Honeywell S8610U User Manual

68-0135-2

Universal Intermittent Pilot Module

APPLICATION

The S8610U Universal Replacement Ignition Module is

designed to provide easy field replacement of a wide range of

intermittent pilot ignition modules manufactured by

Honeywell, Robertshaw, Johnson and others. The S8610U

Module provides ignition sequence, flame monitoring, and

safety shutoff for intermittent pilot central furnaces, residential

boilers, and other heating appliances.

S8610U

PRODUCT DATA

FEATURES

•Provides up to 1.0A pilot and 2.0A main valve current

rating.

• System uses rectification principle for flame sensing.

• For use with separate igniter and sensor or

combination igniter-sensor. Q345, Q348, Q362, Q373

or Q381 Igniter-sensor recommended as combination

igniter-sensor; Q179C with igniter and sensor

mounted on one bracket, or Q354 Sensor with Q345,

Q348, Q362, Q373 or Q381 Igniter-sensor

recommended as separate igniter and sensor.

• Q3450/Q3480 Hot Surface Pilot hardware plugs

directly into system control.

• Can be used on natural or LP gas; provides 100

percent shutoff on ignition failure. Waits six minutes

nominal following shutoff, then reinitiates the pilot

ignition sequence. The ignition trial-shutoff-wait cycle

repeats until the pilot lights or the call for heat ends.

• Replaces numerous Honeywell and competitor

modules.

• Capacitive discharge spark output.

•Temperature rating is -40°F to 175°F (-40°C to 79°C)

when used with 1.0A or less main valve; -40°F to 165°F

(-40°C to 74°C) when used with 1.0 to 2.0A main valve.

Contents

Application........................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Planning the Installation ...................................................... 4

Installation ........................................................................... 6

Startup and Checkout ......................................................... 15

Maintenance........................................................................ 15

Operation ............................................................................ 16

Troubleshooting .................................................................. 17

ANSI Standards .................................................................. 21

® U.S. Registered Trademark

Copyright © 1996 Honeywell Inc. • All Rights Reserved

S8610U UNIVERSAL INTERMITTENT PILOT MODULE

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

units may not exactly match the listed specifications

Also, units are tested and calibrated under closely

controlled conditions, and some minor differences in

performance can be expected if those conditions are

changed.

SUPER TRADELINE® Models

SUPER TRADELINE® models are selected and packaged for

ease of handling, ease of stocking, and maximum replacement

value. SUPER TRADELINE® model specifications are the

same as those of standard models except as noted.

SUPER TRADELINE® Model Available:

S8610U Universal Intermittent Pilot Module.

Electrical Ratings:

Voltage: 24V, 60 Hz.

Current Draw: 1A pilot valve, 2A main valve.

Valve Contact Rating: 0.2A.

Trial for Ignition:

90 seconds maximum, then 100% shutoff (pilot and main

gas).

Continuous Retry:

Five-minute minimum (six-minute nominal) delay if pilot fails

to light during trial for ignition. After delay, trial for ignition is

repeated. This sequence (trial, delay, trial, delay) continues

until pilot lights or call for heat ends.

Spark Generator Output:

13 kV peak at 25 pF load.

Thermostat Anticipator Setting:

0.2A plus pilot valve rating plus main valve rating.

Relative Humidity Rating:

5 to 90% RH at 95°F.

Flame Failure Response Time:

0.8 sec at 1.0 mA flame current.

Terminals:

SENSE: 3/16 in. male quick connect.

All Other Terminals Including Ignition: 1/4 in. male quick

connects. Molex plug for connection to Honeywell

D80D or D892 Vent Damper.

Flame Current:

1 uA minimum.

