Page 1

I

N

LXi SERIES DISHWASHER

S

LXi SERIES DISHWASHER

T

R

U

C

T

I

O

N

S

MODELS

LXiC ML-130016

LXiH ML-130017

LXiGC ML-130018

LXiGH ML-130019

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34779 Rev. B (Sept. 2005)

Page 2

© HOBART CORPORATION, 2003

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL ............................................................................................................................................ 4

INSTALLATION ................................................................................................................................... 5

Unpacking ...................................................................................................................................... 5

Location .......................................................................................................................................... 5

Leveling........................................................................................................................................... 5

Water Requirements ...................................................................................................................... 5

Plumbing Connections ................................................................................................................... 6

Electrical Connection ..................................................................................................................... 7

Electrical Data ................................................................................................................................7

Detergent and Rinse Aid................................................................................................................ 8

Operator Programming Mode ........................................................................................................ 9

Chemical Sanitizer (LXiC and LXiGC)........................................................................................ 12

OPERATION...................................................................................................................................... 12

Before First Use ........................................................................................................................... 12

Controls ........................................................................................................................................ 12

Operating the LXi Dishwasher .................................................................................................... 13

Diagnostic Messages .................................................................................................................. 14

Wash/Rinse Cycle Times (LXi) ................................................................................................... 14

Wash/Rinse Cycle Times (LXiG) ................................................................................................ 14

Preparation ................................................................................................................................... 15

Do's and Don'ts For Your New Hobart Dishwasher .................................................................. 16

CLEANING......................................................................................................................................... 17

Priming Chemical Pumps ............................................................................................................ 18

MAINTENANCE................................................................................................................................. 19

Deliming ........................................................................................................................................19

Lubrication .................................................................................................................................... 19

TROUBLESHOOTING ...................................................................................................................... 20

– 3 –

Page 4

Installation, Operation and Care of

LXi SERIES DISHWASHERS

SAVE THESE INSTRUCTIONS

GENERAL

The LXi Series dishwashers are fully automatic, front-loading dishwashing machines that are capable

of 30 racks per hour.

All LXi Series dishwashers shut down automatically 4 hours after last use to conserve energy.

All LXiH and LXiGH dishwashers include

during rinse.

Standard equipment includes two 20" x 20" racks, electronic controls, drain pump, fill hose and drain

hose.

MODEL DESCRIPTION

LXiC Fresh water rinse; low-temperature, chemical-sanitizing models for use

with 6% sodium hypochlorite solution (bleach) as the sanitizing agent.

Note: If 8.40% bleach is to be used, contact Hobart Service to change the

sanitizer pump settings. (Charges will apply)

LXiH Fresh water rinse with a built-in 70°F rise booster heater. This allows an

incoming water temperature of 110°F.

Sense-A-TempTM

to insure proper hot water temperature

– 4 –

Page 5

INSTALLATION

UNPACKING

Immediately after unpacking the dishwasher, check for possible shipping damage. If this machine is

found to be damaged, save packaging material and contact the carrier within 15 days of delivery.

LOCATION

Prior to installation, verify that the electrical supply agrees with the specifications on the machine data

plate, which is located on the top of the door.

Steam generated from normal operation may escape from the door. Wood, laminates, veneers, etc. are

unsuitable materials for use in areas exposed to dishwasher steam and detergents. Stainless steel or

other moisture-resistant shields are recommended for surfaces adjacent to LXi sides and top.

LEVELING

The machine must be level to operate properly. Place the dishwasher in its operating location. Level

the machine before any connections are made. Using a carpenter's level placed diagonally on the rack

tracks, level the machine front to back and side to side by threading the adjustable feet in or out. After

leveling the machine, cover the exposed threads of the adjustable feet with black rubber tubing

supplied. (See separate instructions furnished with machine.)

WATER REQUIREMENTS

Proper water quality can improve warewashing performance by reducing spotting, lowering chemical

supply costs, enhancing effectiveness of labor and extending equipment life. Local water conditions

vary from one location to another. The recommended proper water treatment for effective and efficient

use of this equipment will also vary depending on the local water conditions. Ask your municipal water

supplier for details about local water specifics prior to installation.

Recommended water hardness is 4 - 6 grains of hardness per gallon. Chlorides must not exceed 50

parts per million. Water hardness above 6 grains per gallon should be treated by a water conditioner

(water softener or in-line treatment). Water hardness below 4 grains per gallon also requires

treatment to reduce potential corrosion. Water treatment has been shown to reduce costs associated

with machine cleaning, reduce deliming of the dishwasher, reduce detergent usage and reduce

corrosion of metallic surfaces in the booster water heater and dishwasher.

Sediment, silica, chlorides or other dissolved solids may lead to a recommendation for particulate

filtration or reverse osmosis treatment.

If an inspection of the dishwasher or booster heater reveals lime buildup after the equipment has been

in service, in-line treatment should be considered. If recommended, follow suppliers installation and

use instructions. Contact your local Hobart Service Office for specific recommendations.

Water

– 5 –

Page 6

Water Supply

A water hammer arrestor (meeting ASSE-1010 Standard or equivalent) should be installed (supplied

by others) in the common water supply line at the service connection.

Water must be proper hardness. Higher hardness may cause excessive formation of lime scale.

The plumber connecting this machine is responsible for making certain that water lines are

THOROUGHLY FLUSHED OUT BEFORE connecting to the dishwasher. This "flush-out" is necessary

to remove all foreign matter, such as chips (resulting from cutting or threading of pipes) pipe joint

compound from the lines; or, if soldered fittings are used, bits of solder or cuttings from the tubing.

Debris, if not removed, may lodge in the dishwasher's plumbing components and render them

inoperative. Manual valves or solenoid valves fouled by foreign matter and any expenses resulting from

this fouling, are NOT the responsibility of the manufacturer.

