Page 1

OM-2098C

040105 – Original

070308 – Revision 9

Operation and Maintenance Manual

with

Illustrated Parts List

for

60CU24

60 kVA, 3 Phase, 115/200 Volt,

400 Hz. Generator Set

Series 500060C

ITW GSE Group

Hobart Ground Power

Troy, Ohio 45373

U.S.A.

Page 2

Page 3

Data Sheet 165

Warranty

HOBART GROUND POWER

TROY, OHIO 45373

1. Hobart Brothers Company (hereinafter called HOBART) warrants that each new and unused Hobart Ground Power

Equipment, (hereinafter called the PRODUCT) is of good workmanship and is free from mechanical defects,

provided that (1) the PRODUCT is installed and operated in accordance with the printed instructions of HOBART,

(2) the PRODUCT is used under the normal operating conditions for which it is designed, (3) the PRODUCT is not

subjected to misuse, negligence or accident, and (4) the PRODUCT receives proper care, lubrication, protection,

and maintenance under the supervision of trained personnel.

2. This warranty expires 15 months after shipment by HOBART to the first user, or 12 months after installation,

whichever first occurs.

3. This warranty does not apply to: primary and secondary switch contacts, cable connectors, carbon brushes, fuses,

bulbs, and filters unless found to be defective prior to use.

4. Hobart DOES NOT WARRANT THE FOLLOWING COMPONENTS: Engines, engine components; such as:

starters, alternators, regulators, governors, etc., and cable retrieving devices. Many of the foregoing components

are warranted directly by the manufacturer to the first user and serviced by a worldwide network of distributors and

others authorized to handle claims for component manufacturers. A first user’s claim should be presented directly

to such an authorized component service outlet. In the event any component manufacturer has warranted its

component to HOBART and will not deal directly with a first user then HOBART will cooperate with the first user

in the presentation of a claim to such manufacturer. Under NO circumstances does HOBART assume any liability

for any warranty claim against or warranty work done by or in behalf of any manufacturer of the foregoing

components.

5. This warranty is extended by HOBART only to the purchaser of new PRODUCTS from HOBART or one of its

authorized distributors. The PRODUCTS purchased under this warranty are intended for use exclusively by the

buyer and his employees and by no other persons and, therefore, there shall be no third party beneficiary to this

warranty.

6. A claim of defects in any PRODUCT covered by this warranty is subject to HOBART factory inspection and

judgment. HOBART’S liability is limited to repair of any defects found by HOBART to exist, or at HOBART’S

option the replacement of the defective product, F.O.B. factory, after the defective product has been returned by the

purchaser at its expense to HOBART’S shipping place. Replacement and exchange parts will be warranted for the

remainder of the original Warranty, or for a period of ninety (90) days, whichever is greater.

7. UNDER NO CIRCUMSTANCES whatsoever shall HOBART and its authorized distributors be liable for any

special or consequential damages, whether based on lost goodwill, lost resale profits, work stoppage impairment

of other goods or otherwise, and whether arising out of breach of any express or implied warranty, breach of

contract, negligence or otherwise, except only in the case of personal injury as may be required by applicable law.

8. Continued use of the PRODUCT(S) after discovery of a defect VOIDS ALL WARRANTIES.

9. Except as authorized in writing, this warranty does not cover any equipment that has been altered by any party

other than HOBART.

10. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HERE

OF. HOBART MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

11. HOBART neither assumes nor authorizes any person to assume for HOBART any liability in connection with the

PRODUCTS sold, and there are no oral agreements or warranties collateral to or affecting this written Warranty.

This warranty and all undertakings of HOBART thereunder shall be governed by the laws of the State of Ohio,

United States of America.

Index: 990223

Replaces: 980601

AT ALL TIMES, SAFETY MUST BE CONSIDERED AN IMPORTANT FACTOR IN THE INSTALLATION,

SERVICING AND OPERATION OF THE PRODUCT, AND SKILLED, TECHNICALLY QUALIFIED

PERSONNEL SHOULD ALWAYS BE EMPLOYED FOR SUCH TASKS.

WARNING

Page 4

Page 5

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Safety Warnings and Cautions

WARNING

IMPORTANT

WARNING

ELECTRIC SHOCK can KILL. Do not touch live electrical parts.

ELECTRIC ARC FLASH can injure eyes, burn skin, cause equipment damage, and

ignite combustible material. DO NOT use power cables to break load and prevent tools

from causing short circuits.

IMPROPER PHASE CONNECTION, PARALLELING, OR USE can damage this and

attached equipment.

Protect all operating personnel. Read, understand, and follow all instructions in the

Operating/Instruction Manual before installing, operating, or servicing the equipment.

Keep the manual available for future use by all operators.

CALIFORNIA PROPOSITION 65 - DIESEL ENGINES. Diesel engine exhaust and

some of its constituents are known to the State of California to cause cancer, birth

defects and other reproductive harm.

1) General

Equipment that supplies electrical power can cause serious injury or death, or damage to other equipment or

property. The operator must strictly observe all safety rules and take precautionary actions. Safe practices

have been developed from past experience in the use of power source equipment. While certain practices

below apply only to electrically-powered equipment, other practices apply to engine-driven equipment, and

some practices to both.

2) Shock Prevention

Bare conductors, terminals in the output circuit, or ungrounded, electrically live equipment can fatally shock a

person. Have a certified electrician verify that the equipment is adequately grounded and learn what

terminals and parts are electrically HOT. Avoid hot spots on machine. Use proper safety clothing, procedure s,

and test equipment.

The electrical resistance of the body is decreased when wet, permitting dangerous currents to flow through it.

When inspecting or servicing equipment, do not work in damp areas. Stand on a dry rubber mat or dry wood,

and use insulating gloves when dampness or sweat cannot be avoided. Keep clothing dry, and never work

alone.

a) Installation and Grounding of Electrically Powered Equipment

Equipment driven by electric motors (rather than by diesel or gasoline engines) must be installed and

maintained in accordance with the National Electrical Code, ANSI/NFPA 70, or other applicable

codes. A power disconnect switch or circuit breaker must be located at the equipment. Check the

nameplate for voltage, frequency, and phase requirements. If only 3-phase power is available,

connect any single-phase rated equipment to only two wires of the 3-phase line. DO NOT CO NNECT

the equipment grounding conductor (lead) to the third live wire of the 3-phase line, as this makes the

equipment frame electrically HOT, which can cause a fatal shock.

April 01, 2005 Safety Warnings

Page 1

Page 6

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Always connect the grounding lead, if supplied in a power line cable, to the grounded switch box or

building ground. If not provided, use a separate grounding lead. Ensure that the current (amperage)

capacity of the grounding lead will be adequate for the worst fault current situation. Refer to the

National Electrical Code ANSI/NFPA 70 for details. Do not remove plug ground prongs. Use correctly

mating receptacles.

b) Output Cables and Terminals

Inspect cables frequently for damage to the insulation and the connectors. Replace or repair cracked

or worn cables immediately. Do not overload cables. Do not touch output terminal while equipment is

energized.

3) Service and Maintenance

This equipment must be maintained in good electrical condition to avoid hazards stemming from

disrepair. Report any equipment defect or safety hazard to the supervisor and discontinue use of the

equipment until its safety has been assured. Repairs should be made by qualified personnel only. Before

inspecting or servicing this equipment, take the following precautions:

a) Shut off all power at the disconnecting switch, or line breaker, or by disconnecting battery, before

inspecting or servicing the equipment.

b) Lock switch OPEN (or remove line fuses) so that power cannot be turned on accidentally.

c) Disconnect power to equipment if it is out of service.

d) If troubleshooting must be done with the unit energized, have another person present who is trained

in turning off the equipment and providing or calling for first aid.

4) Fire And Explosion Prevention

Fire and explosion are caused by electrical short circuits, combustible material near engine exhaust

pipes, misuse of batteries and fuel, or unsafe operating or fueling conditions.

a) Electrical Short Circuits and Overloads

Overloaded or shorted equipment can become hot enough to cause fires by self-destruction or by

causing nearby combustibles to ignite. For electrically powered equipment, provide primary input

protection to remove short circuited or heavily overloaded equipment from the line.

b) Batteries

Batteries may explode and/or give off flammable hydrogen gas. Acid and arcing from a ruptured

battery can cause fires and additional failures. When servicing, do not smoke, cause sparking, or use

open flame near the battery.

c) Engine Fuel

Use only approved fuel container or fueling system. Fires and explosions can occur if the fuel tank is

not grounded prior to or during fuel transfer. Shut unit DOWN before opening fuel tank cap. DO NOT

completely fill tank, because heat from the equipment may cause fuel expansion overflow. Remove

April 01, 2005 Safety Warnings

Page 2

Page 7

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

all spilled fuel IMMEDIATELY, including any that penetrates the unit. After clean-up, open equipment

doors and blow fumes away with compressed air.

5) Toxic Fume Prevention

Carbon monoxide - Engine exhaust fumes can kill and cause health problems. Pipe or vent the exhaust

fumes to a suitable exhaust duct or outdoors. Never locate engine exhausts near intake ducts of air

conditioners.

6) Bodily Injury Prevention

Serious injury can result from contact with fans or hot spots inside some equipment. Shut DOWN such

equipment for inspection and routine maintenance. When equipment is in operation, use extreme care in

doing necessary trouble-shooting and adjustment. Do not remove guards while equipment is operating.

7) Medical and First Aid Treatment

First aid facilities and a qualified first aid person should be available for each shift for immediate treatment

of all injury victims. Electric shock victims should be checked by a physician and taken to a hospital

immediately if any abnormal signs are observed.

EMERGENCY

FIRST AID

Call physician immediately. Seek additional assistance. Use First Aid techniques

recommended by American Red Cross until medical help arrives.

IF BREATHING IS DIFFICULT, give oxygen, if available, and have victim lie down.

FOR ELECTRICAL SHOCK, turn off power. Remove victim; if not breathing, begin

artificial respiration, preferably mouth-to-mouth. If no detectable pulse, begin external

heart massage. CALL EMERGENCY RESCUE SQUAD IMMEDIATELY.

8) Equipment Precautionary Labels

Inspect all precautionary labels on the equipment monthly. Order and replace all labels that cannot be

easily read.

April 01, 2005 Safety Warnings

Page 3

Page 8

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

This page intentionally left blank.

April 01, 2005 Safety Warnings

Page 4

Page 9

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Introduction

This manual contains operation and maintenance information for a 60CU24, 400 Hz Generator Set

manufactured by ITW GSE Group, Hobart Ground Power, Troy, Ohio 45373.

This manual is not intended to be a textbook on electricity or electronics. Its primary purpose is to provide

information and instructions to experienced operators, electricians, and mechanics who have never operated

this equipment. It is the intent of this manual to guide and assist operators and maintenance people in the

proper use and care of the equipment.

Use of the manual should not be put off until a trouble or need for help develops. Read the instructions

before starting the unit. Learn to use the manual and to locate information contained in it. Its style and

arrangement are very similar to commercial aircraft manuals.

The manual is divided into five chapters plus an appendix. Each chapter is divided into as many sections as

required. Each new section starts with page 1. Each page is identified by chapter, section and page number,

which are located in the lower, outside corner. When information located in another portion of the manual is

referred to, its location is identified by a chapter, section, and paragraph or figure number.

For example: “(see Section 2-3, Paragraph 1.a.)” refers to information located in Chapter 2, Section 3,

Paragraph 1.a. If a chapter and section are not indicated in a reference, the referenced material is located in

the same section as the reference, for example: “(see Paragraph 1.a.).”

In addition to operation and maintenance instructions, the manual contains an illustrated parts list in Chapter

4, and a collection of manufacturer’s literature and supplemental information in Chapter 5.

The Appendix is the last section. Its contains a list of available options that may be purchased with that unit.

Items on the list with check marks next to them, have been added to the standard unit per the customers

order. Literature for each option follows. The Appendix will help control the information in the manual:

making it unique to the unit purchased.

Contents of the manual is arranged as follows:

Chapter 1. Description/Operation

Chapter 2. Servicing/Troubleshooting

Chapter 3. Overhaul/Major Repair

Chapter 4. Illustrated Parts List

Chapter 5. Manufacturer’s Literature

Appendix A Options

April 01, 2005 Introduction

Page 1

Page 10

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

If you have any questions concerning your Hobart Ground Power equipment, immediately contact our Service

Department by mail, telephone, FAX, or E-Mail.

Write: ITW GSE Group

Hobart Ground Power

Service Department

1177 Trade Road East

Troy, Ohio 45373

U.S.A.

