Page 1

Rev. K

P/N D01-4002-000

MeshGuardTM

Monitor

User’s Guide

January 2019

Page 2

© Copyright 2019 RAE Systems by Honeywell.

2

Page 3

MeshGuard User’s Guide

3

Contents

1 Standard Kit ........................................................................................................................................................ 6

2 General Information ............................................................................................................................................ 6

3 Physical Description ........................................................................................................................................... 8

3.1 LCD Display......................................................................................................................................... 9

3.2 Specifications .................................................................................................................................... 10

4 Operating The MeshGuard ............................................................................................................................... 11

4.1 Turning The MeshGuard On ............................................................................................................. 11

4.2 Turning The MeshGuard Off ............................................................................................................. 12

4.3 Low Battery Indicator & Action .......................................................................................................... 12

4.4 Wireless Communication Indicator .................................................................................................... 13

5 Operation Modes .............................................................................................................................................. 13

5.1 Detection Mode ................................................................................................................................. 14

5.2 Manually Sending Data ..................................................................................................................... 15

5.3 Detection Mode (When Portable Mode Is Enabled) ......................................................................... 15

5.4 Programming Mode ........................................................................................................................... 17

5.4.1 Entering Programming Mode ......................................................................................................... 18

5.4.2 Exiting Programming Mode ........................................................................................................... 19

5.4.3 Zero Calibration ............................................................................................................................. 19

5.4.4 Span Calibration ............................................................................................................................ 20

5.4.5 Change High Alarm ....................................................................................................................... 22

5.4.6 Change Low Alarm ........................................................................................................................ 23

5.4.7 Change STEL setting (Portable Mode Only) ................................................................................. 24

5.4.8 Change TWA setting (Portable Mode Only) .................................................................................. 25

5.4.9 Change SPAN value ...................................................................................................................... 26

5.4.10 Change Pan ID ............................................................................................................................ 27

5.4.11 Join Mesh Network ...................................................................................................................... 27

5.4.12 Change Communication Interval ................................................................................................. 27

6 Diagnostic Mode ............................................................................................................................................... 28

6.1 Entering Diagnostic Mode ................................................................................................................. 28

6.2 Exiting Diagnostic Mode .................................................................................................................... 28

6.3 Diagnostic Mode Readings ............................................................................................................... 29

6.3.1 Sensor Raw Count ......................................................................................................................... 29

6.3.2 Battery Raw Count ......................................................................................................................... 29

6.3.3 Temperature Raw Count ............................................................................................................... 29

6.3.4 Zero Raw Count ............................................................................................................................. 29

6.3.5 Calibration Delta Counts ................................................................................................................ 30

6.4 Diagnostic Mode Programming ......................................................................................................... 30

6.4.1 Fixed Or Portable Operation Selection .......................................................................................... 32

6.4.2 Radio Enable/Disable .................................................................................................................... 32

6.4.3 Std Enable or Rtr Enable ............................................................................................................... 32

6.4.4 Factory Setting ............................................................................................................................... 33

6.4.5 Audible & Visible Alarm Enable/Disable ........................................................................................ 33

7 Sensor And Battery Replacement ................................................................................................................... 34

7.1 Battery replacement .......................................................................................................................... 34

7.2 Sensor Filter Replacement ................................................................................................................ 35

7.3 Sensor Replacement ......................................................................................................................... 36

8 Troubleshooting ................................................................................................................................................ 37

9 Alarm Signal Summary ..................................................................................................................................... 38

10 Appendix A: Installation ............................................................................................................................ 39

10.1 Magnet-Mount Installation ................................................................................................................. 39

10.2 Fixed Installation ............................................................................................................................... 40

10.3 Magnetic Mount Alternative Installation ............................................................................................ 43

11 MeshGuard Sensor Specifications ........................................................................................................... 44

Page 4

MeshGuard User’s Guide

4

IMPORTANT! BUMP TEST THE MONITOR

BEFORE EACH DAY’S USE

Prior to each day’s use, every gas detection monitor should be bump tested to confirm the response of all sensors

and activation of all alarms by exposing the monitor to a concentration of target gas that exceeds the low alarm set

point. A bump test is also recommended if the monitor has been subjected to physical impact, liquid immersion, an

Over Limit alarm event, or custody changes, or anytime the monitor’s performance is in doubt.

To ensure greatest accuracy and safety, only bump test and calibrate in a fresh air environment.

The monitor should be calibrated every time it does not pass a bump test, but no less frequently than every six

months, depending on use and exposure to gas and contamination, and its operational mode.

• Calibration intervals and bump test procedures may vary due to national legislation.

• Honeywell recommends using calibration gas cylinders containing the gas that is appropriate to the sensor you

are using, and in the correct concentration.

Waste Electrical & Electronic Equipment Disposal

EU Directive 2012/19/EU: Waste Electrical and Electronic Equipment (WEEE)

This symbol indicates that the product must not be disposed of as general industrial or domestic

waste. This product should be disposed of through suitable WEEE disposal facilities. For more

information about disposal of this product, contact your local authority, distributor, or the

manufacturer.

Page 5

5

WARNINGS

2460

Read Before Operating

This manual must be carefully read by all individuals who have or will have the responsibility of using, maintaining,

or servicing this product. The product will perform as designed only if it is used, maintained, and serviced in

accordance with the manufacturer’s instructions.

FCC Part 15 statement and CE

This device complies with Part15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Warning

Use only the Lithium battery or external rechargeable battery provided by RAE Systems. This instrument has not

been tested in an explosive gas/air atmosphere having an oxygen concentration greater than 21%. Substitution of

components may impair suitability for intrinsic safety. Replace batteries only in non-hazardous locations.

STATIC HAZARD: Clean only with a damp cloth.

For safety reasons this equipment must be operated and serviced by qualified personnel only. Read and

understand instruction manual completely before operating or servicing. Any rapid up-scale reading followed by a

declining or erratic reading may indicate a gas concentration beyond upper scale limit, which may be hazardous.

