Page 1

INSTALLATION &

OPERATION MANUAL

V SERIES HEAVY DUTY SECTIONAL GAS RANGE

WITH STANDARD OVEN OR SNORKEL® CONVECTION OVEN

MODELS

V36 Standard Oven W/ Standing Pilot ML-44905Z

V36 Standard Oven W/ Spark Ignition ML-44906Z

V36 Convection Oven ML-44907Z

MODEL V3HT36

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 31165 (Jan. 2001) www.vulcanhart.com

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION OR MODIFICATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

© VULCAN-HART COMPANY, 2001

— 2 —

Page 3

TABLE OF CONTENTS

CONFIGURATIONS OF MODEL V SERIES HEAVY DUTY RANGES ............................................ 4

GENERAL ............................................................................................................................................ 8

INSTALLATION.................................................................................................................................... 8

Unpacking................................................................................................................................. 8

Location .................................................................................................................................... 9

Installation Codes and Standards ........................................................................................... 9

Ranges Mounted on Casters................................................................................................. 10

Leveling .................................................................................................................................. 10

Connection of Manifolds in Battery ....................................................................................... 11

Installing Overlapping Griddle Top ....................................................................................... 12

Gas Connections.................................................................................................................... 12

Testing the Gas Supply System ............................................................................................ 12

Flue Connections ................................................................................................................... 13

Electrical Connections ........................................................................................................... 13

Lighting and Shutting Down Pilots ........................................................................................ 13

OPERATION ...................................................................................................................................... 15

Before First Use ..................................................................................................................... 15

Controls .................................................................................................................................. 15

Operating Suggestions .......................................................................................................... 15

A Guide for Cooking Times and Temperatures.................................................................... 17

Cleaning.................................................................................................................................. 19

MAINTENANCE ................................................................................................................................. 22

Pilot Lights .............................................................................................................................. 22

Lubrication .............................................................................................................................. 22

Gas Odor ................................................................................................................................22

Flue ......................................................................................................................................... 22

Service Frequency ................................................................................................................. 22

Service and Parts Information ............................................................................................... 22

TROUBLESHOOTING ....................................................................................................................... 23

Oven........................................................................................................................................ 23

Top Burner Operation ............................................................................................................ 24

— 3 —

Page 4

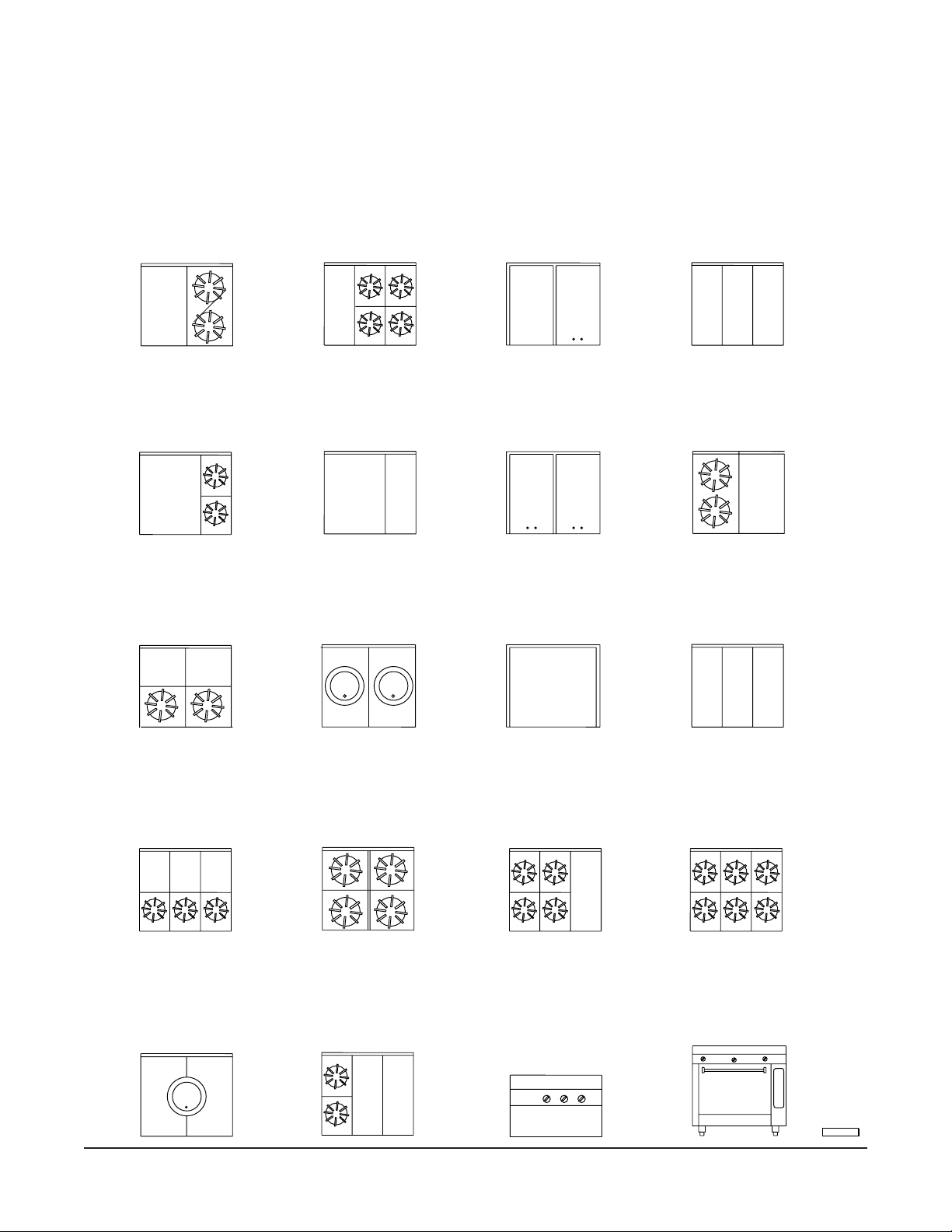

V436

V436C

V436M

V436S

V41H36

12"

