Page 1

N

S

T

R

U

C

T

I

O

N

S

I

HP15E SERIES

ELECTRIC PRESSURE FRYERS

MODELS

HP15ES ML-126820

HVH23 ML-126819 (Optional Hood)

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937-332-3000

– 1 –

www.hobartcorp.com

FORM 34521, Rev. A (October 2001)

Page 2

TABLE OF CONTENTS

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Optional Ventless Exhaust Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reprogramming Set Temperature and/or Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Filling the Kettle with Liquid Shortening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Using the Pressure Fryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Food Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cooking Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

High-Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pop-Off Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Draining and Filtering Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

O-Ring Seal Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

© HOBART CORPORATION, 2001

– 2 –

Page 3

INSTALLATION, OPERATION, AND CARE OF

HP15E SERIES ELECTRIC PRESSURE FRYERS

PLEASE KEEP THIS MANUAL FOR FUTURE USE

GENERAL

The HP15E Series electric pressure fryers produce uniform, high quality product and operate at a low

temperature (325°F/163°C) and pressure (13 psig). Fast, pressure frying increases production,

improves energy efficiency, preserves food flavor, and reduces shrinkage. Up to 15 pounds of product

can be cooked in each batch.

The optional hood (Model HVH23) includes a nonvented exhaust fan with a three-stage air filtration

system. Models with the hood also include an ANSUL

Model HMF50 is a portable 115-volt filter, available from Hobart, which may be used to filter the cooking

oil. Use of the HMF50 is covered in a separate manual shipped with the filter.

Standard equipment includes:

Drain pipe extension

1

1

/4" diameter exhaust pipe (for models without the hood)

1

/4" pipe plug (for models with the hood)

1

Stainless steel vat

Open-end wrench (used for teardown during cleaning)

Flexible cleaning rod

Four casters

Extra O-Ring seals for the lid, the kettle pressure regulator assembly, and the cleaning port plug screw

are also included.

Models are designed for a 208- or 240-volt, 1- or 3-phase electrical supply. Standard wiring is 208-volt,

3-phase. Single-phase models are rated at 75 amps; 3-phase models are rated at 35 amps.

®

Fire Suppression System.

INSTALLATION

Before installing, verify that the electrical service agrees with the specifications on the rating plate

located on the right side panel as you face the pressure fryer. If the supply and equipment requirements

do not agree, do not proceed with the installation. Contact Hobart Corporation immediately.

UNPACKING

This pressure fryer was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the pressure fryer is found to be damaged, save the packaging material

and contact the carrier within 15 days of delivery.

– 3 –

Page 4

Carefully unpack the pressure fryer and place in a work-accessible area as near to its final installed

position as possible.

Do not use the door to lift or move the pressure fryer.

Check off the accessories packed with the pressure fryer and the optional ventless exhaust hood (if so

equipped).

Pressure Fryer Optional Hood

Frying basket and handle

Instruction manual and parts list

Hood and fire suppression system

ANSULEX® Fire Suppressant, 1.5 gal. (5.7 L)

Four legs, pressure fryer cabinet Rear (outer) exhaust manifold

Four swivel casters (two locking, two standard) Front (inner) exhaust manifold

Drain pipe extension Drip cup, inner manifold

Solenoid wrench and flexible cleaning rod Two manifold gaskets

Two replacement diaphragm gaskets Spacer bar, drilled

Wooden doughnut stick (for clearing kettle drain) Grease filter

Crumb catcher Air filter

Warranty registration (inside manual) Charcoal filter

Tube of RTV108 adhesive sealant

Pipe plug for condensation tank

Mounting Hardware:

Four 1/4-20 x 1" hex head screws

Four 1/4-20 wing nuts

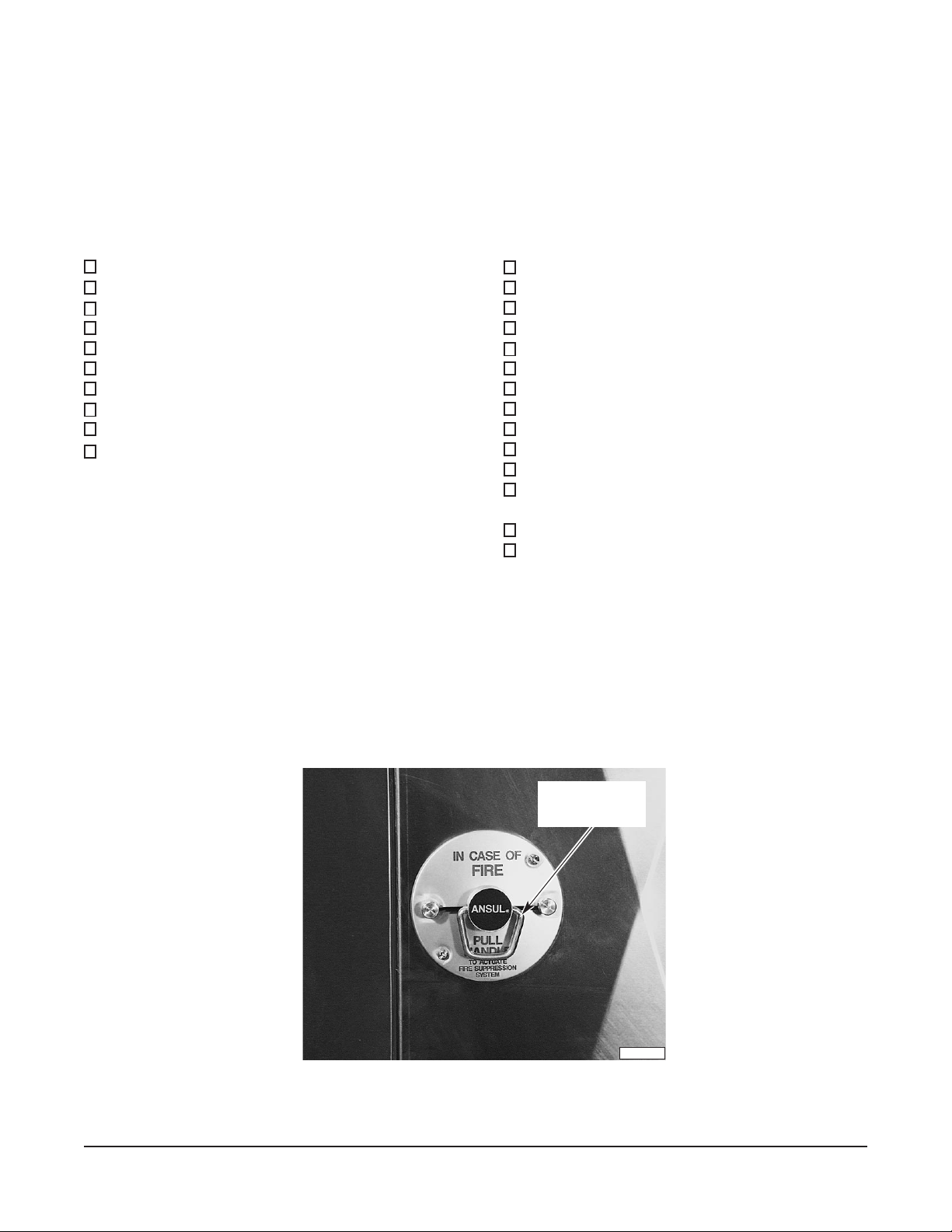

LOCATION

The installation location must allow adequate clearances for servicing and proper operation. Required

minimum clearance from side and back is 1" (2.5 cm)

. If your pressure fryer is equipped with the optional

hood, a minimum clearance of 30" (76 cm) is required on the left side of the exhaust hood to permit

operation of the manual actuator of the fire suppression system (Fig. 1).