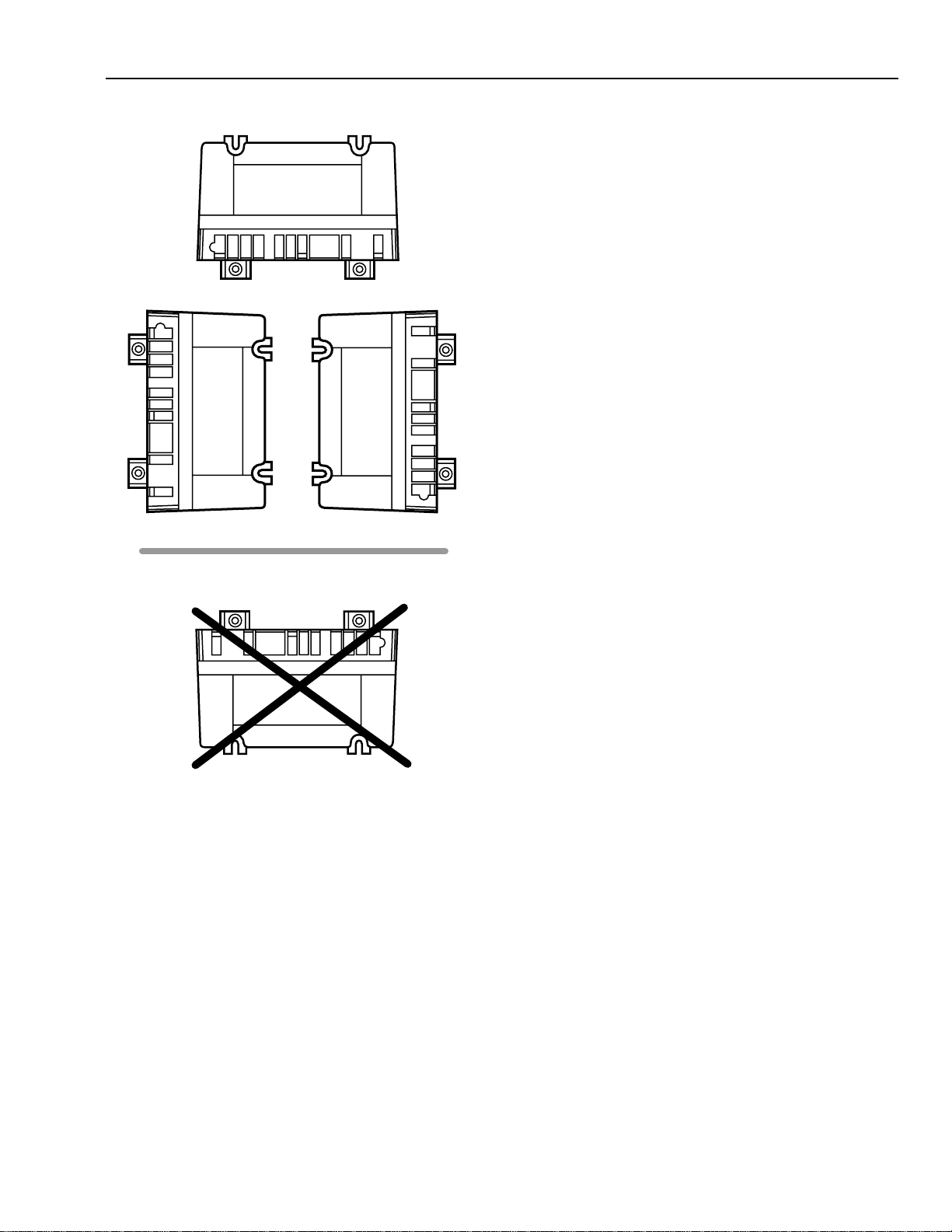

Mounting:

Mounts in any position except with terminals up. However,

recommended mounting position is with terminals down to

provide maximum protection from dripping water or dust

accumulation. Fasten with no. 6-32 machine or no. 8

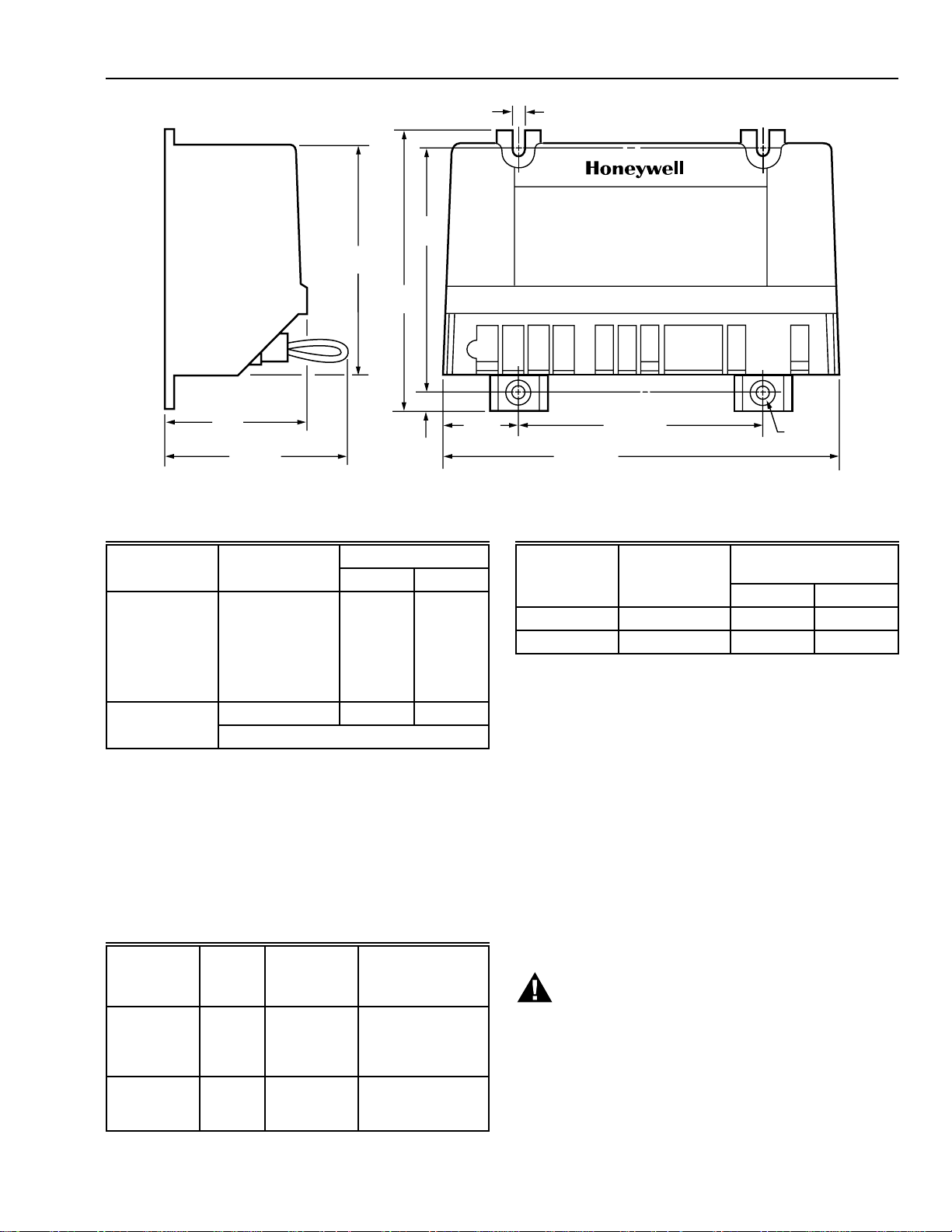

sheetmetal screws of appropriate length. See Fig. 1.

