Hobart UX-30 EH, UX-30 ESH, UX-30 EB, UX-30 E, UX-30 ES Installation And Operating Instructions Manual

...Page 1

Utensil Washing Machine

UX-30 EH / UX-30 ESH

INSTALLATION OPERATION

VERSION 23/11/99

Page 2

Installation and Operation Instructions

for HOBART Utensil Washing Machine

Model UX-30 EH / UX-30 ESH

Content Page

1 Installation............................................................................................. 3

2 Connections .......................................................................................... 3

3 Controls................................................................................................. 6

4 First run................................................................................................. 7

5 Adjustment of detergent concentration ................................................. 8

6 Adjustment of rinse agent concentration............................................... 8

7 Softener ................................................................................................ 9

8 Operation ............................................................................................ 10

9 Cleaning the machine ......................................................................... 11

10 Frost prevention .................................................................................. 12

11 Maintenance ....................................................................................... 12

12 Trouble shooting.................................................................................. 13

Machine noise level is ≤ 70 dB (A)

Important Notes

● Use in Accordance with Regulations

Hobart Utensil Washing Machines are only intended for cleaning pots

and pans, baking sheets, cutlery, trays etc.

Do not use for electrically heated cooking and heat conservation

appliances.

● Safety

Never hose down the machine.

The "Attention" symbol is shown beside instructions that are essential

for the safe operation of the machine. Please read these passages

very thoroughly.

● Liability

Installations and repairs which are not carried out by authorized

technicians or the use of other than original spare parts, and any

technical alterations to the machine, may affect the warranty

set out in the standard conditions of sale.

2

Page 3

1 Installation

1.1 Location

– Wall clearance of 150 mm is required.

– Level machine by turning the feet.

– Distribute machine weight equally onto all feet.

0

9

¡C

5

8

0

0

8

7

5

5

6

7

0

0

6

7

0

5

5

6

5

0

0

6

5

5

4

0

4

2 Connections

2.1 Electrical connection

Must be carried out by an authorized technician

according to the national and local codes.

– The appliance is intended for a fixed electrical connection.

Main-switch is required according EN 60 204.

– Check machine specifications to make sure they correspond to

those of the site supply and to wiring diagram.

– Check site fuse rating.

According to EN 60 335 the appliance must be connected to an

equipotential conductor. The connecting screw is located beside

the cable inlet.

3

Page 4

2.2 Water connection

Must be carried out by an authorized technician

according to the national and local codes.

The machine must be operated with water of drinking quality.

For water with an extremely high mineral content, water

treatment is recommended.

Machines without Softener:

(U.K. only: this machines are fitted with Class "A" Air Gap.)

– Connection if possible to soft (4° Clark) and warm (max. 60°C)

water.

– Line flow pressure 0.4 – 6 bar.

If line flow pressure is below 0.4 bar: provide rinse booster

pump at site.

Machines with Softener (S-models only):

For U.K. see separate infor mation*.

– Connection if possible to warm water (max. 60°C).

– Line flow pressure 1.5 – 6 bar.

If line flow pressure is below 1.5 bar: provide rinse booster

pump at site.

If line flow pressure is above 6 bar: provide a pressure

reducing valve.

– Connect flexible supply hose with union nut 3/4" to site

connection.

– Fit shut-off valve.

* U.K. only: Machines with softener

All United Kingdom installations must be supplied from

storage not mains. Direct connections to the mains supply

contravenes Water Authority regulations.

– Connection if possible to warm water.

The supply water temperature into the machine should not

exceed 60°C.

For temperatures in excess of 60°C, a thermostatic mixing valve

should be fitted at installation.

This valve is available from HOBART Service Centres.

– Fit shut-off valve.

Low Pressure Situations

Below 0.4 bar (6 psi) flow pressure there are two solutions.

a) Provide a suitable water storage tank at a height which will

create a pressure in excess of 0.4 bar or,

b) fit a water pump to increase the pressure.

A suitable pump can be supplied by HOBART at extra cost.

Medium Pressure Situations

0.4 - 0.7 bar (6-10 psi) flow pressure.