Intrinsically Safe Marking

Cl. I, Div. 1, Gr A, B, C, D T4

Ta = -40° C to +50° C

IECEx SIR 19.0015X

Sira 19ATEX2036X

Ex ia IIC T4 Ga

Ex ia I Ma

Ui = 3.6V, Ci=63µF, Li/Ri=3.5µH/ohm

MeshGuard User’s Guide

Page 6

MeshGuard User’s Guide

6

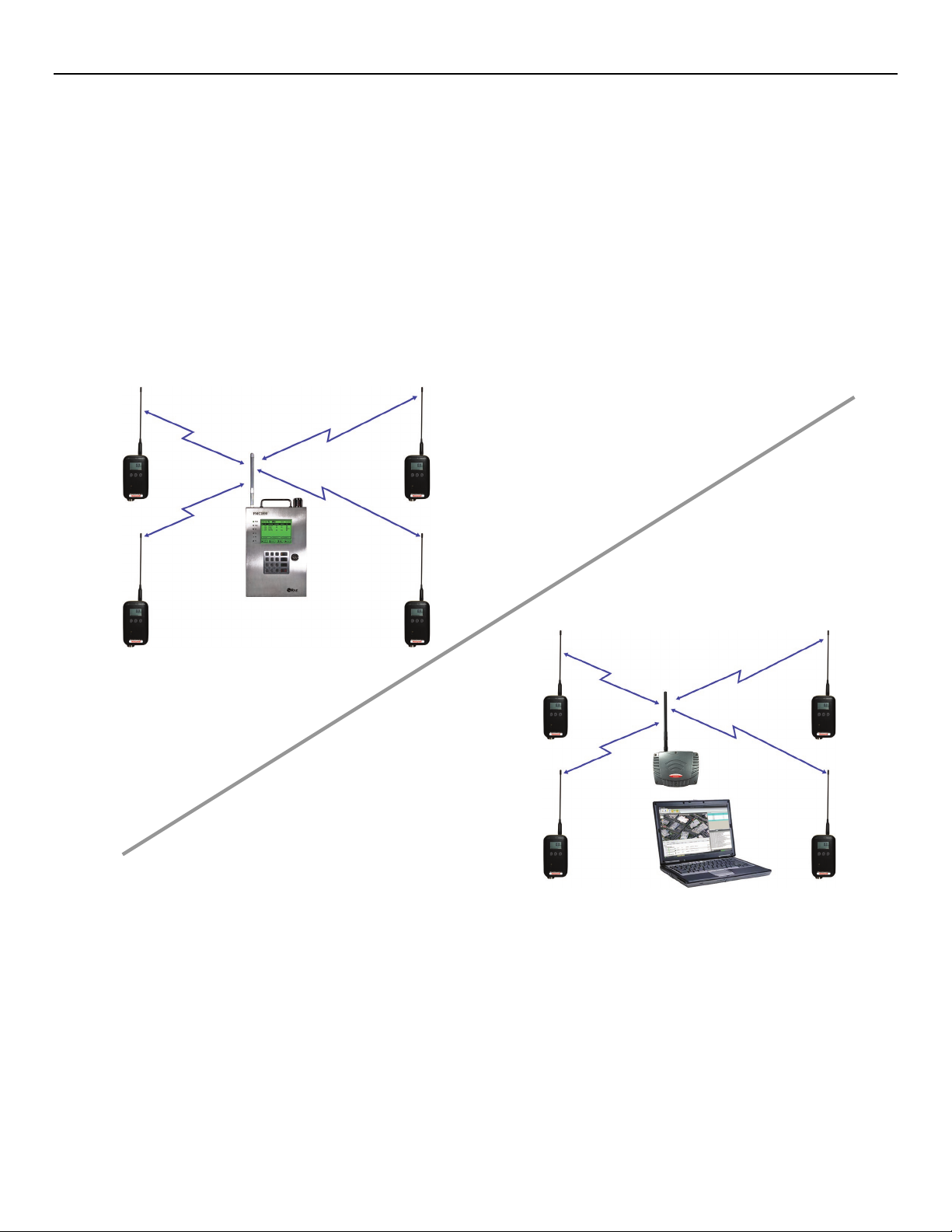

Meshguard network

ProRAE Guardian

1 Standard Kit

Monitor with antenna

User’s Guide

CD with resources

Maintenance tool

Calibration certificate

Calibration adapter

2 General Information

MeshGuard (FTD-2000) is a single toxic gas detector integrated with a wireless mesh network-enabled

transmission radio module. It can work as a fixed device or as a portable device. The detector has the option of

relaying the wireless signal to other MeshGuards as needed, to bypass obstacles. The MeshGuard’s built-in radio

board operates on a frequency of 2.4GHz and complies with IEEE 802.15.4 standard. The FTD-2000 works with the

FMC-2000 wireless controller on a flexible, robust wireless network to provide reliable, low-cost operation. It also

works in a ProRAE.net network with a PC, and it supports point-to-point and point-to-multi-point networks.

with FMC-2000

controller

network with

PC controller

Page 7

MeshGuard User’s Guide

7

Key Features

Up to 6 months continuous operation

IEEE 802.15.4 Mesh network functionality with 64-bit encryption

Robust wireless mesh network with auto network forming and configuration

Operating distance: up to 300 m (985 ft), line of sight

Very low-cost installation − no hardwiring involved

Large area coverage with multi-hop mesh network

Field-replaceable battery

Loud audio alarm, 90dB @ 30cm (12″)

Large, easy-to-read continuous display

Bright red flashing alarm

Highly resistant to RFI interference

IP-65 rated for outdoor use in harsh environments

Sensors supported: See section 14, “MeshGuard Sensor Specifications”

Field-replaceable sensor.

User-adjustable high and low alarms

User-adjustable STEL and TWA alarms (in portable mode)

Simple calibration

Page 8

MeshGuard User’s Guide

8

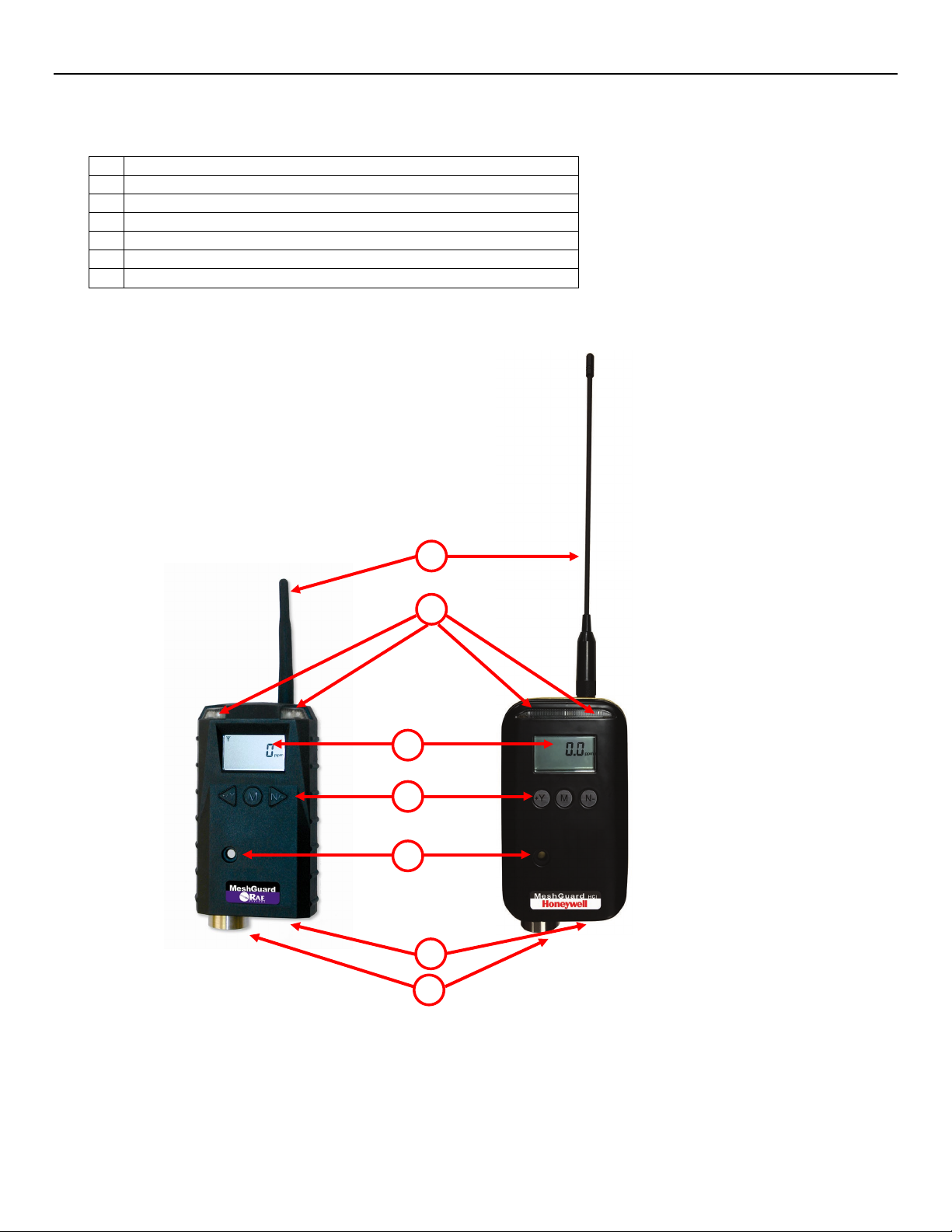

1

LED alarm

2

LCD (with backlighting)

3

Buzzer alarm

4

Sensor gas inlet

5

Battery cover (on bottom)

6

Y/+, MODE, and N/- keys

7

Antenna

7

1

2

3 6 5

Plastic Housing

Metal Housing

4

3 Physical Description

Note: The physical appearance of the MeshGuard is virtually identical, whether in a metal enclosure or a plastic

enclosure. Functionality is identical, regardless of the enclosure.

