Honda CRF50F (2009), CRF50F (2006), CRF50F (2010), CRF50F (2011), CRF50F (2005) Service & Repair Manual

...

1.

GENERAL INFORMATION

SERVICE RULES ............................................ 1-2

MODEL IDENTIFiCATION .............................. 1-2

GENERAL

SPECiFiCATIONS

..

· .......... · ...... · .... 1-5

LUBRICATION SYSTEM SPECIFICATIONS · 1-6

FUEL

SYSTEM SPECiFiCATIONS ........ · ........ 1-6

CYLINDER HEAD/

VALVES SPECIFICATIONS .......................... · 1-6

CYLINDER/PISTON SPECiFiCATIONS

........ · 1-7

CLUTCH/GEARSHIFT

LINKAGE SPECIFICATIONS · .......... · .... ·

..

· ...... 1-7

ALTERNATOR /

CAM

CHAIN TENSIONER

SPECiFiCATIONS

.......... ···

.. ··

.... ·· .... · ...... ·

.. · ..

··· 1-7

CRANKSHAFT/TRANSMISSION/

KICKSTARTER SPECIFICATIONS

.... · ........ · .... 1-8

FRONT WHEEL/BRAKE/SUSPENSION/

STEERING SPECIFICATIONS·

..

·· .... · ......

··

..

· .... 1-8

REAR

WHEEl/BRAKE

/

SUSPENSION SPECIFICATIONS ...... · .... ·

..

· .... 1-8

IGNITION SYSTEM SPECIFICATIONS · ........ ·1-9

TORQUE VALUES

...... · ........ · ........................ 1-10

LUBRICATION

& SEAL POINTS ·

.. · ..

· .... ·

.. · ..

·1-13

CABLE & HARNESS ROUTING ·

..

· ...... ·

.. · .. · ..

1-14

EMISSION CONTROL SYSTEMS ........ · ...... ·1-

17

•

1-1

GENERAL INFORMATION

SERVICE RULES

1.

Use

genuine

Honda

or

Honda-recommended

parts

and

lubricants

or

the

ir

equivalents

. Parts that

don

't

meet

Honda's

design specifications

may

cause

damage

to

the

motorcycle.

2.

Use the special

tools

designed

for

this

product

to

avoid

damage

and incorrect assembly.

3.

Use

only

metric

tools

when servicing the motorcycle.

Metric

bolts, nuts and screws are

nol

interchangeable

with

English fasteners.

4.

Install

new

gaskets, O-rings. cotter pins, and lock plates

when

reassembling.

5.

When

tightening

bolts

or

nuts, begin

with

the

larger

diameter

or inner

bolt

first. Then

tighten

to

the

specified

torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts

in

cleaning solvent

upon

disassembly. Lubricate

any sliding

surfaces before reassembly.

7.

After

reassembly, check all parts

for

proper

installation

and

operation.

8.

Route all electrical

wires

as

shown

on

page 1-14, Cable

and

Harness

Routing

.