Fig.1

– 4 –

MANUAL PULL FOR

FIRE SUPPRESION

SYSTEM

PL-41452-1

Page 5

INSTALLATION CODES AND STANDARDS

The pressure fryer and ventless exhaust hood (if so equipped) must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 01169.

3. NFPA Standard #96,

Vapor Removal from Cooking Equipment,

available from The National Fire

Protection Association, Batterymarch Park, Quincy, MA 01169. (The optional ventless exhaust

hood and the fire suppression system, if so equipped, already meet NFPA Standard #96 without

requiring a separate exhaust hood.)

In Canada:

1. Local codes.

2. Canadian Electrical Code, CSA C22.1 (latest edition). Copies may be obtained from The

Canadian Standard Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

ASSEMBLY

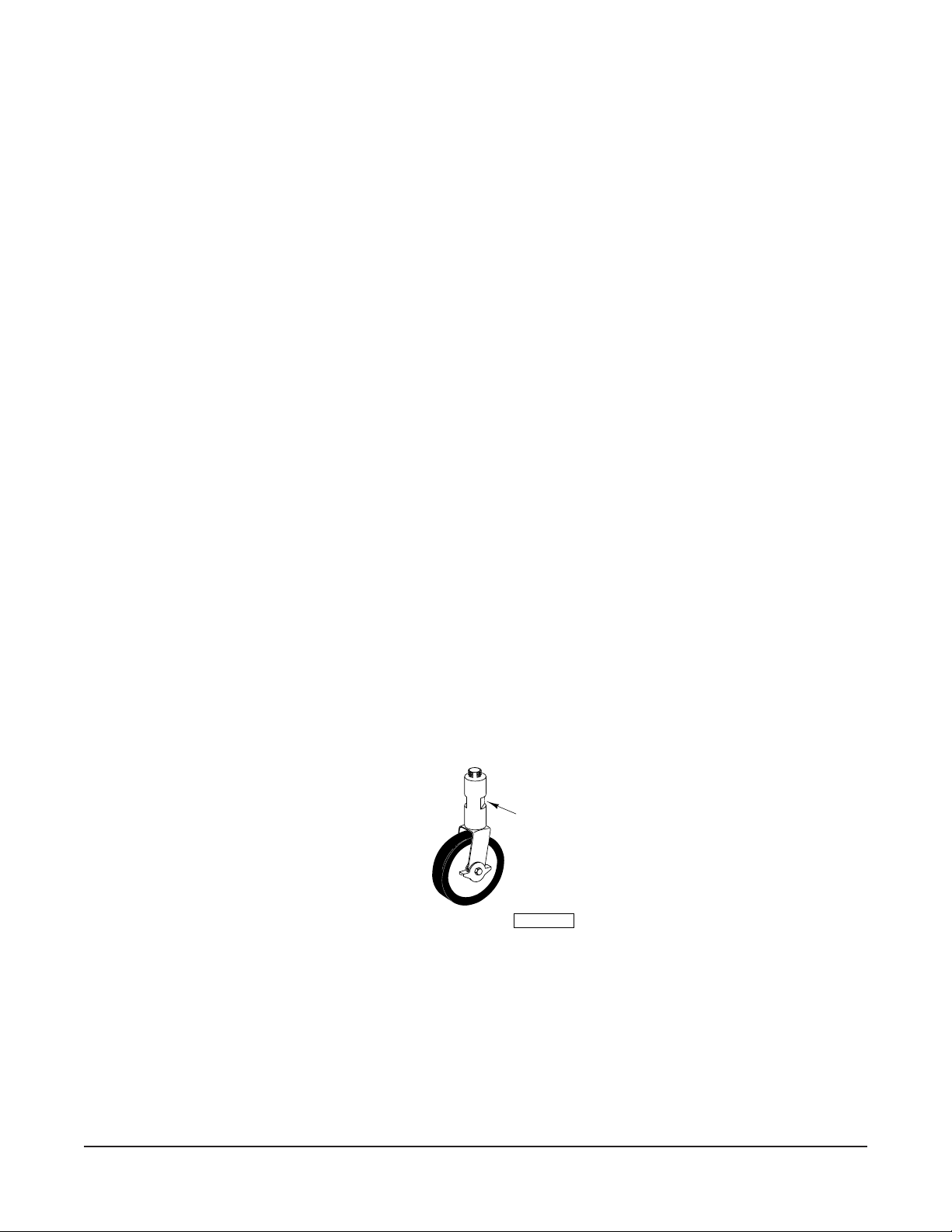

Casters (Fig. 2)

Place the pressure fryer on its side, being careful to avoid scratching the surface. Use only the casters

supplied with the pressure fryer. Thread the four casters to the flanges on the bottom corners of the

pressure fryer. Use the open-ended wrench supplied to tighten (apply wrench at the flat surfaces on

leg extensions). The two locking casters mount at the front; the nonlocking casters mount at the rear.

Fig. 2

– 5 –

TIGHTEN AT FLATS

PL-51559

Page 6

Exhaust Pipe (Models Without the Ventless Exhaust Hood)

Thread the 1

1

/4" diameter exhaust pipe (supplied) to the top of the exhaust tank at the rear of the fryer

(Fig. 3). This pipe should be at least 60" (1.5 m) in length. Use teflon tape or equivalent to seal.

