Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

HO851G REVOLVING

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Stainless steel front and sides

■ Windowed loading door slides upward, out of the

way, to expose a full width 12" high opening

■ Two full-height service doors provide

unobstructed access to controls and gas supply

■ Solid metal trays with 3.5" back riser

■ Oven is shipped knocked-down in quick

assembly modules

■ Digital controls

■ Push-button controls in the sill ensure easy-

access loading or unloading of the oven

■ Hand-crank for emergency power outage

■ Hood with grease lters accommodates Type I

and Type II ventilation standards

TRAY OVEN - GAS

MODELS

❑ HO851G-18 – 18-pan

❑ HO851G-24 – 24-pan

❑ HO851G-30 – 30-pan

❑ HO851G-36 – 36-pan

Specications, Details and Dimensions on Back.

■ Natural gas with OSHA pre-purge

OPTIONS & ACCESSORIES

❑ Propane gas with OSHA pre-purge

❑ Perforated metal trays with 3.5" back riser

❑ Two-side seam nish trim

❑ Rear seam nish trim

❑ Advanced controller with auto-start

❑ Hi – low burner (use only with standard controls)

Ansi Z83.11a – 2004/CGA 1.8 –

2004 Gas Food Service

Equipment

HO851G REVOLVING TRAY OVEN - GAS

F-39964 – HO851G Revolving Tray Oven - Gas Page 1 of 2

Page 2

HO851G REVOLVING

TRAY OVEN - GAS

SPECIFICATIONS:

NATURAL

GAS PROPANE

WGT MAX. GAS

(LBS) CAPACITY BTU/HR BTU/HR CFM DUCT. DIA.

5121 8"

(2323 kg)

5812 10"

(2636 kg)

6429 10"

(2916 kg)

7122 10"

(3231 kg)

