Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

LXeR

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Racks per hour Light Normal Heavy

LXeR 30 24 13

■ .62 gallons of water per rack – LXeR

■ Hot water sanitation

■ Steam Elimination and Energy Recovery

■ NSF Certied pot and pan cycle on heavy cycle

■ Low chemical alert indicators

■ Sense-A-Temp™ booster heater capable of

70°F rise

■ Chemical pump “auto-prime”

■ Advanced Service diagnostics

■ Clogged wash arm sensing

■ Custom cycle selection – light, normal, heavy

■ Automated delime cycle – includes booster

deliming

■ Deep drawn stainless steel tank

■ Microcomputer, top mounted controls with

advanced digital cycle/temperature display

■ Revolving upper and lower anti-clogging wash

arms

■ Snap in revolving upper and lower rinse arms

■ Removable stainless steel scrap screen

■ Corrosion resistant pump

■ Energy Saver mode

■ Automatic pumped drain

■ 17" door opening

■ Dirty water indicator

■ Automatic ll

■ Detergent, rinse aid and delime pumps standard

■ Electric tank heat

■ Two dishracks – one peg and one combination

type

■ Customizable “advansys” button to select

favorites function

■ Auto clean cycle washes down inside of

machine at shutdown

HOT

MODEL

❑ LXeR – Energy Recovery

STANDARD VOLTAGE

❑ 120/208-240(3W)/60/1

OPTIONS AT EXTRA COST

❑ 208-240(2W)/60/1

❑ 208-240/60/3

❑ 220-240/50/1

❑ Door lock (prevents door from opening until

completion of cycle)

ACCESSORIES

❑ Power cord kits

❑ Stainless steel base with 6" legs

❑ 17" stainless steel stand with storage

❑ External caster kit

❑ DWT-L Xe drain water tempering kit

Specications, Details and Dimensions on Back.