Most installations will fall into this category and the machine will

arrive fitted with a solenoid valve designed for this pressure range.

High Pressure Situations

Above 0.7 bar flow pressure.

a) Fit a water storage tank at a suitable height.

b) Fit a pressure reducing valve during installation.

4

Page 5

2.3 Hot water connection

(hot-water heated machines only)

Must be carried out by an authorized technician

according to the national and local codes.

– Connection to hot water supply (DN 20) on customer site

PN 25 (110°C - 200°C). See data plate !

– The machine is equipped with all necessary fittings.

– Dimension of hot water flow and return piping has to be

according to the requirements.

– Make sure that permissible pressures and temperatures will not

be exceeded.

– All pipework has to be insulated with water and heat resistant

material.

2.4 Steam connection

(steam heated machines only)

Must be carried out by an authorized technician

according to the national and local codes.

– Connection to steam supply (DN 20) at customer site

0.3 - 3.5 bar (max. 150°C) or 3.5 - 10 bar (max. 200°C).

See data plate !

– Dimension of steam and condensate piping has to be according

to the requirements.

– The machine is equipped with all necessary fittings.

– Make sure that permissible pressures and temperatures will not

be exceeded.

– All pipework has to be insulated with water and heat resistant

material.

A

2.5 Adjustment of shut-off valve with flow reducer for

steam and hot water supply

– The built-in shut-off valve is equipped with an adjustment device

(A) to limit the heating supply medium.

A special tool is necessary for adjusting the valve-seat.

– The correct adjustment is very important particulary for higher

pressure, and therefore must be done by a HOBART trained

service man at first installation or after any changes are done

at the customer site.

– The adjustment is correct if the heating-up time of the boiler is

as long as the shortest wash cycle, while the valve is opened to

maximum.

– If adjusted too far open pressure shocks may occur when the

solenoid valve closes. This could cause damage at the installation.

If adjusted too far close the required heating-power cannot be

achieved.