EXHAUST PIPE

SUPPLIED BY INSTALLER

1 1/4" PIPE

THREAD

CONDENSATION

TANK

AC CONDUIT

AC INSPECTION BOX

Fig. 3

DRAIN VALVE,

CONDENSATION

TANK

EXHAUST PIPE

PL-53522

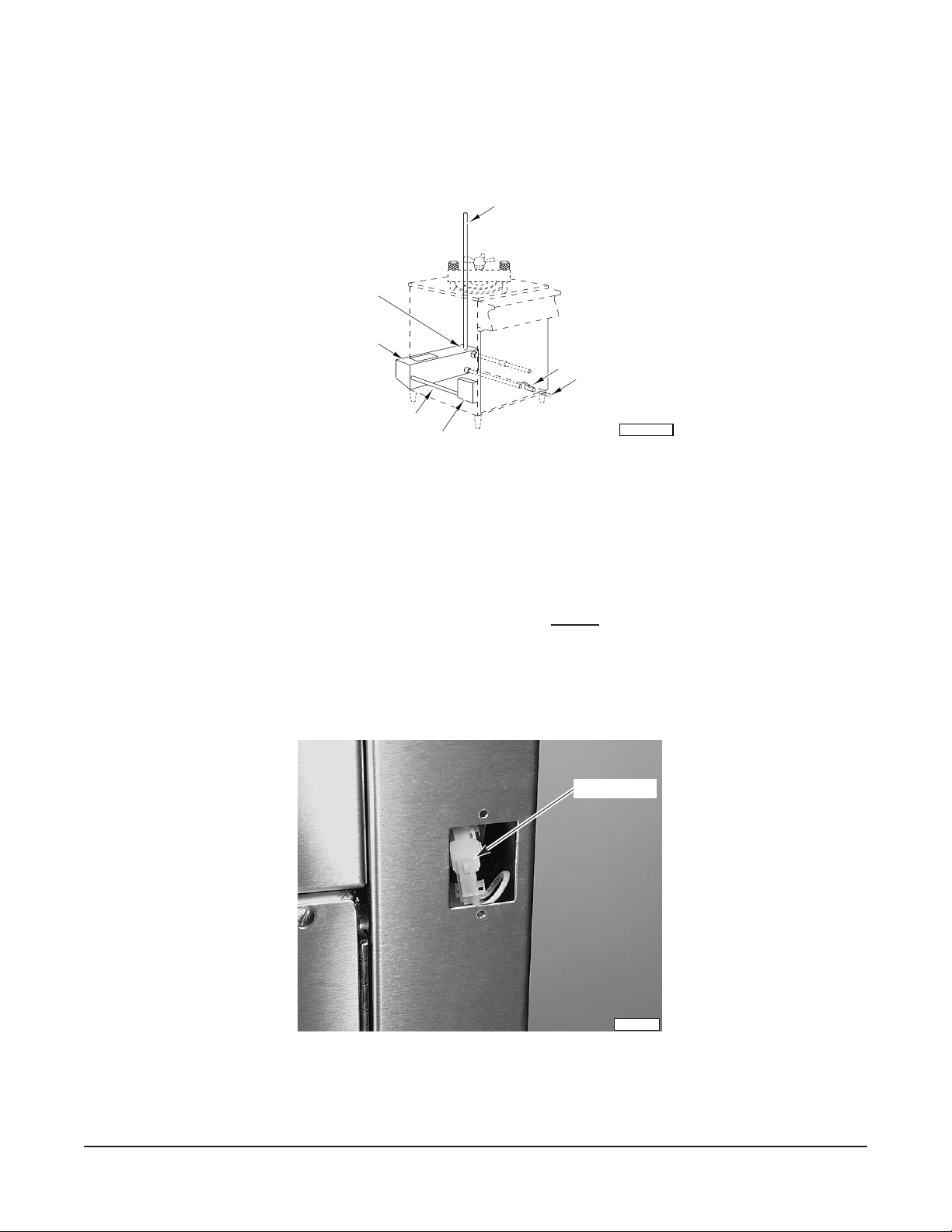

Jumper Plug (Models Without the Ventless Exhaust Hood)

A single-wire jumper plug, with male pins in positions 1 and 2, MUST be plugged into the floating five-pin

hood receptacle located behind the cover plate at the rear of the pressure fryer (Fig. 4). This receptacle,

with five female pins, would otherwise mate to the five-pin hood plug. The fryer

will not operate

without

either the hood plug or the jumper plug in place.

JUMPER PLUG

PL-41453-1

Fig. 4

– 6 –

Page 7

LEVELING

Casters for this pressure fryer are of the nonadjustable type. Therefore, the floor must be level. If floor

surface is not level, the pressure fryer will experience cooking problems.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE YOU ARE WORKING ON THE CIRCUIT.

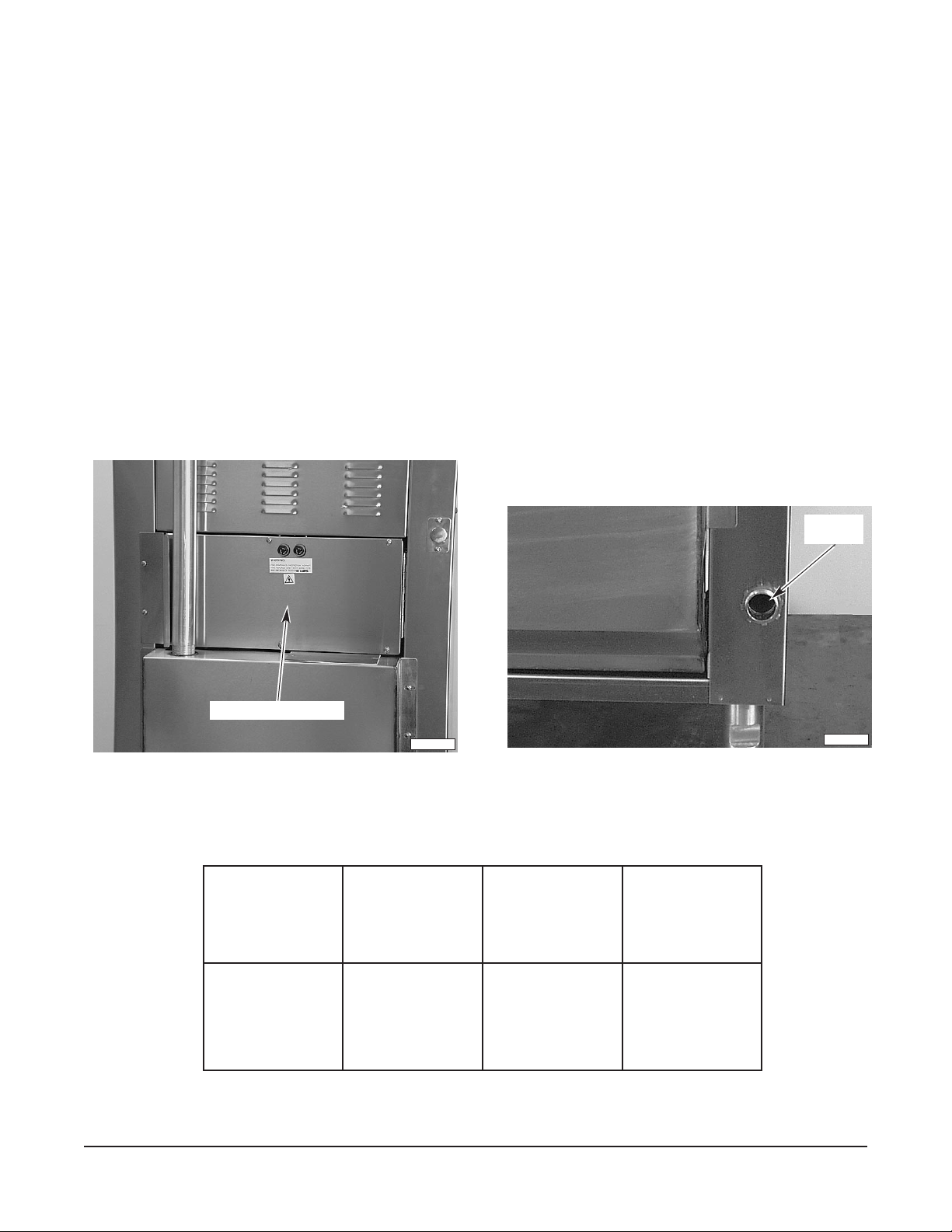

The wiring compartment is located behind the panel (Fig. 5) at the rear of the pressure fryer. Open the

wiring compartment cover and make electrical connections per the wiring diagram located on the inside

of the compartment door. Feed cord through the conduit hole (Fig. 6), exiting at the rear of the fryer.

CORD

CONDUIT

WIRING COMPARTMENT

PL-41454-1

Fig. 5 Fig. 6

ELECTRICAL DATA

STLOVZTREHESAHP

022-802/021

042/021

802

042

* Three-wire system requires three copper wires insulated to 90°C.

** Maximum Circuit Breaker Size/Minimum Circuit Amperage compiled in accordance with the National Electrical Code, latest edition.

06

06

06

06

1

1

3

3

57

57

53

53

**EZISTIUCRIC

)spmA(

PL-41455-1

– 7 –

Page 8

OPTIONAL VENTLESS EXHAUST HOOD

The ventless exhaust hood is a self-contained air filtration system and includes a fire suppression

system manufactured by ANSUL

®

Fire Protection, 1 Stanton Street, Marinette, Wisconsin 54143. It

enables operation of the pressure fryer in a location without an externally-exhausted ventilation hood

and wall-mounted fire suppression system. The three-stage filtration system removes oil particles,

®

steam and condensation, and cooking odors from the exhaust air. The ANSUL

Fire Suppression

System actuates automatically if the temperature below the hood exceeds 165°F (74°C), or it can be

manually triggered by the operator. In either case, fryer operation will be disabled. A damper at the

blower outlet will close automatically to restrict air flow to the fire.

The ANSUL® Fire Suppression System must be charged and certified by an authorized ANSUL® dealer.

®

Hobart Corporation is not permitted to service the fire suppression system; only an ANSUL

®

properly maintain the fire suppression system. The ANSUL

representative must also adjust the nozzle

dealer may

of the system at the time of charging.

The ANSUL

A separate instruction manual is provided that details the ANSUL

®

system must be fully charged and operational for your appliance to be operational.

