Page 1

Excel 50/500/800

LONWORKS® MECHANISMS

HONEYWELL EXCEL 5000 OPEN SYSTEM

INTERFACE DESCRIPTION

Copyright © 2007 Honeywell Inc. • All Rights Reserved

EN0B-0270GE51 R0307

Page 2

Excel 50/500/800 LONW

ORKS

Mechanisms

Trademark Information Echelon, LON, LONM

LonTalk, LonUsers, LonPoint, Neuron, 3120, 3150, the Echelon logo, the LONM

logo, and the LonUsers logo are trademarks of Echelon Corporation registered in

the United States and other countries. LonLink, LonResponse, LonSupport, and

LonMaker are trademarks of Echelon Corporation.

ARK

, LONW

ORKS

, LonBuilder, NodeBuilder, LonManager,

ARK

EN0B-0270GE51 R0307 2

Page 3

Excel 50/500/800 LONW

ORKS

Mechanisms

CONTENTS

Revision overview ........................................................................................................................................................................ 5

Excel 5000 LONWORKS System Architecture ........................................................................................................................... 6

Excel 50/500 Firmware Version 2.04.xx.................................................................... 6

Building Management Functionality...................................................................... 6

Excel 50/500 Firmware Version 2.06.xx and Excel 800............................................ 7

Building Management Functionality...................................................................... 7

Compatibility of Excel 50/500/800 Controllers and Distributed I/O Modules........................................................................... 8

Freely Programmable LonWorks Excel 50/500/800 Controllers ............................................................................................. 11

Number of NVs supported ...................................................................................... 11

Memory Requirements ....................................................................................... 11

Extending the Number of Physical I/Os using NVs............................................. 12

Node Object NVs .................................................................................................... 13

Activating and Configuring LonWorks plus BMF ................................................ 16

Standard NVs ......................................................................................................... 17

Network Interface Program ID ................................................................................ 19

External Network Interface File (XIF)...................................................................... 20

Binding and Mapping NVs ...................................................................................... 20

Binding Options.................................................................................................. 20

Mapping Options ................................................................................................ 22

Data Priority of NVs and Data-Points...................................................................... 26

Data-Point Types for NV Mapping .......................................................................... 27

Boardless Data-Points ............................................................................................ 27

Conversion of Data-Points to NVs .......................................................................... 27

NV-BOOSTER® ..................................................................................................... 27

Device Heartbeat Activation.................................................................................... 29

Bit-Field NVs........................................................................................................... 29

Restoring Binding Information................................................................................. 30

Excel 500 with Firmware Version 2.04.xx........................................................... 30

Excel 50/500 and CARE 4.xx with Firmware Versions 2.06.00 through 2.06.03 30

Excel 800 and CARE 7.2.xx / Excel 50/500 and CARE 4.xx with Firmware

Version 2.06.04 .................................................................................................. 30

System Alarms Defined for LONW

Distributed I/O Modules ............................................................................................................................................................. 33

Handling with Excel 50/500 Firmware Version 2.04.xx ........................................... 33

Operating Modes of Distributed I/O Modules ..................................................... 33

Autobinding (Excel 500, only)............................................................................. 33

Assignment (Excel 500, only)............................................................................. 34

Manual Binding .................................................................................................. 35

Use of E-Vision .................................................................................................. 35

Handling with Excel 50/500 Firmware Version 2.06.xx and CARE 4.xx.................. 35

Distributed I/O Node Object NVs ............................................................................ 36

Summary of Distributed I/O NVs............................................................................. 37

Excel 800 LON I/O Node Object NVs ..................................................................... 40

Distributed I/O Plug-Ins........................................................................................... 40

Guidelines for Specifying LONW

LONW

ORKS

System Engineering ................................................................................................................................................ 45

ORKS

Excel 500 Systems....................................................................................................... 41

Determining the Operating Mode of a New LonWorks System............................... 41

Implications of Changes to an Existing LONW

Application Changes............................................................................................... 43

Download Scenarios and Impacts........................................................................... 43

Effects of Hardware/Software Resetting ................................................................. 44

LONW

ORKS

Network Layout .................................................................................... 45

LONW

ORKS

Bus Termination............................................................................... 47

Network Segment Load Management..................................................................... 48

Total Network Segment Load............................................................................. 49

Minimization Measures....................................................................................... 51

XFLx22x and XL50/500 Response Times............................................................... 52

New Application Opportunities ........................................................................... 52

Excel 50/500/800 Limitations .................................................................................. 53

Firmware Version-Independent Limitations ........................................................ 53

Firmware Version-Dependent Limitations........................................................... 53

Dial-Up Access Options.......................................................................................... 54

Option 1: Dial-Up Access without Using a C-Bus............................................... 54

Option 2: Dial-Up Access Using a C-Bus ........................................................... 55

ORKS

Applications............................................... 32

ORKS

System.................................... 42

EN0B-0270GE51 R0307

3

Page 4

Excel 50/500/800 LONW

ORKS

Mechanisms

Option 3: Dial-Up Access via LonWorks plus BMF............................................. 55

Option 4: Dial-Up Access Using an SLTA to Connect a Modem ........................55

Applicable Literature.................................................................................................................................................................. 55

Abbreviations and Acronyms .................................................................................................................................................... 55

Index ............................................................................................................................................................................................ 58

EN0B-0270GE51 R0307 4

Page 5

Excel 50/500/800 LONW

ORKS

Mechanisms

REVISION OVERVIEW

The following pages have been changed from the previous issue of this document:

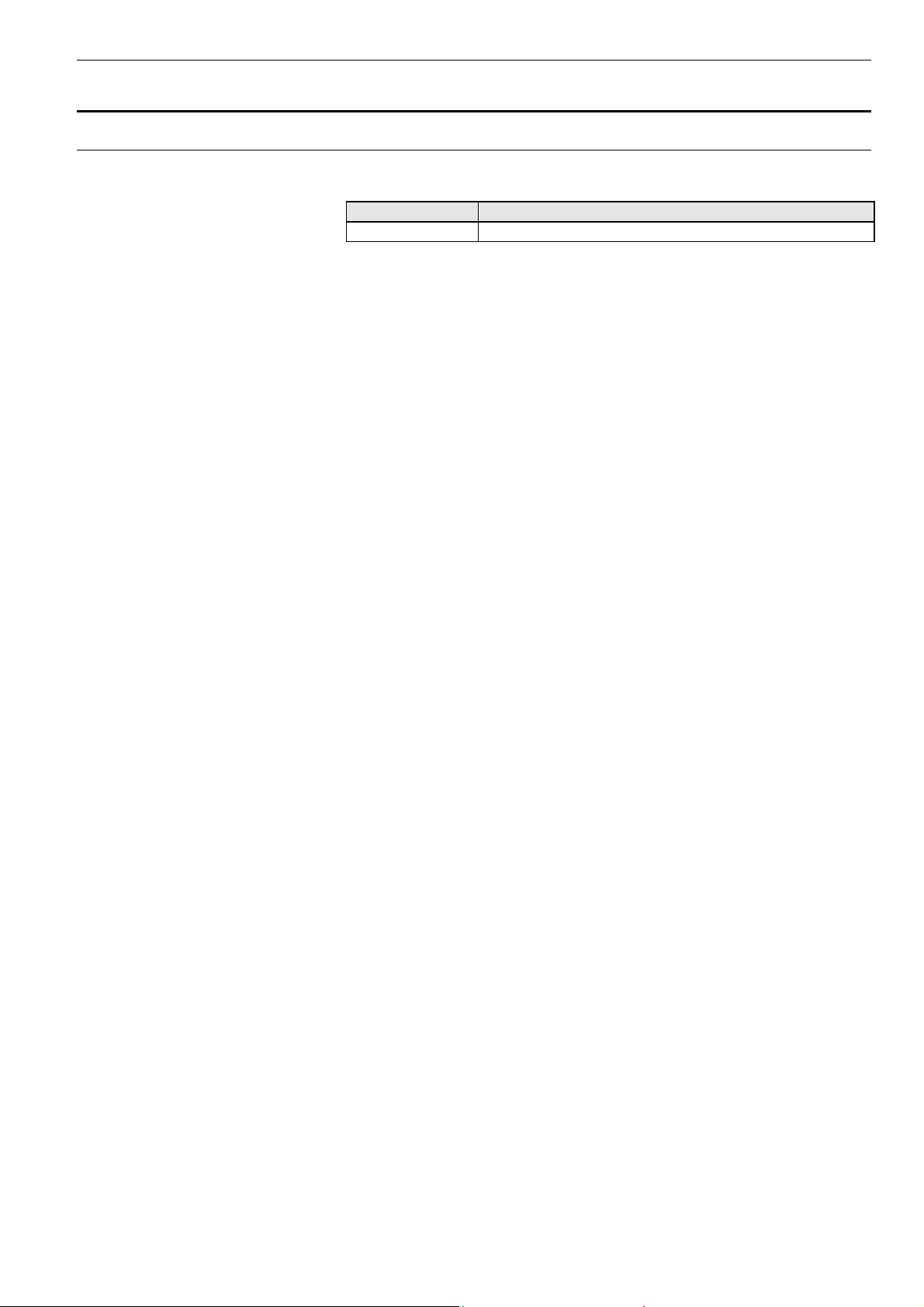

page change

Throughout The entire document has been updated to include Excel 800.

