Page 1

HONEYWELL EXCEL 5000 OPEN SYSTEM

FEATURES

Various state-of-the-art communication options: Open

Unique features in open L

Reduced engineering and start-up costs: Huge variety

Easy and flexible installation: Screw terminals; mounting

Operating options: Integrated operator interface, XI582

GENERAL

The Excel 50 controller has built-in communication capability,

allowing it to be integrated into a Honeywell EXCEL 5000®

System or into an open L

with Excel 10 controllers as room/zone controllers or with 3

party products. It can also serve as a stand-alone controller.

Typical areas of application include heating systems, district

heating systems, and air conditioning plants for restaurants,

shops, offices, and small branch government buildings.

The Excel 50 supports standard LonMark™ Network Variables according to the LonMark™ Interoperability Guidelines

V.3.0. It can serve 22 integrated I/Os and supports peer-topeer communication; thus, in the case of larger-scale applications, several different controllers can be linked and

accessed. The system firmware is stored in Flash EPROM

located in the application module (a separate module plugged

into the controller housing.) Flash EPROM allows easy

upgrading of the operating system via download.

The Excel 50 is a freely programmable controller engineered

using Honeywell’s CARE programming tool. For L

interoperability, a maximum of 46 LonMark™ NVs are

available.

ONWORKS® network communicating

ONWORKS®

DESCRIPTION

The Excel 50 controller is available in two housing versions,

one with and one without a Man-Machine-Interface (MMI.)

The MMI version allows buswide access to other controllers.

The XI582 operator interface or the PC-based XL-Online

rd

operator and service software can be used in conjunction with

either version. The housing can be mounted inside a cabinet

on a DIN-rail or in a cabinet front door.

The Excel 50 has eight analog inputs, four analog outputs,

four digital inputs (three of which can be used as totalizers,)

and six digital outputs. The digital outputs allow the direct

drive of 3-position actuators (up to the max. load.) The controller can be wired either with screw terminal blocks directly

at the housing.) Pre-wiring is possible in both cases, and a

controller can be replaced without rewiring.

The application modules – all with Flash EPROM – are

available in five bus-wide access versions and one standalone version. They feature a variety of bus interfaces (see

Table 1.) Large RAMs provide for increased trending

capability.

All changeable parts or switches are accessible without

opening the housing. Communication capabilities and

memory are easily upgraded by replacing application

modules.

Excel 50

CONTROLLER

SPECIFICATION DATA

L

ONWORKS® bus, Meter-bus, or C-bus communication

Booster® reduces the number of required NVs and thus

also the number of required controllers; NV bindings can

be restored after controller reset (and thus need not be

redone after exchanging controllers); 46 NVs supported for

L

ONWORKS® integration

of pre-tested and fully documented applications

inside cabinet (DIN rail) or in cabinet front door

Remote Interface, XI882 Remote Touch-Panel Interface,

and XL-Online PC-based interface

ONWORKS® networks: NV-

® U.S. Registered Trademark

Copyright © 2015 Honeywell Inc. • All Rights Reserved EN0B-0088GE51 R0215

Page 2

EXCEL 50 CONTROLLER – SPECIFICATION DATA

SPECIFICATIONS

Versions

Housing

XL50A-MMI and XL50A-CY (with Man-Machine Interface);

XL50A (without MMI.)

Versions with MMI

Both the XL50A-MMI and the XL50A-CY feature a keypad

(with eight function keys and four fast-access keys) and an

LCD display.

The LCD display of the XL50A-MMI has four lines, 16

characters per line, adjustable contrast, and backlight.

The LCD display of the XL50A-CY features 128 X 64 dot

graphics, adjustable contrast, and backlight.

Application Modules

The Excel 50 controller can be upgraded by direct firmware

download via serial port or C-Bus. Contact your local

Honeywell affiliate for more information on the available

firmware and applications.