®

Fire Suppression System.

Safety interlocks disable operation of the fryer if (a) the fire suppression system is not charged and

cocked; (b) one or more filters are missing or incorrectly installed; or (c) the exhaust blowers are not

operating. Indicator lights aid troubleshooting by pinpointing open interlock switches.

Installation

The ventless exhaust hood is shipped separately from the pressure fryer. Assembly of the ventless

exhaust hood to the pressure fryer will require a minimum of two people. It is recommended that you

install and connect the hood assembly prior to powering the fryer.

To prepare the pressure fryer:

1. Make sure the front casters on the pressure fryer are locked before installing the hood.

2. Remove and retain the four 10-32 pan head screws from the upper rear of the cabinet below the

countertop lip of the pressure fryer (Fig. 7).

REMOVE 2 SCREWS FROM

REMOVE 4 SCREWS

RIGHT REAR SIDE PANEL

AND 2 SCREWS FROM

LEFT REAR SIDE PANEL

PL-41456-1

Fig. 7 Fig. 8

– 8 –

PL-41457-1

Page 9

3. Remove and retain two 10-32 pan head screws from the left side panel on the upper rear of the

cabinet and two from the upper rear right side of the cabinet (Fig. 8).

4. Remove the hood from the skid.

• Remove four screws at the rear of the hood.

• Remove two screws from the right side and two screws from the left side of the hood.

5. With two people, lift the hood from the skid and place it on top of the pressure fryer.

6. While one person holds the hood in place, line up the holes of the pressure fryer with the holes

in the hood. Start the four side screws (supplied) first.

7. Slide the drilled spacer bar under the rear overhanging lip of the hood and secure, using the four

rear screws.

8.

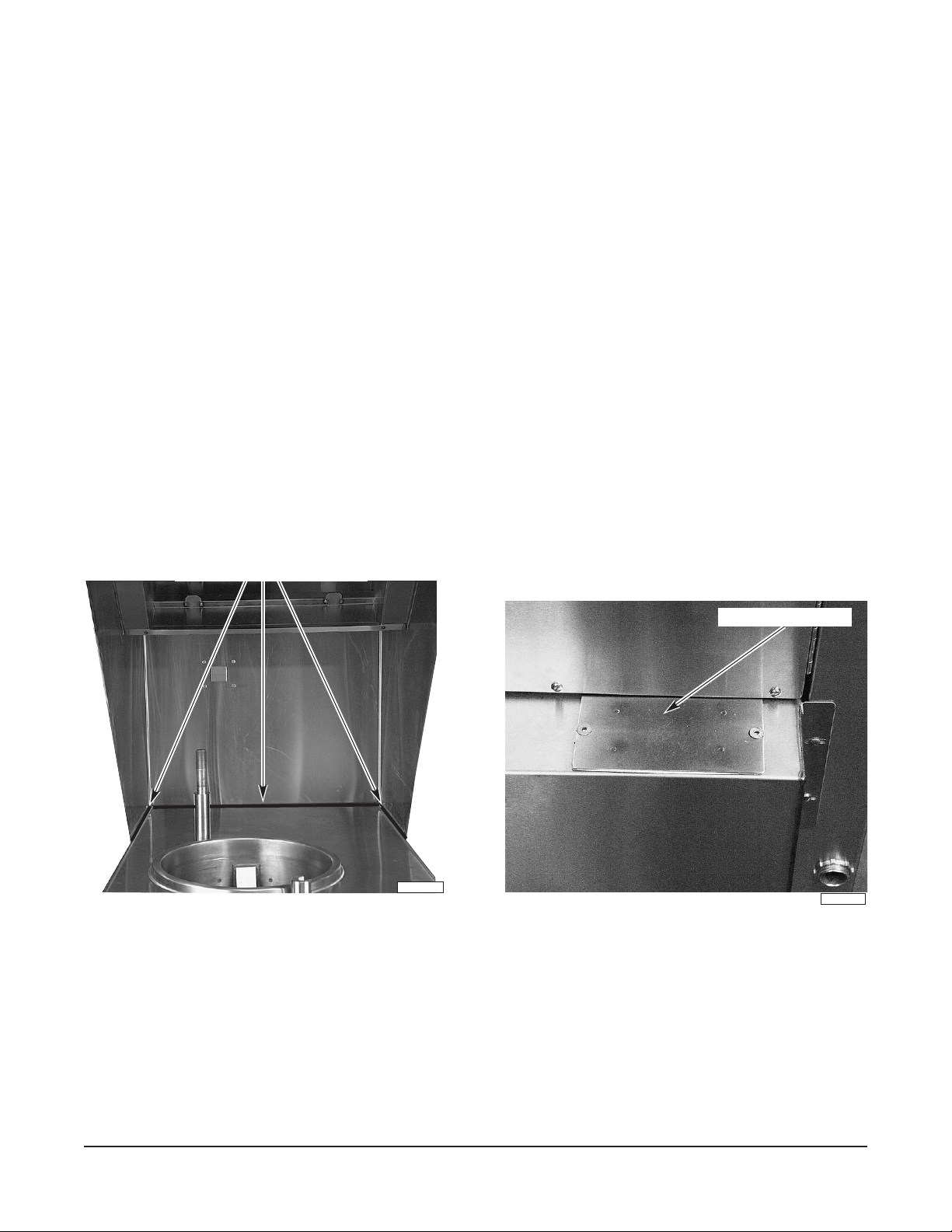

Caulk the joints between the hood and the pressure fryer countertop on the inside surface (Fig. 9).

Use silicone rubber adhesive sealant (General Electric RTV108, or equivalent). Observe

manufacturer's instructions for correct application. Allow the sealant to cure thoroughly before

using the pressure fryer.

9. Remove and discard the cover plate from the top of the condensation tank (Fig. 10) at the rear

of the pressure fryer. Retain the screws and leave the gasket in place.

APPLY ADHESIVE SEALANT RTV108

Fig. 9 Fig. 10

PL-41458-1

REMOVE COVER PLATE

PL-41459-1

– 9 –

Page 10

10. Mount the base of the outer exhaust manifold to the top of the condensation tank (Fig. 11) and

PL-41461-1

DRIP CUP

INNER EXHAUST MANIFOLD

10. Mount the base of the outer exhaust manifold to the top of the condensation tank (Fig. 11) and

secure with the two flat head

secure with the two flat head

1

1

/4-20 screws.

/4-20 screws.

11. Install the inner exhaust manifold (Fig. 12) to the inside of the hood using the four

1

/4-20 hex head

screws and four wing nuts provided. Insert a gasket between each manifold and its mating

surface of the hood.

12. Slide the drip cup (Fig. 12) into the slots below the trough.

OUTER

EXHAUST

MANIFOLD

CONDENSATION

TANK

PL-41460-1

Fig. 11 Fig. 12

Fig. 11 Fig. 12

13. Remove the cover plate (Fig. 13) at the right rear of the fryer.

13. Remove the cover plate (Fig. 13) at the right rear of the fryer.

14. Locate the five-pin female receptacle at the right of the solenoid box (Fig. 14). Remove and

14. Locate the five-pin female receptacle at the right of the solenoid box (Fig. 14). Remove and

discard the jumper plug (if present).

discard the jumper plug (if present).

15. Connect the five-pin male hood plug to the five-pin female receptacle.

15. Connect the five-pin male hood plug to the five-pin female receptacle.

16. Install the 1

1

/4" pipe plug (supplied) into the opening on the left side of the condensation tank.

COVER PLATE

PL-41462-1

JUMPER PLUG

PL-41463-1

17. Apply power to the fryer.

Fig. 13

Fig. 14

– 10 –

Page 11

Positioning Hood Filters

The three hood filters must be in their proper positions or your appliance will not function. Figure 15

shows the long, welded pins (three on the right and three on the left) against which the filters rest.

