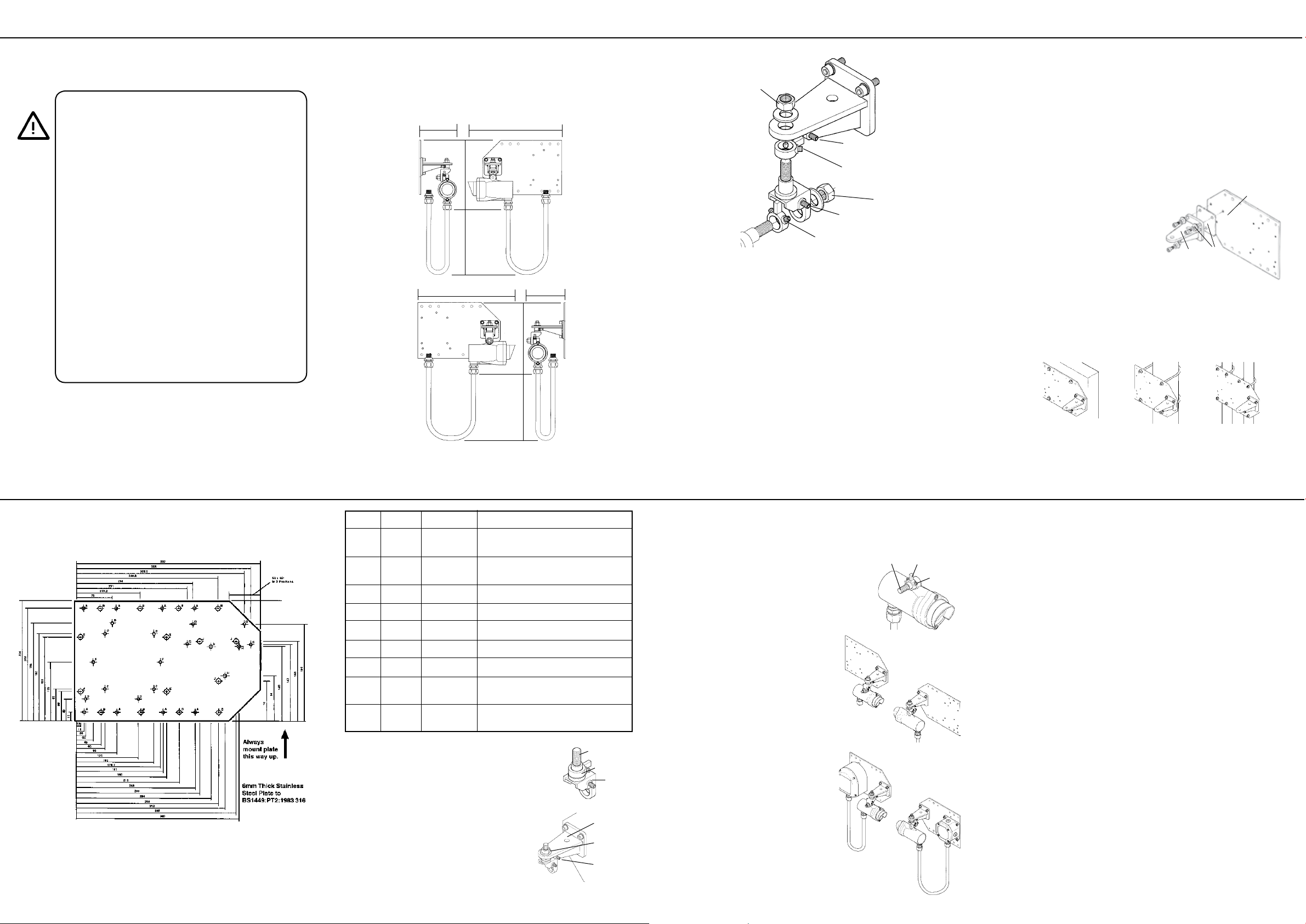

Identify the mounting holes using the following diagram and the

accompanying table. The subsequent diagrams show the different types

of mountings.

Notes: 1. Mounting plate fixing holes are clear. Searchline Excel system

component mounting holes are threaded.