Call Inside U.S.A.: (800) 422-4166 (Parts)

(800) 422-4177 (Service)

Call From Foreign Countries: (937) 332-5050 (Parts)

(937) 332-5060 (Service)

FAX Inside U.S.A. (800) 367-4945

FAX From Foreign Countries: (937) 332-5121

E-Mail : service@itwgsegroup.com

Web Page : www.itwgsegroup.com

April 01, 2005 Introduction

Page 2

Page 11

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Table of Contents

Chapter 1 Description/Operation Chapter-Section/Page#

Section 1

Section 2

Section 3

Chapter 2 Servicing / Troubleshooting Chapter-Section/Page#

Section 1

Section 2

Description 1-1/1

General

Orientation

Optional Equipment - Appendix A

Special Features

Canopy

Engine and Generator

Control Box Assembly

Power Module Panel Assembly

Cold Weather Starting System

Preparation for Use, Storage or Shipping 1-2/1

Preparation For Use

Tips on Cold Weather Starting

Preparation For Storage

Preparation For Shipment

Operation 1-3/1

General

400 Hz. Operation Procedure

DC Operation Procedure

Maintenance Inspection/Check 2-1/1

General

Maintenance Schedule

Inspection / Check

Maintenance Procedures 2-2/1

General

Lubrication

Servicing The Air Cleaner

Engine Fuel

Engine Fuel System

1-1/1

1-1/1

1-1/2

1-1/2

1-1/2

1-1/4

1-1/10

1-1/21

1-1/22

1-2/1

1-2/3

1-2/3

1-2/5

1-3/1

1-3/1

1-3/6

2-1/1

2-1/1

2-1/3

2-2/1

2-2/1

2-2/5

2-2/6

2-2/7

November 16, 2007

Revision 8

Table of Contents

Page 1

Page 12

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Section 2

(cont.)

Section 3

Section 4

Engine Cooling System

Generator Maintenance

Drive Belt

Adjustments / Tests 2-3/1

General

Testing the 400 Hz. Generator Set

Generator Set Adjustments

Generator and Exciter Test

Diode Test

Testing the Transformer-Rectifier

Troubleshooting Procedures

General

Equipment for Troubleshooting

Parts Replacement

400 Hz. Test Values

Check Connections and Leads

Engine Troubleshooting

Illustrations

Connection and Schematic Diagrams

GPU Control Monitoring

Troubleshooting Charts

…Engine Controls

…Generator Excitation Circuits

…No. 1 Load Contactor Operating Circuit

…No. 2 Load Contactor Operating Circuit

…Protective Circuit

…Generator

Troubleshooting Tables – GPU Commands

Troubleshooting Tables – GPU Faults

2-2/10

2-2/13

2-2/13

2-3/1

2-3/1

2-3/12

2-3/15

2-3/16

2-3/16

2-4/1

2-4/1

2-4/1

2-4/2

2-4/2

2-4/2

2-4/2

2-4/2

2-4/3

2-4/11

2-4/11

2-4/14

2-4/15

2-4/17

2-4/19

2-4/20

2-4/22

2-4/26

Chapter 3 Overhaul / Major Repair Chapter-Section/Page#

Section 1

Exciter Armature 3-1/1

General

Exciter Armature

Exciter Armature Replacement

Installation Exciter Armature

3-1/1

3-1/2

3-1/3

3-1/6

November 16, 2007

Revision 8

Table of Contents

Page 2

Page 13

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Section 2

Section 3

Dual Bearing Flexible Coupling

General

Disassembly

Coupling Service

Coupling Installation

Reassemble Engine and Generator

Run-in and Periodic Check

Generator Assembly

General

Generator Assembly Removal

Generator Assembly Installation

3-2/1

3-2/1

3-2/4

3-2/5

3-2/6

3-2/7

3-3/1

3-3/1

3-3/2

Chapter 4 Illustrated Parts List Chapter-Section/Page#

Section 1

Section 2

Section 3

Introduction 4-1/1

General

Purpose

Arrangement

Explanation of Parts List

Manufacture's Codes 4-2/1

Explanation of Manufacture's (Vendor) Code List

Illustrated Parts List 4-3/1

Explanation of Parts List Arrangement

Symbols and Abbreviations

Figure 1: General Assembly

Figure 2: Frame Assembly

Figure 3: Canopy Assembly

Figure 4: Internal Components

Figure 5: Control Box Door Panel Assembly

Figure 6: Control Box Interior Components

Figure 7: Control Switch Panel Components

Figure 8: Push-Buttons Details

Figure 9: 400 Hz. Power Module Assembly

Figure 10: Cooling System Components

4-1/1

4-1/1

4-1/1

4-1/1

4-2/1

4-3/1

4-3/1

4-3/2

4-3/6

4-3/8

4-3/10

4-3/12

4-3/14

4-3/16

4-3/18

4-3/20

4-3/22

November 16, 2007

Revision 8

Table of Contents

Page 3

Page 14

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Section 3

(cont.)

Figure 11: Fuel System Components

Figure 12: 12 VDC Battery System

Figure 13: Air Cleaner Components

Figure 14: Engine Components

Figure 15: Engine Exhaust Components

Figure 16: Generator Assembly

Figure 17: Trailer Components

Numerical Index 4-4/1Section 4

Explanation of Numerical Index

Chapter 5 Manufacture's Literature

Appendix A Options/Features

Wet Stacking

Unusual Service Conditions

4-3/24

4-3/26

4-3/28

4-3/30

4-3/32

4-3/34

4-3/36

4-4/1

November 16, 2007

Revision 8

Table of Contents

Page 4

Page 15

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Chapter 1 Description/Operation

Section 1 Description

1) General

Hobart Ground Power part of the ITW GSE Group in Troy, Ohio, manufactures the basic generator set

covered in this manual. Is rated at 60 kVA and designed to produce and deliver 115/200-volt, 400 Hz, 3phase AC, or 28.5V DC power to a parked aircraft or to Hobart approved test banks only.

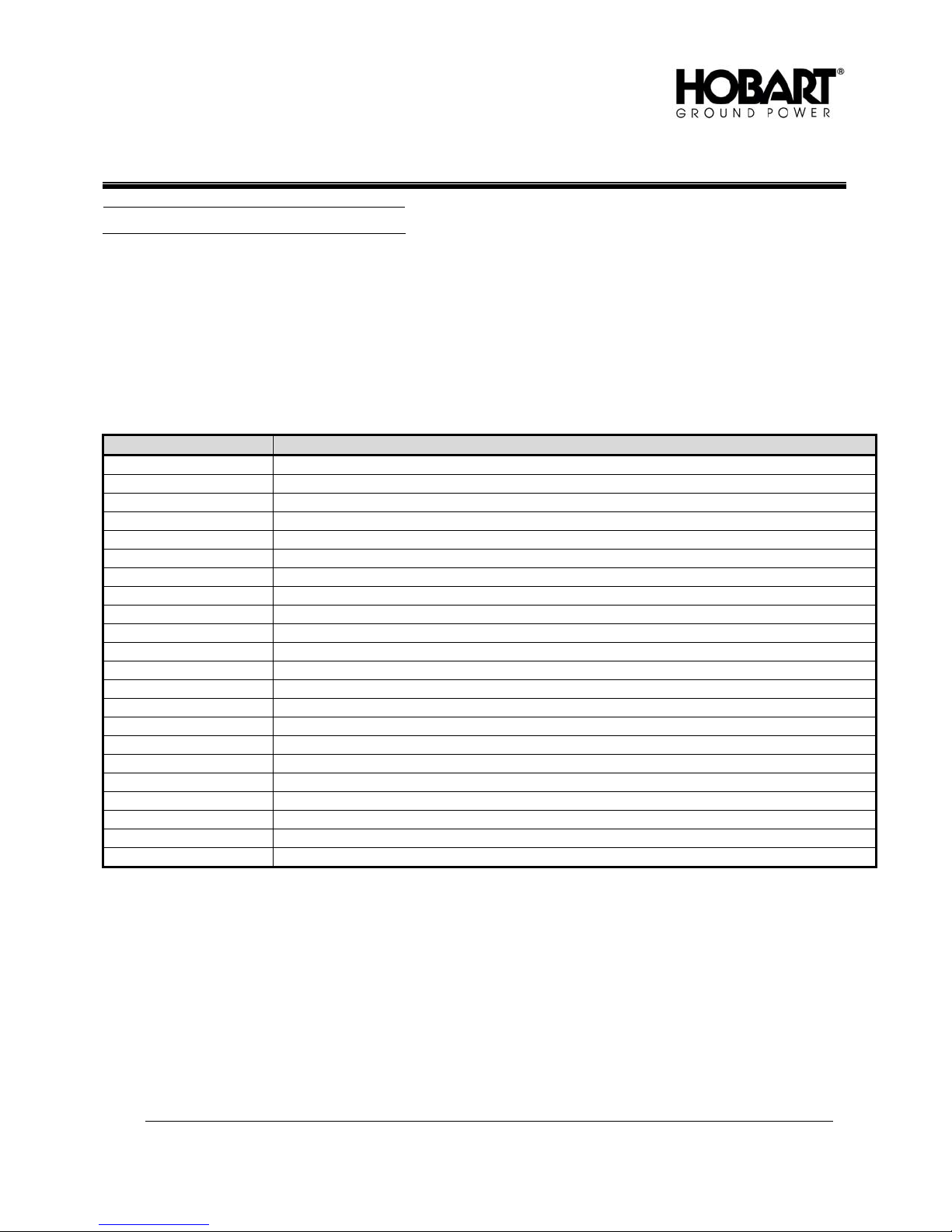

The number 500060C identifies the “model or series” of the GPU. The part number is followed by a

different dash number that separates the basic units available. Figure 1 uses the part number to identify

the variations covered in this manual.

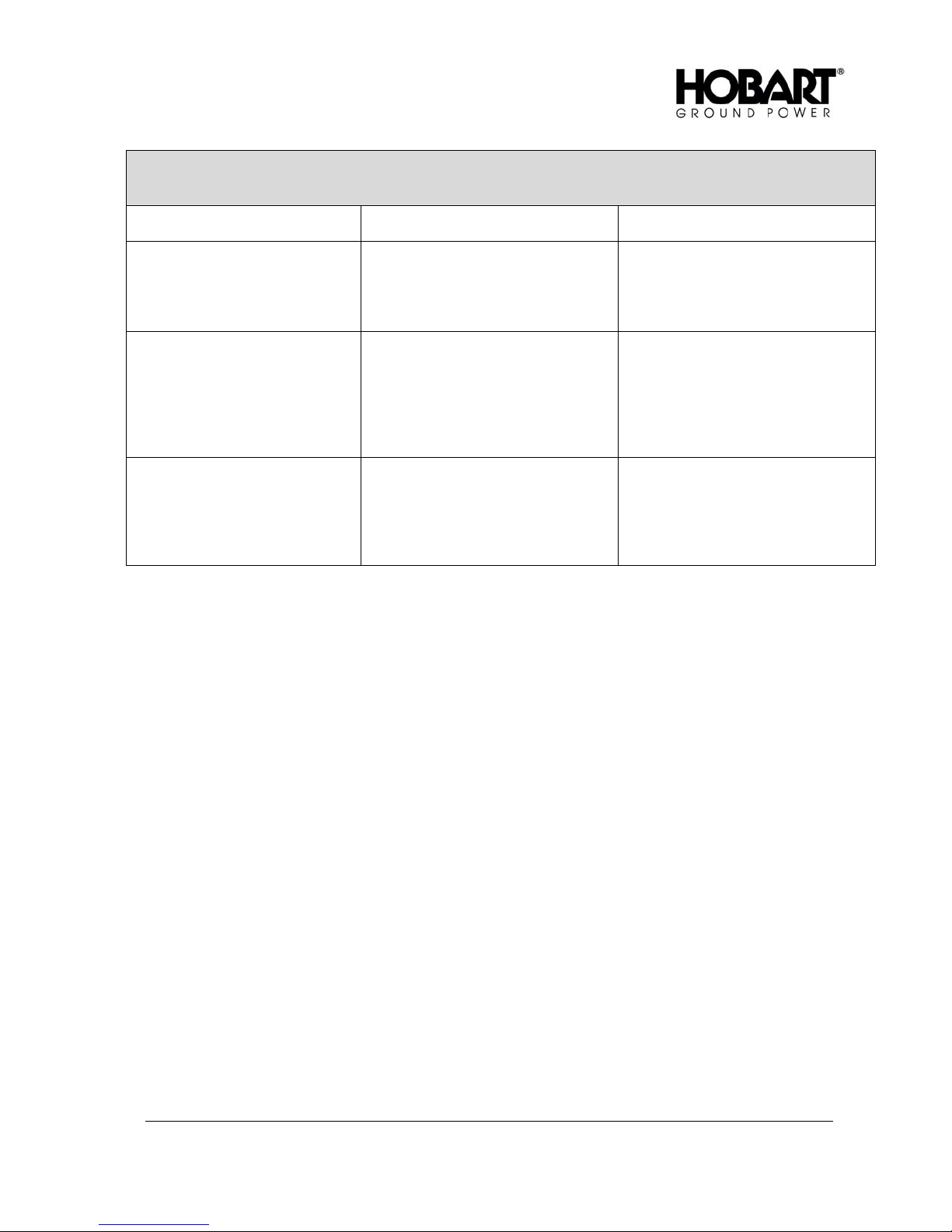

Part & Dash Number Model Description

500060C-001 Single Output, Trailer Mounted (Stainless Steel Fuel Tank)