Directly behind the pins on the left side are three shorter filter actuator switch pins that push in and out.

Place each filter so that it pushes its filter actuator switch pin in, or your appliance will not operate.

WELDED PINS

GREASE FILTER

ACTUATOR PIN

AIR FILTER

ACTUATOR PIN

CHARCOAL FILTER

ACTUATOR PIN

PL-40086-1

Fig. 15

Remove the plastic cover from the charcoal filter. The charcoal filter goes to the rear of the hood. Make

certain it is pulled downward to engage the actuator of the interlock switch. Notice (Fig. 16) that the

actuator pin is pushed in and the filter is resting against the last set of welded pins.

CHARCOAL FILTER ACTUATOR PIN

CHARCOAL

FILTER

Fig. 16

– 11 –

PL-40087-1

Page 12

Install the air filter onto the center set of pegs (Fig. 17), again making certain that the switch actuator

is engaged. The grease filter is installed last at the front of the hood (Fig. 18). It rests into front and

rear support channels. Pull the handles down to ensure a close fit and to engage the interlock switch

actuator.

AIR FILTER

PL-40088-1

Fig. 17 Fig. 18

GREASE FILTER

Insertion and removal of the filters is described in the CLEANING section of this manual.

Indicator Lights

PL-40089-1

Interlock Light — When lit, indicates all hood interlock switches are closed.

ANSUL

®

Light — When lit, indicates the fire suppression system is cocked and charged.

FIP (Filter-In-Place) Light — When lit, indicates all filters are properly installed.

Sail Light — When lit, indicates the exhaust blower is operating and moving an

adequate volume of air.

Reset Pushbutton Switch — Momentarily overrides sail switch to allow the exhaust blower to start.

BEFORE FIRST USE

WARNING: DISCONNECT ELECTRIC POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE YOU ARE WORKING ON THE CIRCUIT BEFORE CLEANING.

Clean the pressure fryer and hood (if so equipped) with warm soapy water. Rinse thoroughly and drain

in a drainage receptacle. Wipe completely dry with a soft, clean cloth. Clean all fryer and hood (if so

equipped) accessories. Rinse thoroughly after cleaning and wipe dry.

– 12 –

Page 13

SYSTEM TEST

1. Make certain the drain valve below the bottom of the kettle is in the CLOSED position. Pour liquid

shortening into the kettle to the MINIMUM line (Fig. 19). Heat will cause the oil to expand and

reach the MAXIMUM line when hot. Use ONLY liquid, all-vegetable, hydrogenated shortening in

the pressure fryer. Never use drippings, lard, suet, or olive oil.

MINIMUM MAXIMUM

Fig. 19

CRUMB CATCHER

PL-41595-1

2. Turn the power switch to the ON position. If the fryer is equipped with the optional ventless

exhaust hood, all three hood filters must be in place.

3. After the fryer is turned on, the L.E.D. screen will display PrE-HEAt, alternating with the rising oil

temperature in degrees Fahrenheit. When the oil temperature reaches 325°F (163°C) or the

programmed temperature, the screen will display rEAdy, and an audible tone will sound for

seconds. The screen will then display idLE until a program (frying cycle) is initiated.

2

4. Turn the power switch to the OFF position.

– 13 –

Page 14

OPERATION

WARNING: HOT OIL AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING, CLEANING

AND SERVICING THE FRYER.

WARNING: SPILLING HOT OIL CAN CAUSE SEVERE BURNS. DO NOT MOVE THE PRESSURE

FRYER WITHOUT DRAINING ALL OIL FROM THE TANK.

CONTROLS (Fig. 20)

Display Screen — Shows temperature, times and current mode of operation.

Power Switch — Press ON to turn the fryer on; press OFF to turn the fryer off. The digital

controller maintains a cooking temperature of 325°F (163°C), or preset

programmed temperature.

Keypad —

(Program keys 1 thru 6.) After allowing the fryer to complete its heating period,

press a numbered program key to start a preprogrammed cooking cycle.

Key Preprogrammed Time

1 12 minutes (fresh chicken)

2 19 minutes (frozen chicken)

3 4 minutes (chicken strips)

4 7 minutes (potatoes)

5 5 minutes (fish)

6 1 minute (fresh vegetables)

Red Heat Light — When lit, indicates the heating elements are providing heat to the pressure

fryer.

Red High-Limit Light — When lit, indicates oil temperature is higher than normal. The pressure fryer

will shut off and the pressure will be exhausted. The high limit thermostat will

reset automatically once the oil temperature cools to below the high-limit

temperature.

Pressure Gauge — (Not shown. Located on top of kettle lid.) Indicates internal kettle pressure

in pounds per square inch, gauge (psig).

DISPLAY

SCREEN

POWER

SWITCH

RED HEAT

LIGHT

00:00.00

1

2

EDIT

EXIT

ENTER

4

BACK-UP

3

5

6

RED HIGH

LIMIT LIGHT

KEYPAD

Fig. 20

– 14 –

ON

OFF

PL-55682

Page 15

REPROGRAMMING SET TEMPERATURE AND/OR TIME

Any of the program keys may be reprogrammed if a different time or temperature is desired.

ACTION

1. Enter Program Mode

•

Press both Keys 3 (Up) and 6 (Down), and hold for 2 seconds.

• Key 1 is already programmed for fresh chicken, so press

Key 3 (Up) to change display.

2. Change Temperature

• Press Key 1 tells controller you are changing temp.

• Press Key 1 (Edit) a second time.

• Hold Key 3 (Up) or Key 6 (Down) to set temperature.

• Press Key 2 (Enter) to save the setting.

3. Change Time

• Press Key 3 (Up) tells controller you are changing time.

• Press Key 1 (Edit) and set the desired cooking time for

Menu Item 2; for example, 19 minutes for frozen chicken.

DISPLAY SHOWS

M 1 (Menu Number 1)

M 2 (Menu Number 2)

StPt 1 (Setpoint 1),

alternating with 32°F

Temperature selection

Temperature selection

tinE 1 (Time 1),

alternating with :00

Time selection

• Hold Key 3 (Up) or Key 6 (Down) until the display reads

19:00.

• Press Key 2 (Enter) to save the setting.

4. Exit Programming Mode

• Press and hold Key 4 (Exit) until the display screen blanks.

This exits the programming mode and returns the controller

to normal operating mode.

The controller memory will remember only the last figures programmed under any key. Turning the

fryer off, or any other power interruptions, will not affect the controller settings last saved into memory.

If a program key with no preprogrammed cooking time is pressed, the controller will not respond. The

display will continue to show idLE until a programmed key is selected.

Any program, once initiated, can be cancelled by pressing and holding the lighted program key until

the light on the key extinguishes.

In the event of a program malfunction or error message, turn the power switch OFF, pause for

seconds, then turn power switch ON. The display should read prE-HEAt, and the red heat light will

10

glow if the oil has cooled. If the error message reappears, contact your local Hobart service office.

19:00

19:00

Blank

idLE (Idle)

– 15 –

Page 16

FILLING THE KETTLE WITH LIQUID SHORTENING

Oil Capacity: 26 pounds (12 kg).

Use only a pure, vegetable, hydrogenated oil prescribed for use in pressure fryers, such as Mel Fry,

Crystal, FryMax, or Gold Label. Never add suet.

Close drain valve (Fig. 21). Fill kettle with liquid shortening; solid shortening is not recommended.

• If shortening is hot, fill kettle to the MAXIMUM line on the crumb catcher probe cover (Fig. 22).

• If shortening is room temperature, fill kettle to the MINIMUM line. This level allows for oil

expansion when heated. Do not overfill.

Regularly add enough oil to keep the oil level in the kettle to the MAXIMUM line.

When changing to new oil, keep the level at the MINIMUM line.

