Hobart 60SE200 Operation And Maintenance Manual

OM-2155

071406 – Original

060707 – Revision 3

Operation and Maintenance Manual

Model: 60SE200

60 kVA, 3 Phase, 115/200 Volt,

400 Hz. Solid State Frequency Converter

Series 500381

ITW GSE Group

Hobart Ground Power

Troy, Ohio 45373

U.S.A.

Data Sheet 165

Warranty

1. Hobart Brothers Company (hereinafter called HOBART) warrants that each new and unused Hobart Ground Power

Equipment, (hereinafter called the PRODUCT) is of good workmanship and is free from mechanical defects,

provided that (1) the PRODUCT is installed and operated in accordance with the printed instructions of HOBART,

(2) the PRODUCT is used under the normal operating conditions for which it is designed, (3) the PRODUCT is not

subjected to misuse, negligence or accident, and (4) the PRODUCT receives proper care, lubrication, protection,

and maintenance under the supervision of trained personnel.

2. This warranty expires 15 months after shipment by HOBART to the first user, or 12 months after installation,

whichever first occurs.

3. This warranty does not apply to: primary and secondary switch contacts, cable connectors, carbon brushes, fuses,

bulbs, and filters unless found to be defective prior to use.

4. Hobart DOES NO T WARRANT THE FOLLOWING COMPONENTS: Engines, engine components; such as:

starters, alternators, regulators, governors, etc., and cable retrieving devices. Many of the foregoing components

are warranted directly by the manufacturer to the first user and se rviced by a worldwide network of distributors and

others authorized to handle claims for component manufacturers. A first user’s claim should be presented directly

to such an authorized component service outlet. In the event any component manufacturer has warranted its

component to HOBART and will not deal directly with a first user then HOBART will cooperate with the first user

in the presentation of a claim to such manufacturer. Under NO circumstances does HOBART assume any liability

for any warranty cl aim against or warranty work done by or in behalf of any manufacturer of the foregoing

components.

5. This warranty is extended by HOBART only to the purchaser of new PRODUCTS from HOBART or one of its

authorized distributors. The PRODUCTS purchased under thi s warranty are intended for use exclusively by the

buyer and his employees and by no other persons and, therefore, there shall be no third party beneficiary to this

warranty.

6. A claim of defects in any PRODUCT covered by this warranty is subject to HOBART f actory inspection and

judgment. HOBART’S liability is limited to repair of any defects found by HOBART to exist, or at HOBART’S

option the replacement of the defective product, F.O.B. factory, after the defective product has been returned by the

purchaser at its expense to HOBART’S shipping place. Replacement and exchange parts will be warranted for the

remainder of the original Warranty, or for a period of ninety (90) days, whichever is greater.

7. UNDER NO CIRCUMSTANCES whatsoever shall HOBART and its authorized distributors be liable for any

special or consequential damages, whether based on lost goodwill, lost resale profits, work stoppage impairment

of other goods or otherwise, and whether arising out of breach of any express or implied warranty, breach of

contract, negligence or otherwise, except only in the case of personal injury as may be required by applicable law.

8. Continued use of the PRODUCT(S) after discovery of a defect VOIDS ALL WARRANTIES.

9. Except as authorized in writing, this warranty does not cover any equipment that has been altered by any party

other than HOBART.

10. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HERE

OF. HOBART MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

11. HOBART neither assumes nor authorizes any person to assume for HOBART any liability in connection with the

PRODUCTS sold, and there are no oral agreements or warranties collateral to or affecting this written

Warranty. This warranty and all undertakings of HOBART thereunder shall be governed by the laws of the State

of Ohio, United States of America.

HOBART GROUND POWER

TROY, OHIO 45373

Index: 990223

Replaces: 980601

WARNING AT ALL TIMES, SAFETY MUST BE CONSIDERED AN IMPORTANT FACTOR IN THE

INSTALLATION, SERVICING AND OPERATION OF THE PRODUCT, AND SKILLED, TECHNICALLY

QUALIFIED PERSONNEL SHOULD ALWAYS BE EMPLOYED FOR SUCH TASKS.

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Safety Warnings and Cautions

WARNING

IMPORTANT

1) How to read this manual

To avoid hazards the following safety instructions noted in this section and throughout the manual must be

followed to ensure personnel’s health and safety during installation, daily operation and during maintenance

interventions.

The PoWerMaster EV can be delivered with several optional features. Therefore, kindly refer to Appendix A

for information about the configuration of this particular equipment before installing, operating or performing

maintenance of the equipment.

2) General

Equipment that supplies electrical power can cause serious injury or death, or damage to other equipment or

property. The operator must strictly observe all safety rules and take precautionary actions. Safe practices

have been developed from past experience in the use of power source equipment. While certain practices

below apply only to electrically powered equipment, other practices apply to engine-driven equipment, and

some practices to both.

3) Installation and Shock Prevention

Bare conductors, terminals in the output circuit, or ungrounded, electrically live equipment can fatally shock a

person. Have a certified electrician verify that the equipment is adequately grounded and learn what

terminals and parts are electrically HOT. Avoid hot spots on machine. Use proper safety clothing,

procedures, and test equipment.

The electrical resistance of the body is decreased when wet, permitting dangerous currents to flow through it.

When inspecting or servicing equipment, do not work in damp areas. Stand on a dry rubber mat or dry wood,

and use insulating gloves when dampness or sweat cannot be avoided. Keep clothing dry, and ne ver work

alone.

a) General Installation and Grounding of Electrically Powered Equipment

This equipment must be installed and maintained in accordance with the National Electrical Code,

ANSI/NFPA 70, or other applicable codes. A power disconnect switch or circuit breaker must be

located at the equipment. Check the nameplate for voltage, frequency, and phase requirements. If

ELECTRIC SHOCK can KILL. Do not touch live electrical parts.

ELECTRIC ARC FLASH can injure eyes, burn skin, cause equipment damage, and

ignite combustible material. DO NOT use power cables to break load. Prevent tools

from causing short circuits.

IMPROPER PHASE CONNECTION, PARALLELING, OR USE can damage this and

attached equipment.

Protect all operating personnel. Read, understand, and follow all instructions in the

Operating/Instruction Manual before installing, operating, or servicing the equipment.

Keep the manual available for future use by all operators.

July 14, 2006 Safety Warnings

Page 1

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

only 3-phase power is available, connect any single-phase rated equipment to only two wires of the 3phase line. DO NOT CONNECT the equipment grounding conductor (lead) to the third live wire of

the 3-phase line, as this makes the equipment frame electrically HOT, which can cause a fatal shock.

Always connect the grounding lead, if supplied in a power line cable, to the grounded switch box or

building ground. If not provided, use a separate grounding lead. Ensure that the current (amperage)

capacity of the grounding lead will be adequate for the worst fault current situation. Refer to the

National Electrical Code ANSI/NFPA 70 for det ails. Do not remove plug ground prongs. Use

correctly mating receptacles.

b) Converter Installation safety instructions

Prior to the installation of this equipment, you should read all relevant chapters and sections within

this manual. Special attention must be given to Chapter 1, Section 3, which describes the

requirements for the building installation, the interlock safety system, short circuit protection and

minimum cable dimensions to get the maximum performance of the equipment.

For safety reasons the interlock cables must be connected in accordance to this manual. If the

interlock cables are not correctly mounted, this may cause hazard to operators, as the output plug

would then be left with voltage on, when the start push button has been pushed.

After installation of interlock cables, output cable(s) and plug(s), the phase sequence and the function

of the interlock system must be thoroughly checked prior to connection of any aircraft.

c) Output Cables and Terminals

Inspect cables frequently for damage to the insulation and the connectors. Replace or repair cracked

or worn cables immediately. Do not overload cables. Do not touch output terminal while equipment

is energized.

4) Operator safety instructions

The manual should be read thoroughly be fore operating equipment. The user will gain an overall

introduction of how to operate the equipment.

If the equipment is plugable at the input by means of an industrial plug and in the case that you are not

sure that the building installation complies with the requirements of the equipment to be connected,

please refer to the installation safety instructions or contact a qualified service technician. .

5) Service and Maintenance

Service personnel should study the complete manual carefully. It is important not only to be confident with

the equipment, but also to be aware of local health and safety rules applicable where the equipment is

installed.

This equipment must be maintained in good electrical condition to avoid hazards stemming from

disrepair. Report any equipment defect or safety hazard to the supervisor and discontinue use of the

equipment until its safety has been assured. Repairs should be made by qualified personnel only.

Before inspecting or servicing this equipment, take the following precautions:

a) Shut off all power at the disconnecting switch, or line breaker before inspecting or servicing the

equipment.