500060C-002 Dual Output, Trailer Mounted (Stainless Steel Fuel Tank)

500060C-003 Single Output, Fixed/Truck Mounted (Stainless Steel Fuel Tank)

500060C-004 Dual Output, Fixed/Truck Mounted (Stainless Steel Fuel Tank)

500060C-005 Single Output, Trailer Mounted, 28.5V DC TR (Stainless Steel Fuel Tank)

500060C-006 Single Output, Fixed/Truck Mounted, 28.5V DC TR (Stainless Steel Fuel Tank)

500060C-007 Single Output, Fixed Mounted, 28.5V DC TR (Special) (Stainless Steel Fuel Tank)

500060C-008 Single Output, Trailer Mounted, Digital AC Meters (Stainless Steel Fuel Tank)

500060C-009 Single Output, Fixed/Truck Mounted, Digital AC Meters (SS Fuel Tank)

500060C-010 Single Output, Trailer Mounted, 28.5V DC TR, Digital AC/DC Meters(SS Tank)

500060C-011 Single Output, Fixed/Truck Mounted, 28.5V DC TR, Digital AC/DC Meters (SS Tank)

500060C-101 Single Output, Trailer Mounted (Composite Fuel Tank)

500060C-102 Dual Output, Trailer Mounted (Composite Fuel Tank)

500060C-103 Single Output, Fixed/Truck Mounted (Composite Fuel Tank)

500060C-104 Dual Output, Fixed/Truck Mounted (Composite Fuel Tank)

500060C-105 Single Output, Trailer Mounted, 28.5V DC TR (Composite Fuel Tank)

500060C-106 Single Output, Fixed/Truck Mounted, 28.5V DC TR (Composite Fuel Tank)

500060C-107 Single Output, Fixed Mounted, 28.5V DC TR (Special) (Composite Fuel Tank)

500060C-108 Single Output, Trailer Mounted, Digital AC Meters (Composite Fuel Tank)

500060C-109 Single Output, Fixed/Truck Mounted, Digital AC Meters (Composite Fuel Tank)

500060C-110 Single Output, Trailer Mounted, 28.5V DC TR, Digital AC/DC Meters (C Tank)

500060C-111 Single Output, Fixed/Truck Mounted, 28.5V DC TR, Digital AC/DC Meters (C Tank)

Series 500060C Generator Set Part Number Descriptions

Figure 1

2) Orientation

For purpose of orientation, the radiator is considered to be at the FRONT of the unit. The generator and

controls are at the REAR. LEFT and RIGHT are determined by standing at the REAR end facing the

control box.

November 16, 2007

Revision 8

Chapter 1-1

Page 1

Page 16

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

3) Optional Equipment - Appendix A

Chapters 1 through 5 of this Operation and Maintenance Manual identifies only the “strip down” version of

the 60CU24 generator set. A list of optional equipment which make this manual unique to the generator

set that you have purchased, appears in Appendix A. A few items included in Appendix A are cable trays,

trailers, 28-volt DC power transformer-rectifiers, etc.

4) Special Features

The generator set has special features that are described more fully under the assemblies in which they

appear. Three features: protective monitor, voltage regulator and electric governor are mentioned here

and described briefly.

Protective Monitoring

The protective monitoring system receives signals from the fault sensing units in the generator output

circuit and functions to cause the load to be disconnected from the generator if an abnormal condition

of voltage, frequency, or load develops.

a) Voltage Regulator

A microprocessor-type, adjustable voltage regulator provides automatic voltage regulation at the

aircraft. The regulator is also adjustable for a variety of output cable sizes and lengths.

b) Engine Electronic Control Module

The engine is equipped with an electronic control module that monitors, records, and controls engin e

performance.

5) Canopy

A sheet metal enclosure, identified as a canopy, provides protection for the engine, generator and

electrical controls. The canopy is designed to reduce the operational noise level in the immediate area of

the machine.

November 16, 2007

Revision 8

Chapter 1-1

Page 2

Page 17

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

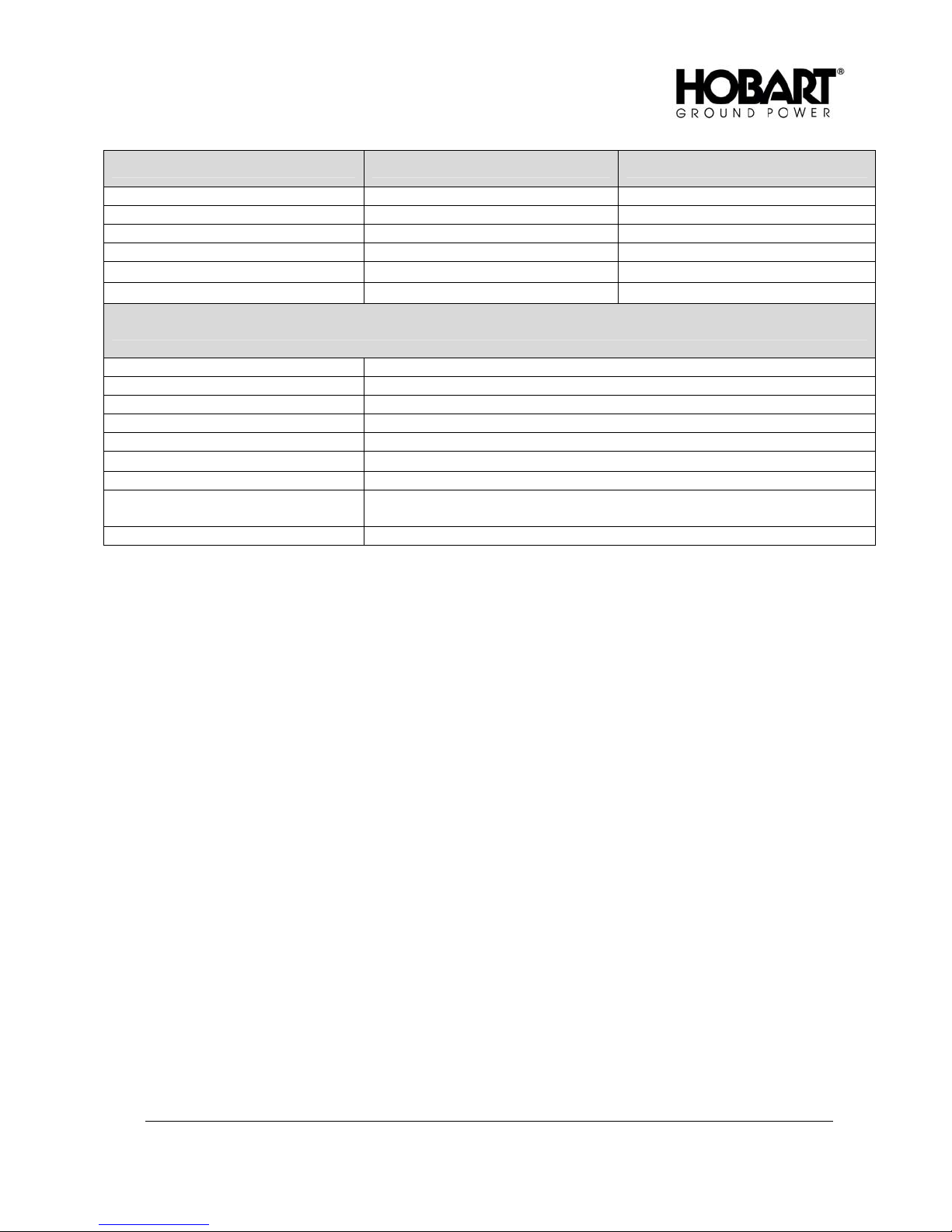

Physical Basic Unit (Fixed Mount) Trailer Mounted Unit

Length 68 in. (172.7 mm) 94.5 in. (240 mm)

Width 37 in. (94 mm) 67 in. (170.1 mm)

Height 46 in. (116.8 mm) 62 in. (157.5 mm)

Weight (Single AC output only) 2595 lb. (1107 kg.) 3070 lb. (1393 kg.)

Weight (Dual AC output only) 2700 lb. (1225 kg.) 3175 lb. (1440 kg.)

Weight (AC & DC outputs) 2875 lb. (1304 kg.) 3350 lb. (1519.5 kg.)

AC GENERATOR

Output power rating 60 kVA 48 kW

Output voltage 115 / 200 VAC

Rated load capacity 174 Amps

Frequency 400 Hz.

Power factor 0.8

Duty Cycle 100%

Operating speed 2400 RPM

Overload capacity, both outputs

217.5 Amps

125% rated load

Output cable size 2/0

Specifications and Capabilities

Figure 2 (Sheet 1 of 2)

November 16, 2007

Revision 8

Chapter 1-1

Page 3

Page 18

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

GENERATOR PROTECTIVE SYSTEM

Over voltage Trips at 126 volts after a 1 second time delay.

Trips at 140 volts in 160 milliseconds.

Trips at 180 volts in 50 milliseconds.

Under voltage Trips at any voltage below 100 volts after 7 seconds.

Over frequency Trips at any value between 420 Hz and 480 Hz after a 5 second time

delay. Trips immediately at any frequency exceeding 480 Hz.

Under frequency Trips at 380 Hz. or less after a 7 second time delay.

Overload time delay Trips in app roximately 5 minutes at 125% load of 90 kVA on either

output or 125% of 120 kVA on both outputs combined.

DC OUTPUT (OPTIONAL, SEE APPENDIX A)

Output Voltage 28.5 VDC

Amps (Continuous) 600 A

Amps (Peak/Starting/Overload) 2700 A for 2 seconds

2000 A for 10 seconds

1500 A for 30 seconds

1200 A 90 seconds

750 A 600 seconds

ENGINE

Manufacturer Cummins Engine Company

Model No. QSB4.5

Type In-Line 4 cylinder, 4 cycle diesel, electronic controlled

Bore and Stroke 4.02 in. x 5.42 in. (102 mm x 138 mm)

Displacement 275 in3 (4.5 L)

Horsepower 110 hp (82 kW)

Idle speed 1000 ± 50 rpm

High speed limiting 2750 ± 75 rpm

Normal governed speed 2400 rpm

Firing Order 1-3-4-2

Electrical system 12 VDC

Ground Negative

Lubricating oil capacity (w/ filter) 10 quarts (9.5 liters)

Coolant capacity system 38 quarts (36 liters)

Specifications and Capabilities

Figure 2 (Sheet 2 of 2)