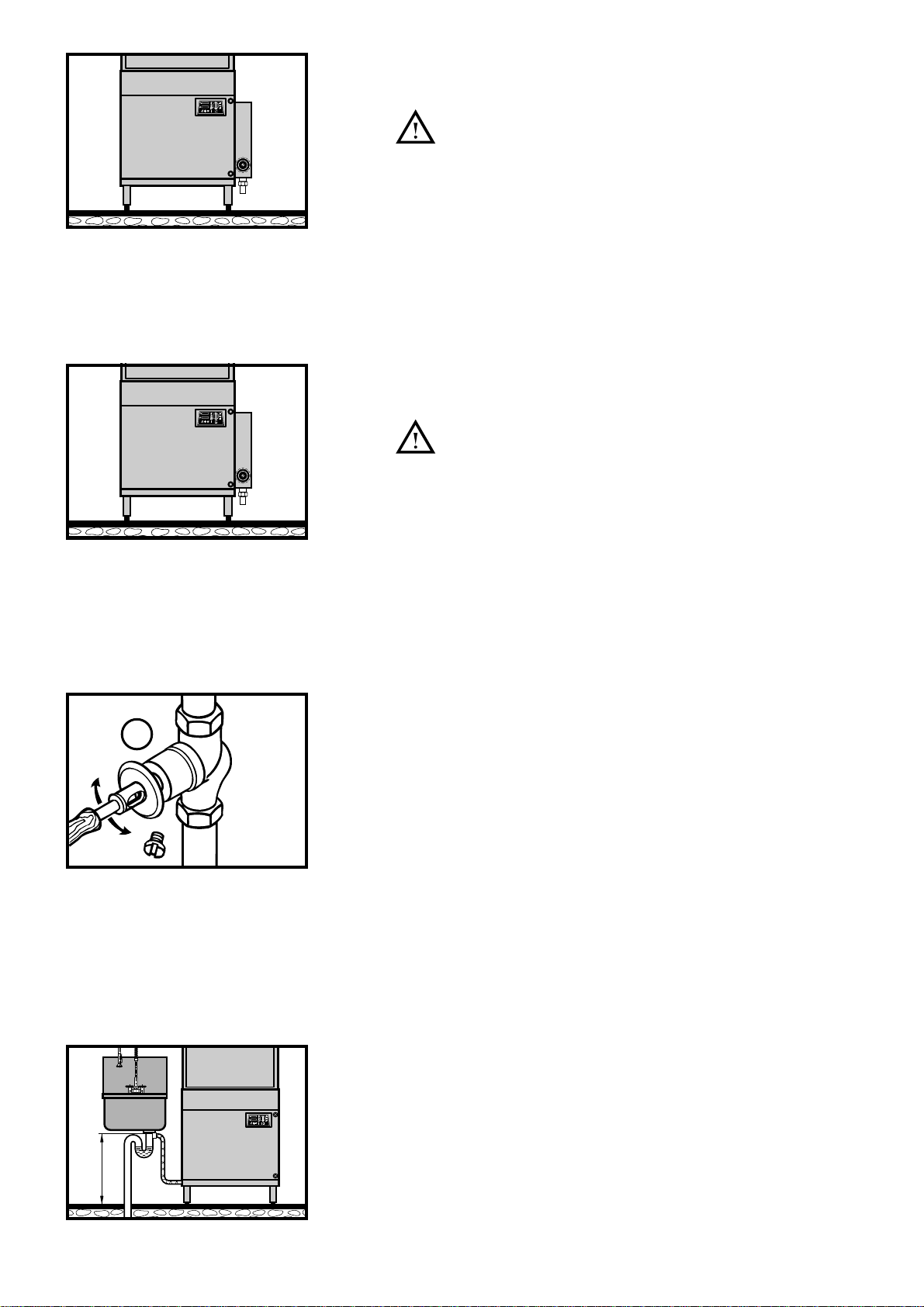

2.6 Drain connection

– Connection between machine and site drain must not exceed

max. height of drain pump lift of 0.8 m.

– Do not kink drain hose.

max. 0,8 m

5

Page 6

3 Controls

1 4 5 6

3 72

0

70

65

60

55

50

45

40

°C

90

85

80

75

70

65

60

891011

1. Detergent dispenser Pilot light illuminates: dispenser operates.

(built-in dosing pump Pilot light blinks continously through 2 - 3 cycles:

on option only) Container is empty or conductivity probe (located inside the wash tank)

must be cleaned.

For machines without dispenser: add detergent to tank.

2. Regeneration Pilot light blinks: indicating that regeneration is required.

(S-models only) Pilot light illuminates permanently: regeneration prog r amme is running

(duration approx. 45 minutes).

3. Filling Pilot light illuminates during fill cycle.

4. Drain Pilot light illuminates during drain cycle.

(At the end of drain cycle machine switches off automatically.)

5. Machine OFF

6. Thermometer At the end of a wash cycle the thermometer switches ov er.

Wash °C

°C

70

65

60

55

50

45

40

Now a light point moves up and down in short sequences

90

and indicates the end of the wash cycle.

85

80

After the doors are opened the display will s witch back into

75

70

the temperature mode.

65

60

7. Thermometer At the end of a wash cycle the thermometer switches ov er.

Rinse °C

°C

70

65

60

55

50

45

40

Now a light point showes the status of the softener.

90

The 1st light (top) illuminates: the softener has full capacity.

85

80

The 6th light (middle) illuminates: the softener has only

75

70

50 % capacity.

65

The 12th light (bottom) illuminates and the regeneration

60

pilot light blinks: the softener capacity is zero and needs

to be regenerated.

After the doors are opened the display will s witch back into

the temperature mode.

8. Programme button I 120 sec. Light duty programme

9. Programme button II 240 sec. Normal programme

10. Programme button III 360 sec. Heavy duty programme

11. Timer Pilot light illuminates during cycle.

6

Page 7

4 First run

4.1 Detergent

With built-in dispenser (option):

– Put suction hose (white) into detergent container.

If there is no dispenser in use:

– pre-dosage of detergent is necessary (approx. 150 gram).

4.2 Rinse agent

– Put suction hose (blue) into rinse agent container.

Be careful that you do not confuse the rinse agent

and detergent containers.

