Page 1

TWO-STROKE PETROL LINE

TRIMMER

ORIGINAL INSTRUCTIONS

HLT25CDSNC

Important! It is essential you read the instructions in this manual before assembling,

operating, and maintaining the product.

Subject to technical modications.

Page 2

2

■ Dangerous Environments. To avoid falling, do not

use the product in damp or wet locations.

■ Controlling the Product. During carburetor

adjustments, the cutting attachment may spin.

Therefore, you should wear protective equipment

and observe all safety instructions when adjusting

the carburetor. For products equipped with a clutch,

be sure the cutting attachment stops turning when the

engine idles. When the product is turned off, make

sure the cutting attachment has stopped before setting

down the product.

■ Use the Right Product. Use the product for the

intended purpose only.

■ Save these instructions. Refer to them frequently

and use them to instruct others who may use the

product. If you loan someone the product, loan them

these instructions also.

GENERAL SAFETY WARNINGS

WARNING

Read and understand all instructions. Failure to follow

all instructions may result in serious personal injury as

well as damage to the product.

■ Physical Condition of the Operator. Do not operate

the product when tired, ill or under the inuence of

alcohol, drugs or medication.

■ Clothing Requirements. Always wear long, heavy

pants, boots and gloves. Do not wear loose clothing,

jewellery, short pants, sandals or go barefoot.

Secure hair so that it is above shoulder level to avoid

entanglement in moving parts.

■ Protective Accessories Requirements. Wear eye

and hearing protection when operating the product.

Before use, inspect the condition of the trimmer.

Replace damaged parts. Check for fuel leaks. Make

sure all fasteners are in place and secure. Replace

cutting attachment parts that are cracked, chipped or

damaged in any way. Make sure the cutting attachment

is properly installed and securely fastened. Be sure

the cutting attachment shield is properly attached and

in the position recommended by the manufacturer.

Use only exible, non-metallic line recommended by

the manufacturer. For example, never use wire or wire

rope, which can break off and become a dangerous

projectile.

■ Proper Stance. Keep firm footing and balance. Do

not overreach. Keep the cutting attachment below

waist level. Keep all parts of your body away from the

rotating cutting attachment and hot surfaces.

■ Exhaust Gases. Never start or run the product inside

a closed room or building. Breathing exhaust fumes

can cause illness or death.

■ Fueling. Mix and pour fuel outdoors where there are

no sparks and ames. Slowly remove the fuel cap only

after stopping the engine. Do not smoke while fueling

or mixing fuel. Wipe spilled fuel from the product.

Move at least 30 ft. (9 m) away from the fueling source

and site before starting the engine.

■ Work Area. Clear the work area to be cut before each

use. Remove all objects, such as rocks, broken glass,

nails, wire, or string, that can be thrown or become

entangled in the cutting attachment. Clear the area

from children, bystanders and pets. At a minimum,

keep all children, bystanders, and pets outside a 50

ft. (15 m) radius. Because there still may be a risk of

injury to bystanders from thrown objects, bystanders

should be encouraged to wear eye protection. If you

are approached while operating the product, stop the

engine and the cutting attachment.