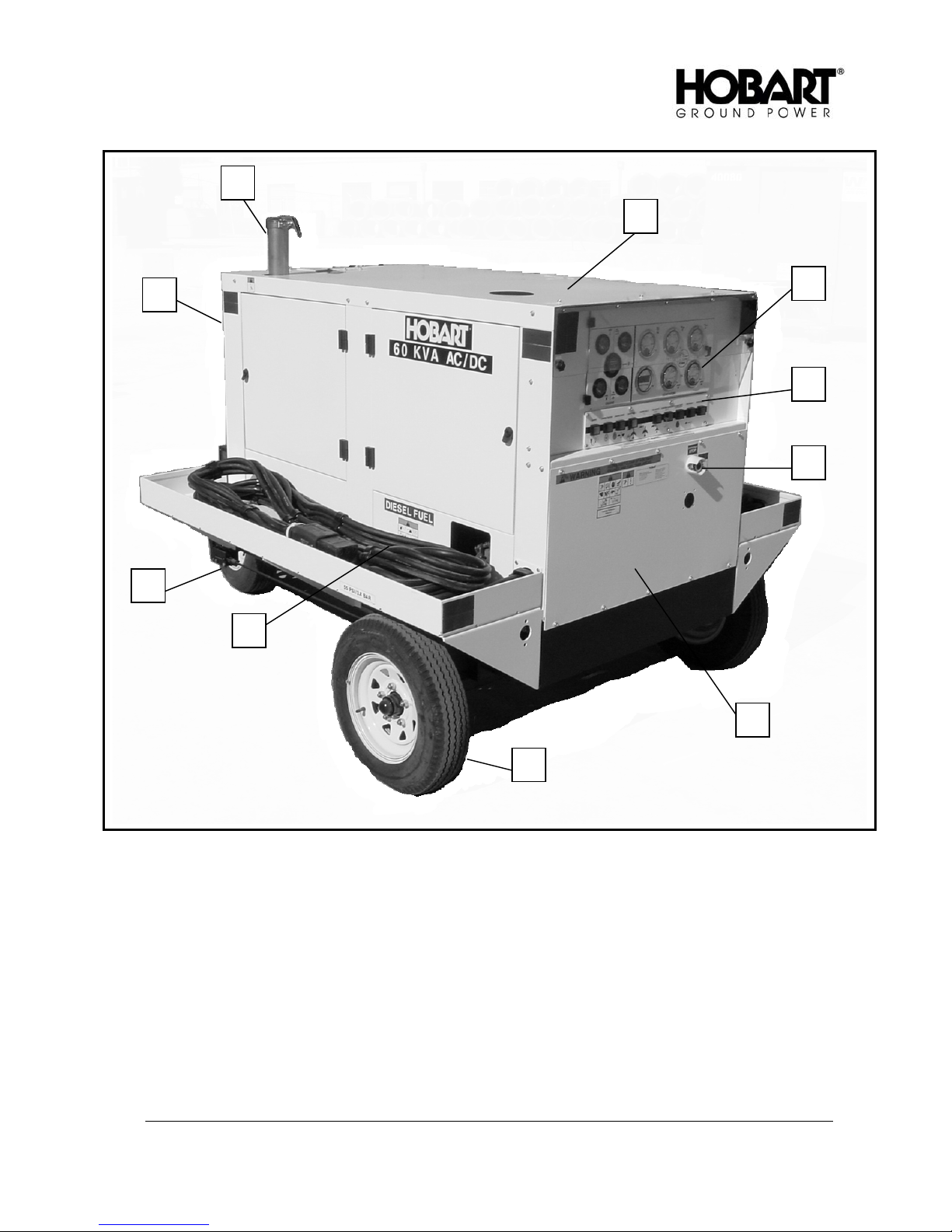

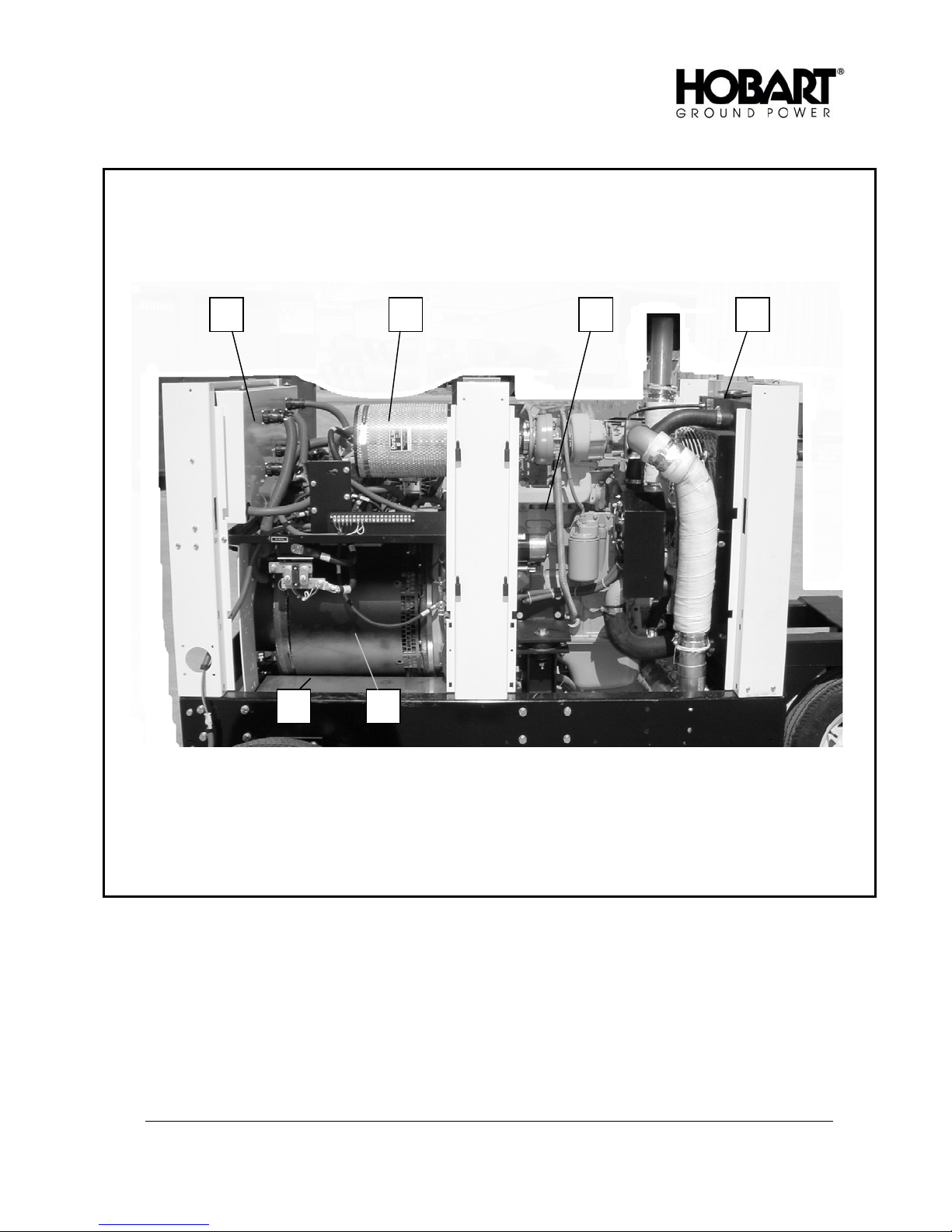

6) Engine and Generator

The engine and generator comprise the principal components of the gene rator set. They are mounted on

the welded steel frame of the chassis. The engine coolant radiator is also mounted on the frame just

forward of the engine-generator combination. Figures 4 and 5 are illustrations showing the location of all

major components and sub-assemblies.

November 16, 2007

Revision 8

Chapter 1-1

Page 4

Page 19

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

a) Basic Engine

The basic diesel engine is a in-line 4-cylinder, electronically controlled engine rated at 110

horsepower. See Figure 2 for specifications and capabilities.

b) Engine Manufacturer’s Equipment

As received from the engine manufacturer, the engine includes the following equipment, which is

more fully described in the engine manufacturer’s operation manual.

(1) Electrical System

The 12 VDC electrical generating and starting system include an alternator, voltage regulator,

and starter with solenoid switch.

(2) Fuel Filter

The fuel filter is a spin-on disposable, vacuum type connected between the fuel lift pump and

injector pump.

CAUTION

The use of low lubricity fuels can shorten life and/or damage the engine’s fuel pump.

Only diesel fuel is recommended by the engine manufacturer.

(3) Oil Filter

The engine oil filter is a spin-on, full-flow type, located on the left side of the engine near the front.

(4) Pre-programmed Electronic Control Module (ECM)

The ECM is a pre-programmed engine control module, mounted directly to the engine block.

c) Engine-cooling fan

The engine fan is designed to blow air outward through the radiator, rather than pulling the air inward

as a conventional fan does.

d) Hobart Installed Equipment

This generator set is modified at Hobart Brothers by the addition of the following equipment:

(1) Shut Down/Reset device

In addition to the other devices provided by the engine manufacturer, the factory also added an

engine shutdown/reset feature.

a EMERGENCY SHUTDOWN/RESET SWITCH (S28)

The emergency shutdown switch has two purposes. One is to reset the starting circuit

following a failed starting sequence. The other is to provide instant manual shut off of the

generator set by disconnecting power to the ECM through the control box. It is located on the

left side of the generator set near the control box (See Figure 3)

November 16, 2007

Revision 8

Chapter 1-1

Page 5

Page 20

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

To operate the EMERGENCY SHUTDOWN/RESET SWITCH:

• Push button in until engine stops or until button travel stops

• Pull the button back out to reset

b Coolant high temperature shutdown system

The coolant temperature shutdown system consists of a factory supplied temperature switch.

This switch is monitored by the microprocessor on the EIB (“Engine Interface Board”) PC

Board, which will stop the engine if the temperature reaches 230º F (110º C).

c Oil pressure shutdown system

The oil pressure shutdown system consists of a factory supplied oil pressures switch. This

switch is monitored by the microprocessor on the EIB (“Engine Interface Board”) PC Board,

which will stop the engine if the oil pressure is under 12 PSI (82.7 kPA).

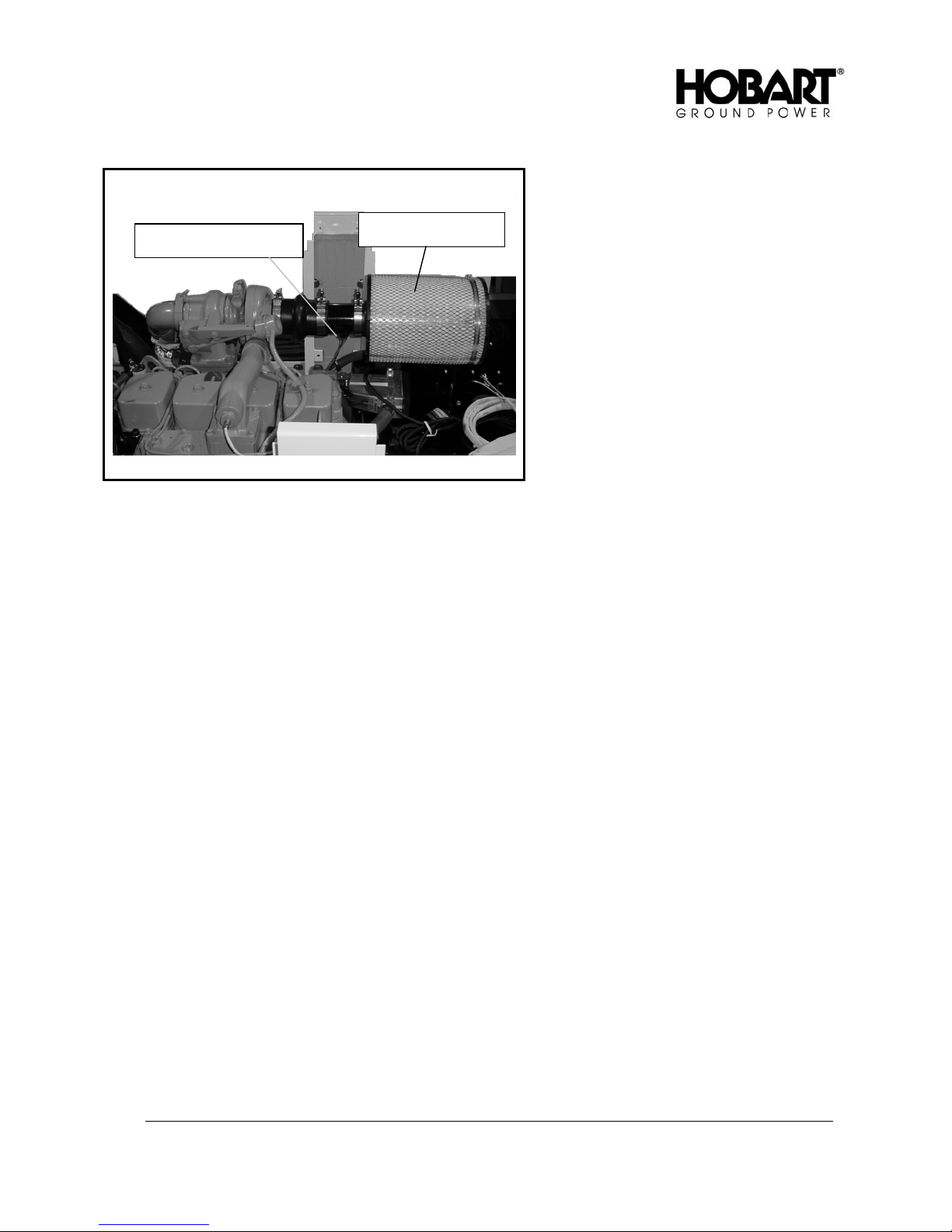

(2) Air cleaner (Figure 6)

The diesel engine air cleaner is so constructed that air enters through its cylindrical body, and

then is filtered in the process before being passed onto the engine turbo-charger assembly. An

air cleaner service indicator device is mounted on the air cleaner assembly to monitor the airflow

into the air cleaner. As the air cleaner becomes filled with dust, dirt, and carbon, the intake

system airflow becomes increasingly restricted. This restriction causes a diaphragm inside the

indicator to move toward an electrical contact. When the maximum allowable restriction level is

reached, the circuit closes and the air cleaner indicator fault appea rs on the control panel fault

display to warn the operator that the air cleaner must be changed. The electrical indicator

automatically resets when the restriction level drops sufficiently.

