Page 1

70 - 550*

Construction

The filling valve comprises:

• Housing with PN16 flanges per ISO7005-2, EN1092-2

• Pilot float valve 70-550*

Pilot float valve 70-610*

• Control circuit with ball valves on inlet and outlet

• Control circuit with integral rinsable filter insert

Materials

• Ductile iron housing, cover plate and diaphragm plate

(ISO 1083), powder coated

• Red bronze/stainless steel regulating cone

• Stainless steel pressure spring and control rod

• Fibre-reinforced NBR diaphragm

• NBR and EPDM seals

• Stainless steel valve seat

• High quality synthetic material control circuits

• Brass compression fittings

• Brass float valve housing

EN0H-1328GE23 R1009 • Subject to change

• Stainless steel filter insert

• High quality synthetic material spherical float

* not included in delivery

70 - 610*

FV300

Filling valve

Product specification sheet

Application

Filling valve of this type can be used in water supplies and for

industrial and commercial applications for the filling of reservoirs,

tanks and cisterns.It is controlled by the main storage medium via

a float valve and impulse link pipework.

Filling valve of this type is prevented from filling constantly by the

use of a pilot valve, which can be adjusted to provide varying fill

level differentials for opening and closing the valve.

Special Features

• High flow capacity

• Light weight

• Compact construction

• Powder coated inside and outside - Powder used is physiologically and toxicologically safe

