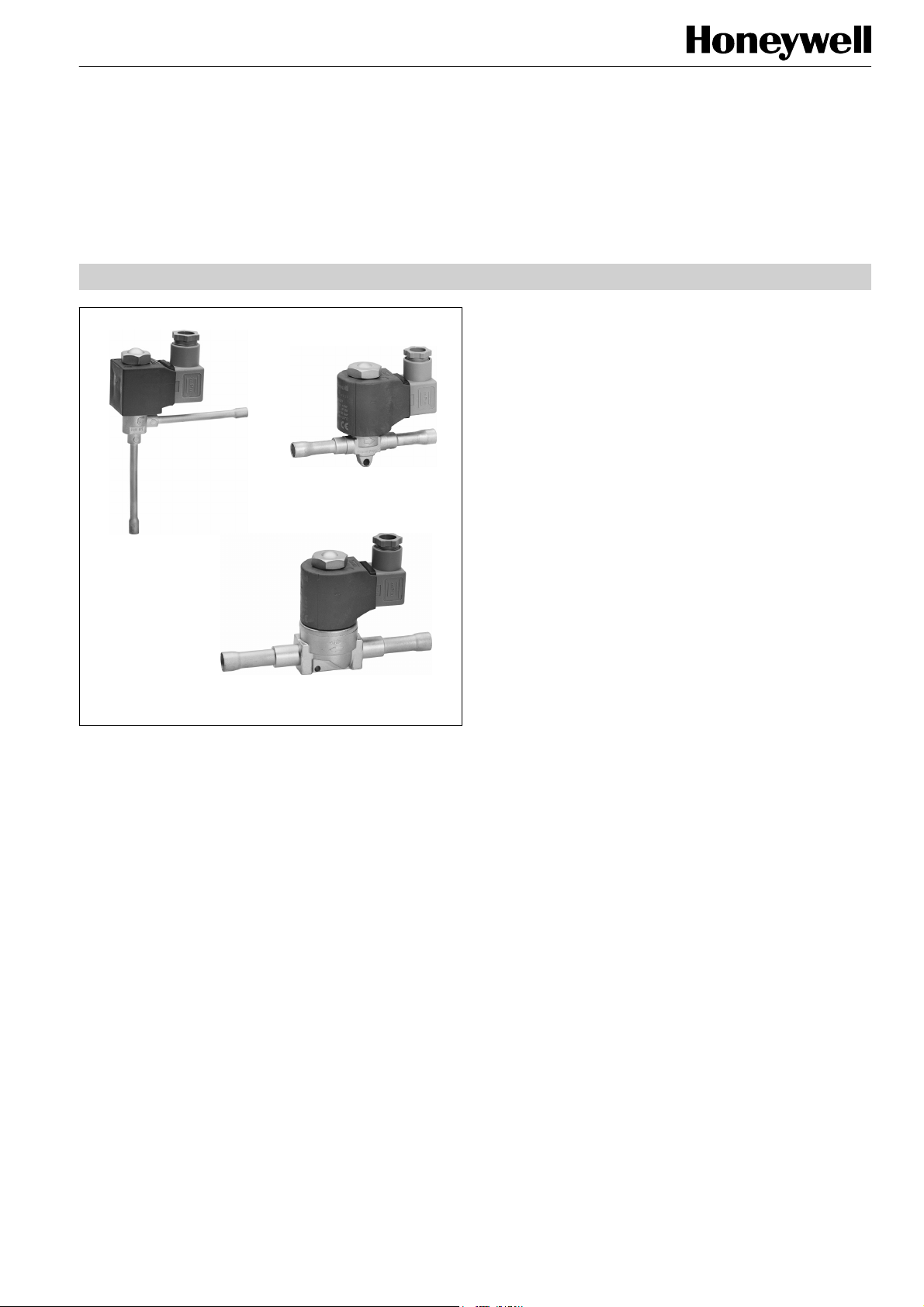

MA

MD

MS

Application

Solenoid valves series M are used in general refrigeration

and for original equipment to cut off/activate the refrigerant

flow in a refrigerating plant.