Underwriters Laboratories Inc. Component Recognized:

File no. MH15564, Guide no. MCCZ2.

IAS Design Certified: C2030011.

Other System Components

These modules provide operating control of an intermittent

pilot system. Additional components required to complete the

system must be ordered separately:

• Dual valve combination gas control designed for

intermittent pilot.

• Combination pilot burner/igniter-sensor or separate igniter

and sensor on pilot burner bracket.

• Ignition cable.

•Transformer.

• 24V thermostat.

• High limit and other auxiliary controls, as required.

Ambient Temperature Rating:

-40°F to +175°F (-40°C to +79°C) with main valve rated

1.0A or less.

-40°F to +165°F (-40°C to +74°C) with main valve rated

1.0A to 2.0A.

Dual Valve Combination Gas Control:

Any that meet current ratings listed below. VR8204,

VR8440 or VR8520 are recommended.

S8610U: 1.0A pilot, 2.0A main valve.

Pilot Burner/Igniter-Sensor:

See Table 1.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number, or specify:

1. SUPER TRADELINE® order number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0135—2

2

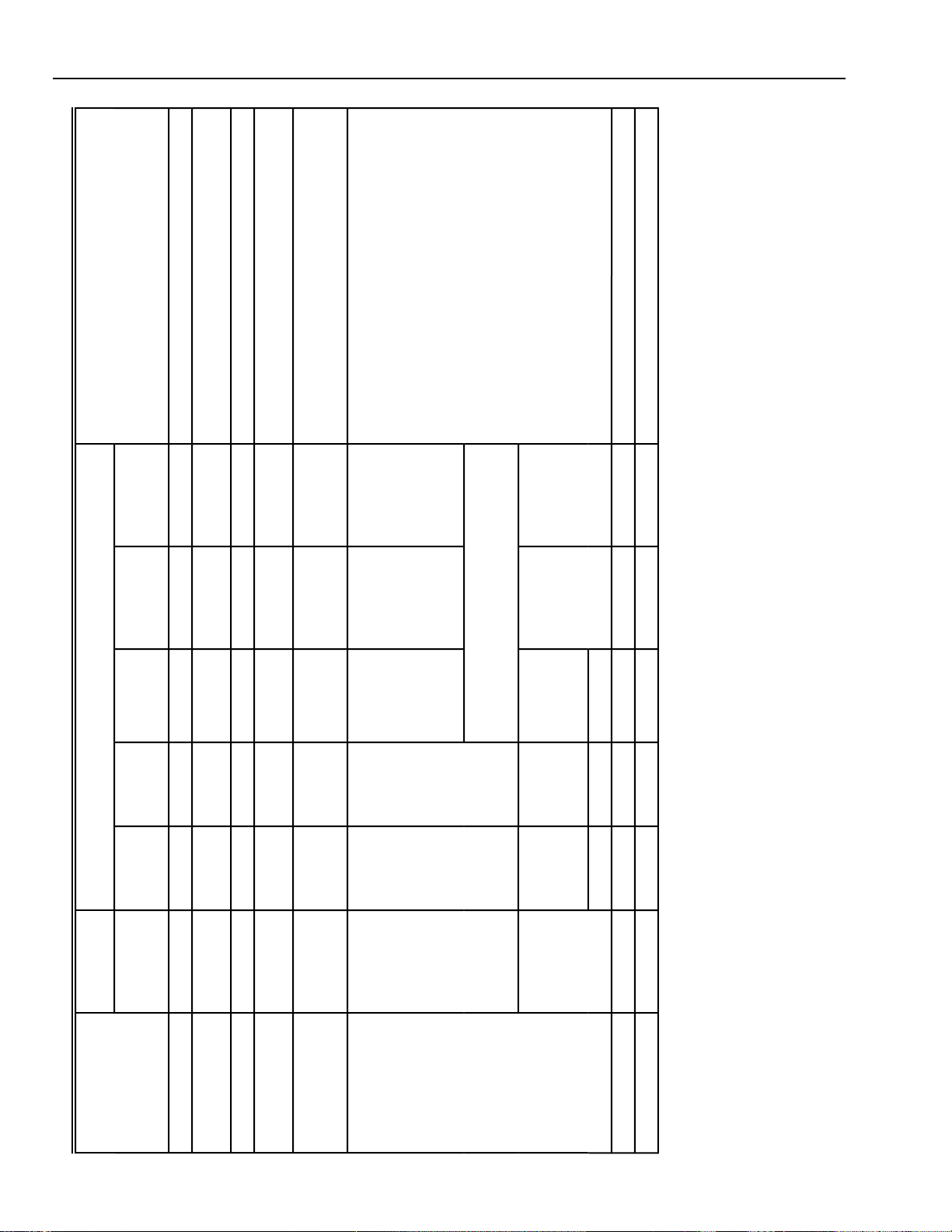

3-3/16

(81)

3-15/16

(100)

3-3/8

(86)

S8610U UNIVERSAL INTERMITTENT PILOT MODULE

3/16

(2)

(5)

2 (51)

2-5/8 (67)

1/4

(6)

Fig. 1. Approximate ignition module dimensions in in. (mm).