• Integral control circuit and ball valves

Range of Application

Medium Water

Operating pressure Max. 16 bar

Switching level differential

Technical Data

Operating temperature

Nominal pressure PN 16

Minimum pressure 0.7 bar + pressure resulting from differential

Connection size DN 50 - 450

5 - 80 cm with

Pilot float valve 70-550

160 cm on request

5 - 40 cm with

Pilot float valve 70-610

Max. 80 °C

PN 25 on request

in physical height of the impulse link pipe

www.honeywell.com 51

Page 2

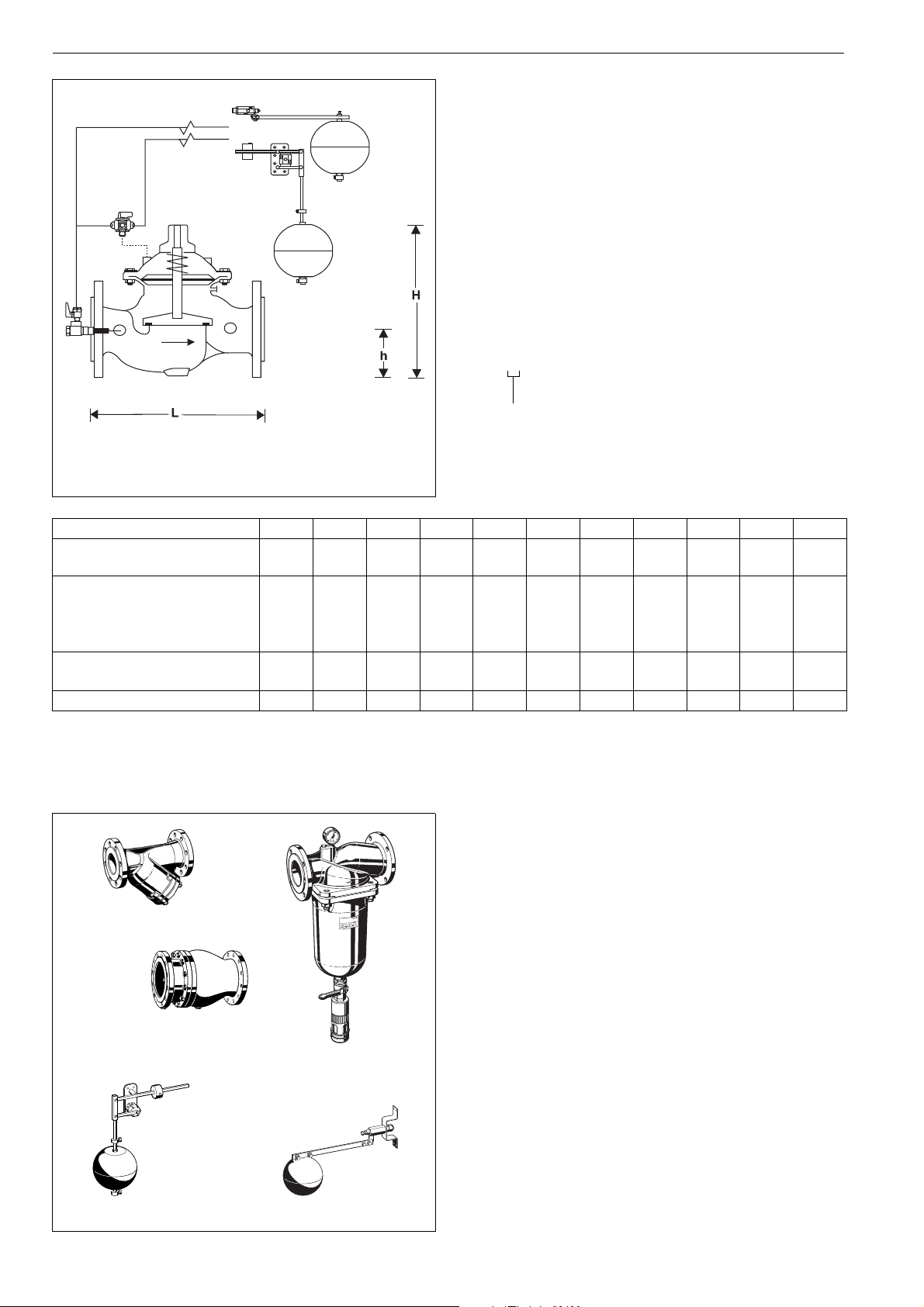

FV300 Filling valve

Method of Operation

At zero pressure conditions the diaphragm valve is closed. If flow

is opened to the filling valve of this type, water enters the inlet

area and the increasing pressure opens the valve so that water

in the outlet area can flow into the container. If the water level in

the container reaches the preset level, then the float valve closes.

The inlet pressure in the diaphragm chamber increases and

closes the diaphragm valve. If the water level in the container

falls, the float valve opens, the pressure in the diaphragm

chamber falls and the inlet pressure opens the diaphragm valve

for as long as the set water level in the container is not reached.

Options

FV300- ... A =Housing with flange, PN 16,

ISO 7005, EN 1092-2

FV300- ... Z = PN 25, on request

Please order pilot float valves separately

Connection size

Connection size DN 50 65 80 100 150 200 250 300 350 400 450

Weight approx.kg14 15 24 39 82 159 247 407 512 824 947

Dimensions (mm)

Flow rate (Q

) in m3/h

max

L

230

H

235

h

83

292

294

93

310

400

100

350

433

110

480

558

143

600

650

173

730

823

205

850

944

230

980

990

260

1100

1250

290

40 40 90 160 350 480 970 1400 1900 2500 3150

1200

1250

310

- V=5.5 m/s

kvs-value m3/h 43 43 103 167 407 676 1160 1600 1600 3300 3300

Accessories

5

r

15

ba

0

16

FY69P Strainer

With double mesh, grey cast iron housing, powder

coated inside and outside.

A = Mesh size approximately 0.5 mm

FY69P

F76S-F Reverse-rinsing filter

Red bronze housing and filter bowl. Available in sizes

DN 65 to DN 100, with filter mesh sizes 100 µm

or 200 µm

RV283P

70-550

52 www.honeywell.com

F76S-F

70-610

RV283P Check valve

Grey cast iron housing, powder coated inside and

outside. DIN/DVGW tested in compulsory test sizes

DN 65, DN 80 and DN 100

70-550 Pilot float valves

Level switching differential 5 - 160 cm

70-610 Pilot float valve

Level switching differential 5 - 40 cm

EN0H-1328GE23 R1009 • Subject to change

Page 3

Installation Example

FV300 with pilot float valve 70-550

FV300 Filling valve

FV300 with pilot float valve 70-610

Installation Guidelines

• Install shutoff valves on both sides of the pressure sustaining

valves

• Install strainer upstream of filling valve

o Protects against damage from coarse dirt

• Note flow direction (indicated by arrow)

• Ensure good access

o Simplifies maintenance and inspection

• It is recommended that the pilot float valve be fitted with a

stabiliser to prevent fluctuating water levels

• Install connectors for removal and refitting for maintenance

Flow Diagram

[

l/s

1000

500

100

50

10

5

EN0H-1328GE23 R1009 • Subject to change

1

3

]

[m

5000

1000

/h]

500

100

50

10

5

Typical Applications

Filling valves of this type, within the limits of their specifications,

are suitable for installation in water supply systems, in residential

buildings and in commercial and industrial installations.

The following are some typical applications:

• Potable water supplies, for example water reservoirs etc.

• Swimming pools

• Firefighting systems - sprinkler installations

• Ship construction (fire tenders)

• Watering systems in market gardens and in agriculture

• Water supply networks in large building developments (eg.

high rise blocks)

• Mining applications

• Gravel pits, concrete mixing plants etc.

DN 450

DN 400

DN 350

DN 300

DN

250

DN 200

DN 150

DN 100

DN 80

DN 65

DN 50

1

0,01

0,05 0,1 0,5 1 105

www.honeywell.com 53

[

bar

]

Page 4

FV300 Filling valve

Spare Parts

Filling valve FV300, from 2002 onwards

2

No. Description Dimension Part No.

1 Pilot float valve

DN 50 - 450 70-550

Level switching differential 5 - 160 cm

3

1

2 Pilot float valve

Level switching diffe-

DN 50 - 450 70-610

rential 5 - 40 cm

3 Set of seals DN 50 0903750

DN 65 0903751

DN 80 0903752

DN 100 0903753

DN 150 0903754

DN 200 0903755

3

3

3

3

DN 250 0903756

DN 300 0903757

DN 350 0903758

DN 400 0903759

DN 450 0903760

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Rolle, Z.A. La

Pièce 16, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1328GE23 R1009

Subject to change without notice

© 2009 Honeywell GmbH

Loading...

Loading...