Page 1

Fusion4 MSC-L

Installation & Operation Manual

Fusion4 MSC-L

Page 2

For service-related questions, contact:

T echnical Assistance Centre

Phone:

+1 800 423 9883 or

+1 215 641 3610

E-mail:

HFS-TAC-SUPPORT@honeywell.com

© 2021 - Honeywell International Inc.

Page 3

Table of Contents

CHAPTER 1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Functionality Overview . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Target Audience for this Manual . . . . . . . . . . . . . . . . . 1-3

CHAPTER 2 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Safety Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.2 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Safety Instructions for the MSC-L . . . . . . . . . . . . . . . . 2-2

2.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.1.1 EC Declaration of Conformity (for EU) . . . . . . . . . . . . . . . . . . .2-2

2.2.1.2 Control Drawings for FM & CSA . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.1.3 Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.1.4 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.1.5 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.3 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.4 Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.4.1.1 Opening the MSC-L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.5 Commissioning and Maintenance. . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.5.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.6 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.6.1 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.7 Accordance to Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.7.1 Explosion Safety Limiting Values . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.7.2 Explosion Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.7.3 Low-Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.7.4 The MSC-L Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.3 Safety Instructions for the LAD . . . . . . . . . . . . . . . . . . 2-8

2.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.3.1.1 EC declaration of conformity (for EU) . . . . . . . . . . . . . . . . . . .2-10

2.3.1.2 Control Drawings for FM & CSA . . . . . . . . . . . . . . . . . . . . . . .2-10

2.3.2 Explosion Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 1

Page 4

Table of Contents

2.3.3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.3.4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.3.5 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . .2-10

2.3.6 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.3.7 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.3.8 The LAD Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.4 Safety Instructions for the IR Controller . . . . . . . . . . 2-13

2.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.4.2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.4.2.1 EC declaration of conformity (for EU) . . . . . . . . . . . . . . . . . . .2-15

2.4.3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.4.4 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.4.5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.4.6 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . .2-15

2.4.7 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.4.8 IR Controller Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.5 Liability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

CHAPTER 3 SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1.1 Transactions and Batches. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.2 Batch principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.2.1 Batch Flow Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.3 Types of Blending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.1.3.1 Straight Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.1.3.2 Ratio Blending. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.1.3.3 Side Stream Blending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.1.3.4 Sequential Blending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.1.4 Additive Injection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.1.5 Loading Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.1.5.1 Device loading capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.1.6 Menu-based MSC-L Control . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3.2 MID Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3.2.2 MID Approval Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3.2.3 Component-level Requirements . . . . . . . . . . . . . . . . . . . . . . .3-10

Fusion4 MSC-L Part No.: 4418309_Rev11

2 Installation & Operation Manual

Page 5

Table of Contents

3.2.4 System-level Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3.2.5 The Fusion4 MSC-L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3.3 System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.4 FlexConn Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.5 Hardware Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.5.1 Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.5.2 Interior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.5.3 Grounding Concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.6 PCB Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.6.1 PCB Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.6.1.1 CAN-HMI-MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.6.1.1.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.6.1.1.2 Component Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3.6.1.2 CAN-ARM-MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

3.6.1.2.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

3.6.1.2.2 Component Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

3.6.1.3 CAN-IN-OUT-MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3.6.1.3.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3.6.1.3.2 Component Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

3.6.2 CAN-PSF-MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

3.6.2.1 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

3.6.2.2 Power Board Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

3.6.2.3 Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

3.6.2.4 Fuse Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

3.6.2.4.1 MSC-SHORTCUT-BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

3.6.3 Device Electrical Features . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

3.6.4 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

3.6.5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

3.7 Available Input/Output Functions of the MSC-L. . . . 3-39

3.8 Input Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

3.8.2 Digital Input DC (DI DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

3.8.2.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

3.8.2.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-43

3.8.3 Single Pulse Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-43

3.8.3.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-43

3.8.3.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 3

Page 6

Table of Contents

3.8.4 Dual-Pulse Input (Quad PI). . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

3.8.4.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

3.8.4.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-47

3.8.5 Analog Input (AI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-47

3.8.5.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-47

3.8.5.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-49

3.8.6 Resistance Temperature Detector. . . . . . . . . . . . . . . . . . . . . .3-49

3.8.6.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-49

3.8.6.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51

3.8.7 Digital Input AC (DI AC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51

3.8.7.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51

3.8.7.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52

3.9 Output Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3.9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3.9.2 Pulse Output (PO DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3.9.2.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3.9.2.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-55

3.9.3 Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-55

3.9.3.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-55

3.9.3.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-56

3.9.4 Digital Output Electromechanical Relay (AC or DC). . . . . . . .3-56

3.9.4.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-56

3.9.4.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-58

3.9.5 Digital Output Solid State Relay AC . . . . . . . . . . . . . . . . . . . .3-59

3.9.5.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-59

3.9.5.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-61

3.10 Communication Functions . . . . . . . . . . . . . . . . . . . . . 3-62

3.10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62

3.10.2 RS-485 Communication (2-wire or 4-wire) . . . . . . . . . . . . . . .3-62

3.10.2.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62

3.10.2.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

3.10.2.3 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

3.10.3 Ethernet Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

3.10.3.1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

3.10.3.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-65

3.10.3.3 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-65

3.11 Security Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

3.11.1 Device Security Recommendations . . . . . . . . . . . . . . . . . . . .3-66

Fusion4 MSC-L Part No.: 4418309_Rev11

4 Installation & Operation Manual

Page 7

Table of Contents

3.11.2 Network and Security Control Recommendations . . . . . . . . .3-66

3.11.3 How to report a security vulnerability . . . . . . . . . . . . . . . . . . .3-67

CHAPTER 4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Mounting and Dimensions . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Gland Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.2.2 Metric Gland Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.2.3 NPT Cable Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.3 Opening the MSC-L . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4 Closing the MSC Lid . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.5 Removing/Replacing the PCBs . . . . . . . . . . . . . . . . . 4-12

4.6 Fusing and Power Consumption . . . . . . . . . . . . . . . . 4-13

4.6.1 Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4.6.1.1 Internal Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4.6.1.2 External Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.6.2 Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.6.3 Disconnecting/breaker device. . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.7 Wiring Termination Guidance. . . . . . . . . . . . . . . . . . . 4-17

4.7.1 Wiring Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.7.2 Backplane Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4.7.2.1 ARM-1-BACKPLANE-MSC. . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.7.2.2 Floorplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

4.7.2.3 Connector Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

4.7.2.4 ARM-2-BACKPLANE-MSC. . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

4.7.2.5 Floorplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

4.7.2.6 Connector Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

4.7.3 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

4.7.3.1 Wire Sizes and Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

4.7.4 Recommended Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

4.7.5 Wire Crimps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

4.7.6 Internal Wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

4.7.6.1 AC Cable 1 (Gland 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

4.7.6.2 AC Cable 2 (Gland 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

4.7.6.3 DC cable 1 (Gland 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

4.7.6.4 AC Cable 3 (Gland 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

4.7.6.5 AC Cable 4 (Gland 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 5

Page 8

Table of Contents

4.7.6.6 Analog Cable 1 (Gland 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

4.7.6.7 AC Cable 5 (Gland 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

4.7.6.8 DC Cable 2 (Gland 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

4.7.6.9 DC Cable 3 (Gland 9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

4.7.6.10 DC Cable 4 (Gland 10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

4.7.6.11 DC Cable 5 (Gland 11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

4.7.6.12 Comms Cable 1 (Gland 12) . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

4.7.6.13 DC Cable 6 (Gland 13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

4.7.6.14 DC Cable 7 (Gland 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

4.7.6.15 Comms Cable 2 (Gland 15) . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

4.7.6.16 DC Cable 8 (Gland 16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

4.7.6.17 DC Cable 9 (Gland 17) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

4.7.6.18 AC Cable 6 (Gland 18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

4.7.6.19 DC Cable 10 (Gland 19) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

4.7.6.20 DC Cable 11 (Gland 20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

4.7.6.21 AC Cable 7 (Gland 21) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

4.7.6.22 AC Cable 8 (Gland 22) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

4.7.6.23 Analog Cable 2 (Gland 23) . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

4.7.6.24 AC Cable 9 (Gland 24) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-47

4.7.6.25 AC Cable 10 (Gland 25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-48

4.7.6.26 DC Cable 12 (Gland 26) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

4.7.7 Connecting MSC-L to NexWatch DR4208S Card Reader . . .4-49

4.7.8 ARM-1-BACKPLANE-MSC Terminal Assignment Guide . . . .4-49

4.7.9 ARM-2-BACKPLANE-MSC Terminal Assignment Guide . . . .4-69

4.8 Display Replacement Instructions. . . . . . . . . . . . . . . 4-84

CHAPTER 5 OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1.2 Text Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Service Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.1 Fusion4 IR Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3.2 Fusion4 Local Access Device . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.3.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.3.2.2 LAD Application Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.3.3 Integrated Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.3.4 Navigation with Fusion4 IR Controller and Fusion4 LAD . . . . .5-8