Table 1. Pilot Burner/Igniter-Sensors.

Pilot Burner/

Igniter-Sensor

Flow Rate*

cfh m

3

/hr

Combined Q345 0.8 0.02

Q348 1.5 0.04

Q362 0.5 0.014

Q373 0.8 0.02

Q381 0.5 0.014

Separate Q179C 1.8 0.05

Q354 with Q345, Q348, Q362 or Q381.

*With natural gas at 7.0 in. wc (1.7 kPa).

Ignition Cable:

Use Honeywell preassembled cable, see Table 2, or

assemble locally. Use the cable recommended in Table 3 (or

equivalent), insulated female 1/4 in. quick connect and

insulated Rajah connector receptacle. Maximum

recommended length is 36 in. (914 mm).

Table 2. Honeywell Preassembled Ignition Cables

(UL Style 3257).

Cable

Part Module

Number

Length

394800-30 30 in. 1/4 in. quick

End

connect,

insulated

Igniter End

Rajah connector

receptacle, 90

degree rubber

boot

394801-30 30 in. 1/4 in. quick

connect,

insulated

Rajah connector

receptacle, straight

rubber boot

1-1/32

(26)

3-3/8 (86) (2)

5-7/16 (138)

3/16

(5)

(2)

M1123A

Table 3. Recommended Ignition Cable for Field Assembly.

Temperature Rating

°C °F

Cable Type

Voltage

Rating (rms)

UL Style 3217 10,000 150 302

UL Style 3257 10,000 250 484

Transformer:

Add current ratings of module, pilot valve, main valve, vent

damper and any other components of the control system to

determine transformer-size requirement. Use a 30 VA or

larger transformer if a vent damper will be connected to the

S8610U Vent Damper Connector.

Thermostat:

Use open-close switch type, or independently-powered

electronic, 24V thermostat capable of switching rated control

system load. Before using electronic thermostat powered

through the heating/cooling controls, consult thermostat

manufacturer to assure proper control system operation.

High Limit and Other Auxiliary Controls:

As specified by the heating appliance manufacturer.

Ignition Modules Replaced

WARNING

Check Table 4 before replacing an existing intermittent

pilot module with the S8610U. If the existing module is

not listed, do not use the S8610U to replace it unless

you are certain the specifications of the S8610U

match those of the existing module.

3

68-0135—2

S8610U UNIVERSAL INTERMITTENT PILOT MODULE

The S8610U replaces existing flame rectification type

intermittent pilot ignition modules with the following

characteristics:

• Single rod (local sense) or two rod (remote sense) flame

sensing.

• Non-100 percent shutoff, 100 percent shutoff/lockout, or

100 percent shutoff/continuous retry.

• Natural or LP gas.

• Shutoff/lockout times of 30 seconds or longer.

• Prepurge times of four seconds or shorter.

• Pilot burners with flow rates of 1500 Btuh or less.

• With or without vent dampers.

A complete list of the specific Honeywell and other modules

that the SUPER TRADELINE® S8610U is designed to

replace is provided in Table 4.

The S8610U SUPER TRADELINE® package contains

complete, easy-to-use instructions, plus the accessories

required to adapt the existing spark cable (Rajah, stud, nail,

or other) to the spark terminal on the S8610U. It also provides

labels to help assure proper marking of the wires attached to

the existing module.

The S8610U SUPER TRADELINE® Universal Module is not

designed to replace controls with the following characteristics:

• Flame sensing other than by flame rectification (White

Rodgers Cycle-Pilot®, Robertshaw thermal sensing).

• Flame rectification modules with shutoff/lockout times of

less than 30 seconds, prepurge times of more than four

seconds, or pilot burners larger than 1500 Btuh.

• Standing pilot appliances.

Honeywell provides additional control packages to

accomplish these replacements. See the Honeywell

Electronic Ignition Service Manual, form 70-6604, or call your

Honeywell wholesaler.

Frequent Cycling

These controls are designed for use on appliances that

typically cycle three to four times an hour only during the

heating season only. In year-round applications with greater

cycling rates, the control can wear out more quickly. Perform

a monthly checkout.

Water Or Steam Cleaning

If a module or gas control gets wet, replace it. If the appliance

is likely to be cleaned with water or steam, protect (cover) the

controls and wiring from water or steam flow. Mount the

controls high enough above the bottom of the cabinet so they

do not get wet during normal cleaning procedures. Use a

NEMA 4 enclosure for the ignition module; see the Electronic

Ignition Service Manual, form 70-6604.

High Humidity or Dripping Water

Dripping water can cause the module to fail. Never install an

appliance where water can drip on the controls.

In addition, high ambient humidity can cause the gas control

to corrode and fail.

If the appliance is in a humid atmosphere, make sure air

circulation around the controls is adequate to prevent

condensation. Also, regularly check out the system. A NEMA

4 enclosure is recommended for the ignition module; see the

Electronic Ignition Service Manual, form 70-6604.

Corrosive Chemicals

Corrosive chemicals can attack the module and gas control,

eventually causing a failure. If chemicals are used for routine

cleaning, make sure they cannot reach the controls. Where

chemicals are suspended in air, as in some industrial or

agricultural applications, use a NEMA 4 enclosure for the

ignition module; see the Electronic Ignition Service Manual,

form 70-6604.

PLANNING THE INSTALLATION

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY OR DEATH.

Follow these warnings exactly:

1. Plan the installation as outlined below.

2. Plan for frequent maintenance as described in

the Maintenance section.