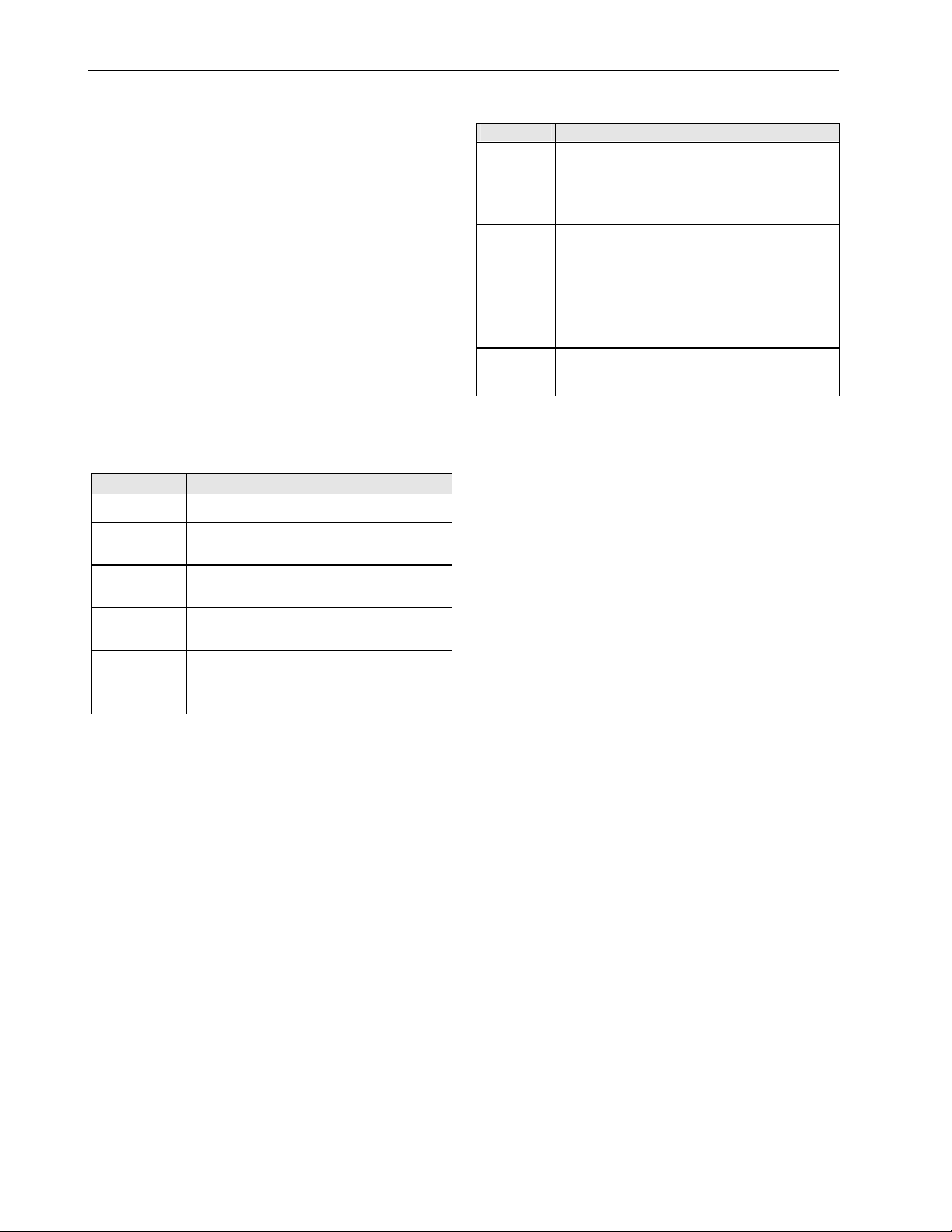

Table 1. Module versions

module description

XD50C-F

XD50C-FC

XD50C-FL

XD50C-FCL

XD50-FCS Bus-wide access via C-Bus / Meter-Bus; 1 MB

XD50-FLS Bus-wide access via LONWORKS® / Meter-Bus;

Mounting Options

Front door mounted with sealing ring.

Cabinet mounted on DIN-rail (rail clips shipped with device.)

I/O Terminal Connection

Screw terminal blocks directly attached to housing.

Power Supply

Voltage

24 Vac, ±20 %, 50/60 Hz from external transformer.

Current

3 A (2 A if digital output current 1.5 A.) In case of power

failure, the super gold capacitor saves RAM content and realtime clock for 72 hours (thus, no battery disposal necessary.)

Power Consumption

Max. 10 VA without load at digital outputs.

Stand-alone; 2 MB Flash EPROM; 256 KB RAM;

European and Chinese language support

Bus-wide access via C-Bus; 2 MB Flash EPROM;

256 KB RAM; European and Chinese language

support

Bus-wide access via L

Flash EPROM; 256 KB RAM; European and

Chinese language support

Bus-wide access via C-Bus /

2 MB Flash EPROM; 256 KB RAM; European

and Chinese language support

Flash EPROM; 256 KB RAM

2 MB Flash EPROM; 256 KB RAM

ONWORKS® Bus; 2 MB

LONWORKS® Bus;

Input/Output Specifications

type characteristics

eight analog

inputs

(universal)

four digital

inputs

four analog

outputs

(universal)

six digital

outputs

Voltage: 0...10 V (software-controlled switches

Current: 0...20 mA (via external 499 resistor)

Resolution: 10-bit

Sensor: NTC 20k, -58...+302 °F (-50...150 °C)

Voltage: max. 24 Vdc ( 2.5 V = logical status of

Voltage: 0...10 V, max. 11 V, ±1 mA

Resolution: 8-bit

Relay: via MCE3 or MCD3

Voltage: 24 Vac per triac

Current: max. 0.8 A, 2.4 A for all six triacs

for high impedance)

0, 5 V = logical status of 1,) 0...0.4 Hz

(0...15 Hz for three of four inputs when

used as totalizer, 4

parameter requirements)

together

th

input only for static

All inputs and outputs protected against overvoltage up to

24 Vac and 35 Vdc. Digital outputs protected against short

circuits via a changeable fuse (built-in fuse, 5 x 20 mm, 4 A

quick-blow.)