As high pressure and high circulation is needed for the

cleaning of utensils, use only commercial low foaming

detergent and rinse agent.

Do not use any acidic detergent products with the built-in

detergent pump.

Please pay attention to the manufacturers safety rules and

instructions.

0

0

0

4.3 Filling of rinse booster heater and predosing

°C

90

70

85

65

80

60

55

75

50

70

65

45

40

60

°C

90

70

85

65

80

60

55

75

50

70

65

45

40

60

°C

90

70

85

65

80

60

55

75

50

70

65

45

40

60

– Switch on the main switch.

– Open shut-off valve.

– Close the doors.

– Push fill button and wait until pilot light of programme II button

illuminates.

The filling time depends on the rinse booster heater and the

water feed temperature (approx. 30 min with 9 kW booster

and 10°C water feed temperature).

– Push programme III button, open and close machine doors.

– Push the timer button, timer pilot light illuminates.

Detergent pump operates, detergent dispenser light illuminates,

wash cycle starts.

– When wash and rinse cycle is over and detergent dispenser

light is still blinking (sign for a too low concentration), repeat the

wash cycle until the light goes off. Open and close machine doors.

4.4 Check

– Open doors and check if upper and lower wash arms rotate

smoothly.

– Check and eliminate any leakages of supply and drain pipew ork.

– Check direction of rotation of pump motor (see direction sign).

If motor runs against the indicated direction (pump is running

noisily and circulates only a little water) interchange 2 phases

(threephase current only).

This must be carried out by an authorized

technician.

7

Page 8

5 Adjustment of detergent concentration

The detergent concentration can be adjusted within 12 steps,

depending upon the water quality and wash result.

The concentration is set at step 4 at the factory.

If the concentration needs to be changed:

– Shut off machine (press machine OFF button).

– Open machine doors.

90

¡C

85

0

8

70

65

75

0

0

6

7

0

65

55

0

6

50

5

4

40

0

°C

90

70

85

65

80

60

55

75

50

70

65

45

40

60

– Press and hold programme button II, tap the timer button.

The wash thermometer column indicates the detergent

concentration (e.g. 50°C means step 4 of 12 steps).

– Each time the timer button is tapped, the dosage is increased

by one step. When level 12 is reached, the dosage will start

again at level 1 if procedure continues.

– After approx. 8 seconds the thermometer column switches off.

– After adjustment close doors and operate machine as usual.

6 Adjustment of rinse agent concentration

The rinse agent concentration can be adjusted within 8 steps,

depending upon the water quality and wash result.

The concentration is set at step 3 at the factory.

If the concentration needs to be changed:

– Shut off machine (press machine OFF button).

– Open machine doors.

0

9

¡C

5

8

0

0

8

7

5

5

6

7

0

0

6

7

0

5

5

6

5

0

6

50

5

4

40

0

°C

90

70

85

65

80

60

55

75

50

70

65

45

40

60

– Press and hold programme button III, tap the timer button,

the rinse thermometer column indicates the rinse agent

concentration between 60°C and 80°C (ignore 80°C to 90°C).

– Each time the timer button is tapped, the dosage is increased

by one step. When level 8 is reached, the dosage will start again

at level 1 if procedure continues.

– After approx. 8 seconds the thermometer column switches off.

– After adjustment close doors and operate machine as usual.

The dosage of rinse agent and detergent depends on the

quality of water.

For economical use of detergent and rinse agent at optimal

levels, adjustment should be in accordance with chemical

suppliers recommendations.

8

Page 9

7 Softener (S-models only)

0

0

°C

70

65

60

55

50

45

40

°C

70

65

60

55

50

45

40

7.1 Adjustment of water hardness

90

85

80

75

70

65

60

90

85

80

75

70

65

60

– Switch off machine (press OFF button).

– Open machine door.

– Press regeneration button and hold it. Tap timer button.

– The LED’s at the left side of the regeneration button illuminate

one after another. The lowest is position 1, the middle is position

2, the top is position 3.

Adjustment of softener according to schedule.