Page 3

3

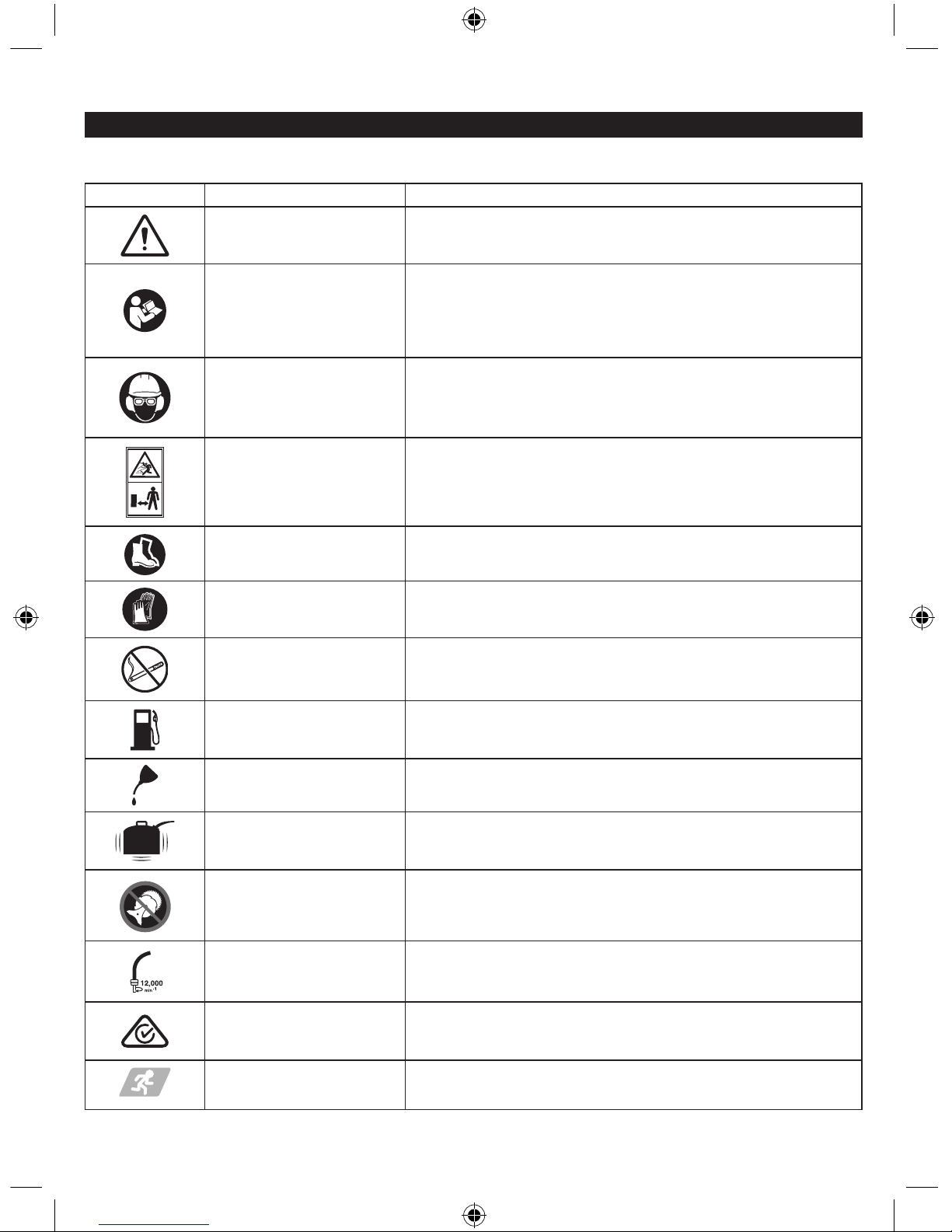

SYMBOLS

Important: Some of the following symbols may be used on the product. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME EXPLANATION

Safety alert

Indicates danger, warning or caution. It means attention. Your safety

is involved.

Read your operator’s

manual

Your manual contains special messages to bring attention to potential

safety concerns as well as operating and servicing information.

Please read all the information carefully to ensure satisfaction and

safe use.

Wear eye, hearing and

head protection

Wear eye, hearing and head protection when operating the product.

Beware of thrown or ying objects. Keep all bystanders (especially

children and pets) at least 15 m away from the work area.

Boots Wear non-slip safety footwear when using the product.

Gloves Wear non-slip, heavy-duty gloves.

No smoking Do not smoke when mixing the fuel or lling the fuel tank.

Petrol

Use regular unleaded petrol intended for motor vehicle use with an

octane rating of 91 ([R+M]/2) or higher. E10 is not recommended.

Oil Use synthetic 2-stroke oil for 2-stroke engines.

Mix petrol and oil Mix the fuel mix thoroughly and also each time before refueling.

No blade Do not install any type of blade on the product.

RPM Decal

Rotational direction and maximum speed of the shaft for the cutting

attachment.

Regulatory Compliance Mark (RCM). The product meets applicable

regulatory requirements.

