[KI(o)[!^[l[LDTr[l*

INSTRUCTIONS & R\RTS UST

42” FRONT BLADE

ASSEMBLY

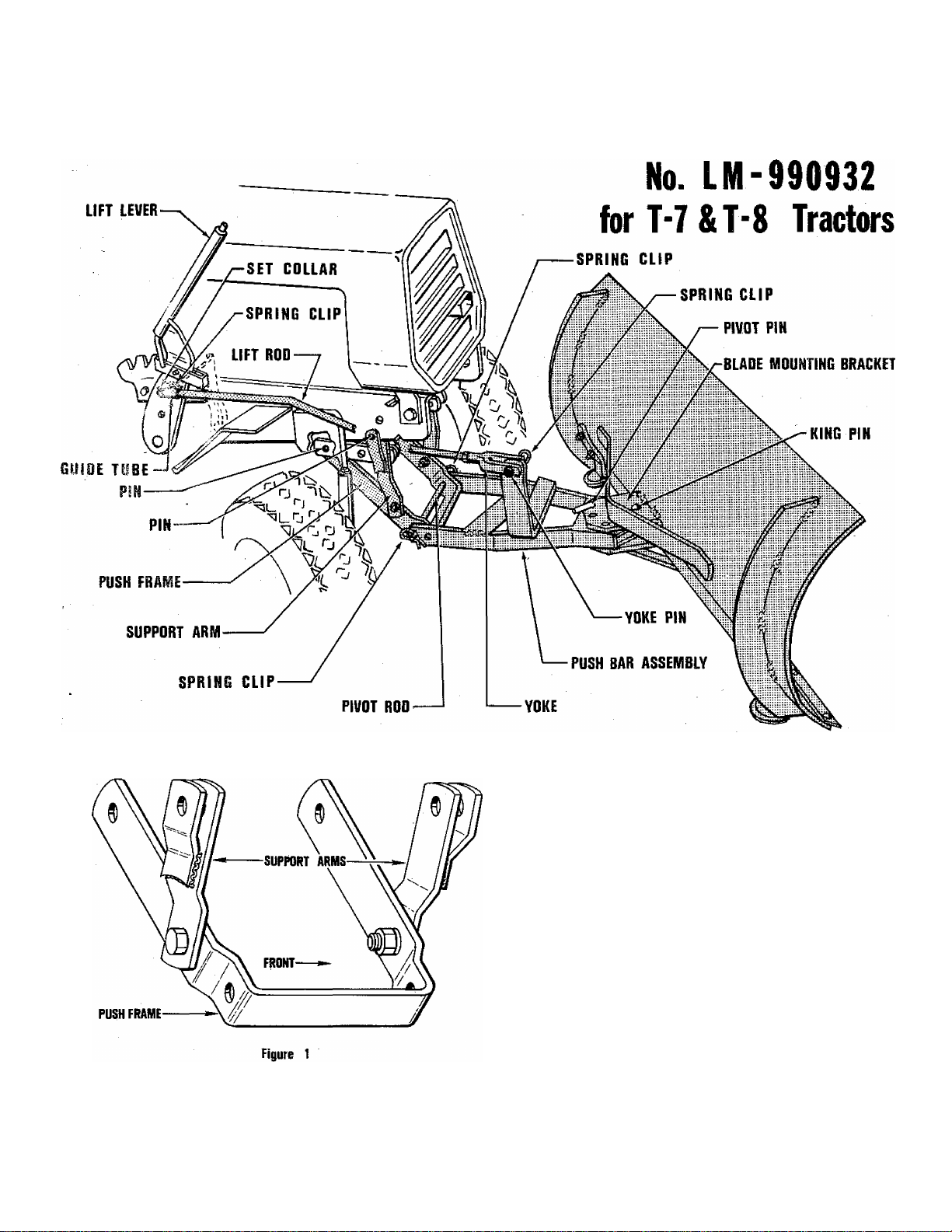

Fasten the two supportami assemblies to the push frame with

a capscrew, lockwas her and hex nut {see fig. 1). Do not tighten

completely until after the combined assemblies are installed

on the tractor.

2. Attach the push frame to the rear holes of the front mounting

brackets on the tractor with a pin and spring clip on eachside.

Mount the support arm assemblies to each side of the tractor

frame (see illustration) with a pin and spring clip on each side.

Now tighten the nuts securing the support arm assemblies to

the push frame.

3. Slide the pivot rod through the push bar assembly and the push

frame and secure with a spring clip on each end.

4. Slide the front of the push bar assembly into the mounting

bracket on the back of the 42" blade. Secure with the king pin

and spring clip in the forward hole. Place the pivot pin the

rear hole.

5. Slide the guide tube and the set collar onto the unthreaded end

of the lift rod and tighten the set collar with the set screw.

Attach a hex nut and the yoke to the threaded end of the lift rod

and connect to the upright arm on the push bar assembly with

the yoke pin and a spring clip. For ease of attachment place

the lift lever in the down position. Push pin side of guide tube

through the hole in the lift lever and secure with a spring clip.