When intermittent pilot systems are used on central heating

equipment in barns, greenhouses, and commercial properties

and on heating appliances such as commercial cookers,

agricultural equipment, industrial heating equipment and pool

heaters, heavy demands are made on the controls. Special

steps may be required to prevent nuisance shutdowns and

control failure due to frequent cycling, severe environmental

conditions related to moisture, corrosive chemicals, dust or

excessive heat. These applications require Honeywell Home

and Building Control Engineering review; contact your

Honeywell Sales Representative for assistance.

Review the following conditions that could apply to your

specific installation and take the precautionary steps

suggested.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause controls to

malfunction. Where dust or grease can be a problem, provide

covers for the module and the gas control to limit

contamination. A NEMA 4 enclosure is recommended for the

ignition module; see the Electronic Ignition Service Manual,

form 70-6604.

Heat

Excessively high temperatures can damage controls. Make

sure the maximum ambient temperature at the control does

not exceed the rating of the control. If the appliance operates

at very high temperatures, use insulation, shielding, and air

circulation, as necessary, to protect the controls. Proper

insulation or shielding should be provided by the appliance

manufacturer; verify that proper air circulation is maintained

when the appliance is installed.

68-0135—2

4

S8610U UNIVERSAL INTERMITTENT PILOT MODULE

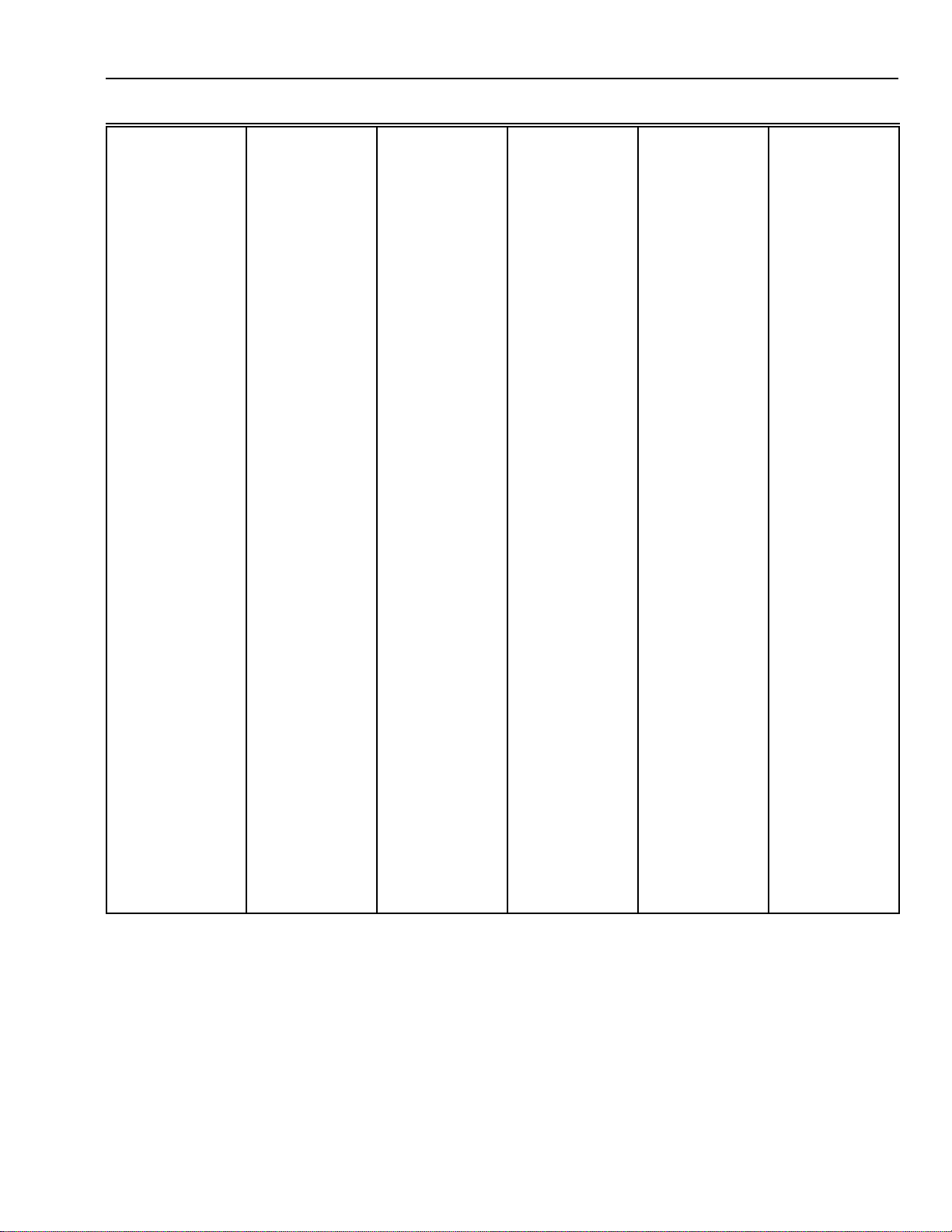

Table 4. S8610U Replaces these Ignition Modules.