Fusion4 MSC-L Part No.: 4418309_Rev11

6 Installation & Operation Manual

Page 9

Table of Contents

5.3.4.1 Basic Navigation (Fusion4 IR Controller + Fusion4 LAD) . . . . .5-8

5.3.4.2 LEDs (Fusion4 IR Controller + Fusion4 LAD) . . . . . . . . . . . . . .5-9

5.3.4.3 Special Function Key (Only LAD) . . . . . . . . . . . . . . . . . . . . . .5-10

5.3.4.4 SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.3.4.4.1 Product Type Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.3.4.4.2 Directory Structure and File Organization. . . . . . . . . . . . . . . . . . . . .5-13

5.3.4.4.3 Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5.3.4.5 Language Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5.3.4.5.1 Building a Local Language Pack for the MSC-L. . . . . . . . . . . . . . . .5-14

5.3.4.5.2 Configuring a User Display Language for the MSC-L. . . . . . . . . . . .5-14

5.4 Menu and Navigation . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5.4.2 Key benefits of the HMI on the Main Menu. . . . . . . . . . . . . . .5-15

5.4.3 Navigation Rules for the Menu-based Screens. . . . . . . . . . . .5-15

5.4.4 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

5.4.5 Stream Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5.4.5.1 Product Streams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5.4.5.2 Additive Streams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5.4.5.3 External Additive Streams. . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

5.4.6 Arm Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

5.4.7 Text Input Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

5.4.8 Numeric Input Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

5.4.9 Enumeration Input Screen . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

5.4.10 Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

5.5 Device Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.5.1 Security Levels (SL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

5.5.2 Rules of Navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

5.6 Device Commissioning. . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.6.1 Using the Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