Page 9

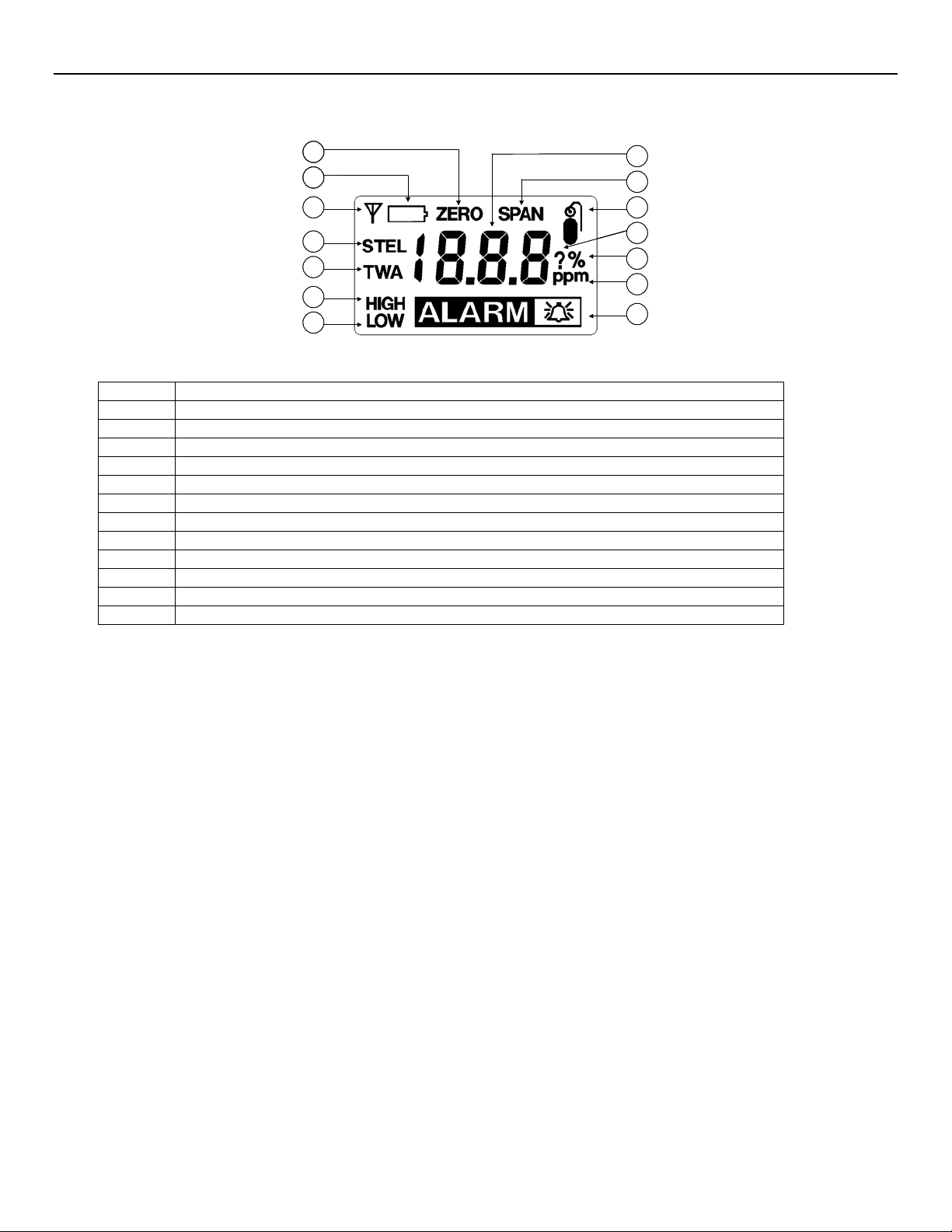

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

11

22

3

4

5

6

7

8

9

10

11

12

13

14

1*

Zero Calibration

2

Low Battery Indicator

3

Wireless Communication (if on, the monitor is in STD; if blinking, the monitor is RTR)

4*

Short Term Exposure Limit (STEL)

5*

Time Weighted Average (TWA)

6, 8*

High Alarm

7, 8*

Low Alarm

9*

Gas Concentration unit, ppm

10*

Gas Concentration unit, %

11

Save Setting

12,13*

Span Calibration

14

Reading Value

Remark:

Concentration unit is shown as either ppm (9) or % (10).

3.1 LCD Display

MeshGuard User’s Guide

Page 10

10

3.2 Specifications

RF Certifications

FCC Part15

ictQATAR Type Approval Reg. No.: R-4465

Display

Customized LCD (1 x 1.5″) with backlight

Audible alarm

90dB @ 30cm

Visual alarm

2 super-bright red LEDs

Calibration

Two-point field calibration

RF

IEEE 802.15.4/Zigbee with mesh stack

Operating Range

Up to 300 meters, line of sight

Transmission

Power

Up to 18dBm (63mw EIRP)

Receiver

Sensitivity

Minimum -95dBm at 2.4GHz

User Interface

Three keys (Y/+, MODE, N/-)

Power Supply

D-size EVE or Xeno Lithium primary battery, +3.6V, 19 Ah

Max Current

Consumption

200mA@3.6V during transmission

<0.5mA@3.6V during standby

Operation Time

Internal Battery:

**RTR is router-function device

Operating

Temperature

-40° to 122° F (-40° to +50° C) for CO, and H2S sensors

Other sensors: -4° to 122° F (-20° to +50° C)

Humidity

0% to 95% relative humidity, non-condensing

Dimensions

Metal Enclosure: 15.7cm x 9.3cm x 5.1cm

(10.5″ x 3.7″ x 2.1″)

Weight

Metal Enclosure: 1.2 kg (2.65 lbs)

Plastic Enclosure: 0.6 kg (1.3 lbs)

Package

IP-65

Mounting

Optional stainless-steel bracket mount or magnetic mount

Radio model: RM2400A

RF power(Tx): 20dBm

Frequency range: 2.400-2.4835GHz

Data rate: 250kbps

Modulation: 802.15.4 DSSS BPSK

CE EN 300328

SRRC (Pending)

Wireless Approval For UAE In Middle East (TRA

REGISTERED No: ER36063/14

DEALER No: HONEYWELL INTERNATIONAL MIDDLE

EAST - LTD - DUBAI BR

Wireless Approval for QATAR In Middle East

MeshGuard User’s Guide

For STD* Mode: up to 6 Months

For RTR** Mode: up to 10 days

*STD is standard-function device

(6.2” x 3.7” x 2.0”)

Plastic Enclosure: 26.5cm x 9.5cm x 5.5cm

Radio Specifications

Page 11

MeshGuard User’s Guide

11

Operation

4 Operating The MeshGuard

Make sure the battery is installed before operating the MeshGuard. Refer to page 34 for information on battery

installation and replacement.

