Hobart 4346 SERIES General Manual

FOOD EQUIPMENT

Qty. Item No.

4346 SERIES

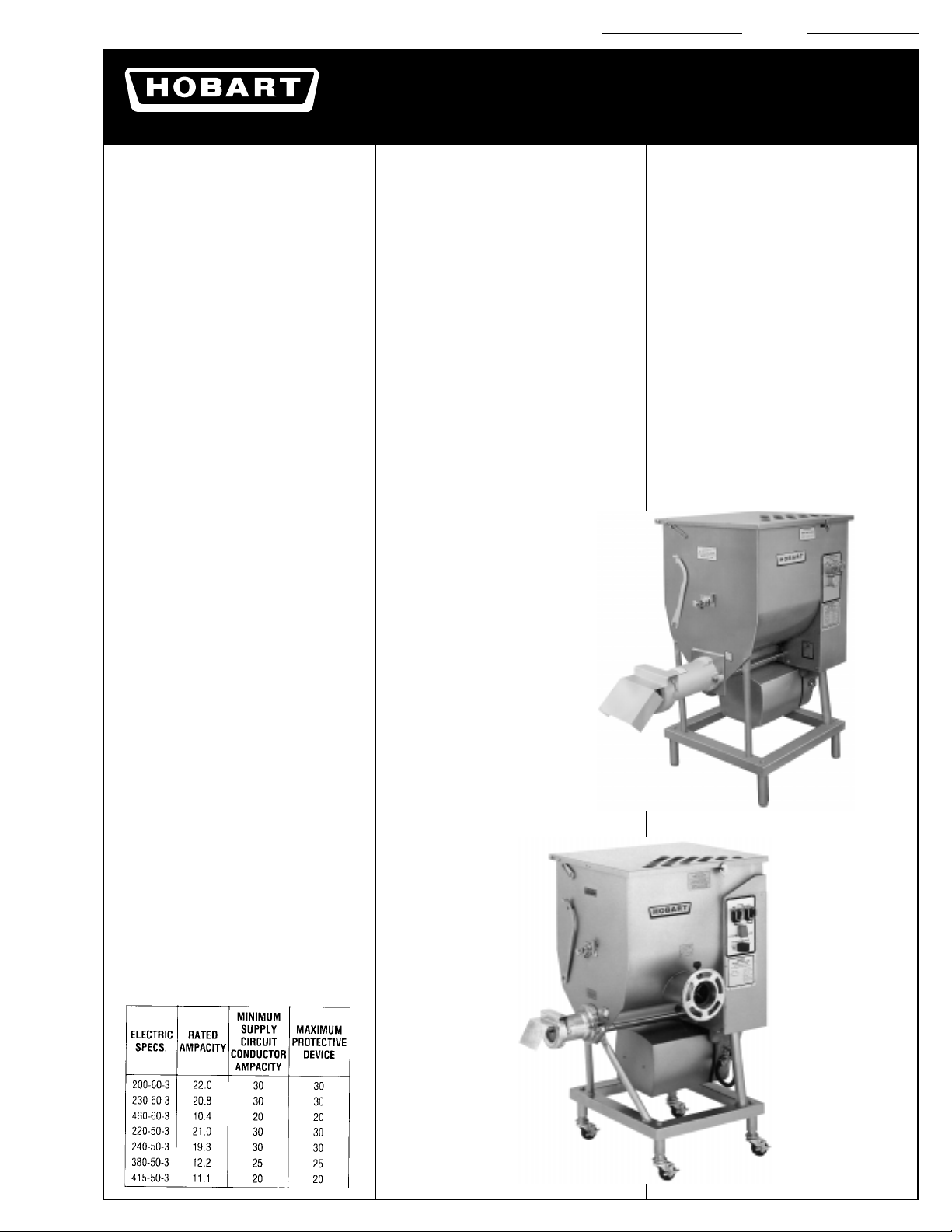

MIXER/GRINDER

The 4346 is a compact self-feeding grinder which will mix and

grind or mix only…fresh meat

trimmings or tempered (above

1

24°F) frozen flaked or 1

⁄4" x 11⁄4"

sticks. The Hobart Model 4346 is

ideal for producing sausage products as well as ground beef.

Fill lugs with ground meat or use

the optional foot control switch for

filling smaller containers. The

4346 can be used with a Hobart

Loaf Forming Machine.

All parts of the 4346 that have

direct contact with the product are

easily removed or readily cleaned

in place. Smooth contours permit

thorough cleaning for maintaining

a sanitary operation.

For fast, clean grinding of

meat…thorough mixing and

blending… where a high quality

product is a prime importance

…specify the Hobart 4346 Mixer/

Grinder.