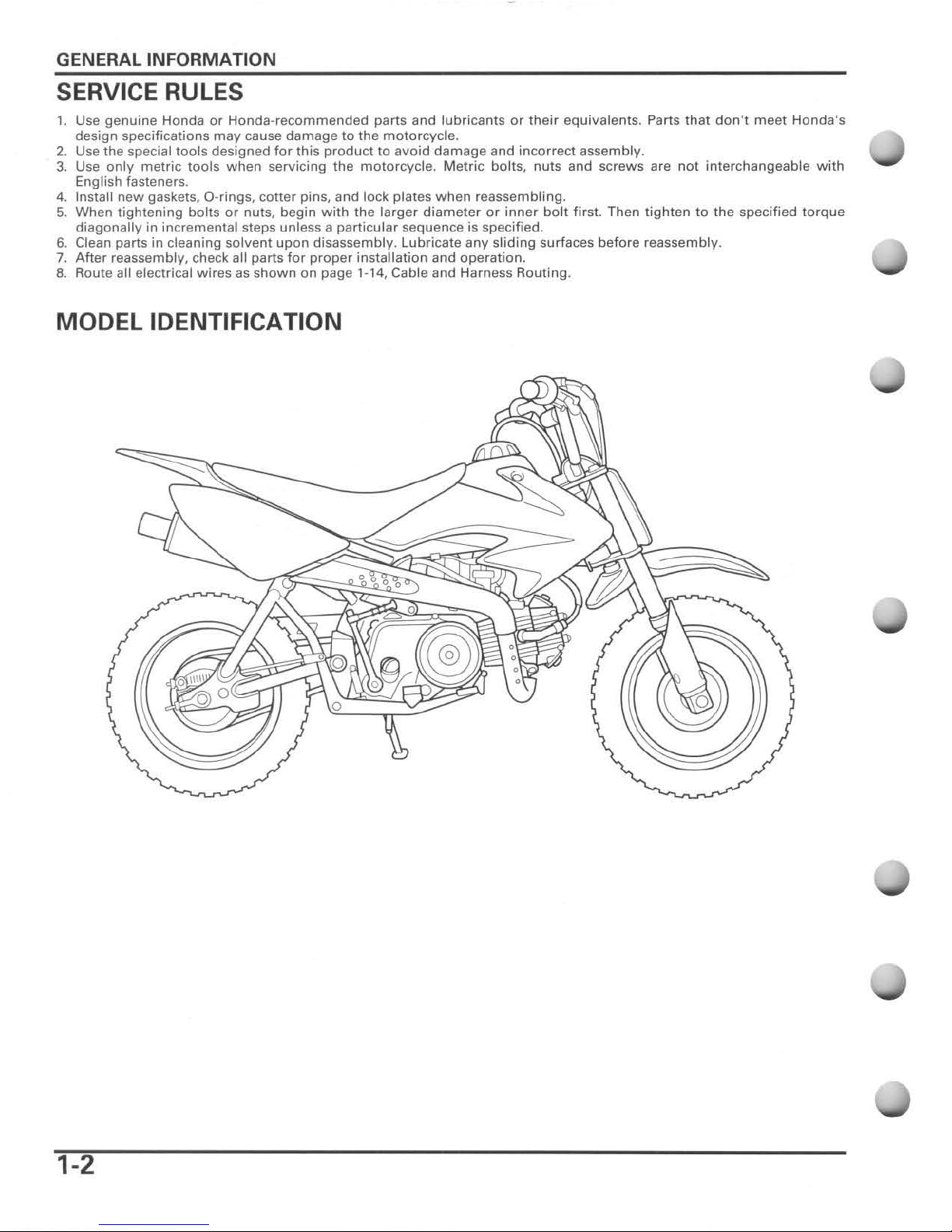

MODEL IDENTIFICATION

1-2

,

The Vehicle Identification

Number

(VIN) is

stamped

on the

left

side

of

the steering head.

The

engine

serial

number

is stamped

on

the

lower

left

side

of

the

crankcase.

The

model

identification

label (U.S.A.)

or the safety Certification label

(Canada) is located on

right

side

of

the

steering

head.

The

carburetor

identification

number

is

stamped

on

the

right

side

of

the

carburetor

body

as

shown

.

