Page 1

INSTRUCTION MANUAL

. . .

with Replacement Parts

MODELS 521 6, 521 6-HS,

MEAT SAWS

ML-19620 5216 (Painted)

ML-19622 5216-HS (Painted)

ML-19621 5216-D

ML-19623 5216-D HS (SST)

(SST)

A

product

FORM 13028A (Rev. 9-80) (Supsds. F. 13028)

of

HOBART CORPORATION TROY, OHIO

45374

Page 2

- THIS PAGE INTENTIONALLY LEFT BLANK -

Page 3

INSTRUCTIONS

Installation, Operation and Care of

MODELS 521 6, 52 16-HS, 52 16-D 8 52 16-D HS MEAT SAWS

Save These Instructions

GENERAL

5216

The 5216 Meat Saw

quantities of product. It

electrical motor. Applications above 250 volts

include reduced voltage pilot circuit. Thermal

overload protection

carriage table, easily moved by operator's body,

and

a

carriage lock are standard.

One long life blade

meat saw.

placements are available through authorized

Hobart offices.

The blade cannot be resharpened and re-

is

designed to process large

is

equipped with a 2 H.P.

is

offered

is

as

an option.

furnished with each

A

INSTALLATION

Place the machine

as

possible. Remove the shipping box. Remove and

unpack all dissassembled components. The pusher

plate and scrap pan are packed in the base compartment.

the underside of the skid and slide the machine off

the skid.

