Page 1

HLT25SDS

HLT25CDS

Page 2

Important!

It is essential that you read the instructions in this manual before assembling,

operating, and maintaining the product.

Subject to technical modifications.

Page 3

Original instructions | English

Safety, performance, and dependability have been given

top priority in the design of your grass trimmer.

INTENDED USE

The grass trimmer is intended to be used only by adults

who have read and understood the instructions and

warnings in this manual and can be considered responsible

for their actions.

The product is only intended for use outdoors in a wellventilated area. For safety reasons, the product must be

adequately controlled using a two-handed operation.

The product is designed for cutting grass, light weeds,

and other similar vegetation at or about ground level.

The cutting plane should be approximately parallel to the

ground surface.

The product should not be used to cut or trim hedges,

bushes, or other vegetation where the cutting plane is not

or about ground surface level.

Do not use the product for any other purpose.

WARNING

To reduce the risk of injury, the user must read and

understand the operator’s manual.

WARNING

Do not attempt to operate the product until you

have read thoroughly and understood completely all

instructions and safety rules contained in this manual.

Failure to comply may result in accidents involving fire,

electric shock, or serious personal injury. Save the

operator’s manual and review frequently for continuing

safe operation, and instructing others who may use the

product.

WARNING

The product is not intended to be used by children or

persons with reduced physical, mental, or sensory

capabilities. Children should be adequately supervised

to ensure they do not play with the product.

GENERAL SAFETY WARNINGS

■ For safe operation, read and understand all instructions

before using the product. Follow all safety instructions.

Failure to follow all safety instructions listed below can

result in serious personal injury.

■ Some regions have regulations that restrict the use of

the product. Check with your local authority for advice.

■ Never allow children or untrained individuals to use the

product.

■ Do not start or run the engine in a closed or poorly

ventilated area; breathing exhaust fumes can kill.

■ Clear the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire, or

string that can be thrown or become entangled in the

string head.

■ Wear full eye and hearing protection while operating the

product. If working in an area where there is a risk of

falling objects, head protection must be worn.

■ Hearing protection may restrict the operator’s ability

to hear warning sounds. Pay particular attention to

potential hazards around and inside the working area.

■ Wear heavy, long trousers, non-slip protective footwear,

and gloves. Do not wear loose fitting clothing, short

trousers, jewellery of any kind, or use with bare feet.

■ Secure long hair so it is above shoulder level to prevent

entanglement in any moving parts.

■ Keep all bystanders, children, and pets at least 15 m

away. Stop the product if anyone enters the area.

■ Never use the product when tired, ill, under medication,

or under the influence of alcohol and drugs.

■ Do not use in poor lighting. The operator needs clear

unrestricted vision to identify potential hazards.

■ Keep firm footing and balance at all times. Do not

overreach. Overreaching can result in loss of balance

or exposure to hot surfaces.

■ Keep all parts of your body away from any moving part.

■ Do not touch the area around the silencer or cylinder of

the product, these parts get hot from operation.

■ Always stop the engine and allow it to cool down before

making any adjustments.

■ Do not smoke when mixing the fuel or when filling the

fuel tank.

■ Mix and store the fuel in a container that is approved

for fuel.

■ Mix the fuel outdoors where there are no sparks or

flames. Wipe up any fuel spillage. Move 9 m away from

refueling site before starting engine.

■ Stop the engine and allow it to cool down before

refueling or storing the product.

■ Allow the engine to cool down, empty the fuel tank, and

secure the product from moving before transporting in

a vehicle.

■ Turn off the engine. Make sure all moving parts have

come to a complete stop:

● before servicing

● before clearing a blockage

● before checking, cleaning, and working on the

product

● before changing accessories

● after striking a foreign object

● whenever leaving the product unattended

● whenever performing maintenance

● whenever the product starts to vibrate abnormally

1

Page 4

Original instructions | English

WARNING

Never use cutting means or attachments, which are not

specified by HOMELITE in this manual. This includes

the use of metal multi-piece pivoting chains and flailblades. These items are known to break up during use

and present a high risk of serious injury to the operator

or bystanders.

WARNING

Inspection after dropping or other impacts: Thoroughly

inspect the product and identify any problems or damage

to it. Any part that is damaged should be properly

repaired or replaced by an authorised service centre.

GRASS TRIMMER SAFETY WARNINGS

■ Replace the string head if cracked, chipped, or

damaged in any way. Be sure the string head is

properly installed and securely fastened. Failure to do

so can cause serious injury.

■ Avoid using on wet grass.

■ Do not walk backwards when using the product.

■ Walk, never run.

■ The small blade fitted to the cutting attachment guard

is designed to trim the new extended line to the correct

length for safe and optimum performance. It is very

sharp; do not touch it, particularly when cleaning the

product.

■ Always ensure that ventilation openings are kept clear

of debris.

■ Before use and after any impact, check that there are

no damaged parts. Examine the cutting means for signs

of cracking or other damage. A defective switch or any

part that is damaged should be properly repaired or

replaced by an authorised service facility.

■ Make sure the head attachment is properly installed

and securely fastened.

■ Make sure all guards, deflectors, handles, bolts, and

fasteners are properly and securely attached.

■ Do not modify the product in any way. This may

increase the risk of injury to yourself or others.

■ Use only the manufacturer’s replacement line in the

cutting head. Do not use any other cutting attachment.

■ Do not operate the product without the cutting

attachment guard in place. Ensure the cutting

attachment is in good condition.

■ Maintain a firm grip on both handles while trimming.

Keep string head below waist level. Never cut with the

string head located more than 76 cm above the ground.

TRANSPORTATION AND STORAGE

■ Stop the engine and allow it to cool down before storing

or transporting.

■ Clean all foreign materials from the product.

■ Drain all fuel from tank into a container approved for

2

petrol. Remember to properly replace and tighten the

fuel cap.

■ Run the engine until it stops, this will remove all fuel

that could become stale and leave varnish and gum in

the fuel system.

■ Drain all lubricant from tank into a container approved

for lubricant. Remember to properly replace the

lubricant cap.

■ Store the product in a cool, dry, and well-ventilated

place that is inaccessible to children. Keep away from

corrosive agents, such as garden chemicals and deicing salts. Do not store outdoors.

■ When transporting the product in a vehicle, secure it

against movement or falling to prevent injury to persons

or damage to the product.

■ Never carry or transport the product while the engine

is running.

■ Abide by all government and local regulations for the

safety storage and handling of petrol.

Short term

■ Stop the engine, and allow it to cool down before

storing.

■ Clean all foreign material from the product.

■ Store the product in a cool, dry, and well-ventilated

place that is inaccessible to children.

■ Keep away from corrosive agents such as garden

chemicals and de-icing salts.

■ Do not store outdoors.

MAINTENANCE

WARNING

Use only original manufacturer’s replacement parts,

accessories, and attachments. Failure to do so can cause

possible injury, can contribute to poor performance, and

may void your warranty.

■ Always stop the engine and allow it to cool down before

making any maintenance.

■ You may make adjustments and repairs described in

this manual. For other repairs, contact an authorised

service centre.