GENERAL

INFORMATION

1-3

GENERAL

INFORMATION

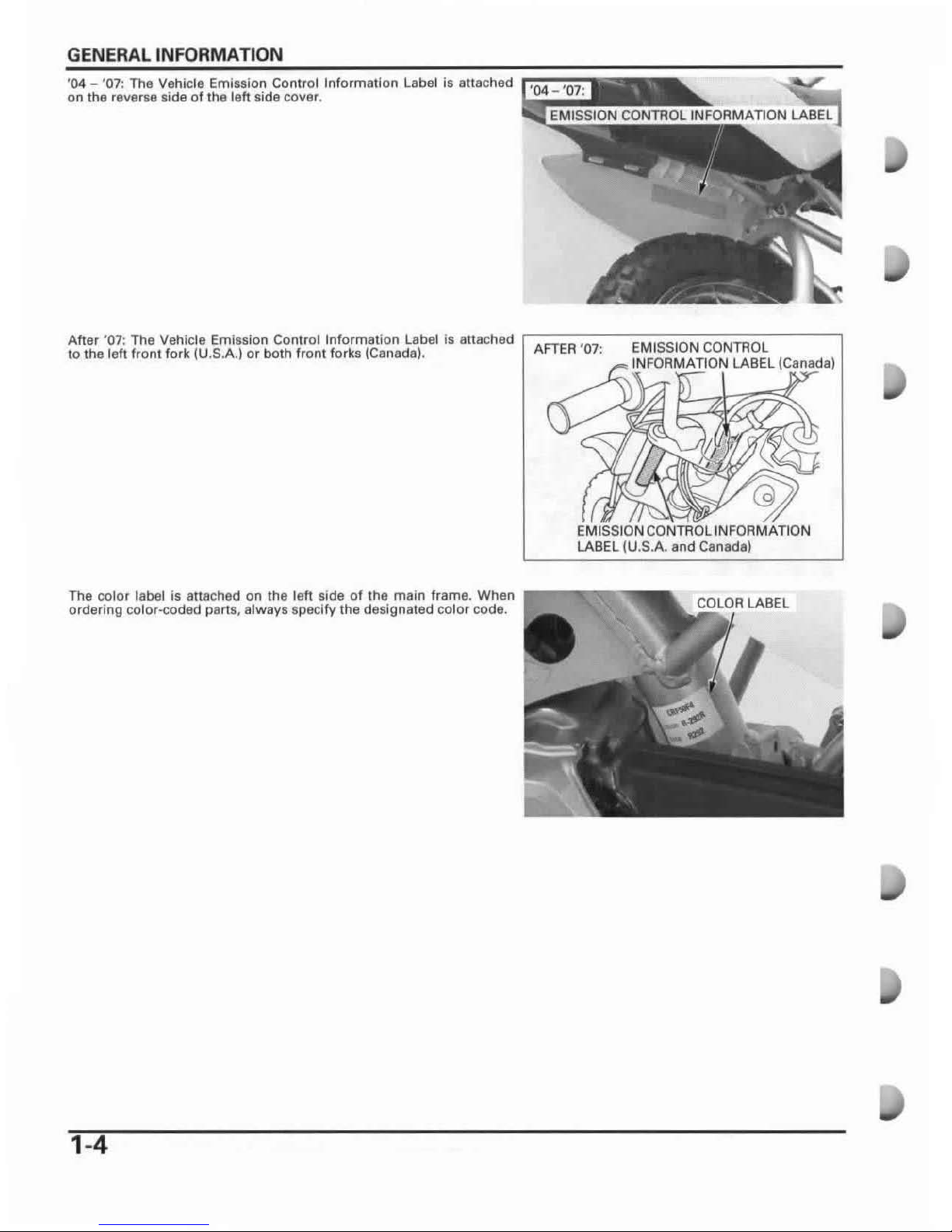

'

04

- '07:

The

Vehicle Emission Conlrol Information

labe

l is attached

on the reverse side of the

left side cover.

After

'07: The Vehicle Emission Control Information label is attach

ad

,----------,-------

- -

to the leh fro

nl

fork (U.S.

A.)

or both front forks (Canada).

AFTER '07

:

EMISSION

CONTROL

INFORMATION LABEL (Canada)

EMISSION

CONTROL

INFORMATION

LABElIU.5A

and Canada)

The

color label

is

allached

on

the left side

of

the main frame. When

P---

....

..,.......,

ordering color.-coded parts, always specify the deslgnaled color code.