EN0B-0270GE51 R0307

5

Page 6

Excel 50/500/800 LONW

ORKS

Mechanisms

EXCEL 5000 LONWORKS SYSTEM ARCHITECTURE

Excel 50/500 Firmware Version 2.04.xx

Beginning with Excel 50/500 firmware version 2.04.xx, the capabilities of the

controllers were greatly expanded:

• Excel 500 controllers, including the XC5210C (whose CPU module features an

expanded RAM) and the Excel 500 Smart controller (XCL5010), can now

operate in open L

definitions of the terms "open," "shared," and "local").

• Distributed I/O modules were made LonMark-compliant and also capable of

use in L

ONWORKS

• Excel 50 controllers (which, in L

applications) can now also be used as freely-programmable controllers.

• Freely-programmable Excel 50/500 controllers can now communicate with the

Excel 10 family of controllers as well as with third-party L

• Excel 50/500 controllers now support standard L

the L

ONMARK

L

ONWORKS

also fully documented in the node’s self-documentation.

ONWORKS

systems (see Table 3 and Table 4 on page 9 for

networks independently of Excel 500 controllers.

ONWORKS

, could operate only with configurable

ONWORKS

ONWORKS

NVs according to

devices.

Interoperability Guidelines. Such NVs can be bound using any

network management tool (LNS-based or non-LNS-based), and are

Building Management Functionality

Table 1 summarizes the Building Management Functionality (BMF) available under

firmware version 2.04.xx via either direct C-bus connection or dial-up. See also

section "Dial-Up Access Options" on page 54.

Table 1. BMF via directly-connected C-Bus or via Dial-up (2.04.xx)

BMF EBI SymmetrE XBS/XBSi

time programs access dial-up / C-bus dial-up / C-bus dial-up / C-bus

alarms access dial-up / C-bus dial-up / C-bus dial-up / C-bus

trends access dial-up / C-bus dial-up / C-bus dial-up / C-bus

parameters access dial-up / C-bus dial-up / C-bus dial-up / C-bus

application download dial-up / C-bus dial-up / C-bus dial-up / C-bus

firmware download1 dial-up / C-bus dial-up / C-bus dial-up / C-bus

bus-wide MMI C-bus C-bus C-bus

1

With the exception of the controller currently operating via the modem.

Fig. 1 presents the Excel 5000 architecture under firmware version 2.04.xx.

Ethernet (TCP/IP)

Enterprise

C-Bus

Buildings

Integrator

group (=same bus name) of

max. 30 controllers

XL50XL50

XC5010 XCL5010 XL50XL50XL50

w/ modem

(CNEP)

XBS

direct hardwire connections

group (=same bus name) of

C-Bus

w/ modem

max. 30 controllers

dial-up

Internet Explorer

(CNEP)

C-Bus

group (=same bus name) of

max. 30 controllers

w/ modem

SymmetrE

(CNEP)

XL50XL50XL50

LonWorks (LonTalk)

3rd-party

products

XL10

FCU

XL10

VAV

Fig. 1. Excel 5000 architecture (firmware version 2.04.xx)

EN0B-0270GE51 R0307 6

XL10

Smart VAV

XL10

Chilled

Ceiling

XL10

Hydronic

XL10

CVAHU,

UVC, I/O

Smart

I/O Module

Distributed

I/O Module

FISS

LION

linear

valves

and

actuators

pressure/

temperature

sensors

inverters

Page 7

Excel 50/500/800 LONW

ORKS

Mechanisms

Excel 50/500 Firmware Version 2.06.xx and Excel 800

Beginning with Excel 50/500 firmware version 2.06.xx, and with Excel 800, the

capabilities of the controllers were further expanded:

• Besides such L

based) as LonMaker for Windows, CARE, too, can now also be used to

perform the L

products.

• In the case of Excel 50/500/800 controllers, Building Management Functionality

is available via direct hardware connections to L

up to L

ONWORKS

Table 2 summarizes the Building Management Functionality (BMF) available under

firmware version 2.06.xx / 3.xx.xx via either direct L

See also section "Dial-Up Access Options" on page 54.

Table 2. BMF via directly-connected LonWorks or Dial-up (2.06.xx or higher)

BMF EBI SymmetrE XBS/XBSi

time program access dial-up / LonWorks dial-up / LonWorks dial-up, only

alarms access dial-up / LonWorks dial-up / LonWorks dial-up, only

trends access dial-up / LonWorks dial-up / LonWorks dial-up, only

parameter access dial-up / LonWorks dial-up / LonWorks dial-up, only

application download dial-up / LonWorks dial-up / LonWorks dial-up, only

firmware download n.a. n.a. n.a.

bus-wide MMI n.a. n.a. n.a.

Fig. 2 presents the Excel 5000 architecture under firmware version 2.06.xx /

3.xx.xx.

Ethernet (TCP/IP)

Enterprise

Buildings

Integrator

direct hardwire connection

group (=same bus ID) of

max. 30 controllers

XL50XL50

w/ modem

ONWORKS

ONWORKS

network management tools (LNS-based or non-LNS-

binding of Honeywell and 3rd-party LONW

systems. See following section.

XBS

XC5010 XCL5010 XL50XL50XL50

w/ modem

ORKS

ONWORKS

systems or via dial-

Building Management Functionality

dial-up

group (=same bus ID) of

max. 30 controllers

ONWORKS

Internet Explorer SymmetrE

connection or dial-up.

group (=same bus ID) of

max. 30 controllers

XL800 XL800 XL50

w/ modem

Synopsis

direct hardwire connections

LonWorks (LonTalk)

3rd-party

products

XL10

FCU

XL10

VAV

XL10

Smart VAV

XL10

Chilled

Ceiling

XL10

Hydronic

XL10

CVAHU,

UVC, I/O

Smart

I/O Module

Distributed

I/O Module

FISS

LION

linear

valves

and

actuators

pressure/

temperature

sensors

inverters

Fig. 2. Excel 5000 architecture (firmware version 2.06.xx and Excel 800)

EN0B-0270GE51 R0307

7

Page 8

Excel 50/500/800 LONW

ORKS

Mechanisms

COMPATIBILITY OF EXCEL 50/500/800 CONTROLLERS AND DISTRIBUTED I/O

MODULES

IMPORTANT:

Excel 800 controllers feature fully open L

Excel 50/500 controllers bearing the L

L

ONWORKS

open L

functionality. Due to RAM limitations of the 3120B1 Neuron chip,

ONWORKS

functionality is not supported in earlier models (week 44 in

2000 = date code: 0044 or earlier) of Excel 50/500 controllers containing that

chip.

In the case of Excel 50/500 controllers, CARE will not support the

engineering of a L

ONWORKS

network interface if the user selects a controller

or an application module containing any L

3120E5. The controller will reject the download of application files containing

the L

ONWORKS

network interface (*.ymp; *.ynv; *.ycv) if any LONW

other than 3120E5 is detected (even if the download source is XBS / XI584 /

CARE). In this case, an alarm message “HW Config. Failure” is also

generated.

ONWORKS

ONMARK

ONWORKS

functionality. Further, all

logo feature fully open

chip other than the

ORKS

chip

L

ONMARK

identification LONM

Devices which comply with the L

there is no L

above without the name “L

The XC5010C bears the L

FL, and XD50-FCL feature the L

application module. The XFL52xB modules bear the L

sticker. In addition, all of the aforementioned hardware features the L

symbol on the unit package label.

Table 3 provides an overview of the L

freely programmable Excel 50 controllers.

NOTE: Configurable L

ARK

-approved devices are identified with the following logos:

or

ONMARK

Fig. 3. L

Object profile are identified with the LONM

ONMARK

ONMARK

ONWORKS

ONMARK

ONMARK

logos

Interoperability guidelines but for which

ARK

symbol shown

”.

symbol on the front label. The XCL5010, XD50-

ONMARK

symbol on the warning label of the

ONWORKS

ONMARK

functionality of the Excel 500 and

logo on the type

ONMARK

applications for the Excel 50 (applications requiring a particular application module [e.g. XD50-FL-AH03-EN] and

configured by Lizard) are L

ONMARK

-compliant, so this feature is affected

by neither the new V2.04.xx, V2.05.xx, or V2.06.xx firmware nor the new

3120E5 Neuron chip. Upgrading either the firmware or the Neuron chip

(via an enhanced application module) is possible but not necessary.