LXeR HOT

F40336 – LXeR Hot Page 1 of 4

Page 2

LXeR

HOT

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 2 of 4 F40336 – LXeR Hot

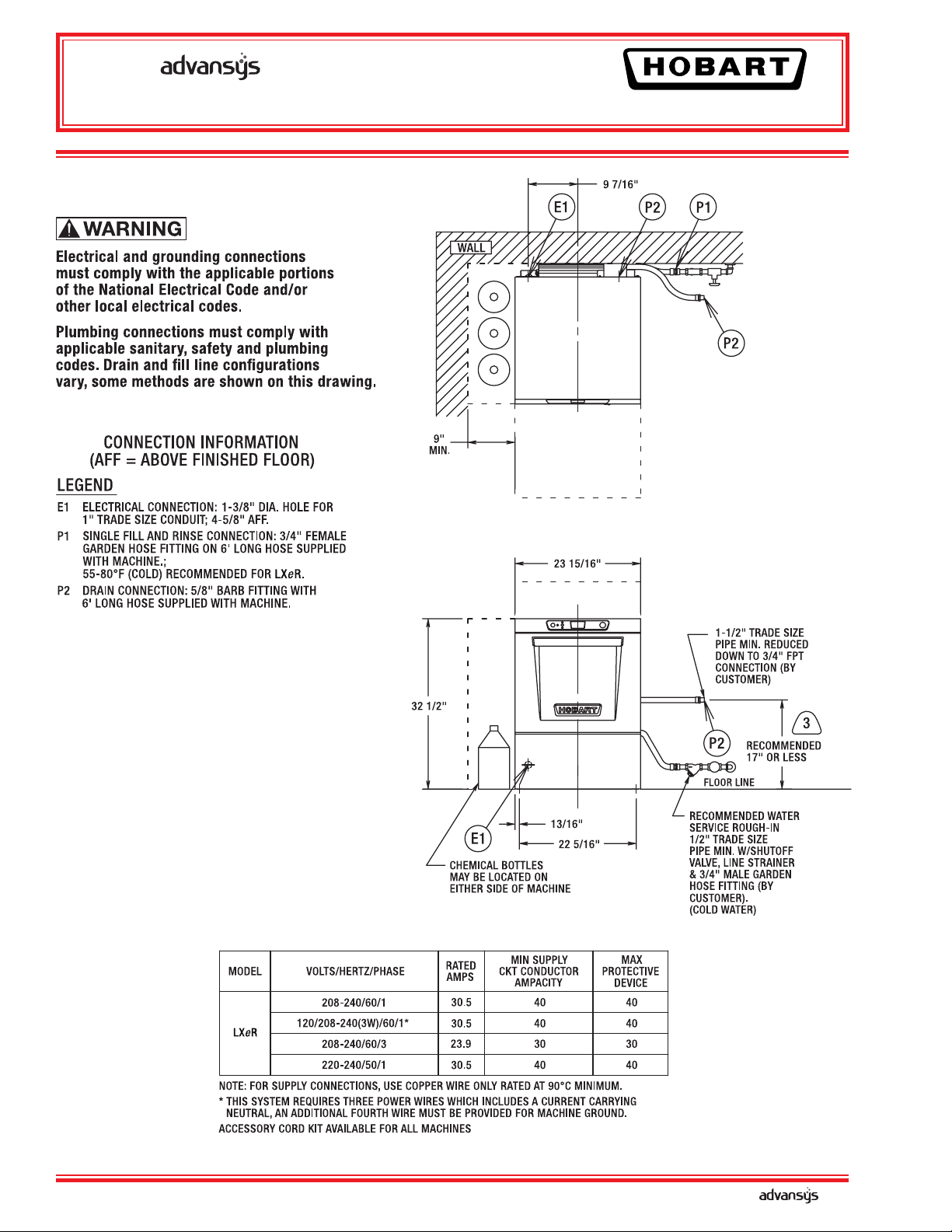

Page 3

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

LXeR

HOT

F40336 – LXeR Hot Page 3 of 4

Page 4

LXeR

HOT

SPECIFICATIONS

DESIGN: Front opening, equipped for installation in either

freestanding or undercounter-type operations.

CONSTRUCTION: 300 series stainless steel tank, door and

top panel.

PUMP: Centrifugal-type, integral with motor, horizontally

mounted. Pump capacity 38 gpm.

MOTOR: Single phase, furnished for all electrical specications. Factory sealed lubrication. Inherent overload protection

with auto reset.

WASH AND RINSE CYCLE: Complete automatic type, controlled by solid-state electronics. Cycle may be interrupted

any time by opening door. Cycle continues when door is

closed.

• Initial cycle lls wash tank, to be recirculated each wash

cycle. Some wash water is drained off before rinse cycle.

Rinse cycle refreshes wash water and tank heat.

RINSE PUMP: Powered by a single phase motor, the rinse

pump is made of high strength engineered composite

material.

BLOWER: The blower is a 60mm x 300mm tangential wheel

powered by a 2-pole single phase motor for quiet and reliable

operation, LXeR only.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

CONDENSER COIL: The condensing system uses a tube

and n coil constructed of copper and corrosion resistant

aluminum. The condenser coil allows for energy recovery

from waste heat in the moisture laden air that would normally

escape into the environment after a dishwashing cycle, LXeR

only.

RINSE AND SANITATION:

• LXeR: Sanitation is accomplished by means of a built-in

booster heater designed to raise temperature of water to a

minimum of 180°F from an incoming water temperature of

55°F.

ENERGY RECOVERY: Heat energy is recovered from the

condensation of vapors in the chamber at the end of each

cycle. This pre-heats the water for the next rinse cycle from

55°F up to 140°F.

PUMPED DRAIN: Machine automatically drains water

through a built-in pump. Maximum 38" drain height permitted.

ELECTRIC BOOSTER HEATER: 4.9 KW electric booster

with Sense-A-Temp™ technology adequately sized to raise

55°F inlet water to 180°F, with the aid of the energy recovery

system.

RACKING: Machines accommodate racks from 10" x 20" to

20" x 20". Also accepts 16" x 18" cafeteria trays.

SPECIFICATIONS: Listed by Underwriters Laboratories Inc.

and NSF International.

MACHINE RATINGS

Racks per Hour Rate 30 24 13

Dishes per Hour (25 per Rack Avg.) 750 600 325

Glasses per Hour (36 per Rack Avg.) 1080 864 468

Controls Microcomputer

Tank Capacity - Gallons 2.9

Overall Dimensions - H x W x D 321⁄2 " x 2315⁄16" x 2613⁄16"

Cycle Time - Seconds 120 146 275

Tank H e a t 1.8 K W

Electric Booster Heater 4.9 KW

Water Usage Per Rack - Gallons .62

Drain Design Pumped

Door Opening Height 17"

Detergent Pump Standard

Rinse-Aid Pump Standard

Delime Pump Standard

Sanitizer Pump N/A

Chemical Prime (auto prime) Standard

Peak Drain Flow - GPM 4.0

Advanced Service Diagnostics Standard

Advanced Cleaning Cycle Standard

70°Rise Sense-A-Temp™ Booster Heater Standard

Incoming Water Temperature Required (minimum) 55°

Light Normal Heavy

LXeR

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 4 of 4 F40336 – LXeR Hot

F40336 (REV. 10/17) LITHO IN U.S.A. (H-01)

Loading...

Loading...