■ Consequences of improper maintenance may include

additional safety hazards, excess carbon deposits

resulting in loss of performance, and discharge of black

lubricant residue dripping from the silencer.

■ For the replacement line, use only nylon filament line

of the diameter described in the specification table of

this manual.

■ After extending the new cutter line, always return the

product to its normal operating position before starting.

■ After each use, clean the product with a soft, dry cloth.

■ Any part that is damaged should be properly repaired or

replaced by an authorised service centre.

■ Check all nuts, bolts, and screws at frequent intervals

Page 5

Original instructions | English

for proper tightness to ensure the product is in a safe

working condition.

RESIDUAL RISK

Even when the product is used as prescribed, it is still

impossible to completely eliminate certain residual risk

factors. The following hazards may arise in use and the

operator should pay special attention to avoid the following:

■ Injury caused by vibration

– Hold the product by designated handles and restrict

working time and exposure.

■ Exposure to noise can cause hearing injury

– Wear hearing protection and limit exposure.

■ Eye injury due to flying debris

– Wear eye protection at all times.

RISK REDUCTION

It has been reported that vibrations from handheld tools

may contribute to a condition called Raynaud’s Syndrome.

Symptoms may include tingling, numbness and blanching

of the ngers, usually apparent upon exposure to cold.

Hereditary factors, exposure to cold and dampness, diet,

smoking and work practices are all thought to contribute to

the development of these symptoms. There are measures

that can be taken by the operator to possibly reduce the

effects of vibration:

■ Keep your body warm in cold weather. When operating

the product, wear gloves to keep the hands and wrists

warm. It is reported that cold weather is a major factor

contributing to Raynaud’s syndrome.

■ After each period of operation, exercise to increase

blood circulation.

■ Take frequent work breaks. Limit the amount of

exposure per day.

If you experience any of the symptoms of this condition,

immediately discontinue use and see your physician.

WARNING

Injuries may be caused, or aggravated, by prolonged

use of a tool. When using any tool for prolonged periods,

ensure you take regular breaks.

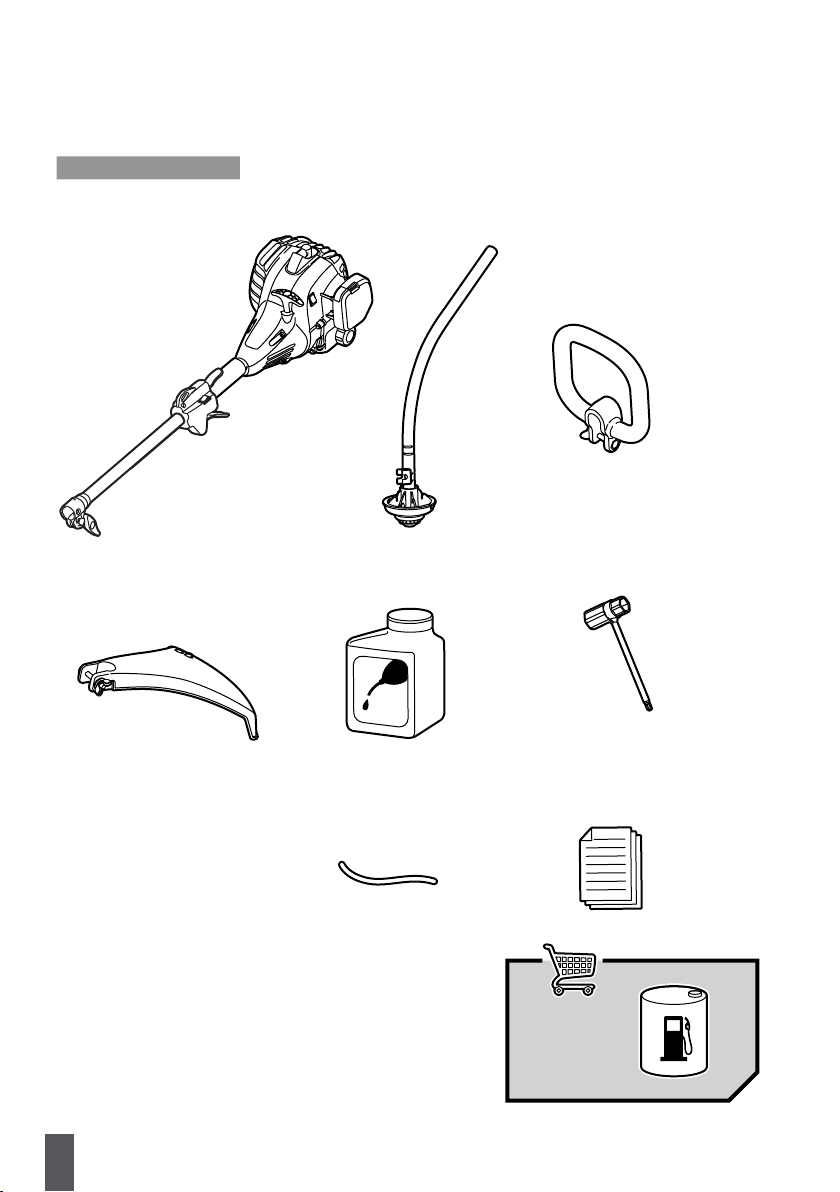

WHAT'S IN THE BOX

■ Power head and upper boom assembly x 1

■ Front handle assembly x 1

■ Safety grass deflector assembly x 1

■ Combination wrench x 1

■ Lower boom and string head assembly x 1

■ 2-stroke lubricant x 1

■ String line x5 (For HLT25CDS only)