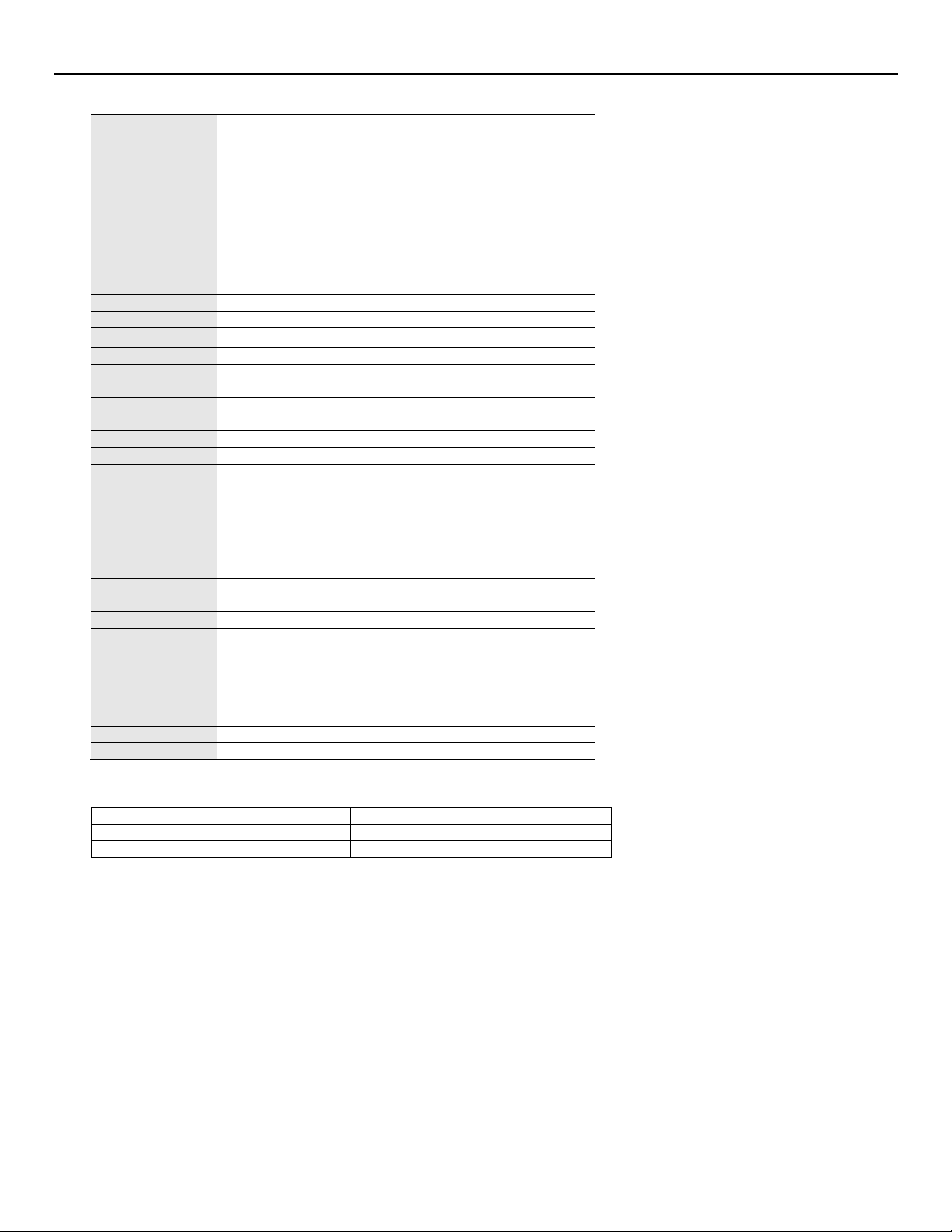

4.1 Turning The MeshGuard On

Hold down the [MODE] key and release it when the MeshGuard beeps. The monitor is now on, as indicated by the

display:

The MeshGuard performs a self-test, followed by warm-up and zero calibration. The display briefly shows the

firmware version (for example, “F1.0” means firmware version 1.0, “F2.0” means firmware version 2.0, etc.):

Then the MeshGuard initializes the wireless network and displays this information:

Note: If MeshGuard is unable to find a radio network to connect with, it searches, and the display alternates

between “rdo” and “Srh” (for “radio search”).

Page 12

MeshGuard User’s Guide

12

Next, the display tells you that MeshGuard is initiating network communication:

Next, if a network is located, an antenna icon appears (if no network is found, then refer to “Join Mesh Network” on

page 27). The current gas concentration reading is also displayed:

Note: When adding a MeshGuard detector to a new network for the first time, it is recommended that you press

[Y/+] to manually initiate a search for the network.

The MeshGuard is now operational.

4.2 Turning The MeshGuard Off

Hold down the [MODE] key through the “5…4…3… 2… 1… oFF” sequence. The monitor is off when the display is

blank. Release the [MODE] key.

The MeshGuard is now off.

4.3 Low Battery Indicator & Action

The MeshGuard’s battery is designed for up to six months’ life in STD mode (in RTR mode, including the

MeshGuard Router’s normal operation, battery life is up to 10 days). When the battery gets low, the MeshGuard

beeps once per minute and an empty battery icon appears. It is recommended that the battery be changed

immediately, to minimize disruption.

When the battery is completely depleted, the LCD displays “OFF,” and the LED, buzzer and vibration alarm activate

once per second. The battery icon also blinks on and off. The MeshGuard shuts down after you press any key, or

shuts down automatically if you do not press a key for 60 seconds.

Page 13

MeshGuard User’s Guide

13

4.4 Wireless Communication Indicator

When wireless communication is turned on, the LCD displays the wireless link status in the upper left corner:

If the MeshGuard finds and joins a wireless network, an antenna icon is shown in the display. If no link or a weak

link is established, no antenna icon is shown. Press [Y/+] to search for a network. (See “Join Mesh Network” on

page 27.)

A flashing antenna means the MeshGuard is in Router Mode (RTR), and the radio is always on.

5 Operation Modes

The MeshGuard can operate as a standard (STD) or a router-mode (RTR) device. In STD mode, the MeshGuard

transmits data to the host at a set interval (the default is 30 seconds) or anytime an alarm occurs. In RTR mode, the

MeshGuard receives data in real time, and it can also work as a router as needed to relay data from STD devices

back to the host.

Note: Operating the MeshGuard in RTR mode reduces battery life.

The interval can be changed in Programming Mode. See page 13 for details.

In addition, there is a Detection Mode for standard operation, Programming Mode for making changes to values

(such as the High Alarm, etc.), Diagnostic Mode (for servicing and checking the sensor, etc.), and Diagnostic

Programming Mode, which is for selecting between STD & RTR modes, etc.