Water supply requirements are as follows:

MODEL TEMPERATURE FLOWING PRESSURE

LXiC 140°F Minimum 15 to 25 psi

LXiH 110°F Minimum 15 to 25 psi

If flowing pressure exceeds 25 psi, a pressure reducing-valve (not supplied) must be installed in the

supply line.

CAUTION: The water pressure regulator must have a relief bypass. Failure to use the proper

type of pressure regulator may result in damage to the unit.

If flowing pressure is less than 15 psi, improper machine operation may result.

A manual shutoff valve (not supplied) should be installed upstream of the fill hose to accommodate

servicing the machine.

It is recommended that a line strainer (not supplied) be installed in the supply line between the manual

shutoff valve (not supplied) and the connection point on the machine. Make plumbing connections with

1

/2" minimum copper piping OD (3/4" recommended), with a 3/4" male garden hose fitting (not supplied).

See installation diagrams, pages 10-11.

NOTE: Iron in the water supply can cause staining. An iron filter is recommended for iron concentration

greater than 0.1 part per million. High chloride levels in the water supply can cause pitting. A chloride

removal system is required if levels exceed 50 parts per million.

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY

AND PLUMBING CODES.

Drain

A drain hose,

3

/4" diameter and 6' long, is provided. This should be securely plumbed into the sink

drain. Use care not to kink hose. See installation diagrams in this manual. Drain must have a minimum

flow capacity of 4 gallons per minute.

– 6 –

Page 7

ELECTRICAL CONNECTION

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

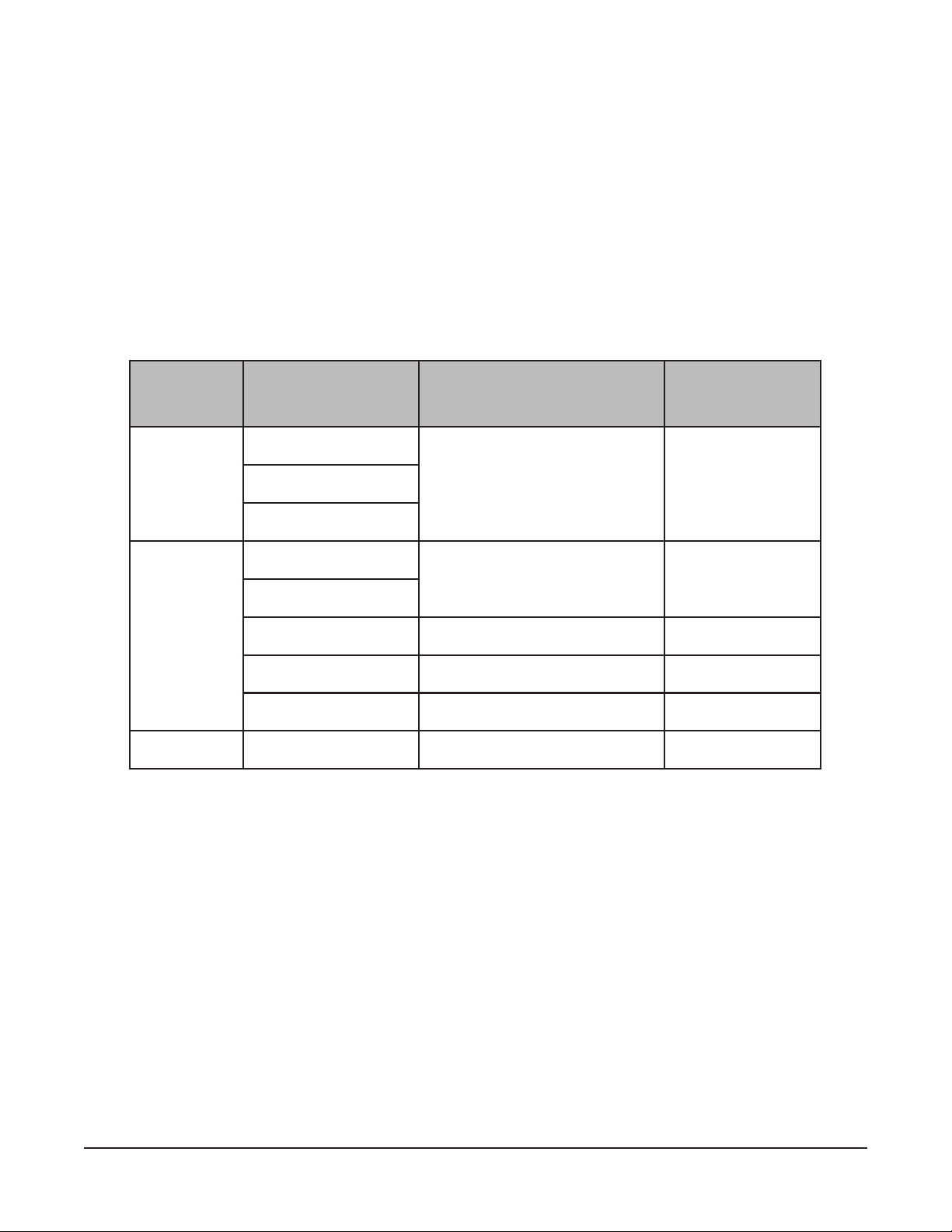

ELECTRICAL DATA

Complied in accordance with the National Electrical Code NFPA-70, latest addition.