5.6.2 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

5.6.2.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

5.6.2.2 Stream Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

5.6.2.3 Arm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

5.6.2.4 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-43

5.6.2.5 Info (Device Information). . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

5.6.2.6 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-46

5.6.2.7 Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-51

5.6.2.8 LAD Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 7

Page 10

Table of Contents

5.7 Loading Application Overview . . . . . . . . . . . . . . . . . . 5-53

5.8 Unloading Application Overview . . . . . . . . . . . . . . . . 5-54

5.9 LPG Loading Application Overview. . . . . . . . . . . . . . 5-56

5.10 LNG Loading Application Overview . . . . . . . . . . . . . 5-61

5.10.1 About LNG Loading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-61

5.10.2 MSC-L Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-61

5.10.3 LNG Loading using MSC-L . . . . . . . . . . . . . . . . . . . . . . . . . . .5-61

5.10.3.1 Nitrogen purging to truck. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-63

5.10.3.2 Release truck pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

5.10.3.3 Recirculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

5.10.3.4 Truck loading process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-67

5.10.3.5 Nitrogen purging to open air . . . . . . . . . . . . . . . . . . . . . . . . . .5-70

5.10.4 LNG Loading Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . .5-71

5.10.5 LNG Loading Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-77

5.11 Dual Bay Loading Application Overview. . . . . . . . . . 5-87

5.11.1 About Dual Bay Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-87

5.11.2 MSC-L Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-87

5.11.3 Dual Bay Loading using MSC-L . . . . . . . . . . . . . . . . . . . . . . .5-87

5.11.4 Authorization Modes supported for Dual Bay Loading . . . . . .5-88

5.11.5 Dual Bay Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-88

5.11.6 Dual Bay Loading Operations . . . . . . . . . . . . . . . . . . . . . . . . .5-97

5.12 Weighbridge Loading Application Overview . . . . . 5-102

5.12.1 About Weighbridge Loading . . . . . . . . . . . . . . . . . . . . . . . . .5-102

5.12.2 MSC-L Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-102

5.12.3 MSCL loading using weighbridge . . . . . . . . . . . . . . . . . . . . .5-102

5.12.4 Weighbridge configuration . . . . . . . . . . . . . . . . . . . . . . . . . .5-103

5.12.5 Weighbridge Loading Operations . . . . . . . . . . . . . . . . . . . . . 5-110

5.13 Interfacing With External Additive Controller. . . . . .5-117

5.13.1 Connecting External Additive Controllers . . . . . . . . . . . . . . . 5-118

5.13.1.1 Topology and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-118

5.13.2 Configuring External Additive Controller . . . . . . . . . . . . . . . . 5-119

5.13.2.1 Device Configuration - Communication. . . . . . . . . . . . . . . . . 5-119

5.13.2.2 Stream Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-120

5.13.2.3 Stream Configuration - Stream n . . . . . . . . . . . . . . . . . . . . .5-120

5.13.2.3.1 Stream Configuration - Stream n - Identification. . . . . . . . . . . . . . .5-120

5.13.2.3.2 Stream Configuration - Stream n - I/O Bindings . . . . . . . . . . . . . . .5-121

5.13.2.3.3 Stream Configuration - Stream n - Control Settings . . . . . . . . . . . .5-121

Fusion4 MSC-L Part No.: 4418309_Rev11

8 Installation & Operation Manual

Page 11

Table of Contents

5.13.2.3.4 Stream Configuration - Stream n - Alarms . . . . . . . . . . . . . . . . . . .5-122

5.13.3 Configuring MSC-L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-122

5.13.3.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-122

5.13.3.2 External Additive Stream Configuration . . . . . . . . . . . . . . . .5-123

5.13.3.3 Arm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-123

5.13.4 Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-124

5.13.4.1 Process Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-124

5.13.4.2 Transaction Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-126

5.13.4.3 Alarm Handling for External additive streams. . . . . . . . . . . .5-127

5.13.4.3.1 Setting Alarm Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-127

5.13.4.3.2 External Additive Alarms Generated by MSC-L . . . . . . . . . . . . . . .5-128

5.13.4.3.3 Mapping of Alarms on External Additive Controller. . . . . . . . . . . . .5-128

5.14 Sequential Blending Overview. . . . . . . . . . . . . . . . . 5-130

5.14.1 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-130

5.14.2 Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-131

5.14.3 Inter mini batch behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . .5-132

5.14.4 Flow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-132

5.14.5 Batch record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-132

5.14.6 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-132

5.14.7 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-132

5.15 Rail Loading Application Overview . . . . . . . . . . . . . 5-133

5.15.1 About Rail Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-133

5.15.2 MSC-L Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-134

5.15.3 Rail Loading using MSC-L . . . . . . . . . . . . . . . . . . . . . . . . . .5-134

5.15.4 Rail Loading Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .5-139

5.15.5 Rail Loading Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-142

5.15.6 Transaction and Batch record. . . . . . . . . . . . . . . . . . . . . . . .5-149

5.16 1010 Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-151

5.16.1 1010BJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-151

5.16.1.1 License type and constraints. . . . . . . . . . . . . . . . . . . . . . . . .5-151

5.16.1.2 Assumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-151

5.16.1.3 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-151

5.16.2 1010RD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-152

5.16.2.1 License type and constraints. . . . . . . . . . . . . . . . . . . . . . . . .5-152

5.16.2.2 Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-152

5.16.2.3 Configurations Required . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-152

5.16.2.4 Transaction Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-153

5.17 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . 5-154

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 9

Page 12

Table of Contents

5.17.1 Device Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-155

5.17.1.1 Device Configuration . General. . . . . . . . . . . . . . . . . . . . . . .5-155

5.17.1.1.1 System Config . General Identification . . . . . . . . . . . . . . . . . . . . . .5-156

5.17.1.1.2 System Config . General . Units . . . . . . . . . . . . . . . . . . . . . . . . . . .5-156

5.17.1.1.3 System Config . General . Display . . . . . . . . . . . . . . . . . . . . . . . . .5-158

5.17.1.1.4 System Config . General . Time . . . . . . . . . . . . . . . . . . . . . . . . . . .5-162

5.17.1.1.5 System Config . Device . Settings . . . . . . . . . . . . . . . . . . . . . . . . .5-162

5.17.1.2 System Config . Device . I/O Binding . . . . . . . . . . . . . . . . . .5-164

5.17.1.2.1 System Config . I/O bindings . Inputs . . . . . . . . . . . . . . . . . . . . . . .5-164

5.17.1.2.2 System Config . I/O bindings . Outputs. . . . . . . . . . . . . . . . . . . . . .5-164

5.17.1.3 System Config . Device . Communication. . . . . . . . . . . . . . .5-165

5.17.1.3.1 Serial. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-165

5.17.1.3.2 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-168

5.17.1.3.3 IR HHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-169

5.17.1.4 System Config . Device. I/O Settings . . . . . . . . . . . . . . . . . .5-170

5.17.1.4.1 DI (for both AC# and DC#) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-171

5.17.1.4.2 PI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-172

5.17.1.4.3 RTD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-174

5.17.1.4.4 AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-176

5.17.1.4.5 AO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-178

5.17.1.4.6 PO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-179

5.17.1.4.7 EMR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-180

5.17.1.5 System Config . Device . Alarms. . . . . . . . . . . . . . . . . . . . . .5-180

5.17.1.5.1 System Config . Alarms . Next scheduled service . . . . . . . . . . . . .5-181

5.17.1.5.2 System Config . Alarms . Programmable Alarms . . . . . . . . . . . . . .5-181

5.17.1.5.3 System Config . Alarms . Deadman . . . . . . . . . . . . . . . . . . . . . . . .5-182

5.17.1.5.4 System Config . Alarms . Permissives . . . . . . . . . . . . . . . . . . . . . .5-184

5.17.1.5.5 System Config . Alarms . Fixed. . . . . . . . . . . . . . . . . . . . . . . . . . . .5-185

5.17.1.6 System Config . Device . Authorization. . . . . . . . . . . . . . . . .5-185

5.17.1.6.1 System Config . Authorization. Setup . . . . . . . . . . . . . . . . . . . . . . .5-186

5.17.1.6.2 System Config . Authorization. Databases . . . . . . . . . . . . . . . . . . .5-187

5.17.1.7 Device Configuration . Base Conditions . . . . . . . . . . . . . . . .5-189

5.17.1.8 Device Configuration . Workflow Settings. . . . . . . . . . . . . . .5-190

5.17.1.8.1 System Config . Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-191

5.17.1.8.2 System Config . Prompts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-195

5.17.1.9 Device Configuration . RIT Panel . . . . . . . . . . . . . . . . . . . . .5-196

5.17.2 Bay Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-198

5.17.2.1 System Config . bay . Identification. . . . . . . . . . . . . . . . . . . .5-198

5.17.2.2 Bay Configuration . I/O Binding. . . . . . . . . . . . . . . . . . . . . . .5-199

5.17.2.2.1 Bay Configuration . I/O Binding . Inputs . . . . . . . . . . . . . . . . . . . . .5-199

5.17.2.2.2 Device Configuration . I/O Binding . Outputs . . . . . . . . . . . . . . . . .5-199

5.17.2.3 Bay Configuration . Alarms . . . . . . . . . . . . . . . . . . . . . . . . . .5-200

5.17.2.3.1 System Config . Alarms . Programmable alarms . . . . . . . . . . . . . .5-201

Fusion4 MSC-L Part No.: 4418309_Rev11

10 Installation & Operation Manual

Page 13

Table of Contents

5.17.2.3.2 System Config . Alarms . Weighbridge alarms . . . . . . . . . . . . . . . .5-202

5.17.2.4 System Config . Bay . Permissives . . . . . . . . . . . . . . . . . . . .5-203

5.17.2.5 Bay Configuration . Weighbridge . . . . . . . . . . . . . . . . . . . . .5-205

5.18 Stream Configuration . . . . . . . . . . . . . . . . . . . . . . . . 5-206

5.18.1 Stream Configuration - Product Streams . . . . . . . . . . . . . . .5-207

5.18.1.1 Stream Config. . Stream n . Identification . . . . . . . . . . . . . . .5-207

5.18.1.2 Stream Config . Stream n . I/O Bindings. . . . . . . . . . . . . . . .5-208

5.18.1.2.1 The I/O Bindings . Input Parameters . . . . . . . . . . . . . . . . . . . . . . .5-209

5.18.1.2.2 The I/O Bindings . Output Parameters . . . . . . . . . . . . . . . . . . . . . .5-211

5.18.1.3 Stream Config. . Stream n . Control Settings . . . . . . . . . . . .5-212

5.18.1.3.1 Product Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-212

5.18.1.3.2 Valve Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-222

5.18.1.4 Volume Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-224

5.18.1.4.1 Volume Conversion Essential Information . . . . . . . . . . . . . . . . . . .5-224

5.18.1.4.2 Volume Conversion Calculation Details . . . . . . . . . . . . . . . . . . . . .5-229

5.18.1.4.3 Stream Config. Stream n . Volume Conversion . . . . . . . . . . . . . . .5-233

5.18.1.5 Stream Config . Stream n . Alarms . . . . . . . . . . . . . . . . . . . .5-235

5.18.2 Stream Configuration . Additive streams. . . . . . . . . . . . . . . .5-245

5.18.2.1 Additive Stream Config. . Stream n . Identification . . . . . . . .5-246

5.18.2.2 Additive Config. Stream n . I/O Bindings. . . . . . . . . . . . . . . .5-246

5.18.2.2.1 The I/O Bindings . Input Parameters . . . . . . . . . . . . . . . . . . . . . . .5-247

5.18.2.2.2 The I/O Bindings . Output Parameters . . . . . . . . . . . . . . . . . . . . . .5-249

5.18.2.3 Additive Stream Config. . Stream n . Control Settings . . . . .5-251

5.18.2.3.1 Additive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-251

5.18.2.3.2 Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-252

5.18.2.4 Additive Stream Config. Stream n . Alarms. . . . . . . . . . . . . .5-253

5.18.2.4.1 Leaking Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-253

5.18.2.4.2 No Additive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-254

5.18.2.4.3 No Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-254

5.18.2.4.4 Block Valve Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-255

5.18.2.4.5 Deviation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-255