DO NOT operate the fryer with no oil in the kettle.

DRAIN VALVE HANDLE

Fig. 21

MINIMUM MAXIMUM

PL-41465-1

Fig. 22

CRUMB CATCHER

PL-41595-1

USING THE PRESSURE FRYER

CAUTION: Before turning the fryer on, the kettle must be filled to the correct level with liquid

shortening. If this is not done, the kettle walls can be damaged. Warpage can cause leaks.

Pressure is created by the containment of moisture escaping from the product being fried. Dry products

that produce little or no moisture will not create sufficient pressure to pressure-fry that product.

Pressure will not build without product in the kettle.

1. Place the power switch in the ON position. If the fryer is equipped with the optional ventless

exhaust hood, all three hood filters must be in place.

2. After the fryer is turned on, the display will show prE-HEAt, alternating with the rising oil

temperature in degrees Fahrenheit.

– 16 –

Page 17

3. When the oil temperature reaches 325°F (163°C) or the programmed temperature, the screen will

display rEAdy and an audible tone will sound for 2 seconds. The screen will then display idLE

until a program (frying cycle) is initiated. After the screen reads idLE, place the frying basket into

the oil and proceed with cooking.

4. Using tongs or other long-handled utensil, place prepared foods evenly around the basket, one

piece at a time. Load food in a circular motion so the basket is loaded uniformly and evenly.

5. After loading ten to twelve pieces of food, use insulated mitts and lift the basket high enough to

clear the bottom of the kettle. Swirl the basket a couple of times in the oil to keep pieces from

sticking together.

6. Lift the basket out of the oil and hang the basket on the lip of the kettle. Continue loading the food

(maximum capacity is 15 pounds (7 kg) of food). When the desired amount of food is placed in

the basket, give the basket one more swirl in the oil. Close the lid. Make sure the lock post is

fastened in the overarm post catch (Fig. 23). Hold the front post in place while tightening the

handle.

WARNING: IF THE LID WILL NOT LOCK, DO NOT OPERATE THE FRYER.

OVERARM

POST CATCH

PL-41596-1

Fig. 23

7. After tightening the lid, press the desired program key (1 to 6). The light above the selected

program key will light. The display screen will show the preprogrammed cooking time, then count

down to 00:00, and cooking will begin. Once a program is started, there is a 5-second delay

before there is any response to further program key presses.

8. If you wish to cancel the cooking cycle before the end of the preset time, press the selected

program key again and hold for 2 seconds. Cooking will stop and the display will show rEAdy.

9. If you press the wrong program key, you can change it, but you must do it within 30 seconds. To

change your selection, press the

wrong program key again and hold it in until the indicator light

on the key extinguishes. The fryer will stop cooking. Then press the correct program key.

– 17 –

Page 18

10. The heat light and the heating elements will continue to cycle on and off and product will continue

to cook until the audible tone sounds at the end of the cooking cycle. Pressure will automatically

begin to release 45 to 60 seconds prior to the audible tone sounding. The selected program key

will flash.

11. At the end of the frying cycle, the audible tone will sound and continue sounding until turned off

manually. Press the flashing program key to silence the audible tone.

12. When the pressure gauge reads 0 and the lid lock releases, turn the handle counterclockwise

until it stops before opening the lid. CAUTION: Seal damage can occur if the handle is not

completely unscrewed. Do not force the lid to open.

When loading and unloading product, always swing the lid to the side. Do not raise the lid.

13. Using insulated mitts, grasp the basket handle and raise the frying basket out of the oil. Hang the

basket on the lip of the kettle. Allow food to drain approximately 20 to 25 seconds. Remove the

food and return the basket to the oil. It is not necessary to turn the fryer off for unloading. Allow

the kettle to recover and maintain the oil temperature, and mimimize the time between loads.

14. It is advisable to inspect the first load. If preparing unusually large pieces, or if product is only

partially thawed, it may be necessary to increase cooking time (not temperature) to compensate.

Turning the Fryer Off

When the display shows idLE, turn the power switch to OFF.

Extended Shutdown

1. When the display shows idLE, turn the power switch to OFF.

2. Clean the fryer following the instructions in the CLEANING section of this manual. The solenoid

assembly must be cleaned thoroughly and routinely.

POWER FAILURE

In the event of a power failure, turn the power switch to OFF. After the pressure gauge indicates 0, open

the kettle lid and remove the basket. If interrupted, the program will automatically cancel after 60

seconds of power loss.

Repeat all startup procedures upon resumption of electrical service. The controller resets to its wakeup mode, and can be restarted by turning the power switch to ON and allowing the fryer to cycle through

its automatic preheat stage.

FOOD PREPARATION

Pressure frying seals in the natural moisture of food products and uses 30% less frying oil. It should

be remembered, however, that no food prepared in the Hobart pressure fryer will be any better than the

quality of the product purchased.

Trim excess skin and fat from product. Coat with your preferred breading. Allow the breading to set

up (become sticky) before frying; this takes about 20 minutes. If breading is not allowed to set up, it

may wash off in the hot oil.

– 18 –

Page 19

Fresh chicken is frequently stored and sold in a hard-refrigerated state. Allow such product to thaw

completely before preparing or frying. Comply with safe handling procedures regarding thawing. Hardrefrigerated chicken may be thawed overnight under refrigeration. Frozen chicken is defined as

product sold as prebreaded chicken parts frozen to 0°F (-18°C) or below, and is intended for immediate

frying without thawing or additional preparation. Use care when loading frozen chicken parts into the

kettle, as ice crystals on the product may cause the hot cooking oil to spatter.

COOKING GUIDELINES

The cooking guidelines in the chart below are suggested only. They are based on average-sized

portions. If unusually large pieces are not thoroughly cooked, increase cooking time, not temperature.

Frozen portions will require a longer cooking time. Maximum capacity is 15 pounds (6.8 kg), or

approximately 45 pieces of chicken. A typical load is considered to be 6 to 9 pounds (2.7 to 4 kg) of

raw, breaded chicken.

Time Temperature

Product (Minutes) (Degrees F) (Degrees C)

Fresh Chicken 12 325 163

Frozen Chicken 19 325 163

Chicken Strips 4 325 163

Fish Filets 5 325 163

Shrimp (Fresh) 4 325 163

Pork Chops 8 325 163

Veal Cutlets 7 325 163

Chicken Fried Steak 8 325 163

French Fries, Curly Fries (Frozen) 4 325 163

Onion Rings 1 325 163

Vegetables 1 325 163

HIGH-LIMIT

The pressure fryer is equipped with a high-temperature-limit switch that senses a higher than normal

temperature. If a higher than normal temperature is sensed by the high-temperature-limit switch, the

fryer will shut off and the pressure will be exhausted. Once the oil temperature cools to below the highlimit temperature, the high-limit thermostat will reset automatically. It is recommended that you turn the

power off and swing the kettle lid open to allow the oil to cool. After the kettle has cooled to normal

operating temperature, turn the power switch back on and resume the programmed cycle.

NOTE: The high-limit switch may activate during initial startup if the oil is hotter at the top of the kettle

than at the bottom. Normal operation will return after the oil temperature has stabilized. If the high-limit

switch activates anytime after initial startup, turn the pressure fryer off and call your local Hobart service

office.

– 19 –

Page 20

POP-OFF VALVE

The pop-off valve is located on the fryer lid. This valve is nonadjustable and preset at the factory to

release the kettle pressure automatically if over 15 psig. The valve is also equipped with a ring (Fig. 24)

that should be lifted if kettle pressure exceeds 15 psig and the valve does not release the pressure

automatically. CAUTION: Do not allow kettle pressure to exceed 15 psig. Keep the exhaust port

of the pop-off valve clear of obstructions.

WARNING: STEAM RELEASED BY THE POP-OFF VALVE MAY CAUSE BURNS. USE CAUTION

WHEN OPENING THE VALVE.

