Page 1

Controllable anti-pollution check valve EA type,

add-on for pressure reducing valves and filters

Construction

The check valve comprises:

• Check valve insert

• Union nut with internal thread

• Male threaded union with flat wrench faces

• Test plug with seal ring

Materials

• Brass union and nut

• NBR seal ring

• High grade synthetic material check valve cartridge

• NBR lip seal ring

• High quality synthetic material test plug

RV277

Product specification sheet

Application

Check valves of this type are particularly suitable for integral use

with pressure reducing valves, filters and filter combinations of all

types.

Check valves are safety devices for independent prevention of

water backflow, for example from drinking water appliances back

into the central water supply system.

They can also be used for industrial, commercial and similar systems where back pressure, back flow and back syphonage

must be prevented.

The classicfications of appliances to meet these requirements

are specified in EN 1717.

Special Features

• DIN/DVGW-approved

• Universal application

• Easy installation

• Quiet operation

• Create no shock pressure loadings

• Meets KTW recommendations for potable water

• Suitable for installation in any position

•Low pressure loss

Range of Application

Medium Water

Max. inlet pressure 25.0 bar

Technical Data

Operating temperature

Operating pressure approx. 0.01 bar

Connection size Male threaded union 1/2“ - 2“

max. 70°C

Female threaded union 1“ - 2

1

/2“

EN0H-1200GE23 R0206 y Subject to change without notice

www.honeywell.com 5

Page 2

RV277 Controllable anti-pollution check valve EA type,

Method of Operation

Spring loaded check valves have a moving seal disc which is lifted off the seat by a greater or lesser amount depending on the

flow rate through the valve. If the flow falls towards zero, then the

spring pushes the disc back onto the seat and seals the waterway.

To ensure continuing correct function it is recommended that

check valves be regularly checked and maintained (as specified

in EN 1717).