HT

12"HT 12"HT 12"

HT

V41H36C

V41H36M

V41H36S

V2G236

V2G236C

V2G236M

V2G236S

V2G1H36

V2G1H36C

V2G1H36M

V2G1H36S

24"

G

18"HT 18"

HT

12"

HT

12"

HT

12"

HT

24"

G

V2H36

V2H36C

V2H36M

V2H36S

V21H36

V21H36C

V21H36M

V21H36S

V636

V636C

V636M

V636S

V3036

"V" SERIES

MODULAR RANGE

"V" SERIES

FULL BODY

36" WIDE

V3036C

V3036M

V3036S

V1G236

V1G236C

V1G236M

V1G236S

V1G436

V1G436C

V1G436M

V1G436S

18"

G

18"G 18"

HT

12"

G

V1G1H36

V1G1H36C

V1G1H36M

V1G1H36S

V1G2H36

V1G2H36C

V1G2H36M

V1G2H36S

12"G 12"HT 12"

HT

V3H36

V3H36C

V3H36M

V3H36S

12"HT 12"HT 12"

HT

18"

HT

18"

18"

V2HT36

V2HT36C

V2HT36M

V2HT36S

V23036

V23036C

V23036M

V23036S

G

36"

18"HT 18"

HT

V3G36

V3G36C

V3G36M

V3G36S

V3HT 36

V3HT36C

V3HT36M

V3HT36S

V22H36

V22H36C

V22H36M

V22H36S

CONFIGURATIONS OF MODEL "V" SERIES HEAVY DUTY

RANGES WITH STANDARD AND CONVECTION OVENS

AND MODULAR RANGES.