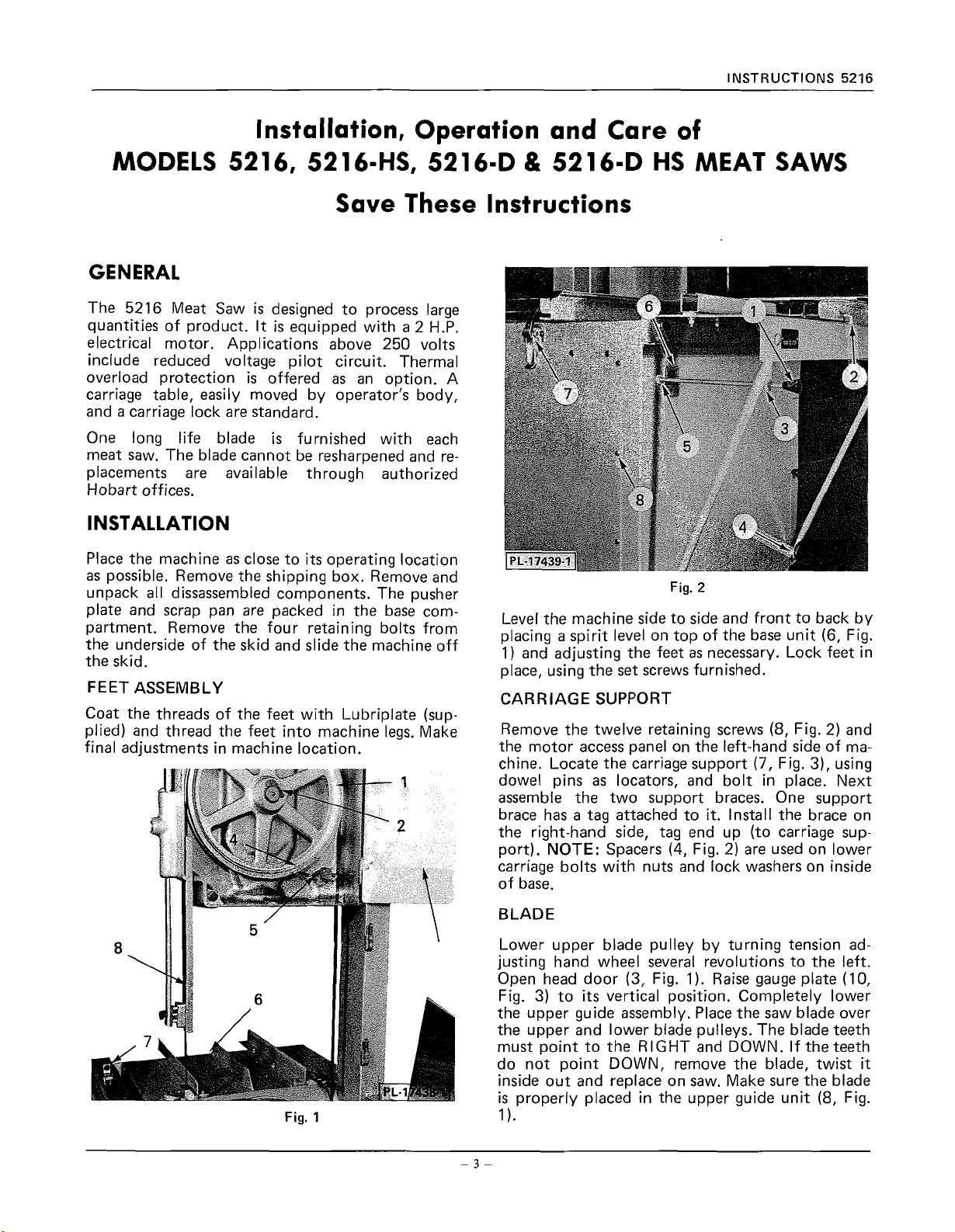

FEET

Coat the threads of the feet with Lubriplate (supplied) and thread the feet into machine legs. Make

final adiustments in machine location.

Remove the four retaining bolts from

ASSElVlBLY

as

close to

its

operating location

Fig.

2

Level the machine side to side and front to back by

placing

1

)

place, using the set screws furnished.

