Page 1

I

N

S

T

R

U

C

T

I

O

N

S

MODEL 5801 MEAT SAW

MODEL

5801 ML-38674

EXECUTIVE OFFICES

701 RIDGE AVENUE

TROY, OHIO 45374-0001

FORM 16322 Rev. A (11-95)

Page 2

Installation, Operation, and Care of

MODEL 5801 MEAT SAW

SAVE THESE INSTRUCTIONS

GENERAL

The 5801 Meat Saw is rugged, durable, and easy to clean. The saw is equipped with a water resistant

3 HP electric motor and direct gear drive transmission that provides a blade speed of 3500 feet per

minute. The carriage (Fig.1) has stainless steel ball bearings providing easy travel and dependability.

The shaped front edge of the carriage is comfortable to the operator's body even when leaned on during

movement. The carriage lock is standard. The upper pulley cover and baffle (Fig. 1) are standard in

durable plastic, optional in stainless steel.

Table, carriage, pulleys, guides, and wiper assemblies can be quickly removed without tools for ease

of cleaning. Moving parts are enclosed but accessible. The blade is guarded above and below the

cutting zone. The pusher plate is provided to eliminate the need of handling items close to the blade;

it can ride on the right "flanged-end" of the carriage so you keep your hands away from the cutting edge

of the blade.

For electrical specifications above 250 volts, a transformer provides a 115 volt control circuit voltage.

Thermal overload protection is an option.

One long-life blade is furnished with each saw as standard equipment. This blade cannot be

resharpened; replacement blades are available through your local Hobart Service Office.