Page 14

MeshGuard User’s Guide

14

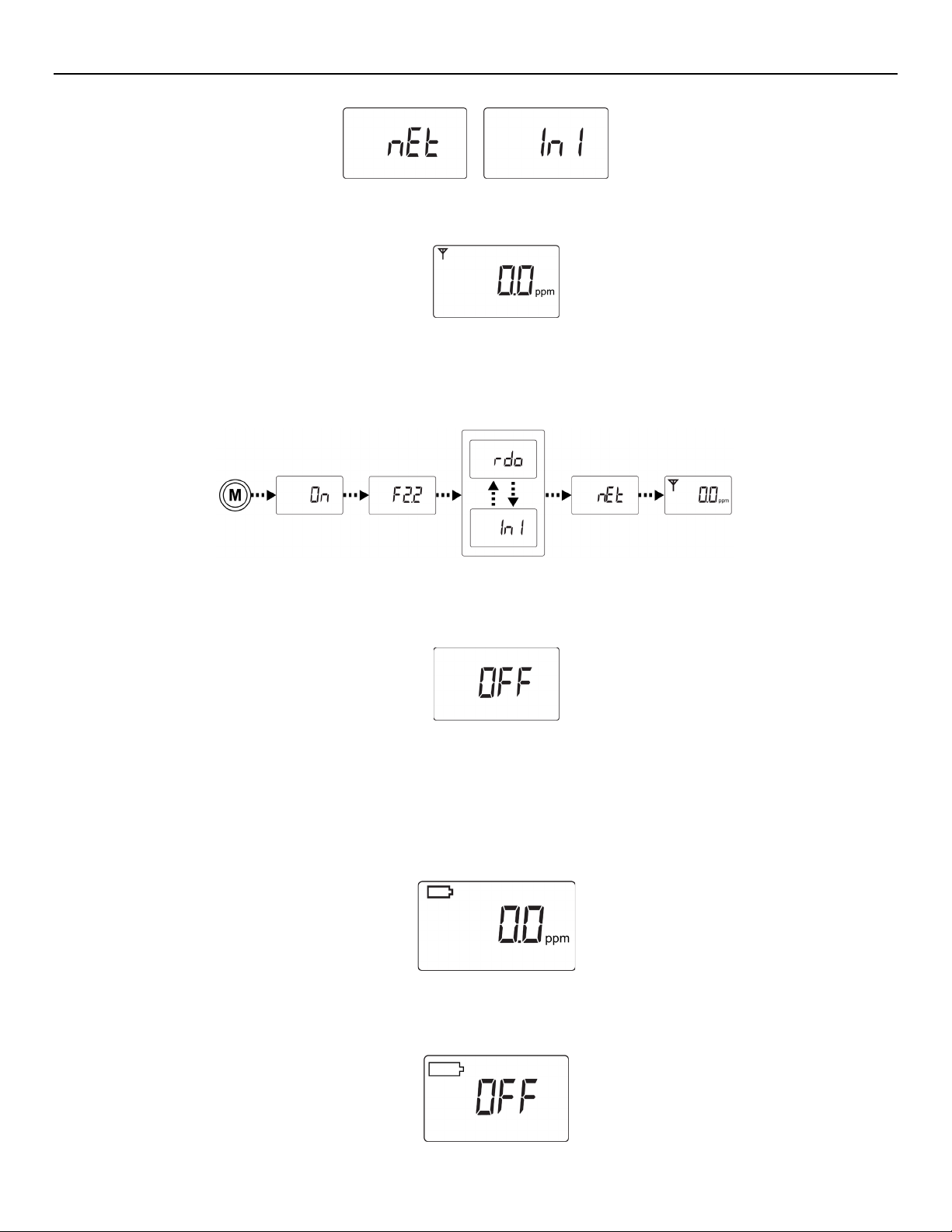

5.1 Detection Mode

The MeshGuard can operate in fixed or portable mode. Whenever you start MeshGuard, it is automatically in fixed

Detection Mode, which is the default.

The MeshGuard displays the current reading:

Pressing [MODE] steps through the Detection Mode screens:

Press [MODE], and it displays the sensor type:

Press [MODE], and it alternates between EUI (Extended Unique Identifier) and its value:

Press [MODE], and it alternates between Pan and ID (Personal Area Network Identifier) and its value:

Press [MODE] to return to the detector reading:

Page 15

MeshGuard User’s Guide

15

5.2 Manually Sending Data

While the MeshGuard typically sends reading data to the network on a fixed interval, you can send the data anytime.

When the monitor is connected to the network, press the [Y/+] key. The screen displays “Ini” and “nEt” one time,

and the monitor sends the current sensor data, and returns to the detector reading.

5.3 Detection Mode (When Portable Mode Is Enabled)

When Portable Mode is enabled (see page 32), pressing [MODE] steps through three more screens, STEL, TWA,

and Peak:

The initial screen is the reading display:

Press [MODE], and it displays STEL. The STEL (short-term exposure limit) is the average reading of the gas

concentration for the last 15 minutes.

Note: The STEL reading does not appear until 15 minutes have elapsed. If the MeshGuard has not been on for 15

minutes, it displays three dashes:

Page 16

MeshGuard User’s Guide

16

Press [MODE], and it displays TWA. The TWA (time-weighted average) is the accumulated reading of the gas

concentration, divided by 8 hours, since the monitor was turned on.

Press [MODE], and the display indicates the Peak reading by alternating between “P” (for “Peak”) and a numerical

value:

Press [MODE] to return to the current reading:

Page 17

MeshGuard User’s Guide

17

5.4 Programming Mode

Programming Mode allows you to perform any of the following actions (listed in order of appearance):

• Calibrate the MeshGuard

• Changing Preset Limits or Span Gas Values

• Set Pan ID

• Join network

• Choose communication interval

The menus accessed in Programming Mode are:

• Zero Calibration

• Span Calibration

• High Alarm

• Low Alarm

• STEL (Portable Mode only)

• TWA (Portable Mode only)

• Set Span Value

• Pan ID

• Join Network

• Communication interval

Page 18

MeshGuard User’s Guide

18

5.4.1 Entering Programming Mode

To enter the Programming Mode, press [MODE] and [N/-] for 3 seconds. “Pro” appears in the display:

Pressing [N/-] steps you through all the screens and then returns to the first programming display:

Each display alternates between its name and a status message or value.

Note: You can exit Programming Mode at any time by pressing [MODE]. Also, if you do not make a change within

one minute, the MeshGuard exits Programming Mode and returns to Detection Mode.

Page 19

MeshGuard User’s Guide

19

Settings can be changed as follows:

1. When a menu is selected, it flashes between two screens. For example:

2. Press [MODE] to exit Program Mode and return to Detection Mode, or press [N/-] to advance to the next menu.

3. Press [Y/+] to enter. The LCD displays “go.”

5.4.2 Exiting Programming Mode

You may exit Programming Mode anytime and return to Detection Mode in either of these two ways:

• Press [MODE]. MeshGuard exits Program Mode and shows the current reading in Detection Mode.

• Do not press any buttons for 1 minute. MeshGuard automatically exits Programming Mode and returns to

Detection Mode, showing the current reading.

5.4.3 Zero Calibration

When “CAL” and “go” are displayed in alternation, and “ZERO” is shown, the MeshGuard is ready to perform a zero

calibration.

Press [Y/+]. The LCD displays “go.”

Page 20

MeshGuard User’s Guide

20

The display counts down from 10 to 0.

After the countdown reaches 0, the LCD displays “dn,” for “done.” The reading should show 0 (zero). Otherwise,

repeat the zero calibration.

Note: To stop zero calibration before the countdown reaches 0, press any key. The LCD displays “no” and

advances to the next programming menu, Span calibration.

5.4.4 Span Calibration

“CAL” and “go” flash in alternation, and “SPAn” is shown. The MeshGuard is now ready to perform a span

calibration.

