Page 1

Characteristic

Parameter

LV (Low Voltage)

HV (High Voltage)

Supply voltage

5 ±0.5 Vdc

10 Vdc to 30 Vdc

Supply current

20 mA max.

32 mA max.

Supply current (during output to ground short)

25 mA max.

47 mA max.

Output

0.5 V to 4.5 V ratiometric

0.5 V to 4.5 V non-ratiometric

Output signal delay

4 ms typ.

Overvoltage protection

10 Vdc

Reverse polarity protection

-10 Vdc

-30 Vdc

Output to ground short circuit protection

continuous

Output load resistance (pull down to ground)

10 kOhm

EMI:

radiated immunity

conducted immunity

100 V/m from 200 MHz to 1000 MHz per ISO11452-2

100 mA BCI per ISO11452-4

from 1 MHz to 200 MHz

100 mA BCI per ISO11452-4

from 1 MHz to 400 MHz

EMC

exceeds CE requirements

Operating temperature range

-40 °C to 125 °C [-40 °F to 257 °F]

Storage temperature range

-40 °C to 125 °C [-40 °F to 257 °F]

Ingress protection

IP67 according to DIN 40050

Expected life

35 M cycles

Media compatibility

heavy transportation fluids

Housing material

PBT plastic

Shock

50 G peak

Vibration

20 G peak tested from 10 Hz to 2000 Hz

Resolution

12 bit

Termination

AMP super seal connector

Mechanical end stop

no

Approvals

CE

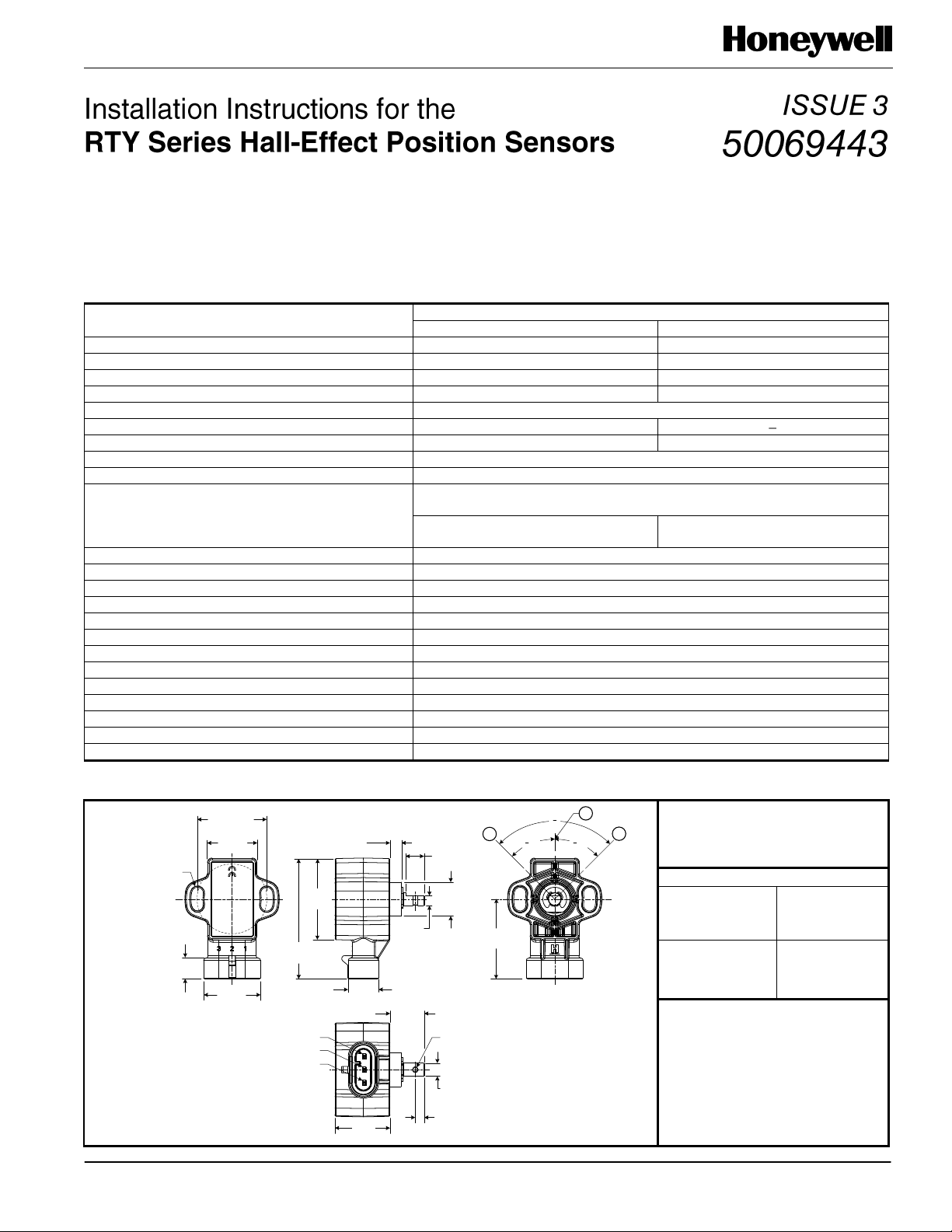

22,0

[0.87]

26,0

[1.02]

9,5

[0.37]

5,35 DIA.

[0.21]

37

[1.46]

55

[2.17]

5,9

[0.23]

8,3

[0.33]

15,50 DIA.

[0.61]

4,60

[0.18]

13,8

[0.54]

15,6

[0.61]

4,12

[0.16]

25

[0.98]

36,4