MOTOR: Hobart designed and

1

built, 7

⁄2 HP, ventilated; flange

mounted with grease packed ball

bearings.

ELECTRICAL CONTROLS:

Hobart designed waterproof magnetic START and STOP rocker

switches, two magnetic

contactors for reversing feature,

solid state motor protection system which prevents excessive

motor temperature, safety interlock switch for hopper guard, 115

V.A.C. pilot circuit transformer, air

heater to deter internal condensation in control box. Offered

optionally, is a safety guarded

foot switch in conjunction with a

control panel mounted selector

switch, for MIX/GRIND intermittent operation.

Specifications, Details and Dimensions on

Reverse Side.

SPECIFICATIONS Listed by

Underwriter Laboratories, Inc.

and National Sanitation Foundation USDA Listed.

GENERAL: For fixed operation,

the branch power circuit is connected directly to the power

supply junction box. Standard

model furnished with casters, a

factory installed 4-wire grounding

flexible cord and plug approximately 8 feet in length, and

receptacle.

ELECTRICAL: 200-60-3, 230-60-3,

460-60-3 — UL Listed. 220-50-3,

240-50-3, 380-50-3, 415-50-3 —

Not submitted for UL Listing.

Optional Side Feeding

Inlet Shown

4346 SERIES

MIXER/GRINDER

SPECIFICATIONS Listed by Underwriters Laboratories Inc and National Sanitation Foundation. USDA Listed.

TRANSMISSION: The grinder transmission

consists of single reduction, hardened helical

gears, oil lubricated. Thrust from the grinder worm

is taken by a large tapered roller bearing mounted

in gear case. Double lip seal prevents loss of oil

or entrance of moisture. The mixing arm is driven

by a roller chain from the main unit.

CAPACITY: The Model 4346 Mixer/Grinder

hopper has meat capacity of up to 215 pounds for

first grind, depending on type of product. It has a

grinding rate of 55 to 60 pounds of fresh boneless

beef per minute, first or second cutting through a

1

⁄8" plate — 60 to 65 pounds of pork per minute,

first cut through a 3⁄4" plate and 55 to 60 pounds

of pork per minute second cut, (after 3⁄4" breaker

plate) through a 3⁄16" plate. Frozen meat must be

tempered to 24°F or higher, and can be in flake

1

or 1

⁄4" x 11⁄4" stick form.

GRINDING END: This Mixer/Grinder is equipped

with a #46 grinding end which includes a heavily

tinned, cast iron cylinder, adjusting ring, and

worm. The cylinder and worm can be easily

removed by use of the spanner wrench provided.

The end is designed for #32 USSA standard size

knives and plates (not furnished).

FEEDING SYSTEM: The grinder worm, rotating at

222 RPM, extends the length of the cylinder and

hopper, and automatically feeds the meat into the

grinder cylinder. When the control is set on MIX/

GRIND, the worm and mixing arm operate; when

set on MIX ONLY, the mixing arm rotates in

opposite direction.

MIXING ARM: Thorough mixing is accomplished

by a heavily tinned steel mixing arm. The arm can

be removed from the hopper for cleaning without

tools by removing the bearing retainer on the front

of the hopper. The arm rotates at 29 RPM.

CLEANING: The mixing arm, mixing arm outer

seal, worm and cylinder should be removed from

the grinder for cleaning.

SAFETY: An electrical interlock switch is provided

for operator safety. Whenever hopper guard is

open, power to motor is cut off. The hopper guard

must be closed before machine can be started.

