Page 1

INSTALLATION & OPERATIONAL MANUAL

1HFD & HFC SERIES ELECTRIC FRYERS

With KleenScreen PLUS® Filtration Systems

1HF50D ML-136500

1HF85CF ML-136819

1HF85CF Shown - Computer Control

ENERGY STAR® Qualified

For additional information on Hobart or to locate an authorized parts

and service provider in your area, visit our website at www.hobartcorp.com

HOBART 701 S. RIDGE AVENUE

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC TROY, OHIO 45374-0001

WWW.HOBARTCORP.COM F-32964 REV. C (August 2012)

MODELS:

Page 2

HFD, HFCF SERIES ELECTRIC FRYER

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRIC EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP

AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

HOBARTCORP F-32964 Rev. C (May 2012)

-2-

Page 3

HFD, HFCF SERIES ELECTRIC FRYER

IMPORTANT FOR YOUR SAFETY………………………………………. 2

INTRODUCTION…………………………………………………………… 4

GENERAL…………………………………………………………… 4

ORDERING PARTS………………………………………………… 4

FRYER CAPACITIES………………………………………………. 4

UNPACKING………………………………………………………… 4

INSTALLATION…………………………………………………………...…… 5

CODES AND STANDARDS……………………………………….. 6

ASSEMBLY …………..…………………………………………… 6

ELECTRICAL CONNECTIONS………………………………….. 7

LEVELING THE FRYER………………………………………..…… 8

OPERATION………………………………………………………… 8

OVER-TEMPERATURE SHUTDOWN……………………………. 8

BEFORE FIRST USE………………………………………………... 8

Cleaning…………………………………………………….... 8

FILLING TANK WITH SHORTENING…………………………… 9

BASIC FRYING INSTRUCTIONS………………………………….. 9

Fry Basket Guidelines………………………………………. 10

EXTENDED SHORTENING LIFE………………………………… 10

TURNING ON THE FRYER …………………………………… .. 10

QUICK START GUIDE SOLID STATE DIGITAL CONTROL ….. 11

QUICK START GUIDE COMPUTER CONTROL ……… 12

TURNING OFF THE FRYER ………………………………….. 13

EXTENDED SHUTDOWN ………………………………….. 13

FILTERING THE OIL…………………………………… ...……. 13

DRAINING THE TANK……………………………….…… 14

BOIL OUT PROCEDURE………………………………………… 14

CLEANING…………………………………………………………. 15

Daily………………………………………………………… 15

ELECTRIC KLEENSCREEN PLUS® INSTALLATION & OPERATION… 16

FILTERING INSTRUCITONS FOR KLEENSCREEN PLUS® …. 17

GENERAL………………………………………………….….. 17

ASSEMBLY…………………………………………………… 17

INSTRUCTIONS TO REMOVE & REPLACE FILTER ENVELOPE 19

OPERATION ……………………………………………………………….. 20

FILTER PROCEDURE ……………………………………………… 20

FILTERING SOLID COMPUTER CONTROLS GUIDE…………. 21

FILTERING TIPS …………………………………………………… 22

REMOVING EXCESS DEBRIS FROM THE FILTER ………….. 22

FLUSH AND DISCARD …………………………………………….. 22

BOIL OUT PROCEDURE …………………………………………. 23

THERMAL OVERLOAD PROTECTION RESET BUTTON …….. 23

MAINTENANCE………………………………………………………….. 24

Service in the US and Canada…………………………………... 24

In Australia…………………………………………………………. 24

TROUBLESHOOTING…………………………………………………….. 24

Troubleshooting Chart………………………………………………. 24

TABLE OF CONTENTS

HOBARTCORP F-32964 Rev. C (May 2012)

-3-

Page 4

HFD, HFCF SERIES ELECTRIC FRYER

Hobart Fryers are produced with quality workmanship and material. Proper installation,

usage and maintenance will result in years of satisfactory performance.

Before installing the fryer, thoroughly read this manual and carefully follow all instruction.