NOTE:For supply connections, use copper wire only rated at 90°C minimum.

ledoM esahP/ztreH/stloV

tiucriCylppuSmuminiM

yticapmArotcudnoC

evitcetorPmumixaM

yticapmAeciveD

1/06/021

CiXL

CGiXL

02021/06/042-802

*1/06/)W3(042-802/021

1/06/042/802

0505

*1/06/)W3(042-802/021

HiXL

HGiXL

3/06/042-8025353

3/06/004-0835252

3/06/0840202

HiXL1/05/042-0220505

*The (3W) systems require three power wires that include a current carrying neutral. An additional

fourth wire must be provided for machine ground.

Refer to the data plate on the door handle of the machine and the label inside the control drawer at the

power connection for proper selection.

Use stranded copper wire suitable for at least 90°C.

– 7 –

Page 8

Connection Method

1. Remove the cover plate at the upper right in the back of the machine (Fig. 1). A hole for 1" trade

size conduit is supplied in the cover plate.

Fig. 1 Fig. 2

2. Remove the two screws (Fig. 2) securing the controls drawer and open it fully.

3. Install 1" trade conduit and fitting to the cover plate. A 90 degree fitting is recommended. Leave

at least four feet of electrical line between wall connection and cover plate connection. This

allows machine to be pulled away from the wall for cleaning.

4. Feed wires over top of tank to individual strain reliefs at rear of drawer. At least 32" and not more

than 36" of the required wire size must extend from the end of the conduit fitting.

5. Reinstall the cover plate (three screws, Fig. 1).

6. For all wires, run one wire through each individual strain relief. (Four strain reliefs are provided.)

Make electrical connections according to wiring diagram supplied with the machine and secure

wires to the machine service connection. Keep excess wire in the drawer to a minimum.

7. Tighten the set screw on the strain relief(s) until they bottom out (on the shoulder of the body).

8. Close the control drawer and replace the screws.

DETERGENT AND RINSE AID

Use only commercial-grade detergents recommended by your chemical professional. Do not use

detergents formulated for residential dishwashers.

The detergent and rinse aid pump "ON" times are factory-set. If adjustments are required, contact your

local Hobart Service Office.

Place the detergent and rinse aid containers (which are obtained from an independent supplier) in a

location where the delivery tubes will reach them.

Remove the detergent bottle cap and put the

Remove the rinse aid bottle cap and place the

red

delivery tube in the detergent container.

blue

delivery tube in the rinse aid container.

Be sure to push the delivery tube standpipes completely to the bottom of each container. Check to make

sure there are no obstructions or kinks in the delivery tubes.

– 8 –

Page 9

OPERATOR PROGRAMMING MODE

The Operator Programming mode allows changes to be made from factory settings to the chemical

pumps’ operation. This includes the Detergent and Rinse Aid pumps, but does not apply to the Sanitizer

pump on the LXiC and LXiGC models. The Detergent and/or Rinse Aid pumps can be turned off by

entering this programming mode. Disabling this feature will eliminate the alarm activation if no chemical

is sensed and turn the chemical pumps off. Machines not equipped with Hobart chemical pumps do not

have this programming mode.

1. To being the process start with the machine off.

2. First press the ON key, then immediately press and hold the OFF key to enter the user

programming mode. While the OFF key is being pressed the display will begin counting from "11"

going up to "99". Hold the OFF key until the counting ends and "WASH" and "Pr" is displayed on

the LED panel (Fig. 3). This indicates you are now in the programming mode. (The OFF key must

be pressed prior to the count reaching "44".)

Fig. 3

NOTE: If the "WASH" and "Pr" icons do not appear and the machine is equipped with the chemical

pumps, turn the unit off and try steps 1 through 3 again.

3. Press the WASH key to advance into the programming mode.

NOTE: The machine will shut off in 15 seconds if either the WASH key or the OFF key are not pressed.

To regain access to this mode follow steps 1 through 3.

4. The "DETERGENT" icon will now display either "On" or "OF" (Figs. 4 and 5). Pressing the WASH

key in either the Detergent or Rinse Aid mode changes the selection from "On" to "OF". When the

desired change is made press the OFF key to advance to the next mode.

Fig. 4 Fig. 5

NOTE: "On" indicates the Detergent or Rinse Aid pump will run and be sensed. "OF"" indicates the

Detergent or Rinse Aid pump is disabled, meaning it will not run or be sensed.

5. Pressing the OFF key advances to the Rinse Aid mode showing "On" or "OF". Press the WASH

key to change to desired setting.

6. When desired changes are completed allow the machine to turn itself off. It will do this

automatically after 15 seconds if no keys are depressed. The machine has saved changes and

is ready for use.

– 9 –

Page 10

WARNING:

REQUIRED FLOWING WATER PRESSURE TO THE DISHMACHINE IS 20 ± 5 PSIG. IF

PRESSURES HIGHER THAN 25 PSIG ARE PRESENT, A PRESSURE REGULATING VALVE

MUST BE INSTALLED IN THE WATER LINE TO THE DISHMACHINE (BY OTHERS).

IMPORTANT: THE SODIUM HYPOCHLORITE (LIQUID BLEACH) CONTAINER SHOULD BE

PLACED NO HIGHER THAN 10" ABOVE FLOOR.

IF BLEACH CONTAINER IS TO BE PLACED IN CABINET ADJACENT TO MACHINE, A 1/2" DIA.

HOLE IS REQUIRED IN THE CABINET TO RUN BLEACH SUPPLY LINE.

USE ONLY 6% SODIUM HYPOCHLORITE (LIQUID BLEACH) AS SANITIZING CHEMICAL TO

INSURE PROPER OPERATION OF DISHMACHINE. IF 8.4% IS TO BE UTILIZED CONTACT

HOBART SERVICE TO CHANGE THE SANITIZER PUMP SETTINGS.

DO NOT PRE-MIX RINSE AGENT AND SODIUM HYPOCHLORITE (LIQUID BLEACH).