[1.43]

0

A

C

B

Pin 1

Pin 2

Pin 3

2,0 DIA.

[0.078]

6 DIA.

[0.24]

32,0 DIA.

[1.25]

0

/2

0

/2

RTYXXXXXXXX

YYDDMMSSSS

A = Left output: 0.5 Vdc

B = Zero reference

C = Right output: 4.5 Vdc

Pinout

N

(North

American)

E

(European)

Pin 1 = VCC

Pin 2 = GND

Pin 3 = Output

Pin 1 = GND

Pin 2 = VCC

Pin 3 = Output

NOTICE

Ferrous or magnetic material

within a 75 mm [2.95 in] radius

from sensor center may affect

sensor performance.

GENERAL INFORMATION

The RTY Series uses a magnetically biased, Hall-effect

integrated circuit (IC) to sense rotary movement of the actuator

shaft over a set operating range. Rotation of the actuator shaft

changes a magnet’s position relative to the IC. The resulting

flux density change is converted to a linear output.

Table 1. Specifications

MOUNTING INFORMATION

Mount the sensor using the two easily accessible mounting

holes and non-magnetic stainless steel M5 screws with flat

washers. Mounting screw tightening torque is 2,5 N m

±0,5 N m [22.1 in lb ±4.4 in lb]. In harsh applications, treat the

screw threads with a suitable thread locking compound.

Figure 1. Mounting Dimensions (For Reference Only: mm/[in].)

Sensing and Control

Page 2

RTY Series

Issue 3 50069443

Sensing and Control

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

www.honeywell.com

50069443-3-EN

October 2012

Copyright © 2012. Honeywell International Inc. All rights reserved.