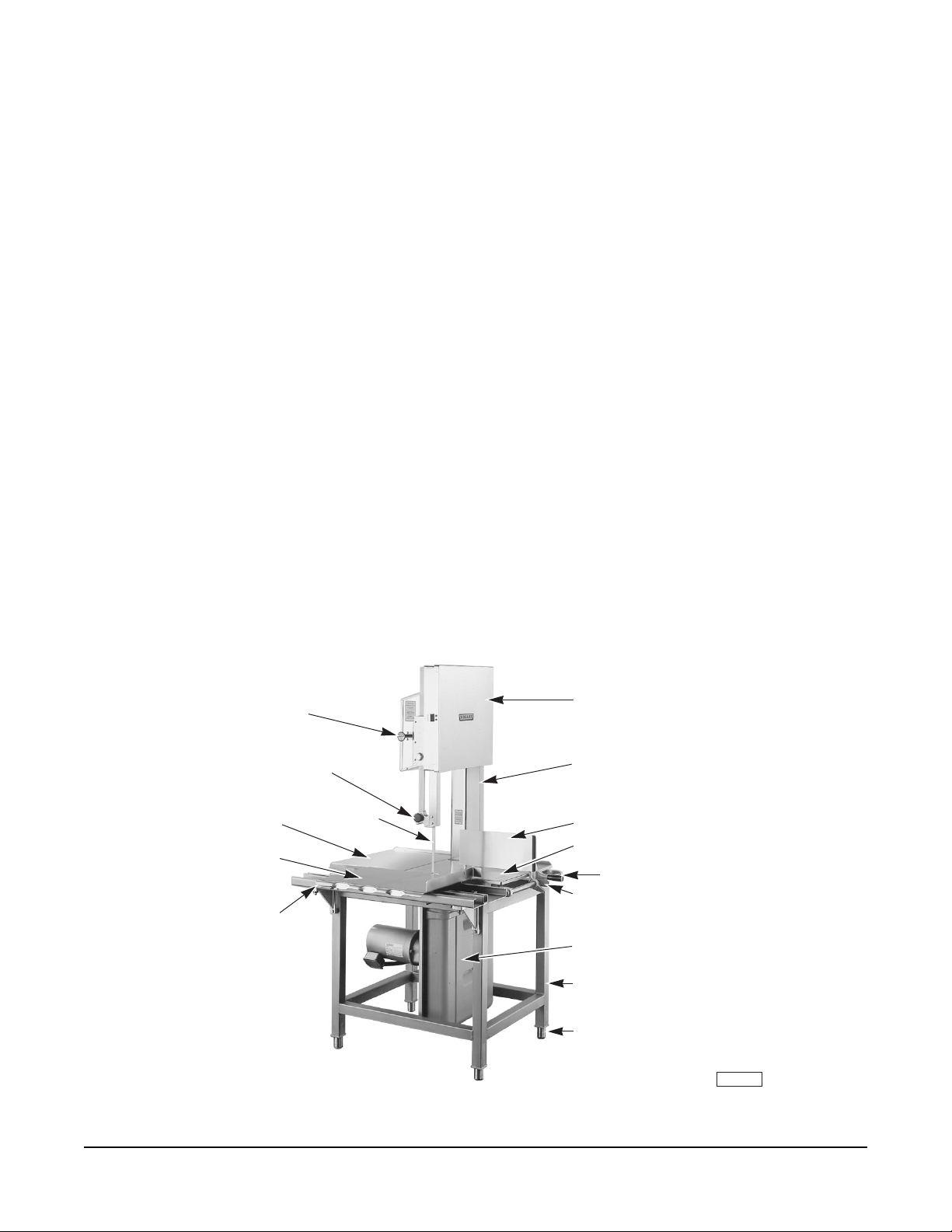

UPPER PULLEY COVER (SST)

SWITCH KNOB

UPPER GUIDE AND GUARD

TABLE (LEFT)

CARRIAGE

CARRIAGE LOCK

SAW BLADE

COLUMN GUARD

GAUGE PLATE

TABLE (RIGHT)

GAUGE PLATE HANDLE

LOCK LEVER

LOWER COVER (SCRAP PAN)

LEGS

© HOBART CORPORATION, 1995

FEET

PL-40830-1

Fig. 1

–2–

Page 3

INSTALLATION

UNPACKING AND ASSEMBLY

Immediately after unpacking the meat saw, check for possible shipping damage. If the meat saw is

found to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, test the electrical service to make sure it agrees with the specifications on the

machine data plate located on the column.