Bus and Port Connections

C-Bus Connection

Optional; located on application module. Up to 76.8 Kbaud,

switch provided for selectable termination.

ONWORKS® Bus Connection

L

Optional; located on application module. 78 Kbaud, FTT-10A

Free Topology Transceiver, using LonTalk® protocol.

Controller Serial Port Connection

9-pin Sub-D connector, RS 232, 9.6 Kbaud for XI582, XLOnline.

Meter-Bus Connection

Optional; located on application module. RS232 serial link

with RJ45 connector (PW3 Meter-Bus adapter also required.)

I/O Connectors

I/O Connector A: 26-pin port, digital outputs and power.

I/O Connector B: 34-pin port, analog and digital inputs, analog

outputs.

EN0B-0088GE51 R0215 2

Page 3

EXCEL 50 CONTROLLER – SPECIFICATION DATA

Environmental Ratings

Operating temperature: 0...50 °C (+32…+122°F)

Storage temperature: -20...+70 °C (-4…+158°F)

Relative humidity: 5...93% non-condensing

Purpose: for home (residential, commer-

cial, and light-industrial) environments

Construction: for incorporate mounting in

cabinets

RFI, EMI according to CE regulations

Pollution degree: Class II

Action: Type 1

Software: Class A

Impulse voltage: 500 V

Protection Standards

IP54 (when front-door mounted with MMI in a cabinet

conforming to IP54 and use of ACC3 mounting clamps and

sealing ring.)

IP20 (when wall-mounted: both with and without MMI.)

UL94-0: Flame-retardant class of housing material.

Certifications

CE

UL 916 and cUL

Meets FCC Part 15, Subpart J for Class A equipment.

Application Module

Firmware

The firmware is downloadable via the PC-based XL-Online

operator and service software or C-Bus.

Housing

Plug-in plastic module, wired with screws.

Application Module LEDs and Ports

LonWorks service button

POWER, GREEN

LonWorks service LED, RED

XD50-FLS

1 2 3

A1

A2

not used

LonWorks BUS

M-BUS TxD, YELLOW

M-BUS RxD, YELLOW

RESERVED

METER BUS

(RJ45 JACK)

LEDs

XD50C-FCL

1 2 3

A1

LonWorks BUS

Fig. 1. Application modules (examples)

4 5 6

C-

A2

C+

SHIELD

not used

LonWorks service button

POWER, GREEN

LonWorks service LED, RED

C-BUS TxD, YELLOW

C-BUS RxD, YELLOW

RESERVED

C-BUS TERMI-

NATION SWITCH

C-BUS

TOP

MIDDLE

BOTTOM

Terminal Blocks

fuse

(4 A, quick-acting)

block A block B

Fig. 2. Removable screw terminal blocks

Block A

24 Vac24 Vac

24 Vac24 Vac

5

1

3

7 9 11 13

42

{

DO1 DO2 DO3 DO4 DO5 DO6

15 33

19

LEDs

16 34

{{{{{{{{{{{{{{{

AO1 AI1AO2 AI2AO3 AI3AO4 AI4DI1

1086

{

{

2117

Fig. 3. Terminal assignment of screw terminal blocks

port for

application

module

port Bport A

hardware

adjustment

reset

for LCD

serial port

12

14

{

{

{

Block B

26 4424 4222 4020 3818 36

28 4630 32 48

DI2 AI6DI3 AI7DI4 AI8

+10 V / 5 mA REF. DI-POWER

{

AGNDGND

37 39234125 43274529 31 4735

AI5

{

3 EN0B-0088GE51 R0215

Page 4

EXCEL 50 CONTROLLER – SPECIFICATION DATA

Dimensions

100

198

cut-out: 186

port for

application

module

70

81

106

34 34

72

1 2

cut-out: 138 150

fuse

hardware

reset

port Bport A

adjustment

for LCD

serial port

85 85

97

126

DIN rail clip position

for models without MMI

1

DIN rail clip position

for models with MMI

2

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone +49 (0) 7031 637 01

Fax +49 (0) 7031 637 740

http://ecc.emea.honeywell.com

EN0B-0088GE51 R0215 Subject to change without notice

Loading...

Loading...