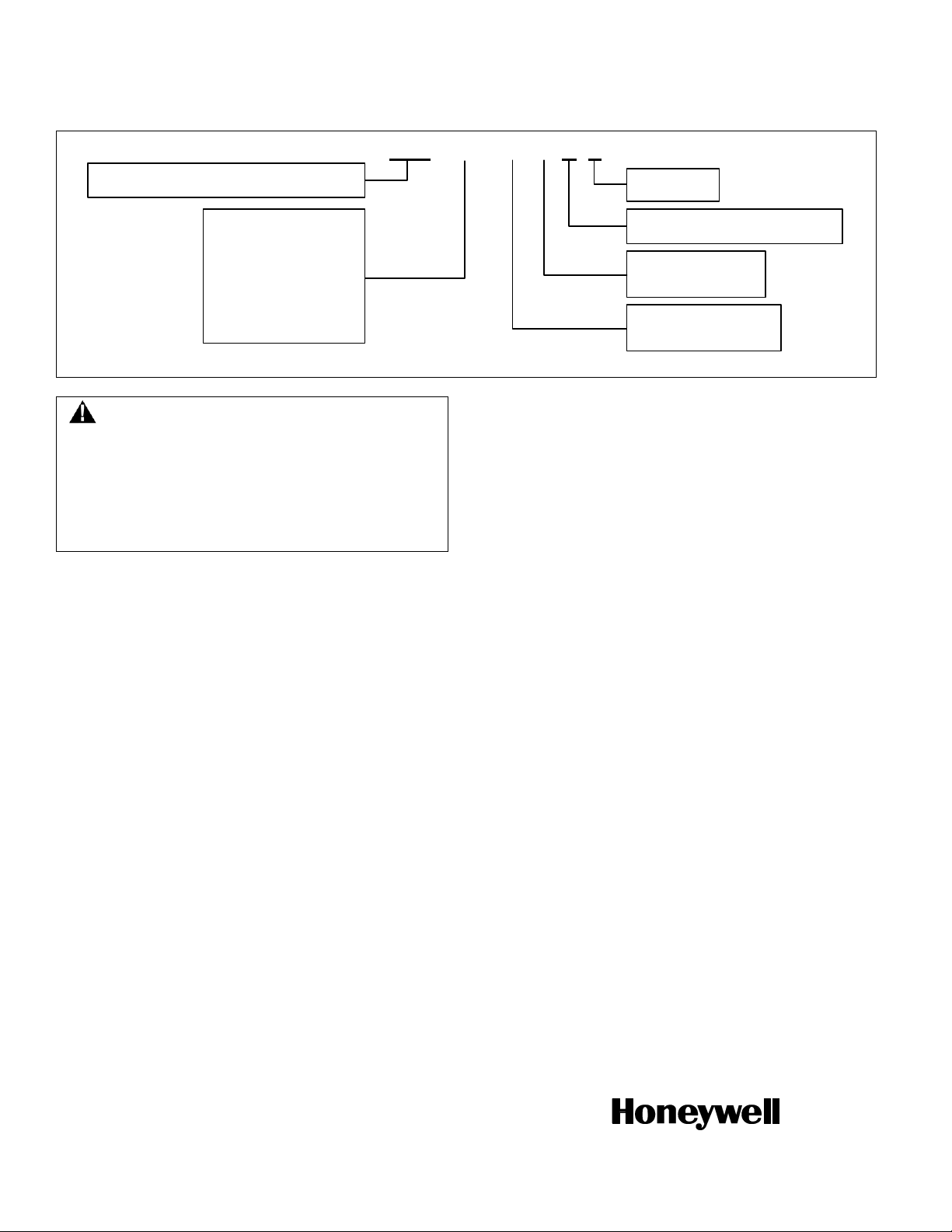

RTY _ _ _ _ _ _ A X

Product Series

RTY = Hall-Effect Rotary Position Sensor

Pinout Style

E = European

N = North American

Sensing Range Angle

050 = 50° (±25°)

060 = 60° (±30°)

070 = 70° (±35°)

090 = 90° (±45°)

120 = 120° (±60°)

180 = 180° (±90°)

270 = 270° (±135°)

360 = 360° (±180°)

Supply Voltage

LV = 5 Vdc

HV = 10 Vdc to 30 Vdc

Output Type

A = 0.5 Vdc (left), 4.5 Vdc (right)

Lever

X = No lever

PERSONAL INJURY

DO NOT USE these products as safety or emergency stop

devices or in any other application where failure of the

product could result in personal injury.

Failure to comply with these instructions could result in

death or serious injury.

Figure 2. Nomenclature and Order Guide

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of

defective materials and faulty workmanship. Honeywell’s

standard product warranty applies unless agreed to otherwise

by Honeywell in writing; please refer to your order

acknowledgement or consult your local sales office for specific

warranty details. If warranted goods are returned to Honeywell

during the period of coverage, Honeywell will repair or replace,

at its option, without charge those items it finds defective. The

foregoing is buyer’s sole remedy and is in lieu of all other

warranties, expressed or implied, including those of

merchantability and fitness for a particular purpose. In no

event shall Honeywell be liable for consequential, special,

or indirect damages.

While we provide application assistance personally, through

our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the

application.

Specifications may change without notice. The information we

supply is believed to be accurate and reliable as of this printing.

However, we assume no responsibility for its use.