The solenoid valves can be installed in the liquid line, hot gas

line and suction line of a refrigerating unit.

Materials

Body

Seal material

Connection tubes

Coil

brass, stainless steel

PTFE

solder: copper

flare: brass

copper, steel, Crastin

Series M

SOLENOID VALVES

NORMALLY CLOSED

PRODUCT DATA

Features

• MA: direct operated, angle construction

• MD: direct operated, two way construction

• MS: pilot operated, two way construction

• Normally closed

• Hermetic construction

• Low pressure drop

• High performance

• Direct operated: no minimum pressure differential

required to open the valve

• Pilot operated: minimum pressure differential of

0.05 bar required to open the valve

• Solder and flare connections

• Coils for AC and DC

• Refrigerants: all CFC, HCFC, HFC,

not for ammonia

Specification

Nominal capacity

Maximum pressure PS

Maximum test pressure PF

Min. pressure differential

Max. pressure differential

Max. opening pressure

differential MOPD

Max. medium temperature

Min. medium temperature

Max. ambient temperature

Min. ambient temperature

Number of operating cycles

Standard coil voltages

Voltage tolerance

see tables on page 2

35 bar(a)

50 bar(a)

MA, MD: 0 bar

MS: 0.05 bar

MS: 2 bar

AC-coil: MA, MD: 25 bar

MS: 30 bar

DC-coil: MA, MD: 21bar

MS: 21 bar

125 °C

-45 °C

80 °C

-40 °C

> 1,5 million

AC: 230V, 110V, 24V

DC: 230V, 24V

further voltages on request

AC: ±10%

DC: +10%, -5%

Copyright © 2009 Honeywell GmbH • Subject to change without notice EN0H-1917GE23 R0709