To start calibration, press [Y/+]. The LCD displays “go.”

The MeshGuard waits for 10 seconds so that you have time to connect the calibration gas. Connect the calibration

gas adapter to the MeshGuard, and connect the gas cylinder to the adapter. Start the flow of gas.

Page 21

MeshGuard User’s Guide

21

When the gas flow starts, the LCD displays “gAS” and the span concentration value.

The MeshGuard now counts down to 0.

Note: The countdown time varies according to the type of sensor used in the MeshGuard.

After counting down and reaching 0, the LCD displays “dn.” The reading should be the span concentration value.

Otherwise, the span calibration should be repeated.

If the MeshGuard does not detect gas after counting down to 0, the LCD displays “Err” (for “error”). The LED glows

red and the buzzer sounds to provide extra warning. The MeshGuard automatically returns to the span calibration

display. In this case, you should attempt another calibration. If the span calibration fails a second calibration, the

sensor may need to be replaced.

Note: To stop span calibration before the countdown reaches 0, press any key. The LCD displays “no” and

advances to the next programming menu, Change High Alarm.

Page 22

MeshGuard User’s Guide

22

5.4.5 Change High Alarm

At the menu for changing the High Alarm setting, “ Set” and “ go” flash in alternation, and both “HIGH“ and

“ALARM” are shown.

Note: It is not recommended to increase the High Alarm setting above the factory default value.

Note: The High Alarm value varies, depending on different sensor types.

Press [Y/+] to enter and change the setting. Press [MODE] to go back to Detection Mode or [N] to advance to the

next menu.

The LCD displays the current value. Change the value if necessary.

To change the value:

1. Press [Y/+] to increase the number and [N/-] to decrease it.

2. Press [MODE] to advance to the next digit.

3. After moving to the last digit and making changes, press [MODE]. A question mark (?) is shown in the display,

asking if you want to save the change.

• Press [Y/+] for yes. The message “dn” means the change is done.

• Press [N/-] for no. A “no” message means that the change was abandoned.

• Press [MODE] to return to the first digit.

Page 23

MeshGuard User’s Guide

23

5.4.6 Change Low Alarm

At the Change Low Alarm menu, “Set” and “go” flash in alternation, and “LOW” and “ALARM” are visible in the

display.

Note: It is not recommended to increase the Low Alarm setting above the factory default value.

Note: The Low Alarm value varies by sensor type.

Press [Y/+] to enter and change the setting. Press [MODE] to exit and return to Detection Mode or [N] to advance to

the next menu.

The LCD displays current value. Change the value if necessary.

To change the value:

1. Press [Y/+] to increase the number and [N/-] to decrease it.

2. Press [MODE] to advance to the next digit.

3. After moving to the last digit and making changes, press [MODE]. A question mark (?) is shown in the

display, asking if you want to save the change.

• Press [Y/+] for yes. The message “dn” means the change is done.

• Press [N/-] for no. A “no” message means that the change was abandoned.

• Press [MODE] to return to the first digit.

Page 24

MeshGuard User’s Guide

24

5.4.7 Change STEL setting (Portable Mode Only)

Note: This menu is only available when the MeshGuard is in Portable Mode. If it is in Fixed Mode, you will not see

this menu and cannot change its settings.

“Set” and “go” flash in alternation, and “STEL” is shown.

Note: It is not recommended to increase the STEL Alarm setting above the factory default value.

Note: The STEL Alarm value varies by sensor type.

Press [Y/+] to enter and change the setting, [MODE] to exit and return to Detection Mode, or [N/-] to advance to the

next menu.

The LCD displays current value. Change the value if necessary.

To change the value:

1. Press [Y/+] to increase the number and [N/-] to decrease it.

2. Press [MODE] to advance to the next digit.

3. After moving to the last digit and making changes, press [MODE]. A question mark (?) is shown in the display,

asking if you want to save the change.

• Press [Y/+] for yes. The message “dn” means the change is done.

• Press [N/-] for no. A “no” message means that the change was abandoned.

• Press [MODE] to return to the first digit.

Page 25

MeshGuard User’s Guide

25

5.4.8 Change TWA setting (Portable Mode Only)

Note: This menu is only available when the MeshGuard is in Portable Mode. If it is in Fixed Mode, you will not see

this menu and cannot change its settings.

“Set” and “go” flash in alternation, and “TWA” is shown.

Note: It is not recommended to increase the TWA Alarm setting above the factory default value.

Note: The TWA Alarm value varies, depending on different sensor types.

Press [Y/+] to enter and change the setting, [MODE] to exit and return to Detection Mode, or [N/-] to advance to the

next menu.

The LCD displays the current value. Change the value if necessary.

To change the value:

1. Press [Y/+] to increase the number and [N/-] to decrease it.

2. Press [MODE] to advance to the next digit.

3. After moving to the last digit and making changes, press [MODE]. A question mark (?) is shown in the display,

asking if you want to save the change.

• Press [Y/+] for yes. The message “dn” means the change is done.

• Press [N/-] for no. A “no” message means that the change was abandoned.

• Press [MODE] to return to the first digit.

Page 26

MeshGuard User’s Guide

26

5.4.9 Change SPAN value

“Set” and “go” flash in alternation, and “SPAN” and a gas cylinder icon are shown.

Note: The Span value varies, depending on different sensor types.

Press [Y/+] to enter and change the setting, [MODE] to exit and return to Detection Mode, or [N/-] to advance to the

next menu.

The LCD displays the current value. Change the value if necessary.

To change the value:

1. Press [Y/+] to increase the number and [N/-] to decrease it.

2. Press [MODE] to advance to the next digit.

3. After moving to the last digit and making changes, press [MODE]. A question mark (?) is shown in the

display, asking if you want to save the change.

• Press [Y/+] for yes. The message “dn” means the change is done.

• Press [N/-] for no. A “no” message means that the change was abandoned.

• Press [MODE] to return to the first digit.

Page 27

MeshGuard User’s Guide

27

5.4.10 Change Pan ID

Press [Y/+] to enter the menu to make changes to the value.

1. Press [Y/+] to increase the number and [N/-] to decrease it.

2. Press [MODE] to advance to the next digit.

3. After moving to the last digit and making changes, press [MODE]. A question mark (?) is shown in the display,

asking if you want to save the change.

• Press [Y/+] for yes. The message “dn” means the change is done.

• Press [N/-] for no. A “no” message means that the change was abandoned.

• Press [MODE] to return to the first digit.

5.4.11 Join Mesh Network

Press [Y/-] to initiate joining a network. Three bars flash in sequence while it searches. When it is done, it alarms

once and displays “dn” for “done.”

5.4.12 Change Communication Interval

This menu allows you to change the interval between wireless transmissions. “SET” and “ItUL” flash, to indicate

that you can change the interval. The interval can be set to 10, 30, 60, 300, or 600 seconds.

Note: The default interval is 30 seconds.

Press [Y/+] to enter and change the setting, [MODE] to exit and return to Detection Mode, or [N/-] to advance to the

next MENU.

Page 28

MeshGuard User’s Guide

28

6 Diagnostic Mode

Diagnostic Mode provides raw data from sensors and about settings.

6.1 Entering Diagnostic Mode

Note: To enter Diagnostic Mode, you must begin with the MeshGuard turned off.

Press and hold [Y/+] and [MODE] until the MeshGuard starts.

The instrument goes through a brief startup, and then displays “dIA” to indicate it is in Diagnostic Mode. It then

switches to showing raw data for the sensor (the display shows “rAU” followed by a number).