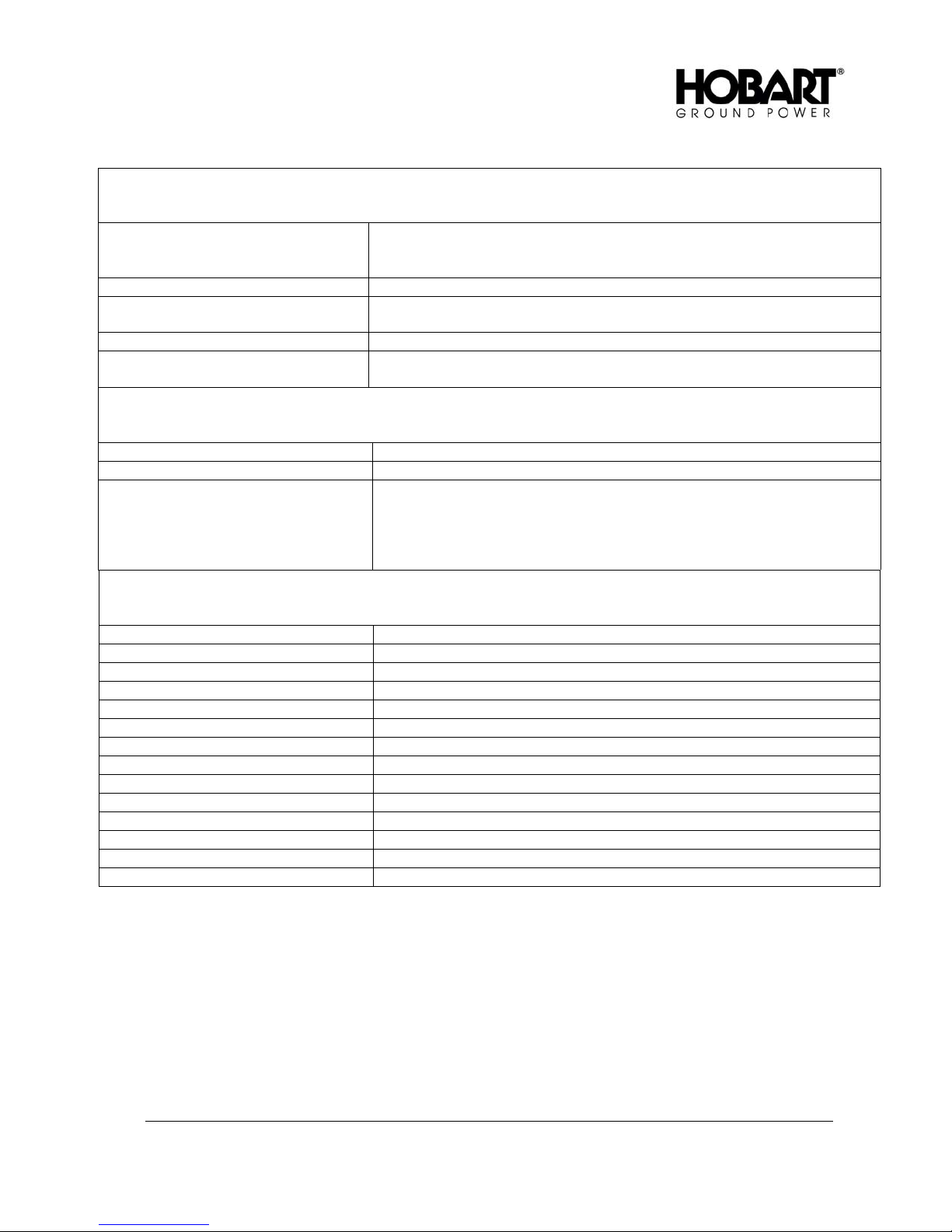

e) Engine faults

The following is a table listing faults, which may occasionally occur. Column two of the table explains

what happens in the engine’s circuitry when the fault occurs, and column three tells how to return the

generator set to service once the problem is solved. Refer to Chapter 2 for more details on all other

faults.

f) Generator

The 400 Hz generator is a brushless, revolving field, three-phase, alternating current type. The

generator set covered by this manual is a dual-bearing type. The front end of the rotor shaft extends

forward beyond the front bearing and is attached to the engine flywheel by a flexible coupling

assembly. The rear end of the rotor shaft extends rearward beyond the rear bearing and into the

exciter stator housing. The exciter rotor is mounted on this shaft extension with a key and is secured

by a washer and 1/2-13 thread cap screw. A rectifier with six diodes is mounted on the exciter rotor

and converts exciter AC output to DC for excitation of the generator revolving fields. The exciter DC

output to the generator fields, and consequently the generator output, is controlled voltage regulator

PC board (REG). A centrifugal, radial-blade fan, which is part of the flexible coupling assembly,

draws cooling air over all internal windings. Air enters at the exciter end and is discharged at the

drive end. The complete generator assembly is bolted to the engine flywheel housing.

November 16, 2007

Revision 8

Chapter 1-1

Page 6

Page 21

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

ENGINE FAULTS

Engine Fault Condition What Occurs How To Reset

Over temperature or low oil

pressure

Shuts down the engine, and will be

indicated will appropriate fault

code.

Low fuel warning and shutdown Turns on the low fuel indication on

the fault code meter. The GPU is

programmed at the factory to warn

1

/4 tank and to shutdown at 1/8

at

tank.

Clogged air cleaner or other

restriction in the combustion air

Turns on the air cleaner restriction

indicating fault code.

inlet.

Engine Faults

Figure 3

a) Press the engine stop button to

reset the fault code and reset the

protective system.

b) Or use E-STOP button for

immediate reset.

a) The low fuel fault indicating

function must be reset by

pressing the engine stop button

Fuel must be added prior to

attempting another engine start.

b) Or use E-STOP button for

immediate reset.

a) Press the engine stop button.

The restriction must be removed

prior to attempting another engine

start.

b) Or use E-STOP button for

immediate reset.

November 16, 2007

Revision 8

Chapter 1-1

Page 7

Page 22

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

7

8

9

1

2

6

4

3

10

1. Control Panel

2. Operator’s Push-Button Panel

3. Output Cable Location

4. Front Axle Assembly

5. Rear Axle Assembly

November 16, 2007

Revision 8

5

6. Emergency Stop Switch (S28)

7. Exhaust Outlet

8. Canopy

9. Radiator End

10. Generator End

General Assembly of Generator Set

Figure 4

Chapter 1-1

Page 8

Page 23

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

4 3 2 1

1. Radiator

2. Cummins QSB Engine

3. Air Cleaner

November 16, 2007

Revision 8

5

6

4. Control Box

5. Fuel Tank

6. Generator

Main Components of Generator Set

Figure 5

Chapter 1-1

Page 9

Page 24

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Service Indicator

Air Cleaner

Air Cleaner and Service Indicator

Figure 6

7) Control Box Assembly

The control box is a sheet metal enclosure that houses and provides mounting facilities for engine and

generator controls and monitoring equipment.

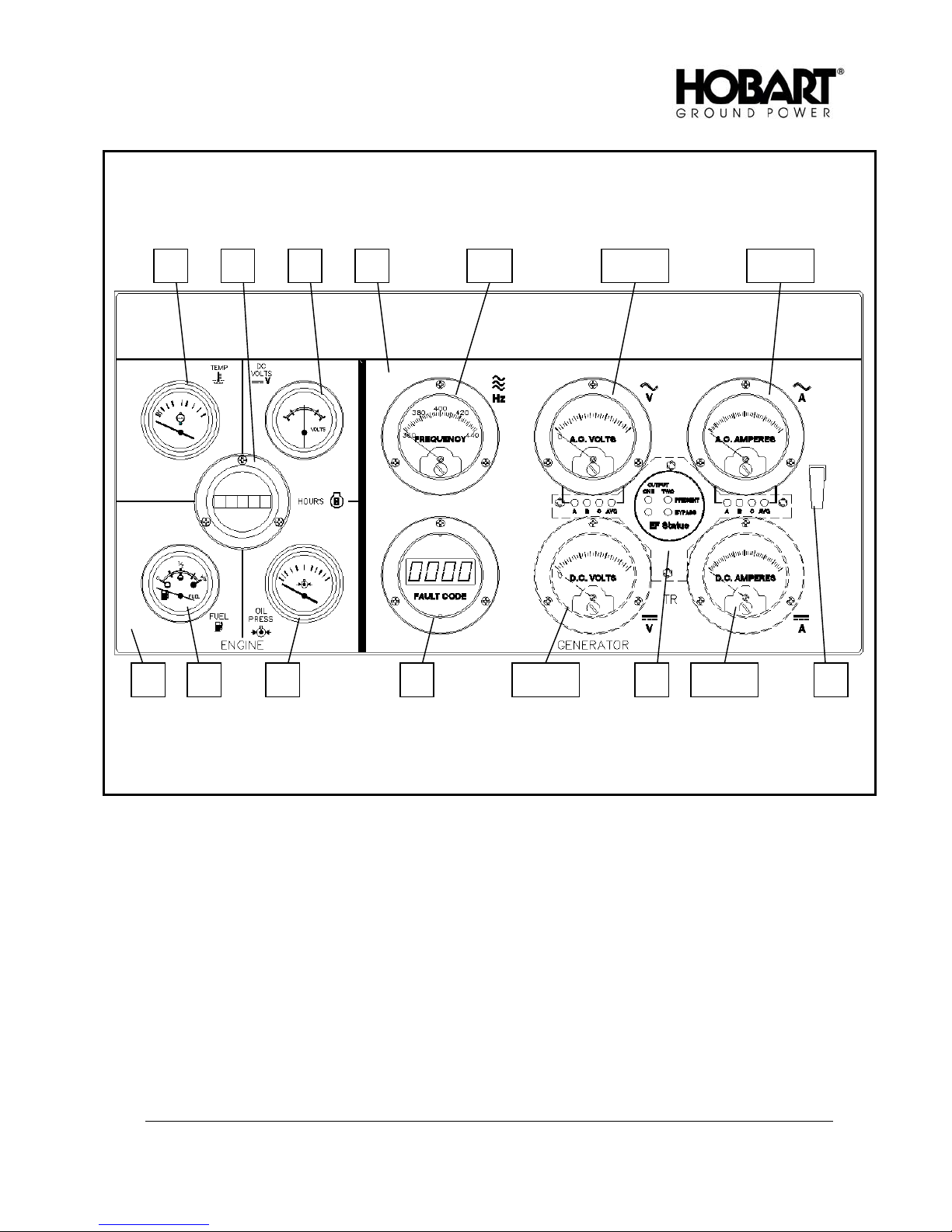

a) Control Panel (Figure 7 and 8)

The control system is divided into two sections. On the left side of the control panel, as one faces it,

are engine meters. On the right side of the control panel are generator meters. Below the control

panel are push-button switches for operating the engine and generator.

(1) Panel lights and panel light push-button switch (S74)

Meters are lighted from inside the control panel. The “LAMPS” push-button switch controls the

lights.

(2) Engine hour meter (M4)

The hour meter is electrically driven from the 12 VDC battery system. The hour meter measures

and records the engine’s running time and will record up to 9999.9 hours on five revolving dru ms.

It is only functional when the engine is running.

(3) Engine oil pressure gage (M24)

The oil pressure gage is an electrical type that is connected by a wire to an oil pressure sensor

installed in the engine lubricating system. The range is 0 to 125 PSI (0 to 862 kPA).

(4) Engine ON indicating light (DS58)

When the engine is running at idle speed, a green indicating light, within the “ENGINE START”

push button switch, flashes at a rate of 1 second on, 1 second off. When the engine is running at

rated speed, the light will stay on continuously.

