Hobart HX-30, HX-30 S, HX-40, HX-40 S, FX-30 Installation & Operation Manual

...

HX-30/40 and HX-30/40 S

Glass and Dishwashers

INSTALLATION OPERATION

VERSION 18/01/00

2

Installation and Operation Instructions

for Model HX-30/40 and

HX-30/40 S (with built-in softener)

Content Page

1 Installation............................................................................................. 4

2 Connections .......................................................................................... 4

3 Controls................................................................................................. 6

4 First run................................................................................................. 7

5 Dispensers ...................................................................................... 8, 10

6 Softener (HX-30/40 S only)............................................................ 9, 11

7 Operation ............................................................................................ 12

8 Cleaning.............................................................................................. 13

9 Frost prevention .................................................................................. 14

10 Maintenance ....................................................................................... 14

11 Trouble shooting guide......................................................................... 15

Machine noise level is ≤ 70 dB (A)

Important Notes

● Use in Accordance with Regulations

This machine is exclusively to be used to wash ware such as plates,

cups, glasses, cutlery, trays etc.

Do not use for electrically heated cooking and heat conservation

appliances.

● Safety

Never hose down the machine.

The "Attention" symbol is shown beside instructions that are essential

for the safe operation of the machine. Please read these passages

very thoroughly.

● Liability

Installations and repairs which are not carried out by authorized

technicians or the use of other than original spare parts, and any

technical alterations to the machine, may affect the warranty set

out in the standard conditions of sale.

3

1 Installation

1.1 Location

– Wall clearance of 100 mm is required.

– Level machine by turning the feet.

– Distribute machine weight equally onto all feet.