The following chart shows how to navigate Diagnostic Mode (pressing N/- repeatedly steps through the screens):

6.2 Exiting Diagnostic Mode

Note: You can exit Diagnostic Mode and enter Programming Mode and calibrate the MeshGuard as usual by

pressing both [MODE] and [N/-] for three seconds.

Note: You can exit Diagnostic Mode and enter Detection Mode by pressing [MODE] and [Y/+] together for three

seconds, or by turning it off and on again. It is not recommended to use the detector in Detection Mode accessed

through the Diagnostic Mode. The unit must be turn off and started in normal operation mode.

Page 29

MeshGuard User’s Guide

29

6.3 Diagnostic Mode Readings

In Diagnostic mode, you can step through readings by pressing [N/-].

6.3.1 Sensor Raw Count

Sensor Raw Count is indicated by “rAU” followed by a number.

• Press [N/-] to advance to the next reading.

6.3.2 Battery Raw Count

Battery Raw Count is indicated by “bAt” followed by a number.

• Press [N/-] to advance to the next reading.

6.3.3 Temperature Raw Count

Temperature Raw Count is indicated by “tNp” followed by a number.

• Press [N/-] to advance to the next reading.

6.3.4 Zero Raw Count

Zero Raw Count is indicated by “0rC” followed by a number.

• Press [N/-] to advance to the next reading.

Page 30

MeshGuard User’s Guide

30

6.3.5 Calibration Delta Counts

Calibration Delta CTS is indicated by “CdC” followed by a number.

• Press [N/-] to return to the first raw count.

6.4 Diagnostic Mode Programming

You can enter a special programming mode from Diagnostic Mode in order to perform advanced programming

functions. These include:

• Enable Portable Mode

• Enable Radio

• Enable STD or RTR

• Return MeshGuard to original factory settings

• Enable/disable audible and visible alarms

Note: When the MeshGuard is in this programming mode, if you do not make a change or press a key for 60

seconds, it reverts to the standard Diagnostic Mode.

Important! After you make changes in Diagnostic Mode, it is recommended that you turn off the MeshGuard and

turn it on again before using it.

Page 31

MeshGuard User’s Guide

31

Enter this programming mode by first entering Diagnostic Mode. Refer to “Entering Diagnostic Mode,” page 30.

Step through the menus by pressing [N/-]. Exit by pressing [MODE], and then shutting off the MeshGuard and

restarting it.

Page 32

MeshGuard User’s Guide

32

6.4.1 Fixed Or Portable Operation Selection

The first menu is for setting the MeshGuard for fixed or portable operation. In Portable Mode, STEL, TWA, and

Peak readings are included.

“SEt” and “ Ptb” flash in alternation, to indicate that the MeshGuard can now be set as fixed or portable. The default

value is “fixed.”

Press [Y/+] to enter and change the setting, [MODE] to exit and return to Detection Mode, or [N/-] to go to the next

menu.

The LCD displays the current value (enabled or disabled). Change the value if necessary by pressing [Y/+] or [N/-].

Press [MODE} to enter your selection. Press [Y/+] to accept at this screen.

Note: “dIS” means fixed (Portable Mode disabled) and “En” means portable (Portable Mode enabled).

6.4.2 Radio Enable/Disable

The next menu is for setting turning the MeshGuard’s radio on or off.

“SEt” and “ rdo” flash in alternation, to indicate that the MeshGuard radio can be turned on (enabled) or off

(disabled). The default value is “on.”

Press [Y/+] to enter and change the setting, [MODE] to exit and return to Detection Mode, or [N/-] to go to the next

menu.

The LCD displays the current value (enabled or disabled). Change the value if necessary by pressing [Y/+] or [N/-].

Press [MODE} to enter your selection. Press [Y/+] to accept at this screen.

Note: “dIS” means disabled (radio off) and “En” means on (radio on).

6.4.3 Std Enable or Rtr Enable

Press [Y/+] to toggle the setting from Std to Rtr, and vice versa. Refer to “Operation Modes” on page 13.

Page 33

MeshGuard User’s Guide

33

6.4.4 Factory Setting

Press [Y/+] to return the MeshGuard to its original factory settings.

Note: This function clears all custom settings and returns all settings their factory default values. This cannot be

undone.

6.4.5 Audible & Visible Alarm Enable/Disable

Press [Y/+] to toggle between the MeshGuard’s audible and visible alarms turned on and off.

Page 34

MeshGuard User’s Guide

34

Battery

Battery cover

3-pin end

Hexagonal end

Sensor compartment

Battery compartment

Sensor and battery

7 Sensor And Battery Replacement

removal tool

(P/N 019-2044-000)

7.1 Battery replacement

1. Use the 3-pin end of the tool to unscrew and open the battery cover by turning it counterclockwise.

2. Remove the battery.

3. Insert the new battery with its positive (“+”) pole towards inside of the unit.

4. Replace the battery cover by turning it clockwise with the 3-pin end of the tool.

Note: Only change internal battery in a safe location and use the battery RAE Systems provided (P/N: 500-0111-000),

model ER34615 or XL-205F.

After changing the battery, wait at least 60 seconds before turning the MeshGuard on.

Page 35

MeshGuard User’s Guide

35

Filter

Filter holder

7.2 Sensor Filter Replacement

1. Use the 3-pin end of the tool to unscrew and open the filter holder by turning it counterclockwise.

2.

Remove and discard the filter.

Place a new filter inside the monitor.

3.

4.

Replace the filter holder by turning it clockwise with the 3-pin end of the tool.

Page 36

MeshGuard User’s Guide

36

Sensor

Sensor cover

Filter

Filter holder

7.3 Sensor Replacement

1. Use the 3-pin end of the tool to unscrew and open the filter holder at the bottom of the monitor.

2. Use the hexagonal end of the tool to open the remove the sensor cover, turning counterclockwise.

3. Pull the old sensor out.

4. Gently push a new sensor into the compartment.

Important! Ensure that the RAE Systems part number matches the sensor that was removed.

WARNING! Use only the same sensor model as the one installed when the monitor was purchased.

5. Replace the sensor compartment cover using by turning it clockwise, using the hexagonal end of the tool.

6. Replace the filter holder by turning it clockwise, using the 3-pin end of the tool.

Note: Always recalibrate the MeshGuard after service to ensure functionality.

Page 37

MeshGuard User’s Guide

37

Cannot turn on

Battery charge too low

use

Replace battery

ation on batteries

Abnormally high

Incorrect gas

to calibration gas

Recalibrate

“-0” Alarm

Sensor zero drift

Perform zero

calibration

Controller cannot

Too much distance

Pan ID numbers

The distance should be

number

No Antenna Icon

There is no reader or

Battery is low

Move the MeshGuard

Replace battery

Others

Turn MeshGuard off

Customer Service.

8 Troubleshooting

Failure Symptom Cause Solution

reading

receive the

MeshGuard’s signal

Battery has been

changed

New battery needs to

be discharged before

calibration

Sensor low sensitivity

between the

MeshGuard and the

controller.

There is an obstruction

between the

MeshGuard and the

controller.

Controller does not

receive completed data

packet

Battery is low

MeshGuard and

controller have different

Wait at least 60

seconds to turn on

MeshGuard

Check RAE Systems

web site for inform-

Replace the sensor

300 m, line of sight.

Deploy RTR MeshGuard

or MeshGuard Router(s).

Relocate the

MeshGuard or deploy

RTR MeshGuard or

MeshGuard Router(s).