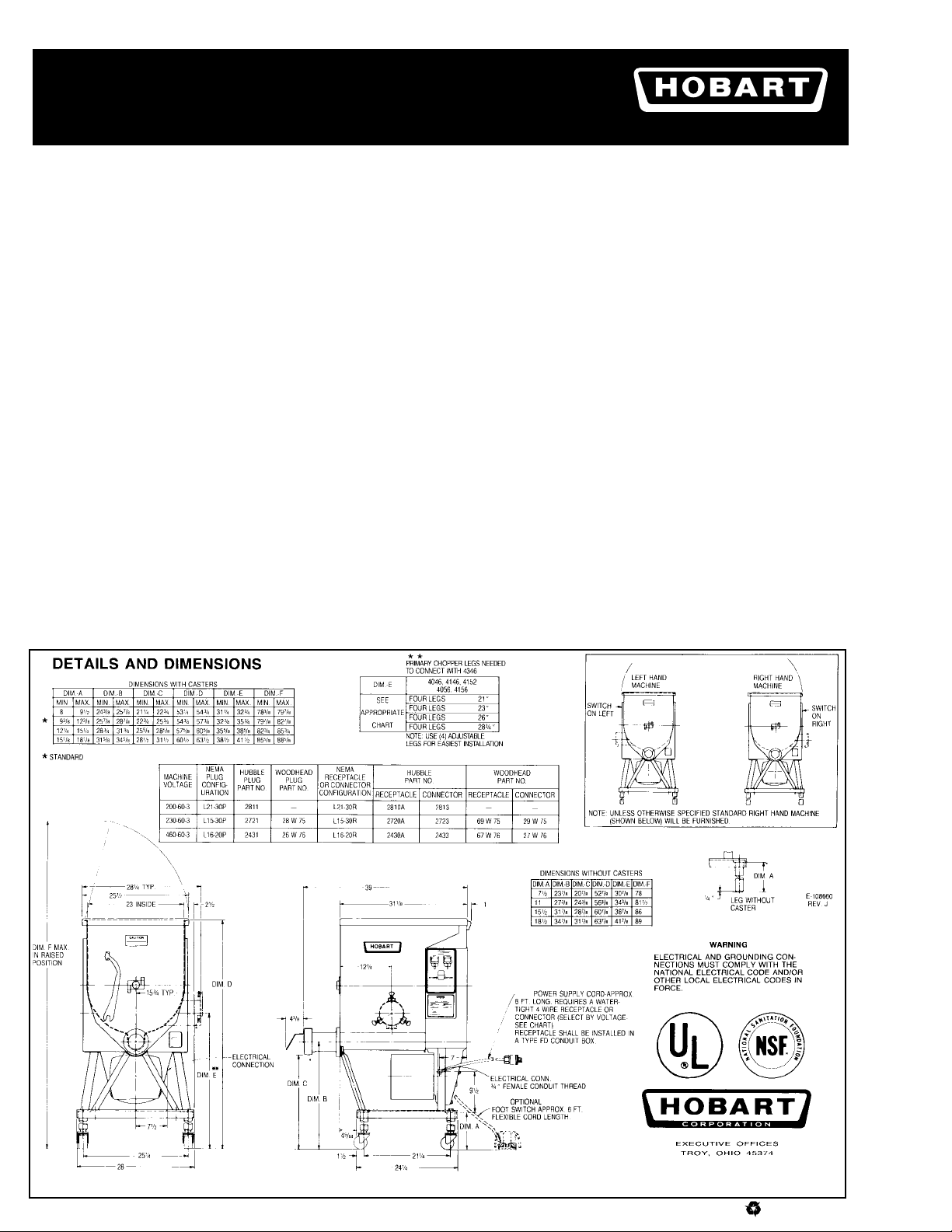

LEGS: Standard legs with casters

3

⁄8"—123⁄8") provide 223⁄4" to 253⁄4"clearance

(9

between floor and lowest point on adjusting ring.

Legs with casters are available in three other

optional lengths (see Details and Dimensions) at

no extra cost. Legs without casters (reduced cost)

are available when ordered (see Details and

Dimensions for available lengths). If not specified

on order, standard length legs with casters

3

(9

⁄8"—123⁄8") will be furnished. Cord and plug and

receptable are required on any machine with

casters.

OPTIONAL EQUIPMENT: (Available at extra

cost)

1. Flexible power supply cord and plug.

(Standard equipment on models with casters.)

2. Receptacle or pendant type connection.

(Receptacle is standard equipment on models

with casters.)

3. Adjustable legs with casters (3 non-standard

lengths available) provide installation flexibility

and machine mobility. Also includes power

supply cord and plug and receptacle.

4. Adjustable legs without casters for fixed

5. Foot switch — used for intermittent grinding

6. Side feed opening. This allows the product,

7. Plug assembly for hopper inlet connection. For

8. Carbon steel or Stay Sharp knives and plates

9. Drip cup.

SPECIAL EQUIPMENT: The Model 4346 can be

used in tandem with Hobart or competitive

grinders in all sizes from #32 through #56.

Adapters or special adjusting rings are available

for this purpose. When ordering, specify make

and model number, along with knife and plate

size.

FINISH: Standard unit consists of stainless steel

hopper, tinned deflector and mixing arm; tinned

cast iron cylinder, adjusting ring and worm;

stainless steel hopper guard, motor shroud and

rear panel; base assembly is galvanized.

WEIGHT: Net—575 lbs. Shipping—675 lbs.

As continued product improvement is a Hobart

policy, specifications may be subject to change

without notice.

FOOD EQUIPMENT

position installations.

operations. Includes switch and special control

on Mixer/Grinder.

from a companion first cut grinder to feed

directly into the hopper. Specify side of mixer/

grinder to be equipped with inlet connection.

(Factory installation only.)

use when inlet hole is not being used.

5

with

⁄64" to 1" diameter holes.

FORM F-7968 (REV. 690) LITHO IN U.S.A. (H-01)

Printed On Recycled Paper

Loading...

Loading...