EN0B-0270GE51 R0307 8

Page 9

Excel 50/500/800 LONW

ORKS

Mechanisms

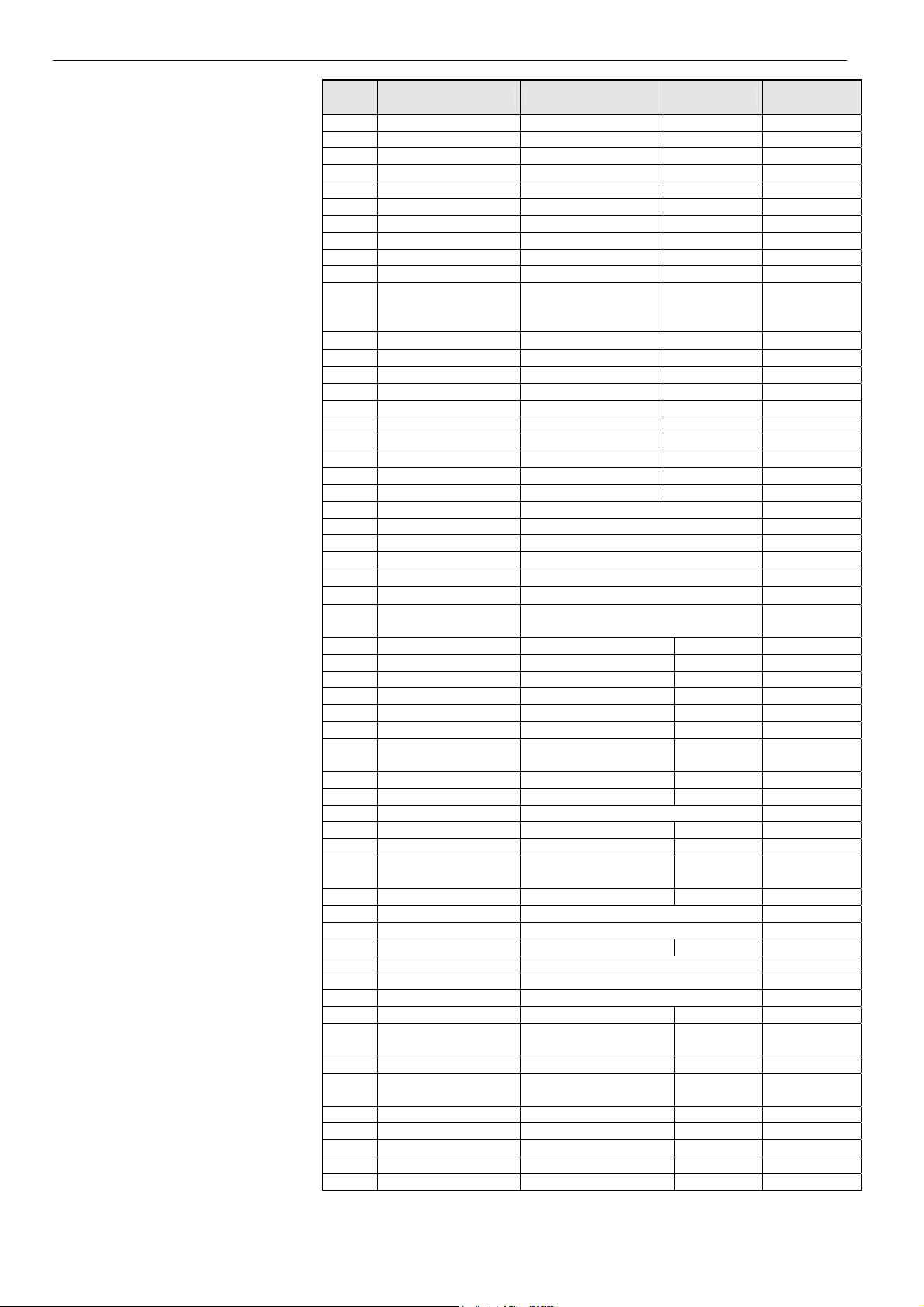

Table 3. Controller compatibility (non-LONM

controller type controller firmware

ARK

CPUs/application modules, date code later than week 44 in 2000)

open

LONW

ORKS

functionality

CPU autobinding1 with

XFL52x XFL52xB

CARE LONW

binding

ORKS

LM4W

binding

2.00.xx – 2.03.xx not possible local local not possible not possible

XC5010C, XCL5010

2.04.xx not possible local local/shared not possible not possible

2.06.xx not possible local local/shared not possible not possible

XD50-FL, XD50-FCL 2.04.xx – 2.06.xx not possible not possible not possible not possible not possible

XD50-FL-xxxx-yy2,

XD50-FCL-xxxx-yy

1

The term "local" refers to an operating mode in which a maximum of 16 modules are assigned (automatically) to each controller

2

and only a single controller is connected to each L

2.00.xx – 2.05.xx possible not possible not possible possible possible

2.06.xx possible not possible not possible possible possible

ONWORKS

bus.

The term "shared" means that a maximum of 16 modules are assigned (manually) to each controller, but that multiple controllers

can be connected to a single L

The term "open" refers to an open L

ONWORKS

ONWORKS

bus.

system, i.e. the use of CARE to generate a LONM

ARK

-compliant external interface

file (XIF) capable of providing NVs which can be bound to other devices (Excel 50 or Excel 10 controllers, third-party devices);

further, the limitation of max. 16 modules per controller can also be exceeded.

See also section "Determining the Operating Mode of a New LonWorks System" on page 41 for more-detailed information on

these operating modes.

2

"xxxx-yy" stands for configurable applications, e.g. AH03-EN.

Table 4. Controller compatibility (LONM

controller type controller firmware

XCL8010A2

3.00.xx in use not possible not possible possible possible

3.00.xx not in use not possible not possible not possible not possible

ARK

CPUs/application modules, date code later than week 44 in 2000)

open

LONW

ORKS

functionality

CPU autobinding1 with

XFL52x XFL52xB

CARE LONW

binding

ORKS

LM4W

binding

2.00.xx – 2.03.xx not possible local local not possible not possible

2.04.xx in use not possible shared/open not possible possible

XC5010C, XCL5210C,

XCL5010

2.04.xx not in use local local/shared not possible possible

2.06.xx in use not possible not possible possible possible

2.06.xx not in use local local/shared not possible not possible

2.04.xx – 2.05.xx in use not possible open not possible possible

XD50-FL, XD50-FCL

2.04.xx – 2.05.xx not in use not possible not possible not possible not possible

2.06.xx in use not possible not possible possible possible

2.06.xx not in use not possible not possible not possible not possible

2.00.xx – 2.05.xx in use not possible not possible not possible possible

XD50-FL-xxxx-yy3,

XD50-FCL-xxxx-yy

3

2.00.xx – 2.05.xx not in use not possible not possible not possible not possible

2.06.xx in use not possible not possible possible possible

2.06.xx not in use not possible not possible not possible not possible

1

The term "local" refers to an operating mode in which a maximum of 16 modules are assigned (automatically) to each controller

and only a single controller is connected to each L

ONWORKS

bus.

The term "shared" means that a maximum of 16 modules are assigned (manually) to each controller, but that multiple controllers

can be connected to a single L

The term "open" refers to an open L

ONWORKS

ONWORKS

bus.

system, i.e. the use of CARE to generate a LONM

ARK

-compliant external interface

file (XIF) capable of providing NVs which can be bound to other devices (Excel 50 or Excel 10 controllers, third-party devices);

further, the limitation of max. 16 modules per controller can also be exceeded.

See also section "Determining the Operating Mode of a New LonWorks System" on page 41 for more-detailed information on

these operating modes.

2

The XCL8010A is likewise not capable of CPU autobinding with Excel 800 I/O modules.

3

"xxxx-yy" stands for configurable applications.

EN0B-0270GE51 R0307

9

Page 10

Excel 50/500/800 LONW

ORKS

Mechanisms

Table 5. Distributed I/O module compatibility

LONW

ORKS

Distributed I/O

modules

XFL521, XFL522A,

XFL523, XFL524A

Excel 500

V2.00.xx to V2.03.xx

1 controller to which Dist.

I/O modules are

assigned on single

L

ONWORKS

bus; op.

mode: local

Functionality, by controller firmware version

Excel 500

V2.04.xx

1 controller to which Dist.

I/O modules are

assigned on single

L

ONWORKS

bus; op.

mode: local

1 controller to which Dist.

I/O modules are

assigned on single

L

mode: local

Excel 500

V2.06.xx

ONWORKS

bus; op.

Excel 800

V3.00.xx

not supported

1 controller to which Dist.

XFL521B,

XFL522B,

XFL523B, XFL524B

XFL821A,

XFL822A,

I/O modules are

assigned on single

L

ONWORKS

enable this backwardscompatible mode

bus (to

1

for

XFL52xB modules, press

L

ONWORKS

service pin

while turning HEX

switch); op. mode: local

not possible

Full LONW

ORKS

functionality: Multiple

Dist. I/O modules and

multiple controllers

possible on single

L

ONWORKS

bus; op.

mode: open

not possible

2

XFL823A, XFL824A

1

To cancel the backwards-compatible mode for XFL52xB modules (date code: 0044 or later), thus allowing full LONW

functionality, press and hold down the L

2

Excel 500 controller with Neuron 3120E5 chip required!

ONWORKS

service pin for at least 3 seconds.

Full L

ONWORKS

functionality: Multiple

Dist. I/O modules and

multiple controllers

possible on single

L

ONWORKS

mode: open

Full LONW

functionality: Multiple

Dist. I/O modules and

multiple controllers

possible on single

L

ONWORKS

mode: open

bus; op.

ORKS

bus; op.

Full L

ONWORKS

functionality: Multiple

2

Dist. I/O modules and

multiple controllers

possible on single

L

ONWORKS

bus; op.

mode: open

Full L

ONWORKS

functionality: Multiple

2

Dist. I/O modules and

multiple controllers

possible on single

L

ONWORKS

bus; op.

mode: open

ORKS

NOTE: The compatibility of Distributed I/O Modules featuring manual overrides is not affected by the firmware version or the

Neuron chip version.

EN0B-0270GE51 R0307 10

Page 11

Excel 50/500/800 LONW

ORKS

Mechanisms

FREELY PROGRAMMABLE LONWORKS EXCEL 50/500/800 CONTROLLERS

Number of NVs supported

Excel 50: The Excel 50's network interface can contain up to 46 NVs (in addition to the Node

Object's NVs).