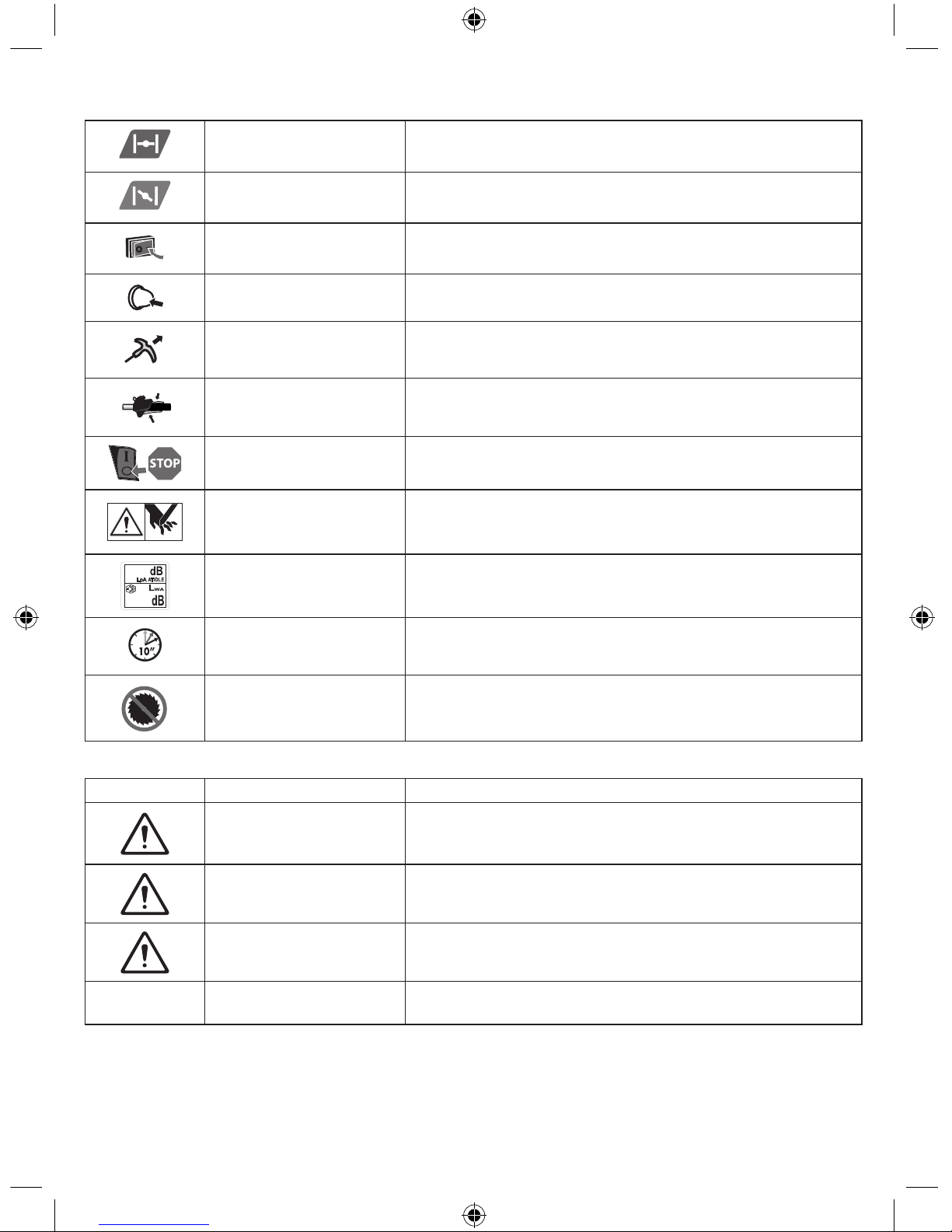

Set the choke lever to “Run” position (no choke).

Page 4

4

Set the choke lever to “Full” position (choke on).

Set the choke lever to “Half” position.

Place the engine switch to the “I” (On) position.

PRIME - Press the primer bulb 10 times slowly.

Pull the starter rope to start.

Squeeze the throttle trigger to start / run.

To stop the product, place the engine switch to the "O" (Off) position.

Blade hazard Warning! Risk of getting cut. Operate carefully.

11186111

86

Guaranteed sound pressure level and sound power level.

Wait for 10 seconds.

Do not use toothed blade.

The following signal words and meanings are intended to explain the levels of risk associated with the product.

SYMBOL SIGNAL MEANING

DANGER:

Indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

CAUTION:

(Without Safety Alert Symbol) Indicates a situation that may result

in property damage.