SALES AND SERVICE

Honeywell serves its customers through a worldwide network

of sales offices, representatives and distributors. For

application assistance, current specifications, pricing or name

of the nearest Authorized Distributor, contact your local sales

office or:

E-mail: info.sc@honeywell.com

Internet: www.honeywell.com/sensing

Phone and Fax:

Asia Pacific +65 6355-2828

+65 6445-3033 Fax

Europe +44 (0) 1698 481481

+44 (0) 1698 481676 Fax

Latin America +1-305-805-8188

+1-305-883-8257 Fax

USA/Canada +1-800-537-6945

+1-815-235-6847

+1-815-235-6545 Fax

Page 3

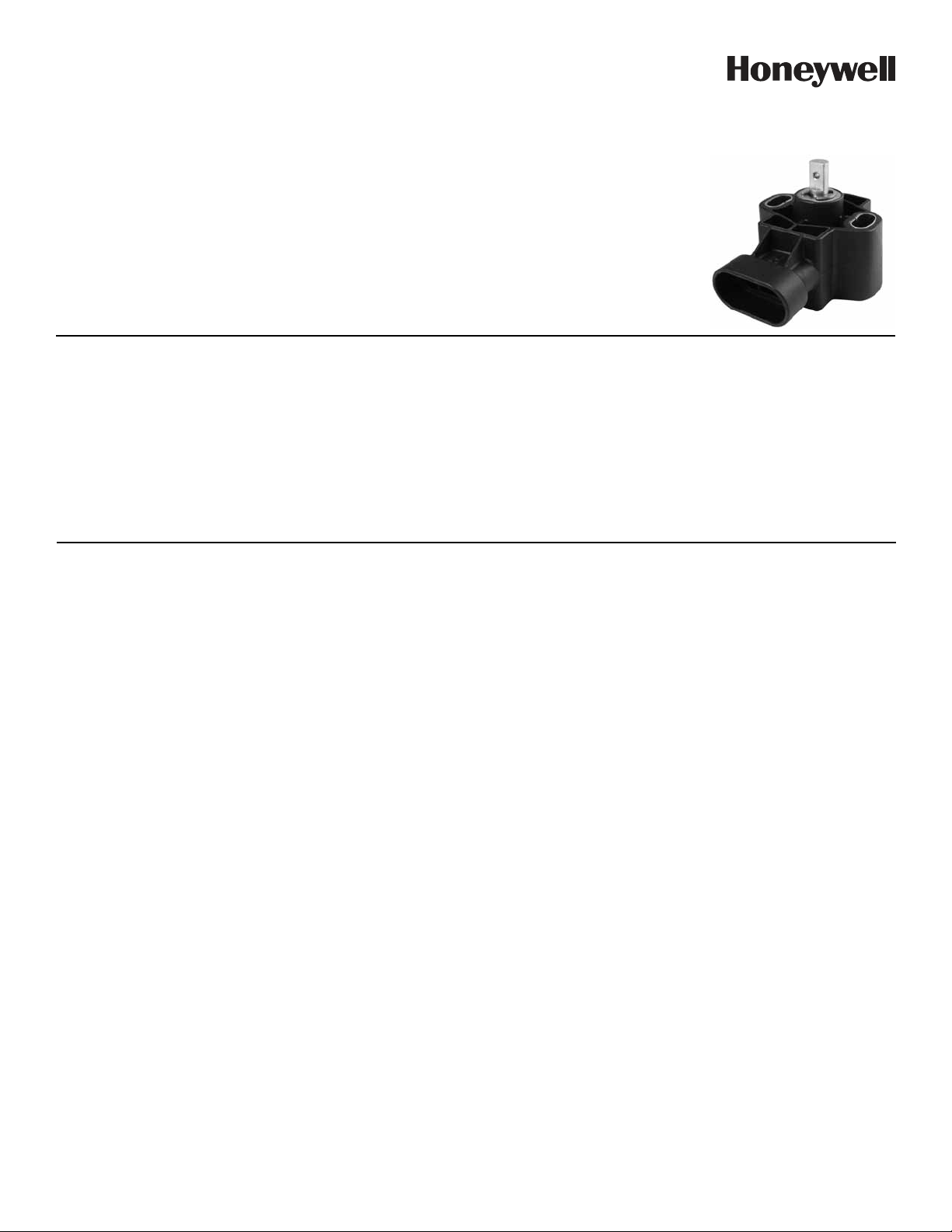

Hall-Effect Rotary Position

Sensors Line Guide

Round and round the globe, it’s Honeywell. So trust Honeywell

Sensing and Control (S&C) for your Hall-effect rotary position

sensor needs. These sensors vary output voltage or current in

response to changes in a magnetic field — using a magnetically

biased Hall-effect integrated circuit (IC) to sense rotary

movement of the actuator shaft. The rotation of the shaft changes

the IC’s position to the magnets, and then detects the change in

FEATURES

HALL-EFFECT ROTARY POSITION

SENSORS

RTY Series.