November 16, 2007

Revision 8

Chapter 1-1

Page 10

Page 25

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

3 4

12

6 8 7,10 10,1110,12

5

139 10,15 10,1617

1. Fuel Gage (M13)

2. Front Panel

3. Engine Coolant Temperature Gauge (M24)

4. Running Time Meter (M4)

5. Oil Pressure Gage (M25)

6. Battery Voltmeter (M5)

7. Frequency Meter (M3)

8. Control Panel Label

9. Fault Code Meter (M6)

November 16, 2007

Revision 8

10. Strip Lights (DS60-DS62) (3) [Not Shown]

11. AC Generator Ammeter (M1)

12. AC Voltmeter (M2)

13. Adjustable Grip Latch

14. Control Panel Door Hinge [Not Shown]

15. DC Voltmeter [Optional with TR]

16. DC Ammeter [Optional with TR]

17. Front LED PC Board (A5) [Shown Opposite Side]

Control Panel Door

Figure 7

Chapter 1-1

Page 11

Page 26

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

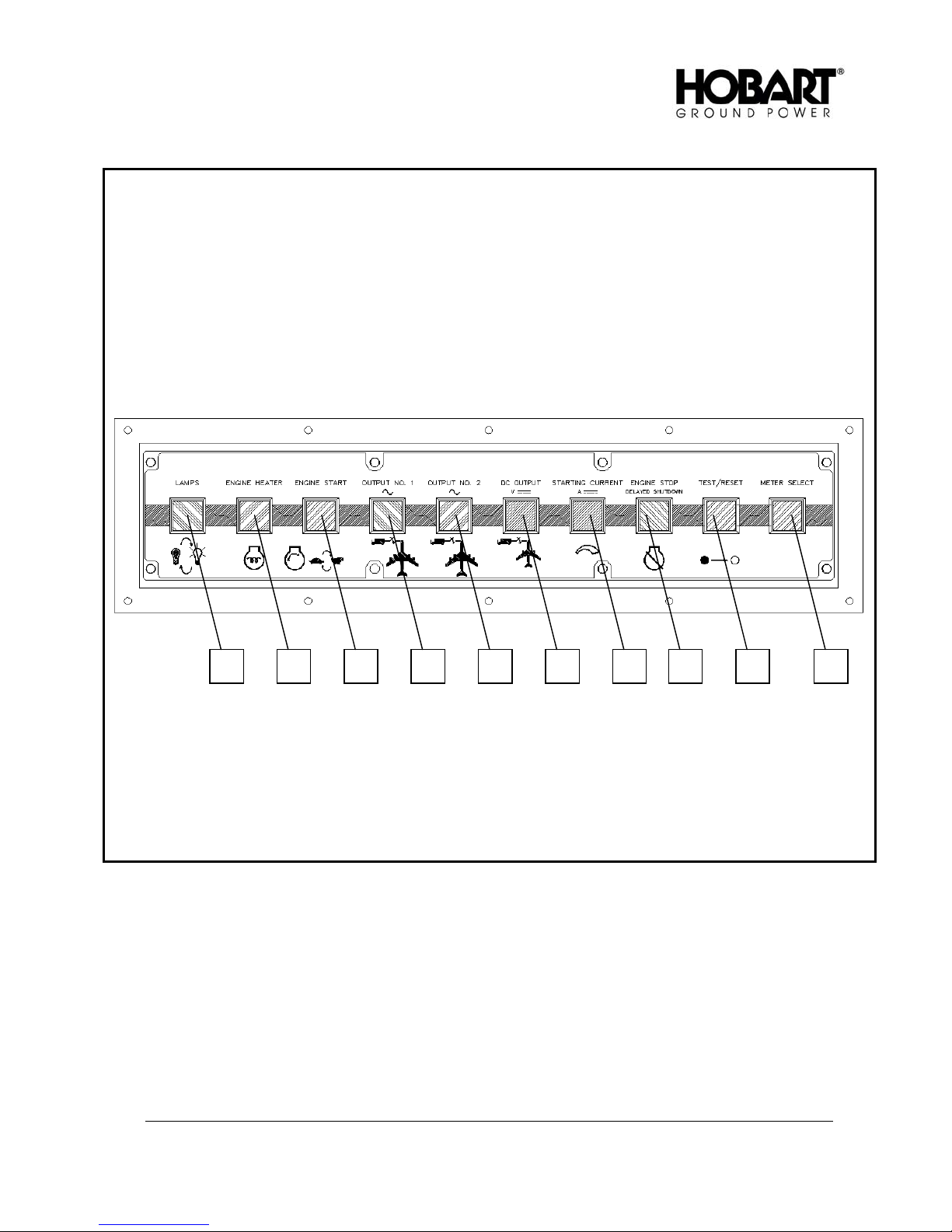

1. Meter Selector Switch (S3)

2. Test/Reset Switch (S77)

3. Engine Stop Switch (S76)

4. DC Starting Current Switch (S431) [Optional with TR]

5. DC Output Contactor Switch (S430) [Optional with TR]

Control Push-Button Switch Panel

Figure 8

1245678910 3

6. AC Output No. 2 (S275) [if applicable]

7. AC Output No. 1 (S75)

8. Engine Start Switch (S24)

9. Air Intake Heater Switch (S79)

10. Panel Light Switch (S74)

November 16, 2007

Revision 8

Chapter 1-1

Page 12

Page 27

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

1

2

4

5

7 6

89

10

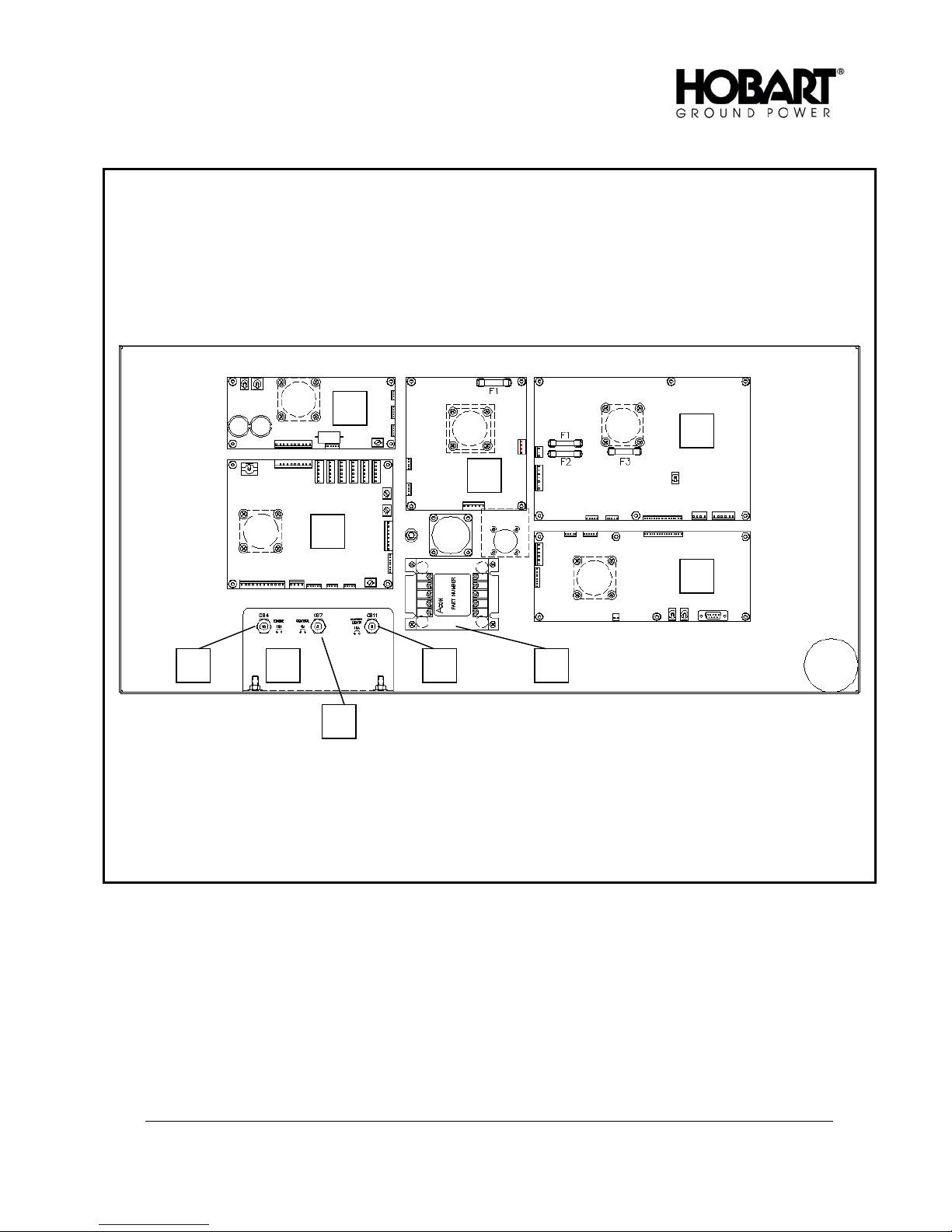

1. Engine Specific PC Board [ESB] (A1)

2. Engine Interface PC Board [EIB] (A2)

3. Digital Control PC Board [CTL] (A3)

4. Voltage Regulator PC Board [REG] (A4)

5. Transformer-Rectifier PC Board [TRB] (A404) {Optional}

3

6. +5, -12 VDC Power Supply (PS1)

7. Circuit Breaker Support Bracket

8. Marker Lights Circuit Breaker, 10 A (CB1)

9. Engine Circuit Breaker, 10 A (CB4)

10. Controls Circuit Breaker, 5 A (CB7)

November 16, 2007

Revision 8

Control Box Interior Components

Figure 9

Chapter 1-1

Page 13

Page 28

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

(5) Engine coolant temperature gage

The temperature gage is an electrical type that is connected by a wire to a water temperature

sensor installed in the engine cooling system. The gage indicates engine coolant temperature in

the range of 100-280 º F (38-138º C).

(6) “ENGINE START” push-button switch (S24)

The “ENGINE START” push-button switch, when pressed, connects 12 VDC power to the starter

solenoid coil, which actuates the solenoid switch to connect power to the engine starting motor.

The 12 VDC power is supplied directly to the engine ECM and the oil pressure shutdown switch is

bypassed (This bypass is necessary for engine starting because the low oil pressure switch is

CLOSED until the engine is running normally). The green indicator light with blink.

When pressed a second time, this push-button switch provides a signal to the ECM to adjust the

engine speed to 2400 RPM. The green indicator light will glow continuously. At the same time, a

ground signal is provided to the regulator, enabling the generator to build up voltage for 400-Hz

generator output. Pressing the push-button switch once more removes these signals and the

engine reverts to idle speed and a blinking green indicator light.

(7) “ENGINE HEATER” push-button switch (S79)

The “ENGINE HEATER” push-button switch activates the standard cold starting aid (manifold air

intake heater), which is totally controlled by the engine’s ECM. Once the heater is activated, the

engine’s ECM will control the operation. The heater typically stays on for a period of

approximately 30 seconds, which is indicated by the light on the push-button. When the light

goes out, the engine is ready to start. Starting a cold engine without first warming the engine will

lead to excessive white smoke exhaust and the engine may be hard to start.

(8) “ENGINE STOP” push-button switch (S76)

When the “ENGINE STOP” push-button switch is pressed, the red indicator will glow. Then a 3 5 minute delay will occur to permit the turbo and other engine components to cool evenly. After

the delay, power is disconnected from the engine ECM causing the engine to shut down.

(9) Engine voltmeter (M5)

The ammeter indicates the direction and value of current flow from or to the 12 VDC battery. Its

graduated 10 V to 16 V.

(10) Engine fuel gage (M13)

An electric fuel gauge receives its controlling signal from a sending unit in the fuel tank. 12 VDC

operating power is supplied to the fuel gauge when the “ENGINE START” push-button switch is

pressed. The fuel level can also be checked when the unit isn’t running by pressing the panel

light “LAMPS” push-button switch.

November 16, 2007

Revision 8

Chapter 1-1

Page 14

Page 29

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

(11) Fault Code meter and “TEST/RESET” push-button switch (M6, S77)

The function of the fault code meter is to indicate to the operator, that an abnormal condition of

over voltage, under frequency, etc. occurred, which caused the protective monitoring system to

function. When one of the circuits are activated, it shows the code on the fault code meter. The

fault will remain on for a short period of time or until the “TEST/RESET” push-button switch is

pressed. Pressing the “TEST/RESET” push-button switch can also test the fault code meter

operation. A meter test should be performed only when disconnected from a load, as the

contactor(s) will open during the test cycle.

(12) Engine systems fault codes

Fault codes will be shown to warn the operator of abnormal engine operations that must be

corrected. These indicators are over temperature, air cleaner restriction, low oil pressure, and

low fuel indication.

(13) AC Generator output monitors (meters)

Three instruments, a frequency meter, a voltmeter, and an ammeter monitor the generator output.