July 14, 2006 Safety Warnings

Page 2

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

b) Lock switch OPEN (or remove line fuses) so that power cannot be turned on accidentally.

c) Disconnect power to equipment if it is out of service.

d) If troubleshooting must be done with the unit energized, have another person present who is trained

in turning off the equipment and providing or calling for first aid.

6) Fire And Explosion Prevention

Fire and explosion are caused by electrical sho rt circuits, combustible material near this equipment, or

unsafe operating conditions. Overloaded or shorted equipment can become hot enough to cause fires by

self destruction or by causing nearby combustibles to ignite. For electrically powered equipment, provide

primary input protection to remove short circuited or heavily overloaded equipment from the line.

5) Bodily Injury Prevention

Serious injury can result from contact with fans or hot spots inside some equipment. Shut DOWN such

equipment for inspection and routine maintenance. When equipment is in operation, use extreme care in

doing necessary troubleshooting and adjustment. Do not remove guards while equipment is operating.

6) Medical and First Aid Treatment

First aid facilities and a qualified first aid person should be available for each shift for immediate treatment

of all injury victims. Electric shock victims should be checked by a physician and taken to a hospital

immediately if any abnormal signs are observed.

EMERGENCY

FIRST AID

Call physician immediately. Seek additional assistance. Use First Aid techniques

recommended by American Red Cross until medical help arrives.

IF BREATHING IS DIFFICULT, give oxygen, if available, and have victim lie down.

FOR ELECTRICAL SHOCK, turn off power. Remove victim; if not breathing, begin

artificial respiration, preferably mouth-to-mouth. If no detectable pulse, begin external

heart massage. ALWAYS CALL EMERGENCY RESCUE SQUAD IMMEDIATELY.

7) Equipment Precautionary Labels

Inspect all precautionary labels on the equipment monthly. Order and replace all labels that cannot be

easily read.

July 14, 2006 Safety Warnings

Page 3

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

This page intentionally left blank.

July 14, 2006 Safety Warnings

Page 4

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Introduction

This manual contains operation and maintenance information for a PoWerMaster EV, 400 Hz Solid State

Frequency Converter manufactured by ITW GSE Group, Hobart Ground Power, Troy, Ohio 45373.

This manual is not intended to be a textbook on electricity or electronics. Its primary purpose is to provide

information and instructions to experienced operators, electricians, and mechanics who have never operated

this equipment. It is the intent of this manual to guide and assist operators and mai ntenance people in the

proper use and care of the equipment.

Use of the manual should not be put off until a trouble or need for help develops. Read the instructions

before starting the unit. Learn to use the manual and to locate information contained in it. Its style and

arrangement are very similar to commercial aircraft manuals.

The manual is divided into chapters . Each chapter is divided into as many sections as required.

In addition to operation and maintenance instructions, the manual contains an options list Appendix A, and a

collection of manufacturer’s literature and supplemental information in Chapter 4.

If you have any questions concerning your Hobart Ground Power equipment, immediately contact our Service

Department by mail, telephone, FA X, or E-Mail.

Write: ITW GSE Group

Hobart Ground Power

Service Department

1177 Trade Road East

Troy, Ohio 45373

U.S.A.

Call Inside U.S.A.: (800) 422 -4166 (Parts)

(800) 422 -4177 (Service)

Call From Foreign Countries: (937) 332-5050 (Parts)

(937) 332 -5060 (Service)

FAX Inside U.S.A. (800) 367 -4945

FAX From Foreign Countries: (937) 332-5121

E-Mail : service@itwgsegroup.com

Web Page : www.itwgsegroup.com

July 14 , 2006 Introduction

Page 1

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

This page intentionally left blank.

July 14 , 2006 Introduction

Page 2

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Table of Contents

Chapter 1 Description / Operation Chapter- Section/Page#

Section 1

Section 2

Section 3

Section 4

Section 5

July 14 , 2006 Table of Contents

General Description 1-1/1

Technical Specifications 1-2/1

Standards 1-2/1

Electrical Specifications 1-2/1

Efficiency 1-2/1

Setup 1-2/2

Protections 1-2/2

Physical 1-2/2

Environmental 1-2/2

Life, Etc. 1-2/2

Preparation, Adjustment, Maintenance 1-3/1

Storage Before Installation 1-3/1

Operational and Environmental Conditions after Commissioning 1-3/1

Mounting of Bottom Filter 1-3/1

Connection of Cables 1-3/1

Setup of Parameters 1-3/4

Maintenance 1-3/6

Instruction for Use 1-4/1

Input Breaker 1-4/1

Emergency Stop 1-4/1

Control Panel 1-4/1

Display/Keyboard Interface 1-4/2

Setup of Parameters 1-3/4

Maintenance 1-3/6

Functional Description of Power Part 1-5/1

Input Breaker 1-5/1

Input Filter 1-5/1

12-Pulse Transformer / DC/AC Module 1-5/1

Isolation Transformer 1-5/2

Output Filter 1-5/2

Output Contactor 1-5/2

Page 1

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Section 6

Functional Description of Electronic Part 1-6/1

Facilities 1-6/1

Composition of Processor Module and Interfaces 1-6/1

Chapter 2 Service/Troubleshooting Chapter- Section/Page#

Section 1

Error Diagnostics 2-1/1

Error Numbering / Groupin g 2-1/1

Display Readings / Causes / Suggestions 2-1/2

Listing of DC/AC Modules 2-1/26

Errors Related to Possible Options 2-1/27

Chapter 3 Overhaul/Major Repair Chapter- Section/Page#

Section 1

Overhaul/Major Repair 3-1/1

General 3-1/1

Service Information and Factory Repair 3-1/1

Workmanship 3-1/1

Converter Bridge Mount Removal and Installation 3-1/2

Component Removal and Replacement 3-1/4

PC Board Removal and Replacement 3-1/7

Chapter 4 Illustrated Parts List Chapter- Section/Page#

Section 1

Section 2

Introduction 4-1/1

General 4-1/1

Purpose 4-1/1

Arrangement 4-1/1

Explanation of Parts List 4-1/1

Manufacture's Codes 4-2/1

Explanation of Manufacture's (Vendor) Code List 4-2/1

July 14 , 2006 Table of Contents

Page 2

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Section 3

Section 4

Illustrated Parts List 4-3/1

Explanation of Parts List Arrangement 4-3/1

Symbols and Abbreviations 4-3/1

Figure 1: General Assembly 4-3/2

Figure 2A: Transformer Section Assembly 4-3/4

Figure 2B: Transformer Section Assembly 4-3/6

Figure 3: Power Module Panel Assembly 4-3/8

Figure 4: Input/Output Panel Assembly 4-3/10

Figure 5: Cooling Fan Box Assembly 4-3/12

Figure 6: Control Panel Assembly 4-3/14

Figure 7: AC Filter Capacitor Bank Assembly 4-3/16

Figure 8: DC Filter Capacitor Bank Assembly 4-3/18

Figure 9: DC/AC and Rectifier Module Panel Assembly 4-3/20

Figure 10: Frame and Exterior Panel Components 4-3/22

Numerical Index 4-4/1

Explanation of Numerical Index 4-4/1

Chapter 5 Manufacture's Literature

Appendix A Options

Unusual Service Conditions

July 14 , 2006 Table of Contents

Page 3

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

This page intentionally left blank.

July 14 , 2006 Table of Contents

Page 4

OM-2155 / Operation and Maintenance Manual

Power

Electronic

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Section 1 General Description