Features: 35 M cycle product life

• Solid-state Hall-effect technology

• Rugged IP67-sealed package with

integral connector • Automotive-grade

EMI/EMC testing, integrated reverse

polarity, and short circuit • Industrystandard AMP termination, 32 mm

mounting pitch, North American and

European pinout styles, and compact

package • Eight sensing ranges up to

360° • Low voltage and high voltage

versions

Benets: Angle monitoring in harsh

transportation and industrial applications

at a competitive cost. 12 M cycle product

life provides long life in the application.

Solid-state Hall-effect technology provides

non-contact operation, long service

life, low torque actuation and reduces

worn-out mechanisms. IP67 sealing and

integral connector allows for use in harsh

environments. EMI/EMC testing, reverse

polarity and short circuit provide protection

against installation errors and frequencies

in the environment. Industry standard

termination, mounting pitch and pinout

provide drop-in replacement for existing

applications. Choice of sensing ranges

provides flexibility in multiple applications,

allowing OEMS the range of travel needed

for the application. Potential applications

include position and movement detection of

pedals, throttles, gear shift, levers, steering,

linkages, and hitches (trucks, buses,

off-road vehicles, industrial/construction/

agricultural vehicles and equipment,

cranes); suspension displacement/kneeling

(buses, trucks); tilt/trim position (boat

engines, tilling equipment), as well as

industrial valve and HVAC damper control,

and irrigation pivot control

RPN Series.

Features: Solid-state Hall-effect

technology • 30 M cycle product life

• Eight sensing ranges up to 360°

• Reverse polarity, short circuit and EMC

protection • Choice of operating ranges,

outputs, and levers • IP67- or IP69K-

sealed package with integral connector

Benets: Long service life, low torque

actuation, and reduced mechanism wearout. Enhanced resistance to damage from

incorrect wiring and electrical noise. Wide

choice of sensing ranges provides range

of travel for most applications; tolerant

to overtravel. Output choices provide

flux density. The output of the IC is converted to a linear output

up to 360 degrees of travel. Honeywell S&C seals the IC together

with conditioning and protection circuitry and two permanent

magnets in a rugged package featuring enhanced reliability.

What’s more, our non-contacting approach to Hall-effect rotary

position applications provides longer-life solutions that excel in

most harsh environments.

application flexibility. Sealed package

with integral connector for durability.

Often ideal for detecting position and

movement of potential applications such

as pedals, throttles, gear shift levers,

linkages, suspension and hitches in trucks,

offroad vehicles, cranes and construction/

agricultural/industrial equipment.

HRS100 Series.

Features: Solid-state Hall-effect

technology • 10 M cycle product life

(typical) • Two sensing ranges • Choice of

termination

Benets: Use of magnetically coupled

technology in place of a mechanical wiper

assembly provides long life and a costeffective solution for harsh environments

that include temperature, vibration, dither,

moisture and dirt. Non-contact operation,

long service life, low torque actuation

and reduced wear-out of mechanisms.

Potential applications include position and

movement detection of pedals, throttles,

gear shift, levers, steering, linkages, and

hitches (off-road vehicles and industrial/

construction/agricultural vehicles/

equipment), tilt/trim position (boat engines),

and industrial material handling equipment

(forklifts, robotics)

continued on page 3

Page 4

Hall-Effect Rotary Position Sensors Line Guide

More are turning to

Honeywell, for more value.

Honeywell S&C RTY and

RPN Series Hall-effect rotary

position sensors respond

to the presence or to the

interruption of a magnetic

field, using a solid-state

Hall-effect IC to sense rotary

movement of the actuator

shaft and then producing a

proportional output. The IC,

circuitry and magnets are

galvanized with an integral

connector — more than a

match for the most unforgiving

conditions. The HRS100 Series

uses magnetically-coupled

technology in place of a

mechanical wiper assembly

which provides long life and

a cost-effective solution for

harsh environments.

These sensors are often ideal

for potential transportation

applications, such as throttle

and speed position and

control, inboard lever control,

foot pedal, gearshift, steering,

lever, linkage, seat, mirror, tilt

and manipulator arm position.