Page 5

5

2. Upper shaft

3. Guide recess

4. Button

5. Knob

6. Lower shaft

7. PRO-CUT I - Fixed line head

8. Grass shield

9. Cutting line

15. Lock out lever

16. On/Off switch

17. Throttle trigger

18. Primer bulb

19. Starter grip

Figure 2

1. Front handle

2. Upper shaft

10. Wing nut

11. Bolt

Figure 3

8. Grass shield

12. Bolt

13. Flat washer

14. Wing nut

Figure 4a – 4b

20. Full choke position (choke on)

21. Half choke position

22. Run position (no choke)

Figure 7

23. Latch

24. Air lter element

25. Air box cover

Figure 9

26. Spark plug boot

27. Spark plug

ASSEMBLY

UNPACKING

The product requires assembly.

■ Carefully remove the product and any accessories

from the box. Make sure that all items listed in the

packing list are included.

■ Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

SPECIFICATIONS

Weight without fuel

and trimmer head

4.50 kg

Weight without fuel

with trimmer head

4.72 kg

Fuel tank volume 250 ml

Cutting swath 432 mm

Diameter of cutting line 2.4 mm

Engine displacement 26 cc

Maximum engine performance

(in accordance with ISO 8893)

0.65 kW

Maximum rotational frequency of

the spindle

12000 min

-1

Engine speed (rotational

frequency) at idle

2800-3800 min

-1

Fuel consumption (in accordance

with ISO 8893) at max. engine

performance

0.37 kg/h

Specific fuel consumption (in

accordance with ISO 8893) at

max. engine performance

0.57 kg/kw.h

Vibration level - Idling

Front handle 3.3 m/s

2

Rear handle 3.4 m/s

2

Vibration level - Racing

Front handle 9.2 m/s

2

Rear handle 8.3 m/s

2

Measured sound pressure level (in accordance with

EN ISO22868)

Idle

82.7 dB(A)

KpA=3 dB(A)

Racing

103.1 dB(A)

KpA=3 dB(A)

Measured sound power level (in accordance with EN

ISO22868)

Idle

90.0 dB(A)

KWA=3 dB(A)

Racing

107.9 dB(A)

KWA=3 dB(A)

DESCRIPTION

Figure 1

1. Front handle

Page 6

6

shaft (item 2).

■ Loosen the knob (item 5) by turning it counter

clockwise.

■ Align the button (item 4) on the lower shaft ( item 6 )

with the guide recess (item 3) on the upper shaft.

■ Slide the lower shaft into the upper shaft until the

Lower shaft clicks into place.

■ Tighten the knob securely by turning it clockwise.

WARNING

Improper assembly could result in serious personal

injury.

REMOVING THE LOWER SHAFT FROM THE UPPER

SHAFT.

Follow these steps to remove the lower shaft from the

upper shaft.

■ Loosen the knob by turning it counterclockwise.

■ Push the button while pulling out the Lower shaft.

ATTACHING THE FRONT HANDLE

See gure 2.

■ Loosen and remove the bolt (item 11) and wing nut

(item 10) from the upper handle (item 1).

■ Install the front handle onto the upper shaft (item 2) at

the position between foam and warning label.

■ Replace the bolt and wing nut. Tighten the wing nut

securely.

SAFETY GUARD

See gure 3.

■ Remove wing nut (item 14), flat washer (item 13) and

bolt (item 12) from the owner's kit.

■ Place safety guard (item 8) over shaft and bracket.

■ Install bolt through the slots in the tabs on safety guard

and bracket on driveshaft housing.

■ Install flat washer and wing nut.

■ Tighten securely.

ATTACHING THE PRO-CUT I HEAD

■ Remove the paper tube

■ Install PRO-CUT I head assembly on drive shaft.

Secure with spool retainer.

OPERATION

FUEL AND REFUELING

Handling the fuel safely

Always handle fuel with care, it is highly flammable.

■ Always refuel outdoors where there are no sparks and

flames. Do not inhale fuel vapors.

■ Do not let petrol or oil come in contact with your skin.

■ Keep petrol and oil away from the eyes. If petrol

or oil comes in contact with the eyes, wash them

■ Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

PACKING LIST

1. Trimmer (1 unit)

2. Lower shaft assembly (1 pc)

3. Front handle assembly (1 pc)

4. Safety guard assembly (1 pc)

5. PRO-CUT I head and cutting head assembly (1 pc)

6. Combination wrench (1 pc)

7. 2-Stroke Lubricant (1 bottle)

8. Operation manual (1 pc)

WARNING

If any parts are damaged or missing, do not operate the

product until the parts are replaced. Failure to heed this

warning could result in serious personal injury.