The frequency meter is an analog type and indicates the frequency of the generator output

alternating current in the range of 360 to 440 Hz (cycles per second). The voltmeter indicates the

generator output voltage in each phase-to-neutral (A-N, B-N and C-N) or phase-to-phase (A-B, BC and C-A) as selected by the “METER SELECT” switch. The voltmeter has a scale of 0 to 300

V. The ammeter has a scale of 0 to 500 A. The amperage value in each of the three phases

may be read on the ammeter by selecting the desired phase with “METER SELECT” switch. The

ammeter current transformers, located in the output power module circuit, lower the output load

current to a lesser value, of definite ratio, which is sent to the Voltage Regulator PC Board (REG).

The ammeter dial scale is numbered so that the pointer will indicate the true load current value.

(14) Load contactor indicating lights [Yellow # 1 and Orange # 2] (S75, S275)

Indicating lights within the respective contactor control push-button switches (“OUTPUT NO. 1”

and or “OUTPUT NO. 2”, if applicable) glow when the circuit is energized, indicating that power

is available at the plug. When the load contactor opens for any reason, the light is turned OFF.

(15) Front LED Display (A5)

The front LED display signifies to the operator which voltage (A-N, A-B, etc…) and amperage are

shown on the meters, as well as, when “EF BY-PASS” is present or bypassed. This “EF BY-

PASS” indicator serves to warn the operator that if the plug interlock system was by-passed any

exposed cable may be live.

(16) DC Generator output monitors (meters) [Optional with TR, Reference Appendix A]

Two instruments, a voltmeter and an ammeter, monitor and display the transformer-rectifier’s

output. The voltmeter and ammeter meters are both analog type and indicate the output voltage

from 0 to 50 VDC and the amperage from 0 to 2500 A.

(17) “STARTING CURRENT” Switch (S431) [Optional with TR, Reference Appendix A]

Each time the “STARTING CURRENT” push-button switch is pressed, the BLUE indicator will

glow. The present current limiting amperage setting will be displayed on the fault code meter for

a short time delay, before incrementing, at 100 A increments, up to 2500 A. Once 2500 A has

been reached, the incrementing will start over from the beginning.

November 16, 2007

Revision 8

Chapter 1-1

Page 15

Page 30

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

(18) “DC OUTPUT” Contactor Switch (S430) [Optional with TR, Reference Appendix A]

Each time the “DC OUTPUT” push-button switch is pressed, the BLUE indicator will glow when

the circuit is energized, indicating that power is available at the plug. When the load contactor

opens for any reason, the light is turned OFF.

b) Control Box Interior Components (Figure 9)

(1) EF Bypass switches (located on CTL)

For each load contactor circuit, a single-pole, single-throw “EF1 BYPASS” for “OUTPUT 1” (or

“EF2 BYPASS” for “OUTPUT 2”, if applicable) provides a means of bypassing the 28 VDC

interlock circuit for the contactor when supplying power to a load bank or to an aircraft not

equipped with a plug interlock system.

(2) Regulated-diagnostic switch (located on the REG)

When the “REGULATED/DIAGNOSTIC” switch is in the “REGULATED” (down) position, the

generator output voltage is regulated by the PC board for 115/200 VAC output to an aircraft.

When this switch is placed in the “DIAGNOSTIC” (up) position, 12 VDC is applied to the

generator exciter with the engine running at rated RPM, in order to check the operation of the

generator. This is done to determine if a particular power output malfunction is caused by a

defective generator or by a defective voltage regulator. When this switch is in the

MAINTENANCE position, no current is supplied to the generator exciter. In this condition, a lowlevel, unregulated voltage of approximately 30 VAC will be produced at the generator output

terminals due to the residual magnetism of the exciter.

(3) Circuit breakers (CB1, CB4, CB7)

A 10-ampere “ENGINE” circuit breaker, protects the 12 VDC engine electrical and fault circuits,

and another 10-ampere “MARKER LIGHTS” circui t breaker p rotects the 12 VDC lighting system.

A 5-ampere “CONTROL” circuit breaker protects the 12 VDC control system.

(4) Digital Control PC Board [CTL] (A3)

The digital control PC board (see Figure 10) is the center for all communications throughout the

entire control system. All push-button panel commands run through the digital control PC board

and communicates the commands to the appropriate area (i.e. other PC boards) in the control

system. The digital control PC board also controls the real time clock, monitors the over/under

voltage and overload protection, push-button panel indicator lights, generator output meters, EF

bypass switches, and communicates with the optional service tool.

(5) Engine Interface PC Board [EIB] (A2)

The EIB (see figure 11) is common between all engine models and monitors coolant temperature,

oil pressure, battery voltage, and fuel tank level monitoring. The EIB is also responsible for the

monitoring the warning switches for high coolant temperature, low oil pressure, hi gh air

restriction, and low coolant level (optional). The warning switches signal the EIB when a fault

occurs, which then the EIB relays this information to the CTL. The CTL will issue the command

to the system that fits the fault event.

The EIB also controls the power distribution in the control system, hour meter, lights, and the

engine starter operation.

November 16, 2007

Revision 8

Chapter 1-1

Page 16

Page 31

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

J54 Connector

PC Board Software

EF1 Bypass

EF2 Bypass (if applic able)

Digital Control PC Board

Figure 10

Service Tool Connect or

(6) Engine Specific PC Board [ESB] (A1)

November 16, 2007

Revision 8

The ESB (see figure 12) is unique only to the engine model used in the GPU purchased. The

ESB is the primary interface between the control system and the engine’s electronic control

module. When the CTL senses the engine start button has been pressed it signals to the ESB,

which then communicates to the engine control module what mode of operation is required (idle

or rated speed).

The ESB controls the “FREQUENCY ADJUST” switch that is used to enable the “FREQUENCY

ADJUST ENABLE/DISABLE” potentiometer to test the over/under frequency fault limits of the

generator set system. The ESB also controls the “DATA REQUEST” button and diagnostic

indicator light to read the engine’s ECM diagnostic error codes.

Chapter 1-1

Page 17

Page 32

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Starter Disable/Enable

J51 Connector

PC Board Software

Engine Interface PC Board

Figure 11

Engine Sta tus Switch

Frequency Adjustment &

Enable/Disable Switch

J52 Connector

Engine S tatus Lights PC Board Software

November 16, 2007

Revision 8

Engine Specific PC Board

Figure 12

Chapter 1-1

Page 18

Page 33

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Regulated/Diagnostic J53 Connector

PC Board Software

Voltage Adjustment, Coarse

Voltage Adjustment, Fine LDC Control

(7) Voltage regulator PC board [REG] (A4)

November 16, 2007

Revision 8

Voltage Regulator PC Board

Figure 13

This voltage regulator PC board (see Figure 13) is designed to provide voltage regulation for a

three-phase, four-wire, 115/200-volt, 400-Hz brushless alternator. This regulator provides field

excitation power as required to meet varying alternator load conditions to hold the alternator

voltage constant. In addition, the voltage regulator PC board circuitry provides line drop

compensation. Any deviation of the alternator voltage from its set, regulated level is sensed at

the voltage regulator PC board. The sensing signal is compared to a reference signal, and, with

associated circuitry, varies the field power supplied to the rotary exciter.

a When the machine is started, and the engine is at rated speed, the rotary exciter is excited

from alternator residual magnetism through the half-wave rectifier-bridge, located on the

voltage regulator PC board assembly. As the rotary exciter voltage increases, alternator

excitation increases and the alternator voltage builds up. The sensing circuit of the voltage

regulator PC board then compares the input voltage to a reference voltage and adjusts the

field power of the rotary exciter to bring the voltage into regulation limits.

Chapter 1-1

Page 19

Page 34

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

b When the alternator is loaded, its terminal voltage decreases, lowering the rectified three-

phase voltage of the voltage sensing circuit. The sensing voltage is low in respect to its

reference voltage, causing the voltage regulator PC circuitry to increase the power to the field

of the rotary exciter. The alternator voltage increases until the voltage returns to its regulated

value.

c When a load is removed from the alternator, the alternator voltage ri ses. The rectified three-

phase voltage-sensing signal increases, causing this signal to be higher than the reference

signal. The associated voltage regulator circuitry causes the field power of the rotary exciter

to decrease, lowering the alternator voltage until the voltage returns to regulated value. The

line drop voltage compensation circuit consists of a current transformer on each phase of the

load circuit, and fixed resistance in parallel with each current transformer. The current

transformers detects the magnitude of current flowing through the power cables from the

alternator to its load and feeds a signal into the voltage regulator PC board. The PC board

processes this signal to change the output voltage proportional to the current draw. The

regulator output increases slightly so that the alternator output voltage is equal to the

regulated voltage plus the voltage drop in the lines. The line drop compensation

potentiometer may be adjusted to match exactly the voltage drop of the power cables

carrying the load current.

The under/over frequency protection, EF signal, and lost neutral detection are also monitored by

the REG and will signal the CTL when a fault has occurred. The CTL issues the appropriate

command that corresponds to the fault.

(8) Transformer-Rectifier PC Board [TRB] (A404) {Optional with TR, Reference Appendix A}

The TRB PC Board (see Figure 15) is only used when the optional 28.5 VDC transformer-rectifier

assembly is installed. The TR monitors the output voltage, output current, controls the input and

output contactors, and monitors all fault events associated with the DC output. When a fault event

does occur the TRB relays this information to the CTL. The CTL will issue the command to the

system that fits the fault event.

(9) +5, -12 VDC Power Source (PS1)

Supplies the internal power distribution of +5 VDC and –12 VDC into the control system.

November 16, 2007

Revision 8

Control System Power Source

Figure 14

Chapter 1-1

Page 20

Page 35

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

PC Board Software

J401 Connector

Transformer-Rectifier PC Board

Figure 15

8) Power Module Panel Assembly (Figure 16)

The power module panel assembly sometimes referred to as the contactor panel, is located at the left

front of the machine under the control box. The panel assembly provides a means of connecting and

disconnecting generator output to and from the load (aircraft).

a) Load contactor(s)

The load contactor(s) each contain a magnetic operating coil and four sets of contacts. The three

larger contacts conduct three-phase AC generator output. A small contact set is connected to the

Digital Control PC Board (CTL) to activate the protective monitor circuit. Three-phase, 400-Hz

generator output power is conducted to the load contactors by 2/0 cables that pass through current

transformers.

b) Current transformers (CT1-CT3 or CT6 if 2

On each individual output a set of current transformers are used to monitor and control the line-drop

compensation, ammeter, and overload circuit.

nd

output installed)

November 16, 2007

Revision 8

Chapter 1-1

Page 21

Page 36

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

(1) Line-Drop Compensation

The current transformers detects the magnitude and power factor of current flowing from

generator to load. They feed a signal to the voltage regulator that interprets the signal and alters

the exciter field current as required to maintain a constant predetermined voltage at the load.

(2) Ammeter

The current transformers convert a current signal to a voltage signal, which is sent to the Voltage

Regulator PC Board (REG). The ammeter is really a voltmeter graduated and numbered in

amperes to show current proportional to the voltage signal received.

When there is overload on the output for more than 5 minutes (load exceeding 326 amperes per

output or 125% of rated load), the main overload sensing circuit sends signals the load the

contactor(s) circuit to open both load contactors.

(3) Overload, No 1 and/or No. 2 output (if applicable)

On each individual output the current transformers converts a current signal to a voltage signal.

The voltage signal is sent to the ammeter and to the overload monitoring circuit for that output.

The overload monitoring circuit will open the contactors when the output current rea ches 125% of

the normal rated output current. The monitoring circuit moniters each individual output, as well

as, the overall current for a dual output machines.

The following is a list of overload module characteristics:

• At 125% load the module will function in 5 minutes.

• At 150% load the module will function in 30 seconds.

• AT 200% load the module will function in 10 seconds.

NOTE: The overload protective system will function when any phase carries 123% to 127% of

rated load. All times are plus or minus 25% and are non-adjustable.

9) Cold Weather Starting System

CAUTION

The block heater kit is installed inside the enclosure of the engine/generator set, and is connected to the

cooling system of the diesel engine. Its purpose is to keep the coolant warm when the engine is shut

down for extended periods of time in cold weather, and thus permit the engine to start more quickly.

The block heater unit is mounted to the engine/generator frame with a bracket and attaching hardware.

Hoses, clamps, and fittings connect the block heater to the engine’s cooling system.

Mounted low in the system, a head pressure is maintained at the heater’s intake and a simple one-way

valve in the heater unit ensures the direction of coolant flow.

Drain the engine coolant system before working on the block heater. Afterwards, refill

the cooling system and bleed at highest point to remove any air locks.