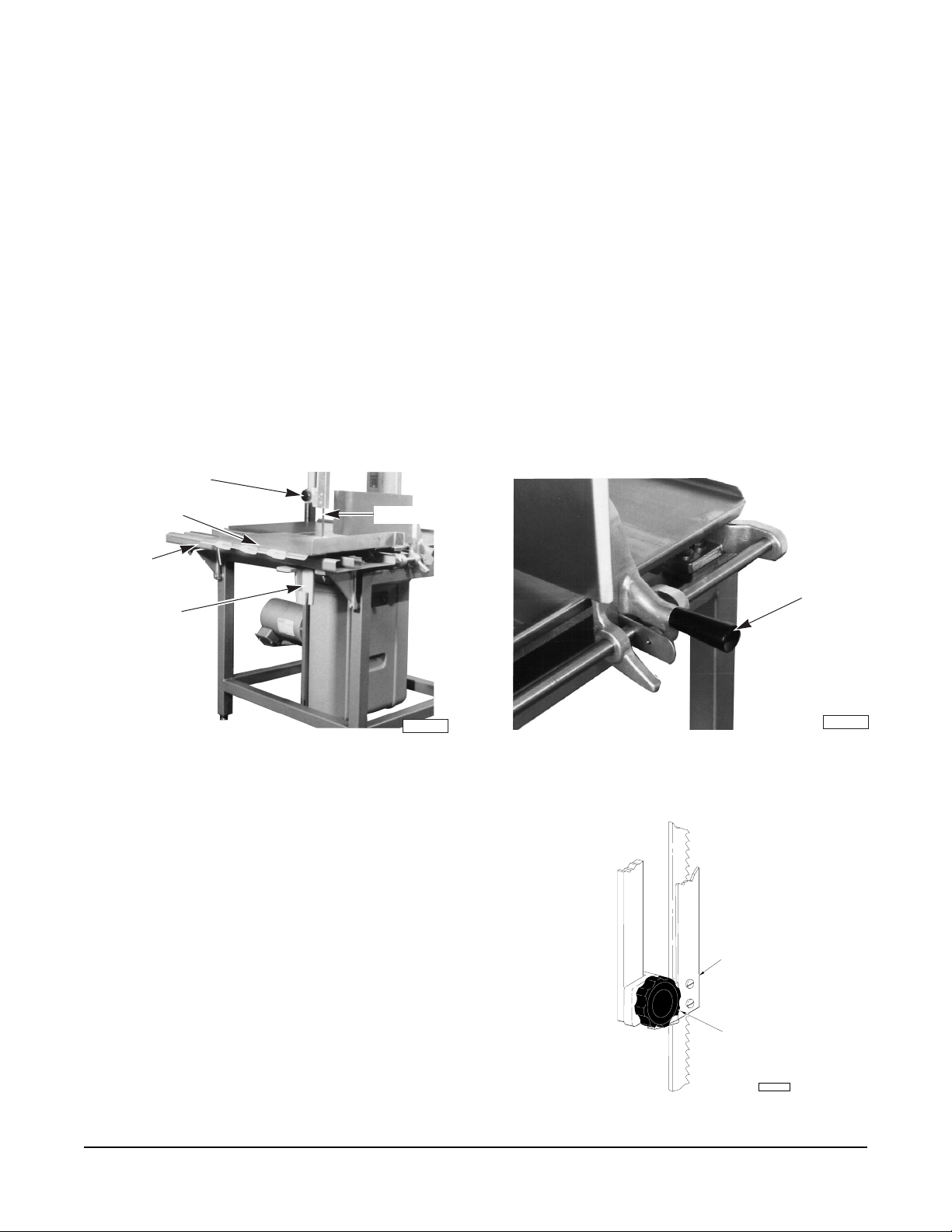

Packed in a packet attached to the table compartment are the pusher plate and the gauge plate handle.

Place the pusher plate in its storage location under the carriage support (Fig. 2). Assemble the gauge

plate handle to the gauge plate support by screwing the stud into the threaded hole (Fig. 3).

LEVELING

Place the saw in its operating location. Using a spirit level, level the meat saw front-to-back and sideto-side by turning the threaded feet in or out.

HAND KNOB

CARRIAGE

CARRIAGE SUPPORT

PUSHER PLATE

Fig. 2 Fig. 3

SAW BLADE

PL-40831-1

GAUGE PLATE HANDLE

PL-40847-1

WARNING: DISCONNECT ELECTRICAL POWER AND PLACE A TAG AT THE DISCONNECT

SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

SAW BLADE

The saw blade must be installed so the teeth point

to the right and down (Fig. 4).

UPPER GUIDE AND GUARD ASSEMBLY

Upper Guide

and Guard

When the saw is off, the hand knob (Fig. 4) can be

used to raise or lower the upper guide and guard

assembly so the cutting zone is only as high as

Hand Knob

necessary for the piece being cut. The hand knob is

not loosened during raising or lowering — it should

remain tightly secure.