PART NO. 24715-4

Supersedes No, 24715

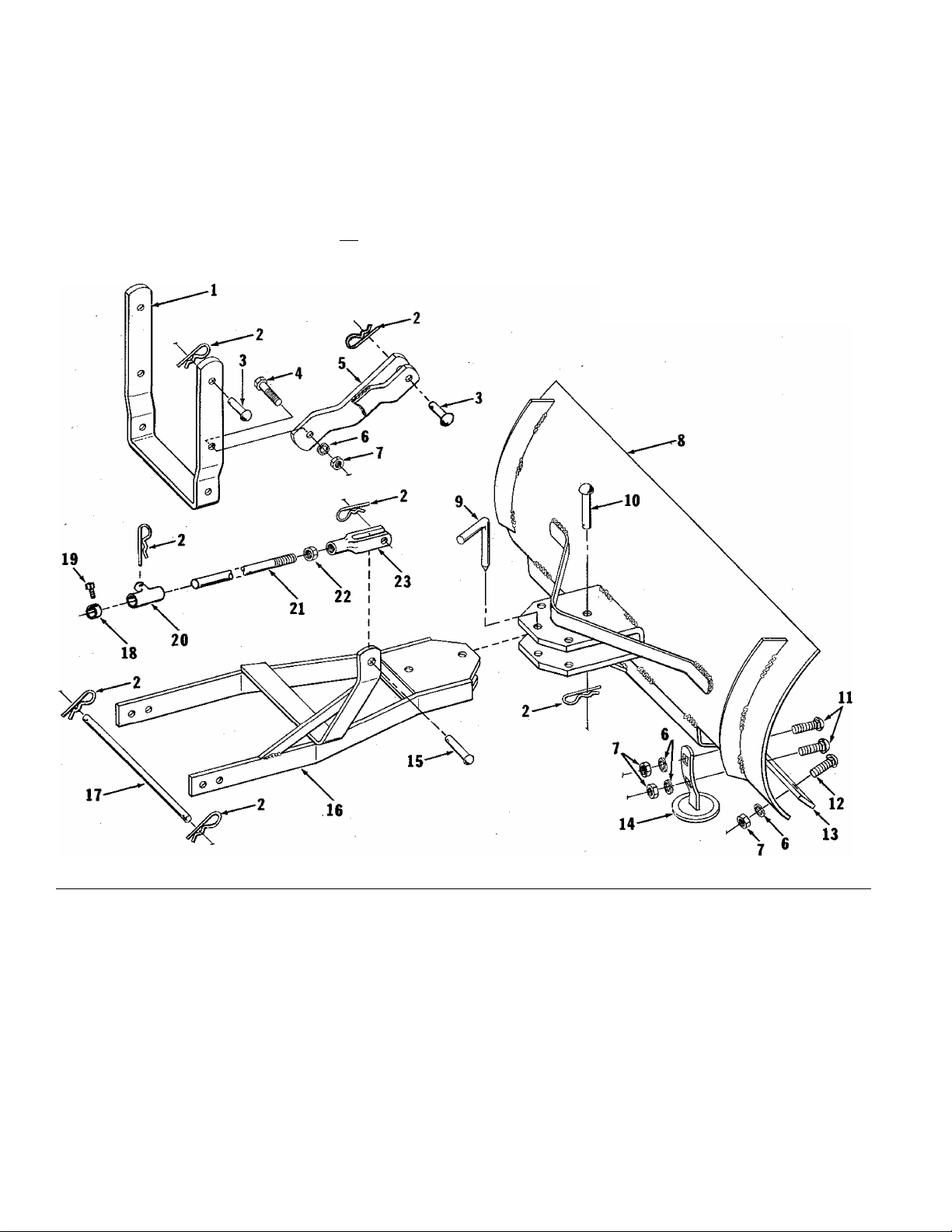

6. The shoe assemblies are to be mounted to the blade with four

(two each skid) 3/8-16 x 1 carriage bolt, lock washers and hex

nuts.

The angle of the blade is adjustable to permit plowing to either the

right or left. Remove the pivot pinandangle the blade to the desired

position. Replace the pin in the hole to secure angle of the blade.

OPERATION

Alternate holes are provided in the blade to permit adjustment of

the shoe assemblies for various types of ground surfaces to be plowed.

The blade should be raised when plowing gravel drives or walks.

Lower the blade when plowing asphalt or concrete drives and walks.

Recommended Equipment

Wheel Weights LM-09904-49

Tire Chains

T-7

T-8

Note: Loose mounting of chains will make them self cleaning.

LM-09906-93

LM-09903-01

42” FB

No.

1

2

3 PIN

4

5

6

7

8

9

10

11

12 BOLT-carriage, 3/8-16 x 3/4

13

Description

FRAME-push

CLIP-spring

SCRJEW-hex hd. cap, 3/8-16, x 1-1/4

ARM-support

WASHER-lock. 3/8

NUT-hex, 3/8-16

BLADE-42"

PIN-pivot

PIN-king

BOLT-carriage, 3/8-16 x 1

PLATE-wear

PRINTED IN U.S.A.

Part No.

LM-16 06 5-4 7

LM-81610-45 9

LM-01180-53

LM-09174-00 2

LM-16065-46 2

LM-09169-65 12

LM-09169-50 12

LM-01070-47 1

LM-16036-01

LM-16036-02 1

LM-09232-32 4

LM-07020-03 6

LM-01070-45 1

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Qty.

1 14 SHOE

4

1

No.

15

16 BAR-push

17 ROD-pivot

18

19

20

21 ROD-lift

22 NUT-hex, 1/2-20

23 YOKE-end adj.

Accessories

PAINT-blaek, 12 oz. spray can 22772

Description

PIN-yoke LM-01543-05 1

COLLAR-set

SCREW-set, 5/16-18 x 3/8

TUBE-guide

HOMELITE'

\ textronl DIVISION, PORT CHESTER, N.Y. 10573

Part No. Qty.

LM-01070-24 2

LM-16065-79 1

LM-01070-89 1

LM-83010-42 1

LM-09287-09

LM-01704-36

LM-01767-27 1

LM-09194-23

LM-01576-31 1

1

1

1

Loading...

Loading...