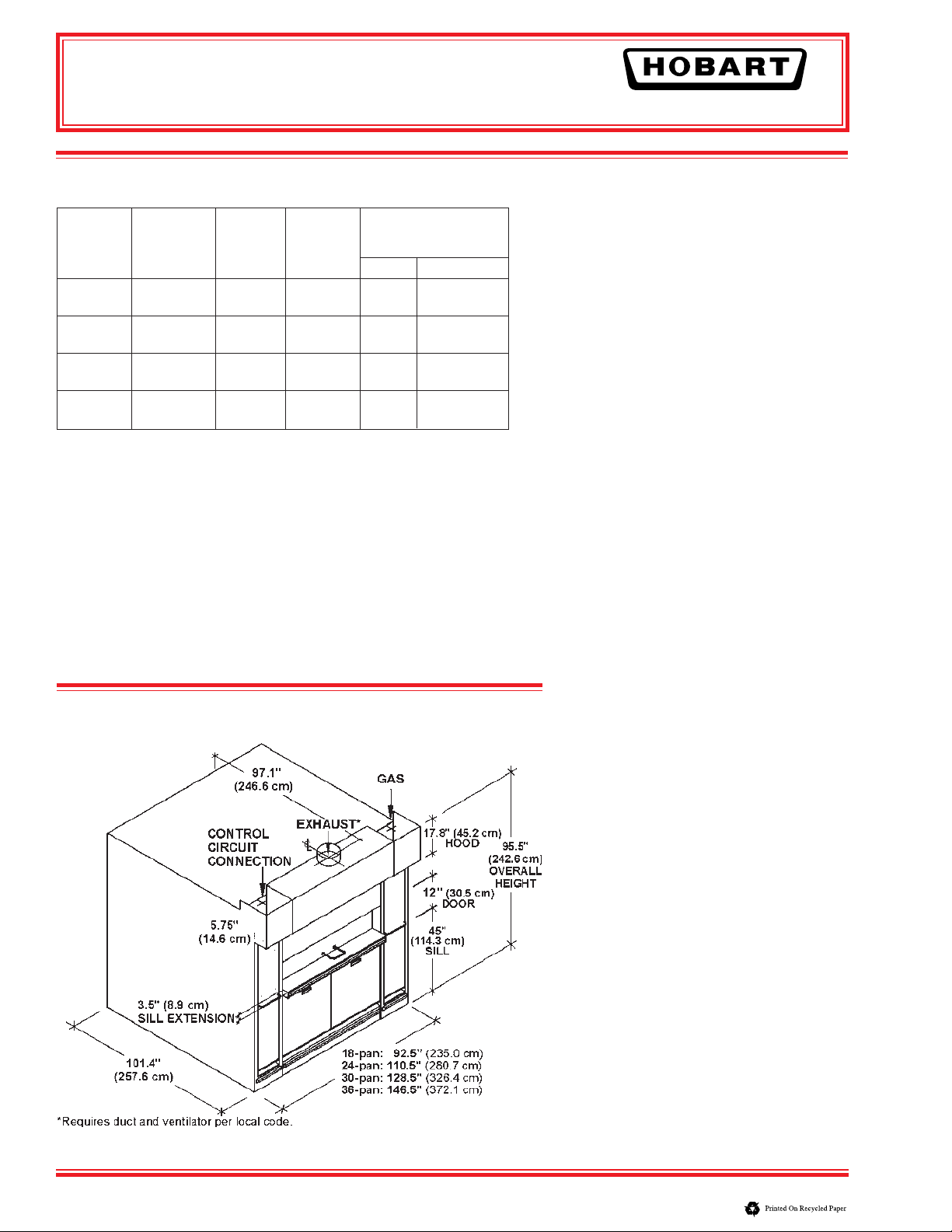

18-PAN 250,000 200,000 700

24-PAN 300,000 250,000 900

30-PAN 300,000 250,000 1200

36-PAN 350,000 300,000 1400

Gas – 1" NPT pipe size; Standard – Natural Gas @

5"-14" w.c.; Optional – Propane Gas @ 13"-14" w.c.

Must not exceed 14" w.c.

Electrical – 120V/60Hz/1 PH. Oven control: 12.0

amps.

Oven provided relay with 120V output for fan operation, 4.0 amp max 1⁄6 H .P.

Hood – Suitable for Type I or Type II applications.

See table for duct size and fan cfm requirement by

model. 0.6"w.c. static pressure drop at hood.

DETAILS AND DIMENSIONS

VENTING

(20.3 cm)

(25.4 cm)

(25.4 cm)

(25.4 cm)

Type II: For heat, steam, odors and products of

combustion.

NOTES

1. Level oor required. Floor should be level within

1

not exceed 3/4" in all directions under the unit.

2. The purchaser is responsible for proper installation

in order to validate the warranty.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Customer to supply duct and roof mounted

fan per local code. If accepted by local

building ofcials, suitable for connection

to Type B pipe except when products of

baking are grease laden. Airow proving

switch is factory installed and integrated

with burner system operation. Oven

provided relay with 4.0 amp max 1/6 H.P.

@ 120V output for fan control.

Type I: For grease laden vapors, products

of combustion. (See NFPA 96 and consult

local building ofcials.)

/8" per foot for proper installation. Slope should

A factory technician or factory

authorized installation technician

must supervise and approve any

installation.

3. Purchaser is responsible for all

installation costs and for providing:

labor to unload oven upon arrival;

installation mechanics; all local

service connections - electricity,

vents, gas per local code; and

disposal of packaging material.

4. Minimum clearances to combustible

construction: 1 inch from sides and

back, 3 inches from top. Caution:

To reduce the risk of re, the oven

is to be mounted on oors of

non-combustible construction

with non-combustible ooring

and surface nish and with no

combustible material against the

underside thereof.

5. Do not route utilities (wiring,

plumbing, etc.) in or under the noncombustible oor beneath the oven.

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 2 of 2 F-39964 – HO851G Revolving Tray Oven - Gas

F-39964 (REV. 08/08) LITHO IN U.S.A. (H-01)

Loading...

Loading...