This manual is applicable to model listed on the cover page. Procedures in this manual

will apply to all models unless specified. Pictures and illustrations can be of any model

unless the picture or illustration needs to be model specific.

Customers may order parts directly from their local authorized service center. If not

known, call Hobart Customer Service 1-888-4HOBART.

To speed up your order, provide the model number, serial number, electrical

specifications, part needed, item part number (if known) and quantity needed.

This fryer was carefully inspected before leaving the factory. Upon acceptance of the

shipment, the transportation company assumes full responsibility for safe delivery.

Immediately after unpacking the fryer, check for possible shipping damage. If the fryer is

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Check that the following have been included:

Crumb Rack(s)

Tank Brush

Adjustable (4) Legs. Fryer Batteries with the KleenScreen PLUS® Filtration System

have legs installed from the factory.

Drain Pipe Extension for freestanding fryers only.

Twin Fry Baskets (2) per fry tank

Cleanout Rod (non-filtered fryers only)

Fryer Batteries with the KleenScreen PLUS® Filtration System

Filter Pan

Suction Tube

Screen Assembly

Boil Out ByPass™ Extension

Complimentary Pack of Micro-Filtration Envelopes

High temperature discard hose

Manual and Warranty

Sample Boil Out Tablets

CD with Fryer Menu Editor Software – Computer Models Only

INTRODUCTION

GENERAL

ORDERING PARTS

UNPACKING

HOBARTCORP F-32964 Rev. C (May 2012)

-4-

Page 5

HFD, HFCF SERIES ELECTRIC FRYER

Do not use the door or its handle to lift the fryer.

MODEL - GMO Kw per Fry Tank Width Inch (cm) Total

System

1HF50D 17 15.5" (39) 50 (23)

1HF85CF 24 21.0" (53) 85 (39)

Shortening lbs. (kg)

Each Fry Tank

Voltage ranges are: 208, 3 Phase - 50 – 60 Hz

240, 3 Phase - 50 – 60 Hz

480, 3 Phase - 50 – 60 Hz

The number preceding the model number of the fryer refers to the number of fryers in a

battery.

INSTALLATION

Before installing the fryer, verify that the electrical requirements agree with the

specifications on the fryer data plate, which is located on the inside of the door panel.

Record your fryer model, device, and serial numbers for future reference in the space

provided below. This information can be found on the fryer data plate.

Fryer Model No: ___________________________

Device: ___________________________________

Serial No: ________________________________

HOBARTCORP F-32964 Rev. C (May 2012)

-5-

Page 6

HFD, HFCF SERIES ELECTRIC FRYER

The fryer must be installed in accordance with:

In the United States:

State and local codes, or in the absence of local codes, with:

National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained

from The National Fire Protection Association, Batterymarch Park, Quincy,

MA. 02169-7471.

In Canada:

Local codes

CSA C22.1 Canadian Electric Code L4W 5N6.