CERTAIN MATERIALS INCLUDING SILVER PLATE, ALUMINUM AND PEWTER ARE ATTACKED

BY SODIUM HYPOCHLORITE (LIQUID BLEACH). SEE INSTRUCTIONAL MANUAL.

STEAM GENERATED FROM NORMAL OPERATION MAY ESCAPE FROM THE DOOR. WOOD

LAMINATE, VENEERS, ETC. ARE UNSUITABLE MATERIALS FOR USE IN AREAS EXPOSED

TO DISHWASHER STEAM AND DETERGENTS. STAINLESS STEEL OR OTHER MOISTURERESISTANT SHIELDS ARE RECOMMENDED FOR SURFACES ADJACENT TO LXi SIDES

AND TOP.

NOTES:

1. ALL VERTICAL MACHINE DIMENSIONS TAKEN FROM FLOOR MAY BE INCREASED BY 1".

2. MOIST AIR ESCAPES FROM THE DOOR.

USE ONLY MOISTURE RESISTANT MATERIALS ADJACENT TO LXi SIDES AND TOP.

3. A VENT HOOD IS NOT RECOMMENDED ABOVE THE LXi UNDERCOUNTER DISHWASHER

SINCE IT DOES NOT PRODUCE EXCESSIVE VAPORS

PLUMBING NOTES:

1. WATER HAMMER ARRESTOR (MEETING ASSE-1010 STANDARD OR EQUIVALENT) TO BE

SUPPLIED (BY OTHERS) IN COMMON WATER SUPPLY LINE AT SERVICE CONNECTION.

2. RECOMMENDED WATER HARDNESS TO BE 4-6 GRAINS FOR BEST RESULTS.

3. MINIMUM WATER CONDUCTIVITY REQUIRED - 30 MICRO-MHOS/CM.

4. IF DRAIN HOSE IS LOOPED ABOVE A SINK, THE LOOP MUST NOT EXCEED 38" AFF.

CONNECTION INFORMATION

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE

FOR 1" TRADE SIZE CONDUIT; 31-3/4" AFF.

P1 SINGLE FILL AND RINSE CONNECTION:

3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE; 140°F WATER

MIN. FOR LXiC, 110°F WATER MIN. FOR LXiH,

1-1/2" AFF.

P2 DRAIN CONNECTION: 3/4" MPT FITTING WITH

6' LONG HOSE SUPPLIED WITH MACHINE;

3-9/16" AFF.

MACHINE TYPE & RATED

SPECIFICATION AMPS

LXiC (120/60/1)

USE 90°C STRANDED 15.4 20 20

COPPER WIRE ONLY.

LXiC (120/208-240(3W)/60/1*)

LXiC (208-240/60/1)

USE 90°C STRANDED 13.6 20 20

COPPER WIRE ONLY.

LXiH (120/208-240(3W)/60/1*)

LXiH (208-240/60/1)

USE 90°C STRANDED

COPPER WIRE ONLY. 37.7 50 50

ELECTRICAL OPTIONS BELOW ARE NON STANDARD VOLTAGES AVAILABLE

AT EXTRA COST. CONSULT FACTORY FOR PRICING AND LEAD TIME.

LXiH 208-240/60/3 29.5 35 35

480/60/3 14.8 20 20

220-240/50/1 38.1 50 50

380-400/60/3 17.1 25 25

MIN SUPPLY MAX

CKT CONDUCT PROTECTIVE

AMPACITY DEVICES

INSTALLATION DIAGRAM (LXiC & LXiH)

– 10 –

* THIS SYSTEM REQUIRES THREE POWER WIRES WHICH INCLUDES

A CURRENT CARRYING NEUTRAL, AN ADDITIONAL FOURTH WIRE

MUST BE PROVIDED FOR MACHINE GROUND.

ACCESSORY CORD KITS AVAILABLE FOR ALL MACHINES

SHIPPING WEIGHTS (LBS) LXiC LXiH

NET WEIGHT OF MACHINE 190 lbs. 210 lbs.

DOMESTIC SHIPPING WEIGHT 235 lbs. 255 lbs.

ELECTRICAL AND GROUNDING CONNECTIONS

MUST COMPLY WITH THE APPLICABLE PORTIONS

OF THE NATIONAL ELECTRICAL CODE AND/OR

OTHER LOCAL ELECTRICAL CODES.

PLUMBING CONNECTIONS MUST COMPLY WITH

APPLICABLE SANITARY, SAFETY AND PLUMBING

CODES. DRAIN AND FILL LINE CONFIGURATIONS

VARY, SOME METHODS ARE SHOWN ON THIS DRAWING.

WARNING

Page 11

WARNING:

REQUIRED FLOWING WATER PRESSURE TO THE GLASSWASHER IS 20 ± 5 PSIG. IF

PRESSURES HIGHER THAN 25 PSIG ARE PRESENT, A PRESSURE REGULATING VALVE

MUST BE INSTALLED IN THE WATER LINE TO THE GLASSWASHER (BY OTHERS).

IMPORTANT: THE SODIUM HYPOCHLORITE (LIQUID BLEACH) CONTAINER SHOULD BE

PLACED NO HIGHER THAN 10" ABOVE FLOOR.

IF BLEACH CONTAINER IS TO BE PLACED IN CABINET ADJACENT TO GLASSWASHER, A

1/2" DIA. HOLE IS REQUIRED IN THE CABINET TO RUN BLEACH SUPPLY LINE.

USE ONLY 6% SODIUM HYPOCHLORITE (LIQUID BLEACH) AS SANITIZING CHEMICAL TO

INSURE PROPER OPERATION OF DISHMACHINE. IF 8.4% IS TO BE UTILIZED CONTACT

HOBART SERVICE TO CHANGE THE SANITIZER PUMP SETTINGS.