B

A

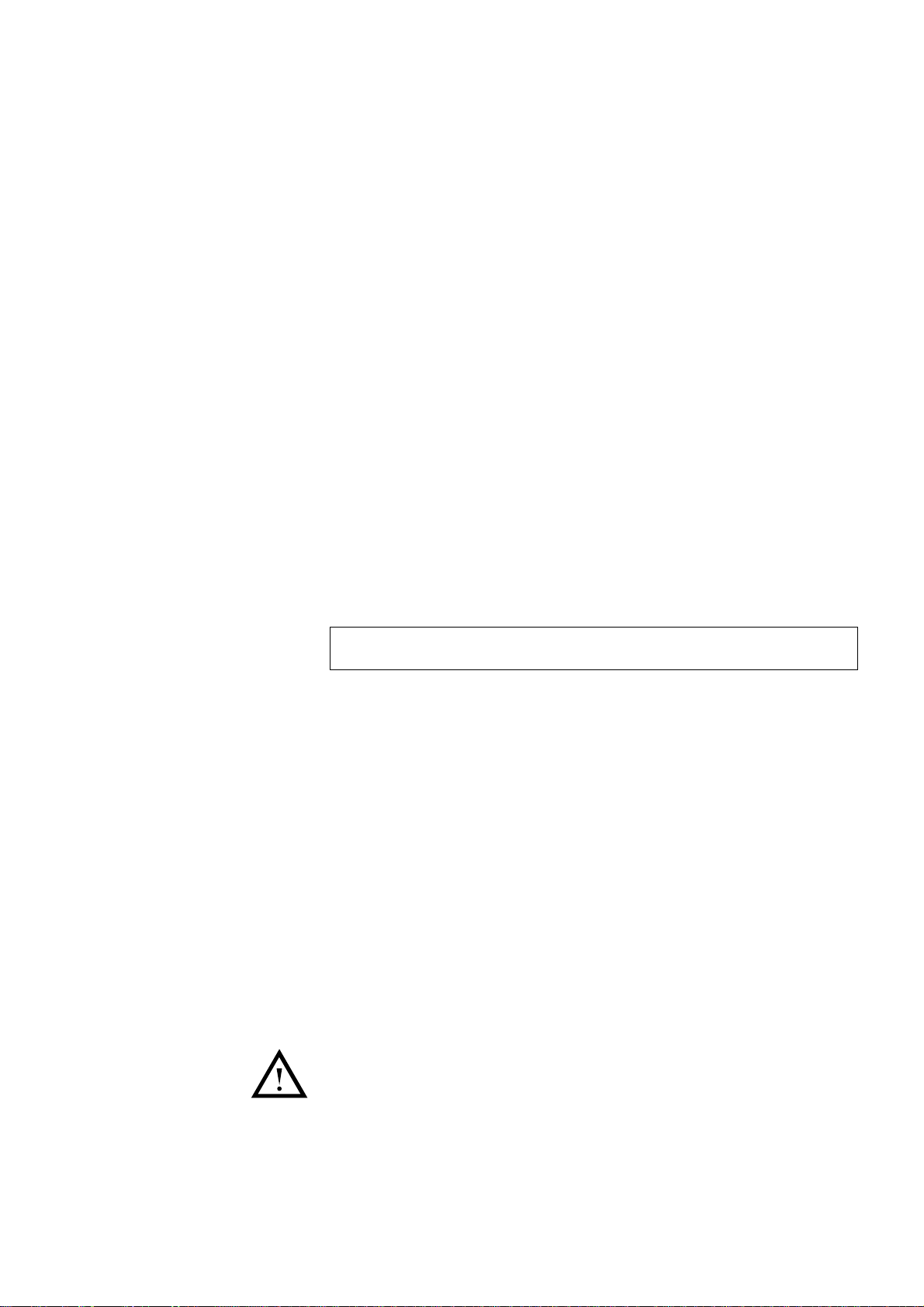

1.2 Converting to corner version

– Open the hood, unscrew guide rail A and fix it to position B.

– To set the tables see installation plan.