The Excel 50 will reject applications having more than 46 NVs. In this case, the

following system alarm will be issued:

Alarm number: 61; alarm text: “Too many Globals”

Excel 500: The Excel 500's network interface can contain up to 512 NVs (in addition to the

Node Object's NVs).

The Excel 500 supports 128 physical data-points (I/Os) and 256 pseudo datapoints. Every data-point can be mapped to an input NV, or to an output NV, or to

both. The data-points can be mapped to a maximum of 512 L

theoretical maximum of 381 physical data-points (I/Os) are supported via NVs.

Excel 800: The Excel 800's network interface can contain up to 512 NVs (in addition to the

Node Object's NVs).

The Excel 800 supports 381 data-points in a random mix of physical and pseudo

data-points. Every data-point can be mapped to an input NV, or to an output NV, or

to both. The data-points can be mapped to a maximum of 512 L

ONWORKS

ONWORKS

NVs. A

NVs.

Memory Requirements

The memory requirements (in bytes) can be calculated by adding together the

memory requirements attributable to the following individual items:

Default texts (ASPECD, descriptors, alarm texts, engineering units, status texts): The maximum

memory allotted to default texts is 21,780 bytes

On-line changes to the time program All annual programs are automatically erased by the controller when they turn more

than one year old. The maximum memory allotted to on-line changes to the time

program is 4,096 bytes.

The time program, itself The first switching point requires 12 bytes, and each additional switching point with

the same switching time requires another 6 bytes. A time interval with an exception

day program in the annual program requires 9 bytes. A holiday with an exception

day program in the holiday list requires 2 bytes. A today exception for a point

requires 17 bytes. A day program requires 21 bytes X no. of switching points X 12.

Thus, the total time program requires 35 bytes + (size, in bytes, of all day

programs) + (no. of today exceptions X 17 bytes) + (no. of time intervals with an

exception X 9 bytes) + (no. of holidays with an exception X 2 bytes).

The CARE application program Assuming one time program, five control loops, five switching tables, CARE

(including RAL, RAP, RAT, RAZ) will require 10,000 bytes. Assuming several time

programs, ten control loops, ten switching tables, CARE will require 20,000 bytes.

NOTE: The use of complex ModAL XFMs can further boost that portion of the

memory requirements attributable to the control loops.

Data-points Each data-point requires 67 bytes.

NVs Memory requirements depend upon the number of structural components (n) of

each NV. The maximum memory allotted for all NVs is 2,048 bytes. The NVdependent memory requirements can be calculated as follows:

(number of NVs) X (3 bytes + (n X 3 bytes))

For example: Given 100 NVs with four structural components per NV:

100 X (3 bytes + (4 X 3 bytes)) = 1500 bytes

Many-to-one (M-T-O) bindings The memory requirements of many-to-one bindings depends upon the number of

NVs and the number of structural components (n) per NV. The maximum memory

requirements due to all many-to-one bindings = 12,800 bytes. The actual memory

requirements depend upon whether the NVs are analog or digital, and can be

EN0B-0270GE51 R0307

11

Page 12

Excel 50/500/800 LONW

ORKS

Mechanisms

calculated as follows:

no. of analog NVs X (9 bytes + no. of analog M-T-O X (4 bytes + 4 bytes)) +

no. of digital NVs X (9 bytes + no. of digital M-T-O X (4 bytes + 1 byte)

Example: Given ten analog NVs and five digital NVs, each with 20 M-T-O,

10 X (9 bytes + 20 X (4 bytes + 4 bytes) +

5 X (9 bytes + 20 X (4 bytes + 1 byte) = 1690 + 545 = 2235

The maximum memory allotted for all many-to-one bindings is 12,800 bytes.

The remote trend buffer Each trend entry requires 47 bytes. Centrals A, B, and C can each contain a

maximum of 100 trend entries. Further, unused application memory (if any) can be

allotted to Central A, thus enabling it to contain more than 100 trend entries. The

number of additional trend entries which central A can contain =

(128 Kbytes – application size in Kbytes) X 1,024 bytes / 47 bytes

Size constraints, Excel 50/500/600 If the memory requirements amount to less than 110 KB, then the size is OK.

If the memory requirements amount to between 110 and 128 KB and the RAL is

greater than 18 KB (in which case RAL will run from the flash memory), then the

size is OK.

If the memory requirements amount to between 110 and 128 KB and the RAL is

less than 18 KB and the rest of the application is less than 110 KB, then the size is

OK.

If the memory requirements amount to between 110 and 128 KB and the RAL is

less than 18 KB and the rest of the application is greater than 110 KB, then the

application is too large and must be reduced.

If the memory requirements exceed 128 KB, then the application size must be

reduced (e.g. by lowering the complexity of the application by reducing the number

of or simplifying control loops).

Size constraints, Excel 800 The application without RACL must not exceed 100 KB.

The RACL must not exceed 128 KB.

The application plus RACL must not exceed 192 KB.

Extending the Number of Physical I/Os using NVs

General Typically, one NV will be needed for each physical input and two NVs for each

physical output.

Excel 50 It is possible to extend the number of physical I/Os to more than 22. This is done by

mapping pseudo data-points to one or more of the 46 NVs, and then binding these

NVs to physical I/Os on the L

This will allow for

• 46 additional physical inputs, or

• 23 additional physical outputs, or

• a mixture of inputs and outputs.

Excel 500 It is possible to extend the number of physical I/Os to more than 128. This is done

by mapping pseudo data-points to one or more of the 512 NVs, and then binding

these NVs to physical I/Os on the L

Note that the 256 pseudo-points available must be split between usage for the

application (e.g. set-points or 3

additional physical I/Os. Typically, these pseudo-points are split equally between

the two usages.

This will allow for

• 125 additional physical inputs, or

• 62 additional physical outputs, or

• a mixture of inputs and outputs.

Excel 800 It is possible to have a maximum of about 200 physical L

the same principles regarding extending the number of physical I/Os and splitting

usage apply as described above for Excel 500.

ONWORKS

ONWORKS

rd

-party LONW

network.

network.

ORKS

integration) and usage for

ONWORKS

I/Os. Otherwise,

EN0B-0270GE51 R0307 12

Page 13

Excel 50/500/800 LONW

ORKS

Mechanisms

Node Object NVs

Fig. 4 presents controller Node Object NVs, categorized according to whether they

are mandatory or optional and listing optional configuration properties.

Controller Node Object

type no. 0

input

input

NV 0

NV 1

input

input

NV 7

NV 1

input

input

NV 2

NV 1

input

input

NV 3

NV 1

input

input

NV 4

NV 1

nviRequest

SNVT_obj_request

SNVT_obj_request

nviRequest

UNVT_uword

SNVT_obj_request

nviRequest

SNVT_time_sec

SNVT_obj_request

nviRequest

SNVT_time_sec

SNVT_obj_request

nviRequest

SNVT_str_asc

SNVT_obj_request

nviRequest

nviInUse

nciHrtBtRcv

nciHrtBtSnd

nciLocation

mandatory

Network

Variables

optional

Network

Variables

optional

configuration

properties

output

NV 1

output

NV 8

output

NV 10

output

NV 11

input

output

NV 6

NV 1

input

output

NV 9

NV 1

nvoStatus

SNVT_obj_status

nvoAlarm

UNVT_alarm

nvoLocalTime

USNVT_time_stamp

nvoDayOfWeek

SNVT_date_day

nroPgmVer

nviRequest

UNVT_pgm_id

SNVT_obj_request

nroOsVersion

nviRequest

SNVT_str_asc

SNVT_obj_request

nviRequest

input

input

NV 5

NV 1

input

input

NV 12

NV 1

nciDeviceName

SNVT_str_asc

SNVT_obj_request

nciXL500BusSetup

nviRequest

UNVT_XL500BusSetup

SNVT_obj_request

Fig. 4. Controller node object NVs

Table 6 presents information on the L

L

ONWORKS

Excel 50/500 controller.

ONWORKS

Node Object NVs in each

EN0B-0270GE51 R0307

13

Page 14

Excel 50/500/800 LONW

ORKS

Mechanisms

Table 6. Node Object NVs (left)

NV

NV Field NV Type States / engineering units + range Value

Index

0 nviRequest object_id SNVT_obj_request

RQ_NORMAL

RQ_DISABLED

nviRequest object_request SNVT_obj_request

1 nvoStatus SNVT_obj_status

2 nciHrtBtRcv

3 nciHrtBtSnd

4 nciLocation

5 nciDeviceName

6 nroPgmVer id UNVT_pgm_id

nroPgmVer major_ver UNVT_pgm_id 0

nroPgmVer minor_ver UNVT_pgm_id 0

nroPgmVer bug_ver UNVT_pgm_id 0

nroPgmVer node_type UNVT_pgm_id 0

7 nviInUse UNVT_uword

8 nvoAlarm UNVT_alarm

9 nroOsVersion SNVT_str_ascii

10 nvoLocalTime year SNVT_time_stamp

nvoLocalTime month SNVT_time_stamp 0 to 12

nvoLocalTime day SNVT_time_stamp 0 to 31

nvoLocalTime hour SNVT_time_stamp 0 to 23

nvoLocalTime minute SNVT_time_stamp 0 to 59

nvoLocalTime second SNVT_time_stamp 0 to 59

11 nvoDayOfWeek SNVT_date_day

12 nciXL500BusSetup message code BYTE 0 to 99 0x4D

nciXL500BusSetup bus ID BYTE 0xFF

nciXL500BusSetup controller no. BYTE 0xFF

nciXL500BusSetup heartbeat BYTE 0x14 seconds

nciXL500BusSetup domain BYTE 0x00

nciXL500BusSetup dom. ID length BYTE 0xFF / unused

nciXL500BusSetup dom. ID value BYTE 0

nciXL800BusSetup?