WARNING

Do not attempt to modify the product or create

accessories not recommended for use with the product.

Any such alteration or modication is misuse and could

result in a hazardous condition leading to possible

serious personal injury.

WARNING

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark

plug wire from the spark plug when assembling parts.

WARNING

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark

plug wire from the spark plug when assembling parts.

WARNING

Never attach or adjust any attachment while power

head is running. Failure to stop the engine may cause

serious personal injury.

WARNING

Be certain the knob is fully tightened before operating

the product. Check it periodically for tightness during

use to avoid serious injury.

ATTACHING THE POWER HEAD TO THE TRIMMER

ATTACHMENT

See gure 1.

Follow these steps to connect the lower shaft to the upper

Page 7

7

immediately with clean water. If irritation is still present,

see a doctor immediately.

■ Clean up spilled petrol immediately.

Mixing the fuel

■ The product is powered by a 2-stroke engine and

requires pre-mixing petrol and 2-stroke oil. Store premix unleaded petrol and 2-stroke engine oil in a clean

container approved for petrol.

■ The engine is certified to operate on unleaded petrol

intended for automotive use with an octane rating of

91 ([R + M] / 2) or higher.

■ Do not use any type of pre-mixed petrol / oil from fuel

service stations, this includes the pre-mixed petrol / oil

intended for use in mopeds, motorcycles, etc.

■ Use synthetic 2-stroke oil only. Do not use automotive

oil or 2-stroke outboard oil.

■ Mix 2% synthetic 2-stroke oil into the petrol. This is a

50:1 ratio.

■ Mix the fuel thoroughly and also each time before

fuelling.

■ Mix in small quantities. Do not mix quantities larger

than usable in a 30 day period. Synthetic 2-stroke oil

containing a fuel stabilizer is recommended.

Filling the tank

■ Clean surface around fuel cap to prevent

contamination.

■ Loosen fuel cap slowly to release pressure and to

keep fuel from escaping around the cap.

■ Carefully pour fuel mixture into the tank. Avoid spillage.

■ Prior to replacing the fuel cap, clean and inspect the

gasket.

■ Immediately replace fuel cap and hand tighten. Wipe

up any fuel spillage. Move 9 m away from refueling site

before starting engine.

NOTE: It is normal for smoke to be emitted from a new

engine during and after rst use.

WARNING

Always shut off engine before fueling. Never add fuel to

a machine with a running or hot engine. Move at least

9 m from refueling site before starting engine. Do not

smoke!

50:1 Petrol to Oil Mixing Chart

1 Litre + 20 ml = 50:1 (2%)

2 Litres + 40 ml = 50:1 (2%)

3 Litres + 60 ml = 50:1 (2%)

4 Litres + 80 ml = 50:1 (2%)

5 Litres + 100 ml = 50:1 (2%)

WARNING

The product may throw objects during operation,

causing injury to the operator or to bystanders. Always

wear suitable eye protection, heavy, long pants and

boots while operating the product.

STARTING THE PRODUCT

See gures 4a - 4b.

Starting the product differs depending on whether the

engine is cold (not yet started today) or warm (has been

running in the last hour). Always refer to the Starting

Instructions label on the air lter when starting the engine.

Refer below for full instructions.

To start a cold engine:

Follow these steps to start a cold engine.

NOTE: Lay the product on a flat, bare surface.

1. Ensure the engine switch is in the "I" (ON) position.

2. Press the primer bulb approximately 10 times.

3. Set the choke lever to Full choke (choke on) position

.

4. Hold down the throttle lock out button and squeeze

and hold in the throttle trigger. Holding in the trigger

is “wide open throttle” (WOT). With wide open throttle,

pull the starter grip with a quick, rm and consistent

upward motion (No more than 4 pulls).

NOTE: The engine may start after these 4 pulls.

Proceed following steps if it starts. The engine may be

flooded if you continue to pull the starter grip.

5. Set the choke lever to Half choke position .

6. Hold down the throttle lock out button and squeeze

and hold in the throttle trigger (WOT). With wide open

throttle, pull the starter grip with a quick, rm and

consistent upward motion until the engine starts (No

more than 6 pulls).

NOTE: If engine does not start (after 6 pulls with the

choke lever in the Half position), return to step 3 and

repeat the steps.