Press [Y/+] on the

detector to force it to

send data packets

Replace battery

Set both units to have

the same Pan ID

controller nearby.

The controller or

reader’s network has

changed.

The MeshGuard is out

of its RF range.

closer to a working

controller or reader.

Perform the network

searching function in

diagnostic mode.

Move the MeshGuard

close to a working

controller or reader

and Press [Y/+]

and on again.

Consult RAE Systems

Page 38

38

9 Alarm Signal Summary

MeshGuard User’s Guide

Alarm

Mode

Over Range

High Alarm

Low Alarm

TWA

STEL

When LCD

Gas readings

exceed the

maximum value

of the sensor

> high alarm

setting

> low alarm

setting

> TWA

setting

> STEL

Setting

Buzzer & LED

3 beeps per second

3 beeps per second

2 beeps per second

1 beep per second

1beep per second

Zero Drift < 0 ppm

Battery Low < 3.2V

Battery

Exhausted

1 beep per second

1 beep per minute

1 beep per second

< 3.1V

Page 39

MeshGuard User’s Guide

39

Magnet

Rear of

10 Appendix A: Installation

Two methods for mounting MeshGuard make it easy to install. The first method uses a magnet that screw onto the rear of

the MeshGuard, making ideal for moving from one location to another. The second method uses a specially designed

stainless-steel enclosure that is permanently mounted. It protects the plastic-body MeshGuard from damage in industrial

settings.

10.1 Magnet-Mount Installation

For

Mounting

MeshGuard

This magnet is powerful enough to support the MeshGuard when it is placed against a flat steel or iron surface.

Important! Keep the magnet away from computer hard drives. The strong magnet can corrupt or erase data on these.

MeshGuard

Page 40

MeshGuard User’s Guide

40

Side

Front

Mounting

Sensor

Vertical pole

Horizontal pole

10.2 Fixed Installation

Four reinforced holes in the rear of the enclosure allow for a screw to pass through to the mounting brackets.

Holes

View

Cover

The enclosure can be mounted to a vertical or horizontal pole.

View

Page 41

MeshGuard User’s Guide

41

Slip the screws through the two holes that are side by side in order to mount the enclosure to a vertical pole.

Otherwise slip the screws through the two vertically aligned holes to attach the enclosure to a horizontal pole.

Loosely assemble the clamp parts around the pole. Note that the screws have nuts that fit into the clamp parts. The

clamp parts are designed to hole the nut so that you do not need to use a wrench. Hand-tighten the parts until snug.

Tighten the hex screws from the front of the enclosure:

Once the clamp parts and the enclosure are securely held against the pole, stop tightening.

Note: The pole must be between 25mm (1″) and 63mm (2.5″) in diameter.

Page 42

42

1 2 5

4

3

Next, place the MeshGuard into the enclosure:

1. Lift up the hinged cover of the enclosure.

2. Slide the MeshGuard into the enclosure from the top.

3. Close the cover of the enclosure.

4. Insert the hex screw into the cover’s locking portion, and tighten it.

5. The MeshGuard is now ready to use.

MeshGuard User’s Guide

Note: The sensor cover on the bottom of the enclosure can be removed so that the filter and sensor can be

inspected without removing the MeshGuard from the enclosure. Simply pull off the cover and follow the

maintenance procedures in this guide.

Page 43

MeshGuard User’s Guide

43

Side

Rear

10.3 Magnetic Mount Alternative Installation

The magnet-mount disc can be attached to the steel enclosure instead of the clamps. This approach provides the

protection of the enclosure with the ease of installation afforded by the magnetic mounting.

1. Insert screw through magnetic disc.

2. Place the magnetic disc over the bottom hole on the rear of the enclosure.

3. Tighten the screw until the disc is snug.

View

View

Page 44

MeshGuard User’s Guide

44

Sensor

Normal

Range

Resolution

Response

Time

Temperature

Range

H2S

0 to100 ppm

0.1 ppm

T

< 30 sec

-20° C to +50° C

H2S

0 to1000 ppm

1 ppm

T

< 45 sec

-40° C to +50° C

LEL/

0 to 100% LEL

1% LEL

T

< 30 sec

-40° C to +50° C

CO

0 to 2000 ppm

1 ppm (0 to 2000 ppm)

T

< 30 sec

-40° C to +50° C

CO2 IR

0 to 5% vol

0.01% vol

T

< 30 sec

-40° C to +50° C

O2

0 to 25%

0.10%

T

< 15 sec

-20° C to +50° C

NH3

0 to 100 ppm

1 ppm

T

< 30 sec

-20° C to +50° C

CL2

0 to 10 ppm

0.1 ppm

T

< 30 sec

T10 < 30 sec

-20° C to +50° C

(-4° F to 122° F)

SO2

0 to 20 ppm

0.1 ppm

T

< 60 sec

-20° C to +50° C

HCN

0 to 50 ppm

0.5 ppm

T

< 200 sec

T10 < 200 sec

-20° C to +50° C

(-4° F to 122° F)

NO

0 to 250 ppm

0.5 ppm

T

< 45 sec

T10 < 45 sec

-20° C to +50° C

(-4° F to 122° F)

PH3

0 to 20 ppm

0.1 ppm

T

< 60 sec

T10 < 60 sec

-20° C to +50° C

(-4° F to 122° F)

HCL

0 to 15 ppm

1 ppm

T

< 200 sec

T10 < 200 sec

-20° C to +50° C

(-4° F to 122° F)

ETO-A

0 to100 ppm

1 ppm

T

< 45 sec

T10 < 10 sec

-20° C to +50° C

(-4° F to 122° F)

ETO-B

0 to10 ppm

0.1 ppm

T

< 45 sec

T10 < 10 sec

-20° C to +50° C

(-4° F to 122° F)

ETO-C

0 to 500 ppm

10 ppm

T

< 45 sec

T10 < 10 sec

-20° C to +50° C

(-4° F to 122° F)

NO2

0 to 20 ppm

0.1 ppm

T

< 45 sec

T10 < 10 sec

-20° C to +50° C

(-4° F to 122° F)

HF

0 to 10 ppm

0.1 ppm

T

< 200 sec

T10 < 200 sec

-20° C to +50° C

(-4° F to 122° F)

11 MeshGuard Sensor Specifications

90

T10 < 30 sec

90

T10 < 45 sec

LEL IR*

90

T10 < 30 sec

(-4° F to 122° F)

(-40° F to 122° F)

(-40° F to 122° F)

0 to 100% vol

0 to 100 ppm

0.1% vol

1 ppm

90

T10 < 30 sec

90

T10 < 30 sec

90

T10 < 15 sec

90

T10 < 90 sec

90

90

T10 < 60 sec

90

90

90

90

90

90

90

(-40° F to 122° F)

(-40° F to 122° F)

(-4° F to 122° F)

(-4° F to 122° F)

(-4° F to 122° F)

* FTD-3000 only.

Ordering Replacement Parts: If you need replacement parts, a list is available online: http://www.raesystems.com

90

90

Page 45

MeshGuard User’s Guide

45

Letter

Year

V

2018

W

2019

A

2020

B

2021

C

2022

D

2023

E

2024

F

2025

G

2026

H

2027

I

2028

J

2029

K

2030

To identify the year of manufacture, refer to the serial number of the instrument.

The letter in the serial number indicates the year of manufacture. For example, “M” indicates the manufacturing year

is 2010.

Page 46

For more information

www.raesystems.com

D01-4002-000

Rev K January 2019

© 2019 Honeywell International

Loading...

Loading...