November 16, 2007

Revision 8

Chapter 1-1

Page 22

Page 37

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

1

2

3

November 16, 2007

Revision 8

1. Output #1 Contactor (S75)

2. Wire Harness

3. Output #2 Contactor (S275) (If Applicable)

Output Power Module Components

Figure 16

Chapter 1-1

Page 23

Page 38

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

This page intentionally left blank.

November 16, 2007

Revision 8

Chapter 1-1

Page 24

Page 39

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Section 2 Preparation for Use, Storage, or Shipping

1) Preparation for Use

a) Inspection/Check

Inspect the unit thoroughly prior to operation.

(1) Remove blocking, banding, ties, and other securing material.

(2) Inspect exterior for shipping damage such as broken lights, damaged sheet metal, etc.

(3) Open all canopy doors and inspect interior for foreign material such as rags, tools, shipping

papers, etc.

(4) Check fuel, coolant, oil hoses and connections for visible leaks. Visually inspect the compartment

floor and ground surface under the unit for signs of leakage. If leaks are found, corre ct by

tightening hose clamps, tube fitting, etc., as required.

(5) Check security of generator set retaining components.

(6) Check the following for sufficient quantity:

a Fuel

Press “LAMPS” push-button button to energize fuel gage when engine is stopped. Fuel is

supplied from a customer-furnished source.

NOTE: For recommended fuel specifications refer to the Engine Manufacturers Operation and

Maintenance Manual provided with this manual.

b Engine coolant

Remove radiator cap to check coolant level. Coolant level should be at the bottom of the filler

neck.

CAUTION

NOTE: For antifreeze protection, use a solution of 50% permanent antifreeze (Ethylene glycol) and

50% clean water.

Lubricating oil capacity (w/ filter) 10 quarts (9.5 liters)

Coolant capacity system 38 quarts (36 liters)

BE SURE the cooling system antifreeze solution is adequate to protect below the

lowest temperature expected.

ENGINE OIL AND COOLANT CAPACITIES

April 01, 2005 Chapter 1-2

Figure 1

Page 1

Page 40

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

c Engine lubricating oil level

The oil gage rod has “H” high mark and “L” low level marks to indicate the operating

lubrication oil supply. Oil level should be kept as near the high mark as possible, without

going over it. See Figure 1 for capacity.

CAUTION

NOTE: See the Engine Manufacturer’s Operation Maintenance Manual for oil recommendations.

NEVER operate the engine with oil level below the “L” level mark or above the ”H”

level mark.

Oil Fill

Oil Fill and Oil Level Check Locations

Figure 2

Oil Level Check

d Check Batteries

Inspect the batteries for proper connection of the terminals and also check the electrolyte

level (if possible). Service or replace if necessary.

b) Installing Three-Phase AC Output Cables

The generator set may be shipped without aircraft cables. The load contactors, to which cables must

be connected, are located on the power module assembly (left side of the unit beneath the engine

control panel).

The conductor size recommended for AC output cables is 2/0 AWG. Use No. 12 size for control (E

and F) terminals. Large cables (A, B, C, and N) should be equipped with terminals having at least a

3/8-inch diameter, mounting holes. Mounting holes in the small leads (E and F) should be at least

1/4-inch diameter.

April 01, 2005 Chapter 1-2

Page 2

Page 41

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

To install AC output cables proceed as follows:

(1) Open control box door of the generator set and remove the lower panel.

(2) Remove Plexiglas cover in front of the power module assembly.

(3) Remove the cover panel on the cable tray covering the cable clamps.

(4) Loosen screws on cable clamps.

(5) Route cables through cable clamps, and up to the load side of the load contactor(s).

(6) Connect the phase cable terminal lugs to the appropriate terminal studs on the contactor(s): cable

lug “A” to terminal stud “A”, “B” to “B”, and “C” to “C”.

(7) Connect the cable’s neutral terminal lug securely to the neutral (ground) stud on the power

module assembly.

(8) Connect the “E” and “F” cables to the “E” and “F” studs on the power module assembly.

(9) Tighten clamp screws securely, but avoid damage to cable insulation.

(10) Replace Plexiglas cover panel, lower panel, and close canopy door.

2) Tips on Cold Weather Starting

a) Battery and Cables

To start in cold weather, a diesel engine must crank at a fairly high speed. A worn out battery,

partially discharged battery, and poor or loose cable connections will reduce cranking speed. Battery,

cables and connections should be cleaned and tightened regularly.

b) Fuel

For an engine to start and continue running, fuel must flow through the injection system. Unblended

#2 diesel fuel “clouds”, forming filter –clogging waste at temperature around +15° F (-10° C) making

starting and running impossible. Most engine manufactures recommend that fuel have a cloud point

at least 10° F (5° C) below the coldest anticipated temperature.

c) Lube Oil

Engine lubricating oil gets thicker at lower temperatures. Many oils that flow freely at 70º F (21º C)

are extremely thick at 0º F (-18º C). Follow your engine manufacturer’s recommendations regarding

oil viscosity for the coldest temperatures you expect your engine to encounter.

3) Preparation for Storage

When a generator set is to be stored or removed from operation, special precautions should be taken to

protect the internal and external parts from rust, corrosion, and gumming in the engine fuel system.

April 01, 2005 Chapter 1-2

Page 3

Page 42

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

a) General

Pull all circuit breakers and/or disconnect battery negative terminal.

(1) The unit should be prepared for storage as soon as possible after being removed from service.

(2) The unit should be stored in a building which is dry and which may be heated during winter

months.

(3) Moisture absorbing chemicals (Factory Part No. 76A1354-001) are available for use where

excessive dampness is a problem; however, the unit must be completely packaged and sealed if

moisture absorbing chemicals are to be effective.

b) Temporary Storage

When storing the unit for 30 days or less, prepare as follows:

(1) Lubricate the unit completely in accordance with instructions in Section 2-2. This will include

changing engine oil, and all filter elements.

(2) Start the engine and operate for about two minutes so that all internal engine components will be

coated with new oil.

NOTE: Do not drain the fuel system or crankcase after this run.

(3) Make certain the cooling system antifreeze solution is adequate to protect below the lowest

temperatures expected during the storage period. Be sure the solution is thoroughly mixed.

(4) Clean the exterior of the engine. Dry with clean rags and compressed air.

(5) Seal all engine openings. Use a waterproof, vapor proof material that is strong enough to resist

puncture damage from air pressures.

c) Long Time Storage (Over 30 Days)

To protect the generator and other electrical components, the complete unit should be packaged

using moisture proof packaging material and sealing material. Place containers of moisture

absorbing chemicals (Factory Part No. 76A-1354-001) in the unit before packaging. The unit may be

stored for long periods with no special preparation if it is possible to operate the engine once each

week. When starting once a week proceed as follows:

(1) Make certain the cooling system is adequately protected.

WARNING

ENSURE adequate ventilation before starting the engine.

(2) Start the engine and operate under full load until coolant temperature has reached at least 176ºF

(80ºC).

April 01, 2005 Chapter 1-2

Page 4

Page 43

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

(3) While the engine is running, ensure that normal operating controls are in good working condition

before shutdown and storage. If weekly operation is not possible, contact the nearest engine

manufacturer distributor for instructions.

4) Preparation for Shipment

a) Disconnect battery negative terminal before shipping.

b) During long shipments, vibration, jolting, etc may loosen the generator set retaining hardware.

CAUTION

When shipping the unit, provide sufficient retaining materials to ensure the generator

set cannot roll out or off the vehicle in which it is being transported.

NOTE: It is suggested that strong banding be used to secure the generator set, or a strong steel bar

be either welded or bolted across the front of the generator set frame.

April 01, 2005 Chapter 1-2

Page 5

Page 44

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

This page intentionally left blank.

April 01, 2005 Chapter 1-2

Page 6

Page 45

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

Section 3 Operation

1) General

This section contains information and instructions for the safe and efficient operation of the equipment.

Operating instructions are presented in step-by-step sequence of procedures to be followed in supplying

400-Hz power or 28.5V DC power.

NOTE: Read ALL of the operating instructions before attempting to operate the equipment.

WARNING

Ear protection equipment may be necessary when working close to this equipment.

2) 400 Hz. Operating Procedure

a) Pre-start inspection

(1) Be sure the fuel shutoff valve on the unit is open.

(2) Ensure 12 VDC power is available to the engine starting system.

(3) Check the engine and generator compartments to make certain they are free of rags or other

foreign materials.

(4) Make certain there is sufficient lubricating oil and coolant in the engine.

(5) Check that all circuit breakers are reset.

(6) Make certain the “STARTER ENABLE/DISABLE” switch is enabled, and the “FREQUENCY

ADJUST” switch is disabled.

b) Normal Engine Starting Procedures

Engine starting procedures are outlined below. The engine’s operating controls and monitori ng

instruments are illustrated in Figure 1 and 2.

CAUTION

NOTE: The engine manufacturer’s operation manual is provided with this manual.

(1) If illumination is required, press “LAMPS” push-button switch one time. Pressing this button

switch also activates the fuel gage.

(2) On days when the ambient temperatures are below 60° F, press the “ENGINE HEATER” push-

button to engage the air intake heater prior to starting the engine. The light in the button will

illuminate when the intake heater is engaged (if the light does not illuminate, the engine is ready

to start) and will go off when the intake heater is disengaged, thus signifying the engine is ready

to start.

Refer to operating instructions in the engine manufacturer’s operation manual, when

starting engine for the first time.

April 01, 2005 Chapter 1-3

Page 1

Page 46

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

3 4

12

6 8 7,10 10,1110,12

5

139 10,15 10,1617

1. Fuel Gage (M13)

2. Front Panel

3. Engine Coolant Temperature Gauge (M24)

4. Running Time Meter (M4)

5. Oil Pressure Gage (M25)

6. Battery Voltmeter (M5)

7. Frequency Meter (M3)

8. Control Panel Label

9. Fault Code Meter (M6)

April 01, 2005 Chapter 1-3

10. Strip Lights (DS60-DS62) [Not Shown]

11. AC Generator Ammeter (M1)

12. AC Voltmeter (M2)

13. Adjustable Grip Latch

14. Control Panel Door Hinge [Not Shown]

15. DC Voltmeter [Optional with TR]

16. DC Ammeter [Optional with TR]

17. Front LED PC Board (A5) [Shown Opposite Side]

Control Panel Door

Figure 1

Page 2

Page 47

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

1. Meter Selector Switch (S3)

2. Test/Reset Switch (S77)

3. Engine Stop Switch (S76)

4. DC Starting Current Switch (S431) [Optional with TR]

5. DC Output Contactor Switch (S430) [Optional with TR]

Control Push-Button Switch Panel

Figure 2

1245678910 3

6. AC Output No. 2 (S275) [if applicable]

7. AC Output No. 1 (S75)

8. Engine Start Switch (S24)

9. Air Intake Heater Switch (S79)

10. Panel Light Switch (S74)

April 01, 2005 Chapter 1-3

Page 3

Page 48

OM-2098C / Operation and Maintenance Manual

60CU24 / Series 500060C / 400 Hz. Generator Set

CAUTION

Never use an ether start system in conjunction with the air intake heater.

(3) Press the green “ENGINE START” push-button switch and hold until engine starts. The engin e

will start at idle speed, and the green light in the “ENGINE START” push-button switch will flash

to indicate that power is available to the engine’s ECM circuit.

CAUTION

Do not attempt to bring to rated speed for at least 5 seconds after engine starts.

Damage to the starter and flywheel will result.

CAUTION

If the engine fails to start within 5 seconds, the control system will automatically

disable the starting motor and indicate a low oil pressure fault. The emergency stop

switch must be pressed to reset the control system and allow another starting attempt.

If the engine fails to start after four attempts, an inspection should be made to

determine the cause.

If the engine fires sufficiently to disengage the starter gear, but does not start, allow

the starting motor to come to a complete stop before attempting to engage the starter

again, then press the start push button switch.

(4) Check oil pressure to make certain that it is normal, and observe all other engine instruments for

normal operation.

(5) Allow engine to idle and warm for 3 - 5 minutes before bringing it up to rated speed.

CAUTION

To eliminate the possibility of wet stacking (See Appendix A), DO NOT allow the

engine to idle for long periods of time.

c) Failed Starting Procedure

In the event that the engine fails to start, the circuitry must be reset before the next attempt. To do

this:

(1) Push the red “EMERGENCY STOP/RESET BUTTON” on the control box door to the right of the

control panel.

(2) Pull the red “EMERGENCY STOP/RESET BUTTON” back out before the next attempt to start

the generator set.

d) AC Power Delivery

(1) Press “ENGINE START” push button switch a second time to bring engine from idle speed to