DO NOT PRE-MIX WETTING AGENT AND SODIUM HYPOCHLORITE (LIQUID BLEACH).

CERTAIN MATERIALS INCLUDING SILVER PLATE, ALUMINUM AND PEWTER ARE ATTACKED

BY SODIUM HYPOCHLORITE (LIQUID BLEACH). SEE INSTRUCTIONAL MANUAL.

NOTES:

1. ALL VERTICAL MACHINE DIMENSIONS TAKEN FROM FLOOR MAY BE INCREASED BY 1".

2. MOIST AIR ESCAPES FROM THE DOOR.

USE ONLY MOISTURE RESISTANT MATERIALS ADJACENT TO LXiG SIDES AND TOP.

3. A VENT HOOD IS NOT RECOMMENDED ABOVE THE LXiG UNDERCOUNTER

GLASSWASHER SINCE IT DOES NOT PRODUCE EXCESSIVE VAPORS

PLUMBING NOTES:

1. WATER HAMMER ARRESTOR (MEETING ASSE-1010 STANDARD OR EQUIVALENT) TO BE

SUPPLIED (BY OTHERS) IN COMMON WATER SUPPLY LINE AT SERVICE CONNECTION.

2. RECOMMENDED WATER HARDNESS TO BE 4-6 GRAINS FOR BEST RESULTS.

3. MINIMUM WATER CONDUCTIVITY REQUIRED - 30 MICRO-MHOS/CM.

4. IF DRAIN HOSE IS LOOPED ABOVE A SINK, THE LOOP MUST NOT EXCEED 38" AFF.

CONNECTION INFORMATION

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE

P1 SINGLE FILL AND RINSE CONNECTION:

P2 DRAIN CONNECTION: 3/4" MPT FITTING WITH

(AFF = ABOVE FINISHED FLOOR)

FOR 1" TRADE SIZE CONDUIT; 31-3/4" AFF.

3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE; 140°F WATER

MIN. FOR LXiGC, 110°F WATER MIN. FOR LXiGH,

1-1/2" AFF.

6' LONG HOSE SUPPLIED WITH MACHINE;

3-9/16" AFF.

MACHINE TYPE & RATED

SPECIFICATION AMPS

LXiGC (120/60/1)

USE 90°C STRANDED 15.4 20 20

COPPER WIRE ONLY.

LXiGC (120/208-240(3W)/60/1*)

LXiGC (208-240/60/1)

USE 90°C STRANDED 13.6 20 20

COPPER WIRE ONLY.

LXiGH (120/208-240(3W)/60/1*)

LXiGH (208-240/60/1)

USE 90°C STRANDED

COPPER WIRE ONLY. 37.7 50 50

ELECTRICAL OPTIONS BELOW ARE NON STANDARD VOLTAGES AVAILABLE

AT EXTRA COST. CONSULT FACTORY FOR PRICING AND LEAD TIME.

LXiGH 208-240/60/3 29.5 35 35

480/60/3 14.8 20 20

220-240/50/1 38.1 50 50

380-400/60/3 17.1 25 25

MIN SUPPLY MAX

CKT CONDUCT PROTECTIVE

AMPACITY DEVICES

INSTALLATION DIAGRAM (LXiGC & LXiGH)

– 11 –

* THIS SYSTEM REQUIRES THREE POWER WIRES WHICH INCLUDES

A CURRENT CARRYING NEUTRAL, AN ADDITIONAL FOURTH WIRE

MUST BE PROVIDED FOR MACHINE GROUND.

ACCESSORY CORD KITS AVAILABLE FOR ALL MACHINES

SHIPPING WEIGHTS (LBS) LXiGC LXiGH

NET WEIGHT OF MACHINE 194 lbs. 214 lbs.

DOMESTIC SHIPPING WEIGHT 239 lbs. 259 lbs.

WARNING

ELECTRICAL AND GROUNDING CONNECTIONS

MUST COMPLY WITH THE APPLICABLE PORTIONS

OF THE NATIONAL ELECTRICAL CODE AND/OR

OTHER LOCAL ELECTRICAL CODES.

PLUMBING CONNECTIONS MUST COMPLY WITH

APPLICABLE SANITARY, SAFETY AND PLUMBING

CODES. DRAIN AND FILL LINE CONFIGURATIONS

VARY, SOME METHODS ARE SHOWN ON THIS DRAWING.

Page 12

CHEMICAL SANITIZER (LXiC AND LXiGC)

CAUTION: Items such as pewter, aluminum and silver will be attacked by sodium hypochlorite

(bleach). Therefore, chemical-sanitizing dishwashers should not be used to wash such items.

On model LXiC only, the chemical sanitizer pump is factory-set for use with 6% sodium hypochlorite

solution. If 8.40% sodium hypochlorite solution is to be used, contact your local Hobart Service

Office.

Place a 1-gallon bottle of 6% or 8.40% sodium hypochlorite solution (bleach) in a suitable location no

higher than 10 inches off the floor. Do not pre-mix sanitizing solution with water or any other liquid.

WARNING: NEVER PREMIX A WETTING AGENT WITH THE SANITIZING SOLUTION. MIXING

MAY CAUSE HAZARDOUS GAS TO FORM.

Remove the sanitizer bottle cap and place the

to push the delivery tube standpipe completely to the bottom of the container. Check to make sure there

are no obstructions or kinks in the delivery tube.

The LXi Series Dishwasher has an auto-prime cycle. (See Operating the LXi Dishwasher.)

Frequently check your sanitizer bottle to make sure there is a sufficient chemical supply.

white

delivery tube in the sanitizer container. Be sure

OPERATION

CAUTION: Items such as pewter, aluminum and silver will be attacked by sodium hypochlorite

(bleach). Therefore, chemical-sanitizing dishwashers should not be used to wash such items.