Options

RV277-... A = Standard version

Special Versions available on request

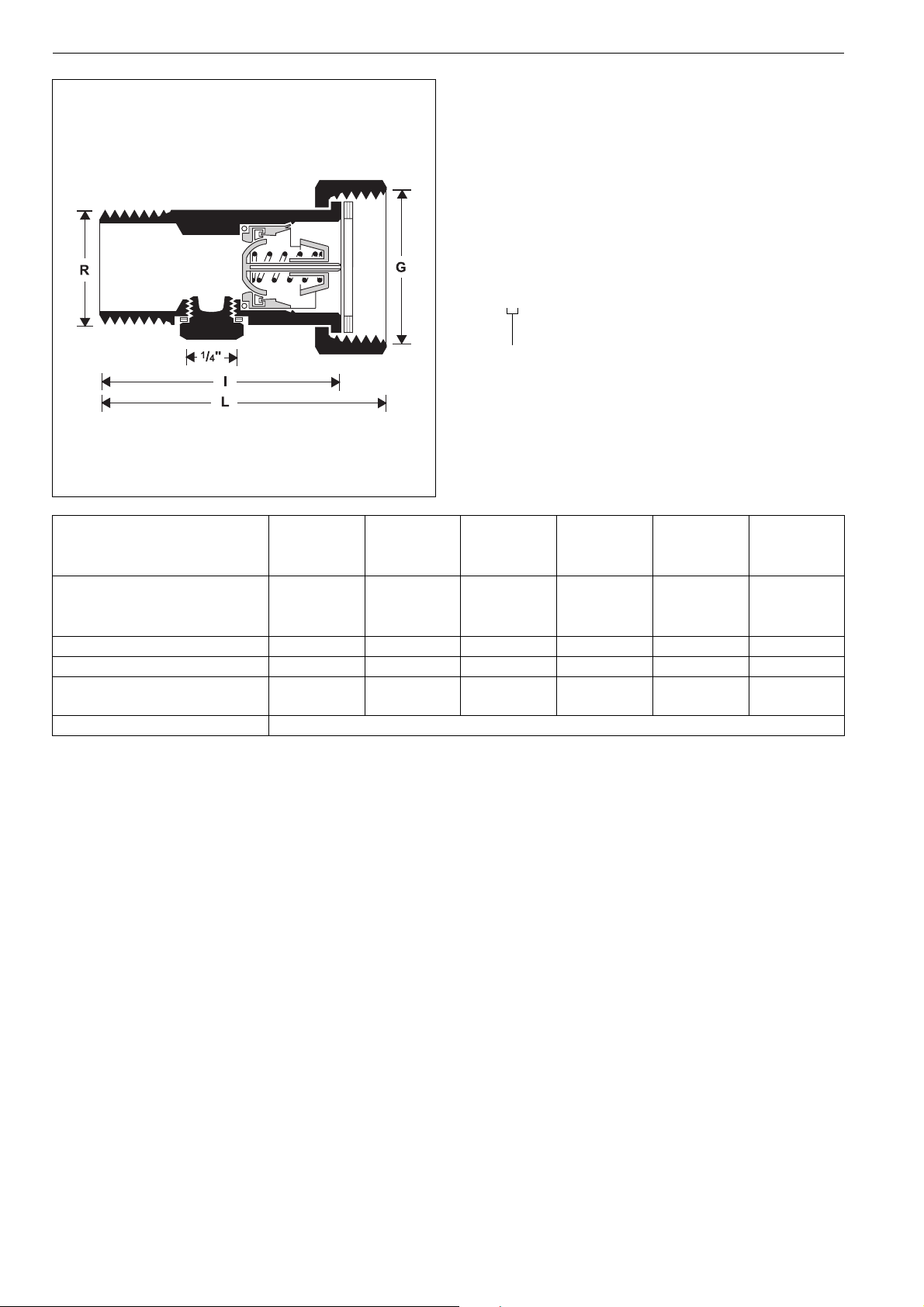

Connection size

Connection size R

1

/2"*

Nominal size diameter G 1" 1" 1

3

/4"1"1

1

/4"1

1

/4"1

1

/4"2“2

1

/2"2"

1

/2"

Weight approx. kg 0.20 0.22 0.35 0.52 0.86 1.56

Dimensions mm

L69 7482,594103,5121

l57 6369,580 90106

Test and drain plug R

-value m3/h6 1015284170

k

vs

Nominal flow rate in m

3

/h

1

/4"

1.8 3.8 5.8 10.8 15.9 27.1

1

/4"

1

/4"

1

/4"

1

/4"

1

/4"