Hall-Effect Rotary

Position Sensors

RTY Series

Sensing range

Redundant version no

Input voltage

Output

Input current

Operating temperature range -40 °C to 125 °C [-40 °F to 257 °F]

Connector AMP super seal

Life 35 M cycles

EMI/EMC

Housing material PBT plastic

Dimensions 55 mm L x 43 mm W x 41 mm H [2.17 in L x 1.69 in W x 1.61 in H]

50° (±25°), 60° (±30°), 70° (±35°), 90° (±45°), 120° (±60°), 180° (±90°),

270° (±135°), 360° (±180°)

low voltage: 5 Vdc ±0.5 Vdc

high voltage: 10 Vdc to 30 Vdc

low voltage: 0.5 V to 4.5 V ratiometric

high voltage: 0.5 V to 4.5 V non-ratiometric

low voltage: 20 mA max.; during output to ground short, 25 mA max.

high voltage: 32 mA max.; during output to ground short, 47 mA max.

• EMI radiated immunity: 100 V/m from 200 MHz to 1000 MHz per ISO11452-2

• EMI conducted immunity:

- low voltage: 100 mA BCI per ISO11452-4 from 1 MHz to 200 MHz

- high voltage: 100 mA BCI per ISO11452-4 from 1 MHz to 400 MHz

• EMC: exceeds CE requirements

Other benefits include:

360-degree operating range

with multi-turn allowable

rotation, low torque actuation

and greatly reduced wearout mechanisms, enhanced

resistance to damage from

incorrect wiring and electrical

noise, wide operating

angle tolerant to overtravel,

integrated reverse polarity,

short circuit and EMC

protection.

2 www.honeywell.com/sensing

Page 5

Hall-Effect Rotary

Position Sensors

RPN Series HRS100 Series

Sensing range

Redundant version yes no

Input voltage 5 Vdc, 8 to 30 Vdc, 10 Vdc to 30 Vdc 5 Vdc ±10%

Output

Input current 20 mA max. 5 mA typ.

Operating temperature range -40 °C to 125 °C [-40 °F to 257 °F] -40 °C to 85 °C [-40 °F to 185 °F]

Connector

Life 30 M cycles 10 M cycles

EMI/EMC EMC: 200 V/m ISO 11452-3 EMI: 30 V/m, 10 kHz to 1000 MHz at 3 m

Housing material PA66 plastic metal

Dimensions

50° (±25°), 60° (±30°), 70° (±35°), 90° (±45°), 120° (±60°),

180° (±90°), 270° (±135°), 360° (±180°)

0.25 V to 4.75 V, 0.5 V to 4.5 V, 1 V to 9 V, 3 V to 5 V, 4.5 V to

0.5 V, 4.75 V to 0.25 V, 4 mA to 20 mA, 20 mA to 4 mA

AMP 1-1419168-1, AMP Superseal 282087-1,

Deutsch DT04-3P

63 mm L x 38,8 mm W x 56 mm H

[2.48 in L x 1.53 in W x 2.20 in H]

90° ±2°, 180° ±2°

5% to 95% of applied Vdd, approx. (programmable)

(output ratiometric to supply)

solder lug, flying wire leads

32,27 mm [1.3 in] H x 27,79 mm [1.1 in] W

Page 6

Warranty. Honeywell warrants goods of

its manufacture as being free of defective

materials and faulty workmanship.

Honeywell’s standard product warranty

applies unless agreed to otherwise by

Honeywell in writing; please refer to your

order acknowledgement or consult your

local sales office for specific warranty

details. If warranted goods are returned to

Honeywell during the period of coverage,

Honeywell will repair or replace, at its

option, without charge those items it finds

defective. The foregoing is buyer’s sole

remedy and is in lieu of all warranties,

expressed or implied, including those

of merchantability and tness for a

particular purpose. In no event shall

Honeywell be liable for consequential,

special, or indirect damages.

While we provide application assistance

personally, through our literature and

the Honeywell web site, it is up to the

customer to determine the suitability of the

product in the application.

Specifications may change without notice.

The information we supply is believed to

be accurate and reliable as of this printing.

However, we assume no responsibility for

its use.

For more information about Sensing and

Control products, visit www.honeywell.

com/sensing or call +1-815-235-6847

Email inquiries to info.sc@honeywell.com

Sensing and Control

Automation and Control Solutions

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422 USA

+1-815-235-6847

www.honeywell.com/sensing

005892-4-EN IL50 GLO

October 2012

Copyright © 2012 Honeywell International Inc. All rights reserved.

Page 7

RTY Series

Hall-Effect Rotary

Position Sensors

FEATURES AND BENEFITS (=competitive differentiator)

POTENTIAL APPLICATIONS

DESCRIPTION

The RTY Series Hall-Effect Rotary Position Sensors provide

angle monitoring in harsh transportation and industrial

applications at a competitive cost.