■ Manual x 1

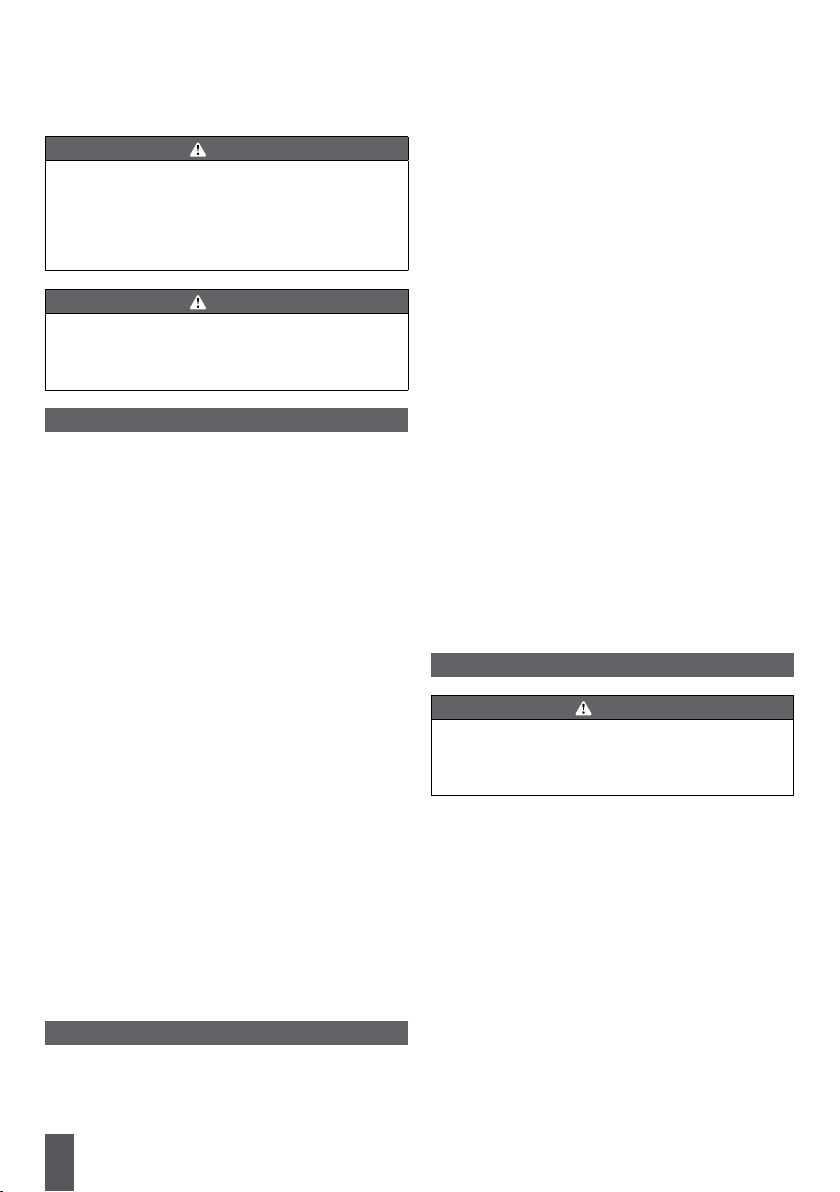

SYMBOL

10,000

Safety alert

Please read the instructions carefully

before starting the product.

Wear eye, hearing, and head protection

when operating the product.

Beware of thrown or ying objects. Keep

all bystanders, especially children and

pets, at least 15 m from the operating

area.

The product is not intended for use with

a toothed saw type blade.

Do not use blade(s) on the product.

HLT25CDS: Rotational direction and

maximum speed of the shaft for the

cutting attachment.

HLT25SDS: Rotational direction and

maximum speed of the shaft for the

cutting attachment.

Wear non-slip safety footwear when

using the product.

Wear non-slip, heavy duty gloves.

Handle position

Set switch to "I/STOP".

PRIME - Press the primer bulb 10 times

slowly.

Run position

Half choke position

Full choke position

3

Page 6

Original instructions | English

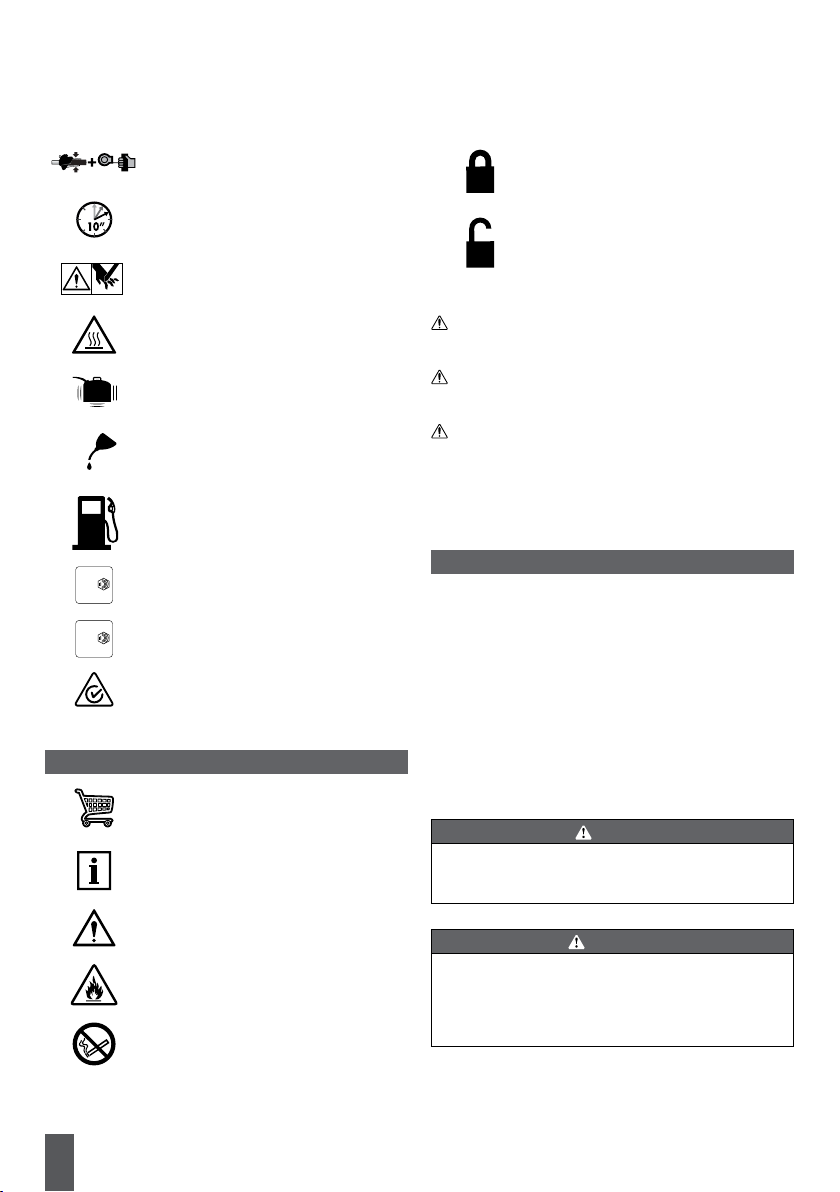

Squeeze the trigger and pull the starter

grip.

Wait for 10 seconds.

Keep hands away from blades.

To reduce the risk of injury or damage,

avoid contact with any hot surface.

Mix the fuel mix thoroughly and also

each time before refueling.

Use 2-stroke lubricant for air cooled

engines.

Use unleaded petrol intended for motor

vehicle use with an octane rating of 91

([R+M]/2) or higher.

Per ANSI B175.3

80.1dB(A)

Per ANSI B175.3

78.6dB(A)

HLT25SDS: Sound power level

HLT25CDS: Sound power level

Regulatory Compliance Mark (RCM).

Product meets applicable regulatory

requirements.