7. Run the engine with Half choke for 10 seconds.

8. Set the choke lever to the Run position .

NOTE: With choke lever in the Run position, allow

engine to idle for up to 30 seconds prior to operation.

This will allow the engine to warm up. A warm engine

will perform better than a cold engine.

To start a warm engine:

Follow these steps to start a warm engine.

NOTE: Lay the product on a flat, bare surface.

1. Ensure the engine switch is in the "I" (ON) position.

Page 8

8

2. Press the primer bulb approximately 10 times.

3. Ensure the choke lever is set to Run position .

4. Hold down the throttle lock out button and squeeze

and hold in the throttle trigger. Holding in the trigger

is “wide open throttle” (WOT). With wide open throttle,

pull the starter grip with a quick, rm and consistent

upward motion until the engine starts (No more than

6 pulls).

NOTE: If engine does not start (after 6 pulls with the

choke lever in the Run position), return to step 3 under

"TO START A COLD ENGINE" instructions, and repeat

the steps.

5. With choke lever in the Run position , run the

engine with wide open throttle for 10 seconds prior to

operation.

STOPPING THE PRODUCT

See gure 4c.

■ Release the throttle trigger.

■ Hold down the engine switch to the "O" (OFF) position.

OPERATING THE TRIMMER

See gure 5.

Follow these steps to operate the curved shaft trimmer.

■ Start the trimmer.

■ Hold the trimmer at waist level with your right hand

on the trigger handle and your left hand on the front

handle.

■ Place the product on the right side of your body with

the engine behind and away from your body.

■ Trim grass and weeds with the line parallel to the

ground.

WARNING

Injuries may be caused, or aggravated, by prolonged

use of a tool. When using any tool prolonged periods,

ensure you take regular breaks.

ALWAYS OPERATE TRIMMER AT FULL THROTTLE.

Cut tall grass from the top down. This will prevent grass

from wrapping around the shaft ho

using and PRO-CUT I head, which may cause damage

from overheating. If grass becomes wrapped around the

PRO-CUT I head, stop the engine, disconnect the spark

plug wire, and remove the grass. Prolonged cutting at

partial throttle will result in oil dripping from the silencer.

MAINTENANCE

WARNING

When servicing, use only original manufacturer's

replacement parts. Use of any other parts may create a

hazard or cause product damage.

WARNING

Always wear safety goggles or safety glasses with side

shields during product operation. If operation is dusty,

also wear a dust mask.

WARNING

Before inspecting, cleaning, or servicing the machine,

shut off engine, wait for all moving parts to stop, and

disconnect spark plug lead and move it away from

spark plug. Failure to follow these instructions can

result in serious personal injury or property damage.

WARNING

Neglected or poorly conducted maintenance may

create additional hazards. Do not attempt to repair or

maintain this product if you are not qualied to do so.

If in doubt, return to a service centre for professional

assistance.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, lubricant, grease.

WARNING

Do not at any time let brake uids, petrol, petroleum-

based products, penetrating lubricants, etc., come

in contact with plastic parts. Chemicals can damage,

weaken, or destroy plastic, which may result in serious

personal injury.

You can often make adjustments and repairs described in

this manual. For other repairs, have the trimmer serviced

by a service dealer.

LINE REPLACEMENT

See gure 6.

1. Take one 500 mm length of 2.4 mm diameter

monolament pre-cut line.

2. Place the middle of the line under the hook/notch

inside the spool.

3. Feed the ends of the line through the eyelets on the

side of the PRO-CUT I xed line head.

4. Pull the line outwards so it is tight and even on both

sides of the spool.

CLEANING THE AIR FILTER

See gure 7.

A dirty air lter will cause starting difculty, loss of

performance, and shorten the life span of the engine.

Check the air lter monthly. For best performance, replace

the air lter at least once a year.

2017728v2

Page 9

9

■ Remove the air filter cover (item 25) by pushing down

on the latch (item 23) with your thumb while gently

pulling on the cover.

■ Remove the air filter (item 24).

■ Clean the foam filter element with warm soapy water.

Rinse and let dry.

NOTE: If the foam filter element is damaged, it should

be replaced.

■ Apply a light coat of engine oil to the foam filter

element, then squeeze it out.

■ Reinstall the air filter.