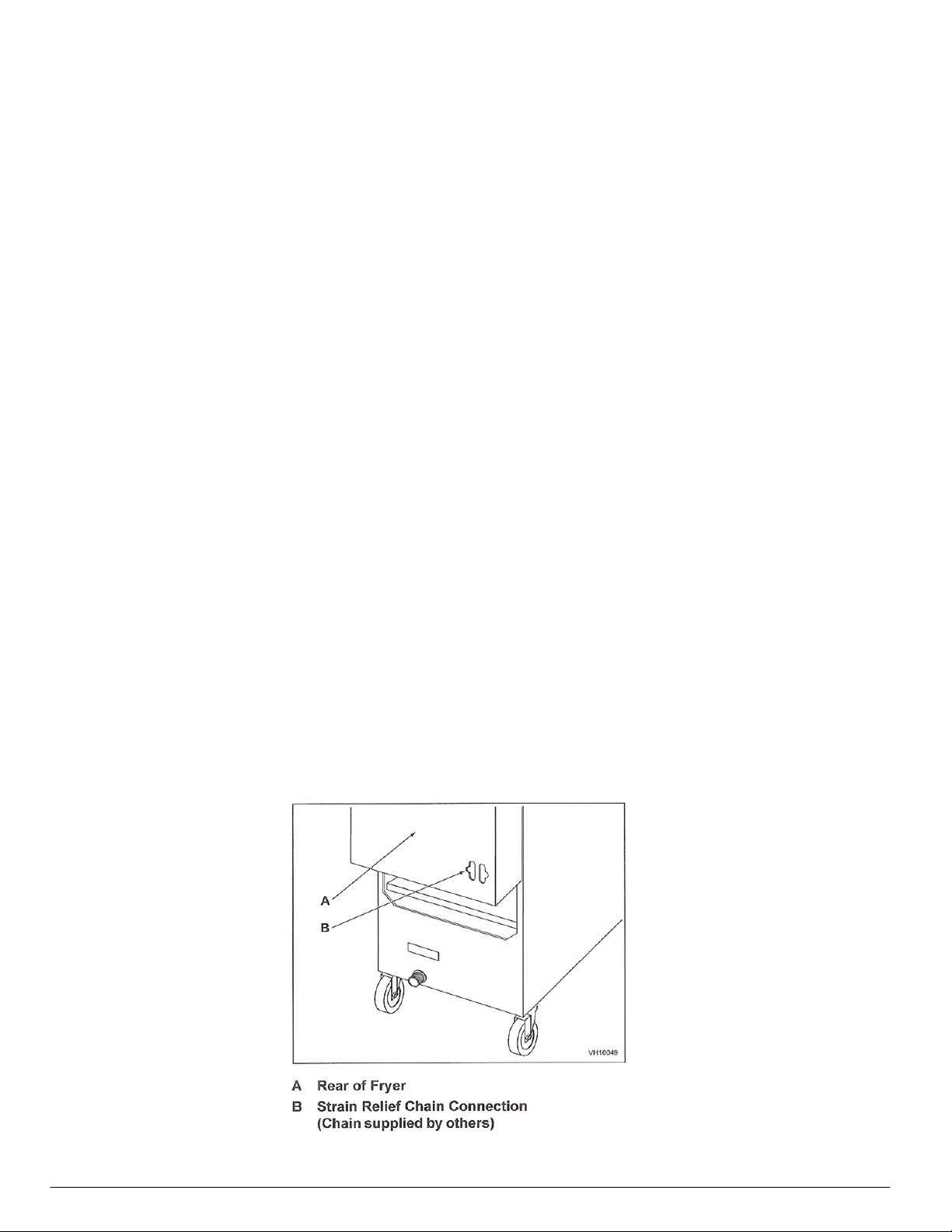

The fryer must be restrained to prevent tipping and the splashing of hot liquid. The means

of restraint may be the manner of installation, such as connection to a battery of

appliances, installing the fryer in an alcove, or by separate means such as adequate ties.

Fryers with Casters: (Optional)

Separate instructions for installing casters are included with the casters:

The restraining device should be attached to the cutout on the back panel. See

illustration for location.

CODES AND STANDARDS

ASSEMBLY

HOBARTCORP F-32964 Rev. C (May 2012)

-6-

Page 7

HFD, HFCF SERIES ELECTRIC FRYER

Australia, use only the caster supplied by the manufacturer for the fryer

device. The fryer must be installed using a hose assembly restraining device to

limit the movement of the appliance in accordance with AS1869.

The fryer must be installed with a connector (not supplied by Hobart)

complying with the above codes.

The fryer must be installed with restraining means to guard against

transmission of strain to the connector. See illustration.

The fryer must be installed with the casters provided.

If the restraint is ever to be disconnected, turn off electric supply to the fryer.

Electrical and Grounding connections must comply with the National Electrical Code

and/or other local codes.

Disconnect the electrical power supply to the machine and follow lockout / tag out

procedures.

Appliances equipped with a 120V flexible electric supply cord are provided with a three-

prong grounding plug. It is imperative that this plug be connected into a properly

grounded three-prong receptacle. If the receptacle is not the proper grounding type,

contact an electrician. Do not remove the grounding prong from this plug.