If your dishwasher is a chemical-sanitizing model, frequently check the sanitizer bottle to make sure

there is a sufficient chemical supply.

BEFORE FIRST USE

This machine must be cleaned after installation and before being put into operation. (See Cleaning.)

CONTROLS

Fig. 6

– 12 –

Page 13

OPERATING THE LXi DISHWASHER

SIHTOD SWOHSYALPSID SKRAMER

.NOsserP

.gnillif

lliF

sehsidfokcaredils;roodnepO

ddadnarehsawhsidotni

.roodesolC.tnegreted

.rebmunledoM

erutarepmetpmusdnatilLLIF

sienihcamnehwdeyalpsid

sehsalf

.setunim8

.deyalpsidsi

.erutarepmetpmuShtiwdeppiuqesiseireSiXLledoMruoyfI

siretsoobnehw

.HiXLledomnognitaeherp

otpuekatdluoctaeherpsihT

erutarepmetpmus,llifgniruD

.elcyc

.sdnoces01-5sekat

.deppotstierehwseunitnoc

.eciffOecivreStraboHlacol

.pmusro/dnaretsoob

sihT.kcehc-flessmrofreprehsawhsiD

,dellifnehW.retawhtiwsllifrehsawhsiD

.sdnoces01rofnosnrutpmup

lliwllif,elcycllifgniruddeneposiroodfI

ssecorpeht,desolcsiroodretfA.pots

a,elcycllifagniruddesserpsiHSAWfI

.elcyclliffodnetanigeblliwelcychsaw

,lliftonlliwenihcamdnasdnuosrepeebfI

yrtdna,noneht,fforekaerbtiucricnrut

ruoytcatnoc,stsisrepmelborpfI.niaga

naniatniamlliwenihcam,dellifnehW

htobnideniatniamsitaeH.etatseldi

tnegreted,pmuptnegretedlanoitpoeht

hsawgnirudyllacitamotuadeddaeblliw

.HSAWsserPerutarepmetpmus;tilHSAW

daoler,etelpmocsielcycnehW

;elcycesnir/hsawtxenrofenihcam

lliwenihcam,esunitonfi,ro

.edomeldiniatniam

.FFOsserp,yadfodneehttA

.elcychsawgniruddeyalpsid

erutarepmetesnir;tilESNIR

.elcycesnirgniruddeyalpsid

.erutarepmetpmuSehtfinwodtuhsdnaniardlliwenihcaM

ehtnitneserpsiretawfI

nehtdeyalpsidsi"dP",pmus

.nwodstuhsyalpsideht

.elcycesnirdnahsawasetaitinienihcaM

elcyc,elcychsawgniruddeneposiroodfI

siroodnehwgninnigebmorftratserlliw

.desolc

niardroesnirgniruddeneposiroodfI

erehwtnioptaeunitnoclliwelcyc,elcyc

.roodgnisolcnopudeneposawrood

enihcam,elcycgniruddesserpsiFFOfI

.nwodtuhsdnaniardlliw

siemitnwodtuhseldidemmargorp

.dehcaer

lliwenihcam,desserpsiyekFFOnehW

.nwodtuhsdnaniard

– 13 –

Page 14

DIAGNOSTIC MESSAGES

In the event of a problem with a temperature probe, the display will flash P1, P2 or P3 every second.

The respective heaters will shut down. Other functions will continue to operate normally. Contact your

local Hobart Service Office.

Drain and fill error messages are displayed as E0, E1, E2, E3, E4, E5, E6 or E7. In all cases, the

dishwasher will terminate current cycle operations, turn off all heat sources and display the message

until the OFF button is pressed. (A power drain will not occur when turned off.) (See Troubleshooting.)

If problem persists, contact your local Hobart Service Office.

If the control detects that the water level probe is becoming less sensitive, CL and Pr are displayed in

the control window. Clean all three water level probes. (See Cleaning.)

WASH/RINSE CYCLE TIMES (LXi)

Spritz 2 Sec.

Wash 85 Sec.**

Drain 22 Sec. Max.*

Dwell 1 Sec.

Rinse 10 Sec.

Dwell 5 Sec.

* Drains off about

3

/4 gallon of water.

** Maximum wash time may vary, depending on operation voltage and incoming water temperature

for 70°F rise.

WASH/RINSE CYCLE TIMES (LXiG)

Spritz 2 Sec.

Wash 45 Sec.**

Drain 22 Sec. Max.*

Dwell 1 Sec.

Rinse 10 Sec.

Dwell 5 Sec.

* Drains off about

3

/4 gallon of water.

** Maximum wash time may vary, depending on operation voltage and incoming water temperature

for 70°F rise.

– 14 –

Page 15

PREPARATION

Make sure the coarse (Fig. 7) and fine (Fig. 8) strainers are in place and free of debris. Check both wash

arms and rinse arms to make sure they spin freely and are not clogged.

COARSE STRAINER

Fig. 7 Fig. 8

FINE STRAINER

Dishes must be scraped and/or rinsed to remove food particles and other debris. Never use steel wool

on ware to be loaded into the dishwasher. Place dishes in a rack. Do not stack dishes on top of each

other as water must have free access to all sides of every dish. Stand plates edgewise in a peg-type

rack (Fig. 9). Cups, glasses and bowls should lay upside down in an open or compartment-type rack

(Fig. 9). Silverware and other small pieces should lay loosely on the bottom of a flat-bottom rack. See

Operator Card (supplied) for other loading patterns. Do not allow foreign objects to enter the unit,

especially metallic contaminants such as staples and paper clips.

Check to see if any detergent, rinse aid or sanitizer chemicals need to be replenished. Use only

commercial-type detergents, as prescribed by your chemical professional.