CARRIAGE SUPPORT

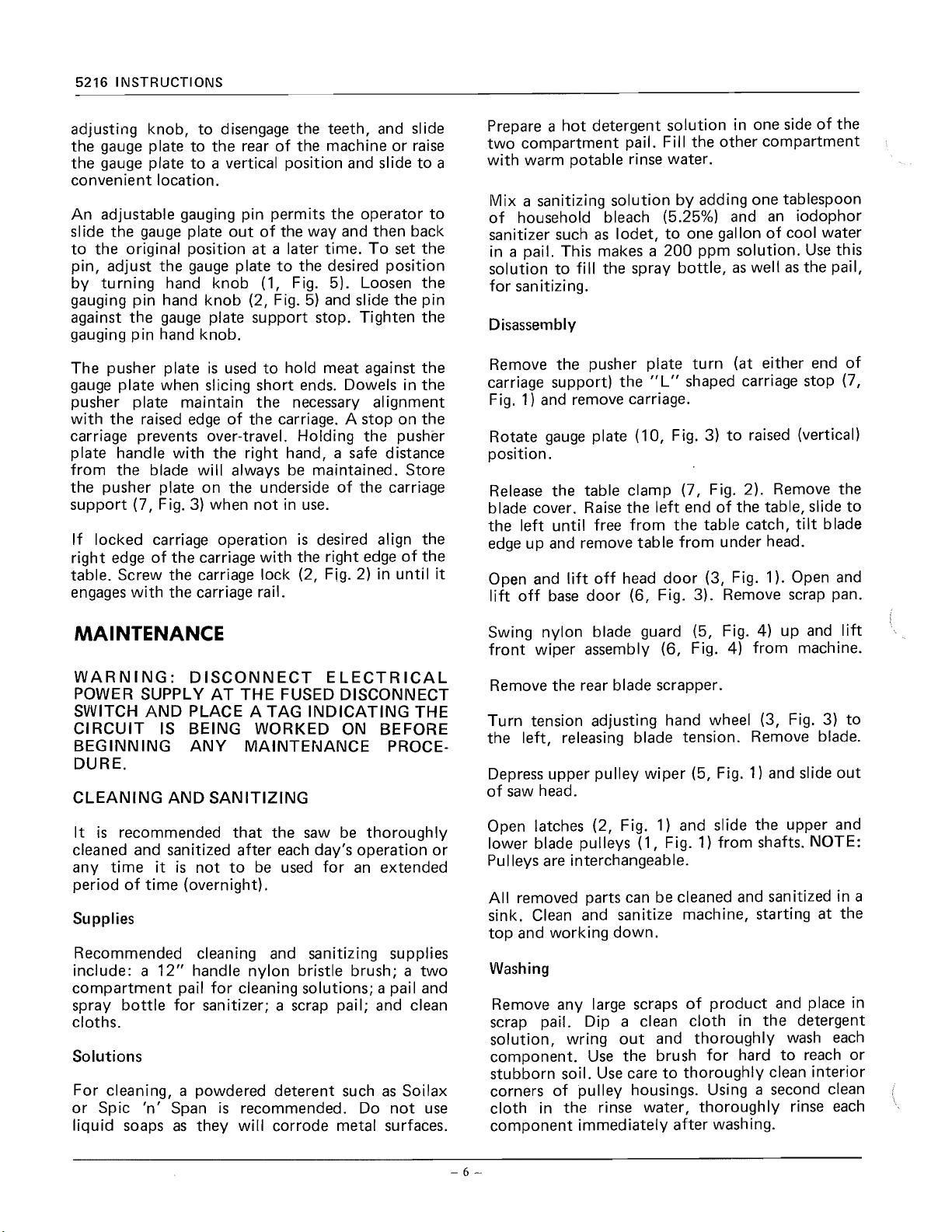

Remove the twelve retaining screws (8, Fig. 2) and

the motor access panel on the left-hand side of machine. Locate the-carriage support

dowel pins as locators, and bolt in place. Next

assemble the two support braces. One support

brace has a tag attached to

the right-hand side, tag end up (to carriage sup-

port). NOTE: Spacers

carriage bolts with nuts and lock washers on inside

of base.

a

spirit level on top of the base unit

and adjusting the feet

(4,

(6,

Fig.

as

necessary. Lock feet in

(7,

Fig. 3), using

it.

Install the brace on

Fig. 2) are used on lower

Fig.