CAMSTAT

IPI-24-00

FENWAL

05-203025-005

05-203026-005

HONEYWELL

S86A1001

S86A1019

S86A1027

S86A1035

S86B1009

S86B1017

S86B1025

S86C1007

S86C1015

S86C1031

S86C1049

S86C1056

S86D1005

S86D1021

S86E1002

S86E1010

S86E1028

S86E1036

S86E1044

S86E1051

S86E1069

S86E1077

S86E1101

S86E1119

S86E1127

S86F1000

S86F1018

S86F1026

S86F1042

S86F1059

S86F1067

S86F1075

S86F1083

S86F1091

S86G1008

S86G1016

S86G1032

S86G1057

S86G1073

S86H1006

S86H1022

S86H1048

S86H1089

S86H1097

S86H1105

S86H1121

S86H1147

S90A100

S90B1003

S90B1011

S8600A1001

S8600B1009

S8600C1015

S8600F1000

S8600F1034

S8600F1042

S8600H1006

S8600H1022

S8600H1048

S8600H1055

S8600H1089

S8600H1105

S8600M1005

S8600M1013

S8610A1009

S8610B1007

S8610B1015

S8610C1005

S8610F1008

S8610F1016

S8610F1024

S8610F1032

S8610H1012

S8610H1038

S8610H1046

S8610H1053

S8610H1079

S8610M1003

S8610M1029

S8620H1028

HSC

1003-3

1003-300

PENNJOHNSON

CSA35A-617R

CSA35A-618R

CSA42A-600R

CSA42A-601R

CSA42A-603R

CSA42A-604R

CSA43A-600R

CSA44A-600R

CSA45A-601R

CSA45A-602R

CSA46A-600R

CSA48A-600R

CSA49A-600R

CSA49A-605R

CSA51A-601R

CSA52A-600R

G60AAA-1

G60AAG-1

G60AAG-3

G60AAG-4

G60AAG-5

G60AAG-6

G60CAA-1

G60CAA-3

G60CAG-1

G60CAG-2

G60CAG-3

G60CAG-4

G60CAG-5

G60CAG-6

G60CAG-7

G60CAG-8

G60CAG-9

G60CBA-1

G60CBA-3

G60CBG-1

G60CBG-10

G60CBG-11

G60CBG-14

G60CBG-16

G60CBG-17

G60CBG-3

G60CBG-4

G60CBG-9

G60CCA-1

G60CCG-1

G60CPG-1

G60DBG-1

G60DCG-1

G60DCG-2

G60PAG-1

G60PAG-2

G60PAG-3

G60PAG-4

G60PAG-5

G60PAG-6

G60PAJ-1

G60PAK-1

G60PAK-2

G60PFH-1

G60PFH-2

G60PFL-1

G60PFQ-1

G60PVL-1

G60QAG-2

G60QAG-3

G60QAK-1

G60QBG-1

G60QBG-2

G60QBG-3

G60QBG-4

G60QBG-5

G60QBG-6

G60QBG-7

G60QBG-8

G60QBG-9

G60QBH-1

G60QBK-1

G60QBK-3

G60QBL-1

G60QBL-2

G60QCG-1

G60QCJ-1

G60QCL-1

G60QDG-1

G60QFL-1

G60QHL-1

G60QJL-1

G60QLG-1

G60QPL-1

G60QRH-1

G60QRL-1

G60QRL-2

G60QRL-3

G60QSL-1

G60QTH-1

G60QTL-1

G60RAG-1

G60RAK-1

G60RBG-1

G60RBG-2

G60RBG-3

G60RBK-1

G60RBK-2

G60RCG-2

G60RCJ-1

G60RDG-1

G60RDK-1

G60RGL-1

G60RHL-1

G60RHP-1

G60RPL-1

G60RSL-1

G60ZAG-1

G65BBG-1

G65BBG-2

G65BBG-3

G65BBG-4

G65BBG-5

G65BBG-6

G65BBG-7

G65BBG-8

G65BBM-1

G65BBM-2

G65BBM-3

G65BBM-4

G65BCG-1

G65BCM-1

G65BFG-1

G65BFM

G65BKG-1

G65BKG-2

G65BKG-3

G65BKM-1

G65BKM-2

G65BKM-3

G65DBG

G65DBM-1

G65DBM-3

G65DCM-1

G65DFG

G65DFM-1

G65DKG

G65DKM

G65FBG

G65FFG

G65FKG

G66AG-1

G66BG-1

G66MG-1

G66NG-1

G67AG-3

G67AG-4

G67AG-7

G67AG-8

G67BG-2

G67BG-3

G67BG-4

G67BG-5

G67MG-1

G67MG-4

G67NG-2

G600AX-1

G600AY-1

G600MX-1

G600NX-1

G600RX-1

G670AW-1

G770MGA-1

G770MGA-2

G770MGC-1

G770MGC-2

G770MGC-3

G770MHA-1

G770NGA-1

G770NGC-4

G770NGC-5

G770NGC-6

G770NGC-7

G770RGA-1

G770RHA-1

G770MHA-2

G770MHC-1

G770NHA-1

G770NHC-1

G770RHA-2

ROBERTSHAW

780-715

780-735

780-737

SP715

SP715A

SP735

SP735D

SP735L

USI 715U

5

68-0135—2

S8610U UNIVERSAL INTERMITTENT PILOT MODULE

INSTALLATION

1. Read these instructions carefully. Failure to follow them

could damage the components or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

components to make sure they are suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out component

operation as provided in these instructions.

WARNING

FIRE OR EXPLOSION HAZARD CAN CAUSE

PROPERTY DAMAGE, SEVERE INJURY, OR

DEATH.

1. If it gets wet, the ignition module can malfunction,

leading to accumulation of explosive gas.

• Never install where water can flood, drip or

condense on the module.

• Never use a module that has been wet.

Replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and will not vent upward naturally.