SCPTmaxRcvTime

(SNVT_time_sec)

SCPTmaxSendTime

(SNVT_time_sec)

SCPTlocation

(SNVT_str_asc)

SCPToemType

(SNVT_str_asc)

RQ_UPDATE_STATUS

RQ_SELF_TEST

RQ_UPDATE_ALARM

RQ_REPORT_MASK

10 to 150 seconds

10 to 150 seconds

empty string

NO_ALARM

ALARM_WARM_BOOT

ALARM_RACL_ERROR

ALARM_POWER_FAIL

ALARM_APPLICATION_STOPPED

RETURN_TO_NORMAL

0 to 3000

DAY_SUN

DAY_MON

DAY_TUE

DAY_WED

DAY_THU

DAY_FRI

DAY_SAT

DAY_NUL

0

1

2

3

4

5

Initialized by CARE

(90s default)

Initialized by CARE

(60s default)

initialized from controller

name in application (unless

changed by a LONW

tool)

Initialized by CARE

initialized to 65,535 at startup

0

1

2

3

4

128_U

0

1

2

3

4

5

6

0xFF

ORKS

EN0B-0270GE51 R0307 14

Page 15

Excel 50/500/800 LONW

ORKS

Mechanisms

Table 3. Node Object NVs (right)

Comments

This input NV belongs to the Node Object and provides the mechanism for requesting a particular object within a node.

See above, but for object status.

This output NV reports the status of the controller upon request through nviRequest. If bound, a change of data will be sent. If not bound, the

data is updated internally, only, and can be polled.

This is the configuration property used to control the maximum time that elapses after the last update to certain NVs before these input NVs

adopt their default values. For each input NV, CARE can be used to set whether an NV is to be checked according to nciHrtBtRcv, and all

mapped NVs are checked in this way by default. If the controller does not receive an update within the specified interval, it will try to poll the

output NV from the source device. In this way, the heartbeat mechanism also works for nodes without periodic updates. If the polling also fails,

the data-point mapped to this NV is set to NO RESPONSE and the invalid value (if specified) is adopted. If the value of nciHrtBtRcv is

changed using a L

This is the configuration property used to control the maximum time that expires before the controller automatically sends the current values of

certain NVs, even if its value did not change. This provides a heartbeat output NV that can be used by the destination objects to ensure that

the node is still healthy. CARE can set whether an NV is to be sent periodically, and all mapped NVs are sent in this way by default. If the

value of nciHrtBtSnd is changed using a LONW

saved as well.

Contains an empty string of 31 bytes that can be used to store installation location information.

Controller or application module name (up to 18 characters). If it is changed by a LONW

application changes too, and if the application is saved to Flash memory, the name is saved as well.

Program version ID identifies the LONW

program ID.

not used

not used

not used

not used

This is initialized to 0xFFFF at start-up. It is then set by an engineering tool or other supervisory node that is “logged-on” to the node to prevent

concurrent access by two such devices. When the updating of a node's configuration is finished, the initial value is restored. This input NV is

stored in RAM and is lost after a restart.

When bound, this output NV will be sent whenever a system or application alarm condition occurs. Alarm values 5 through 127 are for

application alarms, where data-point alarms are mapped to nvoAlarm using CARE (TRUE for alarm status and FALSE for OK status, with

application alarm number assigned). The alarm is added to RETURN_TO_NORMAL (128) when the alarm condition is no longer true.

Contains the controller firmware version number.

The current local time of the controller, updated every minute (seconds field always equals 0). When the real-time clock of the controller is

changed, it may take up to one minute until that change is reflected in the output NV.

See above.

See above.

See above.

See above.

See above.

Updated with the current day enumerator, typically at midnight. When the real-time clock of the controller is changed, it may take up to one

minute until that change is reflected in the output NV.

The message code can be changed in the event of trouble with 3rd-party devices.

The bus ID distinguishes between virtual C-buses (0x00 = physical C-bus active, 0xFF = initialized by controller).

The controller number is the same as the C-bus controller number (0x00 = communication disabled, 0xFF = initialized by controller).

The heartbeat is the time between wink messages.

The domain is a flag (0 = 1st domain or 1 = 2nd domain).

The domain ID length is valid only for the 2nd domain.

The domain ID value is valid only for the 2nd domain.

ONWORKS

network management tool, and if the application is saved to Flash memory, the value is saved as well.

ORKS

network management tool, and if the application is saved to Flash memory, the value is

ORKS

network management tool, the name in the

ORKS

application running in each controller (unique for each controller). Also called network interface

EN0B-0270GE51 R0307

15

Page 16

Excel 50/500/800 LONW

ORKS

Mechanisms

Activating and Configuring LonWorks plus BMF

With XL50/500 firmware 2.06.xx and higher, and with Excel 800, the node object

will support the configuration property nciXL500BusSetup.

This configuration property defines whether the XL50/500/800 supports

• C-bus and/or standard L

• L

ONWORKS

complete L

plus Building Management Functionality (which employs the

ONTALK

In the event that you opt for L

instead, you should use NVs for communication between Excel 50/500/800

controllers. The purpose of this restriction is to limit the traffic load on the

L

ONWORKS

bus by avoiding frequent message updating and broadcast messaging

in the Excel 50/500/800 controllers.

CARE-related actions When creating an application using CARE 4.01.03 and higher (or, for Excel 800,

CARE 7.2.xx), you will be called upon to define each individual bus (i.e. group of

max. 30 controllers with the same bus ID) as communicating either by means of Cbus and standard L

ONWORKS

the other. This is done in CARE by clicking the (automatically generated) name of

each individual bus appearing beneath "Bus", going to the "Properties" pane, and

selecting the desired radio button: Select either "C-Bus" for C-bus and standard

L

ONWORKS

or "LON-Bus" for LONW

"LON-Bus", CARE will then automatically do the following two things:

• ensure that the LONW

• ensure that no two buses in the same L

ID.

ONWORKS

or

protocol, including telegrams of the type "explicit message").

ONWORKS

on one hand or by means of LONW

ORKS

bus contains not more than 30 controllers;

plus BMF, global points should not be used;

ORKS

plus BMF on

ORKS

plus BMF, as appropriate. If you choose

ONWORKS

network have the same bus

Lizard If you have created a configurable Excel 50 application using Lizard, you must

define the bus ID using either one of the following two procedures:

• setting the bus ID during the MMI's start-up sequence or

• using EBI, Excelon, or any LON tool to edit the ”bus ID” byte in the

configuration property nciXL500BusSetup.

NOTE: Downloading an application created using CARE 4.01.03 will overwrite the

results of any such procedure.

Table 7. nciXL500BusSetup

attribute type default remark

Message Code BYTE 0x4D

changeable in case of trouble with

rd

3

party devices

distinguish virtual C-buses

bus ID BYTE 0xFF

0x00 = physical C-bus active

0xFF = initialized by controller

same as C-bus Controller no.

controller number BYTE 0xFF

0x00 = communication disabled

0xFF = initialized by controller

heartbeat BYTE 0x14 sec time between wink messages

domain BYTE 0x00 flag, 0=1st domain or 1=2nd domain

domain ID length BYTE

0xFF /

unused

only for 2nd domain

domain ID value BYTE[6] 0 only for 2nd domain

LonWorks Bus ID priority handling Excel 800 and Excel 50/500 firmware 2.06.00 through 2.06.03: The L

ONWORKS

Bus ID setting residing in the controller has priority over and will override any

L

ONWORKS

XL50/500 firmware 2.06.04: The L

priority over and will override any L

Bus ID setting set using CARE.

ONWORKS

ONWORKS

Bus ID setting set using CARE has

Bus ID setting residing in the

controller.

EN0B-0270GE51 R0307 16

Page 17

Excel 50/500/800 LONW

ORKS

Mechanisms

Standard NVs

Table 8 list the standard LONW

controller firmware version 2.06.xx onwards, NVs having a SNVT index of 132 and

higher are also supported.