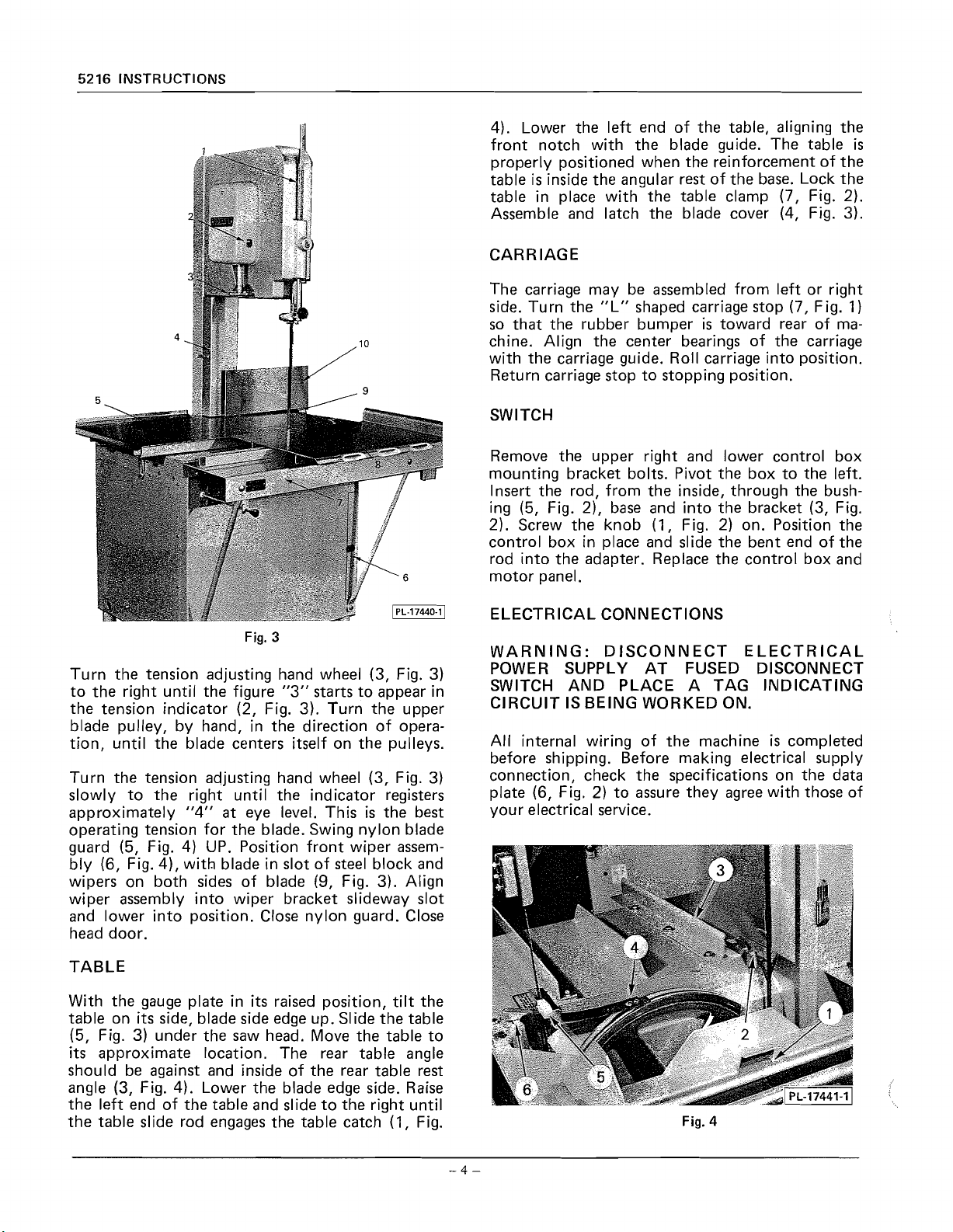

BLADE

Lower upper blade pulley by turning tension adjusting hand wheel several revolutions to the left.

Open head door (3, Fig. 1). Raise gauge plate (10,

its

Fig. 3) to

the upper guide assembly. Place the saw blade over

the upper and lower blade pulleys. The blade teeth

must point to the RIGHT and DOWN. If the teeth

do not point DOWN, remove the blade, twist

inside out and replace on saw. Make sure the blade

is

properly placed in the upper guide unit (8, Fig.

1

1).

vertical position. Completely lower

it

Page 4

5216

INSTRUCTIONS

4). Lower the left end of the table, aligning the

front notch with the blade guide. The table

is

properly positioned when the reinforcement of the

table

is

inside the angular rest of the base. Lock the

table in place with the table clamp

(7, Fig.

2).

Assemble and latch the blade cover (4, Fig. 3).

CARRIAGE

The carriage may be assembled from left or right

side. Turn the "L" shaped carriage stop (7, Fig. 1)

so that the rubber bumper

is

toward rear of machine. Align the center bearings of the carriage

with the carriage guide. Roll carriage into position.

Return carriage stop to stopping position.

SWITCH

Remove the upper right and lower control box

mounting bracket bolts. Pivot the box to the left.

Insert the rod, from the inside, through the bushing

(5,

Fig. 2), base and into the bracket (3, Fig.

2). Screw the knob (1, Fig. 2) on. Position the

control box in place and slide the bent end of the

rod into the adapter. Replace the control box and

motor panel.

Fig.

3

Turn the tension adjusting hand wheel (3, Fig. 3)

to the right until the figure

"3" starts to appear in

the tension indicator (2, Fig. 3). Turn the upper

blade pulley, by hand, in the direction of operation, until the blade centers itself on the pulleys.

Turn the tension adjusting hand wheel (3, Fig. 3)

slowly to the right until the indicator registers

approximately

eye level. This

is

the best

"4"

at

operating tension for the blade. Swing nylon blade

guard (5, Fig. 4) UP. Position front wiper assembly (6, Fig. 4), with blade in slot of steel block and

wipers on both sides of blade

wiper assembly into wiper bracket

(9,

Fig. 3). Align

slideway slot

and lower into position. Close nylon guard. Close

head door.