Fig. 4

PL-52107

–3–

Page 4

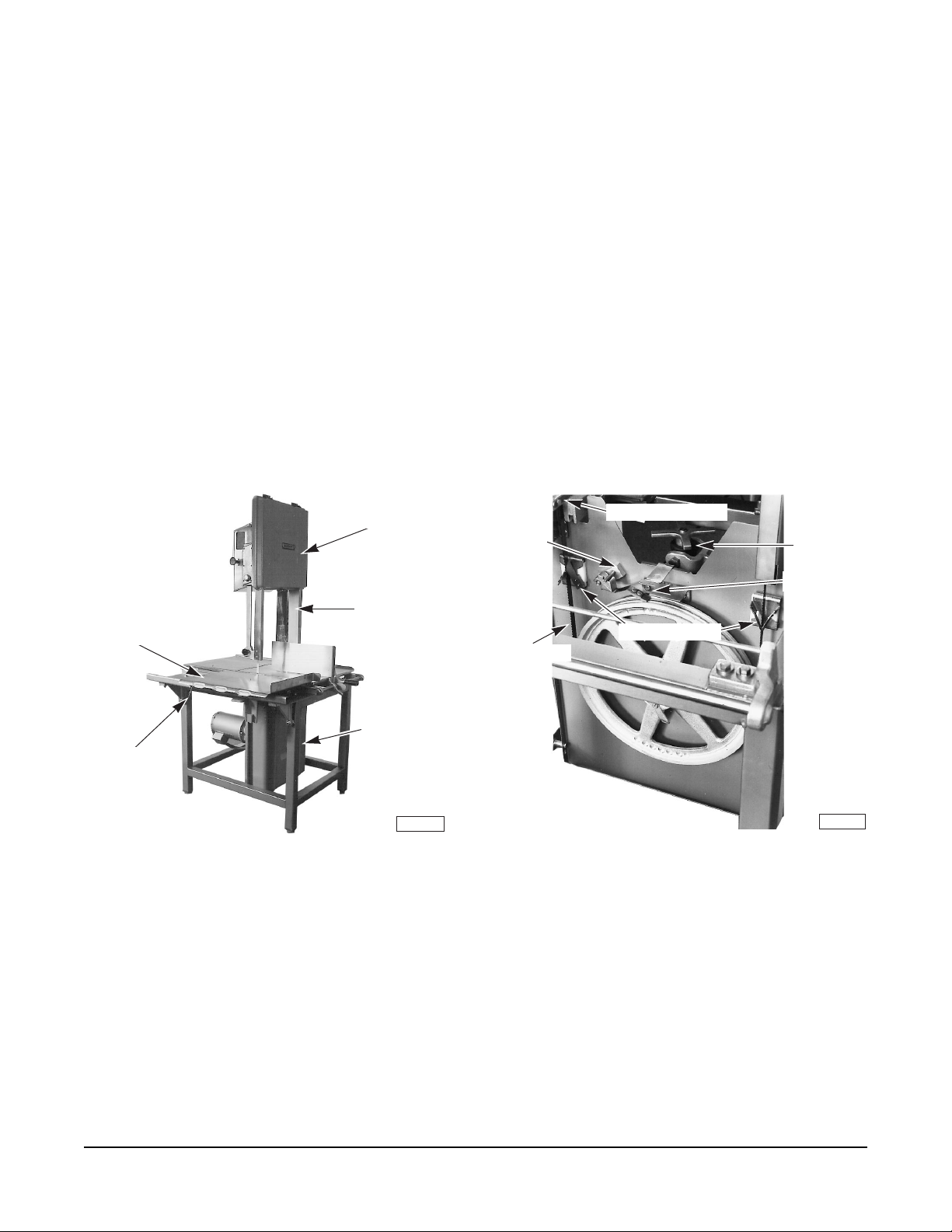

UPPER PULLEY COVER (Plastic - Standard)

The plastic upper pulley cover (Fig. 5) should be installed on the two hinge-retainers at the top and

securely latched at the bottom during use. To remove the plastic upper pulley cover for cleaning,

release the latch at the bottom and remove from the hinge-retainers at the top.

UPPER PULLEY COVER (Stainless Steel - Optional)

The stainless steel upper pulley cover (Fig. 1) should be installed on the two hinge pins of the stainless

steel upper pulley baffle and securely latched during saw use. To remove the stainless steel upper

pulley cover for cleaning, unlatch and open the stainless steel upper pulley cover; then, lift straight up

off the hinge pins.

LOWER COVER (Scrap Pan)

During use, the lower cover (Fig. 5) acts as a scrap pan, accumulating bone dust and debris from the

blade scrapers and pulley wiper that are located on the lower panel (Fig. 6). To remove the lower cover

(scrap pan) for cleaning, release the clip at the top; pull out and lift the lower cover from the groove

at the bottom of the lower panel.

CARRIAGE

CARRIAGE LOCK

BLADE SCRAPERS

UPPER PULLEY COVER

(PLASTIC)

BLOCK

COLUMN GUARD

SAW BLADE

LOWER COVER

(SCRAP PAN)

PL--40833-1

Fig. 5 Fig. 6

LOWER GUIDE BLADE

BLADE SCRAPERS

TENSION

ADJUSTER

PULLEY WIPER

PL-40848-1

Two blade scrapers wipe the blade during sawing to accumulate bone dust and debris inside the lower

cover (scrap pan). The left scraper points up and the right scraper points down (Fig. 6). After the blade

is removed, the scrapers can slide off their mounting blocks for cleaning.