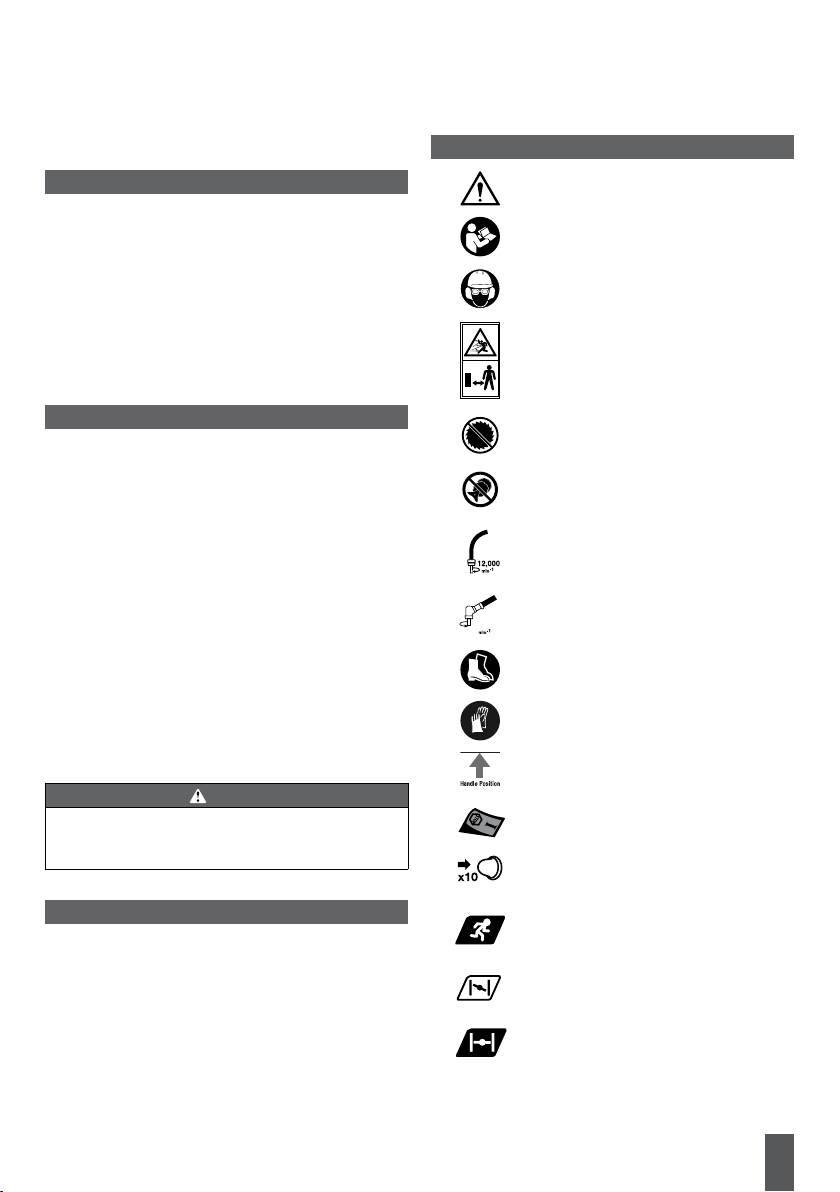

SYMBOLS IN THIS MANUAL

Parts or accessories sold separately

Note

Lock

Unlock

The following signal words and meanings are intended to

explain the levels of risk associated with this product.

DANGER

Indicates an imminently hazardous situation, which, if

not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation, which, if not

avoided, may result in minor or moderate injury.

CAUTION

Without safety alert symbol

Indicates a situation that may result in property damage.

ASSEMBLY

UNPACKING

The product requires assembly.

■ Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing

list are included.

■ Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

■ If any parts that require assembly have already been

assembled, return the product to the supplier.

■ Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

WARNING

If any parts are damaged or missing, do not operate the

product until the parts are replaced. Failure to heed this

warning could result in serious personal injury.

Warning

WARNING

Do not attempt to modify the product or create

Risk of re

accessories not recommended for use with the product.

Any such alteration or modification is misuse and could

result in a hazardous condition leading to possible

Do not smoke

serious personal injury.

4

Page 7

Original instructions | English

WARNING

Never attach or adjust any attachment while power head

is running. Failure to stop the engine may cause serious

personal injury.

WARNING

To avoid serious injury, ensure that all grass deector

and covers are correctly tted and all xings and

fasteners are tight before use. Re-check tightness after

a period of use.

ATTACHING THE FRONT HANDLE

■ Remove the bolt and wing nut from the front handle.

■ Install the front handle onto the top side of the drive

shaft in the area indicated by the label.

■ Place the bolt through the front handle.

NOTE: The hex bolt head fits inside the hex recess

molded into one side of the handle.

■ Reinstall the wing nut.

■ Tighten wing nut securely.

ASSEMBLING THE GRASS DEFLECTOR (HLT25SDS)

■ Remove the wing screw from the grass deflector.

■ Insert the tab on the mounting bracket in the slot on the

grass deflector.

■ Align the screw hole in the mounting bracket with the

screw hole in the grass deflector.

■ Insert the wing screw through the mounting bracket and

into the grass deflector.

■ Tighten the screw securely.

ATTACHING THE CURVED SHAFT GRASS DEFLECTOR (HLT25CDS)

■ Remove the bolt and wing nut from grass deflector.

■ Press the grass deflector onto the bottom of the curved

shaft.

■ Insert the bolt through the grass deflector and the

bracket on the curved shaft.

■ Place the wing nut on the bolt and tighten securely.

ATTACHING THE LOWER BOOM TO THE POWER

HEAD

WARNING

Never attach or adjust any attachment while power head

is running. Failure to stop the engine may cause serious

personal injury.

■ The lower boom connects to the power head by means

of a coupler device.

■ Loosen the knob on the coupler of the power head upper

boom and remove the end cap from the attachment.

■ Push in the button located on the lower boom. Align the

button with the guide recess on the power head coupler

and slide the two booms together.

■ Rotate the lower boom until the button locks into the

positioning hole.

NOTE: If the button does not release completely in

the positioning hole, the booms are not locked into

place. Slightly rotate from side to side until the button

is locked into place.

■ Tighten the knob securely.

ATTACHING THE STRING LINE IN THE PRO-CUT I

HEAD (HLT25CDS)

■ Place the middle of the line under the hook/notch inside

the spool.

■ Feed the ends of the line through the eyelets on the

side of the PRO-CUT I fixed line head.

■ Pull the line outwards so it is tight and even on both

sides of the spool.

WARNING

To avoid serious injury, ensure that all grass deector

and covers are correctly tted and all xings and

fasteners are tight before use. Re-check tightness after

a period of use.

REMOVING THE LOWER BOOM FROM THE POWER

HEAD

■ Loosen the knob.

■ Push in the button and twist the lower boom to remove

and separate ends.

WARNING

Always stop the engine and remove the spark plug

wire before making any adjustments such as changing

cutting heads; this is to reduce the risk of serious

personal injury.

OPERATION

FUEL AND REFUELING

Handling the fuel safely

■ Always handle fuel with care, it is highly flammable.

■ Always refuel outdoors where there are no sparks and

flames. Do not inhale fuel vapors.

■ Do not let petrol or oil come in contact with your skin.

■ Keep petrol and oil away from the eyes. If petrol or oil

comes in contact with the eyes, wash them immediately

with clean water. If irritation is still present, see a

physician immediately.

■ Clean up spilled petrol immediately.