PL-53598

— 4 —

Page 5

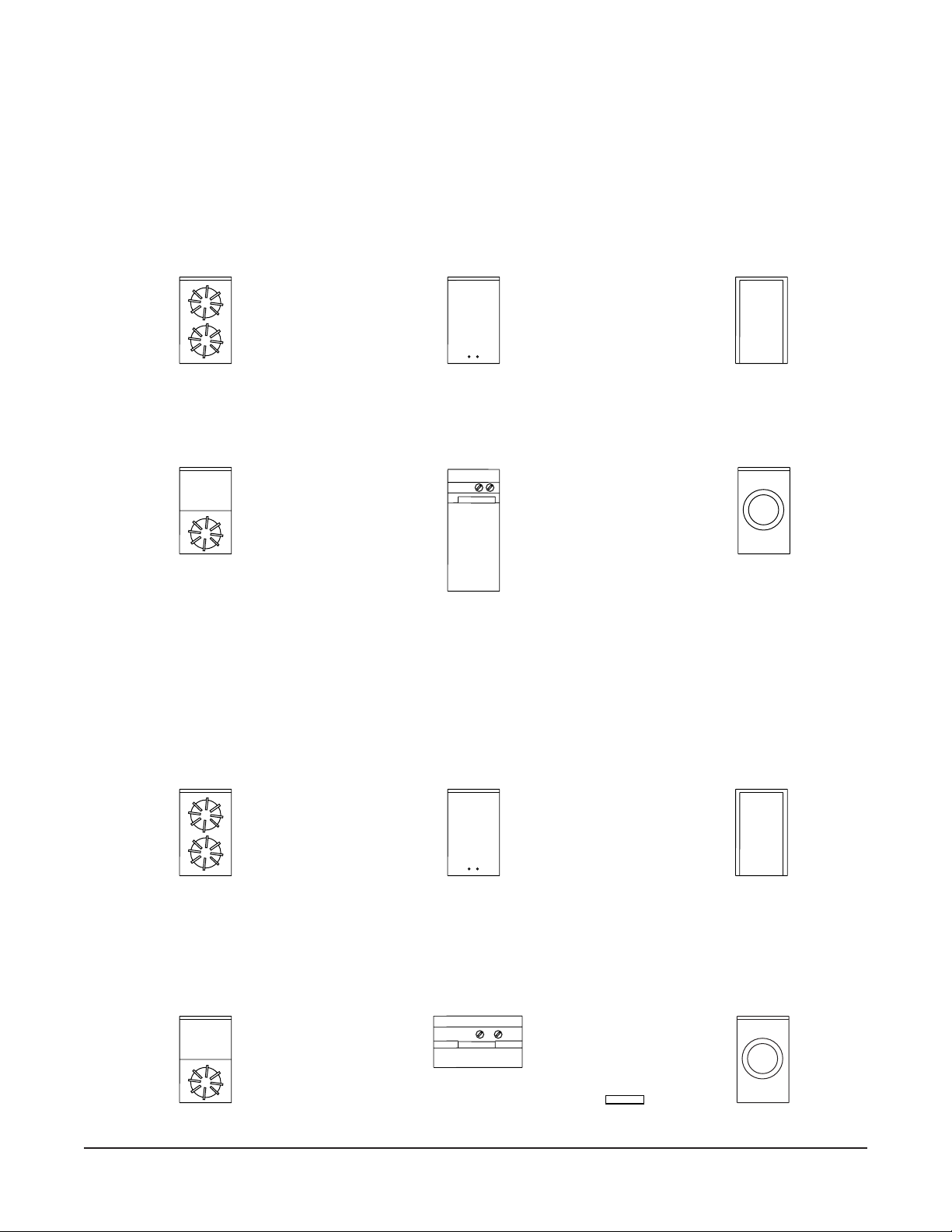

CONFIGURATIONS OF MODEL "V" SERIES

12" & 18" HEAVY DUTY EXPANDO & MODULAR RANGES

MODEL "V" SERIES EXPANDO RANGES WITH CABINETS

V212S

V218S

V1HT12S

V1HT18S

HT

V1H12S

V1H18S

HT

"V" SERIES 18" WIDE

FULL BODY WITH

CABINET

V1G12S

V1G18S

G

V13018S

V212M

V218M

V1HT12M

V1HT18M

HT

MODEL "V" SERIES MODULAR EXPANDO RANGES

V1H12M

V1H18M

HT

18" WIDE

MODULAR RANGE

PL-53599

V1G12M

V1G18M

G

V13018M

— 5 —

Page 6

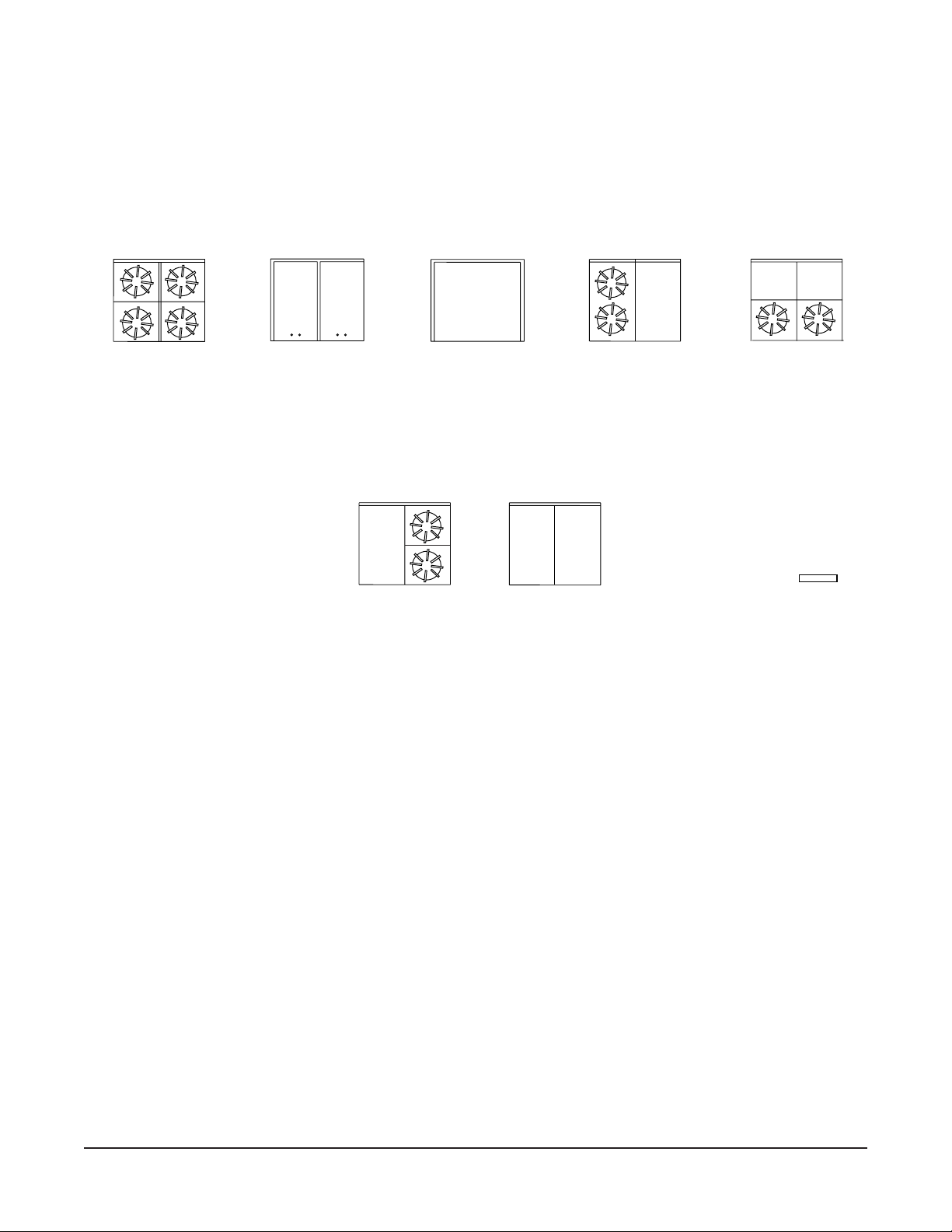

CONFIGURATIONS OF MODEL "V" SERIES 24" HEAVY DUTY

EXPANDO AND MODULAR RANGES

V424S

V424M

V2H24

V2H24M

12"HT 12"

HT

V1G224S

V1G224M

12"

G

V1G24S

V1G24M

G

V1G1H4S

V1G1H4M

12"G 12"

HT

V21H24S

V21H24M

12"

HT

V2HT24S

V2HT24M

12"HT 12"

HT

PL-53600

— 6 —

Page 7

CONFIGURATIONS OF "V" SERIES HEAVY DUTY OVENS

VO36

SINGLE

OVEN

WORK TOP VIEW

VO36C

SINGLE

CONVECTION

OVEN

OVEN

ON MODULAR

STAND

VO236

DOUBLE

STACKED

OVEN

PL-53601

— 7 —

Page 8

Installation, Operation and Care Of

MODEL V SERIES HEAVY DUTY SECTIONAL GAS

RANGES WITH STANDARD OVEN OR SNORKEL

®

CONVECTION OVEN

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

Vulcan ranges and ovens are produced with quality workmanship and material. Proper installation,

usage and maintenance of your range will result in many years of satisfactory performance.

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNPACKING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the range is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Carefully unpack range(s) and place in the approximate installation position, whether as a battery or

single stand-alone range.

Remove parts (packed in a cardboard box) from oven cavity, or cabinet body, or on top of modular

range(s).

Remove wire or nut from rear of each burner before installing the range.

Before installing, check the electrical service (Convection Oven Models only) and type of gas supply

(natural or propane) to make sure they agree with the specifications on the rating plate located on the

inside of the burner box lower panel. The rating plate will show the voltage, phase, cycle, full load

ampere, BTU, as well as the type of gas. If the supply and equipment requirements do not agree, do

not proceed with the installation. Contact your dealer or Vulcan-Hart Company immediately.