2. The mounting plate fixings are not supplied.

7

Approximately 300mm

4

INSTALLATION

Identity Quantity Size Used For

A 8

∅ 7.5mm

B 8

C 4

D 3

E 4

F 2

G 4

H 3

J 3

∅ 9.5mm

M6 tapped.

M6 tapped.

M10 tapped

M6 tapped

M6 tapped

M8 tapped

M10 tapped

4. Fit an adjustment clamp to the unit’s pivot

block mounting stud so that it sits on the

stud’s shoulder with the correct orientation

as shown in the diagram.

5. Tighten the adjustment clamp’s

grubscrews until they just grip the

unthreaded part of the mounting stud.

6. Fit the pivot block to the mounting bracket

using a self-locking clamp nut and washer

(M12 or M20) with the correct orientation

as shown in the diagram.

Do not fully tighten the nut.

Duel 2 ‘’ pipe or pole mounting, at

surface mounting.

Single 6’’ pole, at surface mounting,

dual 2.5’’ ID pipe.

PL612/Bartec mounting.

DVC100 mounting.

DX100 mounting.

Killark/Akron mounting.

Sun/heat shade mounting.

Short range transmitter, all receiver

brackets.

Me d ium/ L ong ran g e tr ansm i tter

mounting bracket.

8 9 10

Mounting Stud

Adjustment

Clamp

Pivot

Block

Mounting

Bracket

Self-locking

Clamp Nut and

Washer

Mounting

Bracket

Grubscrew

5

INSTALLATION INSTALLATION

Ensure that the adjustment clamp’s stub lever is positioned

approximately centrally between the mounting bracket’s grubscrews.

Adjust the screws if required.

7. Fit an adjustment clamp to the unit’s

pivot block mounting stud so that it

sits on the stud’s shoulder with the

correct orientation as shown in the

diagram.

8. Tighten the adjustment clamp’s

grubscrews until they just grip

the unthreaded part of the unit’s

mounting stud.

9. Fit the unit to the pivot block using

a self-locking clamp nut and washer

(M12 or M20).

Do not fully tighten the nut.

Ensure that the adjustment clamp’s

stub lever is approximately centrally

positioned between the pivot block’s

grub screws. Adjust the screws if

required.

10. Fit a suitable junction box, e.g.

DVC100/DX100 or other suitable type

of junction box, to the mounting plate

Note: For information about alternative

types of junction box see Section

4.2 Electrical Installation.

11. Measure the distance (in metres)

between the transmitter and receiver

units.

This distance is required by the

system commissioning personnel.

Mounting

Stud

Stub Lever

Adjustment

Clamp

Surface Mounting

Single Pipe / Pole

Dual Pipes / Poles

6

4.3 ELECTRICAL INSTALLATION

4.3.1 Electrical Connections

All ranges of Searchline Excel comply with the EMC requirements

EN50081 & EN50082. In order to maintain compliance with these

standards it is essential that the electrical installation of Excel is

engineered correctly.

Electrical installation standards vary for different countries, companies

and applications and it is the responsibility of the installation design

authority to determine the applicable standards and ensure compliance

with them. When designing electrical installations for Excel,

Honeywell Analytics Limited recommend that the installation design

authority considers the following:

1. Where possible the unit cases should not be electrically connected

to electrically noisy (dirty) metalwork or conductors. An electrical

isolation kit is available (see Technical Handbook) to provide the

required electrical insolation between the units mountings and

its mounting plate. The case is internally connected to the green/

yellow GND wire which should preferably be connected to a low

noise (clean) earth line. See also 5 of this section.

2. The entire length of the eld cabling connected to each unit should

be fully shielded with the shield connected to a low noise (clean)

earth line.

3. The low noise (

clean) earth line should only be connected to safety

earth (usually dirty) at a single point. This connection should be

made in such a manner that it does not introduce noise onto the

low noise earth. Star earthing arrangements minimise earth current

crosstalk.

4. The shields of the eld cabling should not be connected such that

earth loops are produced, or in a manner that will result in the

shields carrying large currents from heavy plant or equipment.

5. Ideally, the eld cable shield should be connected to the unit’s

green/yellow GND wire, providing a single, continuous earth shield.

This connection mus t not be allowed to complete an earth loop.

Loading...

Loading...