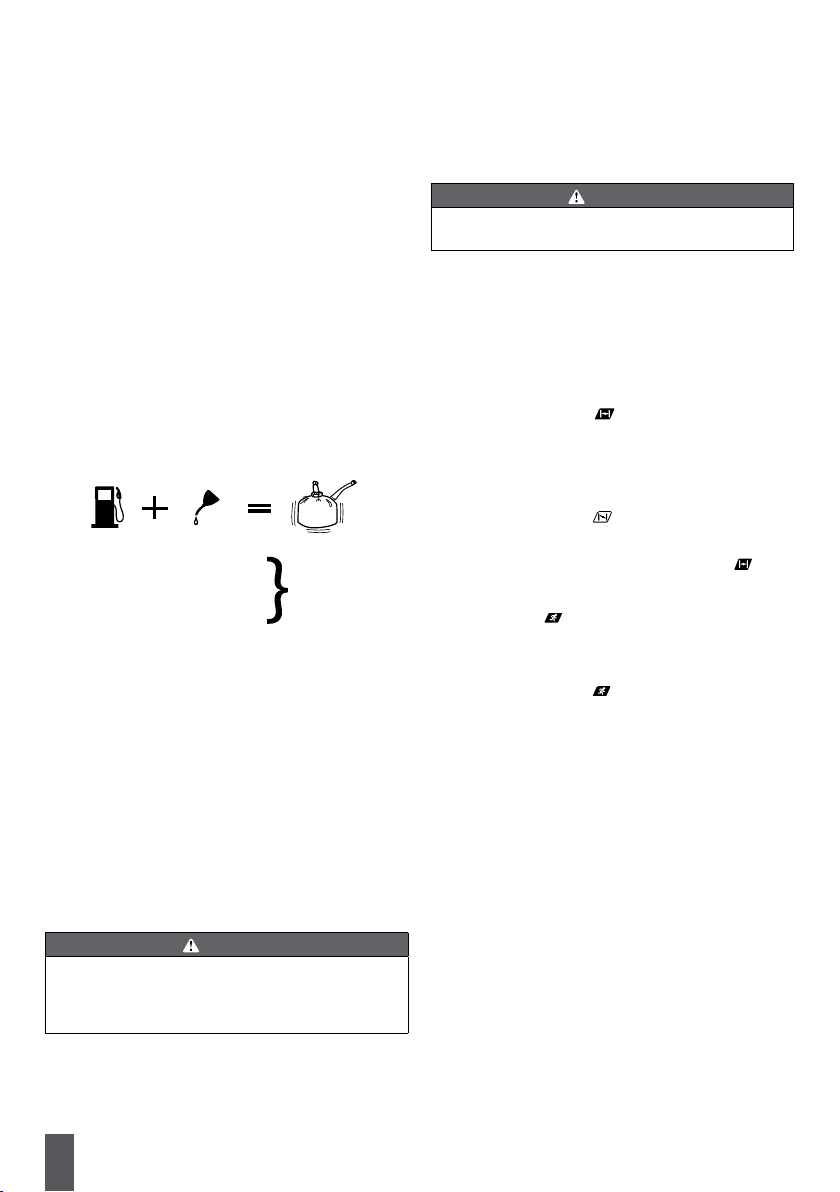

Mixing the fuel

■ The product is powered by a 2-stroke engine and

5

Page 8

Original instructions | English

requires pre-mixing petrol and 2-stroke oil. Store premix unleaded petrol and 2-stroke engine oil in a clean

container approved for petrol.

■ This engine is certified to operate on unleaded petrol

intended for automotive use with an octane rating of 91

or higher.

■ Do not use any type of pre-mixed petrol / oil from fuel

service stations, this includes the pre-mixed petrol / oil

intended for use in mopeds, motorcycles, etc.

■ Use synthetic 2-stroke oil only. Do not use automotive

oil or 2-stroke outboard oil.

■ Mix 2% synthetic 2-stroke oil into the petrol. This is a

50:1 ratio.

■ Mix the fuel thoroughly and also each time before

fuelling.

■ Mix in small quantities. Do not mix quantities larger

than usable in a 30 day period. Synthetic 2-stroke oil

containing a fuel stabilizer is recommended.

1 Litre + 20 ml =

2 Litres + 40 ml =

3 Litres + 60 ml = 50:1 (2%)

4 Litres + 80 ml =

5 Litres + 100 ml =

Filling the tank

■ Clean the surface around the fuel cap to prevent

contamination.

■ Loosen the fuel cap slowly to release pressure and to

keep fuel from escaping around the cap.

■ Carefully pour the fuel mixture into the tank. Avoid

spillage.

■ Prior to replacing the fuel cap, clean and inspect the

gasket.

■ Immediately replace fuel cap and hand tighten. Wipe

up any fuel spillage. Move 9 m away from refueling site

before starting engine.

NOTE: It is normal for smoke to be emitted from a new

engine during and after rst use.

WARNING

Always shut off the engine before fueling. Never add fuel

to a machine with a running or hot engine. Move at least

9 m from refueling site before starting engine. Do not

smoke!

STARTING THE PRODUCT

Starting the product differs depending on whether the

engine is cold (not yet started today) or warm (has been

running in the last hour). Always refer to the Starting

Instructions label on the air lter when starting the engine.

Refer below for full instructions.

WARNING

Never start or run the engine inside a closed or poorly

ventilated area; breathing exhaust fumes can kill.

NOTE: Before starting the product, make sure the trimmer

is lying on a flat and bare surface.

Starting a cold engine:

1. Ensure the switch is in the "I" (ON) position.

2. Press the primer bulb 10 times.

NOTE: After the 7th press, the fuel should be visible in

the primer bulb. If not, continue pressing until the fuel

is visible.

3. Set the choke lever to

4. Squeeze the throttle lock and throttle trigger completely

and pull the starter grip until the engine attempts to

start. Do not pull the starter grip more than 4 times.

NOTE: Keep the throttle lock and throttle trigger

squeezed completely through steps 4 to 7.

5. Set the choke lever to choke position.

6. Pull the starter grip until the engine starts. Do not pull

the starter grip for more than 6 times.

NOTE: If the engine does not start, return to choke

position and repeat the process beginning at step 2.

7. Allow the engine to run for 10 seconds, then set the

choke lever to position.

Starting a warm engine:

1. Ensure the switch is in the "I" (ON) position.

2. Press the primer bulb 10 times.

3. Set the choke lever to

4. Pull the starter grip until the engine starts. Do not pull

the starter grip for more than 6 times.

NOTE: If the engine does not start, return to step 2

under "To starting a cold engine".

Stopping the engine:

1. Release the throttle trigger

2. Hold the engine switch in the "STOP" (OFF) position.

OPERATING THE TRIMMER

Follow these steps to operate the trimmer.

■ Start the trimmer.

■ Hold the trimmer at waist level with your right hand on

the rear handle and your left hand on the front handle.

■ Place the product on the right side of your body with the

engine behind and away from your body.

■ Trim the grass and weeds with the line parallel to the

ground.

NOTE: Always operate the trimmer at full throttle.

Prolonged cutting at partial throttle will result in oil dripping

from the silencer.

choke position.

position.

6

Page 9

Original instructions | English

CUTTING TIPS

When cutting, make sure the cutter head is at a slight angle

while still approximately parallel to the ground surface. In

tall grass, cut from the top down to ensure the moving parts

do not get tangled with the long grass.

If grass becomes wrapped around the trimmer head, stop

the engine, wait for all moving parts to stop and remove

the grass.