For 480 volt fryers a separate cord and NEMA 15-5P plug is required (not supplied with

the fryer). Plug in the wire connection into an approved outlet.

Place fryer as near to its final position as possible. Connect 3 phase line to X, Y and Z on

terminal block. To reach terminal block, remove electric cover plate from fryer.

For each 15½” (39 cm) and 21” (53 cm) section, a 3 phase supply line capable of handling

the required KW at the fryer’s rated voltage (208, 240, and 480) is needed. Refer to the

fryer data plate for this electrical information.

To shield electric connection supply wiring, a permanently connected or direct

wired device must be installed using flexible conduit sleeve with the appropriated

connectors.

ELECTRICAL CONNECTION

HOBARTCORP F-32964 Rev. C (May 2012)

-7-

Page 8

HFD, HFCF SERIES ELECTRIC FRYER

Check the level of the fryer by placing a level on top of the fryer after electrical

connections have been made.

Ensure that the fryer is level front-to-back and side-to-side in the final installed position.

If using casters, lock the wheels after unit is level.

Hot oil and parts can cause burns. Use care when operating,

cleaning and servicing the fryer.

Spilling hot frying compound can cause severe burns. Do not move

fryer without draining all frying compound from the tank.

OVER-TEMPERATURE SHUTDOWN

If the shortening becomes overheated, a high-temperature shutoff device will turn the

heating elements off shutting down the fryer.

If the fryer shuts down due to overheating, do not turn fryer on until the shortening

temperature is below 300°F (149°C).

If an overheating situation persists, contact your local Hobart authorized service office.

Cleaning

New units are wiped down at the factory to remove any visible signs of dirt, oil, grease,

etc. remaining from the manufacturing process.

Before any food preparation, thoroughly wash the protective oil from all surface parts and

the tank interior with hot soapy water to remove any film residue and dust or debris.

Do not use chlorine or sulfate/sulfide cleaners.

Wash any accessories shipped with unit.

Rinse fryer and accessories thoroughly and drain the fryer.

LEVELING THE FRYER

OPERATION

BEFORE FIRST USE

HOBARTCORP F-32964 Rev. C (May 2012)

-8-

Page 9

HFD, HFCF SERIES ELECTRIC FRYER

Wipe tank completely dry with a soft, clean cloth.

Close the drain valve.

Fill the fryer tank with shortening. Hobart recommends using liquid shortening.

Shortening level should be between the MIN and MAX lines in the fryer tank.

Shortening will expand when heated. Do not fill the fryer tank past the MAX line.

Press the melt switch to liquid or solid shortening.

Add fresh shortening as needed to maintain oil level.

Solid Shortening: Do not set a complete block of solid shortening on top of an

electric fryer’s heating elements. Doing this may damage the elements and increase

the potential for shortening flash fire. If solid shortening is to be used in an electric

fryer, remove the baskets and crumb screen (s), and raise the elements from the

tank. Pack the bottom of the tank completely with solid shortening, lower the

elements and then pack the shortening completely around and over top of the

elements. Lay crumb screen (s) in the tank on top of the packed shortening. Follow

the melt instructions in this manual. Once all shortening has been melted and the

fryer has met the set temperature, fill baskets and resume frying.

Set the desired temperature and allow shortening to heat up to that temperature.

Fry items that are the same size to ensure equal doneness.

Drain or wipe dry raw or wet foods to minimize splatter when lowering into hot

shortening.

Add fresh shortening as needed.

Fry Basket Guidelines

Do not overfill baskets. (See fry basket capacity below) Carefully lower basket into

oil.

When frying doughnuts and fritters, turn product only once during frying.

When cooking French fries or onion rings, shake the basket several times.

FILLING TANK WITH SHORTENING

BASIC FRYING INSTRUCTION

HOBARTCORP F-32964 Rev. C (May 2012)

-9-

Page 10

HFD, HFCF SERIES ELECTRIC FRYER

Batter covered foods should be dropped carefully , one by one, into shortening or

basket. If you use the basket, first dip the basket into the shortening to

reduce batter-build up on basket surfaces.