Pos. Water Water quantity until Rack quantity until

hardness next regeneration next regeneration

1 7-12° clark 1300 litres approx. 150 racks

2 13-24° clark 650 litres approx. 80 racks

3 25-36° clark 430 litres approx. 60 racks

– To ascertain water hardness level ask local water authority.

– The softener is factory adjusted to position 3.

0

0

7.2 Regeneration

When the machine is delivered, the softener is already

regenerated.

– When regeneration pilot light blinks (indicating that salt is

required), press drain button.

– When the drain pilot light switches off, open the doors.

– Unscrew the softener lid.

– Fill dispenser with 1 kg powdered salt (salt tablets are not

recommended). Clean seal and rim of softener lid and

border carefully befor closing the lid.

– Close lid and tighten.

IMPORTANT: only fill with salt just before starting the

regeneration programme.

The running regeneration cycle cannot be interrupted.

°C

90

70

85

65

80

60

55

75

50

70

65

45

40

60

°C

90

70

85

65

80

60

55

75

50

70

65

45

40

60

– Close the doors and press regeneration button.

The pilot lights regeneration and timer illuminate permanently,

cycle is running.

Attention:

Do not open the doors during regeneration.

– After approx. 45 minutes the pilot lights of regeneration and

timer button switch off, the regeneration is finished.

– Press the fill button.

– After filling, programme button II pilot light illuminates.

Machine is ready for operation. Select a washing programme.

Notice:

The regeneration can even be done, when regeneration pilot lamp

does not blink (for instance at the end of the day before leaving).

The regeneration button has to be pressed for at least 5 seconds.

9

Page 10

0

40

45

50

55

60

65

70

75

80

85

90

60

65

70

°C

8 Operation

8.1 Preparation

Do not confuse the

containers!

Detergent (only on option):

White hose!

Rinse agent:

Blue hose!

Check correct position of wash Check level of detergent and rinse Close the doors and push the fill

arms, rinse arms, foam sheet and agent containers. button. Tank will be filled.

strainers. Do not run the dosing pumps for

Open shut-off valve and switch long periods without a liquid in the

on the main switch. containers.

Remove coarse food soil. Insert sheets into the frame. Put pots and pans facing down-

wards into the racks.

8.2 Racking

Protect light washware

by putting on a rack.

10

Page 11

8.3 Washing

0

4

0

4

5

5

0

5

5

6

0

6

5

7

0

7

5

8

0

8

5

9

0

6

0

6

5

7

0

¡C

for lightly soiled

washware

for normally soiled

washware

when food soil

is dried on

90

¡C

85

80

70

65

75

60

70

0

65

55

60

50

45

40

Select programme. Put rack into the machine, close When wash cycle is finished (see

door and press timer button. chap. 3), open doors and take out

Wash cycle starts. rack.

Allow washware to dry for 1 min.

approx.

9 Cleaning the machine (daily)

NOTE:

During the drain cycle, the

interior of the machine is

cleaned automatically.

A final inspection is

90

¡C

85

80

70

65

75

60

70

0

65

55

0

60

5

45

0

4

recommended.

Close the doors and push the drain When drain pilot light switches off, Take out strainers and foam sheet.

button. open doors and switch off machine.

Pilot light drain illuminates, drain Set main switch to "0" and close

cycle is running. shut-off valve.

11

Page 12

Flush strainers and foam sheet. Put strainers and foam sheet back

into place.

Leave the doors open f or ventilation.

If required:

2

1

Take out wash and rinse arms. Open plugs of wash and rinse arms Clean the pins of the conductivity

Use the strainer as a spanner to and flush. probe (on tank bottom) with fine

loosen the hexagon screw (1) by sand paper (grain 180).

turning it counter-clockwise (2).

12

10 Frost prevention

In case of frost or longer operation pauses (e.g. during seasonal

operations) the machine must be completely drained.

This should be carried out by HOBART after sales service.

Please contact your local HOBART Office.

Reset for operation according to chapter 4.

11 Maintenance

For trouble free operation we recommend you enter into a

service contract with your local HOBART Service Office.