5.18.2.4.6 Fixed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-256

5.18.3 Stream Configuration - External Additive streams . . . . . . . .5-257

5.18.3.1 Stream Config - Ext add n - Identification . . . . . . . . . . . . . . .5-259

5.18.3.2 Stream Config - Ext add n - Alarms. . . . . . . . . . . . . . . . . . . .5-260

5.19 Arm Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-264

5.19.1 Arm Configuration . Arm n . Identification . . . . . . . . . . . . . . .5-265

5.19.2 Arm Configuration . Arm n . I/O Bindings . . . . . . . . . . . . . . .5-266

5.19.2.1 The I/O Bindings . Input Parameters. . . . . . . . . . . . . . . . . . .5-266

5.19.2.2 The I/O Bindings . Output Parameters . . . . . . . . . . . . . . . . .5-267

5.19.3 Arm Configuration . Arm n . Control Settings . . . . . . . . . . . .5-268

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 11

Page 14

Table of Contents

5.19.3.1 Flow Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-272

5.19.3.2 Preload sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-273

5.19.3.3 Initial flow rate in straight loading . . . . . . . . . . . . . . . . . . . . .5-273

5.19.3.4 Auto High Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-273

5.19.4 Arm Configuration . Arm n . Product Streams. . . . . . . . . . . .5-275

5.19.5 Arm Configuration . Arm n . Additive Streams. . . . . . . . . . . .5-277

5.19.6 Arm Configuration . Arm n . External Additive Streams. . . . .5-277

5.19.7 Arm Configuration . Arm n . Recipes. . . . . . . . . . . . . . . . . . .5-278

5.19.8 Arm Configuration . Arm n . Alarms. . . . . . . . . . . . . . . . . . . .5-284

5.19.8.1 Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-286

5.19.8.1.1 Initial Flow . Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-286

5.19.8.1.2 Full Flow . Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-286

5.19.8.1.3 Pre-stop Flow . Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-287

5.19.8.2 Programmable Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-287

5.19.8.3 Block Valve Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-289

5.19.8.4 Preset Overrrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-289

5.19.8.5 Clean Arm Underrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-290

5.19.8.6 Stop Switch not covered . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-290

5.19.8.7 Fixed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-290

5.20 Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-291

5.20.1 Transaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-292

5.20.2 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-297

5.20.3 Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-299

5.20.4 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-299

5.20.5 Load Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-300

5.21 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-302

5.21.1 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-303

5.21.2 Dashboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-304

5.21.2.0.1 Dashboard I/O Type Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-305

5.21.2.0.2 Digital Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-306

5.21.2.1 Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-306

5.21.2.2 Pulse Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-306

5.21.2.3 Pulse Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-307

5.21.2.4 Analog I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-307

5.21.3 System Health. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-308

5.21.4 Process Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-310

5.21.5 Storage Info. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-311

5.21.6 Accumulated Totals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-311

5.21.7 Comms Info. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-318

Fusion4 MSC-L Part No.: 4418309_Rev11

12 Installation & Operation Manual

Page 15

Table of Contents

5.21.8 Device Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-320

5.21.8.1 Reset Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-320

5.21.8.2 Execute Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-321

5.21.8.3 Clear Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-322

5.21.9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-324

5.21.10 Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-326

5.22 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-329

5.22.1 Why Calibrate? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-329

5.22.2 Calibration Menu Choice. . . . . . . . . . . . . . . . . . . . . . . . . . . .5-332

5.22.3 Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-333

5.22.3.1 Product Stream Selection . . . . . . . . . . . . . . . . . . . . . . . . . . .5-334

5.22.3.2 Additive Stream Selection. . . . . . . . . . . . . . . . . . . . . . . . . . .5-338

5.22.4 Wizard Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-341

5.22.4.1 Product Stream Selection . . . . . . . . . . . . . . . . . . . . . . . . . . .5-342

5.22.4.2 Additive Stream Selection. . . . . . . . . . . . . . . . . . . . . . . . . . .5-349

5.23 Info (Device Information) . . . . . . . . . . . . . . . . . . . . . 5-354

5.23.1 Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-354

5.23.2 Status Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-357

5.24 Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-358

5.24.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-359

5.24.2 Retrieving Transaction Records . . . . . . . . . . . . . . . . . . . . . .5-360

5.24.2.1 Transaction Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-362

5.24.3 Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-365

5.24.4 Events / Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-365

5.24.5 Calibration Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-366

5.24.6 Recipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-367

5.24.7 Language Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-367

5.25 LAD Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-370

5.25.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-370

5.25.2 Firmware Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-371

5.25.2.1 Verify the Firmware Update. . . . . . . . . . . . . . . . . . . . . . . . . .5-374

5.25.3 Test LED and LAD Information Submenus . . . . . . . . . . . . . .5-375

5.25.4 Function Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-376

5.25.5 LAD Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-377

5.25.6 Format SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-378

5.26 Truck Driver Operations . . . . . . . . . . . . . . . . . . . . . . 5-378

5.26.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-378

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 13

Page 16

Table of Contents

5.26.2 Default standalone MSC-L workflow. . . . . . . . . . . . . . . . . . .5-379

5.26.3 STOP Key Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-388

5.26.4 Error Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-391

5.26.4.1 Invalid Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-391

5.26.4.2 Invalid Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-391

5.26.4.3 Batch not Feasible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-392

5.26.4.4 Batch stopped due to an Alarm. . . . . . . . . . . . . . . . . . . . . . .5-392

5.27 Service Technician Operations . . . . . . . . . . . . . . . . 5-393

5.27.1 Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-393

5.27.2 Configuration Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-394

5.27.3 Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-395

5.27.4 Recipe Transfer using the Fusion4 LAD . . . . . . . . . . . . . . . .5-396

5.28 Running Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-396

5.28.1 Loading Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-396

5.28.2 Left Arm Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-399

5.29 Recovery Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-399

5.30 W&M Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-400

5.30.1 W&M Intended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-400

5.30.2 W&M Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-400

5.30.3 Device Health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-402

5.30.4 MSC-L W&M compliance . . . . . . . . . . . . . . . . . . . . . . . . . . .5-402

5.31 Contacting Honeywell TAC. . . . . . . . . . . . . . . . . . . . 5-402

CHAPTER 6 ALARM HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Alarm Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2.2 Alarm Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2.3 Alarm State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2.4 Alarm Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2.5 Date & Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3 Alarm Severity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.1 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.2 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.3 Scenario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.4 Alarm Output Configuration. . . . . . . . . . . . . . . . . . . . . 6-5

Fusion4 MSC-L Part No.: 4418309_Rev11

14 Installation & Operation Manual

Page 17

Table of Contents

6.5 Operations on alarms . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5.1 Raising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.5.2 Clearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.5.3 Resetting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.5.4 Acknowledging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.5.5 Resetting all alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.5.6 Acknowledging all alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.6 Active Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.7 Alarm Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.8 List of all alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.8.1 Device Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

6.8.2 Bay Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.8.3 Arm Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.8.4 Product Stream Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6.8.5 Additive Stream Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6.8.6 External Additive Stream Alarms. . . . . . . . . . . . . . . . . . . . . . .6-17

6.8.7 Dual Bay Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 15

Page 18

Table of Contents

Fusion4 MSC-L Part No.: 4418309_Rev11

16 Installation & Operation Manual

Page 19

General - Product Overview

CHAPTER 1 GENERAL

1.1 Product Overview

Fusion4 Multi Stream Controller - Loading (MSC-L) is a Load Computer,

Batch Controller Unit (BCU) or a Preset, which is typically installed on a

loading bay, at a terminal, in the petro chemical industry. The MSC-L is

capable of operating in an explosion hazardous area. The MSC-L is

mainly used for accurately transferring products from the storage area

into another containment vessel. It takes into account the volume

changes necessary for legal measurements. Apart, from loading a

single product, the MSC-L also provides necessary functionality for

blending products, additive injections and for loading the final products

accurately, as required in the global oil storage and distribution industry.

The MSC-L controls the following:

Loading - Transferring the base or the stock oil, or the petroleum

derivative from a storage tank to a vehicle, for example, road trucks,

rail cars, or barges.

Additive injection - Improving and differentiating the base or stock oil,

or petroleum derivatives by changing the physical properties and

specifications of the oil product (fuel) during loading/transferring.

Blending - Combining two or more fluid products to a predetermined

specification during loading.

The MSC-L utilizes Local Access Device (LAD) for interfacing, local

commissioning, configuration, calibration, troubleshooting, and data

exchange, using the Secure Digital (SD) card.

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 1 - 1

Page 20

General - Product Overview

FIGURE 1-1 Basic MSC-L principle of operation (example)

NOTE: The MSC-L can control up to six loading arms simultaneously.

Fusion4 MSC-L Part No.: 4418309_Rev11

1 - 2 Installation & Operation Manual

Page 21

General - Functionality Overview

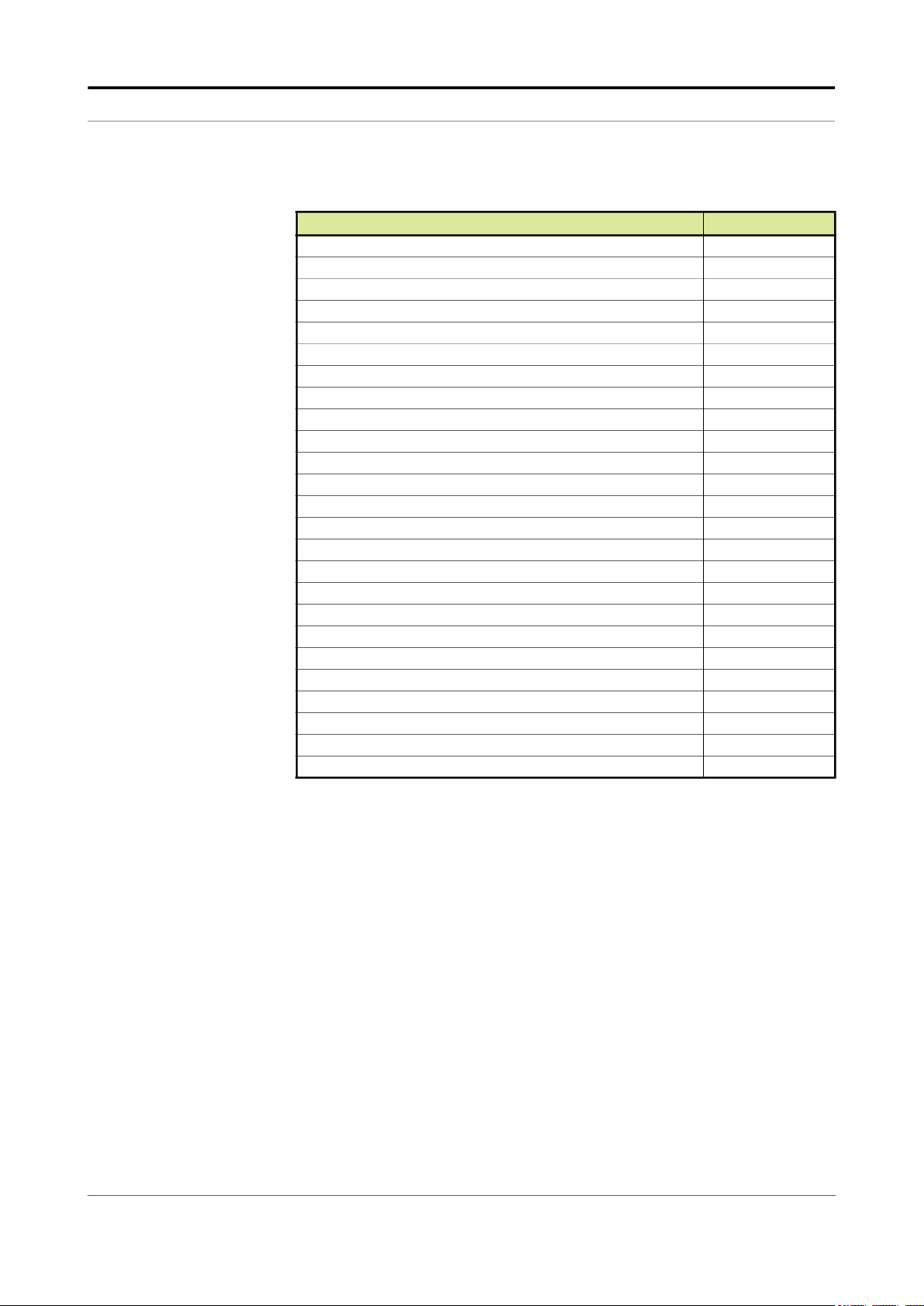

1.2 Functionality Overview

Functionality MSC-L

Global Ex approvals (ATEX, FM, CSA, IECEx) √

Expandable I/O hardware √

Firmware in-situ upgradeable √

Fully configurable I/O binding √

Diagnostics dashboard √

Configuration upload/download √

Transaction and calibration logs upload/download √

Interface to Fusion4 Portal (printing, and so on) √

Multi language display 11

Free programmable language pack 1

Transaction storage 10000

Alarm log records 2000

Calibration log records 1200

Event records 1000

Comms ports 7

Ethernet ports 3

Single pulse inputs 24

Pulse outputs 4

DI-DC 60

DI-AC 12

DO-EMR 40

DO-SSR 40

Analog Inputs 14

Analog Outputs 6

RTD Inputs 6

NOTE: The functionality overview lists the maximum available I/O hardware.

