Page 1

RV181

Check valve

Brass

Product specification sheet

Application

The check valve is a safety device in accordance with

DIN EN 1717 to protect systems against back pressure, back

flow and back syphonage of non-potable water into service pipe,

plants and equipments.

Special Features

• KIWA approved

• Optimal protection of the drinking water supply

• Compact construction

• Corrosion resistant by use of brass and stainless steel

• Universal application

• Low pressure loss

• Quiet operation

• Creates no shock pressure loadings

• No spare parts

• Meets KTW recommendations for drinking water

Construction

The check valve comprises:

•Housing

• Connections (Design A,B and K)

• Check valve insert (DVGW-approved)

• Test plugs with sealing ring

Materials

• Dezincification resistant brass housing

• High grade synthetic material check valve cartridge

• Stainless spring steel closing spring

• Test plugs in high grade synthetic material

• NBR seal ring

Range of Application

Medium Water

Liquid category 2 (no hazardous materials))

Technical Data

Installation position horizontal pipework with test plugs direc-

ted downwards

Operating pressure max. 16 bar

Operating temperature

Connection size

Typical Applications

Check valves of this type are priority suitable for domestic drinking water supply.

The check valve can be used for commercial and industrial applications in consideration of its specifications.

Check valves must be fitted,

• if service pipe, plant and equipment must be protected

against back pressure, back flow and back syphonage of

non-potable water.

max. 70°C (short term 90°C)

1

/2“ to 2“ (threaded and soldering connections)

ø15 and ø22 (compression connection)

EN0H-1228GE23 R1005 y Subject to change without notice

www.honeywell.com 1

Page 2

RV181 Check valve

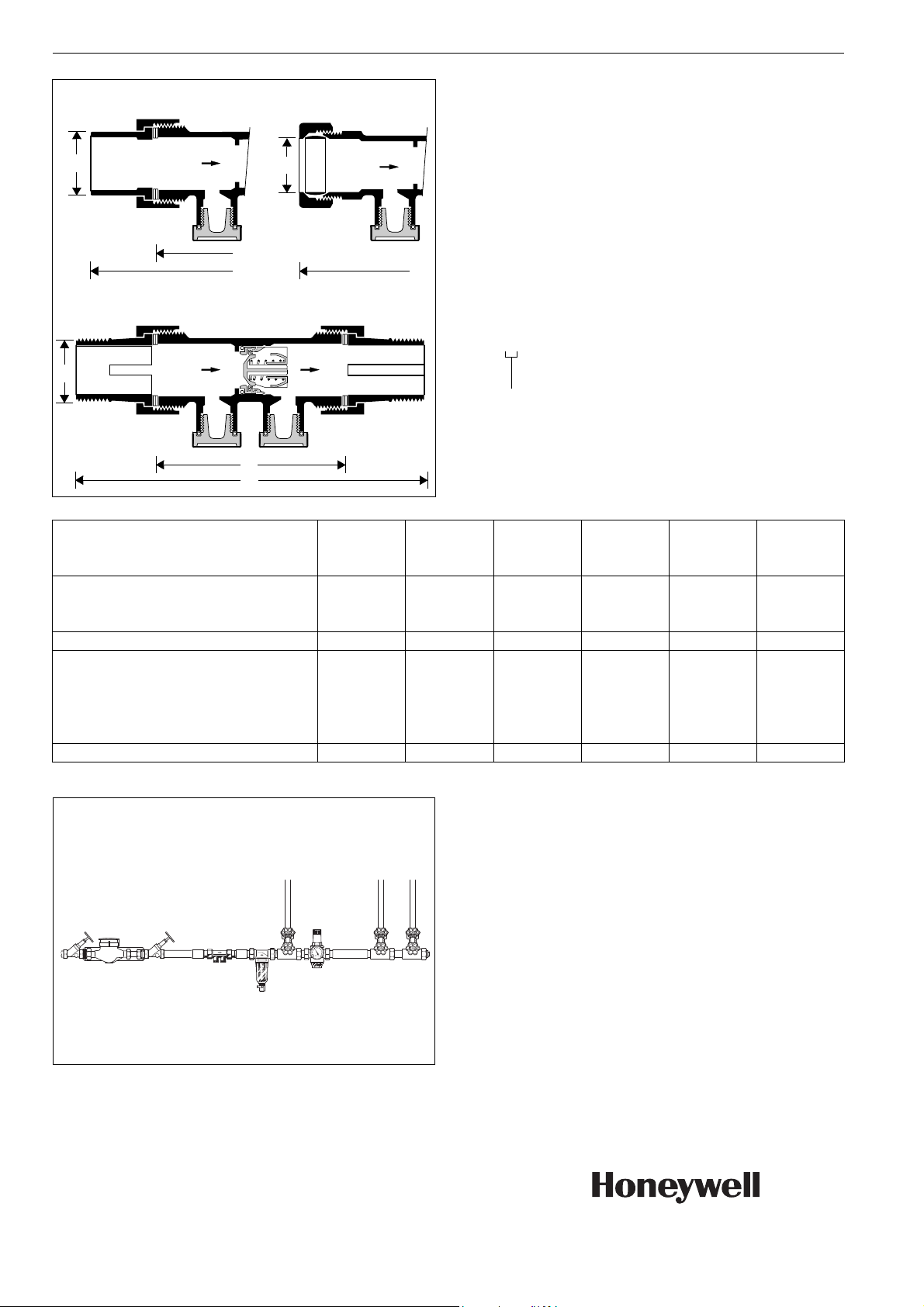

RV181-...A

DN

RV181-...B

Method of Operation

RV181-...K

The check valve protected the service pipe.

Spring loaded check valves have a moving seal disc which is lifted off the seat by a greater or lesser amount depending on the

ø

flow rate through the valve. If the flow falls towards zero, then the

spring pushes the disc back onto the seat and seals the waterway.

To ensure continuing correct function it is recommended that

L

l

2

l

check valves be regularly checked and maintained (as specified

in EN 1717).

3

Options

RV181-...A = Soldering connection

RV181-...B = Threaded connection

RV181-...K = Compression connection

R

Connection size

L

l

1

Connection size R 1/2" 3/4" 1" 11/4" 11/2" 2"

DN 15 20 25 32 40 50

RV181-...K ø 15 22 ----

Weight RV181-...A ca. kg 0,3 0,45 0,78 1,17 1,75 2,65

RV181-...B 0,24 0,35 0,67 0,95 1,52 2,27

RV181-...K 0,16 0,21 ---Test an drain plug G 1/4" 1/4" 1/4" 1/4" 1/4" 1/4"

Dimensions mm

L 66778090100115

l

1

l

2

l

3

k

-value 6,01015284170

vs

Installation Example

137 156 169 185 202 241

97 120 128 148 166 199

90 90

Installation Guidelines

• In a drinking water supply the check valves are fitted immediately after the water meter.

o This position ensures optimum protection for the drinking

water supply.

• Install in horizontal pipework with test plugs directed downwards.

o This position ensures optimum protection efficiency.

4

6

8

2

bar

0

10

o This position is best for testing the valve

• Shut off valves should be fitted on each side of the check valve.

o Shut off valves enables fast testing

• The installation location should be protected against frost

and be easily accessible

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1228GE23 R0106

Subject to change

© 2005 Honeywell GmbH

Loading...

Loading...