When frying is completed, remove basket or product. Hang basket on rear

hanger.

Fry Basket Capacity:

HF50: Recommended pounds per basket are 2.5 lbs. (1.1 kg).

HF85: Recommended pounds per basket are 3.5 lbs. (1.6 kg).

EXTENDING SHORTENING LIFE

Shortening life can be extended by the following guidelines:

Do not salt foods over the fryer.

Use good-quality shortening.

Filter shortening daily (at a minimum).

Replace shortening if it becomes poorly flavored.

Keep equipment and surrounding clean.

Set thermostat correctly.

Remove excess moisture and particles from food products before placing

on fryer.

TURNING ON THE FRYER

Open the door to the fryer. Turn the power switch to the on position.

Set temperature by turning the knob to the desired temperatures. The burners will

light automatically.

The burners will cycle on and off, maintaining the set temperature.

HOBARTCORP F-32964 Rev. C (May 2012)

-10-

Page 11

HFD, HFCF SERIES ELECTRIC FRYER

Programming the Solid State Control

HOBARTCORP F-32964 Rev. C (May 2012)

-11-

Page 12

HFD, HFCF SERIES ELECTRIC FRYER

Programming the Computer Control

HOBARTCORP F-32964 Rev. C (May 2012)

-12-

Page 13

HFD, HFCF SERIES ELECTRIC FRYER

Open the door to the fryer. Press the power switch to the OFF position.

1. Open the door to the fryer. Press the power switch to the OFF position.

2. Thoroughly drain the fryer. Refer to DRAINING THE FRYER.

3. Clean the fryer according to CLEANING.

4. Turn off the main gas shutoff valve.

Hot oil and hot parts can cause burns. Use care when operating,

cleaning, and servicing the fryer.

Filter shortening at least once a day.

1. A cold fryer will not drain properly. Always filter shortening between 250°F and

350°F. The shortening in the cold zone area will remain hard if not heated properly.

If necessary, use the clean-out rod to carefully stir the hard shortening to an area

above the cold zone where it will melt.

2. Open the door to the fryer. The power must remain ON for the fryer to filter

correctly.

3. Insert the drain extens ion into the drain valve. Tighten only hand tight.

4. Direct the drain extens ion in to mobile filtering device.

5. Slowly open the drain valve to allow oil to flow from the fry tank to the filter pan or

discard container. The heating elements will turn off automatically.

6. When fry tank is empty use the tank brush to remove any additional debris.

7. Close the drain valve.

8. Fill tank wit h new shortening. Fill to a minimum of the MIN level but no high that

halfway between MIN and MAX. Oil will expand as it is heated.

9. Press the start button only after step 9 is fully completed. The fryer will begin to

heat the shortening.

TURNING OFF THE FRYER

EXTENDED SHUTDOWN

FILTERING THE OIL

HOBARTCORP F-32964 Rev. C (May 2012)

-13-

Page 14

HFD, HFCF SERIES ELECTRIC FRYER

1. Open the door to the fryer. The power must remain ON for the fryer to filter correctly.

2. Insert the drain extens ion into the drain valve. Tighten only hand tight.

3. Direct the drain spout into the container that you want to drain the shortening into.

4. Open the drain valve slowly allowing the oil to drain into the container. When the

container is full or the fryer tank is empty, close the drain valve. Repeat this step until

the fryer is empty. Remove the drain extension and place it back in holder.

5. It is recommended to now boil out your fry tank. Follow the BOIL OUT PROCEDURE.

Then clean-out as described under CLEANING.

Weekly or when oil is replaced:

1. Drain the tank as described under FILTERING THE OIL.

2. Close the drain valve and fill tank with water. Use Boil-Out solid degreaser low

foaming cleaner

which can be ordered from your local dealer

the side of the package.

Do not use chlorine or sulfate/sulfide cleaners.