1.3 Target Audience for this Manual

This manual is intended for service technicians, and bay operators (for

example, truck drivers) who are assigned to install, commission,

service, or operate the MSC-L.

This Installation and Operations manual is aligned with Fusion4 MSC-L

software version A2440.

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 1 - 3

Page 22

General - Target Audience for this Manual

FIGURE 1-2 Fusion4 Multi Stream Controller - Loading (MSC-L)

Fusion4 MSC-L Part No.: 4418309_Rev11

1 - 4 Installation & Operation Manual

Page 23

Safety - Safety Conventions

CHAPTER 2 SAFETY

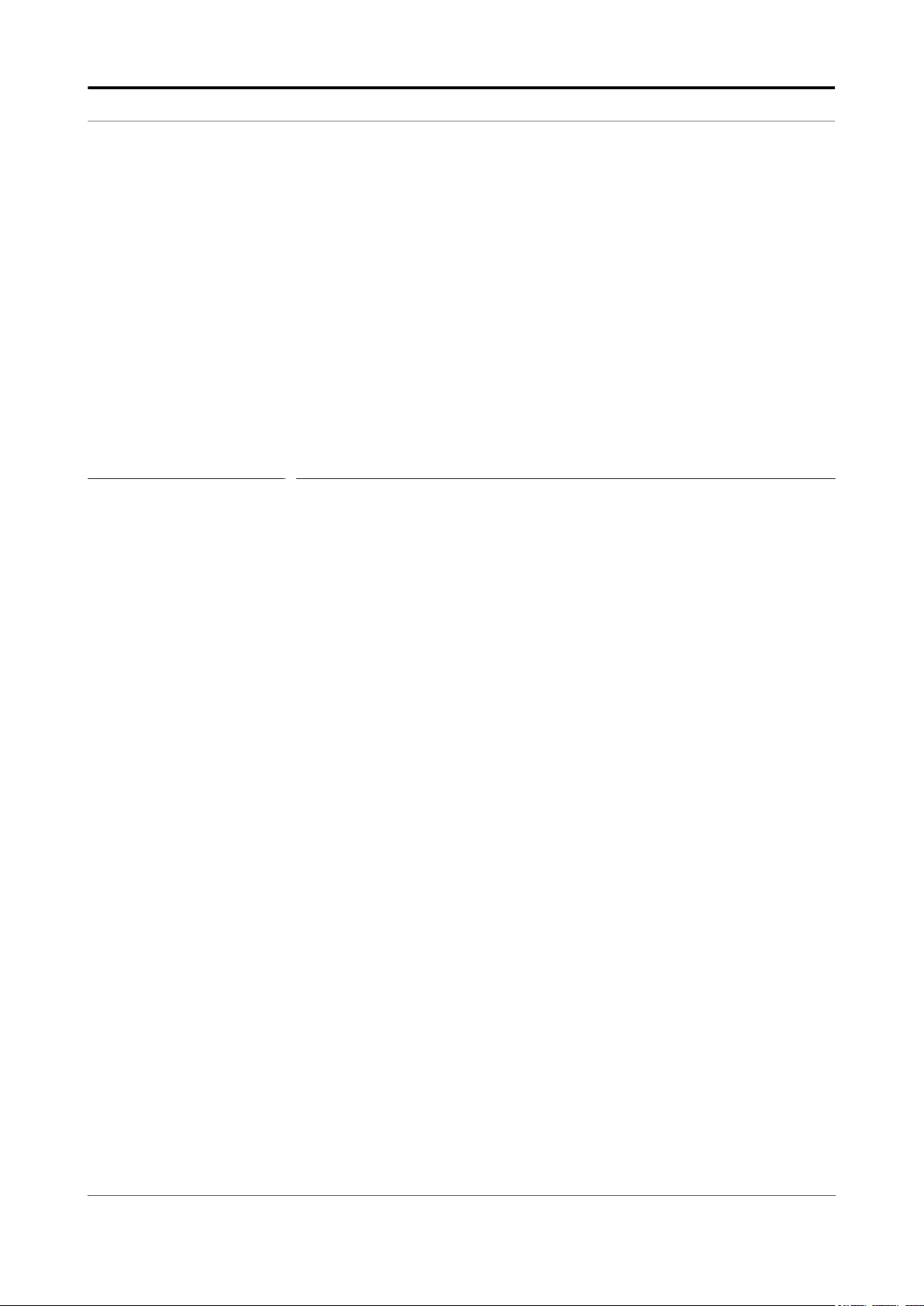

2.1 Safety Conventions

2.1.1 Warnings

The following warning symbol used in the manual recommends your

attention to prevent personal injuries or dangerous situations.

Symbol Description Remark

General warning It is always explained by text.

2.1.2 Cautions

The following caution symbol used in the manual recommends your

attention to prevent damages to the equipment.

Symbol Description

General caution sign

ElectroStatic Discharge (ESD) sensitive device

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 2 - 1

Page 24

Safety - Safety Instructions for the MSC-L

2.2 Safety Instructions for the MSC-L

2.2.1 General

WARNING! You must strictly follow all the safety instructions

mentioned in this manual and the safety instructions

shipped with the MSC-L during installation, commissioning, operation, and maintenance for the safe

operation of the MSC-L.

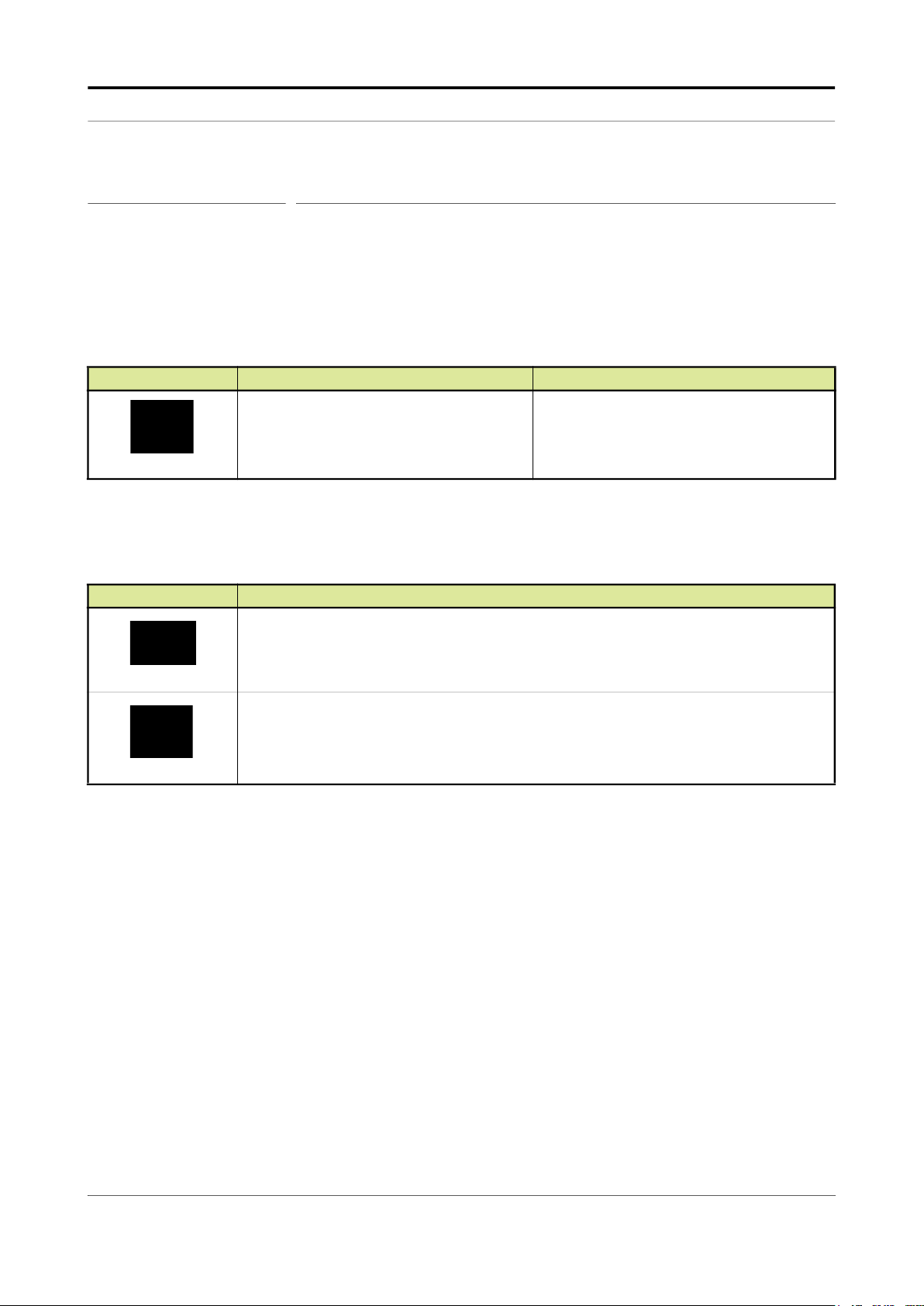

The MSC-L may be located in explosion safety areas as follows:

USA (FM) and Canada (CSA) Canada (CSA)

Safety

level

Class 1,

Division 1

Class 1,

Division 2

Remarks

WARNING!