ADVANCING THE LINE (HLT25SDS)

If the line becomes short, tap the bump head on the ground

as shown at full throttle. More line will extend. Take care

not to bump the head on a hard surface such as concrete

or pavers as this may cause damage to the bump head.

WARNING

When servicing, use only original manufacturer's

replacement parts. Use of any other parts may create a

hazard or cause product damage.

WARNING

Always wear safety goggles or safety glasses with side

shields during product operation. If operation is dusty,

also wear a dust mask.

WARNING

Before inspecting, cleaning, or servicing the product,

shut off the engine, wait for all moving parts to stop.

Failure to follow these instructions can result in serious

personal injury or property damage.

WARNING

Neglected or poorly conducted maintenance may create

additional hazards. Do not attempt to repair or maintain

the product if you are not qualified to do so. If in doubt,

return to a service centre for professional assistance.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, lubricant, and grease.

WARNING

Do not at any time let brake fluids, petrol, petroleumbased products, penetrating lubricants, etc., come in

contact with plastic parts. Chemicals can damage,

weaken or destroy plastic, which may result in serious

personal injury.

You can often make adjustments and repairs described in

this manual. For other repairs, have the trimmer serviced

by a service agent.

REPLACING THE LINE (HLT25SDS)

■ Ensure the product is in "STOP" (OFF) position.

■ Unlock the retainer clockwise and then remove the

retainer and spool.

■ Remove all old cutter line, and replace with the correct

replacement line (diameter- 2.4 mm, length-1.8 m x 2

pcs.).

■ Once you have reloaded the line on the spool, locate it

in the correct channels.

■ Replace the spool back into the head making sure all

the lines are located correctly.

■ Have 15 cm of line protruding from each of the eyelets

of the string head housing.

■ Press the head into the drive shaft of lower boom to

hold it steady.

■ Replace the retainer and then tighten it

counterclockwise.

■ Pull excess line out to ensure no tangles in the head.

REPLACING THE PRO CUT I STRING HEAD AND LINE

(HLT25CDS)

■ Stop the engine and wait for all moving parts to stop

completely.

■ Loosen the spool retainer by turning it counterclockwise

and then remove the string head.

■ Take a new PRO-CUT I string head and a 500 mm

length of 2.4 mm diameter monofilament pre-cut line.

■ Place the middle of the line under the hook/notch inside

the spool.

■ Feed the ends of the line through the eyelets on the

side of the PRO-CUT I fixed line head.

■ Pull the line outwards so it is tight and even on both

sides of the spool.

■ Install the PRO-CUT I head assembly on the drive shaft

and then secure with spool retainer

CLEANING THE EXHAUST PORT AND SILENCER

Depending on the type of fuel used, the type and amount

of lubricant used, and/or your operating conditions, the

exhaust port and silencer may become blocked with

carbon deposits. If you notice a power loss with your petrol

powered product, a qualied service technician will need to

remove these deposits to restore performance.

SPARK ARRESTOR

The spark arrestor must be cleaned or replaced every

25 hours of operation or yearly to ensure proper

performance of the product. Spark arrestors may be found

in different locations depending on the model purchased.

Please contact your nearest service centre for the location

of the spark arrestor for your model.

7

Page 10

Original instructions | English

CLEANING THE AIR FILTER

For proper performance and longer life, keep the foam air

filter clean.

■ Remove the air filter cover by pushing down on the

latches while gently pulling off the cover.

■ Remove the air filter.

■ Clean the foam filter element with warm, soapy water.

Rinse and let dry.

NOTE: If the foam lter element is damaged, it should be

replaced.

■ Apply a light coat of engine oil to the foam filter element,

then squeeze it out.

■ Reinstall the air filter.

NOTE: Make sure the lter is seated properly inside the

cover. Installing the lter incorrectly will allow dirt to enter

the engine, causing rapid engine wear.

■ Replace the air filter cover by placing the slots on the air

filter cover over the latches on the housing, then push

the cover down until it snaps securely in place.

CHECKING THE FUEL CAP

WARNING

A leaking fuel cap is a fire hazard and must be replaced

immediately.

The fuel cap contains a non-serviceable lter and a check

valve. A clogged fuel lter causes poor engine performance.

If performance improves when the fuel cap is loosened, the

valve may be faulty or the lter may be clogged. Replace

the fuel cap if necessary.

REPLACING THE SPARK PLUG

This engine uses a Champion RCJ6Y, TORCH L7RTC or

equivalent spark plug with 0.63 mm electrode gap. Use an

exact replacement and replace annually.

Follow these steps to replace the spark plug.

■ Stop the engine.

■ Remove the spark plug boot.

■ Loosen the spark plug by turning it counterclockwise

with a combination wrench.

■ Remove the spark plug.

■ Hand thread the new spark plug, turning it clockwise.

■ Tighten with a combination wrench to 22~25 Nm torque

or one-half of a turn from finger tight. Do not overtighten.

CLEANING THE EXHAUST HOLE OF THE CYLINDER

AND INTAKE HOLE OF THE MUFFLER

CAUTION

Always stop the engine and allow it to cool down before

cleaning the exhaust hole.

■ Make sure the product is in the "STOP" (OFF) position.

■ Remove the screws on the top and rear portions of the

housing counterclockwise.

■ Remove the rear housing from the engine.

■ Remove the muffler screws counterclockwise, and then

remove the muffler cover, muffler, and gasket from the

cylinder.

■ Use the brush to clean the exhaust hole of the cylinder

and intake hole of the muffler.

■ Replace the gasket, muffler, and muffler cover. Replace

the screws and then tighten it clockwise.

■ Replace the rear housing. Replace the screws, and

then tighten it clockwise.

CAUTION

Be careful not to cross-thread the spark plug.

Crossthreading will seriously damage the engine.

8

Page 11

HLT25SDS

x 1

x 1

x 1

x 1

x 1

x 1

x 1

9

Page 12

HLT25CDS

x 1

x 1

0.5m

x 1

x 1

x 1

x 1

x 1x 5

10

Page 13

1. Ignition module

2. Choke lever

3. Fuel cap

4. Throttle lock

5. Switch

6. Throttle trigger

7. Muffler shield

21

8. Muffler

9. Knob

10. Air filter

11. Curved shaft (HLT25CDS)

12. Grass deflector

13. Retainer

14. String line

15. String head

16. Straight shaft (HLT25SDS)

17. Front handle

18. Strap hanger

19. Primer bulb

20. Starter grip

21. Spark plug

20

19

18

17

16

HLT25SDS

1

2

3

4

5

6

7

8

9

10

HLT25CDS

11

12

15

13

14

11

Page 14

1 2

4

3

Always wear safety goggles or safety glasses with side

shields when operating the product. Failure to do so could

result in objects being thrown into your eyes resulting

in possible serious injury. When handling the trimmer

assembly, wear non-slip, heavy-duty protective gloves.

Wear nonskid, protective footwear that will protect your feet

and improve your footing on slippery surfaces.

4

4

3

2

1

2

1

Install the lower shaft.

5

50 : 1 / 2%

(50 : 1)

5

Attach the D-handle.