PULLEY WIPER

The pulley wiper (Fig. 6) scrapes bone dust or debris from the lower pulley during use. The pulley wiper

can be removed for cleaning by springing the wiper up and sliding it off the pins.

–4–

Page 5

UPPER AND LOWER PULLEYS

The upper and lower pulleys are assembled on the upper and lower pulley shafts; the latch on each

pulley should be seated in the groove of the pulley shaft (Fig. 7). Pulleys can be removed after the blade

has first been loosened and removed. Upper and lower pulleys are interchangeable.

COLUMN GUARD

The column guard (Fig. 5) covers the return loop of the moving blade and must always be in place

during sawing. To remove the column guard for cleaning or blade change, first remove the right table

and the upper pulley cover. You may want to remove the lower cover (scrap pan) as well. Then, lift

the column guard up to free it from the two drive-pin or shoulder-screw heads on the column that it

hangs from.

LATCH

SHAFT

PULLEY

PL-40832-1

Fig. 7 Fig. 8

SCRAP TRAY

PL-40835-1

TABLES — RIGHT and LEFT

During use, the right and left tables (Fig. 1) are secured underneath by pins and clamps. To remove

the tables for cleaning: Raise the gauge plate to its vertical position; lift the right side of the right table

up; and, remove the table from the two pins. After the right table is removed, the left table can be

removed: Lift the left side of the left table up; and, shift it to the right to free it from the two pins.

SCRAP TRAY

During use, the scrap tray should be installed between the left-hand table and the carriage support

(Fig. 8). The scrap tray slides into place, resting on the frame between the carriage support and table.

The angled side of the scrap tray is located nearest the blade.

–5–

Page 6

CARRIAGE

In use, the carriage can roll back and forth between the left carriage stop (Fig. 9) and the right carriage

stop, assuming the spring loaded carriage lock (Fig. 5) has not locked the carriage in a stationary

position.

To remove the carriage, turn either of the carriage stops 90 degrees so the bumper is toward the rear

(Fig. 10). Roll the carriage off either end while lifting it free of the carriage support structure (Fig. 9).

To reinstall the carriage, hold the carriage so the bearings (underneath) are aligned with the carriage

support structure. Roll the carriage into place. Return the carriage stops so the carriage is stopped

at both ends.

RIGHT TABLE

UPPER GUIDE AND GUARD

LEFT TABLE

LEFT CARRIAGE STOP

CARRIAGE SUPPORT

CARRIAGE

PL-40836-1

LEFT CARRIAGE STOP

WITH BUMPER TOWARDS

THE REAR

PL-40837-1

Fig. 9 Fig. 10

LOWER BLADE GUIDE

The lower blade guide assembly fits in the lower guide holder (Fig. 11). The blade fits in the slots of

both the steel saw blade guide and the plastic guide. When the right table is removed and the plastic

guide is hinged up, the lower blade guide assembly can be removed for cleaning by lifting it out of the

lower guide holder.

The steel saw blade guide is available in various widths depending on the blade being used. Contact

Service to change the steel saw blade guide for other blade widths.

LOWER BLADE GUIDE ASSEMBLY

LOWER GUIDE HOLDER

Fig. 11

–6–

PL-40838-1

Page 7

REMOVING THE BLADE

Remove the upper and lower pulley covers. Raise the gauge plate to its vertical position. Remove

the right table by lifting its right side and sliding the table to the right to free it from the locating pins.

Remove the column guard. Turn the tension adjuster counterclockwise until it stops (this will release

tension on the blade by raising the lower pulley). Raise the plastic blade guide on the lower blade guide

assembly and release the blade from the upper and lower blade guides. Free the blade from the blade

scrapers in the lower pulley area and release it from the pulleys. Remove the blade.