These products use a magnetically biased, Hall-effect

integrated circuit (IC) to sense rotary movement of the actuator

shaft over a set operating range. Rotation of the actuator shaft

changes a magnet’s position relative to the IC. The resulting

flux density change is converted to a linear output.

The IC, together with conditioning and protection circuitry, and

the permanent magnet, is sealed in an IP67-qualified rugged

package for durability in most harsh environments.

35 M cycle product life: Provides long life in the

application

Solid-state Hall-effect technology: Provides non-contact

operation, long service life, low torque actuation and

reduces worn-out mechanisms

Rugged IP67-sealed package with integral connector:

Allows for use in harsh environments

Automotive-grade EMI/EMC testing, integrated reverse

polarity, and short circuit: Provides protection against

installation errors and frequencies in the environment

Industry-standard AMP termination, 32 mm mounting

pitch, North American and European pinout styles, and

compact package: Provide drop-in replacement

Eight operating ranges up to 360°: Provides flexibility in

multiple applications, allowing OEMs the range of travel

needed for the application

Eight operating ranges (50°, 60°, 70°, 90°, 120°, 180°, 270°

and 360°) are tolerant to over-travel and allow use in most

common applications. Low voltage and high voltage versions

cover an input voltage range of 4.5 Vdc to 30 Vdc.

Most applications require no lever, and no brackets are

necessary.

Honeywell’s industry-leading capabilities in research and

development provide the customer with known quality and

support.

Transportation:

Position and movement detection of pedals, throttles, gear

shift, levers, steering, linkages, and hitches (trucks, buses,

off-road vehicles, industrial/construction/agricultural

vehicles and equipment, cranes)

Suspension displacement/kneeling (buses, trucks)

Tilt/trim position (boat engines, tilling equipment)

Industrial:

Valve control

HVAC damper control

Irrigation pivot control

Page 8

RTY Series

Characteristic

Parameter

LV (Low Voltage)

HV (High Voltage)

Supply voltage

5 ±0.5 Vdc

10 Vdc to 30 Vdc

Supply current

20 mA max.

32 mA max.

Supply current (during output to ground short)

25 mA max.

47 mA max.

Output

0.5 V to 4.5 V ratiometric

0.5 V to 4.5 V non-ratiometric

Output signal delay

4 ms typ.

Overvoltage protection

10 Vdc

Reverse polarity protection

-10 Vdc

-30 Vdc

Output to ground short circuit protection

continuous

Output load resistance (pull down to ground)

10 kOhm

EMI:

radiated immunity

conducted immunity

100 V/m from 200 MHz to 1000 MHz per ISO11452-2

100 mA BCI per ISO11452-4

from 1 MHz to 200 MHz

100 mA BCI per ISO11452-4

from 1 MHz to 400 MHz

EMC

exceeds CE requirements

Operating temperature range

-40 °C to 125 °C [-40 °F to 257 °F]

Storage temperature range

-40 °C to 125 °C [-40 °F to 257 °F]

Ingress protection

IP67 according to DIN 40050

Expected life

35 M cycles

Media compatibility

heavy transportation fluids

Housing material

PBT plastic

Shock

50 G peak

Vibration

20 G peak tested from 10 Hz to 2000 Hz

Salt fog

concentration 5% ±1% for 240 hr per SAE M1455 Section 4.3.3.1

(at 5.0 Vdc. 38 °C [100 F °])

Resolution

12 bit

Mating connector

AMP Superseal 282087-1

Mechanical end stop

no

Approvals

CE

Table 1. Specifications

2 http://sensing.honeywell.com

Page 9

Hall-Effect Rotary Position Sensors

22,0

[0.87]

26,0

[1.02]

9,5

[0.37]

5,35 DIA.

[0.21]

37

[1.46]

55

[2.17]

5,9

[0.23]

8,3

[0.33]

15,50 DIA.

[0.61]

4,60

[0.18]

13,8

[0.54]

15,6

[0.61]

4,12

[0.16]

25

[0.98]

36,4

[1.43]

0

A

C

B

Pin 1

Pin 2

Pin 3

2,0 DIA.

[0.078]

6 DIA.

[0.24]

32,0 DIA.