— 8 —

Page 9

LOCATION

CAUTION: The equipment area must be kept free and clear of combustible substances.

The minimum installation clearances from combustible and noncombustible construction for ranges

using inputs of 30,000 Btu/Hr per open top burner are:

Combustible Noncombustible

Sides 20" (51 cm) 0"

Rear 2" (5 cm) 0"

The minimum installation clearances from combustible and noncombustible construction for ranges

using inputs of 20,000 Btu/Hr per open top burner are:

Combustible Noncombustible

Sides 6" (15 cm) 0"

Rear 2" (5 cm) 0"

The ranges are suitable for installation on combustible floors when 6" (15 cm) adustable legs are used.

When legs are removed, use only on noncombustible floors, curb, or platform, with front appliance

projecting 3" (8 cm) beyond curb or platform.

Ranges with Snorkle ovens should be installed on 6" (15 cm) legs or casters, allowing 6" (15 cm)

clearance from the rear of the range. If ranges with Snorkle ovens are installed directly on curbs,

without legs, or in back-to-back installations, provisions must be made for adequate air circulation,

and these provisions must be approved by Vulcan-Hart Company Service Department. Contact

Vulcan-Hart Company at the address or phone number shown on the front cover of this manual.

All modular ranges are to be installed only on non-combustible floors.

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 35" (88 cm) is required.

The range(s) must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber(s) must be provided. Make sure

there is an adequate supply of air in the room to allow for combustion of the gas at the burners.

INSTALLATION CODES AND STANDARDS

Your Vulcan range(s) must be installed in accordance with:

In the United States:

1. State and local codes.

2. National Fuel Gas Code, ANSI/Z223.1 (latest edition), available from American Gas Association,

Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code ANSI/NFPA-70 (latest edition). Copies available from The National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

— 9 —

Page 10

In Canada:

1. Local codes.

2. CAN/CGA-B149.1 Natural Gas Installation Code (latest edition).

3. CAN/CGA-B149.2 Propane Installation Code (latest edition), available from The Canadian Gas

Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

4. Canadian Electrical Code, CSA C22.2 No. 3 (latest edition). Copies may be obtained from The

Canadian Standard Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

RANGES MOUNTED ON CASTERS

When ranges are mounted on casters, you must use a connector (available from Vulcan-Hart) that

complies with the Standard for Connectors of Movable Gas Appliances, ANSI-Z21.69 (latest edition),

and a quick-disconnect device that complies with the Standard for Quick-Disconnect Devices

Complying With Gas Fuel, ANSI-Z21.41 (latest edition) or CAN 1-6.9 (latest edition).

Provide a gas line strain relief to limit movement of the range(s) without depending on the connector

and/or any quick-disconnect device or its associated piping to limit movement of the range(s). Attach

the strain relief to the rear of the range (Fig. 1).

Should it be necessary to disconnect the strain relief, turn off the gas supply before disconnection.

Reconnect the strain relief before turning the gas supply on and returning the range(s) to their

installation position.

CONNECT GAS LINE

STRAIN

RELIEF HERE

PL-51219

Fig. 1

LEVELING

Curb Installation

Ranges must overhang curb 3" (8 cm) in front. To level each range, remove oven bottom. Adjust four

corner leveling bolts as required to level the appliance on all sides.

— 10 —

Page 11

Snorkel Oven

Remove lower front kick plate. Remove two screws holding electric gas valve and move valve off to

the side. Pull oven burner out of compartment through opening. Adjust four corner bolts to level range.

Replace burner valve and kick plate.

Floor Installation on Legs

The 6" (15 cm) adjustable legs must be tightened securely. Level each range by turning the foot

portion of the adjustable legs.

Lining up Range Battery

In batteries of ranges, it is recommended that the center range be installed and leveled first. Level

each range, one at a time, to line up high shelf and roll front with adjacent range. Bolt the high

shelves

and roll fronts together.

CONNECTION OF MANIFOLDS IN BATTERY

Two or more ranges can be coupled together at the manifold by removing the front control panel to

make necessary connections. Be sure to cap open ends. To connect:

1. Adjust manifold by loosening U-bolts. In a large battery of eight or more ranges, gas should be

fed from both ends of the battery. "T" gas connections can be installed whenever necessary for

increased gas supply. For further details, consult your gas company. The top roll front may also

be removed for your convenience.

2. Bolt risers together at top rear.

3. If risers have high shelves, bolt the high shelf brackets together. Replace the high shelves.

4. Use clamp to pull ranges together at the rear. (There is a slotted hole in the top frame side at

the rear that can be used to bolt ranges together if necessary. Run a

the slotted hole, drilling from inside out on each range.) Use

1

5

/16" diameter drill through

/4"-2 x 2" bolt that is provided.

5. Replace all top sections. Make manifold union connections at the front. Do not allow manifold

pipe to turn.

6. Bolt the roll front ends together at the front. (Make sure roll fronts match.) Use

1

/4"-20 x 1" bolts

provided.

7. Tighten the front roll front bolts after the roll front ends have been properly bolted together.

8. Before replacing manifold panels, check all gas connections for leaks. (See GAS CONNECTIONS

in this manual.)

If appliance has rear gas connection, carefully check for open gas lines.

The gas pressure regulator must have proper outlet pressure capacity for this battery application.

— 11 —

Page 12

INSTALLING OVERLAPPING GRIDDLE TOP

1. Bolt ranges together and level per instructions in this manual.

2. Remove chrome bull noses from ranges receiving overlapping griddle tops. Bull noses are held

by bolts on the bottom side.

3. MANUAL CONTROLS ONLY — Set griddle tops in place and level with bolts located under the

griddle top in both rear corners. Should you desire griddle plate to slope forward, adjust

accordingly. Make sure hole in front gutter fits into cast iron drain in range. Reinstall bull noses.