Fig. 9

– 15 –

Page 16

DO'S AND DON'TS FOR YOUR NEW HOBART DISHWASHER

DO assure proper water hardness.

DO prescrape dishes thoroughly.

DO use only detergents recommended by your chemical professional.

DO, at the end of the day, thoroughly cleanse the machine, rinse and dry. (Leave door open.)

DO closely follow your chemical professional's prescribed deliming schedule.

DO use only products formulated to be safe on stainless steel.

DO NOT oversoften water. (Recommended water hardness is no less than 4 grains per gallon.)

DO NOT use detergents formulated for residential dishwashers.

DO NOT allow food soil to accumulate on the tank bottom.

DO NOT exceed chemical manufacturer's recommended concentrations for detergent, sanitizer, rinse

aid or lime scale remover.

DO NOT use steel wool to clean ware or warewasher surface.

DO NOT allow foreign objects to enter the unit, especially metallic contaminants.

NOTE: Failure to follow use, care and maintenance instructions may void your Hobart warewasher

warranty.

– 16 –

Page 17

CLEANING

This machine must be cleaned at least once each working day. Use only products formulated to be safe

on stainless steel.

THUMB NUT

1. Press OFF. The machine will drain. When the

display is no longer lit, open the door and remove

any debris from the bottom of the tank. Do not

allow food soil to accumulate on the tank bottom.

2. Remove the lower rinse arm by unscrewing the

thumb nut (Fig. 10). Remove the lower wash arm

by pulling the arm off the shaft. Remove the upper

rinse and wash arms in the same manner. Remove

the coarse and fine strainers. (See Figs. 7 and 8).

Thoroughly clean these items in a sink. Remove

debris from wash/rinse arm nozzles.

Fig. 10

3. With a damp cloth, wipe the interior of the machine. With a nonmetallic scouring pad, clean the

rear water level probes (Fig. 11) and the front water level probe (Fig. 12) under the fine strainer.

DO NOT use steel wool. Wipe the exterior of the machine. When cleaning the inside of the door,

be sure to wipe the lip at the bottom of the door. Remove any remaining debris with a mild cleanser

formulated for stainless steel and a soft cloth or brush.

WATER LEVEL PROBE

Fig. 11 Fig. 12

4. Replace the coarse and fine strainers. Reinstall the lower wash arm by pushing it down on the

shaft and then place the lower rinse arm on the shaft and securely tighten the thumb nut. Spin

arms to make sure they spin freely. Repeat this procedure with the upper wash and rinse arms.

5. Use a soft, damp cloth or sponge and mild cleanser to clean the control keypad and display. DO

NOT use abrasive or harsh cleaners or scouring pads.

6. Leave the door ajar overnight to allow the interior to air out and dry.

– 17 –

Page 18

PRIMING CHEMICAL PUMPS

When a chemical becomes empty, the priming operation starts automatically the next time the machine

is turned on or a wash cycle is started. This feature is only supported on machines with the chemical

sense board installed and where CHEMICAL SENSING is enabled. Note that the initial prime time for

all pumps (Detergent, Rinse Agent and Sanitizer) is 60 seconds during which time the chemical icon

will flash. If the chemical is not sensed within 60 seconds, the chemical icon will remain lit and the control

will beep for about 5 seconds. After the chemical is sensed, the indicator in the display turns off; and

the pump continues to prime for 20 seconds to allow the chemicals to reach the machine. If all

chemicals are empty, the sanitizer will prime first followed by detergent. Only one chemical pump will

run at a time.

If chemicals are not sensed after three consecutive priming operations, the wrench is displayed along

with the empty chemical icon and priming is cancelled. The next time a wash cycle is started, the control

will flash the wrench and empty chemical icon as well as beep. This is to prevent the priming operation

in case the chemical sensors have malfunctioned. Verify that the chemical bottles are not empty. If they

are not empty, the chemical sensor or pumps have malfunctioned; contact your local Hobart Service

Office.

The priming operation can be reset by either:

• Pressing the WASH key a second time while the wrench and empty chemical icon is flashing.

• By turning the dishwasher off, then back on.

NOTE: If the use of chemical pumps is not desired, refer to the Operator Programming Mode section.

– 18 –

Page 19

MAINTENANCE

DELIMING

WARNING: DELIMING SOLUTION, RINSE AGENTS OR ANY OTHER KIND OF ACID MUST NOT

COME IN CONTACT WITH BLEACH OR RINSE SOLUTION CONTAINING BLEACH USED IN

CHEMICAL-SANITIZING MACHINES. MIXING MAY CAUSE HAZARDOUS GAS TO FORM. THIS

ENTIRE PROCEDURE MUST BE FOLLOWED STEP BY STEP FOR SAFE AND SATISFACTORY

RESULTS.

CAUTION: Do not allow the deliming agent to remain in the machine longer than recommended

by the deliming agent manufacturer.

DELIME THE DISHWASHER ON A REGULAR BASIS AS REQUIRED. The regularity will depend on

mineral content of the supply water. Deliming should be done when you can see clear signs of lime

deposits (a white, chalky substance) on the inside walls and on the wash arms. LXi models are

equipped with an automatic delime cycle reminder. It is recommended that deliming be done when

DELIME flashes.

If deliming is necessary, a deliming agent (such as Lime Away or LSR) should be used for best results.

After the preprogrammed number of cycles has expired, which is factory-set for 1500 cycles, the

control will indicate the delime request by displaying DELIME. Machine operation will continue as usual.

To remove the DELIME icon, you must either enter a delime cycle or reprogram the number of cycles

to terminate the DELIME indication. (If the dishwasher needs to be reprogrammed, contact your local

Hobart authorized service office.)