NOTE: Make sure the filter is seated properly inside

the cover. Installing the filter incorrectly will allow dirt to

enter the engine, causing rapid engine wear.

■ Replace the air filter cover by inserting the slot at the

bottom of the air box cover into the latch at the bottom

of the air box base. Push the air box cover up until it

latches securely in place.

WARNING

Make sure the trimmer head stops rotating when you

release the trigger. Contact with a rotating trimmer head

could cause personal injury.

CHECKING THE FUEL CAP

WARNING

A leaking fuel cap is a re hazard and must be replaced

immediately.

The fuel cap contains a non-serviceable lter and

check valve. A clogged fuel lter causes poor engine

performance. If performance improves when the fuel cap

is loosened, the check valve may be faulty or the lter may

be clogged. Replace the fuel cap if necessary.

SPARK ARRESTOR

See gure 8.

Homelite line trimmer (HLT25CDSNC) is tted with a

spark arrestor, please note it is suggested that the spark

arrester should only be cleaned by a recognized service

agent.

REPLACING THE SPARK PLUG

See gure 9.

This engine uses a Champion RCJ6Y or NGK BPMR7A

spark plug. Use an exact replacement and replace

annually.

Follow these steps to replace the spark plug.

■ Remove the spark plug boot (item 26).

■ Loosen the spark plug (item 27) by turning it

counterclockwise with a 16 mm socket.

■ Remove the spark plug.

■ Hand thread the new spark plug, turning it clockwise.

■ Tighten with a socket. Do not overtighten.

CAUTION

Be careful not to cross-thread the spark plug. Cross-

threading will seriously damage the engine.

STORING THE PRODUCT

Storing the product differs depending on the amount of

time it will be in storage.

Follow these steps for short term product storage.

■ Clean all foreign material from the product.

■ Store the product in a well-ventilated place that is

inaccessible to children.

If you do not intend to use the product for more than one

month, follow the storage procedures below.

■ Drain all fuel from the tank into a container approved

for petrol.

■ Run the engine until it stops.

■ Clean all foreign material from the product.

■ Store the product in a well-ventilated place that is

inaccessible to children.

NOTE: Keep the product away from corrosive agents

such as garden chemicals.

Important: Abide by all local and government

regulations for the safe storage and handling of petrol.

2017728v2

Page 10

10

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start.

1. Switch set to the O (OFF) position. 1. Set switch to the I (ON) position.

2. No spark.

2. Remove the spark plug. Reattach the spark plug

cap and lay the spark plug on the metal cylinder.

Pull the starter cord and watch for a spark at the

spark plug tip. If there is no spark, repeat the test

with a new spark plug.

3. No fuel. 3. Push primer bulb until the bulb is full of fuel. If the

bulb does not ll, the primary fuel delivery system

is blocked. If the primer bulb lls, the engine may

be ooded. (See next item.)

4. Flooded engine.

4. Turn On/Off switch to "On" position. Turn choke

lever to "Off" position by pushing the choke lever

to the "Run" position. Squeeze and hold in the

throttle trigger (wide open throttle). Pull the starter

rope at least 20 times or until the engine res and

runs.

5. Starter cord is hard to pull.

5. Contact an authorised service dealer.

Engine does not reach full speed and

emits excessive smoke.

1. Check oil fuel mixture. 1. Use fresh fuel and the correct 2-stroke oil mix.

2. Air filter is dirty.

2. Clean the air filter according to the instructions in

the Maintenance section.

3. Spark arrestor screen is dirty. 3. Contact an authorised service dealer.

Grass wraps around the trimmer

head assembly and the attachment

shaft.

1. Cutting tall grass at ground level. 1. Cut tall grass from the top down.

2. Operating the product at part

throttle.

2. Operate the product at full throttle.

Oil drips from muffler.

1. Operating the product at part

throttle.

1. Operate the product at full throttle.

2. Fuel mixture is incorrect. 2. Use fresh fuel and the correct 2-stroke oil mix.

3. Air filter is dirty.

3. Clean the air filter according to the instructions in

the Maintenance section.

Page 11

Page 12

Techtronic Industries Australia Pty. Ltd.

31 Gilby Road, Mount Waverley, VIC 3149

Melbourne, Australia

Techtronic Industries N.Z. Limited

2 Landing Drive, Mangere

Auckland, 2022, New Zealand

961481016-02

Loading...

Loading...