3. Solution level must be between the MIN and MAX levels on the fryer tank.

4. Press the power switch to the on position. Set the temperature knob to 200°F. Water

boils at 212°F. Do not bring water temperature to an overly active boil.

5. Press the start button to begin heating the boil out solution.

6. Use the tank brush; clean the sides, bottom and heat exchanger tubes.

7. Place the drain extens ion in the drain valve and hand tighten only. Drain the cleaning

solution from the tank into a container.

8. Close the drain valve and refill the tank with water. Add 1 cup (1/4 L) of vinegar to

neutralize alkaline left by the cleaner. Solution level must be between the MIN and

MAX level on the fryer tank. Press the start button to allow the solution to heat up.

Allow solution to stand for a few minutes.

DRAINING THE TANK

BOIL OUT PROCEDURE

. Follow the instructions on

HOBARTCORP F-32964 Rev. C (May 2012)

-14-

Page 15

HFD, HFCF SERIES ELECTRIC FRYER

9. Drain the tank according to DRAINING THE TANK. Rinse thoroughly with clear, hot

water. All traces of cleaner must be removed. Dry the tank thoroughly.

10. Close the drain valve and add shortening. Follow the FILLING TANK WITH

SHORTENING procedure in this manual. The fryer is now ready for use. Press the

start button to begin heating the shortening.

Hot oil and hot parts can cause burns. Use care when operating,

cleaning, and servicing the fryer.

Daily

Clean your fryer regularly with the tank brush along with a damp cloth, and polish with a

soft dry cloth. If regular cleaning is neglected, grease will be burned on and discolorations

may form.

Fingerprints are sometimes a problem on highly polished surfaces of stainless steel. They

can be minimized by applying a cleaner that will leave a thin oily or waxy film.

Clean all exterior surfaces of your fryer at least once daily.

Use a damp cloth with warm water and a mild soap or detergent.

Do not use chlorine or sulfate/sulfide cleaners.

Rinse thoroughly, and then polish with a soft dry cloth.

Keep the fryer exterior clean and free of accumulated grease to prevent

stubborn stains from forming. If regular cleaning is neglected, grease will be

burned on and discolorations may form.

Remove discolorations by washing with any detergent or soap and water.

Use a self-soaping, non-metallic scouring pad for particularly stubborn

discolorations.

Always rub with the grain of the stainless steel.

Do not use a metallic scoring pad or harsh cleaners.

CLEANING

HOBARTCORP F-32964 Rev. C (May 2012)

-15-

Page 16

HFD, HFCF SERIES ELECTRIC FRYER

KleenScreen Plus® Filtration System

Installation and Operational Manual for “HFF” Models

1HF85CF Shown

Electric KleenScreen PLUS® Models

8

1HF85CF ML-136819

HOBARTCORP F-32964 Rev. C (May 2012)

-16-

Page 17

HFD, HFCF SERIES ELECTRIC FRYER

Filtering Instructions for KleenScreen PLUS® Fryers

General

The KleenScreen PLUS® filtration system filters the oil as it is pumped back into its’ respective

tank(s). Only one tank can be drained and filtered at a time. Under no circumstances should both

tanks be drained at the same time.

Assembly

After unpacking, wash the filter pan, crumb basket and filter screen assembly. Make sure

you remove the insert located inside the filter screen. Use dishwashing detergent and warm

water, (parts are dishwasher safe). Rinse the filter pan, crumb basket and filter screen

components completely and wipe all parts dry with a clean cloth.

Pull out the filter drawer all the way leaving the filter pan opening exposed.

Place the filter tank into the filter drawer making sure that the pins on the bottom of the filter

pan line up with the holes in the filter drawer. Position the filter screen assembly into the

suction tube clip in the filter pan positioning the filter screen assembly flat on the bottom of

the filter pan. Place the primary crumb basket onto the left handle of the filter pan.

Carefully line up the suction tube nozzle so that it mates with the oil receptacle block

mounted on the frame of the fryer battery. Close the drawer. See Figures 1, 2 3 and 4.