2 Connections

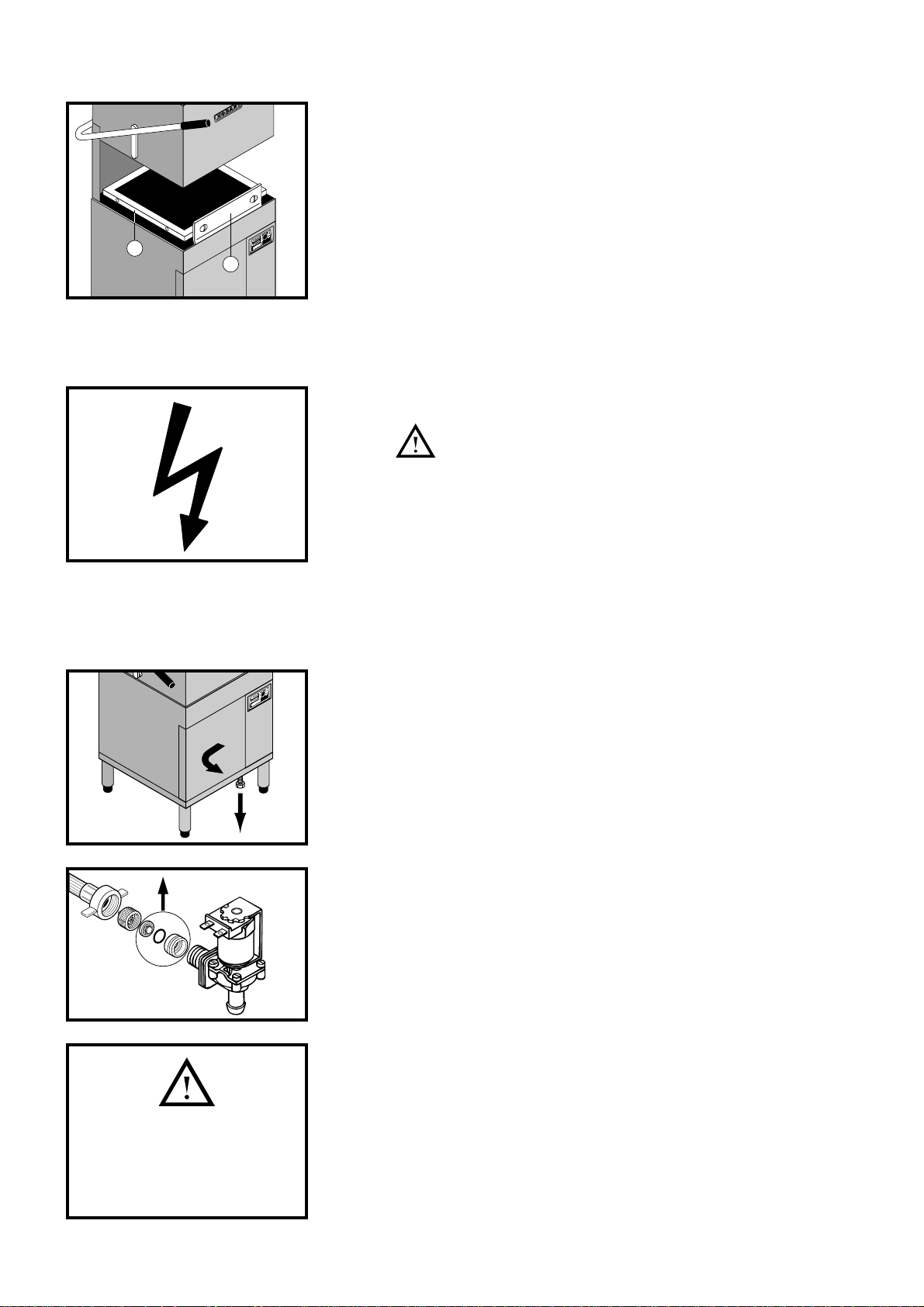

2.1 Electrical connection

must be carried out by an authorized technician

according to the local and national codes.

– Set main circuit breaker.

– Check machine specifications to make sure they correspond to

those of the site supply and to wiring diagram.

– Check site fuse rating.

According to EN 60 335 the appliance must be connected to a

equipotential conductor. The connecting screw is located beside

the cable inlet.

2

1

S

HX-30/40

All machines must be operated

with water of drinking quality.

For water with an extremely high

mineral content, water treatment

is recommended.

2.2 Water connection (HX-30/40)

– If possible to soft and warm water (4° Clark, max. 60°C).

– Line flow pressure 0.6 – 6 bar.

If line flow pressure is less than 0.7 bar:

(must be carried out by an authorized technician)

– Switch Off machine.

– Remove front panel.

– Unscrew panel with electrical parts.

– Disconnect the water supply hose from water inlet valve.

– T ake a way the sie ve (S) and remov e the diaphragm (see drawing).

– Replace the sieve and reconnect supply hose.

– If line flow pressure is above 6 bar pro vide pressure reducer .

– Connect flexible supply hose with union nut 3/4" to site connection.

– Fit shut-off valve.

Water connection (HX-30/40 S)

For U.K. see following page.

– If possible to warm water (max. 60°C).

– Machine is provided for flow pressure 1.4 – 6 bar as standard.

– If flow pressure is below 1.4 bar, please contact the HOBART

service.

– If flow pressure exceeds 6 bar, pressure reducer is required.

– Connect flexible supply hose with union nut 3/4" to site connection.

– Fit shut-off valve.

4

Water connection (HX-30/40 S) only for U.K.

All United Kingdom installations must be supplied from

storage not mains.

Direct connections to the mains supply contravenes Water

Authority Regulations.

– Connect if possible to warm water.

The supply water temperature should not exceed 60°C into the

machine.

For temperatures in excess of 60°C, a thermostatic mixing valve

should be fitted at installation. This valve is available from

HOBART Service Centres.

– Fit shut-off valve.

LOW PRESSURE SITUATIONS

Below 0.4 bar (6 psi) flow pressure there are two solutions.

a) Provide a suitable water storage tank at a height which will

create a pressure in excess of 0.4 bar or,

b) fit a water pump to increase the pressure.

A suitable pump can be supplied by HOBART at extra cost.

max. 1 m

MEDIUM PRESSURE SITUATIONS

0.4 – 0.7 bar (6-10 psi) flow pressure.

– Most installations will fall into this category and the machine will

arrive fitted with a solenoid valve designed for this pressure

range.

HIGH PRESSURE SITUATIONS

Above 0.7 bar flow pressure.

a) Fit a water storage tank at a suitable height.

b) Fit a pressure reducing valve during installation.