• Do not light the pilot or operate electric

switches, lights or appliances until you are

sure the appliance area is free of gas.

3. Do not attempt to disassemble or clean the

module. Improper reassembly and cleaning can

cause unreliable operation.

Mount New Ignition Module

We recommend mounting the S8610U Module in the same

location as the old module, if possible. Otherwise, select a

location close enough to the burner to allow a short (3 ft

(0.9m) maximum) direct cable route to the igniter. Ambient

temperature at the module must be within the range listed in

the Specifications section.

Mount the module with the terminals pointing down to protect

them from dripping water and dust. The module can also be

mounted with the terminals on either side. Do not mount with

terminals pointing up. Refer to Fig. 2 for mounting

recommendations. When it is necessary to drill new mounting

holes, use the S8610U as a template to mark the mounting

hole pattern. Drill new holes as required. Fasten securely with

four no. 6-32 machine or no. 8 sheetmetal screws.

Wire the Module

IMPORTANT

CAUTION

1. Disconnect the power supply before beginning

the wiring to prevent electrical shock or

equipment damage.

2. If a new gas control is to be installed, turn off the

gas supply before starting the installation.

Conduct a Gas Leak Test according to the gas

control manufacturer instructions after the gas

control is installed.

3. If the module must be mounted near moisture or

water, provide a suitable waterproof enclosure.

4. Using the wire labels provided, label all wires

before they are disconnected. Wiring errors can

cause improper appliance operation and

dangerous conditions such as bypassing safety

features.

Perform Preinstallation Safety Inspection

The preinstallation checks described in ANSI Standard

Z21.71 in Exhibit A must be done before the replacement

module is installed. If a condition is detected that could result

in unsafe operation, the appliance should be shut off and the

owner advised of the unsafe condition. Correct any potentially

unsafe condition before proceeding with the installation.

Remove Old Module

Disconnect power supply before doing any work on the unit.

Disconnect and tag the wires from the old module using the

wire labels provided. Remove the old module from its

mounting location.

CAUTION

1. Check the wiring diagram furnished by the

appliance manufacturer, if available, and

compare with Tables 5 through 8. Carefully follow

any special instructions affecting the general

procedures outlined below.

2. Disconnect the power supply before making

wiring connections to prevent electrical shock or

equipment damage.

1. A common ground is required on:

a. The pilot burner mounting bracket, and

b. The GND (BURNER) terminal on the ignition

module. Failure to use the GND (BURNER)

terminal can result in intermittent loss of spark

and/or loss of flame current sensitivity.

2. Make sure the transformer has adequate VA. The

ignition module requires at least 0.2A at 24 Vac. Add

the current draws of all other devices in the control

circuit, including the pilot and main valves in the gas

control, and multiply by 24 to determine the total VA

requirement of these components. Add this total to

4.8 VA (for the ignition module). The result is the

minimum transformer VA rating. Use a Class II

transformer when replacement is required.

3. When a vent damper is connected to the S8610U

vent damper connector, be sure the system

transformer delivers at least 30 VA. The S8610U has

an internal fuse that is intended to prevent appliance

lightoff if the vent damper is not in place or wired

properly. Using a small transformer can interfere with

the proper operation of the fuse and bypass the

intended safety feature.

쐃 Connect the wires to the S8610U Ignition Module as

shown in Tables 5 through 8. Make sure that adequate

system ground is provided as indicated in the wiring

tables.

쐇 Verify the thermostat anticipator setting as explained in

the IMPORTANT above.