12

Use synthetic 2-stroke lubricant only. Do not use automotive

lubricant or 2-stroke outboard lubricant. Mix 2% synthetic 2-stroke

lubricant into the petrol. This is a 50:1 ratio.

Page 15

2

1

HLT25SDS

3

3a

1

3

4

2

HLT25CDS

HLT25SDS: Attach the grass deector. HLT25CDS: Attach the grass deector.

3b

6

3

1

2

Loosen the fuel cap. Remove the fuel cap. Carefully pour fuel

mixture into the tank. Avoid spillage. Immediately replace fuel cap

and hand tighten.

13

Page 16

HLT25SDS HLT25CDS

p.17

p.16

p.18

p.21

14

HLT25SDS HLT25CDS

p.31p.23

p.25

p.32

Page 17

p.26

p.27

p.29

p.33

15

Page 18

1

x10x10

STARTING A COLD ENGINE

1. Lay the product on the ground. Press the

primer bulb 10 times.

NOTE: After the 7th press, the fuel

should be visible in the primer bulb. If

not, continue pressing until the fuel is

visible.

2. Set the choke lever to choke

position.

Squeeze the throttle lock and throttle

trigger completely and pull the starter

grip until the engine attempts to start.

Do not pull the starter grip more than 4

times.

3. Set the choke lever to position. Pull

the starter grip until the engine starts.

Do not pull the starter grip more than 6

times.

NOTE: If the engine does not start,

repeat the procedure again from setting

the choke lever to choke

4. Allow the engine to run for 10 seconds,

then set the choke lever to position.

position.

2

VI4VI

4

4

2

1

3

2

3

4

VI66VI

3

1

4

2

16

1

3

Page 19

1

x10x10

STARTING A WARM ENGINE

1. Lay the product on the ground. Press the

primer bulb 10 times.

2. Set the choke lever to

3. Pull the starter grip until the engine

starts. Do not pull the starter grip more

than 6 times.

4. Allow the engine to run for 10 seconds.

position.

2

3

VI66VI

4

17

Page 20

HLT25SDS

OPERATING THE TRIMMER

NOTE: Hold the product with the right hand

on the trigger handle and the left hand on

the left handle.

WARNING:

ting area. Avoid trees and shrubs. Tree bark,

wood mouldings, cladding, and fence posts

can easily be damaged by the line.

WARNING

using the product.

1. To start operating the product, hold down

Do not cut in a dangerous cut-

:

Exercise extreme caution when

the throttle lock (1) and then squeeze the

throttle trigger (2).

18

1

1

2

Page 21

1

2

2. Tap the knob on the ground to advance

the line. The line advances each time the

head is tapped. Do not hold the knob on

the ground.

NOTE: The line trimming cut-off blade on

the grass deflector will cut the line to the correct length.

NOTE: The small blade fitted to the cutting

attachment guard is designed to trim the

new extended line to the correct length for

safe and optimum performance. It is very

sharp; do not touch it, particularly when

cleaning the product.

NOTE: Cut tall grass from the top down. This

will prevent grass from wrapping around the

shaft housing and bump head, which may

cause damage from overheating.

2

1

2

3

19

Page 22

NOTE: For cutting ease and safety, cut the

grass from the right side to the left side.

20

Page 23

HLT25CDS

OPERATING THE TRIMMER

NOTE: Hold the product with the right hand

on the trigger handle and the left hand on

the left handle.

WARNING:

ting area. Avoid trees and shrubs. Tree bark,

wood mouldings, cladding, and fence posts

can easily be damaged by the line.

WARNING

using the product.

1. To start operating the product, hold down

Do not cut in a dangerous cut-

:

Exercise extreme caution when

the throttle lock (1) and then squeeze the

throttle trigger (2).

1

2

21

Page 24

NOTE: The line trimming cut-off blade on the

grass deflector will cut the line to the correct

length.

NOTE: The small blade fitted to the cutting

attachment guard is designed to trim the

new extended line to the correct length for

safe and optimum performance. It is very

sharp; do not touch it, particularly when

cleaning the product.

NOTE: Cut tall grass from the top down. This

will prevent grass from wrapping around the

shaft housing and bump head, which may

cause damage from overheating.

NOTE: For cutting ease and safety, cut the

grass from the right side to the left side.

22

1

2

3

Page 25

1

1

REPLACING THE LINE (HLT25SDS)

1. Turn off the product.

2. Unlock the retainer by rotating clockwise

and then remove together with the spool.

Remove the old line from the spool.

3. Replace with the new line (diameter - 2.4

mm, length - 1.8 m x 2 pcs).

4. Once you have reloaded the line on the

2

2

3

2

1

3

4

3

1

2

23

Page 26

1

2

1

2

spool, locate it in the correct channels.

5. Put the spool back into the head making

sure all the lines are located correctly.

Have 15 cm of line protruding from the

eyelets of the string head housing.

6. Install the retainer, tighten

counterclockwise, and then pull excess

line out.

5

3

4

6

3

24

Page 27

1

REPLACING THE PRO CUT I STRING

HEAD

1. Turn off the product.

2. Loosen the spool retainer by turning it

counterclockwise and then remove the

string head.

3. Take a new PRO-CUT I string head and

a 0.5 meter length of 2.4 mm diameter

monolament pre-cut line. Place the

middle of the line under the hook/notch

inside the spool. Feed the ends of the

line through the eyelets on the side of

the PRO-CUT I xed line head.

4. Pull the line outwards so it is tight and

even on both sides of the spool. Install

the PRO-CUT I head assembly on the

drive shaft and then secure with spool

retainer.

1

2

2

1

3

2

4

1

3

2

25

Page 28

1

1

REPLACING THE SPARK PLUG

1. Turn off the product.

2. Twist and pull the rubber protect boot of

ignition module, and then remove the old

spark plug.

3. Install the new spark plug, tighten by

turning it in a clockwise direction or one

half of a turn from finger tight.

4. Assemble back the rubber protect boot.

2

3

3

22~25 Nm

1

2

2

4

26

Page 29

1

CLEANING THE FILTER

1. Turn off the product.

2. Remove the air lter cover and the air

lter.

3. Clean the air lter with warm, soapy

water.

4. Rinse, and let the air lter dry completely.

2

1

3

2

3

1

2

4

27

Page 30

1

2

5. Put two drops of lubricant into the air

lter. Replace the air lter (ts only

one way), and then replace the air lter

cover.

NOTE: The air lter should be replaced

annually for best performance.

5

3

28

Page 31

x4

1

CLEANING THE MUFFLER

1. Turn off the product.

2. Loose the 4 screws and remove the rear

housing.

3. Remove the mufer screws

counterclockwise, and then remove the

mufer cover, mufer and gasket from

the cylinder.

4. Use the brush to clean the exhaust hole

of the cylinder and intake hole of the

mufer.

2

1

2

3

345

4

2

2

x2

1

1

29

Page 32

5. Place the gasket, mufer, mufer cover

and screws back to its position. Tighten

the screws by turning it clockwise.

6. Place the rear housing back to its

position. Tighten the screws by turning

it clockwise.