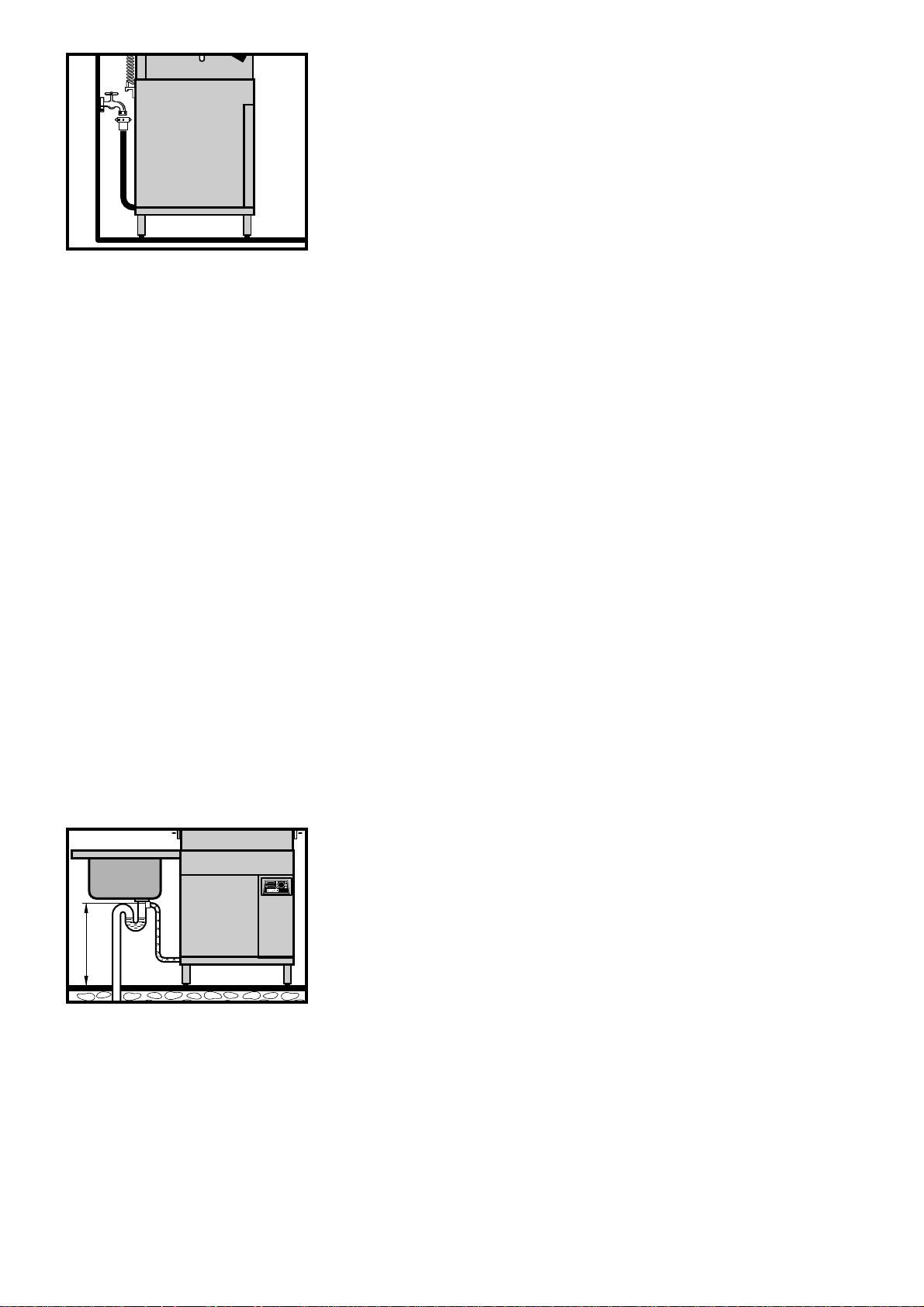

2.3 Drain Connection

– Connect to trapped drain line.

– Connection between machine and site drain may not exceed

max. height of drain pump lift of 1 m.

– Do not kink drain hose.

5

Loading...

Loading...