TABLE

With the gauge plate in

table on

its

side, blade side edge up. Slide the table

its

raised position,

tilt

the

(5, Fig. 3) under the saw head. Move the table to

its

approximate location. The rear table angle

should be against and inside of the rear table rest

angle (3, Fig. 4). Lower the blade edge side. Raise

the left end of the table and slide to the

the table slide rod

errgages the table catch-(1, Fig.

ricrht until

ELECTRICAL CONNECTIONS

WARMING: DISCONNECT ELECTRICAL

POWER SUPPLY AT FUSED DISCONNECT

SWITCH

ARID PLACE A TAG IRIDICATING

CIRCUIT IS BEING WORKED ON.

All internal wiring of the machine

is

completed

before shipping. Before making electrical supply

connection, check the specifications on the data

2)

plate (6, Fig.

to assure they agree with those of

your electrical service.

Fig.

4

Page 5

INSTRUCTIONS

5216

Electrical connections should be made by qualified

workmen who will observe all applicable safety

codes and the National Electrical Code.

SUGGESTED WIRE ARID FUSE SIZES

FOR INDIVIDUAL BRANCH CIRCUITS

Max. Time Min. 60°C CU

Delay Conductor Wire

Volts Ph. Fuse Size

115 1 30 30 10

200-230

200-230

460 3 15 15 14

Connect the individual branch electrical power

supply to the contactor leads. A 1-3/32" diameter

hole (for

connecting rigid or flexible conduit. Circuit conductors and fuse protection should conform to

local,

Fdlotor Rotation

In three phase applications

to verify correct direction of rotation. Apply elec-

trical power and energize the machine momentarily

by pulling then pushing the switch knob. The blade

must travel in the DOWNWARD direction.

If rotation

TRICAL POWER SUPPLY and interchange any

two power supply leads. Re-energize &achine

momentarily and verify correct direction of rota-

tion.

Replace motor access panel and twelve retaining

screws.

CLEANING & SANITIZIIVG

1 15 15 14

3 15 15 14

314" conduit)

as

well

as

national, code requirements.

is

incorrect, DISCONNECT ELEC-

Ampacity Size

is

provided in the base for

a

check must be made

is

The BUTT-END PUSHER PLATE

when slicing short ends, thus keeping operator's

hands away from saw blade.

The GAUGE PLATE (10, Fig. 3)

maximum support of the product being cut while

providing operator protection and facilitating slice

removal.

All doors and inspection covers MUST be in

operating (closed) position while machine

ning.

CONTROLS

The SWITCH

start the machine. To turn machine OFF push

knob in.

Place item to be cut on the carriage

turn saw ON by pulling switch knob

Stand in front of machine, leaning lightly against

the scalloped front of the carriage. Move the

carriage to the left, past the saw blade

a

steady and uniform rate. Use your left hand to

remove and stack product

REACH IN FRONT OF BLADE. Always reach

around the left side or in back of saw blade. On the

return stroke, pull the item back and away from

blade.

To cut slices of uniform thickness, set the gauge

plate

at

justing knob (1, Fig. 5). A scale

table.

If the gauge plate

the work,

KNOB (1, Fig.

the desired position by turning the ad-

is

not needed and interferes with

it

may be moved out of the way. Lift the

2)

must be pulled to

as

it

is

to be used

is

shaped to give

is

run-

(8,

Fig. 3) and

(1, Fig. 2).

(9,

Fig. 3)

is

cut. NEVER

stamped into the

at

It will be necessary to thoroughly clean and sanitize the machine after installation and prior to

being placed into service. Refer to

NANCE for instructions.

MAIhITE-

OPERATION

SAFETY

Safety devices incorporated in the saw MUST be in

correct operating

service.

BEFORE turning machine ON, adjust the UPPER

GLI I DE ASSEMBLY by sliding the guide

up or down

ciose to the work

positon anytime the saw

as

necessarv to keep the auide

as

possibie.

(1,

-

is

in

Fig. 3)

as

Fig.

5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Loading...

Loading...