Make sure the pulleys are properly installed and the pulley latches are seated in the groove of the

pulleys. Install the new blade with the teeth pointing to the right and down as you face the front of the

saw. The blade must fit between the V's on the blade scrapers, in the slots of the upper and lower blade

guides, and must not touch any of the pulley flanges. The lower blade guide must be installed after

the blade is installed. When the blade is in position, see BLADE TENSION, below, to adjust the tension

properly. Refer to LOWER BLADE GUIDE, page 6, if the blade width of the new blade is different than

the old. Reinstall any removed parts.

BLADE TENSION

After the blade has been installed, set the blade tension by turning the tension adjuster clockwise until

it stops.

–7–

Page 8

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THE CIRCUIT IS BEING WORKED ON.

ELECTRICAL DATA

Fuse Circuit Breaker

Model Volts / Hertz / Phase

230 / 60 / 1 25 25 30 30

5801

Compiled in accordance with the National Electrical Code, ANSI / NFPA 70, 1993 Edition.

200 - 230 / 60 / 3 20 20 20 20

460 / 60 / 3 15 10 15 15

Minimum

Circuit Ampacity

AMPS

Maximum

Fuse Size

AMPS

Minimum

Circuit Ampacity

AMPS

Maximum

Circuit Breaker Size

AMPS

A 7/8" diameter hole for 1/2" trade size conduit is located in the lower area of the base. Use watertight

connections. Refer to Electrical Data, the machine data plate, and the wiring diagram located on the

machine when making the electrical connection. Connect the electrical power supply leads to the

pigtail leads; use copper wire rated at least 60°C for the connection.

CHECK MOTOR ROTATION (Three-Phase Machines)

If the motor does not rotate so the teeth of the saw blade run downward as you look at the cutting zone,

correct the rotation using the following procedure:

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

Interchange any two of the incoming power supply leads. Reconnect the power supply and turn

the saw momentarily on and off to verify correct rotation.

CONTROL BOX HEATER

The meat saw has a heater in the control box to keep the controls dry. The heater is automatically ON

when the machine is electrically connected. The meat saw should be connected to the power supply

EXCEPT when performing assembly, disassembly, cleaning, or maintenance on the saw.

CLEAN SAW BEFORE USE

The saw must be thoroughly cleaned and sanitized after installation and before use. Refer to Cleaning,

page 11.

–8–

Page 9

OPERATION

SAFETY DEVICES INCORPORATED IN THIS SAW MUST BE IN THEIR CORRECT OPERATING

POSITIONS ANYTIME THE SAW IS IN USE.

SAFETY FEATURES

Upper Guide and Guard Assembly

Before turning the saw on, raise or lower the upper guide and guard assembly by grasping the hand

knob and sliding up or down so the cutting zone is only as high as necessary for the piece being cut.

Doors, Covers, and Guards

All doors, covers, and guards must be in their operating position

(closed) while the machine is running.

Pusher Plate

Always keep hands well back from the blade and maintain control of the product. Use the pusher plate

as described (page 10) and it will be unnecessary to hold your hand near the cutting edge of the saw

blade.

CONTROLS

Switch Knob P

ULL turns the saw On. PUSH turns the saw Off.

SAWING

Place product on carriage. Set the upper guide and guard assembly and the gauge plate before

starting the machine.

If using the traveling carriage . . .

Stand in front of machine. Lean lightly against the front of the carriage as you move the carriage

to the left, passing the product through the blade at a steady and uniform rate.

Use your left hand to remove and stack cuts, always reaching behind the blade. NEVER REACH

IN FRONT OF THE BLADE. Return the carriage to the right, pulling the product toward you and

away from the blade.

If using the stationary carriage . . .

The carriage may be locked in a stationary

position by pulling the spring loaded carriage

lock out, rotating it 90° and sliding the carriage

until the lock engages (Fig. 12). To unlock the

carriage, pull the carriage lock out and rotate it

90° so it rests on its bracket. When sawing with

stationary table, observe the same safety

procedure of reaching behind the blade when

removing or stacking product. NEVER REACH

IN FRONT OF THE BLADE.