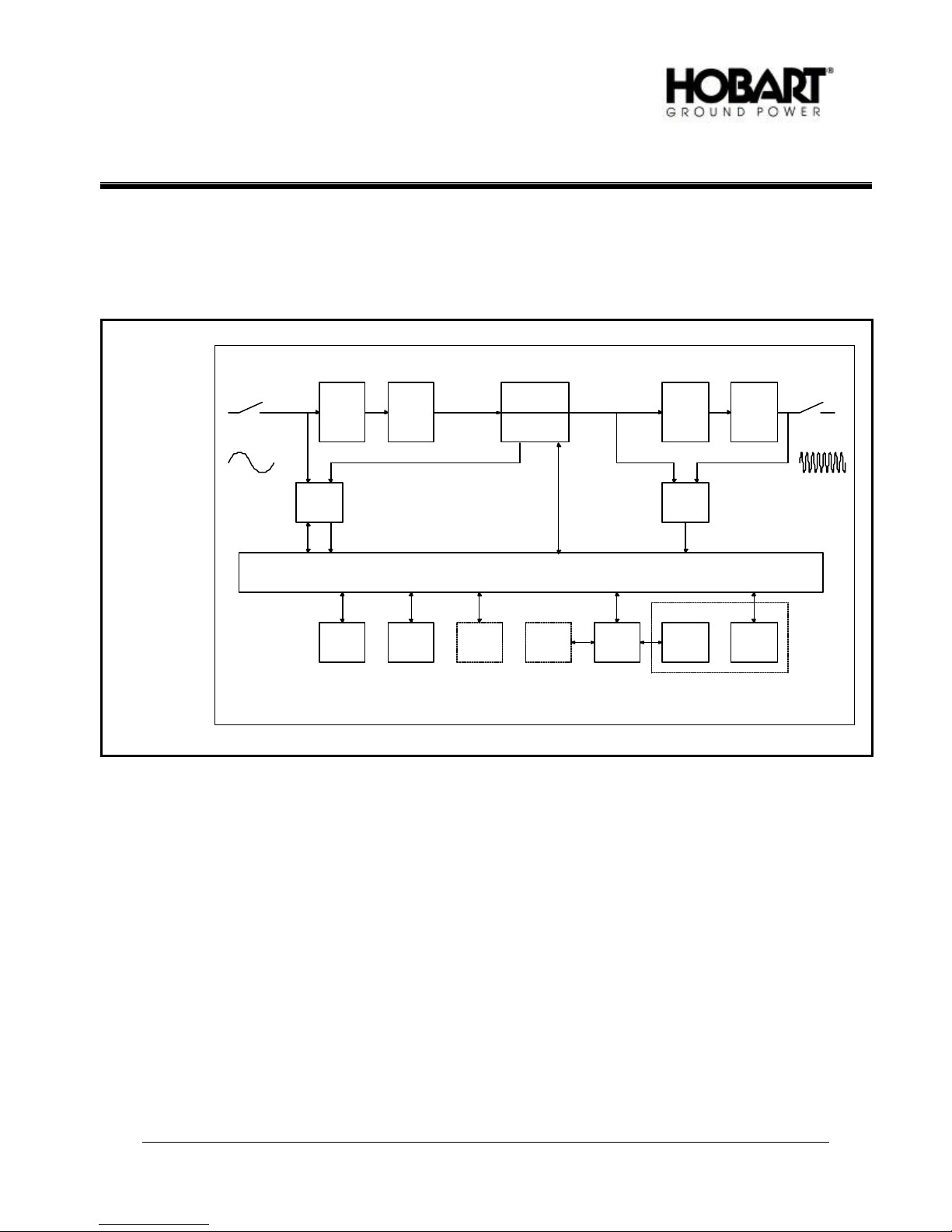

Figure 1 on which the following description is based shows the basic design principle. A detailed description

of the power part is found in Section 5 whereas the electronic part is described in Section 6.

The block diagram shows the power part and electronic part. The power modules and the power switch gear

make up the power part, whereas the electronic modules make up the electronic part.

Part

Part

Input Output

Input breaker

50/60 Hz

AUX

module

Input

filter

12-pulse

transformer

RS232RS485

Relay

module 2

DC/AC-module 1

DC/AC-module 2

Processor module

Remote

control

Relay

module 1

Isolation

transformer

Output feed

module

Control panel

Instrumen-

tation

Users operational zone

Output

filter

Display

Keyboard

module

Output

contactor(s)

400 Hz

Diagram and Design Principle

Figure 1

The input filter protects the convert er from mains transients. After the filtering, the three phases of the mains

are transformed into six phases which are then rectified in a non -regulated 12-pulse full bridge rectifier. The

combination of the 12 pulse rectifier, the related transformer an d the input filter ensures that harmonic feed

back into the mains is reduced to a minimum (i.e. no mains pollution/distortion).

An additional benefit provided by the 12 pulse rectifier is the soft start facility which limits the inrush currents

at the input to a value much lower than the converter’s nominal current.

The filtered DC-voltage supplies the inverter which generates a 3-phase 400 Hz system with a regulated

amplitude and a low harmonic content. The inverter technology is based on a Space Vector Pulse Width

Modulation (SV -PWM) concept which is an advanced type of the PWM technology. The SV-PWM system

provides the converter with extremely fast dynamic properties and a low distortion.

The isolation transformer secures galvanic separation betwee n the mains and the 400 Hz output.

July 14 , 2006 Chapter 1-1

Page 1

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

The converter has individual voltage regulation at each output phase. This secures a precise 400 Hz voltage

at the aircraft plug even in case of a high degree of unbalanced load and long cables. The harmonic content

of the output voltage is further reduced by means of an output filter resulting in a total distortion of less than

2%.

The processor module is based on a micro -controller and a digital signal processor (DSP), which together

regulate, supervise and diagnose external and internal faults. As soon as the converter is connected to the

mains, and constantly during normal operation, the processor module runs through a self-check program

which checks all internal functions. If an internal or external error is detected, the display shows the nature of

the error. All immediate parameters related to a shut-down are stored in the converter’s memory whereas up

to 1000 error situations can be stored.

July 14 , 2006 Chapter 1-1

Page 2

OM-2155 / Operation and Mainten ance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Section 2 Technical Specifications

1) Standards

DFS 400 Specification for 400 Hz aircraft power supply.

ISO 6858 Aircraft ground support electrical supplies- General requirements

BS 2G 219 General requirements for ground support electrical supplies for aircraft

MIL-704E Aircraft electric power characteristics.

EN 50091 -1 General and safety requirements

EN 61000 -6-4 Electromagnetic compatibility, Generic emission standard

EN 61000 -6-2 Electromagnetic compatibility, Generic immunity standard

SAE ARP 5015 Ground equipment – 400 Hz ground power performance requirement

EN2282 Aerospace series characteristics of aircraft electrical supplies

2) Electrical Specifications

a) Input

Voltage: 3 x 460/480V ± 15% or according to customers specification.

Frequency: 50 / 60 Hz ± 5 %

Rectification: 12-pulse

Line Current : 75 A ± 15%

Max. Pre-fusing: 100 A

Line Current Distortion: < 10%

Power Factor: > 0. 96 at 100% load

Inrush current : None, soft start

Power interruption: Up to 20 ms

b) Output

Power: 60 kVA, P.F. = 0.8

Voltage: 3 x 200/115 V.

Power factor: 0.7 lagging to 0.95 leading.

Voltage regulation: < 0.5% for balanced load and 30% unbalanced load

Voltage transient recovery: ∆U < 8% and recovery time < 10 ms at 100% load change

Total harmonic content: < 2% at linear load (typically < 1.5%)

< 2% at non-linear load according to ISO 1540

Crest factor: 1.414 ± 3%

Voltage mo dulation: < 1.0% (typically< 0.5%)

Phase angle symmetry: 120° ± 1° for balanced load

120° ± 2° for 30% unbalanced load

Frequency: 400 Hz ± 0. 1%

Overload: 120% for 600 seconds

150% for 30 seconds

170% for 5 seconds

200% for 1 second

3) Efficiency

Overall efficiency: > 0.93 at 35-90 kVA load

Stand-by losses : < 50 W

No-load losses: < 1500 W

July 14, 2006 Chapter 1-2

Page 1

OM-2155 / Operation and Mainten ance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

4) Setup

Output voltage: 100-128 V

Voltage compensation: 0-9V (individual for each outlet)

Delay to stand -by: 0-15 min.

Time: Year, month, day, hour, minute and seconds

Interlock: Bypass on / off

Fan: Test on / off

Serial Protocol: 3964R or JBUS

Serial Port: RS232 or RS422/485

JBUS slave address: 1-247

Error log / Power log: Reset

Timer (hour counter): Reset

5) Protections

No Break Power Transfer

Input over -and under voltage

Input overload

Internal high temperature

Internal voltage error

Output over-and under voltage (according to DFS 400)

Overload at output

Short circuit at output

6) Physical

Weight

Fixed model: 1102 lbs (500 kg)

Bridge-mounted model: 1102 lbs (500 kg)

Mobile model: 1700 lbs (600 kg)

For dimensions, kindly refer to layout drawings enclosed under Chapter 5.

7) Environmental

Operating temperature: -40 °C to +52 °C

Relative humidity: 10-95%

Noise level: < 65 dB (A) at 1m, typically 60 dB(A)

Standard protection: IP55 (Electronic part)

8) Life, etc.

Operational life: Min 25 years

Mean time between failures (MTBF):

Converter: Min 25.000 hours

Ventilation system: Min. 100.000 hours

Mean time to repair (MTTR): Max. 20 min.

July 14, 2006 Chapter 1-2

Page 2

OM-2155 / Operation and Maintenance Manual

Ground Cable

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Section 3 Preparation, Adjustment and Maintenance

1) Storage Before Installation

To secure optimal storage conditions prior to installation, it is recommended that the converter be stored

inside to protect it from rain and excessive humidity while it is left without power on.

Only equipment in seaworthy packing can be stored outside.