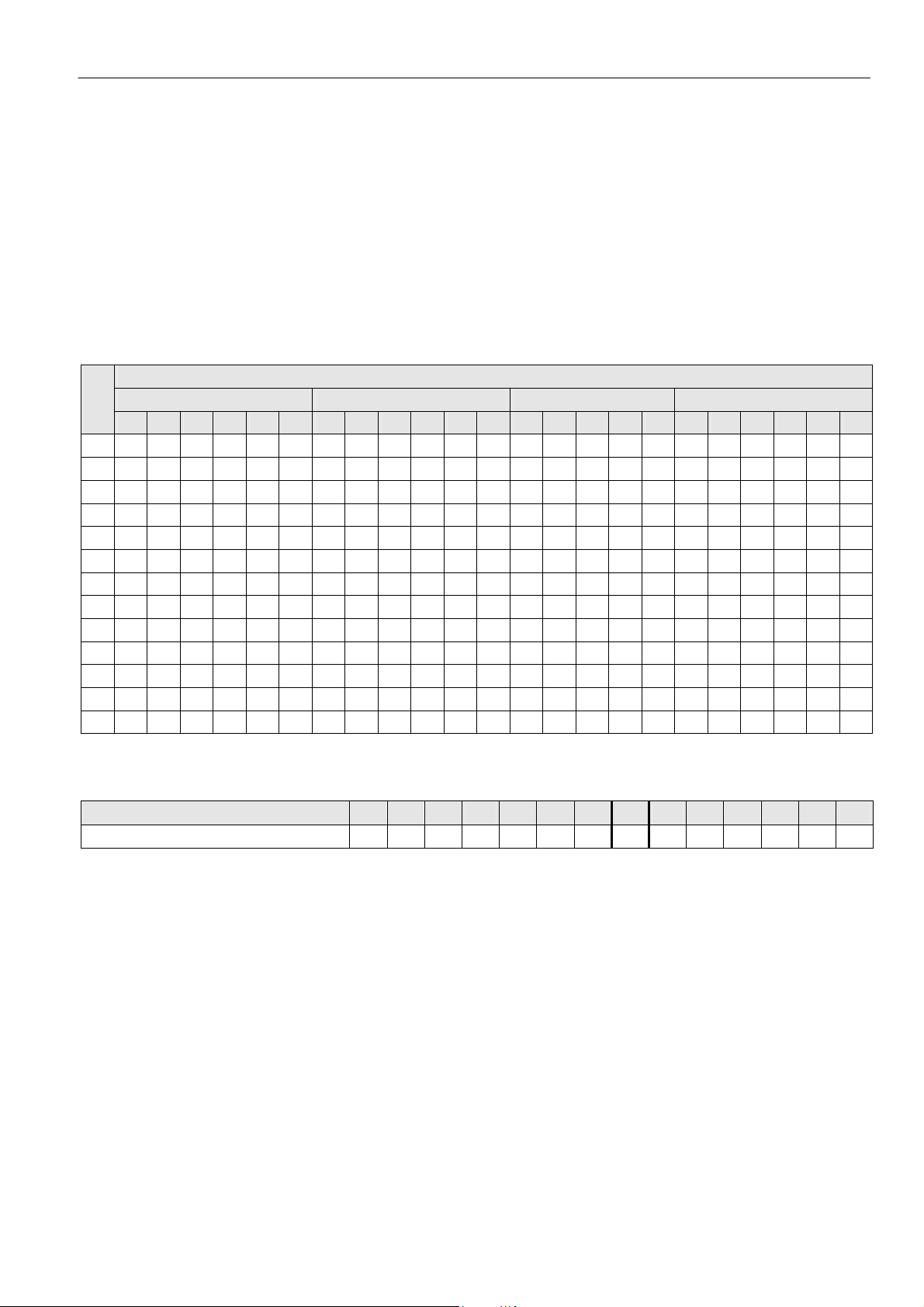

SERIES M

Nominal Capacity QN (kW)

Type

MA 062 0.17 5.21 5.62 5.39 3.87 1.14 1.47 1.45 1.29 - - - -

MD 062 0.17 5.21 5.62 5.39 3.87 1.14 1.47 1.45 1.29 - - - -

MD 102 0.22 6.74 7.27 6.98 5.01 1.48 1.90 1.88 1.67 - - - -

MD 103 0.23 7.05 7.61 7.29 5.24 1.54 1.99 1.96 1.75 - - - -

MS 103 0.9 27.6 29.8 28.5 20.5 6.04 7.78 7.67 6.83 1.54 2.06 1.92 1.80

MS 104 0.9 27.6 29.8 28.5 20.5 6.04 7.78 7.67 6,83 1.54 2.06 1.92 1.80

MS 124 1.6 49.0 52.9 50.7 36.4 10.7 13.8 13.6 12.1 2.74 3.66 3.42 3.19

MS 125 1.6 49.0 52.9 50.7 36.4 10.7 13.8 13.6 12.1 2.74 3.66 3.42 3.19

MS 165 2 61.3 66.1 63.4 45.5 13.4 17.3 17.1 15.2 3.42 4.57 4.27 3.99

MS 167 2 61.3 66.1 63.4 45.5 13.4 17.3 17.1 15.2 3.42 4.57 4.27 3.99

MS 227 4 123 132 127 91.1 26.8 34.6 34.1 30.4 6.85 9.14 8.54 7.98

The nominal capacity QN is based on the following conditions

Medium

Liquid -10 25 1 - 0.4

Hot gas -10 25 1 25 °C 1

Suction gas -10 25 1 - 0.15

Valve selection for other operating conditions see the following tables or consult the Honeywell software

kv-value

(m3/h)

Evaporating

temperature

R134a R22 R407C

t0 (°C) tc (°C)

Liquid Hot gas Suction gas

R404A

R507A

Direct operated

Pilot operated

Condensing

temperature

R134a R22 R407C

Subcooling

Δtc2u (K)

R404A

R507A

temperature

R134a R22 R407C

Hot gas

tH (°C)

Pressure loss

across valve

Δp (bar)

R404A

R507A

EN0H-1917GE23 R0709 2 Honeywell GmbH • Subject to change without notice

SERIES M

Valve size calculation for the liquid line

Refrigeration capacity Q0, multiplied with correcting factor fTF,

multiplied with correcting factor f

nominal capacity Q

N.