SNVT

index

1 SNVT_amp amps 0.1 A 0x7FFF

2 SNVT_amp_mil1 milliamps 0.1 mA 0x7FFF

3 SNVT_angle rads 0.01 rad 0xFFFF

4 SNVT_angle_vel rads per sec 0.1 rad/sec 0x7FFF

5 SNVT_btu_kilo thousands of BTU's 1 KBTU 0xFFFF

6 SNVT_btu_mega millions of BTU's 1 MBTU 0xFFFF

7 SNVT_char_ascii ASCII characters 1 character

8 SNVT_count event count 1 0xFFFF

9 SNVT_count_inc event count 1 0x7FFF

11 SNVT_date_day day names 1 0xFF

13 SNVT_elec_kwh kilowatt-hours 1 kWh 0xFFFF

14 SNVT_elec_whr watt-hours 0.1 Wh 0xFFFF

15 SNVT_flow liters per second 1 l/sec 0xFFFF

16 SNVT_flow_mil milliliters per second 1 ml/sec 0xFFFF

17 SNVT_length meters 0.1 m 0xFFFF

18 SNVT_length_kilo kilometers 0.1 km 0xFFFF

19 SNVT_length_micr microns 0.1 microns 0xFFFF

20 SNVT_length_mil millimeters 0.1 mm 0xFFFF

21 SNVT_lev_cont percentage 0.5 % 0xFF

22 SNVT_lev_disc level names 1 0xFF

23 SNVT_mass grams 0.1 g 0xFFFF

24 SNVT_mass_kilo kilograms 0.1 kg 0xFFFF

25 SNVT_mass_mega tons 0.1 ton 0xFFFF

26 SNVT_mass_mil milligrams 0.1 mg 0xFFFF

27 SNVT_power watts 0.1 W 0xFFFF

28 SNVT_power_kilo kilowatts 0.1 kW 0xFFFF

29 SNVT_ppm parts per million 1 ppm 0xFFFF

30 SNVT_press kilopascals 0.1 kPa 0x7FFF

31 SNVT_res ohms 0.1 Ohm 0xFFFF

32 SNVT_res_kilo kilo-ohms 0.1 kOhm 0xFFFF

33 SNVT_sound_db decibels 0.01 dB 0x7FFF

34 SNVT_speed meters / second 0.1 m/s 0xFFFF

35 SNVT_speed_mil millimeters / second 0.001 m/s 0xFFFF

36 SNVT_str_asc used in Node Object

38 SNVT_telcom

39 SNVT_temp degrees Celsius 0.1 °C 0xFFFF

41 SNVT_vol liters 0.1 liter 0xFFFF

42 SNVT_vol_kilo kiloliters 0.1 kl 0xFFFF

43 SNVT_vol_mil milliliters 0.1 ml 0xFFFF

44 SNVT_volt volts 0.1 V 0x7FFF

45 SNVT_volt_dbmv decibels*millivolts 0.1 db mV 0x7FFF

46 SNVT_volt_kilo kilovolts 0.1 kV 0x7FFF

47 SNVT_volt_mil millivolts 0.1 mV 0x7FFF

48 SNVT_amp_f amps 1 A 0x7F000000

49 SNVT_angle_f rads 1 rad 0x7F000000

50 SNVT_angle_vel_f rads per second 1 rad/sec 0x7F000000

51 SNVT_count_f dimensionless 1 0x7F000000

52 SNVT_count_inc_f dimensionless 1 0x7F000000

53 SNVT_flow_f liters per second float value 0x7F000000

54 SNVT_length_f meters 1 m 0x7F000000

55 SNVT_lev_cont_f percentage 1% 0x7F000000

56 SNVT_mass_f grams 1 0x7F000000

57 SNVT_power_f watts float value 0x7F000000

58 SNVT_ppm_f parts per million float value 0x7F000000

name units/description resolution invalid value

ORKS

NVs (SNVTs) supported for mapping. From

Table 8. Supported SNVTs

telecomm state

names

⎯

⎯

1 0xFF

EN0B-0270GE51 R0307

17

Page 18

Excel 50/500/800 LONW

ORKS

Mechanisms

SNVT

index

59 SNVT_press_f Pascals float value 0x7F000000

60 SNVT_res_f ohms float value 0x7F000000

61 SNVT_sound_db_f decibels float value 0x7F000000

62 SNVT_speed_f meters per second float value 0x7F000000

63 SNVT_temp_f degrees Celsius float value 0x7F000000

64 SNVT_time_f seconds float value 0x7F000000

65 SNVT_vol_f liters float value 0x7F000000

66 SNVT_volt_f volts float value 0x7F000000

67 SNVT_btu_f British Thermal Units float value 0x7F000000

68 SNVT_elec_whr_f watt-hours float value 0x7F000000

69 SNVT_config_src

70 SNVT_color structured

71 SNVT_grammage grams / sq. meter 0.1 g/m2 0xFFFF

72 SNVT_grammage_f grams / sq. meter float value 0x7F000000

75 SNVT_freq_f Hertz float value 0x7F000000

76 SNVT_freq_hz Hertz 0.1 Hz 0xFFFF

77 SNVT_freq_kilohz kilohertz 0.1 kHz 0xFFFF

78 SNVT_freq_milhz megahertz 0.1 mHz 0xFFFF

79 SNVT_lux lux 1 lux 0xFFFF

81 SNVT_lev_percent % of full-scale / ppm 0.005 0x7FFF

82 SNVT_multiplier -- -- 0xFFFF

84 SNVT_time_stamp structured Per NV field

85 SNVT_zerospan structured Per NV field

87 SNVT_elapsed_tm structured Per NV field

91 SNVT_muldiv structured Per NV field

92 SNVT_obj_request structured

93 SNVT_obj_status structured

95 SNVT_switch

97 SNVT_override dimensionless 1 0xFF

98 SNVT_pwr_fact multiplier 0.00005 0x7FFF

99 SNVT_per_fact_f multiplier float value 0x7F000000

100 SNVT_density kilograms / meter3 0.5 kg/m3 0xFFFF

101 SNVT_density_f kilograms / meter3 float value 0x7F000000

102 SNVT_rpm revolutions / minute 1 0xFFFF

103 SNVT_hvac_emerg

104 SNVT_angle_deg degrees of arc 0.02 deg 0x7FFF

105 SNVT_temp_p degrees Celsius 0.01 °C 0x7FFF

106 SNVT_temp_setpt structured Per NV field

107 SNVT_time_sec seconds 0.1 sec 0xFFFF

108 SNVT_hvac_mode HVAC mode names 1 0xFF

109 SNVT_occupancy

110 SNVT_area square millimeters 200 mm2 0xFFFF

111 SNVT_hvac_overid structured 0xFF

112 SNVT_hvac_status structured 0xFF

113 SNVT_angle_deg degrees of arc 0.02 deg 0x7FFF

115 SNVT_scene structured Per NV field

116 SNVT_scene_cfg structured Per NV field

117 SNVT_setting structured Per NV field

118 SNVT_evap_state evaporation states 1 0xFF

119 SNVT_therm_mode

120 SNVT_defr_mode defrost mode names 1 0xFF

121 SNVT_defr_term

122 SNVT_defr_state defrost state names 1 0xFF

123 SNVT_time_min minutes 1 0xFFFF

124 SNVT_time_hour hours 1 0xFFFF

125 SNVT_ph acidity 0.001 pH 0x7FFF

126 SNVT_ph_f acidity (pH) float value 0x7F000000

name units/description resolution invalid value

dimensionless

(defining selfinstallation)

structured, but mapped with a single

data-point

emergency mode

names

occupancy mode

names

thermostat mode

names

defrost termination

names

0xFF

⎯

⎯

⎯

0xXXFF

1 0xFF

1 0xFF

1 0xFF

1 0xFF

EN0B-0270GE51 R0307 18

Page 19

Excel 50/500/800 LONW

ORKS

Mechanisms

SNVT

index

128 SNVT_tod_event

129 SNVT_smo_obscur

130 SNVT_fire_test fire initiator types --131 SNVT_temp_ror ° Celsius / min 0.5 °C/min 0x7FFF

132 SNVT_fire_init type names 1 FN_NUL

133 SNVT_fire_indcte type names 1 FI_NUL

134

135 SNVT_earth_pos direction of latitude, structured --136

137* SNVT_reg_val_ts register value bit fields ---

138 SNVT_volt_ac volts (a.c.) 1 V 0xFFFF

139 SNVT_amp_ac amperage (a.c.) 1 A 0xFFFF

140

141

142

143 SNVT_turbidity

144 SNVT_turbidity_f

145

146 SNVT_elec_kwh_l kilowatt-hours 1_kWh 0x7FFFFFFF

147 SNVT_temp_diff_p degrees C 0.01 °C 0x7FFF

148

149

150

151

152 SNVT_pos_ctrl structured ---153 SNVT_enthalpy kilojoules/kg 0.01 kJ/kg 0x7FFF

154 SNVT_gfci_status

155 SNVT_motor_state

156 SNVT_pumpset_mn

157

158 SNVT_pumpset_sn

159 SNVT_pump_sensor

160

161 SNVT_flow_p cubic meters / hour 0.01 m3/h 0xFFFF

162

163 SNVT_valve_mode valve mode names 1 VALVE_NUL

164

165 SNVT_state_64 64 bits single bits ??

*The XL50/500 supports a special version of SNVT_reg_val_ts (SNVT index: 137)

called SNVT_reg_val_ts_XL500, which provides separate bytes instead of the value

of the bit fields. Via a special XFM (available from CARE) these bytes can be

separated into bit values.

1

The Excel 50/500 controller always converts units to the basic unit, i.e. milliamps to

amps. As a consequence, the SNVT_amp_mil will show amps on the datapoint side

(mapped datapoint).

name units/description resolution invalid value

for inputs, only

current state is read

percentage smoke

obscuration

Nephelometric

Turbidity Units

Nephelometric

Turbidity Units

names of ground

fault circuit

interrupter

names of mechanical

motor

status of main

features of pumpset

sensor readings of

mechanical pumpset

sensor readings of

mechanical vacuum

pumps

1 0xFFFFFFFF

0.001% (0 to

5%)

0.001 NTU 0xFFFF

float value ---

1 GFCI_NUL

1 MOTOR_NUL

1 ---

1 ---

1 ---

0xFFFF

Network Interface Program ID

The program ID of the network interface is provided in the XIF. The XIF itself is

determined by the application programmed in CARE. Along with the application

translation, CARE will create the XIF automatically.