4.

THERMOSTAT CONTROL ONLY — Set griddle top in place and support front with 4" to 6"

cm to 15 cm) blocks. Insert thermostat probe into smaller of two angles on bottom of griddle

(10

top (bend probe slightly while inserting to hold in place). Slide insulation sleeving around probe

lead up to angle on griddle top. Coil excess lead near thermostat, leaving as little as possible

in burner area. Make sure that thermostat probe lead is not over burner or pilot flame. Remove

supporting blocks and lower griddle top in place.

Level griddle top with bolts located under both rear corners. Should you desire griddle plate to

slope forward, adjust accordingly. Make sure hole in front gutter fits into cast iron drain in range.

Reinstall bull noses.

Leveling bolts are provided under each griddle plate at the rear, should you desire griddle plate to slope

forward. Top frame sealing channels are supplied to seal off any space between two or more ranges.

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be resistant to

the action of propane gases.

This appliance must be connected with a gas supply line as large or larger ID (net inside diameter) than

the gas pipe inlet provided on the rear of the appliance. Connect gas supply to the range(s). Make sure

the pipes are clean and free of obstructions, dirt, and piping compound.

Codes require that a gas shutoff valve be installed in the gas line ahead of the range(s).

Ranges manufactured for use with propane gas are equipped with fixed orifices.

A gas pressure regulator must be furnished by the installer or plumber at the time of installation. The

regulator must be listed by a nationally recognized testing agency. These appliances are rated at the

following pressure: Natural Gas - 5" W.C. (Water Column) (1.25 kPa); Propane Gas - 10" W.C. (2.49 kPa).

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

When test pressures exceed

1

/2 psig (3.45 kPa), the range and its individual shutoff valve must be

disconnected from the gas supply piping system.

When test pressures are

1

/2 psig (3.45 kPa) or less, the range must be isolated from the gas supply

system by closing its individual manual shutoff valve.

— 12 —

Page 13

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue duct located on the rear of the range. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

A minimum of 18" (45 cm) must be maintained between the ventilation system and the cooking surface.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition), available from the

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE YOU ARE WORKING ON THE CIRCUIT.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE PROVIDED

WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS PLUG BE CONNECTED

INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT

THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE

GROUNDING PRONG FROM THIS PLUG.

Do not connect the range to electrical supply until after gas connections have been made.

LIGHTING AND SHUTTING DOWN PILOTS

Open Top, Griddle Top, Hot Top, Broiler and Cheesemelter Pilots

1. Turn the main burner valve to the ON position.

2. Turn all burner valves and pilot adjustment valves to the OFF position. Wait 5 minutes.

3. Turn pilot adjusting valve screw counterclockwise, then light the pilot adjacent to each burner.

Adjust each pilot screw until the pilot flame is

1

/4" (0.6 cm) high.

4. If pilot fails to light, repeat steps 1-3 above.

5. For a complete shutdown, turn all burner valves to the OFF position. Turn all pilot valve screws

clockwise until the pilot flames go out. Turn gas shut-off valve OFF.

— 13 —

Page 14

Standard Oven With Standing Pilot (Fig. 2)

1. Turn Thermostat and Shut-off Valve to the OFF position.

2. Wait 5 minutes.

3. Remove lower panel.

4. Depress Red Button on safety valve and light pilot through

observation hole.

5. Hold down Red Button for at least 30 seconds.

6. When button is released, pilot should remain lit. Pilot

flame may be adjusted with screw on pilot adjustment

valve on pilot supply tubing located behind the control

panel. There should be only a slight amount of yellow in

the properly adjusted pilot flame.

7. Replace lower panel.

8. Turn Shut-off Valve to the ON position and turn the

Thermostat to the desired temperature.

9. If pilot flame becomes extinguished, repeat the above

procedure.

10. For a complete shutdown, turn the Thermostat, Shut-off

Valve, and gas shut-off valve to the OFF position.

SHUT-OFF

VALVE

THERMOSTAT

RED BUTTON

(SAFETY)

Fig. 2

PL-53512

Standard Oven with Electric Ignition (Fig. 3)

1. Turn Thermostat and Shut-off Valve to OFF position.

Wait 5 minutes.

2. Turn Shut-off Valve to ON position.

3. Turn Thermostat to desired setting.

4. Oven burner lights automatically.

5. For a complete shutdown, turn the Thermostat, Shut-off

Valve, and gas shut-off valve to the OFF position.

SHUT-OFF

VALVE

THERMOSTAT

PL-53513

Fig. 3

— 14 —

Page 15

Snorkle Convection Oven with Standing Pilot (Fig. 4)

1. Turn Thermostat and Shut-off Valve to OFF position.

Wait 5 minutes.

2. Turn Shut-off Valve to ON position.

3. Remove the lower front panel. Flip up the window that

covers the pilot lighting hole and light the pilot with a lit

taper. Flip window back in place and replace lower front

panel.

4. Turn Thermostat to desired setting.

5. Turn Fan Switch to ON position.

SHUT-OFF

VALVE

THERMOSTAT

FAN SWITCH

FAN

6. Oven burner lights automatically.

7. For a complete shutdown, turn Thermostat, Shut-off

Valve, Fan Switch, and gas shut-off valve to the OFF

position.

Snorkle Convection Oven with Electric Ignition (Fig. 5)

1. Turn Thermostat and Shut-off Valve to the OFF position.

Wait 5 minutes.

2. Turn Shut-off Valve to ON position.

3. Turn Fan Switch to ON.

4. Turn Thermostat to desired setting.

5. Oven burner lights automatically.

SHUT-OFF

VALVE

THERMOSTAT

FAN SWITCH

PL-53514

Fig. 4

FAN

6. For a complete shutdown, turn Thermostat, Fan Switch,

Shut-off Valve, and gas shut-off valve to the OFF

position.