68-0135—2

6

S8610U UNIVERSAL INTERMITTENT PILOT MODULE

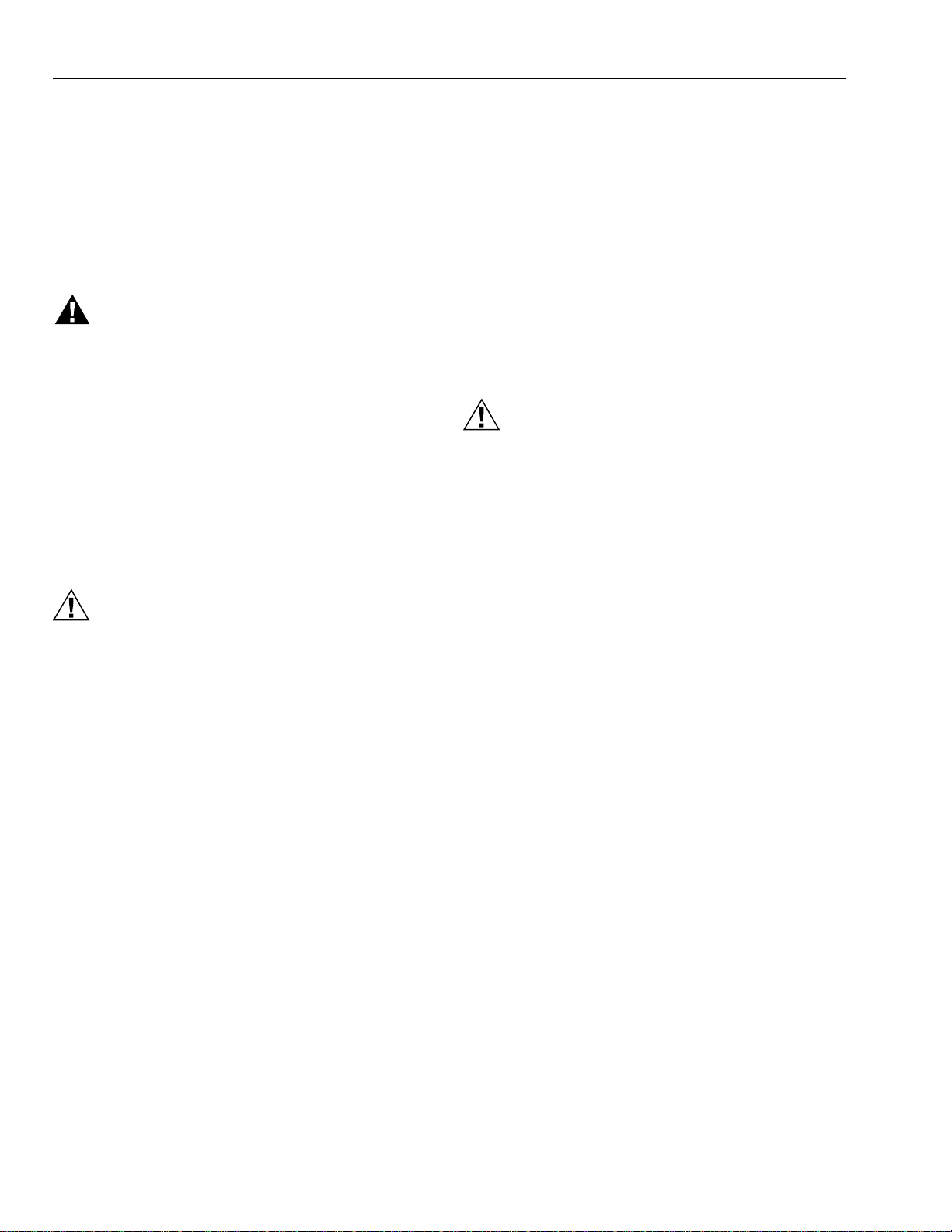

MOUNT IN ONE OF THESE POSITIONS

TERMINALS FACING DOWN

TERMINALS FACING LEFT TERMINALS FACING RIGHT

NOTE: The wiring diagrams in Fig. 5 through 8 show typical

hookups for the S8610U Ignition Module and should

be used for reference only.

Modify Ignition Cable, If Necessary

Use existing ignition cable if it is in good condition. If the

existing ignition cable does not have a 1/4 in. quick-connect

on the module end, either use the Rajah adapter or strip the

wire and replace with the 1/4 in. insulated quick-connect

supplied. If the cable must be replaced, order a Honeywell

ignition cable, see Table 2. It may be necessary to replace the

connector at the pilot burner end to match the pilot burner

spark termination.

NOTE: When using an S8610U to replace an S86, use the

enclosed adapter to convert the S86 Ignition Cable

to an S8610U Ignition Cable. Then, install the

adapter and cable to the S8610U Ignition Module.

NOTE: The cable must not run in continuous contact with a

metal surface or spark voltage is greatly reduced.

Use ceramic or plastic standoff insulators as

required.

DO NOT MOUNT

WITH TERMINALS FACING UP

M2647

Fig. 2. Module mounting recommendations.

7

68-0135—2

S8610U UNIVERSAL INTERMITTENT PILOT MODULE

Replacement

Control Old Control

Terminal Function S8610U1003 S86A,C S86B,D S86E,F,G,H

S8600A,B,C

S8610A,B,C

S90A,B

S8600F,H,M

S8610F,H,M Procedural Notes

Main valve operator MV MV MV MV MV MV

Main valve and pilot

common

MV/PV MV/PV MV/PV MV/PV MV/PV MV/PV

Pilot valve operator PV PV PV PV PV PV

Burner ground

connection

GND

(BURNER)

GND GND GND

(BURNER)

GND

(BURNER)

GND

(BURNER)

Transformer

secondary

(unswitched leg)

24V GND 25V (1) 25V (GND) 25V (1)e 24V GND 24V GND

Transformer

secondary

(switched leg)

24V* 25V (2) 25V 25V (2)

e*

24V* 24V* * Important: If the old module had a vent damper

plug but a vent damper was not installed, or if it

did not have a vent damper plug: leave the vent

damper plug in position on the S8610 and

connect the 25V (2) or 24V wire from the old

module to the TH-W terminal on the S8610U.

Do not use the 24V terminal on the S8610U.

25V (2) or 24V used only in systems where

plug-in cable connects damper to module.

If the old module

had

a vent damper with a plug

connection to a Molex connector, wire the

terminals as indicated in the table.

TH-W TH-R

a

TH-R

a

TH-R

a

TH-W

(This terminal

not included

on S90.)

TH-W

TH-Wb TH-W TH-Wb

Flame sensor SENSE

f

dd d

SENSE

fd

Igniter/sensor SPARK IGN COIL

c

IGN COIL

c

IGN COIL

c

SPARK SPARK

a

If 25V (2) and TH-R have wires connected, disconnect and splice together with solderless connector.

b

If TH-R and TH-W are jumpered together, connect 25V (2) lead from S86 to TH-W on S8610U1003.

c

Use Rajah to quick connector adapter (supplied) or cut Rajah connector off ignition cable at module end; attach insulated quick

connect for connection to S8610.

d

Leave black jumper connected.

e

Terminals may be marked 25V on some models and 24V on later models. These are functionally equivalent.

f

On dual igniter and sensor models, remove jumper quick connect from S8610U1003 Sense terminal, cut jumper wire at circuit board

, and discard.

Table 5. Conversion from Honeywell S86, S90, S8600 and S8610 to S8610U1003.

68-0135—2

8

Loading...

Loading...