[1.25]

0

/2

0

/2

RTYXXXXXXXX

YYDDMMSSSS

A = Left output: 0.5 Vdc

B = Zero reference

C = Right output: 4.5 Vdc

Pinout

N

(North

American)

E

(European)

Pin 1 = VCC

Pin 2 = GND

Pin 3 = Output

Pin 1 = GND

Pin 2 = VCC

Pin 3 = Output

NOTICE

Ferrous or magnetic material

within a 75 mm [2.95 in] radius

from sensor center may affect

sensor performance.

Sensing Angle

Linearity

Error1

Accuracy

Error2

Output Voltage (Vdc)

Actuator Position (°)

0.5

2.5

4.5

-25

-30

-35

-45

-60

-90

-135

+25

+30

+35

+45

+60

+90

+135

0

0

0

0

0

0

0

0.0

A

B C

Clamp High

Clamp Low

Notes:

1. The linearity error is the

deviation of the measured

value from the best fit line

and is the quotient of the

measured output ratio

deviation from the best fit

line at the measured

temperature to the best fit

line output ratio span at the

measured temperature.

2. Accuracy is measured as a

deviation from the index line,

where the index line is

defined as the line with the

ideal slope and sensor

output voltage corrected at

0º position for its ideal value

at 25 °C ±5 °C. Accuracy is

valid only when the sensor

output is correct at 0º

position for its ideal value in

the application.

50° (±25°)

±1.0%

±1.6%

60° (±30°)

70° (±35°)

90° (±45°)

120° (±60°)

180° (±90°)

270° (±135°)

360° (±180°)

Output Voltage (Vdc)

Actuator Position (°)

0.5

2.5

4.5

-180 +180

0

0.0

A

B C

Figure 1. Mounting Dimensions (For Reference Only: mm/[in].)

Figure 2. Functional Characteristics

Honeywell Sensing and Control 3

Page 10

Sensing and Control

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

http://sensing.honeywell.com

005941-3-EN

October 2012

Copyright © 2012. Honeywell International Inc. All rights reserved.

RTY _ _ _ _ _ _ A X

Product Series

RTY = Hall-Effect Rotary Position Sensor

Pinout Style

E = European

N = North American

Sensing Range Angle

050 = 50° (±25°)

060 = 60° (±30°)

070 = 70° (±35°)

090 = 90° (±45°)

120 = 120° (±60°)

180 = 180° (±90°)

270 = 270° (±135°)

360 = 360° (±180°)

Supply Voltage

LV = 5 Vdc

HV = 10 Vdc to 30 Vdc

Output Type

A = 0.5 Vdc (left), 4.5 Vdc (right)

Lever

X = No lever

PERSONAL INJURY

DO NOT USE these products as safety or emergency stop

devices or in any other application where failure of the

product could result in personal injury.

Failure to comply with these instructions could result in

death or serious injury.

MISUSE OF DOCUMENTATION

The information presented in this product sheet is for

reference only. Do not use this document as a product

installation guide.

Complete installation, operation, and maintenance

information is provided in the instructions supplied with

each product.

Failure to comply with these instructions could result in

death or serious injury.

Figure 3. Nomenclature and Order Guide

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of

defective materials and faulty workmanship. Honeywell’s

standard product warranty applies unless agreed to otherwise

by Honeywell in writing; please refer to your order

acknowledgement or consult your local sales office for specific

warranty details. If warranted goods are returned to Honeywell

during the period of coverage, Honeywell will repair or replace,

at its option, without charge those items it finds defective. The

foregoing is buyer’s sole remedy and is in lieu of all other

warranties, expressed or implied, including those of

merchantability and fitness for a particular purpose. In no

event shall Honeywell be liable for consequential, special,

or indirect damages.

While we provide application assistance personally, through

our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the

application.

Specifications may change without notice. The information we

supply is believed to be accurate and reliable as of this

printing. However, we assume no responsibility for its use.

SALES AND SERVICE

Honeywell serves its customers through a worldwide network

of sales offices, representatives and distributors. For

application assistance, current specifications, pricing or name

of the nearest Authorized Distributor, contact your local sales

office or:

E-mail: info.sc@honeywell.com

Internet: www.honeywell.com/sensing

Phone and Fax:

Asia Pacific +65 6355-2828

+65 6445-3033 Fax

Europe +44 (0) 1698 481481

+44 (0) 1698 481676 Fax

Latin America +1-305-805-8188

+1-305-883-8257 Fax

USA/Canada +1-800-537-6945

+1-815-235-6847

+1-815-235-6545 Fax

Loading...

Loading...