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

in 18 inches.

WARNING!

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

in 18 inches.

Safety

level

Zone 1 WARNING!

Zone 2 WARNING!

Remarks

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

in 18 inches.

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

in 18 inches.

Rest of the World

(ATEX/IECEx)

Safety

level

Zone 1 WARNING!

Zone 2 WARNING!

Remarks

Do NOT open

when an

explosive

atmosphere

may be

present.

Do NOT open

when an

explosive

atmosphere

may be

present.

Safe Area - Safe

Zone

2.2.1.1 EC Declaration of Conformity (for EU)

- Safe

Refer to the EC declaration of conformity and ATEX certificate(s),

shipped with the MSC-L for EC declarations.

2.2.1.2 Control Drawings for FM & CSA

Refer to the control drawings shipped with the MSC-L for the FM and

CSA certifications.

Fusion4 MSC-L Part No.: 4418309_Rev11

2- 2 Installation & Operation Manual

-

Zone

Page 25

Safety - Safety Instructions for the MSC-L

2.2.1.3 Users

The mechanical and electrical installation must be performed only by

trained personnels with the knowledge of the requirements for

installation of explosion proof equipment in hazardous areas.

The entire installation procedure for the MSC-L must be implemented in

accordance with national, local, and company regulations.

The entire electrical installation may be performed in accordance with

the national requirements for electrical equipment to be installed in

hazardous areas.

2.2.1.4 Additional Information

For additional information about Honeywell Enraf’s solutions, see the

back cover of this manual to contact Honeywell Enraf or its

representative.

2.2.1.5 Environmental Conditions

The environmental conditions regarding the permissible operating

temperature for the MSC-L is -40 °C to +65 °C (-40 °F to +149 °F).

WARNING! When the MSC-L is used in operating temperatures

above 40 °C the enclosure is hot when it is touched.

2.2.2 Operation

After commissioning, the MSC-L can be used for its flow controller or a

load computer for a multi stream product.

2.2.3 Maintenance and Troubleshooting

In the unlikely event of a malfunction, only a qualified service technician,

trained by Honeywell Enraf, and with the knowledge of safety

regulations for working in hazardous areas, must be allowed to service,

maintain, assemble, and dismantle the MSC-L.

WARNING! Any repairs or part replacements must be done by a

Honeywell Enraf trained service technician.

2.2.4 Personal Safety

National, local and company regulations regarding personal safety must

be followed.

Consider the weight of the MSC-L when moving, installing, or

decommisioning.

WARNING! At high ambient temperature, pay attention to the fact

that the accessible parts on the outside of the MSC-L

can be hot.

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 2 - 3

Page 26

Safety - Safety Instructions for the MSC-L

2.2.4.1 General

2.2.4.1.1 Opening the MSC-L

WARNING! It is forbidden to open the MSC-L in an explosive

hazardous environment, unless otherwise stated on

the safety label.

2.2.5 Commissioning and Maintenance

NOTE: The MSC-L can be mounted on the wall using frame

and bolts. The frame and bolts used must be capable

of holding four times the weight of the MSC-L being

mounted.

WARNING! Treat the flange surfaces of the lid and the housing

with care. Make sure that the flange surface is clean

and undamaged before closing.

This is required to maintain the CSA approval and it

is strongly recommended for all Ex approvals. The Oring must be present and undamaged.

1. National, local, and company regulations regarding installation must

be followed.

2. The bolts of the enclosure lid are captive (property class A2-70).

Contact Honeywell Enraf if you need to replace the bolts.

3. Before closing the lid, check that all grounding connections including

the grounding connection to the lid, are properly connected.

4. All wiring entries must be closed such that the approvals are not

invalidated. See section 4.2 - Gland Entries, to make sure that the

correct thread type is selected. For installations using cable glands,

always use compound barrier glands. For installations using

conduits, each conduit must be sealed within 18 inches of the

enclosure.

5. The limiting values of U

must be respected for all non-intrinsically

m

safe connections. See section 2.2.7.1 - Explosion Safety Limiting

Values, for information regarding the Explosion Safety Limiting

Values.

2.2.5.1 Tools

WARNING! Use non-sparking tools and explosion-proof testers.

Use suitable explosion-proof tools (for example,

testing devices).

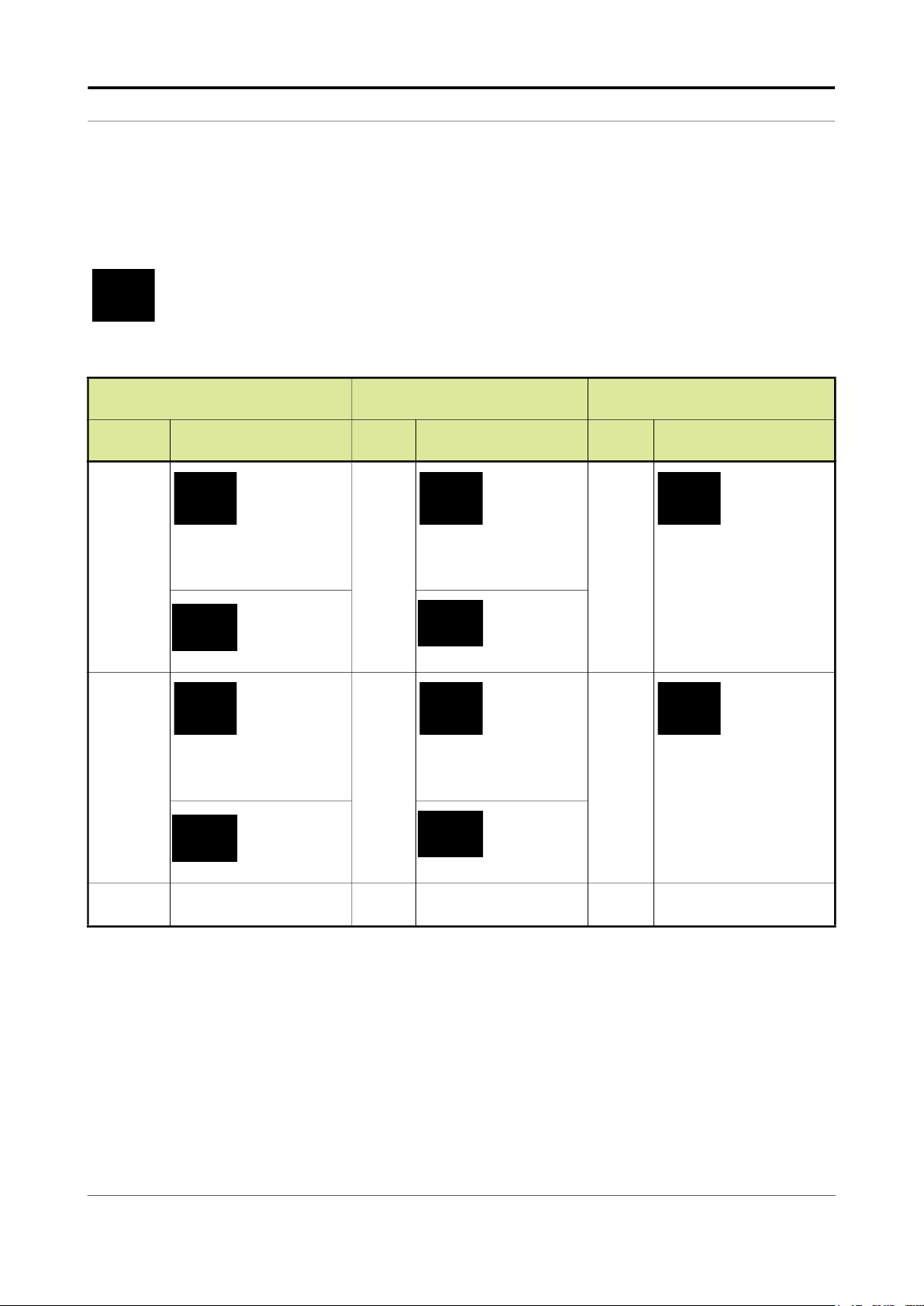

2.2.6 Electrical

2.2.6.1 Grounding

WARNING! Make sure that the housing of the MSC-L is properly

bounded to the Protective Earth (PE). See FIGURE

2-1 for external grounding of the MSC-L and FIGURE

2-2 for bonding any AC mains wire.

Fusion4 MSC-L Part No.: 4418309_Rev11

2- 4 Installation & Operation Manual

Page 27

Safety - Safety Instructions for the MSC-L

3

g

8 point grounding

Also, make sure that the electrical resistance of the

ground connections is below the maximum limit/

value prescribed by national, local, and company

requirements.