2) Operational and Environmental Conditions after Commissioning

When the converter has been installed and commissioned, we recommend that the input always be kept

with input po wer ON to provide optimal conditions for the electronic components and to avoid humidity in

the form of condensation from reaching vital parts.

If for some reason the converter has been without input voltage for a long period, a visual inspection

should be carried out. In case that condensation is discovered on any internal parts, the parts have to

dry out before input voltage is again applied.

3) Mounting of Bottom Filter (only valid for stationary/fixed models)

Due to transport safety, fixed models are delivered without the bottom filter mounted. The filter is

mounted in the hole (designated for fork -lifting) at the bottom by means of the accompanying mounting

devices.

4) Connection of Cables

a) Input

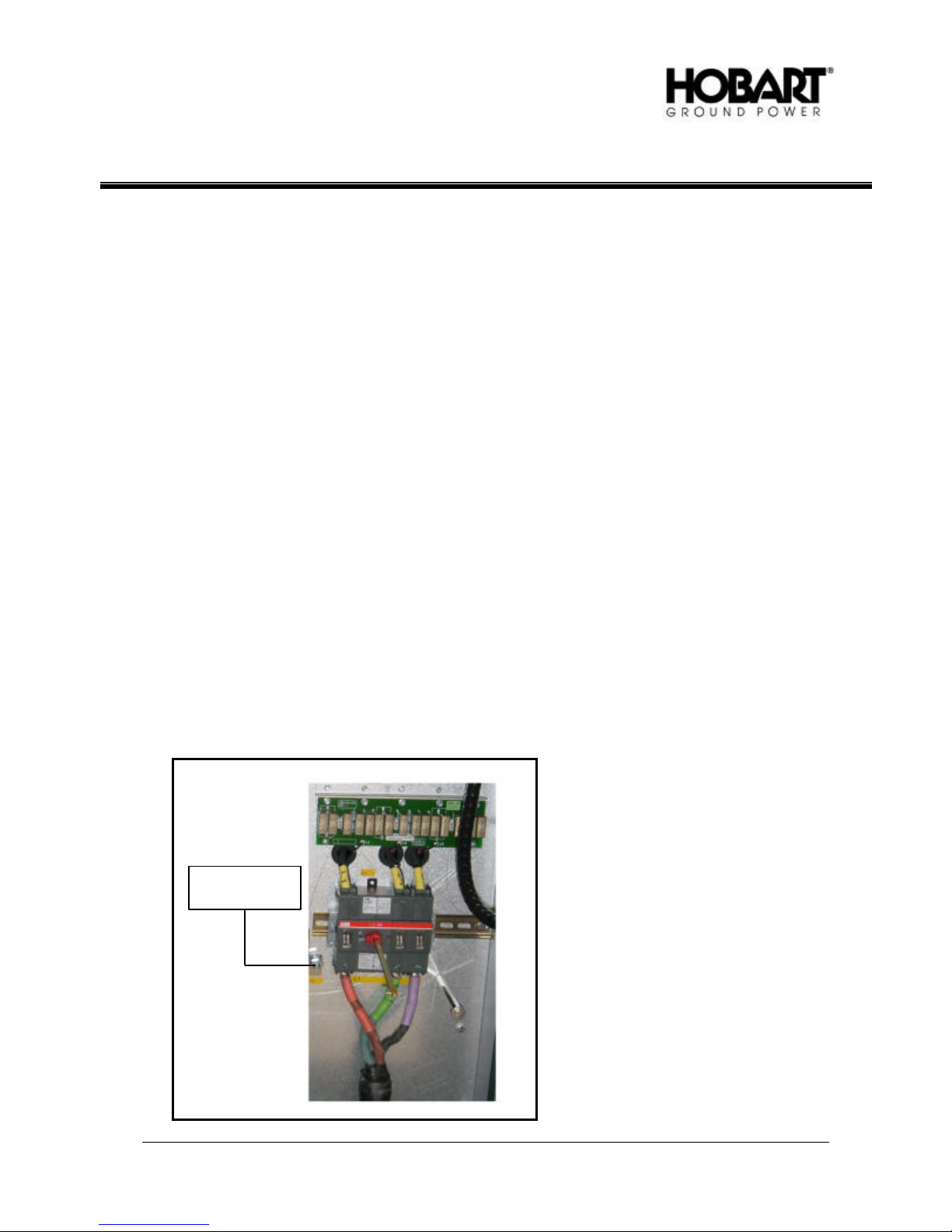

Due to personal safety the converter most be protected by grounding of the PE terminal (Figure 1).

The converter should be pre-fused according to the table below:

PE Terminal

January 18, 2007

Revision 2

Input Cable Connections

Figure 1

Chapter 1-3

Page 1

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

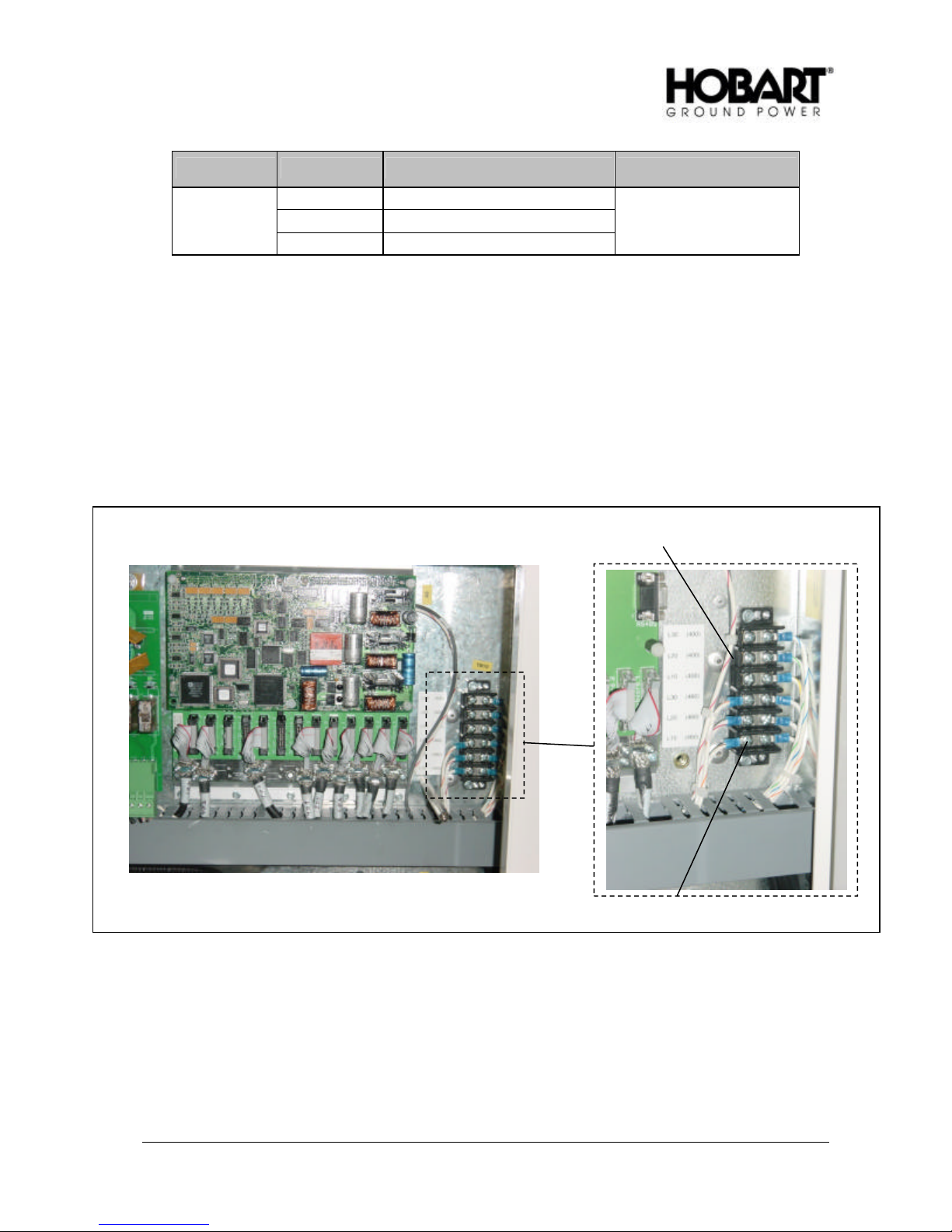

kVA Rating Input Line Current Maximum pre -fuse

400 V 76 A ± 15%

460 V 66 A ± 15% 60

480 V 63 A ± 15%

Input Voltage Requirements

Figure 2

The three phases of the input voltage supply and the earth connection are connected to the terminals

labeled L1, L2, L3 and PE. As the phase sequence is of importance for the converter's function, the

phase sequence is checked by means of the built-in auto test (when input power is applied). If the

phase sequence is wrong, this is shown at the display. If wrong, the correction is made by changing

the two phases. All connection diagrams can be found in Chapter 5.