5

321

4

x2

5

6

2

x4

1

30

Page 33

HLT25SDS

1

CLEANING THE PRODUCT

1. Turn off the product, and allow it to cool

down before cleaning.

2. Clean all foreign material from the

product.

WARNING: Keep away from corrosive

agents such as garden chemicals and

deicing salts.

WARNING: The small blade fitted to the

cutting attachment guard is designed

to trim the new extended line to the

correct length for safe and optimum

performance. It is very sharp; do not

touch it, particularly when cleaning the

product.

2

3

31

Page 34

HLT25CDS

1

CLEANING THE PRODUCT

1. Turn off the product, and allow it to cool

down before cleaning.

2. Clean all foreign material from the

product.

WARNING: Keep away from corrosive

agents such as garden chemicals and

deicing salts.

WARNING: The small blade fitted to the

cutting attachment guard is designed

to trim the new extended line to the

correct length for safe and optimum

performance. It is very sharp; do not

touch it, particularly when cleaning the

product.

2

3

32

Page 35

STORING THE PRODUCT

1. Turn off the product, and allow it to cool

down before storing the product.

Make sure to clean the product

NOTE:

before storing.

2. Drain all fuel from tank into a container

approved for petrol. Remember to

properly replace and tighten the fuel cap.

3. Remove the upper shaft from the handle.

1

2

1

3

2

3

2

4

1

3

1

33

Page 36

NOTE: If a cutting blade is tted, cover

it with the blade protector.

4. Store the product in a cool, dry, and

well-ventilated place that is inaccessible

to children. Keep away from corrosive

agents such as garden chemicals and

deicing salts. Do not store outdoors.

4

20180122v1d3

34

Page 37

MAINTENANCE SCHEDULE

Every 25

hours of

operation

Check if fastener is

fully tightened

Check: Cutting

attachment must not

rotate in idle mode

Clean spark arrestor

Replace spark arrestor

Clean air lter

Change air lter

Check or adjust spark

plug

Replace spark plug

Clean fuel tank and

1

filter

Check fuel hose

Replace fuel filter

Check all hose

connections

Inspect fuel tank vapor

vent (if equipped)

Clean the exhaust port

and silencer

2

1

Before

each use

After rst

month or

20 hours of

operation

Every 3

months or

50 hours of

operation

Every 6

months or

100 hours of

operation

Every year

or after 300

hours of

operation

■

■

■

■

■

■

■

■

■

■

■

■

■

■

1 These items should only be carried out by an authorised service centre.

2 If this requirement is not met, contact an authorised service centre for repair or adjustment.

NOTES:

■ Maintenance should be performed more frequently when product is used in dusty areas.

■ When product has exceeded the maximum figures specified in the table, maintenance should still be cycled according to the intervals of

time or hours stated herein.

Page 38

TROUBLESHOOTING

Problem Possible cause Solution

Engine will not start. No spark. The spark plug may be damaged. Remove it and check for

No fuel. Push primer bulb until bulb is full of fuel. If bulb does not

Engine is ooded. ■ Turn the on/off switch to the “Stop” (OFF) position.

Starter rope is hard to pull. Contact an authorised service centre.

dirt and cracks. Replace with a new spark plug.

ll, primary fuel delivery system is blocked. Contact an

authorised service centre. If primer bulb lls, engine may

be ooded, proceed to next item.

■ Completely remove the spark plug from the engine and

spark plug boot, then turn the product so the spark plug

hole is aimed at the ground.

■ Set the choke lever to

10-15 times. This will clear excessive fuel from the

engine.

■ Remove any expelled fuel from the product.

■ Clean and reinstall the spark plug.

■ Clean up any spilled fuel and move at least 9 m away

before restarting.

■ Pull starter handle 3 times with the choke lever at

position.

■ If the engine does not start, set the choke lever to

choke position and repeat the normal starting

procedure.

■ If the engine still fails to start, repeat procedure with a

new spark plug.

position and pull starter cord

Engine starts but will not

accelerate.

Engine starts but will only

run at

high speed at half choke.

Engine does not reach full

speed and emits excessive

smoke.

Engine starts, runs, and

accelerates but will not idle.

Bump head continues to

rotate at idle speed.

Engine requires approximately

three minutes to warm up.

Lubricant fuel mixture is incorrect.

Carburetor requires adjustment.

Air lter is dirty. Clean air lter. Refer to Cleaning the Air Filter earlier in

Spark arrestor screen is dirty. Contact an authorised service centre.

Idle speed screw on carburetor

requires adjustment.

Carburetor requires adjustment.

Allow engine to completely warm up. If engine does not

accelerate after three minutes, contact an authorised

service centre.

Use fresh fuel and the correct 2-stroke lubricant mix.

Contact an authorised service centre.

this manual.

Contact an authorised service centre.

Contact an authorised service centre.

Page 39

PRODUCT SPECIFICATIONS

Grass trimmer

Model

Weight

- Without fuel, cutting

attachment and

harness

- Without fuel and

harness, with cutting

attachment

Fuel tank volume 250 cm3 or (0.25 L)

Cutting swath 457 mm 430 mm

Engine displacement 26 cm3/cc

Line diameter 2.4 mm

Maximum engine

performance (in

accordance with ISO

8893)

Rated engine

performance

Maximum rotational

frequency of the

spindle

Engine speed

(rotational frequency)

at idle

Fuel consumption (in

accordance with ISO

8893) at max. engine

performance

Specic fuel

consumption (in

accordance with ISO

8893) at max. engine

performance

Vibration (in accordance with ISO

22867)

Front handle

2

- Idling (m/s

- Racing (m/s

) 3.1 3.5

2

- Equivalent (m/s

HLT25SDS HLT25CDS

4.69 kg 4.28 kg

5.10 kg 4.73 kg

0.80 kW

0.65 kW

-

10,000 min

1

2,800-3,600 min

0.4 kg/h

0.5 kg/kW.h

)

2

15.5 5.8

) 11.2 4.8

12,000 min

-

1

Rear handle

- Idling (m/s

- Racing (m/s

- Equivalent (m/s

2

) 4.1 3.7

2

) 13.4 9.9

2

) 9.9 7.5

Uncertainty 1.5

Sound level

Sound pressure

level at the

operator's position

dB(A))

(

Bystander sound

pressure level

dB(A))

(

93.7 90.6

80.1 78.6

REPLACEMENT PARTS

Part

HLT25SDS

Spool retainer N/A 308042003

String head with

cutting line

-

1

Cutting line N/A

Grass deflector N/A

Bump feed

trimmer head

HLT25CDS

Pro Cut 1 xed

line trimmer

head

Spare cutting

line

Grass deflector N/A 308744009

Spool retainer N/A 308042002

Accessory

number

N/A 308743015

HAC121

HAC120

N/A 528721006

Part number

528721007

308743020

-

308895001

Page 40

Imported by:

Techtronic Industries Australia Pty. Ltd.

31 Gilby Road, Mount Waverly, VIC 3149,

Melbourne, Australia

Techtronic Industries N.Z. Limited

2 Landing Drive, Mangere,

Auckland, 2022 , New Zealand

960994102-01

Loading...

Loading...