EN0B-0270GE51 R0307

19

Page 20

Excel 50/500/800 LONW

ORKS

Mechanisms

During CARE engineering; the program ID can be changed by changing its last byte

in the data-point editor. The default setting of the last byte of the program ID

represents the controller number.

External Network Interface File (XIF)

CARE 3.0 or higher will create a XIF (External Interface File) for each application

engineered. This file contains the interface description required by a L

ONWORKS

network management tool for installation and binding.

The following file formats are provided:

1. One file in ASCII format for import into LonMaker for Windows.

2. One file in binary format for download into the controller's Neuron chip for later

upload from the controller's Neuron chip by LonMaker for Windows, when the

controller is online and the application is running.

A device template for commissioning L

ONWORKS

controllers can be created either

by importing the XIF or by uploading online from the controller.

The maximum number of different XIF files per L

ONWORKS

network is 255.

Binding and Mapping NVs

Binding Binding is the process by which NVs from different nodes are connected to each

other for passing data on the L

troller, using a L

ONWORKS

based) such as LonMaker for Windows. Typically, the output NV of one node is

bound to the input NV of another node. Fig. 5 depicts the binding of an output NV

with an input NV.

DEVICE A DEVICE B

ONWORKS

bus. This is achieved, online with the con-

network management tool (LNS-based or non-LNS-

output

NV

input

NV

Fig. 5. NV binding

Mapping Mapping is the process by which Honeywell Excel 5000 controller data-points are

connected internally with NVs. This is performed during CARE engineering. Fig. 6

depicts the mapping of an input NV with the data-point of an Excel 50/500/800

controller.

Excel 50/500/800

Controller

input

NV

Fig. 6. Data-point mapping

data

point

Binding Options

In addition to the simple one-to-one binding relationship shown in Fig. 5, LONW

technology also allows the following other binding relationships to be established.

Many-to-one binding For example, it is allowed to bind several output NVs to a single input NV. This is

referred to as a many-to-one relationship (see Fig. 7).

EN0B-0270GE51 R0307 20

ORKS

Page 21

Excel 50/500/800 LONW

DEVICE A

output

NV

ORKS

Mechanisms

Excel 50/500/800

Controller

DEVICE B

output

NV

DEVICE C

output

NV

Fig. 7. Many-to-one binding (allowed)

NOTE: A maximum of 64 output NVs can be bound to a single input NV.

IMPORTANT:

Although the many-to-one binding is created online with a L

work management tool, for proper memory allocation, the binding must be

specified during CARE engineering. If the user tries to make more many-toone bindings than specified during CARE engineering (a maximum of 64

many-to-one bindings are allowed), an MTO BINDING FAILED alarm will be

issued.

input

NV

ONWORKS

net-

One-to-many binding It is also allowed to bind a single output NV to multiple input NVs of other

L

ONWORKS

multiple input NVs are bound to the same LONW

devices (so-called "one-to-many" binding) as long as no two of these

ORKS

device (see Fig. 8).

Excel 50/500/800

Controller

output

NV

input

NV

input

NV

DEVICE A

DEVICE B

Fig. 8. One-to-many binding (supported)

Turnaround binding Excel 50/500 controllers do not support turnaround binding (in which an output NV

is bound to an input NV of the same device; see also Fig. 9). In the case of 3

rd

-party

controllers, however, turnaround binding is supported, though only from CARE 7.01

onwards.

EN0B-0270GE51 R0307

21

Page 22

Excel 50/500/800 LONW

ORKS

Mechanisms

DEVICE A

input

NV

output

NV

Fig. 9. Turnaround binding (not supported)

Alias binding Alias binding (in which both a copy and the original of a node's output variable are

bound to input variables of another node; see Fig. 10) is not supported. However,

such copies (which have the same data as the original output variable, but which

may have their own address table entries and selectors) can be bound to input

variables of differing nodes (equivalent to making "one-to-many" bindings).

Excel 50/500/800

DEVICE A

Controller

input

NV

input

NV

alias

NV

output

NV

x

Fig. 10. Alias binding (not supported)

Workaround for alias binding The following workaround can be used in place of alias binding. During CARE

engineering, it is possible (using the IDT control icon) to establish a logical

relationship between one data-point (called the trigger data-point; data-point A in

Fig. 11) and other data-points (called triggered data-points; data-points 1, 2, and 3

in Fig. 11). After being connected in this fashion, when the trigger data-point is

updated, it will automatically switch (i.e. trigger) the triggered data-points.

Excel 50/500/800 Controller

data

point 1

data

point A

data

point 2

data

point 3

output

NV

output

NV

output

NV

input

NV

input

NV

input

NV

DEVICE A

Fig. 11. Workaround for alias binding (supported)

Mapping Options

It is allowed to map a single input NV with multiple data-points (see Fig. 12).

EN0B-0270GE51 R0307 22

Page 23

input

XXX

X

NV

Excel 50/500/800 LONW

Excel 50/500/800 Controller

data

point

max.

data

point

ave.

data

point

min.

ORKS

Mechanisms

Fig. 12. Mapping a single NV with multiple data-points (allowed)

It is also allowed to map a single data-point with both a single input and a single

output NV (so-called "double-mapping"; see Fig. 13). This feature also makes it

possible to convert NVs of one type into NVs of another type.

Excel 50/500/800

Controller

input

NV

type “x”

data

point

output

NV

type “y”

Fig. 13. Double-mapping a data-point (allowed)

It is not allowed to map a single data-point with multiple input or output NVs (see

Fig. 14).

input

NV

input

NV

input

NV

Excel 50/500 800

Controller

data

point

/

output

NV

output

NV

output

NV

Fig. 14. Mapping a single data-point with multiple NVs (not allowed)

It is allowed to map multiple data-points with multiple fields of a structured NV (see

Fig. 15).

EN0B-0270GE51 R0307

23

Page 24

Excel 50/500/800 LONW

x

x

x

x

ORKS

Mechanisms

nviX.field1

nviX.field2

nviX.field3

Excel 50/500/800

Controller

data

point 1

data

point 2

data

point 3

Excel 50/500/800

Controller

data

point 1

data

point 2

data

point 3

nviX.field1

nviX.field2

nviX.field3

Fig. 15. Mapping multiple data-points with different fields of a structured NV

(allowed)

It is not allowed to map multiple data-points with a single field of a structured NV

(see Fig. 16).

Excel 50/500/800

Controller

data

point 1

nviX.field1

nviX.field2

nviX.field3

Excel 50/500

/800

data

point 2

data

point 3

Controller

data

point 1

data

point 2

data

point 3

nviX.field1

nviX.field2

nviX.field3

Fig. 16. Mapping multiple data-points with a single field of a structured NV

(not allowed)

EN0B-0270GE51 R0307 24

Page 25

Excel 50/500/800 LONW

ORKS

Mechanisms

The name and the index of mapped NVs can be displayed on an MMI like datapoint attributes. If no NVs are mapped, blanks will be displayed in the index field

and in the name field.

Excel 800 / CARE 7.2.xx and CARE 4.0, Controller Firmware Version 2.06.xx

Automatic manual override mapping With Excel 800 and CARE 7.2.xx, as well as with Excel 50/500 and CARE 4.0 and

controller firmware version 2.06.xx and higher, there is an additional type of datapoint mapping called "automatic manual override mapping". In automatic manual

override mapping, both output control and manual override feedback are effected

via a single data-point.

Automatic manual override mapping functions only with NVs of the type

"SNVT_Switch". Further, it is supported only for:

• Excel 800 / CARE 7.2.xx

• XL500, firmware version 2.04.xx / CARE 3.xx and

• XL50/500, firmware version 2.06.xx / CARE 4.xx

• Those Distributed I/O modules and Smart I/O modules equipped with both

digital outputs and manual overrides (i.e. the XFL524B, as well as the XFC2D

and XFC3D).

With automatic manual mapping, during CARE engineering, you map the "value"

attribute of one of the controller's data-points to one of the controller's output NVs.

During CARE autobinding, the following steps are then automatically performed:

• CARE binds the aforementioned output NV to an input NV (previously specified

by the user during CARE engineering) of one of the I/O modules assigned to

the controller.

• CARE generates a new input NV for the controller and binds it to the output NV

of the I/O module.

If the module's manual override switch is now operated, that output NV of the

module containing information about the status of the I/O module's manual override

switch is updated and sent to the new input NV. The new input NV activates the

data-point's "manual value" attribute.

NV

DEVICE A

(e.g. XL10)

Excel 50/500/800

Controller

invalid

manual value

data

auto/manual flag

point

auto value

output

NV

input

NV

input

NV

output

Fig. 17. Automatic manual override mapping

Automatic auto/manual mapping With Excel 800 and CARE 7.2.xx, as well as with Excel 50/500 and CARE 4.0 and

controller firmware version 2.06.xx and higher, there is an additional type of datapoint mapping called "automatic auto/manual mapping." It can be used to enable an

NV to be overridden and the corresponding value to be displayed – all via a single

data-point. If the data-point's "auto/manual flag" attribute has been set (by using the

MMI to put the data-point into the "manual" mode) to the "manual" value, the datapoint will be in the "manual" mode, and the "manual value" attribute's value is sent;

if its "auto/manual flag" attribute has been set to the "auto" value, the data-point will

be in the "auto" mode, and the invalid value is sent.