The internal converter circuitry operates at 400 VAC, so when setting the converter up to run on one

of the voltage settings in Figure 2, please make the proper connections are made on the terminal

strip in Figure 3.

100 A

400 V Input

b) Output

The supply cables to the aircraft , or to an eventual distribution box, are connected to the terminals

labeled A, B, C and N on the output contactor (Q2). All connection diagrams can be found in

Chapter 5.

January 18, 2007

Revision 2

460/480 V Input

Input Voltage Connecti ons

Figure 3

Chapter 1-3

Page 2

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

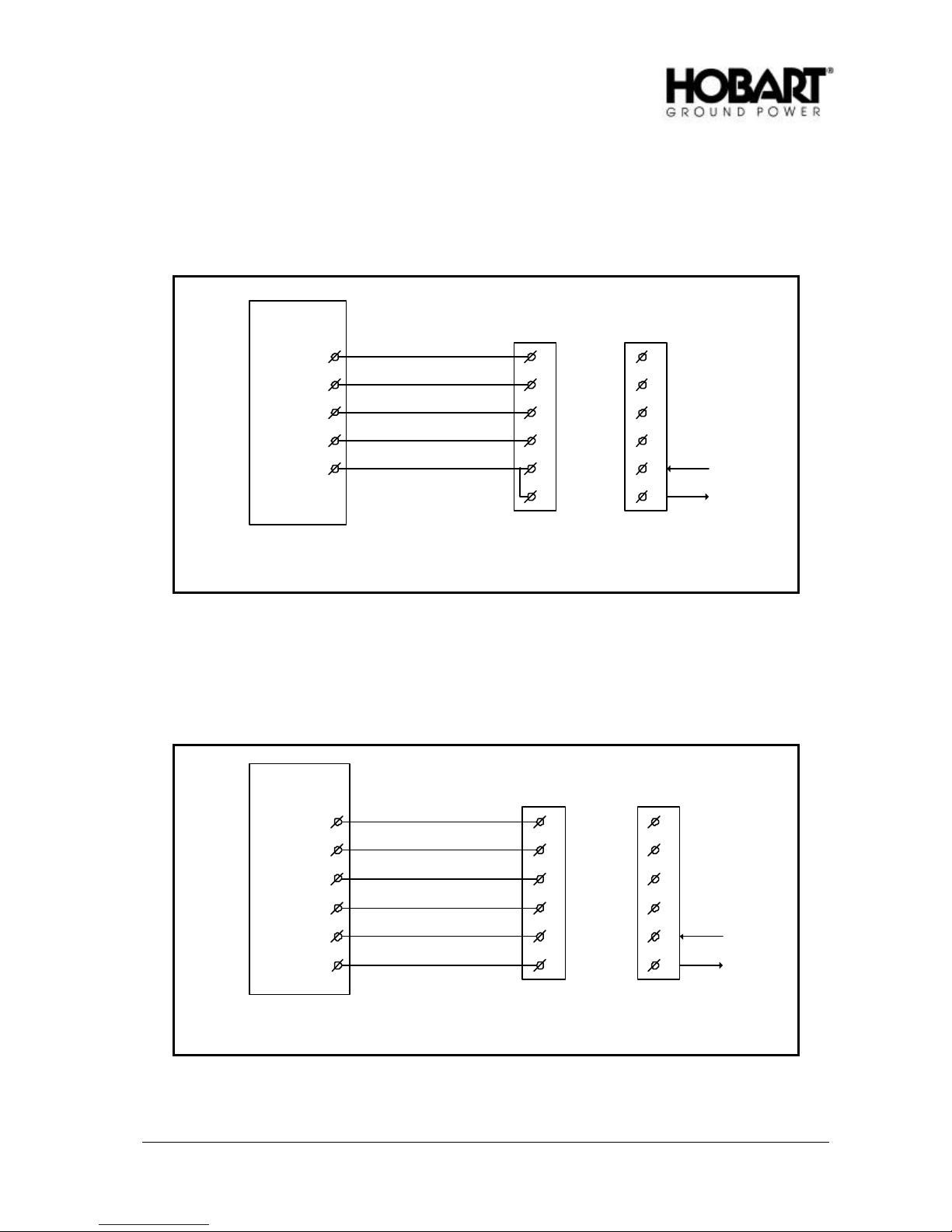

c) Interlock Safety System

To secure personnel’s health and safety, the converter is equipped with an interlock system. The

system ensures that the output contactor only stays energized as long as the plug is inserted in the

aircraft receptacle (i.e. as long as the aircraft provides 28 VDC with respect to 400 Hz neutral to

terminal F ). Standard wiring between converter and plug is shown in Figure 4.

A

B

C

N

F

Jumper

Ground Power Unit Cable Plug

A

B

C

N

F

E

A

B

C

N

+28VDC

F

To control

E

Aircraft Receptacle

Standard wiring diagram, Civil aircraft

Figure 4

When used in connection with some military aircraft, the converter normally has to provide 28 VDC

with respect to 400 Hz neutral to ensure a proper interlock function. Standard wiring between

converter and plug is shown in Figure 5.

Ground Power Unit Cable Plug

January 18, 2007

Revision 2

A

B

C

N

F

E+28VDC

A

B

C

N

F

E

Standard wiring diagram, Military aircraft

Figure 5

A

B

C

N

+28VDC

F

To control

E

Aircraft Receptacle

Chapter 1-3

Page 3

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

For service, maintenance and test purposes, the interlock system can be by -passed via the display

and keyboard set -up. To secure personnel’s health and safety, the unit automatically returns into

normal mode once it receives 28 VDC at terminal F. (i.e. when the converter is connected to an

aircraft).

d) Remote Control

The converter can be operated by means of the remote control terminals, which are label ed in

accordance with the diagrams found in Chapter 5. In case of very long remote control cables, it

might be necessary to use shielded cables. The shield has to be connected at both ends.

5) Setup of Parameters

It is possible to set and to adjust the following parameters by means of the converter's display and

keyboard. The proc edure is described in Chapter 3, Section 4.

a) Language

The display ed text is provided in 3 languages as a standard. It is possible to switch between the

languages by means of the dip switch (S1) situated on the back of the display. The table shows how

to select language.