Do not use the pop-off valve to manually relieve pressure as a regular practice. Allow pressure to

release automatically.

POP-OFF VALVE RING

PL-41467-1

Fig. 24

DRAINING AND FILTERING OIL

WARNING: HOT OIL AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING,

CLEANING, OR SERVICING THE FRYER.

WARNING: DO NOT DRAIN OR FILTER OIL WHILE KETTLE IS UNDER PRESSURE.

To prolong oil life, it is recommended that you filter the oil after 85 to 90 pounds (39 to 41 kg) of product

has been cooked. Filter the cooking oil using the Hobart HMF50 portable filter, or with a vacuum-style

or gravity-style filter by others. Draining through cheesecloth will not clean the oil sufficiently for

pressure frying.

Using the HMF50 Portable Filter: Follow the instructions shipped with the unit.

Filtering Oil and Cleaning Kettle at the End of the Production Day

This procedure must be performed daily while the kettle is still warm. Filtering time increases as the

oil cools.

1. Turn fryer power switch to OFF before draining or filling. Open the lid.

2. If you use filter powder (diatomaceous earth), follow the manufacturer's instructions and add filter

powder to the oil in the kettle. Stir with the wooden doughnut stick provided.

– 20 –

Page 21

3. Position filtering system under the drain, open the drain valve, and drain oil until approximately

2" (5 cm) of oil remains in the kettle.

4. Using a long-handled brush, wash sides and bottom of kettle with the remaining warm oil, then

finish draining tank.

5. While oil is out of the kettle, remove any excess breading from the crumb catcher (see Fig. 22).

Use the wooden doughnut stick provided to dislodge any material that may have collected in the

kettle drain.

6. CAREFULLY pour 2 to 3 gallons (7.6 to 11.3 L) of COLD water into the kettle. Use a nylon pad

(nonabrasive, plastic web-type, nonrusting, nonshredding pad) to wash the kettle completely.

Drain the water into a drainage receptacle. Rinse the kettle well with clear water. Drain again.

Wipe the kettle dry with a soft, clean, lint-free cloth. Close the drain valve.

7. Return the oil to the kettle. Check the oil level.

8. If cooking is to resume following the filtering operation, turn the power switch to ON and allow the

fryer to heat. When the oil reaches cooking temperature (display shows idLE), place the frying

basket into the oil and begin cooking.

9. If cooking has concluded for the day, clean the fryer according to the CLEANING procedures

below.

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE YOU ARE WORKING ON THE CIRCUIT BEFORE CLEANING.

Daily Cleaning

1. Before returning oil to the kettle following the final filtering operation of the day, close the drain

valve and pour 1 or 2 gallons (3.8 or 7.6 L) of cold water into the kettle. Use a web-type,

nonshredding, nylon scrubbing pad and thoroughly wash down the interior of the kettle. Drain the

wash water into a pail and discard. Towel dry the interior of the kettle.

2. Close the kettle drain valve and return the filtered oil to the kettle. Add fresh oil as required to

maintain the correct oil level.

3. Clean stainless steel regularly with a damp cloth and polish with a soft, dry cloth. If regular

cleaning is neglected, grease will be burned on and discolorations may form. These may be

removed by washing with any detergent or soap and water. Particularly stubborn discolorations

may be removed with a self-soaping scouring pad or a paste made of water and a mild scouring

powder applied with a plastic open pad or sponge. CAUTION: Always rub with the grain in a

horizontal direction.

4. It is important to keep the fryer exterior clean and free of accumulated grease. Wash all exterior

surfaces at least once daily. Use a cloth with warm water and a mild soap or detergent. Follow

with a clear rinse, then dry.

5. Wash the frying basket in hot, soapy water. Rinse thoroughly and dry.

– 21 –

Page 22

6. Raise the lid by pulling the back knob (Fig. 25) out and lifting the lid up. Hold the back knob out

until you reach the desired height. Release the knob to hold the lid in that position. Wipe the under

part of the lid clean, including the diaphragm (Fig. 26).

BACK KNOB

PL-41596-2

Fig. 25

DIAPHRAGM

PL-41468-1

Fig. 26

7. Drain the condensation tank (Fig. 27). The condensation tank drain valve is located behind the

front access door at the lower right.

• Attach the drain pipe extension (supplied) to the condensation tank drain line (Fig. 27). Place

a pail below the extension and drain the condensation tank by turning the handle clockwise.

• After draining the condensation tank, turn the handle counterclockwise to close the drain valve,

then remove the drain pipe extension before closing the door.

When cleaning the area immediately surrounding the fryer (floor, walls), it may be necessary to move

the fryer from its installed position.

WARNING: SPILLING HOT OIL CAN CAUSE SEVERE BURNS. DO NOT MOVE THE PRESSURE

FRYER WITHOUT DRAINING ALL OIL FROM THE TANK.

Unplug the electrical cord.

EXHAUST PIPE

SUPPLIED BY INSTALLER

1 1/4" PIPE

THREAD

CONDENSATION

TANK

AC CONDUIT

AC INSPECTION BOX

DRAIN VALVE,

CONDENSATION

TANK

EXHAUST PIPE

PL-53522

Fig. 27

– 22 –

Page 23

Weekly Cleaning

Solenoid Assembly (Fig. 28)

CAUTION: The kettle pressure-relief valve in the solenoid assembly must be cleaned at least

once a week during normal usage or the fryer may malfunction.

1. Open the kettle lid and remove the breather elbow (Fig. 29) from the inside wall of the kettle. Wash

the elbow in hot, soapy water, then rinse well and allow to air dry. Inspect the two O-Rings. If

cracked or worn, contact your local Hobart service office for replacement.

SOLENOID

CLEAN-OUT

PORT

HEX NUT

TEFLON GASKET

(INSIDE FITTING )

PRESSURE RELIEF VALVE

O-RING

PRESSURE REGULATOR

HOUSING

O-RING

THUMB

SCREW

PL-53523-E

Fig. 29Fig. 28

BREATHER ELBOW

PL-41469-1

2. Unplug the electrical cord attached to the upper portion of the solenoid assembly. To unplug, twist

the plug counterclockwise and pull out.

3. Remove thumb screw securing both the solenoid and pressure-relief valve. Separate the

solenoid and valve. The valve seats into the block with two O-Rings and some force may be

required.

.

4. Grasp the kettle pressure-relief valve with a towel and remove the valve from the solenoid. If the

1

hex nut on the base of the solenoid does not release easily, use the 1

/4" end wrench supplied.

Wash the valve in hot, soapy water. Rinse in clear water and set aside to air dry. Do not

disassemble the valve, but inspect the O-Rings and contact your local Hobart service office for

replacement if cracked or worn.

5. With the pressure-relief valve assembly out, run the flexible cleaning rod into the cleanout port

and through the kettle exhaust line to clear any obstructions.

6. Make sure the pressure-relief valve and breather elbow have thoroughly dried. Dip the ends of

the assemblies, with O-Rings, into the oil to lubricate the O-Rings.

7. Insert the breather elbow into the kettle exhaust line with the inlet hole directed upward.

8. Assemble the pressure-relief valve to the solenoid. Make certain the teflon gasket is seated

inside the hex nut. Align the widest opening of the valve to the clean-out port in the solenoid block.

Press the valve downward into the block. Make certain the valve O-Rings snap into their grooves.

– 23 –

Page 24

9. Replace the thumb screw and O-Ring into the cleaning port. If the head of the thumb screw fails

to seat against the O-Ring, check and correct the alignment of the valve opening to the cleanout

port.

10. Plug the cord back into the upper portion of the solenoid and twist clockwise to ensure a good

connection.

Kettle Tilt Lid

Clean the kettle tilt lid weekly.

1.