This mapping is activated during CARE engineering by selecting "auto" for the

invalid match for the output NV of the Excel 50/500 controller.

EN0B-0270GE51 R0307

25

Page 26

Excel 50/500/800 LONW

ORKS

Mechanisms

NV

DEVICE A

(e.g. XL10)

Excel 50/500/800

Controller

invalid

manual value

data

auto/manual flag

point

auto value

output

NV

input

NV

input

NV

output

Fig. 18. Automatic auto/manual mapping

Data Priority of NVs and Data-Points

This section describes the priority between the NVs and the data-points in the

application. The value of a valid input NV always has priority over the value from a

sensor or switch wired directly to the controller or the values from the internal control algorithm or time program.

When an input NV is not bound and its value is invalid, then the value is ignored

and the value from the local sensor/switch, the control algorithm, or the time

program is written to the data-point.

When an input NV is not bound and has valid data, then the data is written to the

mapped data-point. The data-point will then be in the "manual" mode, and values

from the internal algorithm, time program, or local sensor/switch are ignored.

When an input NV is bound and its value is invalid, then this value is ignored and

the value from the local sensor/switch, the control algorithm, or the time program is

written to the data-point.

When an input NV is bound and has valid data, then this data is written to the

mapped data-point. The data-point will then be in the "auto" mode, and values from

the internal algorithm, time program, or local sensor/switch are ignored.

When an input NV is bound and reports NO RESPONSE (sending device or communication failure), then the predefined invalid value (if specified) is written to the

mapped data-point. If no invalid value has been specified, the mapped data-point

will retain the last value. The data-point will then be in the "auto" mode, and values

from the internal algorithm, time program, or local sensor/switch are ignored.

Table 9 summarizes this information:

Table 9. Data-point updates according to status of input NV

status of input NV data-point access

bound, valid value NV value written to “auto value” attribute

bound, invalid value internal value from local I/O, control algorithm, time program

bound, no response no response, predefined invalid value from CARE

unbound, valid value manual mode, NV value written to “manual value” attribute

unbound, invalid value

auto mode, internal value from local I/O, control algorithm,

time program

EN0B-0270GE51 R0307 26

Page 27

Excel 50/500/800 LONW

ORKS

Mechanisms

Data-Point Types for NV Mapping

Table 10 lists the various different types of data-points for which mapping is

allowed.

All hardware modules (XF52xx, XFL52xx, and XFCxx) are supported for NV

mapping.

Table 10. Data-point types supported for NV mapping

data-point type (CARE) subtype (CARE attribute text)

analog input Slow AI

analog input Fast AI

analog output n/a

AO_3_pos n/a

digital input 2-state DI or DO

digital output 2-state DI or DO

digital output Pulse on DO/DI card

pseudo analog n/a

pseudo digital 2-state

pseudo multistage n-state

Boardless Data-Points

Under some circumstances, you may wish to create a data-point which has the

characteristics of a physical data-point but which is also mapped with a L

NV.

This can be accomplished by mapping a data-point with an NV, but not assigning it

to any I/O board or Distributed I/O module. As a result, the NV will have to be

bound using a L

or CARE 4.xx).

In such a case, the board number of the data-point's technical address will be ≥64

and no BOARD MISSING alarm will be issued for that data-point. CARE lists these

points as ≥91.

ONWORKS

network management tool (e.g. LonMaker for Windows

Conversion of Data-Points to NVs

When mapping analog points to analog SNVTs, a linear characteristic can be

defined.

A nonlinear relationship can be defined by a look-up table. In the look-up table, a

conversion for each discrete value or point stage is defined.

Example: A multistage digital data-point is mapped with an output NV:

Table 11. Mapping a multistage digital data-point with an output NV

data-point value NV value

1 state 0

2 state 0

3 state 0

4 state 1

5 state 1

ONWORKS

NV-BOOSTER®

Honeywell controllers provide a mechanism that allows multiple instances of a

single input NV to be combined into a single data-point. This can drastically reduce

the number of controller NVs required. This enhancement not only saves ap-

EN0B-0270GE51 R0307

27

Page 28

Excel 50/500/800 LONW

.

)

ORKS

Mechanisms

plication engineering, it can lower hardware costs in the project by helping to

minimize the number of controllers required.

When selection logic is required to perform a function such as selecting maximum

value, average value, or number of active devices from multiple input values,

standard one-to-one binding of NVs is normally required, and an input NV is required for each output NV as shown in Fig. 19 below. Application engineering is

required to add the selection logic before the desired value can be used by the

application.

DEVICE A

output

NV

DEVICE B

output

NV

DEVICE C

output

NV

Fig. 19. Standard L

input

NV

input

NV

input

NV

ONWORKS

binding, without NV-Booster

CONTROLLER A

without NV-Booster

application

selection

logic*

*Application engineering required (e.g

max. value, min. value, etc.

However, Honeywell’s NV-Booster allows binding all of the output NVs to a single

input NV with a many-to-one binding, with the selection logic(s) chosen using CARE

when the input NV is mapped with a single data-point. The NV-Booster®

mechanism is illustrated in Fig. 20 below.

DEVICE A

output

NV

DEVICE B

output

NV

DEVICE C

output

NV

input

NV

Excel 50/500 800 Controller

/

with NV-Booster

data

point

max.

data

point

ave.

data

point

min.

application

Fig. 20. Many-to-one binding, with NV-Booster

Many-to-one bindings can be established using any of the following selection logics:

• maximum value

• minimum value

• average value

• sum

• number of active devices

NOTE: The number (max.: 64) of source devices in a many-to-one binding must

be specified during CARE engineering, as this is required for calculating

the correct amount of controller application memory to be allocated for the

binding.

In the case of many-to-one bindings, the controller's heartbeat must be activated

(see section "Device Heartbeat Activation") if the NV-Booster is to function properly.

EN0B-0270GE51 R0307 28

Page 29

Excel 50/500/800 LONW

Binding alarm If the user has tried to make more many-to-one bindings during controller runtime

than were specified during CARE engineering, the following System Alarm will be

issued:

Alarm number: 128; alarm text: “MTO Binding failed”

ORKS

Mechanisms

Device Heartbeat Activation

The general heartbeat of the LONW

activated or deactivated for every NV.

For each input NV, CARE can be used to set whether an NV is to be checked

according to nciHrtBtRcv, and all mapped NVs are checked in this way by default. If

the controller does not receive an update within the specified interval, it will try to

poll the output NV from the source device. In this way, the heartbeat mechanism

also works for nodes without periodic updates. If the polling also fails, the data-point

mapped with this NV is set to NO RESPONSE and the invalid value (if specified) is

adopted. Additionally, if alarming has been enabled for the data-point, a NO

RESPONSE alarm will be issued.

If the value of nciHrtBtRcv is changed using a L

tool, and if the application is saved to Flash memory, the changed value is saved as

well.

For each output NV, a heartbeat can be defined that can be used by the destination

objects to ensure that the node is still healthy, and that if an NV update is lost, it will

be re-sent. During CARE engineering, it is possible to set whether an NV should be

sent periodically; all mapped NVs are sent in this way by default. If the value of

nciHrtBtSnd is changed using a L

application is saved to Flash memory, the changed value is saved as well.

These NVs may have multiple fields of bit strings. These bit fields cannot be

mapped with multiple data-points.

Example: SNVT_state

Type Size: 2 bytes

Structure: typedef struct

{

unsigned bit0 : 1;

unsigned bit1 : 1;

…

unsigned bit15: 1;

} SNVT_state;

Each bit indicates a Boolean state with the following interpretations:

ORKS

node (i.e. device, e.g. XCL5010) can be

ONWORKS

ONWORKS

network management tool, and if the

network management

Bit-Field NVs

Table 12. Boolean states

0 1

off on

inactive active

disabled enabled

low high

false true

normal alarm

This NV has up to 16 fields, each of which has a size of 1 bit:

Field 1: bit 0

Field 2: bit 1

…

EN0B-0270GE51 R0307

29

Page 30

Excel 50/500/800 LONW

ORKS

Mechanisms

If you wish to map these bit fields with data-points, the byte value (in this example:

the 2-byte value) must be mapped with data-points using CARE, and the RACL split

statement or a special XFM can be used to isolate single bits.

Restoring Binding Information

Excel 500 with Firmware Version 2.04.xx

Restoration by means of flashing All binding information can be saved into the flash memory together with the

application data, thus allowing it to be completely restored following a reset.

Restoration using CARE Furthermore, by using CARE to upload the application data (including the binding

information), it is possible to exchange a controller and, after downloading the

application into the new controller, to automatically restore all application data and

binding information.

Excel 50/500 and CARE 4.xx with Firmware Versions 2.06.00 through 2.06.03

Restoration by means of flashing The restoration of binding information and/or application data from the flash

memory is not possible with firmware versions 2.06.00 through 2.06.03 and CARE

4.xx. Rather, the binding information exists only in the CARE application. As a

consequence, if you wish to re-establish bindings, you will have to download the

CARE application.

Excel 800 and CARE 7.2.xx / Excel 50/500 and CARE 4.xx with Firmware Version 2.06.04

Restoration by means of flashing For Excel 800 and (from firmware 2.06.04 onwards) for Excel 50/500, the

application (including the L

the L

ONWORKS