UPPER GUIDE AND GUARD

CARRIAGE

CARRIAGE LOCK

PL-40839-1

Fig. 12

–9–

Page 10

GAUGE PLATE

When making several cuts of the same thickness (or when using the pusher plate), set the gauge plate

as desired (Fig. 13) by pushing the lock lever and sliding the gauge plate to the thickness you want.

A reference scale on the table indicates the thickness of cut. If the gauge plate is not needed, you may

release the lock lever and move the gauge plate to the rear; or raise the gauge plate to a vertical position

to keep it out of the way.

GAUGE PLATE

PUSHER PLATE

CARRIAGE

REFERENCE SCALE

RIGHT CARRIAGE STOP

GAUGE PLATE LOCK LEVER

Fig. 13

GAUGE PLATE HANDLE

PL-40840-1

PUSHER PLATE

The pusher plate is used to hold meat against the gauge plate when slicing short ends. A slot in the

pusher plate and a stop on the right "flanged-end" of the carriage is provided for proper positioning of

the pusher plate (Fig. 13). Hold the pusher plate handle with your right hand and always maintain a

safe distance from the blade. When not in use, keep the pusher plate under the carriage support

(Fig. 2).

–10–

Page 11

CLEANING AND SANITIZING

WARNING: DISCONNECT ELECTRICAL POWER AND PLACE A TAG AT THE DISCONNECT

SWITCH INDICATING THE CIRCUIT IS BEING WORKED ON BEFORE CLEANING THIS MACHINE.

The saw must be thoroughly cleaned and sanitized:

Before first use;

After each day's operation;

Anytime it is not to be used for an extended period of time; or

Before being put into operation after an extended downtime.

The meat saw can be cleaned with high-pressure cleaning equipment (available from other suppliers)

or it can be disassembled and its components cleaned in a sink. In either case, a neutral pH cleaning

agent mixed per the supplier's instructions should be used. After washing, thoroughly sanitize, rinse,

and dry the saw and all components.

Disassemble the following saw components to allow access to all areas for cleaning . . .

Upper Pulley Cover

Lower Cover (Scrap Pan)

Tables — Right and Left-Hand

Scrap Tray

Carriage

Column Guard

Pulley Wiper

Blade Scrapers

Lower Blade Guide Assembly

Saw Blade

Upper Guide and Guard Assembly (unscrew Hand Knob to disassemble)

Upper and Lower Pulleys

If using High-Pressure Cleaning Equipment . . .

Scrape the machine and its components to remove any scrap particles before cleaning.

Thoroughly hose the saw and its components following the equipment supplier's instructions. Be

sure to get the hose stream into all corners. Stubborn soil may require a little brushing.

If using Sink Cleaning . . .

Use a cloth or brush on base unit. Thoroughly wash, sanitize, rinse, and dry.

Before reassembly, a light coating of tasteless mineral oil should be applied to all metal surfaces.

Lubricate six ball bearings on the carriage with a small amount of mineral oil. Apply a few drops of

mineral oil to the gauge plate slide rod and work the gauge plate assembly back and forth a few times.

Reassemble the saw components in reverse order of disassembly making sure all parts are properly

assembled.

–11–

Page 12

MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THE CIRCUIT IS BEING WORKED ON.

LUBRICATION

The motor has permanently lubricated ball bearings and requires no additional lubrication.

The slide bar for the upper guide and guard assembly also requires no lubrication.

Occasionally, you should apply a small amount of mineral oil to the six ball bearing rollers underneath

the carriage.

On a more frequent basis, the gauge plate slide rod and the pulley shafts need a few drops of tasteless

mineral oil.

CHANGING SAW BLADES

If changing saw blades, disassemble components as described in R

EMOVING THE BLADE, page 7, and the

instructions for any component throughout the manual. Make sure wipers, scrapers, and all other

components are properly reassembled. Refer to B

LADE TENSION, page 7. Refer to LOWER BLADE GUIDE,

page 6.

SERVICE

Contact your local Hobart Service Office for any repairs or adjustments needed on this equipment.

FORM 16322 Rev. A (11-95) PRINTED IN U.S.A.

–12–

Loading...

Loading...