Remove the tilt lid assembly. To remove, slide the tilt lid clear of the overarm post catch (see Fig. 23),

and remove pivot post knurled cap (see Fig. 23). Pull the back knob at the left, and lift up on the

lid until the overarm bar clears the pivot post.

2. Remove the O-Ring from the underside of the kettle lid by prying it loose at one point with a plastic

knife (Fig. 30) or other blunt, thin tool. Avoid slicing or gouging the O-Ring. Wash the O-Ring

separately in warm, soapy water, then rinse thoroughly and dry with a soft, clean cloth.

CAUTION: Never use a metallic or sharp instrument to remove or insert the O-Ring.

3. Wash the lid assembly in warm, soapy water. Rinse thoroughly and dry with a soft, clean cloth.

4. Before replacing the O-Ring, ensure that the groove (Fig. 31) is free of particles and the edges

of the groove are not sharp or burred.

PL-40909

Fig. 30 Fig. 31

PL-40910

5. The flexible diaphragm of the lid locking device is visible when viewing the underside of the kettle

lid. Make certain the diaphragm material is not torn or punctured. If it is, contact your local Hobart

service office for replacement.

6. Dip the O-Ring in cooking oil for lubrication, and insert it into the groove. IMPORTANT: First,

press the O-Ring into place at the 12-, 6-, 3-, and 9-o'clock positions (Fig. 32). Using finger

pressure only, stretch and work the O-Ring into the groove until it is seated all around. Apply

pressure straight down. Do not twist or roll the ring into the groove; this may fracture the skin of

the ring.

7. To reinstall the kettle tilt lid, reverse the procedure described in Step 1.

– 24 –

Page 25

12

O’CLOCK

9

O’CLOCK

6

O’CLOCK

3

O’CLOCK

PL-50399

Fig. 32

Pop-Off Valve

Once a week, operate the pop-off valve by lifting the ring up (see Fig. 24) and then releasing it.

Monthly Cleaning

Condensation Tank

1. Open the access door and screw the drain pipe extension to the end of the condensation tank

drain valve (see Fig. 27) at the lower right side of the pressure fryer.

2. Place a pail below the extension, open the drain valve, and drain the condensation from the tank.

Clean the condensation tank by removing the cleanout port cover from the top of the tank and

rinsing the tank with hot water.

3. If the pressure fryer is equipped with the optional ventless exhaust hood, empty and wash the drip

cup below the grease filter (see Fig. 12).

Optional Ventless Exhaust Hood (Fig. 33)

Clean the air filters and hood weekly.

CHARCOAL FILTER

AIR FILTER

GREASE FILTER

TRAY

PL-50755

Fig. 33

– 25 –

Page 26

1. Push in the bottom of the grease filter. Using the handles, tilt the top of the filter forward and

remove the filter. Scrub the grease filter in warm, soapy water; rinse, drain and towel dry.

2. Push in the bottom of the air filter. Tilt the top of the filter forward and remove the filter. Scrub

the air filter in warm, soapy water; rinse, drain and towel dry.

3. Push in the bottom of the charcoal filter. Using the handles, tilt the top of the filter forward and

remove the filter. When the charcoal filter needs to be cleaned, remove the charcoal from the

filter. Remove the four screws from the filter frame, being careful not to spill the charcoal.

Remove the frame end piece. Pour the charcoal from the filter and save it for future reuse.

Replace the frame end piece and four screws. Scrub the empty filter frame in warm, soapy water;

rinse, drain and towel dry. Remove the frame end piece again (four screws). Put the charcoal

back in the frame; use either old or new charcoal, as required. Replace the frame end piece and

four screws.

4. Scrub the hood interior and tray with warm, soapy water, nylon pad, or Scotchbrite, as required.

5. Reinstall the charcoal filter, the air filter, and the grease filter. Make sure the filters fit correctly

(see POSITIONING HOOD FILTERS in this manual). Your appliance will not operate unless all

three filters are properly installed.

Replacement activated charcoal may be purchased from your local Hobart sales and service office.

The charcoal used in the charcoal filter is coconut-activated charcoal, 4" x 8" mesh. Approximately

9 pounds (4 kg) is required to refill the filter. Recommended replacement schedule is approximately

once every 4 months of normal use.

MAINTENANCE

WARNING: THE PRESSURE FRYER AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN

OPERATING, CLEANING OR SERVICING THE PRESSURE FRYER.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE YOU ARE WORKING ON THE CIRCUIT BEFORE SERVICING THE PRESSURE

FRYER.

O-RING SEAL REPLACEMENTS

Removal and replacement instructions for the lid O-Ring are described in WEEKLY CLEANING —

KETTLE TILT LID (page 24).

The O-Ring seals on the kettle pressure-relief valve assembly (see Fig. 28) need to be replaced if oil

is leaking from the kettle lid. If steam leaks around the kettle pressure-relief valve O-Rings and goes

into the exhaust tank, pressure will not build in the kettle. Dip the new O-Rings in cooking oil for

lubrication and insert them into the pressure-relief valve assembly.

The O-Ring seal on the clean-out port thumb screw (see Fig. 28) needs to be replaced if liquid is leaking

around the screw.

SERVICE AND PARTS INFORMATION

Contact your local Hobart servicer.

– 26 –

Page 27

TROUBLESHOOTING GUIDE

SYMPTOM

No power when power switch is turned on.

Fryer will not heat.

POSSIBLE CAUSES

1. Tripped breaker, open fuse, check line voltage

at input terminals; should be 208-240 V.

2. Check for loose connections.

3. Problem with power switch.*

4. Problem with high-limit switch.*

One or more hood filters missing or loose (models

5.

with optional exhaust hood).

6. Hood jumper missing or loose (models without

optional exhaust hood).

1. Check electrical input connections.*

2. Check for open thermocouple.*

3. Problem with controller.*

Fryer continues to heat.

Fryer heats, but will not reach desired

temperature.

Pressure too high or too low. Pressure fails to

release.

4. Problem with contactor.*

1. Thermocouple leads reversed or shorted.*

2. Problem with controller.*

3. Problem with contactor.*

Check oil temperature with thermometer. If

1.

elements turn off too soon, replace thermocouple.*

2. Problem with controller.*

1. Solenoid exhaust line restricted or plugged. See

WEEKLY CLEANING procedure.

Pressure-relief valve plugged. Remove and

2.

clean. Replace O-Ring if required.

Check for 208-240 V at solenoid. Check for

3.

looseconnection, or problem with controller.*

4. Improper pressure-relief valve setting.*

*Contact your local Hobart service office.

– 27 –

Page 28

TROUBLESHOOTING GUIDE, CONT'D.

SYMPTOM

Pressure leaking from kettle lid.

Lid will not release.

Pressure releases too slowly.

POSSIBLE CAUSES

1. Check lid O-Ring. Replace if required.

Check diaphragm in lid-locking device. Replace

2.

if required.

Problem with pop-off valve. Replace if required.*

3.

Do not use pop-off valve to manually relieve

pressure as a regular practice. Allow pressure

to release automatically.

Turn fryer OFF. If pressure still fails to release,

1.

pull pressure-release ring on pop-off valve on

lid to relieve all pressure in kettle.* DO NOT

excessive force on lid-opening handles.

use

Condensation line obstructed. Remove thumb

1.

screw and clean out condensation line and

pressure-relief valve (see WEEKLY CLEANING

procedures).

Cooker stops during operation.

*Contact your local Hobart service office.

Check operation of pressure-relief valve.

2.

Center section of valve should move freely.

Repair or replace if required.*

1. Fuse open or circuit breaker tripped.

2. Oil is too hot and high-limit switch is open.

Problem with controller, thermocouple, or

high-limit switch.*

3. Problem with contactor.*

FORM 34521, Rev. A (October 2001) PRINTED IN U.S.A.

– 28 –

Loading...

Loading...