Page 1

Mechanical disconnector with flanges direct actuated

GB type according to EN

Construction

The mechanical disconnectors comprises:

• Housing with pressure gauge

• Outlet check valve

• Spring bonnet

• PN 16 flanged connections to ISO 7005-2, DIN EN 1092-2

• Drain connector

• Valve insert with spring

• Spindle guide with double O-ring seal

Materials

• Grey cast iron housing, powder coated inside and outside

• Steel spring bonnet

• NBR seals

• Stainless steel valve stem and spring

• Red bronze for other internal parts

• Red bronze drain connector up to DN 100, Grey cast iron

drain connector DN 125 - DN 200, powder coated inside and

outside

• Chrome plated balanced-seat piston

• High grade synthetic material bearing surfaces for sliding in-

EN0H-1211GE23 R0206 y Subject to change without notice

ternal parts

1717/ type 1 according to DIN1988 part 4

R295P-F

Product specification sheet

Application

Mechanical disconnectors of this type are suitable for the protection of drinking water systems as required by EN 1717 "The technical regulation of drinking water systems" and correspond to

DIN1988 part 4 type 1 construction.

Their purpose is to protect systems against back pressure, back

flow and back syphonage of non-potable water into the public

water supply network.

Mechanical disconnectors can be used to provide protection up

to and including liquid category 3 (slightly toxic substances) and

therefore offer better protection than check valves.

Special Features

• DIN/DVGW and SVGW approvals in all connection sizes

• Optimal protection of the drinking water supply system

• Enhanced protection against back pressure, back flow and

back syphonage into the water supply network

• Shutoff position visually indicated on the spring bonnet

• Compact construction

• Powder coated inside and outside - Powder used is physiologically and toxicologically safe

• Meets KTW recommendations for potable water

• Low pressure loss and high flow rate

Range of Application

Medium Cold water

Max. inlet pressure 16.0 bar

Technical Data

Installation position Horizontal with spring bonnet upwards

Max. operating

temperature

Opening pressure 0.5, 1.0, 1.5 or 2.0 bar as required

Minimum inlet pressure

Connection size DN 65 - 200

40°C

(DN 65 - DN 100)

0.5, 1.0 bar as required

(DN 125 - DN 200)

= opening pressure + 1,0 bar

www.honeywell.com 37

Page 2

R295P-F Mechanical disconnector with flanges direct actuated

Method of Operation

Type 1 mechanical disconnectors remain in the flow position and

change to the shutoff position only when the inlet pressure falls

below the design opening pressure.

The inlet pressure operates on the annular surface of the valve piston and pushes it against the force of the spring bringing the piston to the open position. If the supply pressure falls below the

opening pressure needed to overcome the spring force (for example because of a broken pipe or during service work by the

supply undertaking) then the integral spring pushes the valve into

the closed position.

Options

R295P-... FA = With flanges, 0.5 bar opening pressure

R295P-... FB = With flanges, 1.0 bar opening pressure (stan-

dard pattern)

R295P-... FC = With flanges, 1.5 bar opening pressure

(DN 65 - DN 100 only)