at ∆p = 0,15 bar

DIN/DVGW Approval No. NW - 6312 AS 2269

* not suitable for D06F-1/2A

6 www.honeywell.com

EN0H-1200GE23 R0206 y Subject to change without notice

Page 3

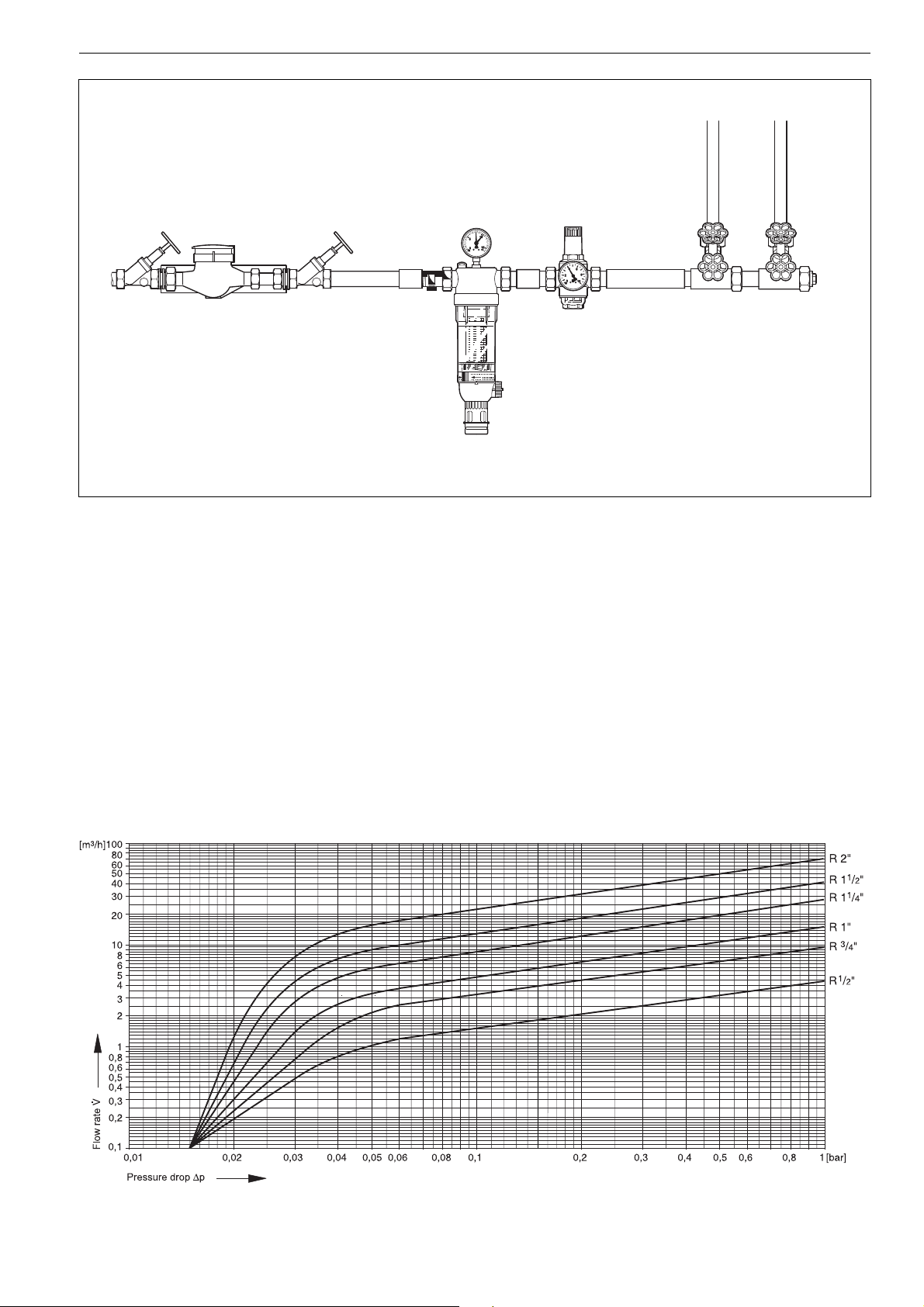

Installation Example

RV277 Controllable anti-pollution check valve EA type,

Installation Guidelines

• Install in horizontal pipework with test and drain plug downwards

o This position is best for draining

• Install shutoff valves

o Shutoff valves provide optimal serviceability

• Ensure good access

o Simplifies maintenance and inspection

Flow Diagram

Typical Applications

Check valves of this type are suitable for use as a safety device

on water installations as specified in EN 1717.

They can also be used within the scope of their specification.

The following are some typical applications:

• In central water supply systems

• After a water meter

• As a safety device up to liquid category 2 of EN 1717

EN0H-1200GE23 R0206 y Subject to change without notice

www.honeywell.com 7

Page 4

RV277 Controllable anti-pollution check valve EA type,

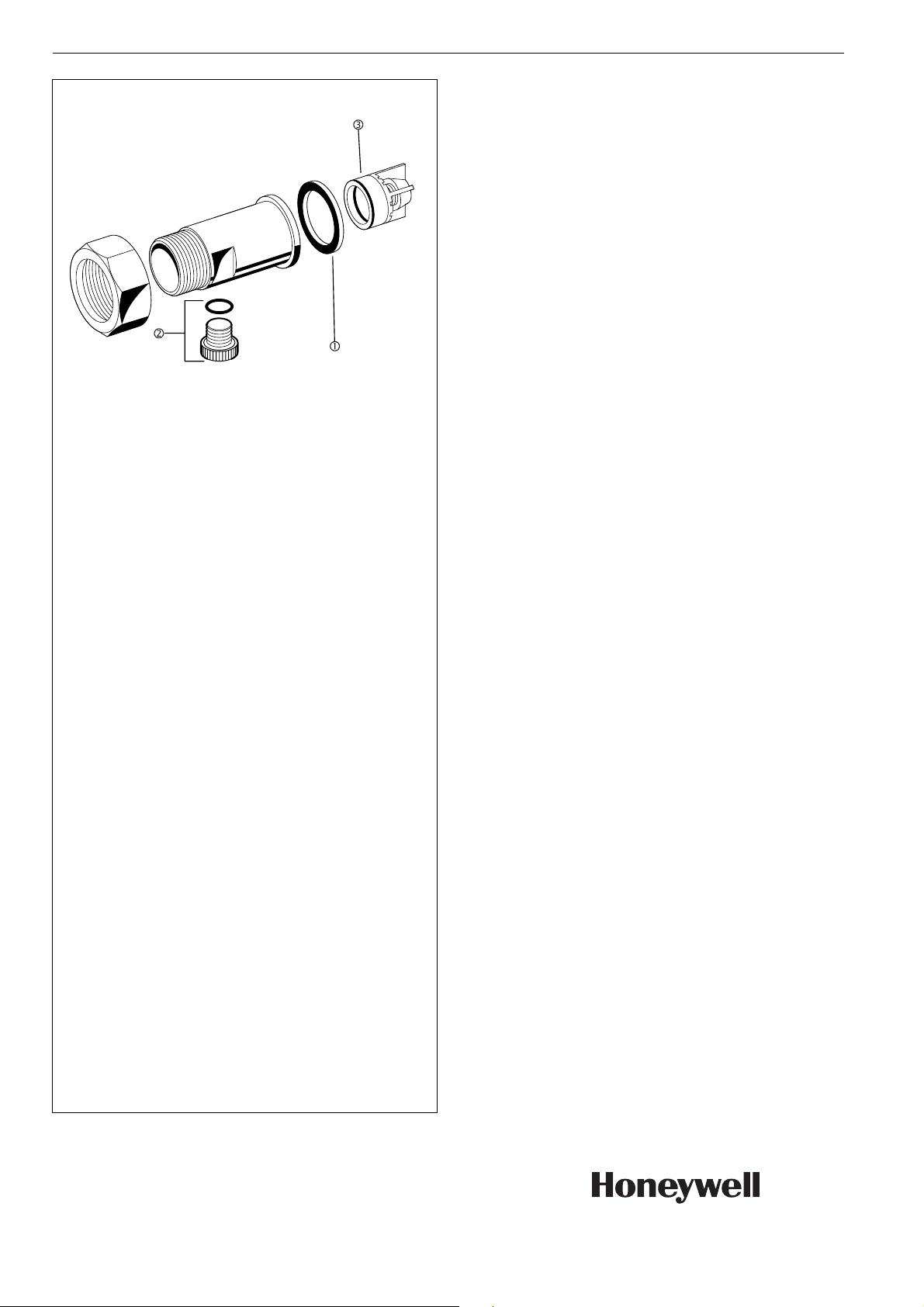

Spare Parts

Inlet check valve RV277, from 1994 onwards

No. Description Dimension Part No.

3

c Union seal washer

/4" 0901444

(10 pcs.) 1" 0901445

11/4" 0901446

1

/2" 0901447

1

2" 0901448

d Blanking plug all S06K-1/4

1

with O-ring R

/4"

(5 pcs.)

e Check valve cartridge

1

/2" 2166200

3

/4" 2110200

1" 2164400

1

/4" 2164500

1

11/2" 2164600

2" 2164700

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1200GE23 R0206

Subject to change

© 2006 Honeywell GmbH

Loading...

Loading...