— 15 —

PL-53515

Fig. 5

Page 16

OPERATION

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE CAREFUL WHEN OPERATING, CLEANING

OR SERVICING THE RANGE.

BEFORE FIRST USE

Griddle Tops: Before using your Vulcan griddle, the protective coating that was applied at the factory

must be completely removed with a commercial degreaser. After a thorough cleaning, apply a high

temperature, salt-free frying oil and you are ready to use your Vulcan griddle.

The griddle requires no "breaking-in" or "seasoning."

CONTROLS

Range Top Valve

Oven Shut-off Valve Allows gas to flow to the oven burner. To open

Red Button

(Standard Oven Only)

Thermostat Regulates the oven temperature. The thermostat temperature

Fan Switch Turns fan on and off. (See Fig's. 4 and 5.)

OPERATING SUGGESTIONS

Standard Oven: If you have a standard oven, use your normal recipe times and temperatures.

®

Snorkel

with less energy consumption. The oven pre-heats faster, and baking time, temperature settings, and

shrinkage are reduced.

In general, reduce temperature 25°F (10°C) from conventional recipes.

Convection Oven: The Vulcan Snorkle® Oven does everything a regular oven can do, but

Allows gas to flow to the range section. To open valve, turn knob

counterclockwise. To close valve, turn knob

counterclockwise. To close valve, turn knob

Fig’s. 2, 3, 4, and 5.)

Allows gas to flow to the oven pilot. To operate, push button

in and

range is from 150°F to 500°F

counterclockwise to increase temperature and clockwise to decrease

temperature. (See Fig’s. 2, 3, 4, and 5.)

follow pilot lighting instructions (See Fig. 2).

(65°C to 260°C). Turn thermostat

clockwise.

valve, turn knob

clockwise. (See

• Bakery Products: Reduce temperature 25°F. Reduce time by 25% to 33%.

• Casserole Cookery: Reduce temperature about 25°F, and time by 25% to 50%.

• Meat Roasting: Reduce temperature to 275-300°F (135-149°C). Use meat thermometer.

Cooking time may be reduced up to 50%.

Use fan for preheating and baking.

Place open-face pies with thin filling mixture in preheated oven 2 to 3 minutes before turning on fan

switch.

Check product at half the time of the regular recipe.

Level pans bake more evenly; warped pans will give uneven baking results.

— 16 —

Page 17

A GUIDE FOR COOKING TIME & TEMPERATURES

The following lists are suggested cooking times and temperatures for convection and standard ovens. These guidelines, which will

vary depending on product temperature, size, shape, etc., are suggestions only and should be adjusted to suit your operation.

(CONVECTION OVEN ONLY)

Suggested Your

Suggested Temperature Your Temp.

Time °F (°C) Time °F (°C)

MEAT, POULTRY, FISH

Roasting 10-15 min./lb (.45 kg) 250-300 (121-149) __________ __________

Braising 20-25 min./lb (.45 kg) 300 (149) __________ __________

Cafeteria Beef Rounds (45 lb./20 kg) 9 hours 225 (107) __________ __________

Steaks (11/2" [4 cm] thick) 10-14 min. 450 (232) __________ __________

Meat Loaf (41/4" x 9" / 11 x 23 cm) 45-60 min. 300 (149) __________ __________

Hamburger Patties 4-8 min. 400 (204) __________ __________

Bacon 6-10 min. 400 (204) __________ __________

Sausage Links 8-12 min. 400 (204) __________ __________

Turkey (24 lb. / 11 kg) 21/2-3 hours 300 (149) __________ __________

Oven Browned Chicken Parts 40-45 min. 350 (177) __________ __________

Fish Fillets (4 oz. [.1 kg] frozen) 20-25 min. 475 (246) __________ __________

Fish Sticks (1 oz. [28 gr.] frozen) 10 min. 400 (204) __________ __________

BAKED PRODUCTS

Sheet Cakes (18" x 26"/46 x 66 cm) 20 min. 325 (163) __________ __________

Bar Cookies 15-20 min. 325 (163) __________ __________

Drop Cookies 8-12 min. 350 (177) __________ __________

Pie Crust 8-10 min. 400 (204) __________ __________

Fruit Pies 30 min. 375 (190) __________ __________

Custard-type Pies 30-45 min. 300-325 (149-163) __________ __________

Meringue, topping for pies 8-10 min. 325 (163) __________ __________

Fruit Cobbler 30-45 min. 350 (177) __________ __________

Cornbread 20 min. 350 (177) __________ __________

Biscuits 8-10 min. 375-400 (190-204) __________ __________

Muffins 12-15 min. 300 (149) __________ __________

Yeast Rolls 10-15 min. 300-325 (149-163) __________ __________

Danish Rolls 10 min. 350 (177) __________ __________

Sweet Rolls 10-15 min. 300 (149) __________ __________

Hamburger Buns 20 min. 325 (163) __________ __________

Yeast Bread 20-30 min. 325 (163) __________ __________

MISCELLANEOUS PRODUCTS

Baked Potatoes (200, 6-8 oz. [.2kg] 45-60 min. 450 (232) __________ __________

Toasted Cheese Sandwiches 8-10 min. 350 (177) __________ __________

Toasty Dog Sandwiches 12 min. 350 (177) __________ __________

Casseroles (12 x 20 x 2" / 20 min. 350 (177) __________ __________

[39 x 51 x 5 cm] pan)

Casseroles (12 x 20 x 4" / 30 min. 275 (135) __________ __________

[30 x 51 x 10 cm] pan)

Rice, covered 30 min. 325 (163) __________ __________

(3 lb. [1.4kg] per 12x20x2" /

[30 x 51 x 5 cm] pan)

FROZEN FOOD PRODUCTS

Fruit Pies 30 min. 400 (204) __________ __________

Pot Pies, individual 20-30 min. 400 (204) __________ __________

Casseroles, covered (12 x 20 x 2" / 45 min. 400 (204) __________ __________

[30 x 51 x 5 cm] pan)