1-4

GENERAL

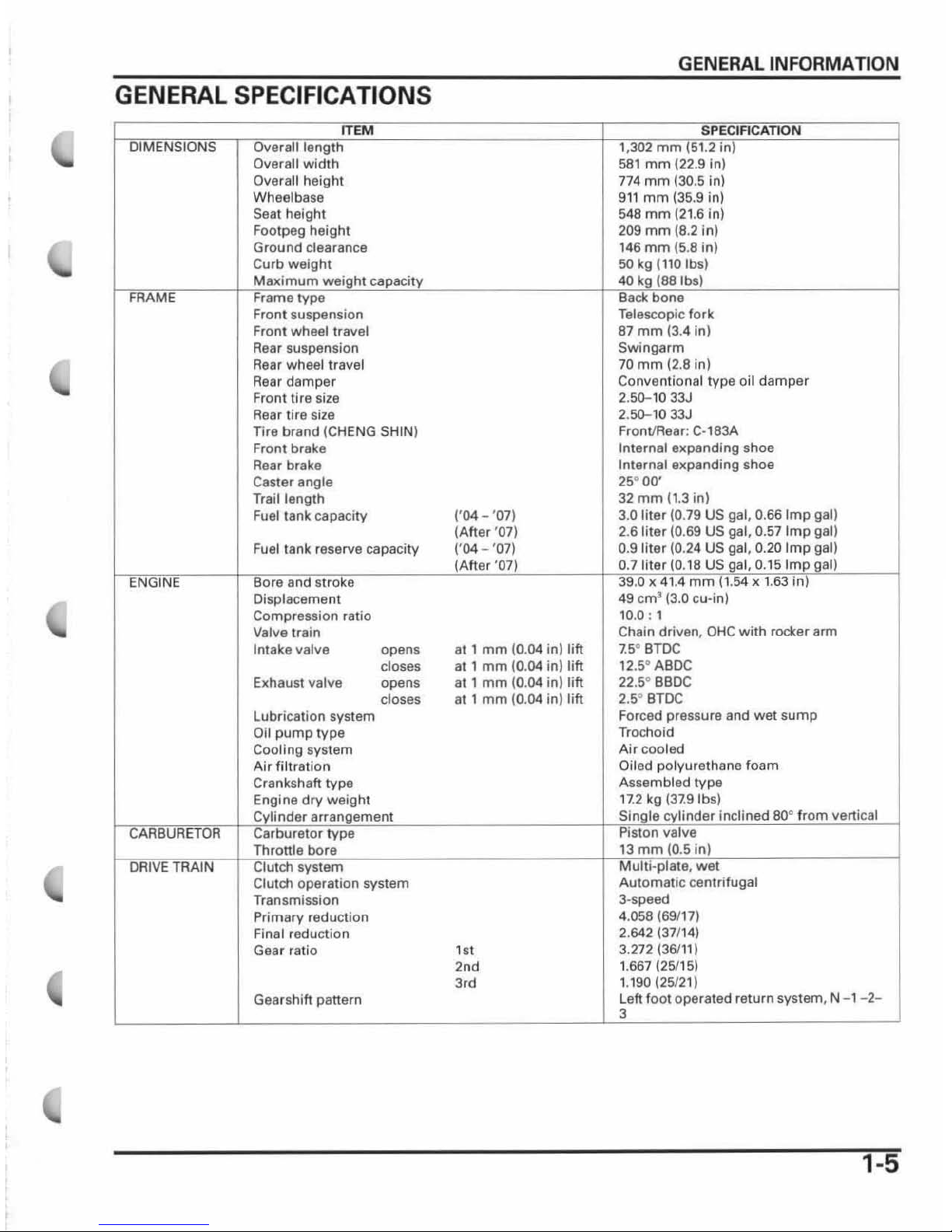

SPECIFICATIONS

I I

Overall width

Overall

height

Wheelbase

Sea

t height

Foolpeg height

Ground

clearance

Curb weight

Front suspension

Front wheel

travel

Rear suspension

Rear wheel travel

Rear

damper

Front tire size

Rear tire size

Tire

brand (CHENG SHIN)

Front brake

Rear

brake

Casler

angle

Trail

length

Fuel lank capacity

Fuel

tank reserve capacity

Displacement

Compression ratio

Valve

train

Intake valve opens

closes

Exhaust valve opens

Lubrication

system

Oil

pump

type

Cooling system

Air filtration

Crankshaft

type

dry weight

system

doses

Clutch operation system

Transmission

Primary reduction

Final reduction

Gear ratio

Gearshift panern

('

04-

'07)

(After

'07)

('04

- '07)

al 1

mm

(0.04 in) tift

at 1

mm

(0.04 in)

lift

at , mm

(0.04 iollift

at 1

mm

(0.04

in)

Jift

,,,

2nd

3,d

GENERAL

INFORMATION

mm

581 mm

(22.9 in)

774

mm

(30.5 in)

911

mm

(35.9 in)

548

mm

(21.6 in)

209

mm

(8.2 in)

146

mm

(5.8

in)

50

kg

(110

Ibs)

Telescopic

fork

87

mm

(3.4 in)

Swingarm

70

mm

(2.8 in)

Conventional type

oil

damper

2.50-1033J

2.

50-1033J

Front/Rear: C·183A

Internal

expanding shoe

Internal expanding shoe

25° 00'

32

mm

(1.3

in)

3.0

liter

(0.79 US gal, 0.66

Imp

gal)

2.61i1er (0.69

US gal, 0.57

Imp

gal)

0.9

liter

(0.

24

US gal, 0.20

Imp

gal)

0.7

.

t8US

0.15 I

49 cm' (3.0 cu·in)

10

.0 : 1

Chain driven ,

OHC

with roctet

arm

7.5

0

BTDC

12

.5°

ABDC

22

.5°

BBDC

2

,so

BTDC

Forced pressure and

wet

sump

Trochoid

Air

cooled

Oiled polyurethane foam

Assembled

type

, 7.2 kg

(37.9

Ibs)

inclined 80°

Automatic

centrifugal

3·speed

4.