3 point grounding

point groundin

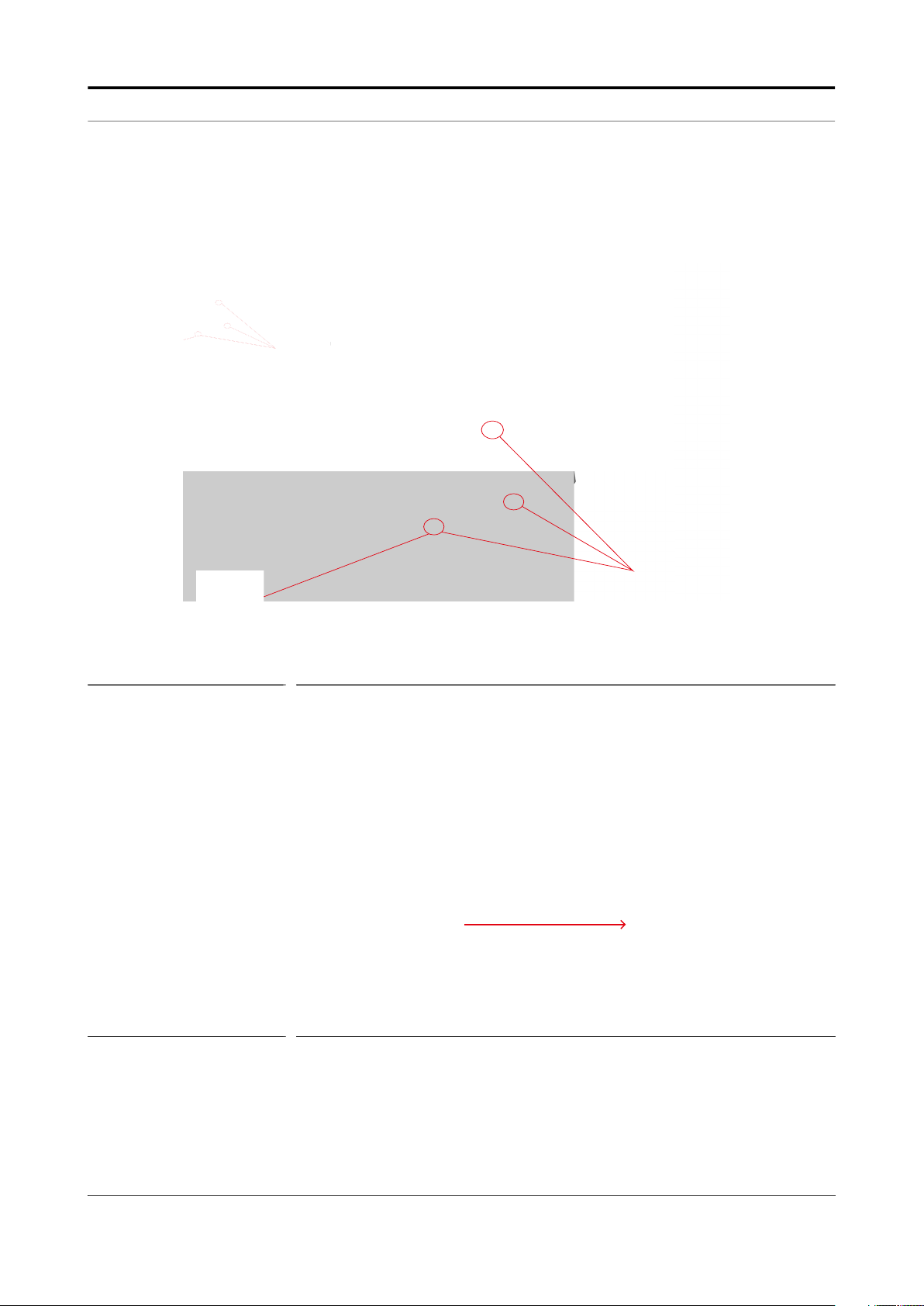

FIGURE 2-1 External grounding connections of the MSC-L

FIGURE 2-2 Internal grounding connections of the MSC-L

3 point grounding

F4 A10 -00 02

WARNING! Maintaining the ground bonding of the lid to the local

Protective Earth (PE) using the lid ground wire is

crucial for ensuring intrinsic safety.

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 2 - 5

Page 28

Safety - Safety Instructions for the MSC-L

2.2.7 Accordance to Regulations

2.2.7.1 Explosion Safety Limiting Values

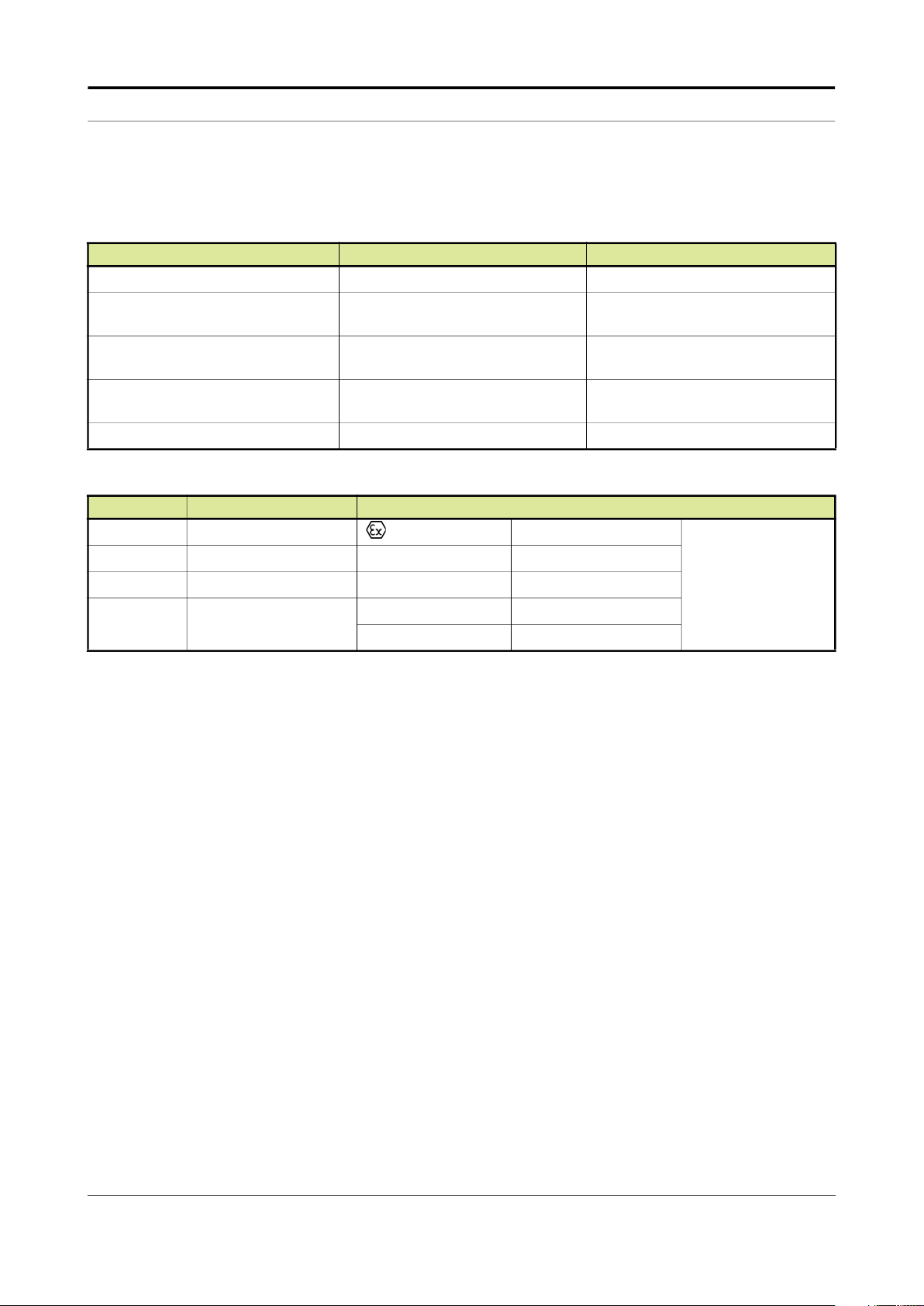

Explosion safety items Limiting values Type of protection

Power supply (Mains input): 100 - 240 VAC, 50 - 60 Hz

Maximum allowed power dissipation

inside the enclosure:

LAD interface circuit (LAD front connector):

Thermal protection, limitation of the

output current

U

m

2.2.7.2 Explosion Safety

90 W

Uo = 15.75 V, Io = 1.49 A, Po = 1.92

W, Co = 2.69 μF; Lo = 62 μH

160 mA

250 V

AC

Type of protection intrinsic safety Ex

ia IIB

Approval Certificate no. Type of protection identification

ATEX DEKRA 12ATEX0101 X II 2 G Ex d [ia] IIB T6 Gb

IECEx DEK 12.0021 X Zone 1 Ex d [ia] IIB T6 Gb

FM 3048063 Class I, Division 1 group C, D T4

CSA 2673172

2.2.7.3 Low-Voltage Directive

Class I, Division 1 Group C & D T6

Class I, Zone 1 Ex d [ia] IIB T6 Gb

The MSC-L is suitable for the following categories.