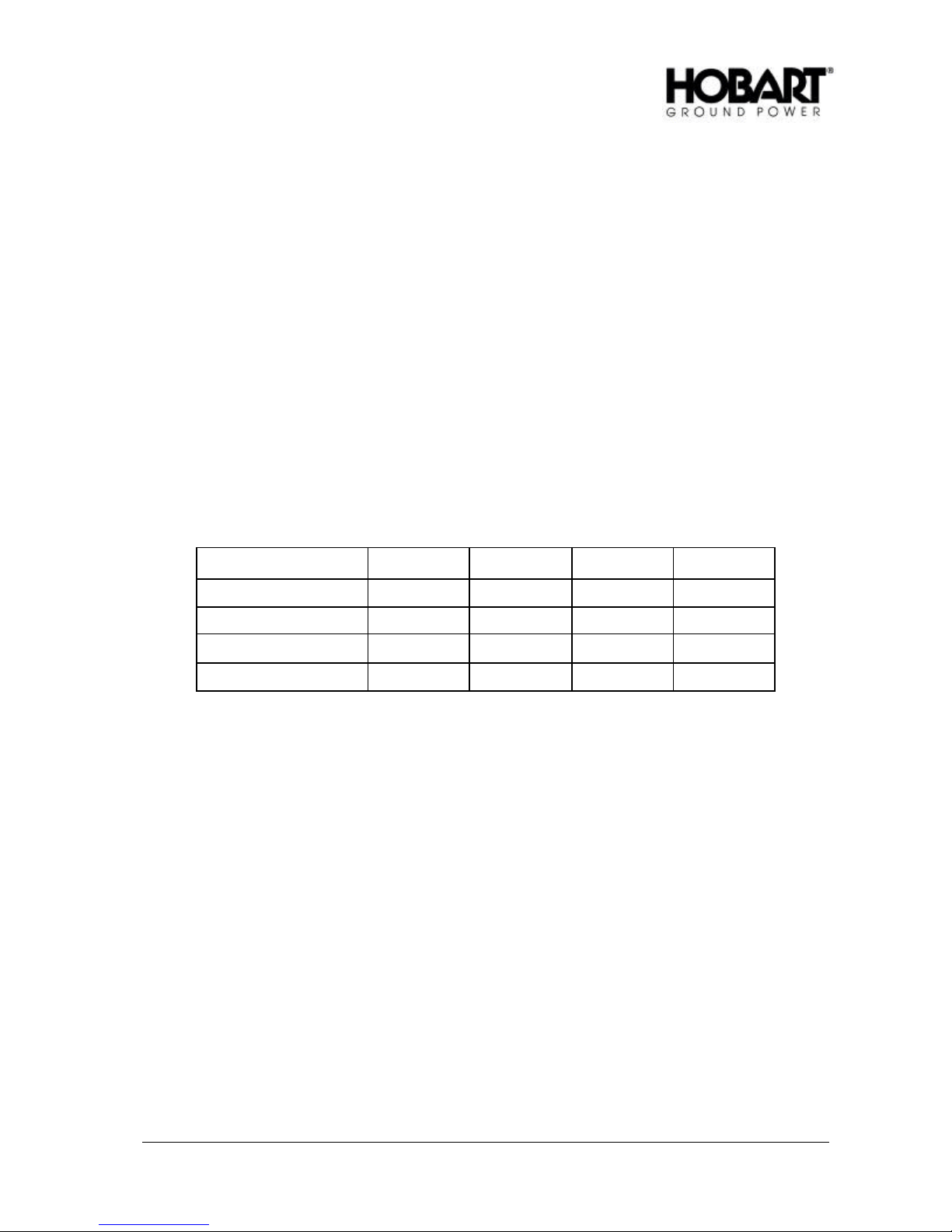

Language/Position S1 - 1 S1 - 2 S1 - 3 S1 - 4

English OFF OFF X X

English ON ON X X

Spanish OFF ON X X

French ON OFF X X

X = position is random

b) Output Voltage Phase-Neutral

At delivery, the converter is set to nominal output voltage. This level can be adjusted, if re quired (i.e.

due to voltage drop in the supply cable ). The adjustment range is nominal voltage of ± 15%.

PLEASE NOTICE! If the voltage level falls outside the converter's operation range under

adjustment, the converter disengages and reports an under or over -voltage fault. The nominal

voltage as well as the levels for under and over -voltage are shown in Chapter 1, Section 2.

c) Output Voltage Compensation

If long output cables are used, the voltage drop becomes considerable during load situations.

However, it is possible to increase the converter's output voltage proportionate to the load current.

The adjustment is made while the converter is loaded and when the output cables have been

mounted. With a load current above 20% of the nominal output current, the voltage at the output plug

is adjusted to the required value (larger load current gives a better result). At delivery, the

compensation is pre -set to 0. The maximum compensation is 9V.

If only one outlet is available, only set up 1 is in use.

If two outlets are available , each output has its own set up (1 and 2). In case both outlets are in

use at the same time, the compensation will be set to half of the mean value of the two set up values.

January 18, 2007

Revision 2

Chapter 1-3

Page 4

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

d) Delay from Contactor OFF to Standby

If the converter's output contactor(s) is (are) not energized, the converter automatically passes into

standby mode after elapse of a pre -set period of time. This time delay can be set to values between

1 and 900 seconds. At delivery, the time delay is set to 15 seconds.

e) Date and Hour

The converter has a built-in real time clock showing the date and the hour. At delivery, the clock is

set to actual hour (USA EST time). The clock does not adjust itself at changes from summer time to

winter time and vice versa (no daylight savings time adjustment). It is possible to set year, month,

day, hour, minutes and seconds.

f) Setup of Interlock By-pass

The interlock safety system can be by -passed by setting the value to 1. For further information of the

interlock system, kindly refer to paragraph 4 in this chapter.

g) Setup of Fan By-pass

From the factory the by-pass value is set to 0, which means that the fan is temperature controlled. In

order to by -pass the temperature control, for instance for test purposes, the by-pass value is set to 1.

This means that the fan will run continuously.

h) Setup of Serial Protocol

There are two protocols available. If the value is set to 1, the Siemens 3964R protocol is chosen. If

the value is set to 2, the JBUS protocol is chosen. For further information about the protocols please

contact HOBART.

i) Setup of Serial Port

It is possible to select an RS232 port and an RS422/485 port. If the value is set to 1, the RS232 port

is selected. With the value set to 2, the RS422/485 protocol is selected.

j) Setup of JBUS Slave Address

If the JBUS protocol is selected, the slave address can be set up. The slave address can be set to

values between 1 and 247. At delivery, the address is set to 1.

k) Setup of Error Log, Power Log, Black Box

From the factory the by-pass value is set to 0. If for some reason it is necessary to clear the memory

log after installation the by -pass value is set to 1. After the reset, the by-pass value is automatically

set to 0.

l) Setup of Counters

The hour counter and the energy counter are reset, when the value is set to 1 (used to clear the

counter memory after installation). The value is automatically set to 0 after reset.

January 18, 2007

Revision 2

Chapter 1-3

Page 5

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

6) Maintenance

At least once a year it is recommended to

1. Check air filters - Wash or change as appropriate.

Note: We recommend, however, checking the air filters once a month to ensure proper air flow in

harsh environments.

2. Check that all fans are running properly.

3. Check bolt/screw and wire connections.

4. Check vibration dampers.

5. Visual inspection of all components.

6. Visual inspection of PCB's - control unit / gate drive.

7. Control of the contactors' contact sets and coil.

8. Control of output voltage.

9. Check of external cables and plugs.

Especially for outside mounted models, we recommend to:

10. Check rubber seals around panels and doors .

Especially for mobile -converters:

11. Check trailer tires for wear and tear.

12. Check that air pressure.

Note: We rec ommend, however, checking the tire pressure on a more frequent basis.

Battery back -up:

Situated on the processor board, a lithium battery assures that set -up data etc. is not lost if input power is

removed. The expected life of the battery is approximately 10 years. However, a low battery voltage

does not affect the internal safety system of the GPU that monitors the output voltage, among other

things. Thus aircraft connected to the GPU is not exposed to any danger. To avoid loss of data we

recommend you to replace the battery after 8 to 9 years of us e.

January 18, 2007

Revision 2

Chapter 1-3

Page 6

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

Section 4 Instruction for Use

The converter is equipped with the following operational controls and indications:

• Input breaker On/Off

• Emergency stop

• Display and keyboard

• Control panel with

Ø Input voltage indication (Mains)

Ø Fault indication (Common Error)

Ø Start / Reset push-button and indication for each output contactor

Ø Stop push-button for each output contactor

Ø Push button for lamp test (in common with indication of input voltage)

1) Input Breaker

When activated it connects the converter to the input power. Upon energizing, the converter runs

through a check program which tests the converter's internal and external conditions. If no faults or

irregularities are detected, the converter passes into standby mode.

2) Emergency Stop

The converter can be immediately stopped by activation of the emergency stop.

PLEASE NOTICE! The emergency stop must be released, before it is possible to restart the converter.