Special Versions available on request

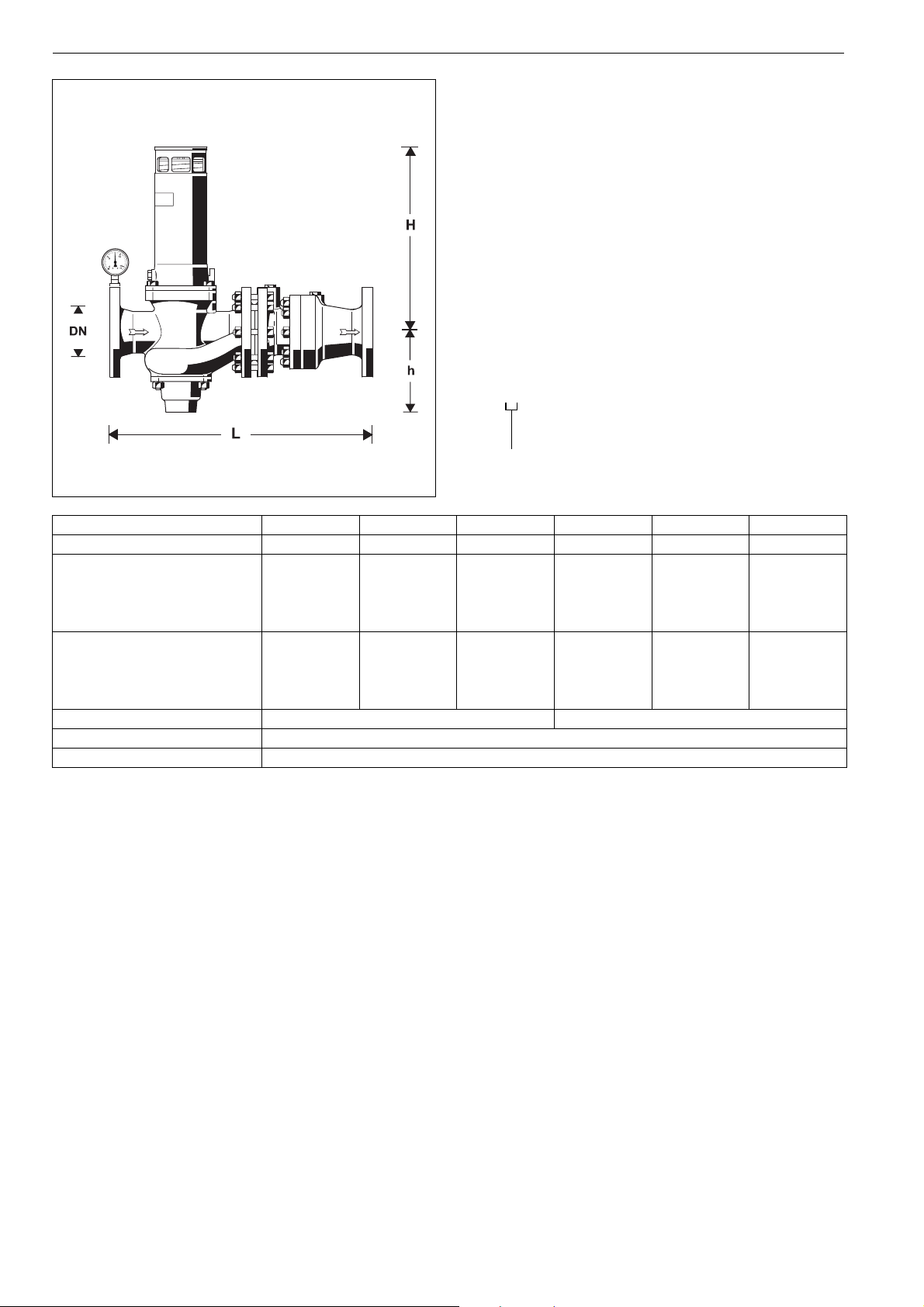

Connection size

Connection size DN 65 80 100 125 150 200

Weight approx. kg 48 67 89 145 206 408

Dimensions mm

L 532 572 652 752 882 1102

H 380 495 475 528 563 851

h 165 208 232 280 313 438

Nominal flow rate m

3

/h

at ∆p = 0.3 bar 27 34 68 114 150 198

kvs-value (full flow) 50 62 125 208 274 362

ξ value 111710 9 1019

Opening pressure 0.5, 1.0 or 1.5 bar as required 0.5 or 1.0 bar as required

DIN/DVGW Approval No. NW - 6301 AT 2322

SVGW Approval No. 8309-1381

38 www.honeywell.com

EN0H-1211GE23 R0206 y Subject to change without notice

Page 3

Installation Example

R295P-F Mechanical disconnector with flanges direct actuated

Installation Guidelines

• Install shutoff valves

• Install in horizontal pipework with spring bonnet directed upwards

o This orientation ensures optimum performance

• Ensure good access

o Pressure gauge can be read off easily

o Simplifies maintenance and inspection

• Mechanical disconnectors must not be fitted in any areas or

ducts where poisonous gases or vapours may be present or

where flooding can occur

Flow Diagram

Typical Applications

Mechanical disconnectors of this type are best suited for commercial and industrial applications.

However they can also be used for supplies to residential buildings within the scope of their specification.

The following are some typical applications:

• Softening and deacidification plants without DVGW approval

• Soda machines

• Boilers and automatic pressure fermentation equipment

• Heating system filling assemblies without DVGW approval,

water without inhibitors

• Air conditioners

EN0H-1211GE23 R0206 y Subject to change without notice

www.honeywell.com 39

Page 4

R295P-F Mechanical disconnector with flanges direct actuated

DN 50 - 150

DN 200

Spare Parts

Mechanical disconnector R295P-F

No. Description Dimension Part No.

c Valve insert complete

0.5 bar DN 65 R295AP-65FA

DN 80 R295AP-80FA

DN 100 R295AP-100FA

DN 125 R295AP-125FA

DN 150 R295AP-150FA

DN 200 R295AP-200FA

1.0 bar DN 65 R295AP-65FB

DN 80 R295AP-80FB

DN 100 R295AP-100FB

DN 125 R295AP-125FB

DN 150 R295AP-150FB

DN 200 R295AP-200FB

1.5 bar DN 65 R295AP-65FC

DN 80 R295AP-80FC

DN 100 R295AP-100FC

d Set of seals DN 65 0901093

DN 80 0901094

DN 100 0901095

DN 125 0901143

DN 150 0901145

DN 200 0901147

e Lip seal ring DN65 5350000

DN80 5350300

DN100 5350400

DN125 2070300

DN150 2067300

DN200 2238900

f Valve disc complete DN 65 0900376

DN 80 0900377

DN 100 0900378

DN 125 0900379

DN 150 0900380

DN 200 0900381

g Pressure gauge M39M-A16

Ranges 0 - 16 bar

h Pressure gauge M07M-A16

Ranges 0 - 16 bar

i Hexagon-plug all S06M-1/4

1

with O-ring R

/4"

(5 pcs.)

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1211GE23 R0206

Subject to change

© 2006 Honeywell GmbH

Loading...

Loading...