Suction Tube

Filter Screen

Filter Insert

Knurled Bottom

Fitting

Fig. 1

HOBARTCORP F-32964 Rev. C (May 2012)

-17-

Page 18

HFD, HFCF SERIES ELECTRIC FRYER

Fully assembled filter screen assembly:

Fig. 2

Secure Tube with

Suction Tube Clip

Filter Screen Lays

Flat On Bottom of

Filter Pan

Fig. 3

Micro-Filtration Fabric Envelope Assembly:

Fabric Envelope Insert

(Different from Screen Assembly)

Fabric Envelope

Same Knurled Knob

Same Suction Tube

Closing Clip

Fig. 4

HOBARTCORP F-32964 Rev. C (May 2012)

-18-

Page 19

HFD, HFCF SERIES ELECTRIC FRYER

INSTRUCTIONS TO REMOVE & REPLACE KLEENSCREEN PLUS® FILTER ENVELOPE

FOR ABSOLUTE FILTRATION & MAXIMUM FLOW RATE WE RECOMMEND YOU CHANGE YOUR FILTER

ENVELOPES AT EVERY OIL CHANGE (10-14 DAYS DEPENDING ON OIL USAGE).

Step 1

Discard all oil from the filter vessel, (see pages 23 or 24). When the

filter pan is empty, use a spatula and scrape off all debris left on the

filter envelope and in the filter pan.

Step 2

Unscrew “S” Tube from filter by turning the Bottom Knurled fitting

counter- clockwise.

Step 3

Remove SST Closure Clip by lifting off one side.

Step 4

Remove SST Filter Screen Insert and wash insert with hot water and

dry thoroughly. The Filter Screen Insert is dishwasher safe. Place the

insert into a new KleenScreen PLUS® Filter envelope.

DO NOT WASH FABRIC ENVELOPE

Step 5

Place Filter Screen Insert into the fabric envelope making sure that the

holes line up. Fold over the other end of the envelope and place SST

Closure Clip on – hinge over and firmly press clip all the way down to

secure and seal filter assembly. Making sure that the folded end is face

down; screw “S” Tube Assembly onto the Filter Assembly. Tighten the

Bottom Knurled fitting. When tightened, the “S” Tube assembly should

be perpendicular to the long side of the filter assembly.

Step 6

Reposition the filter tube into the provided clip. Align filter tube so that

the end of the “S” Tube engages the Oil Receptacle fitting each time the

drawer is opened and closed.

HOBARTCORP F-32964 Rev. C (May 2012)

-19-

Page 20

HFD, HFCF SERIES ELECTRIC FRYER

Operation

Hot oil and parts can cause burns. Use care when operating,

cleaning and servicing the fryer.

Spilling hot frying compound can cause severe burns. Do not move

fryer without draining all frying compound from the tank.

Never run water or boil out solution through filter and motor / pump. Doing so

will void your fryer warranty.

FILTERING PROCEDURE

Oil Temperature should be 300-350° F. Use the provided crumb scoop to remove and suspend

crumbs on the bottom of the tank before proceeding to Step 1.

1. Do not turn off the Fryer. The power must be on throughout the entire filtering process.

Do NOT heat the fryer during the filtering procedure. Permanent damage to your fry

tank may occur and warranty may be voided.

2. Hobart recommends adding an oil treatment media to the oil prior to filtering.

3. Make sure that the filter drawer is closed completely and that the suction tube and

receptacle block are in the correct position. Fig. 5

Fig. 5

HOBARTCORP F-32964 Rev. C (May 2012)

-20-

Page 21

HFD, HFCF SERIES ELECTRIC FRYER

Filtering Instructions for KleenScreen PLUS® Fryers with Computer Controls

HOBARTCORP F-32964 Rev. C (May 2012)

-21-

Page 22

HFD, HFCF SERIES ELECTRIC FRYER

FILTERING TIP:

Open the filtering drawer approximately 1” to allow any oil in the return line to run back into the filter

pan. This will take about 30 seconds to complete. Then open the drawer completely to clean filter

components.