3) Control Panel

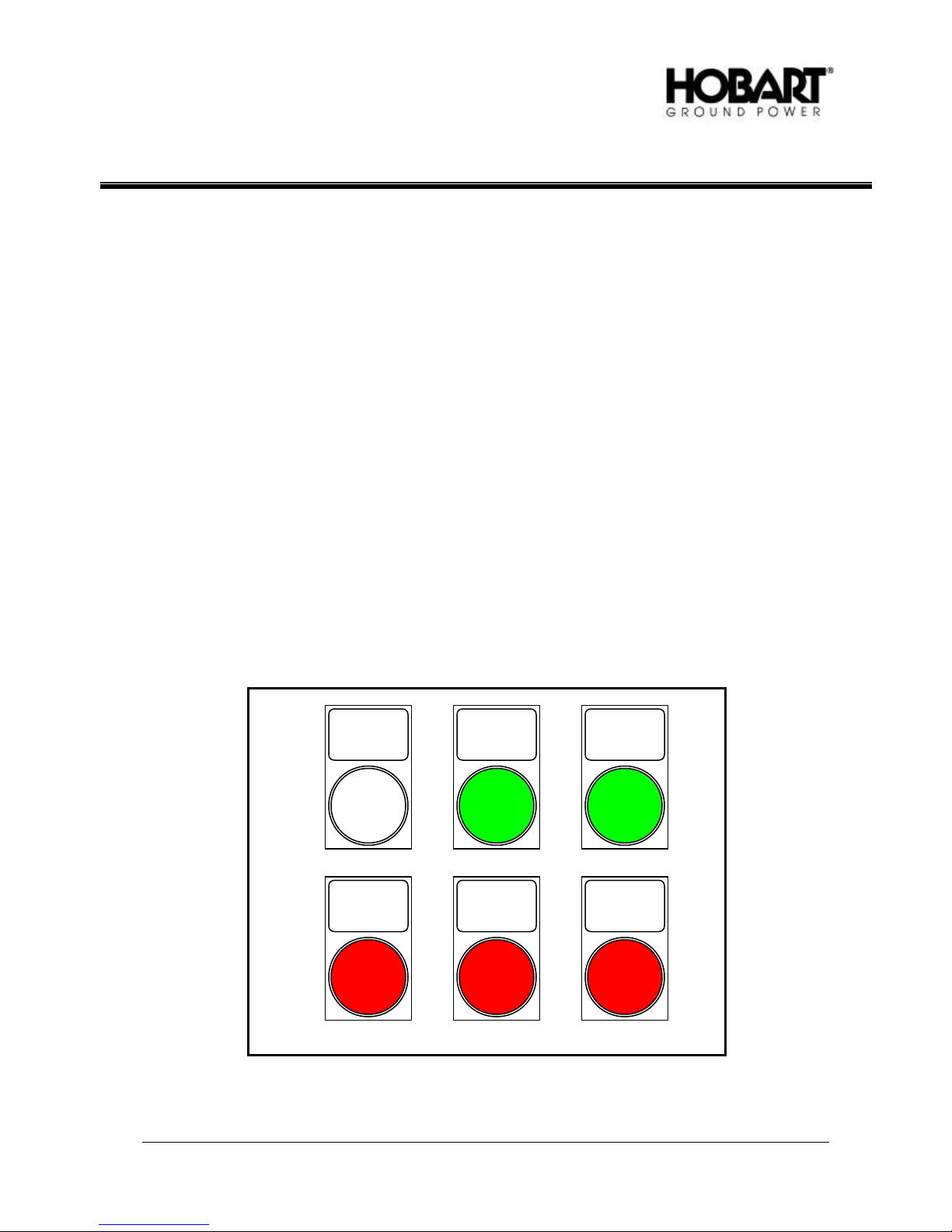

START 1 /MAINS /

LAMP TEST RESET

RESET

START 2 /

June 7, 2007

Revision 3

COMMON

ERROR

STOP 2STOP 1

Control Panel

Figure 1

Chapter 1-4

Page 1

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

a) Mains/Lamp Test

The mains lamp is lit, as soon as the converter is connected to the input power, and the input breaker

is activated. A push-button for lamp test can be built in. If built in, the activation of the button lights

all workable buttons at the control panel and keeps them lit until the button is released.

b) Common Error

This lamp is lit in case of a fault in the converter. The converter passes into alarm mode, and the

fault is displayed (for further information see Chapter F. The lamp is lit as long as the fault has not

been corrected.

c) Start/Reset

(1) Converter in Standby Mode:

A push of the Start/Reset button resets the converter, which then performs an auto-test of

internal and external parameters. If the test program is performed without detection of any errors

the system will state it is ready for use. The corresponding output contactor can now be

energized and the converter automatically passes from standby into 400 Hz available mode. The

Start/Reset button is lit, when 400 Hz is available at the output. The output contactor is activated

for 1 second no matter whether the interlock signal is present or not. If the interlock signal is not

available, the converter passes into standby mode after the elapse of the time delay to standby.

Missing interlock signal is shown at the display.

(2) Converter in 400 Hz Available

The converter is in 400 Hz available when at least one of the output contactors is energized. A

push of Start/Reset engages the output contactor of the corresponding outlet and the button is lit,

indicating that the output contac tor is energized. The converter supplies 400 Hz at the output,

until the output contactor(s) is de-energized. If one (single output) or both (dual output) interlock

signals become unavailable, the converter passes into stand-by mode after the elapse of the time

delay to standby. Missing interlock signal is shown at the display.

d) Stop

A push of the stop button disengages the corresponding output contactor. At de-energizing of both

output contactors, the converter immediately passes into standby mode.

4) Display/Keyboard Interface

a) Basic Information

From the display/keyboard it is possible to:

1. view different internal and external parameters.

2. change GPU settings.

3. browse through the GPU memory.

4. adjust the display contrast.

June 7, 2007

Revision 3

Chapter 1-4

Page 2

OM-2155 / Operation and Maintenance Manual

NORMA

DISP

ALAR

DISP

SETU

GP

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

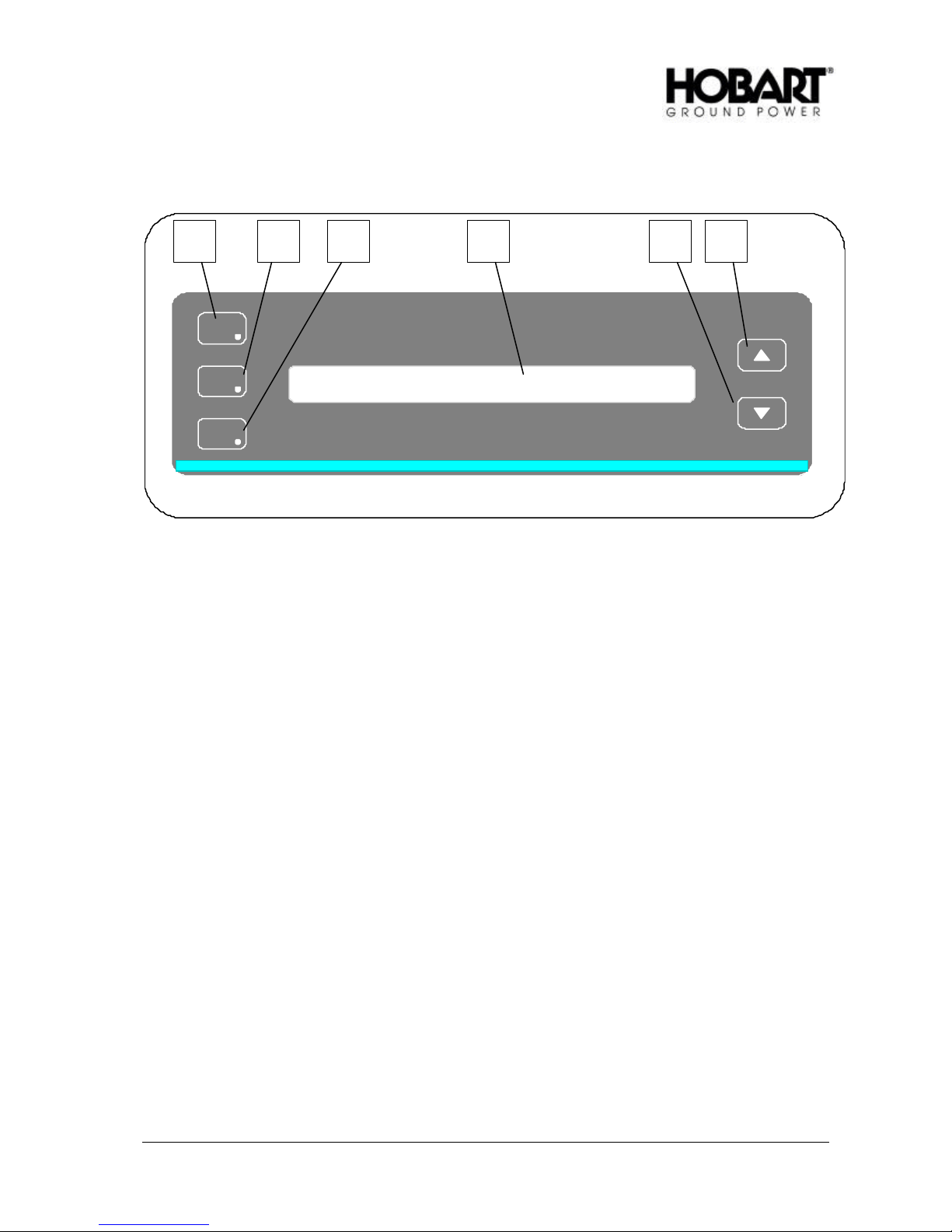

1 2 3 6 4 5

1. Display text area, 2 lines of 40 characters per line.

2. Key and LED : NORMAL DISP.

3. Key and LED : ALARM DISP.

4. Key and LED : SET-UP GPU.

5. Key : ARROW UP.

6. Key : ARROW DOWN.

b) How to Use Display/Keyboard

The display/keyboard reacts in 2 different ways on a key press.

(1) If switching between display modes or selecting a new picture, the display reacts on a key press

when the key is released. In these cases, the LED NORMAL DISP. flashes in order to show that

the key press is registered and that the display is working. The flashing stops when the desired

text appears on the display.

(2) If adjusting GPU-settings or display -contrast the value keeps changing, as long as one of the

ARROW keys is held down.

The keyboard is read 4 times per second. Therefore pressing a key must last longer than 1/4 of a

second to make sure that the key press is registered.