Page 13

12 Trouble shooting guide

TYPE OF FAILURE POSSIBLE CAUSE REMEDY

Poor wash result

Washware is not clean. Wash arms stiff (you should be able Take out wash arms and clean them thoroughly.

to turn them easily by hand). Check water outlet from machine to wash arms is

clear.

Wash arm nozzles are clogged Take out wash arm, remove cleaning cap and

(visual check). rinse wash arm thoroughly until soil is removed.

Replace correctly.

Rinse arm nozzles are clogged Remove rinse arms and decalcify them in

(generally through lime deposit). separate container.

Detergent concentration is too low or Check setting of detergent concentration

too high. (usually on 4).

See also operating instructions point 5.

Coarse strainer soiled. Take out strainer, empty and clean it.

Fine strainer soiled or obstructed Take out fine strainer. If heavily soiled soak in a

through lime. vinegar solution. Then clean it thoroughly until

the pores are free.

Cleaning is to be done daily (see operating

instructions).

Wrong programme selected for heavily Select programme with longer wash cycle.

soiled washware.

Washware does not dry Rinse aid concentration too low. Increase concentration (see operating

properly. instructions).

Washware still greasy. 1. Detergent concentration too low: increase

(see instructions).

2. Check if detergent is appropriate, if not choose

a stronger one.

3. Drain soiled water and refill machine. Check

pre-scrapping procedure.

Washware stays too long in the Take out washware as soon as cycle is completed

machine at the end of programme. to enable it to dry.

Stripes and staines on Rinse aid concentration too high. Reduce quantity (see instructions).

washware.

Hard water or high mineral content. Check water quality.

Obtain details from local water authority.

Recommended values:

Ideal degree of hardness is 4° Clark.

Ideal conductivity value for glasses is max.

200 µS/cm and for dishes max. 400 µS/cm.

Insufficient rinse aid concentration Increase quantity (see instructions).

causes staines.

Machine with softener:

use of wrong type of salt (too coarse). Use only fine salt.

Machine with softener:

salt container is full although softening Only fill with salt just before regeneration

does not take place. programme will be activated.

Trouble with foam

Machine gets much louder Foam production above average Use suitable detergent and rinse agent

during wash cycle. caused by unsuitable detergent and (see chapter 4).

rinse agent.

Foam production above average Pre-clean washware.

caused by contact of foam producing

substances (albumins etc.).

13

Page 14

TYPE OF FAILURE POSSIBLE CAUSE REMEDY

Electronic control panel

All LED lights are flashing. Water supply tap not open or only Open tap.

partly open.

Strainer or water supply line is dirty. Clean it. If necessary replace with heavy duty

filter (available as accessory).

Site line pressure too low. Improve pressure conditions on site

(seek professional advice).

Rinse arm pivot clogged. Clean thoroughly.

All LED’s are flashing plus Control system malfunction. Call HOBART service.

any on the temperature

gauge.

Softener malfunctions

(only applicable to machine

with softener)

Machine fills and Softener lid is not tight. Tighten lid as well as possible.

immediately drains again.

Regeneration pilot light Regeneration programme has been Let regeneration programme run until pilot light

blinks permanently. interrupted as door was opened switches off (duration approx. 45 minutes).

during cycle was running. Never open the door during cycle is running.

Lime deposit in the Regeneration call was "ignored" i.e. Run regeneration programme 2–3 times

machine. the machine went on washing when (refill salt container every time).

regeneration was needed. If required: decalcify the machine.

Strainer in water supply pipe clogged Clean it. If necessary replace it with heavy duty

(in site tape). filter (available as accessory).

Salt container not tight. During filling, salt was split onto Open softener lid, remove salt with a cloth and

the edge and not removed. close lid tightly.

Other malfunctions

Machine suddenly stops Machine is connected to a "maximum Connect machine separately (call electrician).

during wash programme. power supply unit", which cuts out the

energy consumer at a given point, or

machine is interlocked with another

energy consumer unit.

Blown site fuse. Check site fuses.

14

Page 15

15

Page 16

As continued product improvement is a policy of HOBART, specifications are subject to change without notice.

Printed in Germany AG-20937-A-11-99-PC

Loading...

Loading...