Casseroles, refrigerator thawed 30 min. 450 (232) __________ __________

(12 x 20 x 2" / [30 x 51 x 5 cm] pan)

Dinners, individual, covered 10-15 min. 350 (177) __________ __________

Vegetables, covered 20-30 min. 400 (204) __________ __________

(5 lb. [2kg] per 12 x 20 x 2" /

[30 x 51 x 5 cm] pan)

— 17 —

Page 18

A GUIDE FOR COOKING TIME AND TEMPERATURES

Baking Times at Preheated Oven Temperatures

TEMPERATURE TEMPERATURE TIME

PRODUCT °F (°C) °F (°C) Total Minutes

MEAT

Braised Meats 350 (177) 325 (163) 20-22

Meat in Casserole 330 (166) 300 (149) 20-22

Meat Pie with Crust 450 (232) 425 (218) 30-35

(meat previously cooked)

Rare 300 (149) 275 (135) 140 (60) 18-20 (covered)

Medium 300 (149) 275 (135) 160 (71) 22-25 (covered)

Well Done 300 (149) 275 (135) 170 (77) 27-30 (covered)

Pork

Fresh (always well done) 350 (177) 325 (163) 185 (85) 30-35

Smoked 300 (149) 275 (135) 170 (77) 25-30

Lamb and Mutton

Medium 300 (149) 275 (135) 175 (79) 25-30

Well Done 300 (149) 275 (135) 180 (82) 30-35

Veal 325 (163) 300 (149) 170 (77) 25-35

Poultry 325-350 (163-177) 300-325 (149-163) 22-30 (covered)

Chicken 325-350 (163-177) 300-325 (149-163) 20-25 (covered)

Duck, Goose 325-350 (163-177) 300-325 (149-163) 15-25 (covered)

Turkey 325-350 (163-177) 300-325 (149-163) 15-25 (covered)

Fish Total Minutes

Small or Fillets 350-375 (177-190) 325-350 (163-177) 20-25

Large 350 (177) 325 (163) 15-20

Lobster, Stuffed 350 (177) 325 (163) 15-20

VEGETABLES

Beans with Pork 250-350 (121-177) 225-325 (107-163) 6-8 hours

Eggplant, Stuffed 325 (163) 300 (149) 60

Mushrooms 400-450 (204-232) 375-425 (190-218) 15

Onions, Whole (Stuffed) 400-450 (204-232) 375-425 (190-218) 60

Onions, Sliced 400-450 (204-232) 375-425 (190-218) 30

Peppers, Stuffed 350-375 (177-190) 325-350 (163-177) 30

Potatoes, White, in Skins, Large 425 (218) 400 (204) 30-60

Small to Medium 425 (218) 400 (204) 30-45

Scalloped 350-400 (177-204) 325-375 (163-190) 60-90

Sweet Potatoes, in Skins 350 (177) 325 (163) 30-40

Squash 325 (163) 300 (149) 30-40

BREADS

Baking Powder Biscuits 450 (232) 400 (204) 12-15

Cornbread 425 (218) 400 (204) 20-30

Muffins 400-425 (204-218) 375-400 (190-204) 20-25

Nut and Fruit Breads 350-375 (177-190) 325-350 (163-177) 60-75

Yeast Bread - Loaf 375-400 (190-204) 350-375 (177-190) 45-60

Yeast Coffee Cake 350-375 (177-190) 325-350 (163-177) 25-30

Yeast Rolls - Plain 400-425 (204-218) 375-400 (190-204) 15-25

Yeast Rolls - Sweet 375 (190) 350 (177) 20-25

COOKIES

Drop 325-400 (163-204) 300-375 (149-190) 8-15

Rolled 375 (190) 350 (177) 8-10

Bar 350-400 (177-204) 325-375 (163-190) 20-40

Refrigerator 400 (204) 375 (190) 8-10

CAKES

Angel and Sponge 350-375 (177-190) 325-350 (163-177) 30-45

Shortening Type

Cup Cakes 350-375 (177-190) 325-350 (163-177) 15-25

Layer Cakes 350-375 (177-190) 325-350 (163-177) 20-35

Loaf Cakes 350 (177) 325 (163) 45-60

PIES

Pastry Shell 450 (232) 425 (218) 10-12

Double Crust - Berry or Fruit 425 (218) 400 (204) 30-45

Frozen - Berry or Fruit (50 oz./1.4kg) 400 (204) 375 (190) 60-75

Custard or Pumpkin 400-425 (204-218) 375-400 (190-204) 30-45

Standard Oven Convection Oven Roasting Period

Oven Temp. Oven Temp. Internal Temp. Min. per lb. beef

— 18 —

Page 19

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING.

Open Top Burners

Daily

Remove grates and clean under and around open burners.

Weekly

1. Clean each burner thoroughly. Clean stainless steel or chromed surfaces with a damp cloth and

polish with a soft dry cloth. A detergent may be used for cleaning. To remove discolorations, use

a non-abrasive cleaner, always rubbing with the grain of the metal.

2. Clean bottom drip pan. To remove drip pan, reach under and lift rear of pan about 1" (2.5 cm),

slide pan to the rear about

1

/2" (1.3 cm), and drop front end of pan free. Slide pan forward between

the front legs. To replace pan, reverse this procedure.

3. Burner air shutter openings must be kept clean.

4. Main burner ports and throats must be thoroughly cleaned. Venturi must be free from grease

and lint. To clean burners, boil them in a strong solution of lye water for 15-20 minutes, then brush

with a wire brush. DO NOT insert pick in burner port hole.

5. Open burner pilot flash tubes and burner ignition port must be clear for burners to ignite properly

from the pilot.

Griddle Top

Empty grease daily. Clean griddle top regularly.