Pollution degree 2

Overvoltage category II

Class I equipment

= -40 °C ... +65 °C

T

a

(-40 °F ... +149 °F)

Fusion4 MSC-L Part No.: 4418309_Rev11

2- 6 Installation & Operation Manual

Page 29

Safety - Safety Instructions for the MSC-L

2.2.7.4 The MSC-L Labels

NOTE: Type plates are exemplary and subject to change.

FIGURE 2-3 Identification labels with the safety note on the MSC-L

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 2 - 7

Page 30

Safety - Safety Instructions for the LAD

FIGURE 2-4 W&M approvals type plate for Fusion4 MSC

2.3 Safety Instructions for the LAD

FIGURE 2-5 Local Access Device LAD

WARNING! You must strictly follow all the safety instructions

mentioned in this manual and the safety instructions

shipped with the MSC-L during installation, commissioning, operation, and maintenance for the safe

operation of the device.

Fusion4 MSC-L Part No.: 4418309_Rev11

2- 8 Installation & Operation Manual

Page 31

Safety - Safety Instructions for the LAD

The LAD may be used in hazardous areas as follows:

USA (FM) and Canada (CSA) Canada (CSA)

Safety

level

Class 1,

Division 1

Class 1,

Division 2

Safe

Area

Remarks

WARNING!

Substitution of

components

may impair

intrinsic safety.

WARNING!

Substitution of

components

may impair

intrinsic safety.

- Safe

Safety

Level

Class 1,

Division 1

resp.

Zone 1

Class 1,

Division 2

resp.

Zone 2

Zone

Remarks

- Safe

WARNING!

Substitution of

components

may impair

intrinsic

safety.

WARNING!

Substitution of

components

may impair

intrinsic

safety.

Rest of the World (ATEX /

IECEx)

Safety

level

Zone 1 -

Zone 2 -

Zone

Remarks

-

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 2 - 9

Page 32

Safety - Safety Instructions for the LAD

2.3.1 General

The LAD is a hand-held controller used for interfacing with the MSC-L.

WARNING! Only use the instrument for its intended purpose.

2.3.1.1 EC declaration of conformity (for EU)

Refer to the EC declaration of conformity and ATEX certificate(s),

shipped with the device for EC declarations.

2.3.1.2 Control Drawings for FM & CSA

Refer to the control drawings shipped with the MSC-L for FM and CSA.

2.3.2 Explosion Safety

Approval Certificate no. Type of protection identification

ATEX KEMA 10ATEX0152 II 2 G

Ex ia IIB T4 Gb

IECEx IECEx KEM 10.0070 Zone 1

FM 3041202 Class I, Division 1 group C, D T4

Class I, Division 1 group C, D T4

CSA 11.2395571

Zone 1 Ex ia IIB T4

T

= -20 °C ... +65 °C

a

(-4 °F ... +149 °F)

WARNING! This is an intrinsically safe device and may only be

connected to devices with compatible intrinsically

safe parameters, such as the MSC-L.

Connection of non-intrinsically safe signals invalidates the approval. The electrical data of the intrinsically safe circuits is to be taken from the certificate.

2.3.3 Commissioning

The LAD and the Fusion4 parent devices must be commissioned using

this controller trained by Honeywell Enraf. The service technician must

have knowledge of the national, local and company requirements for

electrical equipment in hazardous areas.

2.3.4 Operation

After connecting to the MSC-L, the LAD can be used for its intended

purpose.

2.3.5 Maintenance and Troubleshooting

The LAD hardware is non-servicable, in case of damage contact

Honeywell Enraf for replacement.

Fusion4 MSC-L Part No.: 4418309_Rev11

2- 10 Installation & Operation Manual

Page 33

Safety - Safety Instructions for the LAD

2.3.6 Additional Information

For additional information about Honeywell Enraf’s solutions, see the

back cover of this manual to contact Honeywell Enraf or its

representative.

2.3.7 Environmental Conditions

The environmental conditions regarding the allowable operating

temperature is -20 °C to +65 °C (-4 °F to +149 °F), relative humidity is

RH 5 to 95%, non-condensing, and operating pressure is atmospheric.

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 2 - 11

Page 34

Safety - Safety Instructions for the LAD

2.3.8 The LAD Labels

FIGURE 2-6 Identification labels with safety note on the LAD

Fusion4 MSC-L Part No.: 4418309_Rev11

2- 12 Installation & Operation Manual

Page 35

Safety - Safety Instructions for the IR Controller

2.4 Safety Instructions for the IR Controller

FIGURE 2-7 The IR Controller

WARNING! You must strictly follow all the safety instructions

mentioned in this manual and the safety instructions

shipped with the MSC-L during installation, commissioning, operation, and maintenance for the safe

operation of the device.

The IR Controller may be located in explosion safety areas as follows:

USA (FM) and Canada (CSA) Canada (CSA)

Safety

level

Class 1,

Division 1

Remarks

WARNING!

Do not open

battery

compartment

in a hazardous

area. Use only

approved

batteries, see

label.

Safety

Level

Class 1,

Division 1

Remarks

WARNING!

Do not open

battery

compartment

in a

hazardous

area. Use only

approved

batteries, see

label.

Rest of the World (ATEX /

IECEx)

Safety

level

Zone 1 WARNING!

Remarks

Do not open

battery

compartment

in a hazardous

area. Use only

approved

batteries, see

label.

Part No.: 4418309_Rev11 Fusion4 MSC-L

Installation & Operation Manual 2 - 13

Page 36

Safety - Safety Instructions for the IR Controller

USA (FM) and Canada (CSA) Canada (CSA)

Safety

level

Class 1,

Division 2

Safe

Area

Remarks

WARNING!

Do not open

battery

compartment

in a hazardous

area. Use only

approved

batteries, see

label.

- Safe

Safety

Level

Class 1,

Division 2

Zone

Remarks

- Safe

2.4.1 General

The Fusion4 IR Controller is a hand-held remote controller, which is an

infrared-type control device. The device facilitates programming the

Enraf Fluid Technology IR Controlled Equipment remotely.

The device contains all the necessary program codes installed. Hence,

the user programming is not required.

WARNING!

Do not open

battery

compartment

in a

hazardous

area. Use only

approved

batteries, see

label.

Rest of the World (ATEX /

IECEx)

Safety

level

Zone 2 WARNING!

Zone

Remarks

Do not open

battery

compartment

in a hazardous

area. Use only

approved

batteries, see

label.

-

2.4.2 Precautions

Clean the device with a damp cloth.

Use additional protection in areas where damage may occur.

Do not repair the device without permission to avoid the invalidation

of the certificate.

Do not leave the device in direct sunlight or place it near a heat

source.

Handle the device gently. Do not drop the device or subject it to other

types of stress.

Do not touch any solvent or aggressive substances before touching

the enclosure as it is made of plastic.

Store the device at room temperature in a clean and dry location.

To avoid damage to the device or shortening of battery life, use the

correct type of batteries.

To prevent battery usage when storing the device in an unused

condition for a long time, make sure that the buttons are not pressed.

To prevent damage caused by leaking batteries, remove the

batteries before storing the device in an unused condition for a long

time.

Fusion4 MSC-L Part No.: 4418309_Rev11

2- 14 Installation & Operation Manual

Page 37

Safety - Safety Instructions for the IR Controller

2.4.2.1 EC declaration of conformity (for EU)

Refer to the EC declaration of conformity and ATEX certificate(s),

shipped with the device for EC declarations.

2.4.3 Installation

Perform the following steps to install the device.

1. Remove the security screws from the compartment lid.

2. Slide the battery compartment lid from the device.

3. Install the 3 AAA Alkaline batteries ensuring that the plus (+) and the

minus (-) polarity of the batteries are correct.

NOTE: Removing the batteries does not remove the Fusion4

IR Controller memory.

Always replace the batteries with new ones.

Use only batteries approved for use.

WARNING! Do not open the battery compartment or change the

batteries in a hazardous area.

2.4.4 Commissioning

The IR Controller and the Fusion4 parent devices must be

commissioned using this controller by qualified service technician,

trained by Honeywell Enraf. The service technician must have

knowledge of the national, local, and company requirements. for

electrical equipment in hazardous areas.

2.4.5 Operation

After connecting to a Fusion4 parent device (for example, the MSC-L),

the Fusion4 IR Controller can be used for its intended purpose.

Perform the following steps to use the device.

1. Direct the device at the IR port of the equipment to be programmed.

2. Select ATTN on the IR Controller to turn the device and provide the

initial program command to the MSC-L.

REMARK: Refer to the specific equipment’s user’s manual for

defined programmed functions.

The device automatically stops after 30 seconds if an

activity is not performed. This helps in preserving the

battery life.

2.4.6 Maintenance and Troubleshooting