REMOVING EXCESS DEBRIS FROM THE SCREEN FILTER:

1. Pull the filt er drawer out and remove the crumb basket and empty any debris into the trash.

2. Remove the filter screen assembly. Scrape debris from the filter screen. Then remove the

insert by unlatching the latch. Clean all parts thoroughly.

3. Scrape debris from the bottom of the filter pan and discard in the trash.

4. Reassemble all filter components after being dried thoroughly.

FLUSH AND DISCARD:

1. Follow filtering instructions 1-3, however do not put oil treatment media into the fryer. Drain

the fryer oil into the filter pan.

2. Attach the quick disconnect hose to the discard male quick disconnect fitting, (hose not

supplied with fryer – Accessory Option).

3. Place other end of the discard hose into a container that is large enough to retain the

discarded shortening.

4. With the power switch still ON; pull the Yellow Discard Handle Lever Rod towards you.

Press the FILTER switch and the Motor/Pump will begin to operate. NOTE: Oil will come out

immediately out of the nozzle end of the hose.

5. Once the oil has been discarded completely and the filter pan is empty, push the Discard

Lever back in. Press the FILTER switch to the OFF position to stop motor/pump.

6. Disconnect the discard hose. The hose connection will be hot due to the temperature of the

oil that was discarded. Be careful to let the hose drain before putting away. Close the drain

valve and fill the fry tank with new oil.

HOBARTCORP F-32964 Rev. C (May 2012)

-22-

Page 23

HFD, HFCF SERIES ELECTRIC FRYER

BOIL OUT PROCEDURE:

Use the Boil Out By-Pass™ drain extension allowing the boil

out solution to exit the fry tank without using the filtering

system. Do not allow water to run through the motor / pump.

Drain the boil out solution into a bucket or place a hose on the

end of the drain extension allowing the other end to flow into a

floor drain. In Fig. 6 the arrow is pointing to the drain

extension. It is threaded into the top coupling of the oil drain

tube. Drain extension needs to be only hand tightened.

Boil Out By-Pass™ Extension Tube

Fig. 6

Standard Hose End Drain Tube End

THERMAL OVERLOAD PROTECTION BUTTON:

The motor/pump supplied with the filtering system

has a thermal overload protection circuit that senses

when excess heat occurs due to filtering for long

periods of time or under heavy load prior to

discarding debris buildup. If the thermal overload

protection is tripped, wait 5 minutes and then reset

the motor by pushing in the red button. The arrow in

Figure 7 shows the location of the reset button;

located on the front off the motor / pump facing

towards you.

Fig. 7

HOBARTCORP F-32964 Rev. C (May 2012)

-23-

Page 24

HFD, HFCF SERIES ELECTRIC FRYER

Hot oil and hot parts can cause burns. Use care when operating,

cleaning, and servicing the fryer.

Spilling hot fryer compound can cause severe burns. Do not

move fryer without draining all frying compound from the tank.

Service in the US and Canada

Contact your local Hobart Service office or address on the front of this manual.

In Australia

Contact Hobart Food Equipment PTY. LTD., 16 Hilly Street Morlake, N.S.W. 2137 Australia;

P.O. Box 100, Concord N.S.W. 2137; Tel: (02) 9736 1200; Fax: (02) 9736 1555.

www.hobartfood.com.au

Problem: Probable Cause:

No Heat: Power switch not turned on.

Wire connections loose (call service)

Wires connections need cleaning

High Limit (call service)

Insufficient or too much heat: Temperature not set to desired temperature.

High limit tripped (call service)

Temperature probe (call service)

Tank will not drain: Shortening too cold.

Drain pipe clogged with debris.

Motor / pump will not pump oil: Suction tube not seated correctly in receptacle block.

Filter screen is clogged and needs cleaning.

Shortening is too thick / cold. Heat oil up to min. 300º F.

Discard valve lever not fully engaged either for filtering or

discarding.

MAINTENANCE

Troubleshooting Chart:

HOBARTCORP F-32964 Rev. C (May 2012)

-24-

Loading...

Loading...