058

(69117)

2.642137/

'4)

3.272136111)

1.667

(25115)

1.190

(25121)

Left

foot

operated return system, N - 1- 2-

1-5

GENERAL INFORMATION

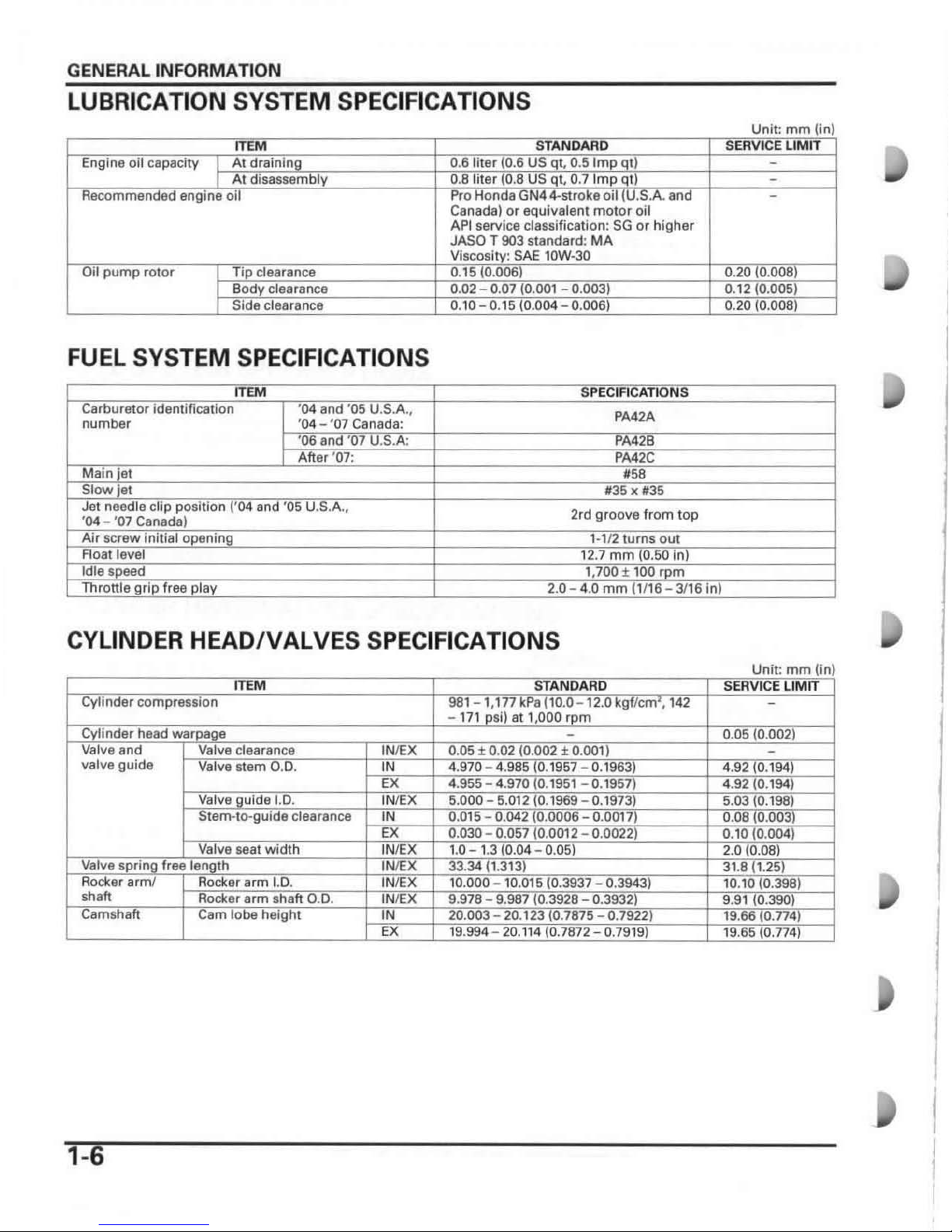

LUBRICATION SYSTEM SPECIFICATIONS

Canada)

or

equivalent mOler oil

API

service classification:

SG

or higher

JASOT .

MA

FUEL SYSTEM SPECIFICATIONS

number

PA42A

2rd groove from top

CYLINDER

HEADIVALVES

SPECIFICATIONS

valve guide

I

I

1-6

I

I

Loading...

Loading...