ΔPF results in the required

QN = Q0 x fTF x fΔPF

QN nominal capacity (according to table on page 2)

Q

0 refrigeration capacity

TF correcting factor for evaporating and liquid

f

temperature

f

ΔPF correcting factor for pressure loss across the valve

Correcting factor fTF for the change of capacity according to the operating temperatures

tL*

(°C)

+10 ±0 -10 -20 -30 -40 +10 ±0 -10 -20 -30 -40 +10 ±0 -10 -20 -30 +10 ±0 -10 -20 -30 -40

0 - - 0.80 0.83 0.85 0.88 - - 0.82 0.83 0.85 0.88 - - 0.80 0.80 0.80 - - 0.73 0.76 0.79 0.83

+5 - - 0.83 0.86 0.89 0.93 - - 0.85 0.87 0.89 0.91 - 0.80 0.80 0.80 0.90 - - 0.77 0.8 0.84 0.88

+10 - 0.84 0.87 0.91 0.94 0.97 - 0.86 0.88 0.90 0.92 0.95 - 0.80 0.90 0.90 0.90 - 0.79 0.82 0.85 0.89 0.94

+15 - 0.88 0.91 0.94 0.98 1.02 - 0.90 0.92 0.94 0.96 0.99 0.90 0.90 0.90 0.90 1.00 - 0.84 0.87 0.91 0.95 1.00

+20 0.89 0.92 0.95 0.99 1.03 1.08 0.92 0.94 0.96 0.98 1.00 1.03 0.90 0.90 0.90 1.00 1.00 0.86 0.89 0.93 0.97 1.02 1.08

+25 0.94 0.96 1.00 1.05 1.09 1.14 0.96 0.98 1.00 1.03 1.05 1.09 0.90 1.00 1.00 1.00 1.10 0.92 0.96 1.05 1.05 1.11 1.18

+30 0.99 1.02 1.06 1.12 1.16 1.22 1.01 1.02 1.05 1.08 1.10 1.14 1.00 1.00 1.00 1.10 1.20 0.99 1.03 1.08 1.14 1.21 1.29

+35 1.04 1.08 1.12 1.18 1.24 1.30 1.05 1.07 1.10 1.13 1.16 1.20 1.10 1.10 1.10 1.20 1.20 1.08 1.13 1.19 1.26 1.34 1.44

+40 1.10 1.14 1.19 1.26 1.32 1.39 1.10 1.12 1.15 1.19 1.22 1.26 1.10 1.20 1.20 1.30 1.30 1.18 1.24 1.32 1.40 1.50 1.63

+45 1.18 1.22 1.28 1.35 1.42 1.50 1.17 1.19 1.22 1.26 1.29 1.34 1.20 1.30 1.30 1.40 1.40 1.32 1.39 1.48 1.59 1.72 1.88

+50 1.25 1.24 1.37 1.45 1.53 1.62 1.23 1.26 1.29 1.33 1.37 1.42 1.30 1.40 1.40 1.50 1.60 1.50 1.59 1.7 1.85 2.02 2.23

+55 1.35 1.41 1.48 1.58 1.67 1.78 1.30 1.33 1.37 1.42 1.46 1.52 1.40 1.50 1.60 1.70 1.80 1.74 1.87 2.02 2.22 2.47 2.79

+60 1.46 1.55 1.61 1.73 1.84 1.97 1.38 1.41 1.46 1.51 1.56 1.63 - - - - - - - - - - -

* Temperature of liquid refrigerant at valve inlet.

Correcting factor f

Pressure loss across valve Δp (bar)

Correcting factor fΔPF

R134a R22 R407C R404A, R507A

ΔPF for the change of capacity according to the chosen pressure loss across the valve

Evaporating temperature t0 (°C)

0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60 0.65

2.83 2.00 1.63 1.41 1.26 1.15 1.07 1.00 0.94 0.89 0.85 0.82 0.78 0.76

0.70

Honeywell GmbH • Subject to change without notice 3 EN0H-1917GE23 R0709

Loading...

Loading...