1. Remove rack from machine. Close door.

2. Press OFF to power down the dishwasher.

3. Press and hold WASH (DELIME) while pressing ON. The display will show DELIME during the

fill cycle.

4. After the fill cycle, the control will prompt you to add delimer by flashing ADD and DELIME. Open

the door and add deliming agent. (Carefully follow supplier's instructions.) The sump holds

approximately 3 gallons of water.

5. After delimer has been added, close the door. Press the WASH (DELIME) key again to continue

the cycle. The machine will enter the wash mode for 5 minutes, then will begin two rinse and drain

operations. The DELIME symbol will flash in the display.

NOTE: DO NOT interrupt the cycle. Should the process be interrupted, restart delime procedure from

the beginning.

6. After the deliming operation is completed, power to the control will be turned off.

7. Inspect the interior of the machine for lime deposits. If necessary, repeat steps 3 through 7.

LUBRICATION

The pump motor has permanently sealed bearings and requires no lubrication.

– 19 –

Page 20

TROUBLESHOOTING

This section outlines various symptoms and possible causes that may be encountered in the event of

abnormal machine operation. If symptoms persist after possible causes have been checked, service

may be required.

Symptom Possible Causes

No machine operation 1. Machine OFF - turn machine ON.

(no display). 2. Blown fuse or circuit breaker off at power supply.

3. Cord not plugged in (corded models only)

No machine operation 1. Display: "dr" "oP" - open and

(with display). close door. If problem persists, contact your local Hobart

Service Office.

2. See "Machine won't fill or won't fill high enough."

Dishes not clean. 1. Strainers clogged causing inadequate water supply to pump -

clean according to instructions. (See Cleaning.)

2. Obstruction in wash arm(s) or wash arms will not turn - clean

according to instructions. (See Cleaning.)

3. Wash or rinse arms will not turn - check that they spin.

4. Detergent dispenser may be clogged.

5. Soil quantity - scrape dishes before cycle.

6. Improper rack loading - see Preparation in this manual.

7. Low water - check water pressure.

8. Water temperature too low - note wash temperature on display

during WASH; should be above 120°F for chemical-sanitizing

machines and above 150°F for other machines.

9. Incoming water supply turned off.

Spotting of silverware, 1. Improperly loaded racks.

glasses or dishes. 2. Water temperature too low.

3. Improper type or concentration of detergent - contact your

local detergent representative.

4. Hard water - install a water softener; use a rinse agent.

5. Insufficient fill - check water pressure.

Chemicals not feeding. 1. Low on chemicals - check levels.

2. Air leak at feeder hose connections - check for snugness.

3. Tubes kinked - check for smooth bends.

Food soils remain in Follow daily cleaning instructions. (See Cleaning.)

dishwasher.

– 20 –

Page 21

Symptom Possible Causes

Unexpected results on 1. Etching - usually caused by any combination of high

dishes. temperatures, soft water, soft glass or high alkaline washing

solutions.

2. Tarnishing - avoid washing silver, silver plates and pewter in

chemical-sanitizing machines.

3. Pitting - stainless steel may pit with lengthy contact of foods

containing salt, fruit juices, vinegar, etc. Wash immediately.

4. Black or gray marks - may have been rubbed with aluminum.

5. Brown stains - may be due to high iron content in water supply.

6. Chipping - improper loading or ware is too delicate.

7. Fading of china patterns - usually due to high water temperature

and strong detergent. Check that china is dishwasher compatible.

8. Wooden ware damage - avoid washing in dishwasher.

9. Rust on cast iron - seasoning is lost in dishwasher. Avoid

dishwasher cleaning.

10. Plastic ware distortion - high temperatures. Check plastic

ware's instructions.

Low-temperature readings. 1. Low water supply temperature - make sure it meets the

recommended limits.

2. Rapid cycle use - if incoming water temperature is low and

cycle use rate is high, the hot water supply may be insufficient

to meet the demand.

3. Heavy ware load cools wash water - do not overload racks.

4. Booster heater or sump heater set low - contact your local

Hobart Service Office.

Machine will not fill or will not 1. Low water pressure - check for clogged hose strainer; ensure

fill high enough. the site water pressure meets minimum flow pressures.

(Display shows E0, E2, 2. Make sure probes are clean. (See Cleaning.)

E3 or E4. Machine will not 3. No water pressure - main water supply valves may not be

run). working.

4. Anti-siphon valve - located in the lower left area of the chamber

just above the water line. Drain the machine and insert toothpick

or similar object into hole to verify ball (3/16" OD) is free to float.

5. Delime machine.

– 21 –

Page 22

Symptom Possible Causes

Machine fills too high or 1. Machine not level - see LEVELING in this manual.

leaks from door. 2. Fill solenoid valve leaking - turn the dishwasher OFF; if water

(Display shows CL/Pr.) continues to come in, contact your local Hobart Service Office.

3. Clean water level probes. (See Cleaning.)

Machine will not drain. 1. Drain pipes restricted - check dishwasher drain line for kinks;

(Display shows E5). ensure proper drain rate is allowed from plumbing.

2. Turn machine OFF. Wait several seconds and then turn back

ON. Repeat this procedure twice if necessary. If problem

persists, contact your local Hobart Service Office.

Some water occasionally This is normal due to expansion of water being heated in the

drips out of rinse arms booster tank.

(H dishwashers only).

Machine displays E6. Contact your local Hobart Service Office.

Machine lights up wrench Contact your local Hobart Service Office.

and flashes P1, P2 or P3.

Machine lights up wrench Refer to Priming Chemical Pumps.

and chemical icon.

– 22 –

Page 23

NOTES

– 23 –

Page 24

NOTES

FORM 34779 Rev. B (Sept. 2005) PRINTED in U.S.A.

– 24 –

Loading...

Loading...