KEEP GRIDDLE PLATE SURFACE CLEAN. To produce evenly cooked, browned products, keep

griddle free of carbonized grease. Carbonized grease on the surface hinders the transfer of heat from

the griddle surface to food. This results in spotty browning and loss of cooking efficiency, and

carbonized grease tends to stick to the griddled foods, giving them a highly unsatisfactory and

unappetizing appearance.

To keep the griddle clean, follow these simple instructions:

After Each Use

Clean griddle with a wire brush or flexible spatula.

Daily

1. Thoroughly clean backsplash, sides and front. Remove grease drawer, empty it and wash it out

in the same manner as any ordinary cooking utensil.

2. Clean griddle surface thoroughly. Use a griddle stone, wire brush or stainless steel wool on the

surface. Rub with the grain of the metal while the griddle is still warm. A detergent may be used

on the plate surface to help clean it, but you must ensure the detergent is thoroughly removed.

3. Clean stainless surfaces with a damp cloth and polish with a soft dry cloth. To remove

discolorations, use a non-abrasive cleaner.

— 19 —

Page 20

Exterior

Daily

Clean exterior finish with a mild solution of soap or grease-dissolving cleaner.

Range Tops

Daily

1. Wipe top while still warm with a soft cloth.

2. Clean drip pan under burners.

Weekly

Boil open top grates and burners in a solution of washing soda and water.

Range Ovens

Daily

Clean oven and door daily.

Do not use scouring powder on finishes. Scouring powder is extremely difficult to remove completely.

It can build up accumulations that will damage the oven or remove corrosion resistant finishes.

STAINLESS STEEL

Here are a few simple cleaning procedures that have been found effective for keeping stainless steel

equipment clean, sparkling and bright.

General Cleaning

Use ordinary soap or detergent and water for routine cleaning of stainless steel. To prevent water spots

and streaks, rinse thoroughly with warm water and wipe dry with a soft clean cloth. The addition of a

rinsing agent will also help prevent spotting.

Fingerprints

Fingerprints are sometimes a problem on highly polished surfaces of stainless steel. They can be

minimized by applying a cleaner that will leave a thin oily or waxy film.

To use these cleaners, simply wipe on and remove excess with a soft dry cloth. After using, subsequent

fingerprints will usually disappear when wiped lightly with a soft cloth or with a cloth containing a little

of the cleaner. If the surface is especially dirty to start, wash first with soap or detergent and water.

— 20 —

Page 21

Burned-On Foods and Grease

Soaking with hot soapy water will help greatly to remove burned-on foods and grease.

Heat Tint

Straw-colored or slightly darkened areas may appear on stainless steel in and around ovens and

ranges where temperatures reach 500°F (260°C) or more. This "heat tint" is caused by a slight

oxidation of the stainless steel and is not harmful.

To control or minimize this condition, never use more heat than is absolutely necessary.

Commercial heat tint remover products may be used.

Precautions

When scraping off heavy deposits of grease or oil from stainless steel equipment, never use ordinary

steel scrapers. Particles of ordinary steel may become embedded in, or lodge on, the surface of the

stainless steel. These will rust, causing unsightly stains and possible contamination of food. Where

it is necessary to scrape, use stainless steel, wood, plastic or rubber tools.

— 21 —

Page 22

MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE OPERATIONS.

PILOT LIGHTS

Pilot lights are to be adjusted at the proper flame height.

LUBRICATION

All moving parts must be checked for wear and lubricated. Contact your local Vulcan authorized

servicer.

All valves and controls should be lubricated by your local Vulcan authorized servicer, using a hightemperature grease.

Motors in Vulcan convection ovens are permanently lubricated and require no additional maintenance.

FLUE

Annually check the flue when it is cool to be sure it is free of obstructions.

SERVICE FREQUENCY

Frequency of service maintenance will be largely dependent on customer usage. Recommended

service frequency is as follows:

1. 10-12 hours operation per day, 7 days a week Every 30-60 days

2. 4-6 hours a day, 5 days a week Every 120 days

3. Limited daily usage Every 180 days

4. All equipment At least once a year

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this range, contact the Vulcan Service Agency

in your area (refer to listing supplied with the range), or Vulcan-Hart Company Service Department at

the address or phone number shown on the front cover of this manual.

— 22 —

Page 23

TROUBLESHOOTING

OVEN

PROBLEM PROBABLE CAUSES

Too Much Bottom Heat. Insufficient heat input.

Overactive flue.

Uneven Bake Too low temperature.

Improper operation.

Side Burning Improper bypass setting.

Fluctuating gas pressure.

Too Much Top Heat Too high temperature.

Faulty ventilation.

Excessive heat input.

Thermostat needs calibration.

Uneven Bake - Side to Side Range not level side to side.

Oven burner, bottom or baffles improperly installed.

Pulling to Edge of Pan Warped pans.

Oven not level.

Uneven Bake - Front to Rear Overactive flue.

Range not level front to back.

Door not closing properly.

Dried Out Products Too low temperature.

Too long baking time.

Thermostat calibration.

Pilot Outage Gas supply not sufficient.

Pilot flame too low.

Restriction in pilot orifice.

Problem with check valve.

CONVECTION OVEN MODELS ONLY:

Cavity leaking.

Gasket problems.

Snorkel tube blocked.

Blower running backwards.

Excessive Meat Shrinkage Roasting temperature too high.

— 23 —

Page 24

TOP BURNER OPERATION

PROBLEM PROBABLE CAUSES

Improper Burner Combustion Improper ventilation.

Excessive Valve Handle Temperatures Poor door fit.

Sticking Top Burner Valves Oven door left open.

Poor Ignition Insufficient gas input.

Poor air-to-gas adjustment.

Restriction in pilot orifice.

Restriction in main burner ignition port.

Restriction in control valve.

Restriction in gas orifice.

FORM 31165 (Jan. 2001) PRINTED IN U.S.A.

— 24 —

Loading...

Loading...