Display/Keyboard

Figure 2

June 7, 2007

Revision 3

Chapter 1-4

Page 3

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

c) Signification of the LED Signals

As already mentioned above, the LED NORMAL DISP flashes when the display has registered a key

press until the instruction has been carried out. Additionally, the LED's are lit as shown below:

Display mode: LED lit:

Default mode: NORMAL DISP.

View mode: NORMAL DISP.

Alarm mode: ALARM DISP.

Black box mode: ALARM DISP. & NORMAL DISP.

Power log mode: ALARM DISP. & SETUP GPU

Setup mode 1: SETUP GPU (constant light)

Setup mode 2: SETUP GPU (flashing light)

d) Parameter Updating

The time from a key press to the new picture shows, and the time between updating of the parameter

values, depend on the number of parameters in the picture. Normally this time will be less than 1

second. However, this is not applicable when adjusting setup parameters, where the update time is

very short.

e) Parameters Measuring Range

If the value of a parameter, in a selected display picture, is below the measuring range the display will

show the parameter as “< xxx”, where “xxx” shows the lowest value of the measuring range.

f) Adjusting Display Contrast (only LCD display)

If the light conditions or the viewer’s position makes it difficult to read the display, the display -contrast

can be adjusted by means of the NORMAL DISP. and ARROW UP/ ARROW DOWN keys. Contrast

adjusting can be made in any display mode.

Start by pressing NORMAL DISP and keep it down. Press ARROW UP or ARROW DOWN until the

display contrast is satisfactory. Release NORMAL DISP. key as the last. If not, the display changes

according to last pressed ARROW key.

g) Display Modes

There are 6 basic display modes:

• Default mode (display shows actual converter status)

• View mode (viewing parameters)

• Alarm mode (browsing through error log)

• Black box mode (browsing through errors and related parameters)

• Power log mode (browsing through logged operation information)

• Setup mode (viewing or changing settings)

The user can switch freely between the different display modes.

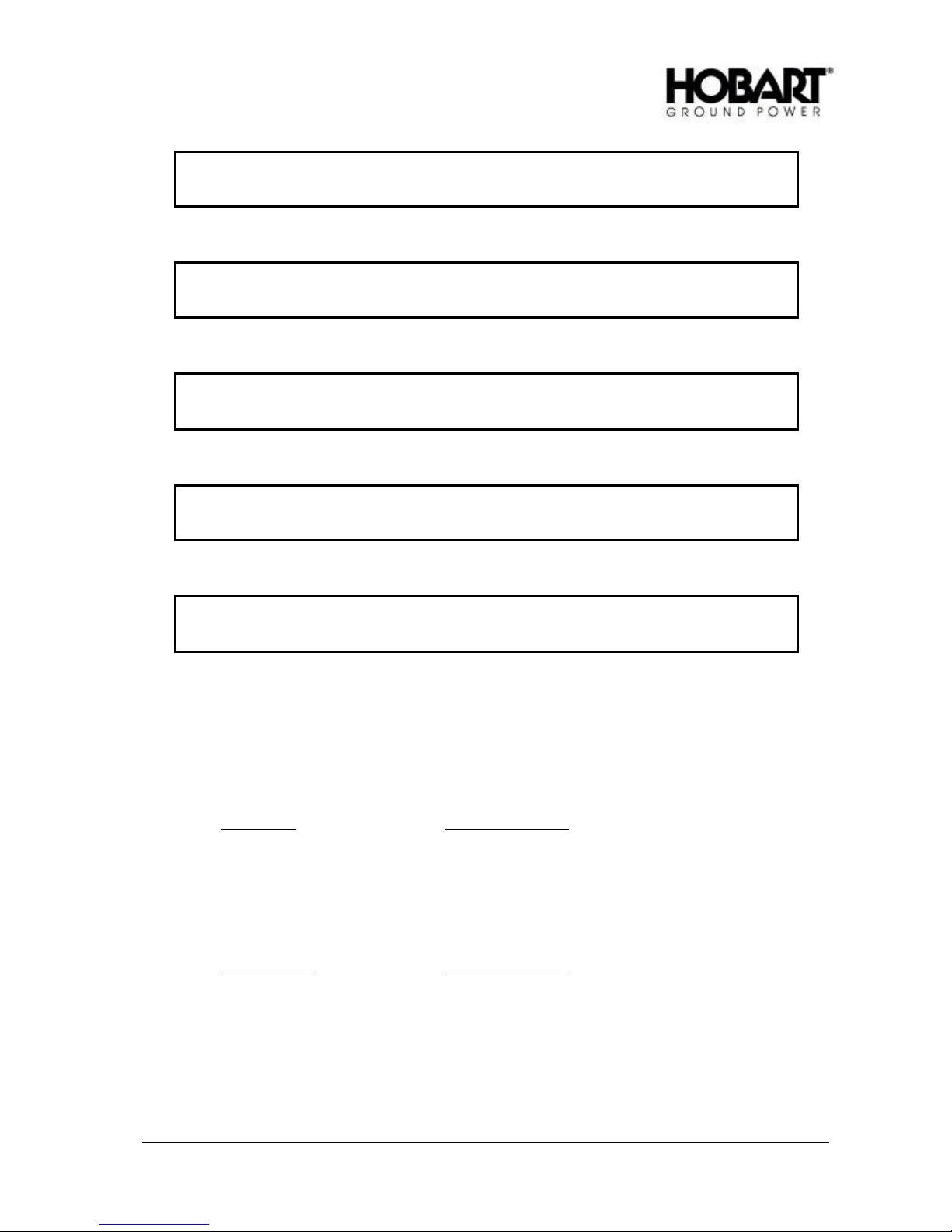

(1) Default Mode

Possibilities in Default mode:

In Default mode, the displayed picture is one of the following 5 pictures or an ALARM picture,

depending on the status of the converter.

June 7, 2007

Revision 3

Chapter 1-4

Page 4

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

STANDBY

SYSTEM READY FOR USE

year-mo-da ho.mi

OR

SYSTEM IN OPERATION

xxx/xxx.x V

year-mo-da

xxx A

OR

INTERLOCK SIGNAL MISSING

VERIFY PLUG POSITION OR CHECK CABLING

OR

EMERGENCY STOP ACTIVATED

SYSTEM STOP

OR

CONTROL UNIT IS WORKING

PLEASE WAIT

OR

ALARM PICTURE, according to Alarm mode

In case of built-in options such as magnetic card readers or 90% switches integrated in the

plug, additional display default pictures may occur.

Switching to other modes from Default mode:

Switch to: By pressing key:

View mode NORMAL DISP. or ARROW UP or ARROW DOWN

Alarm mode ALARM DISP.

Black box mode ALARM DISP. and ARROW UP

Power log mode ALARM DISP. and ARROW DOWN

Setup mode SETUP GPU

Switching to Default mode from other modes :

Switch from: By pressing key:

View mode NORMAL DISP

Alarm mode NORMAL DISP. first key press gives View mode, the

second Default mode

Black box mode NORMAL DISP. first key press gives View mode, the

second Default mode

Power log mode NORMAL DISP. first key press gives View mode, the

second Default mode

Setup mode NORMAL DISP.

June 7, 2007

Revision 3

ho.mi

xxx.x Hz

Chapter 1-4

Page 5

OM-2155 / Operation and Maintenance Manual

60 kVA PoWerMaster EV / Series 500381 / Solid State Converter

(2) View Mode

Possibilities in View mode:

When from one of the other display modes View mode is selected, the first picture shown is:

INPUT VOLTAGE:PHASE-PHASE

L1-L2=xxx

L2-L3=xxx

By pressing and releasing ARROW UP or ARROW DOWN, the user can browse through the

following pictures, including the above shown picture.

ARROW UP : Order as shown below

ARROW DOWN: Reverse order of below

INPUT FREQUENCY

[Hz]

VOLTAGE AT DC CAPACITOR BANK

[V]

OUTPUT VOLTAGE:PHASE-NEUTRAL

A=xxx B=xxx

OUTPUT VOLTAGE:PHASE-PHASE

AB=xxx BC=xxx

CA=xxx

OUTPUT CURRENT

A=xxx B=xxx

INVERTER CURRENT

A=xxx B=xxx

ACTIVE OUTPUT POWER

A=xxx B=xxx

APPARENT OUTPUT POWER

A=xxx B=xxx

OUTPUT FREQUENCY

[Hz]

C=xxx

C=xxx

C=xxx

C=xxx

C=xxx

[V]

L3-L1=xxx

xxx.x

xxx

[V]

Avg=xxx.x

[V]

Avg=xxx

[A]

Avg=xxx.x

[A]

[kW]

S =xxx

[kVA]

S =xxx

xxx.x

June 7, 2007

Revision 3

Chapter 1-4

Page 6

Loading...

Loading...